1. Introduction

Machine tools rely on lubrication and cooling systems to maintain smooth operation and extend the machine’s life. Lubrication helps to decrease friction and wear between moving parts. Cooling removes heat from the cutting process and mechanical components. Cutting fluids (CFs) in machining operations raise severe ethical and environmental issues. In recent years, attempts have been made to find solutions to address their primary disadvantages. The total inhibition of CFs is the ultimate aim [

1]. New CF compositions are encouraged by consumer demand for environmentally friendly goods [

2]. The industry is looking for strategies to decrease the use of lubricants during metal-cutting processes, due to economic and ecological demands [

3]. The family of ISO 14,000 standards’ overarching goal is to safeguard the environment while balancing socioeconomic needs [

4]. The five essential elements—harmful air emissions, water contamination, waste management, land pollution, and protection of natural resources and raw materials—must be quantified and proven to have decreased, for the industry to sign up for these requirements [

5].

CFs are essential for raising productivity. In machining operations, the primary purposes of the CFs are to lubricate and cool (tool–workpiece contact) to reduce tool wear. Therefore, using CFs assists in better energy efficiency and shields the machined surface, tools, and machine tool components from corrosion. Additionally, CFs cool down and move the chips away from the cutting region, removing pollutants and debris in liquid form rather than as airborne particles [

6]. Viscosity and surface tension significantly influence the chips’ evacuation performance. In order to lessen the influence of temperature on the cutting tool and machined workpiece, the cooling effect is crucial. In addition, the lubricant’s low coefficient of friction makes it easier to eliminate chips from the rake surface. This can result in a tool with a less built-up edge and more excellent surface polish [

7].

Flood cooling eliminates the chip produced from the workpiece’s machined surface and cutting tool. Furthermore, a certain quantity of heat is removed by the chips. Flood cooling has been demonstrated to lose effectiveness at higher cutting speeds, due to increased heat generation and the coolant’s inability to reach the key locations (tool–workpiece contact) where cooling is required. To obtain the desired result, a minimal amount of lubrication is yet another option that might be carefully considered [

8]. Any machining process aims to reduce costs by raising performance and efficiency [

9]. Oil (the base) and additives are combined to create CFs, which have a variety of qualities, depending on the machining process [

10]. They have frequently increased machining techniques’ productivity and quality. CFs make it possible to increase cutting speed, extend tool life, lessen workpiece damage, improve surface quality, and satisfy dimensional requirements. As a result, CFs boost output and effectiveness, improve safety requirements and enhance machining accuracy [

11].

Therefore, according to their respective chemical makeup, CFs are divided into straight and water-soluble oils. Straight oils provide superior lubricating and corrosion-resistance qualities, but their lack of cooling ability might result in a hazardous mist for the worker’s health [

6]. Water-soluble oils are designed to lessen friction between the tool, the chips, and the workpiece. They may be made of vegetable, animal, or mineral (petroleum-based) oil. Straight oils lose potency at high speeds and are more beneficial at moderate cutting rates. One explanation is that the fluid cannot approach the tool interface because of the fast chip movement. Another factor is that oils evaporate before they can lubricate at fast speeds because of the high cutting temperatures produced. When cutting at incredible rates, when heat production and high temperatures are an issue, water-soluble oils perform better than straight oils. The end user frequently dilutes oils with water before using them, because they are typically delivered as concentrates [

12]. Water concentration boosts thermal conductivity and specific heat, allowing the coolant to absorb heat from the machining process and resulting in a lower temperature. Water concentration promotes bacterial development, corrosion, and evaporative deficits. Although they occasionally have foaming inclinations that prevent heat transmission, these fluids typically contain additives that offer good cleaning characteristics. Water-soluble oils are non-flammable, and have a lesser propensity to generate aerosols than straight oils [

13].

Emulsions of semi-synthetic fluids and surfactants contain less than 40% oil. Compared to fluids with a lower moisture content, emulsions and nano-emulsions with an oil concentration of more than 40% offer flow ability and superior corrosion prevention [

14]. Oil-free CFs with a more substantial cooling effect are called synthetic fluids. In addition, polymers are translucent, which allows for better sight while machining because they are not susceptible to water hardness in the way that emulsions and semi-synthetic are [

15].

Solid lubrication is substances in a solid matrix, including molybdenum disulfide, tungsten disulfide, and graphite and its allotropic forms. Solid lubrication outperforms CFs in machining operations that run properly at high loads due to their strong heat dissipation and thermal conductivity [

16]. Severe thermal gradients have little effect on these materials’ stability. Additionally, solid lubricants have a higher temperature range than oil-based lubricants. Solid lubricants are effective in oxidizing up to 350 °C and have low friction and wear resistance, due to the ease with which their layers may move over one another. Although solid lubricants are also employed in machining, they are primarily used in the aerospace and automotive industries [

17]. They are vital in situations where it is essential to prevent product or environmental contamination, preserve or lubricate obscure or challenging-to-access locations, or offer extended storage. In addition, solid lubricants can be used as lubricating oil additives. However, they sometimes have unfavourable colours or are attached externally [

18]. In conjunction with the MQL system, graphite is a great substitute for traditional CFs when turning and grinding. Tiny amounts of solid lubricants can lower the cutting temperature, enhancing tool–chip contact and extending tool life, while enabling incredible cutting speed and feed rates [

19].

In cryogenic cooling, refrigerants include liquid nitrogen and solid carbon dioxide. Although cryogenic chilling is frequently thought of as a distinct freezing technique, dependent on how well the cryogen is used, it is more of an atmosphere system. Liquid nitrogen acts as a lubricant by absorbing heat and rapidly evaporating to generate a gas layer between the tool face and the chip. It is a method of cooling that does not pollute the environment in any way [

20]. Liquid nitrogen is a heat-absorbing material for machining. Since 79% of the air is nitrogen, the fluid evaporates as nitrogen gas, and mixes with the atmosphere. Cryogenic cooling is often a costly system. Cryogenic cooling uses high-velocity cryogenic agents’ jets, such as liquid nitrogen or liquid carbon dioxide, to cool the cutting zone while machining quickly [

21]. Although they are rarely used, liquid oxygen and liquid hydrogen also belong to the cryogenic cooling category. In addition to having better cooling efficiency, it is renowned for keeping a clean machining environment (i.e., leaving no oil or liquid behind) and being environmentally friendly [

22].

Cryogenic coolants perform poorly from a lubricating standpoint, since they disappear into the atmosphere as they enter and leave the nozzle. The freezing ingredient rapidly evaporates, which results in a pollution-free atmosphere in terms of climate change. This cutting-edge cooling system guarantees enhanced quality of tool life and machining surface [

23].

Compressed air combined with CFs can help heat-transfer issues in superalloy machining, and minimize fluid usage. At ambient temperature, chemicals in a gaseous condition are known as gaseous coolants. Although it has a limited cooling efficiency that may be boosted by chilling, the air is most often utilized, since it maintains its gaseous state. Other frequent gases include argon, helium, and nitrogen, which are utilized to stop tool and workpiece oxidation. Nevertheless, the high expense of these gases prevents their use in normal applications for cryogenic cooling [

24].

Additionally, the cutting pressures and temperature can be reduced, allowing for high cutting speeds and feed rates, when compressed air and liquid nitrogen are used in conjunction with a vegetable CF in spray mode. Due to limitations, individual demands, and climate change, sustainable CFs are one of the leading development areas for the lubricants business, enabling many potential avenues. For example, the market is looking at replacing petroleum-based goods with biodegradable vegetables or synthetic oils [

25,

26].

Mineral-based oils should be eliminated, due to the sharp rise in the price of petroleum products, increased reliance on foreign sources, diminishing production rates, and the slowing rate of reserve discovery. On the other side, there is a trend in lessening or immediately preventing using harmful ingredients while making CF; for instance, the elimination of aromatic compounds and sodium nitrite, more biodegradable additives, and the effective use of biocides in water-based fluids [

27,

28].

Computer numerical control (CNC) is the automatic control of machine tools (MTs) using a computer. It works automatically without human intervention or a physical operator supervising the cutting process, and can produce/modify complicated/intricate parts with precision and adaptability [

29]. Throughout the industrial revolutions, MTs replaced manual labour, enhancing efficiency and productivity. As a result, the market for MTs is quickly becoming one of the most critical niches in industrial activity [

30]. Between 2014 and 2019, global MT demand doubled, reaching around USD 181 billion, or a 5.5% annualized rate. CNC MTs provide maximum efficiency and productivity, but, at the same time, using electrical energy produced from fossil fuels causes different carbon emissions [

31]. Due to being hot subject in manufacturing, the steady CNC MTs must be equipped to evolve to contend for Industry 4.0. CNC machining facilities’ regular operations are altered, due to Industry 4.0 [

32]. Faster response times and less downtime are possible, along with all the current intelligent technologies and integrated software. The rising necessity to minimize operating costs, enhance efficiency, and drastically diminish the probability of element errors is driving the expansion of CNC MTs in Industry 4.0. CNC machining dominates the turning, milling, and grinding of metal items in Industry 4.0. However, machining is moving toward a simpler, linked machine intelligence, equipment, and system networks, just as in the rest of the manufacturing industry [

33].

Spark, water jet, or plasma cutting are all examples of the automated computer control of equipment referred to as CNC machining. The equipment can be damaged by warming the cutting tools or processed materials, and the machine workers could be hurt. Several production processes have been designed to manage the generated heat, to prevent CNC MTs from overheating. Flood cooling, sometimes known as wet cooling, is one of the cooling methods included in LC [

34]. Other methods include solid lubrication, minimal quantity lubrication, compressed air, and cryogenic cooling. Which approach is ideal? It is still up for debate. There is not a single approach that is superior to the others. Each approach has advantages and disadvantages that may enhance a process, based on the situation in which CNC MTs are required. It is crucial to remember that selecting the best approach to prevent overheating must be performed with the employees’ well-being as the top priority. The selection of a cooling procedure is influenced by the rules that apply to machining operations in many countries [

35]. The power consumption in machining can vary, depending on the machining process and the specific MT utilized. Factors that can affect power consumption include the size and complexity of the workpiece, the cutting speed and feed rate, and the type and condition of the cutting tool [

36]. Additionally, the power consumption of a machining process may be affected by the type of coolant or lubricant being used, as well as the efficiency of the machine’s drive system. Therefore, optimizing the cutting conditions and using high-efficiency machine tools and cutting tools is often beneficial to reduce power consumption in machining [

26].

The recent review studies on lubrication and cooling (LC) and allied techniques are briefly described. Pimenov et al. [

37] studied several cooling-lubrication procedures used to increase the machinability of Ti and its alloys and various CFs. New studies on the application of nanofluids as CFs for Ti and related alloys have yielded encouraging outcomes regarding cutting force and tool-wear reduction. Benedicto et al. [

1] examined the economic elements of lubrication/cooling processes, including system costs, reducing fluid costs, and fluid-disposal costs. The environmental issues include their influence on air and water pollution and the possibility of fire and explosion threats, emphasising the need to consider these variables when choosing a lubrication/cooling system. Sultana et al. [

27] analysed all current cooling/lubrication techniques and their implications in many aspects. Gupta et al. [

34] explored the possessions of traditional and advanced LC methods in the grinding process on outcome measures. They presented the state of the art of the machining of Inconel, while considering LC [

35]. Sharif et al. [

24] discussed the long-term viability of various CFs, as well as cooling solutions for their ecological influence on human health and advancements in eliminating the use of traditional machining fluids. Hamran et al. [

38] analyzed research publications concerning ways to increase machinability with a minimal-quantity lubrication system, and three search sources were utilized from 2014 to 2019. Garca-Martnez et al. [

25] investigated non-traditional lubrication strategies established in turning, drilling, and milling operations since 2015 to present a comprehensive summary of current developments in each approach for the major machining operations. Said et al. [

28] thoroughly evaluated several nanofluids utilized as LC by numerous investigators for machining. Singh et al. [

39] investigated several LC methods and their prospects for sustainable machining through different machining procedures. The findings demonstrated that significant advances in LC methods had been documented. In addition, LC methods were reported for light-weight alloys [

40].

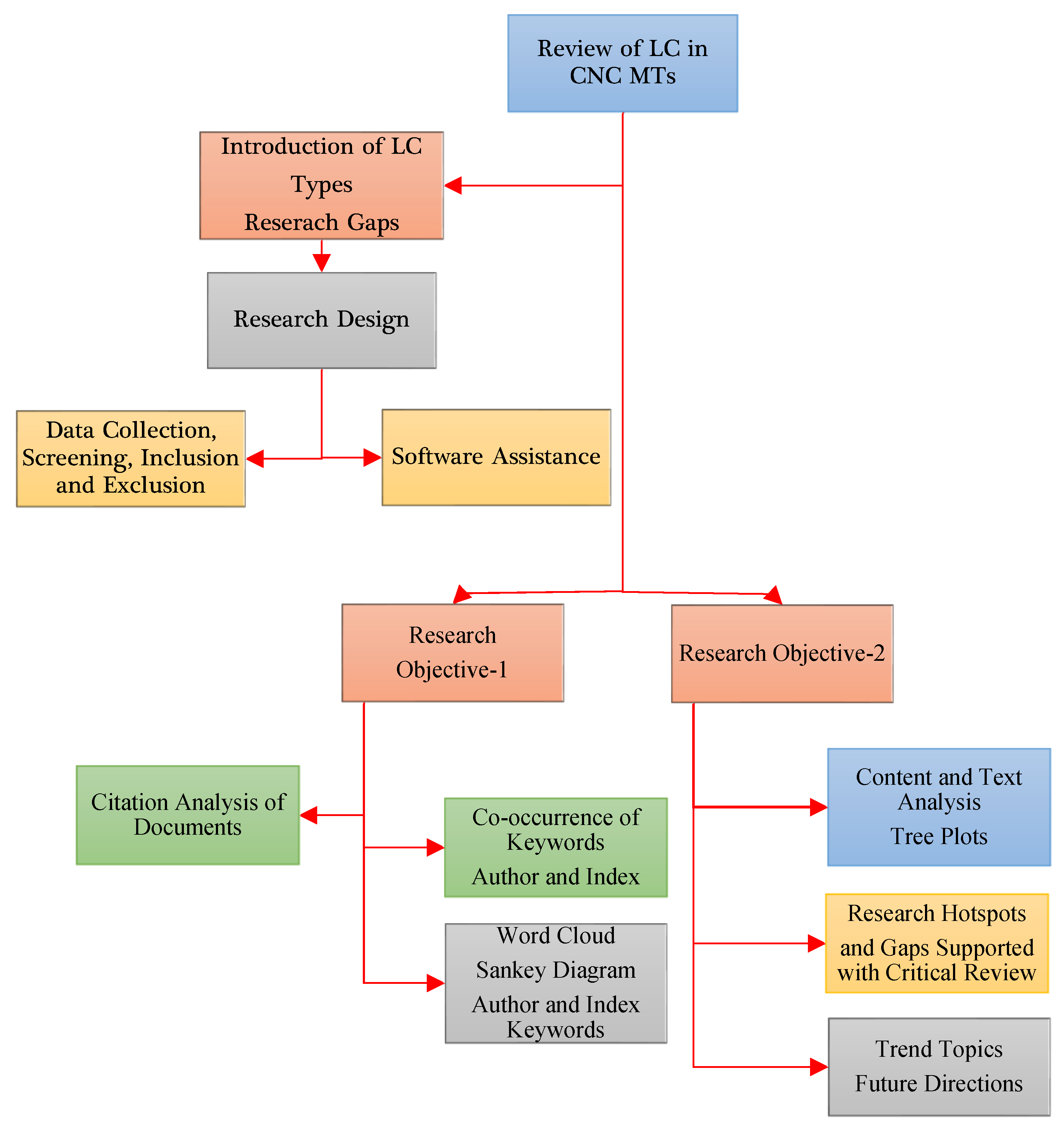

With reference to the knowledge gaps identified in the preceding literature review, the study concentrated on one of the key research concerns.

“Do we need a content and visualization analysis of LC in CNC MTs?”

This research question has an affirmative response; the literature review revealed that in content analysis, no research had shown considerable interest in LC in CNC MTs. According to the LC review of the research, content and keyword analysis is lacking in the literature. Nonetheless, several studies include content analysis, which plays an imperative part in detecting hotspots and gaps.

In the existing literature, content and visualization analysis of LC in CNC MTs can lead to improved understanding; by analyzing the existing literature, researchers and engineers can gain a deeper understanding of the existing state of knowledge and research in the arena of LC in CNC MTs. The analysis can also identify gaps in the existing literature, which can guide future research efforts to fill those gaps. By analyzing the literature over time, researchers can identify trends in the field, such as changes in research focus or methodology. The content and visualization analysis can also benchmark current technologies and systems against existing ones. Finally, it is designed to permit both quantitative and qualitative analysis, delivering excellent outlooks and allowing for descriptive statistics of the text.

We can assume that the suggested study analyzed all the literature methodically, using content and visualization analysis. In such a scenario, it will improve the overall scientific yield of LC in CNC MTs, and provide a thoughtful examination of existing content. This will also assist the research community and practitioners in reaching statistical inferences on LC in CNC MTs. The study has moved on, with the objective of underwriting content and visualization analysis of LC in CNC MTs, providing much-needed future research hotspots and gaps. As a result, the study has organized the research aim and objectives around this research topic.

The investigation is built on the following research aims, gaps, and questions, based on a comprehensive literature evaluation.

- (1)

To conduct a content and visualization analysis of LC in CNC MTs in the existing literature.

- (2)

To present an appropriate research perspective on the use of LC in CNC MTs, explaining its prospective scope.

The study systematized a full content and visualization analysis of LC in CNC MTs using accessible research techniques and software, which will be presented in the following part. The content analysis provides users with a comprehensive view of the research issue of their preference.

3. Results

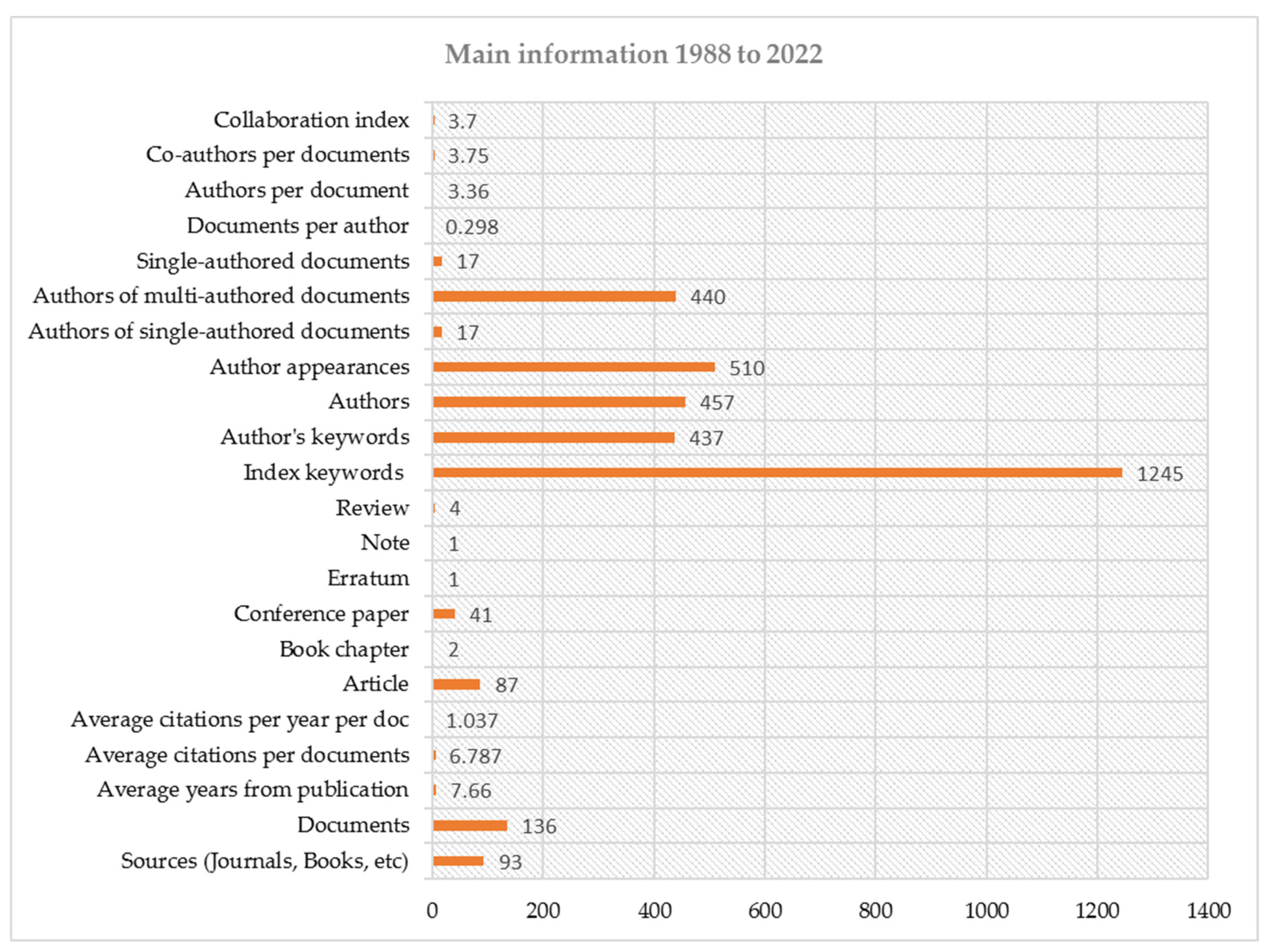

Figure 2 depicts vital information about LC in CNC MTs. It comprises 136 documents retrieved by Scopus between 1988 and 2022. The compiled documents were written by 457 authors, who contributed 510 times. There were 136 documents with several authors, contrasted with the 17 with a single author. The literature on LC in CNC MTs has been published in 93 sources. A total of 437 author keywords were in the texts, whereas 1245 were indexed. Out of 136 documents, there are 4 review documents with a 3% contribution, 1 note and an erratum of 1%, 41 conference papers with a contribution of 30%, 2 book chapters of 1%, and 87 articles with a maximum contribution of 30%. The published work on LC in CNC MTs has an average age of 7.66 years and 6.787 citations.

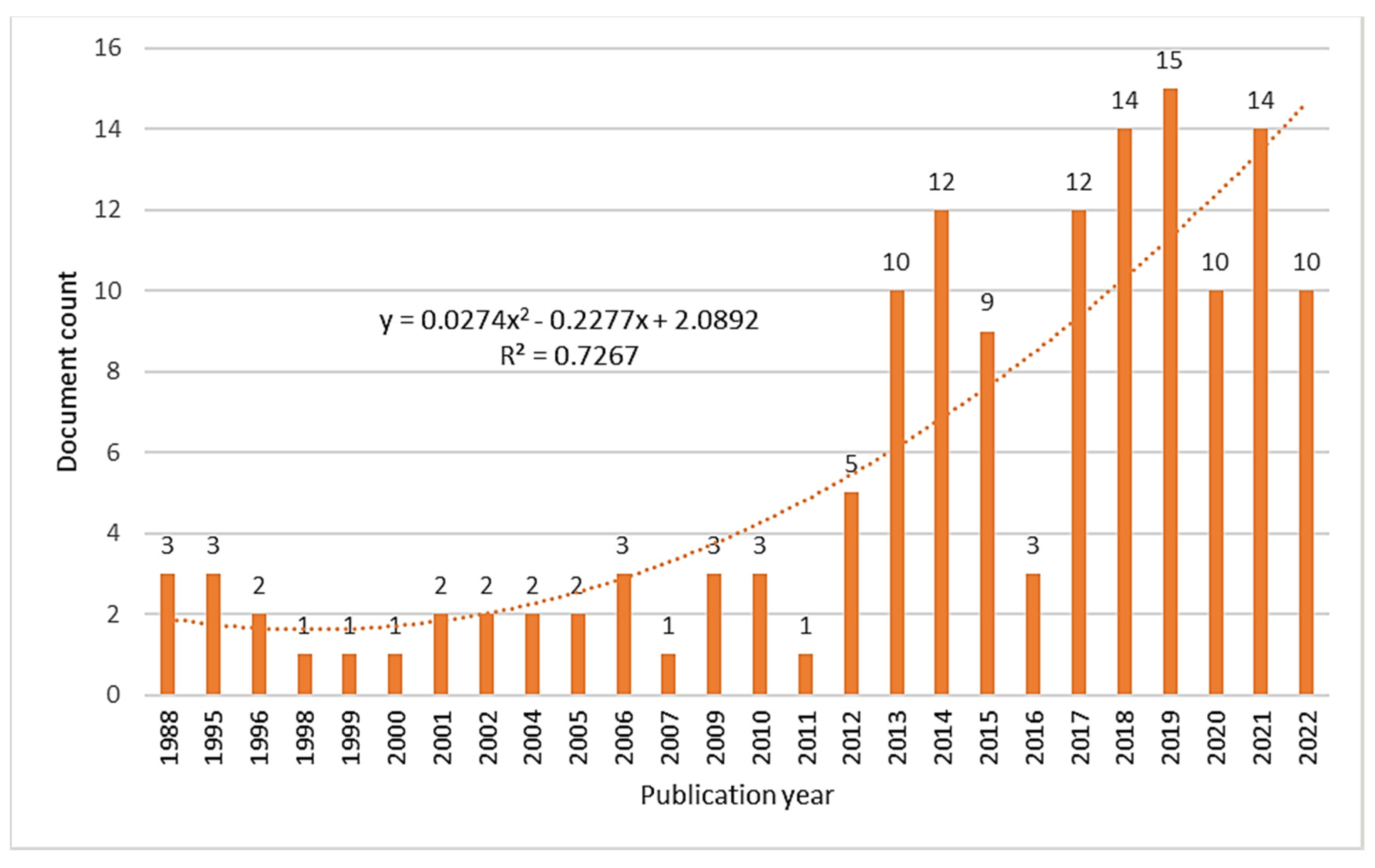

Figure 3 shows how documents on LC in CNC MTs were published yearly from 1988 to 2022. Three documents were published in 1988, but from 1998 to 2000 only one paper was published. From the year 2001 to 2005, two documents were published. After that, the published documents ranged from one to three, from 2006 to 2011. Then, the document publication rate increased by five in the year 2012. In 2013, ten papers were published, followed by twelve in 2014. In 2015, document publication decreased, and nine were published, compared to 2014; in 2016, only three were published. In 2017, there was a spike of nine documents compared to 2016. In 2018, 14 papers were published, followed by 15 documents in 2019, 10 in 2020, 14 in 2021, and only 10 in July 2022.

Before 2000, the average publication rate was two since the inception of LC in CNC MTs. From 2001 to 2010, the average number of publications on LC in CNC MTs was 2, but the total count increased from 11 to 18. From 2011 to July 2022, the average publication rate reached 10, with a count of 115.

Figure 3 also indicates the highest number of 15 documents, in 2019, followed by 14 in both 2018 and 2021.

Figure 4 portrays a citation analysis of the published work of LC in CNC MTs. It shows, starting in the year 2019, cumulative citations. The data was collected on LC in CNC MTs from 1988 to 2022, so there is zero citation of published work from 1988 to 1995. No work was published on LC in CNC MTs from 1988 to 2022. There were zero mean citations per article and per year in 1988, 1997, 1999, 2003, 2005, and 2008. In 2007 there were a maximum of citations per article of 33 and a minimum of citations per article of zero in 2015.

3.1. Co-Occurrence of Keywords

Keyword co-occurrence analysis examines the relationships between keywords or phrases within a text or a collection of texts. The analysis looks for patterns in the way keywords appear together, and can provide insights into the themes or topics present in the text. This analysis method is used in various fields; for example, in digital marketing, keyword co-occurrence analysis is used to identify keywords or phrases that are commonly found together on web pages, which can create content creation. In addition, text mining and co-occurrence analysis can identify the relationships between words in a corpus to understand the text’s topic, sentiment, or hidden meaning. Various techniques and tools exist to perform keyword co-occurrence analysis, such as word clouds, network analysis, or term-document matrix [

46].

Analysis of Author Keywords: LC in CNC MTs

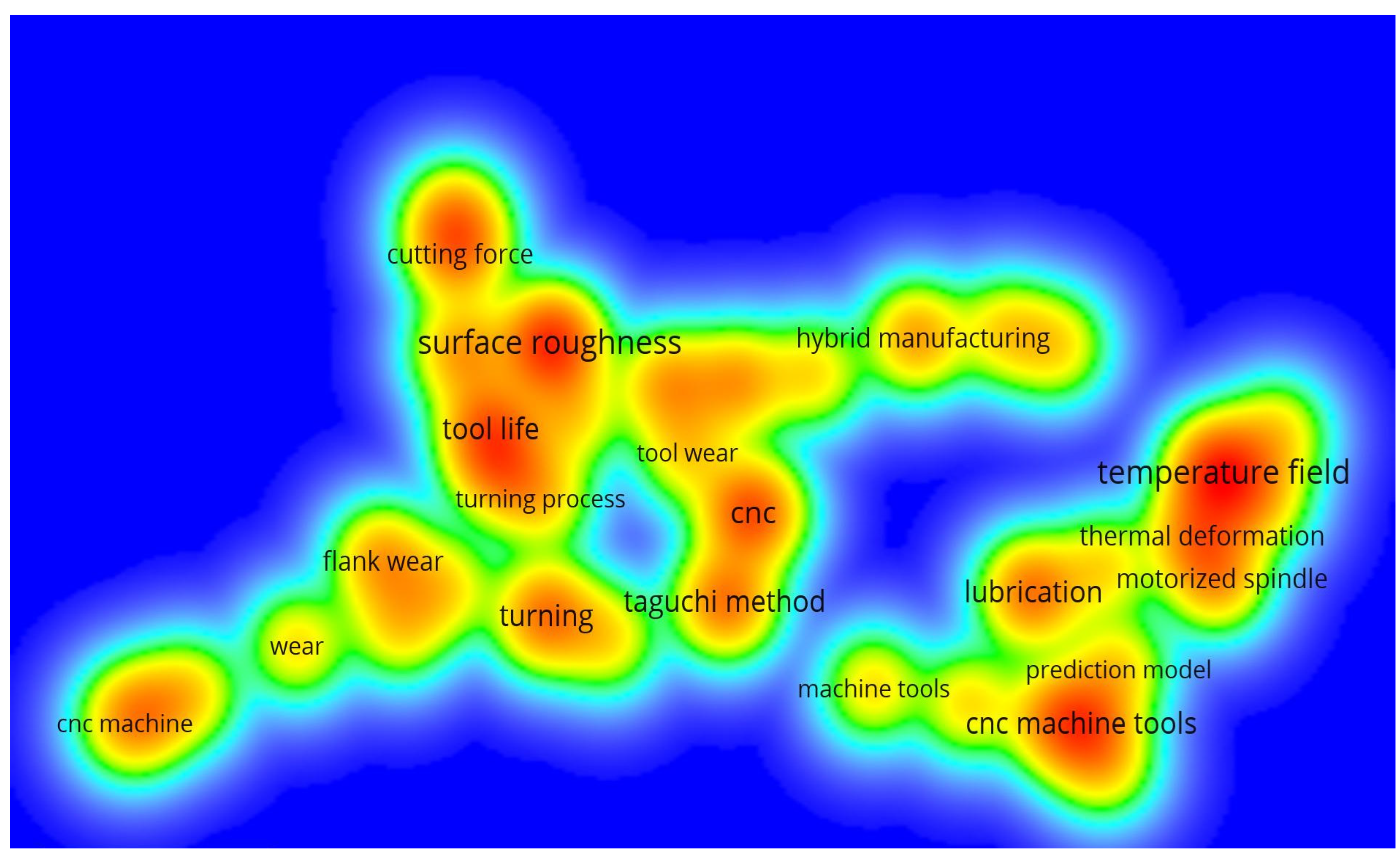

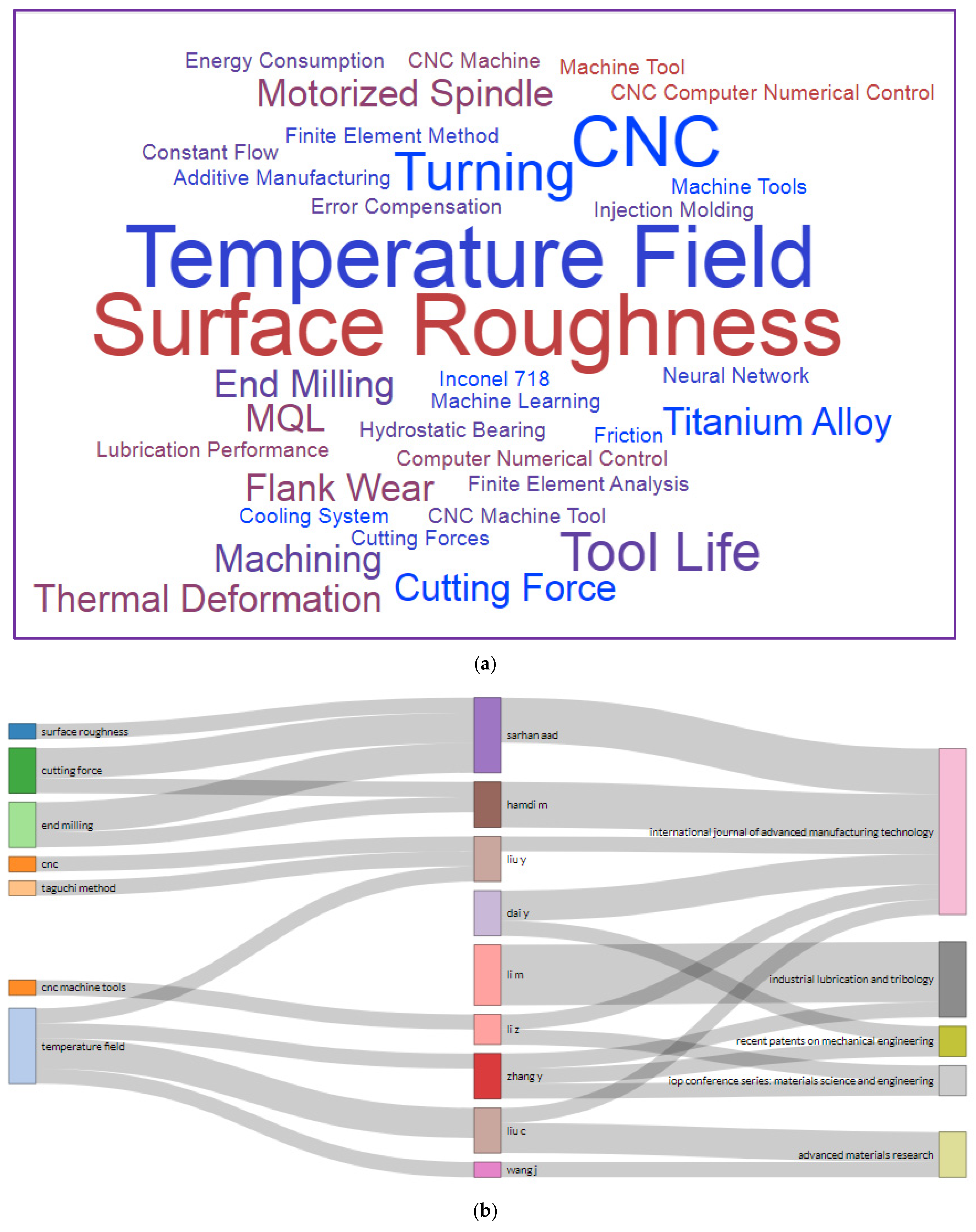

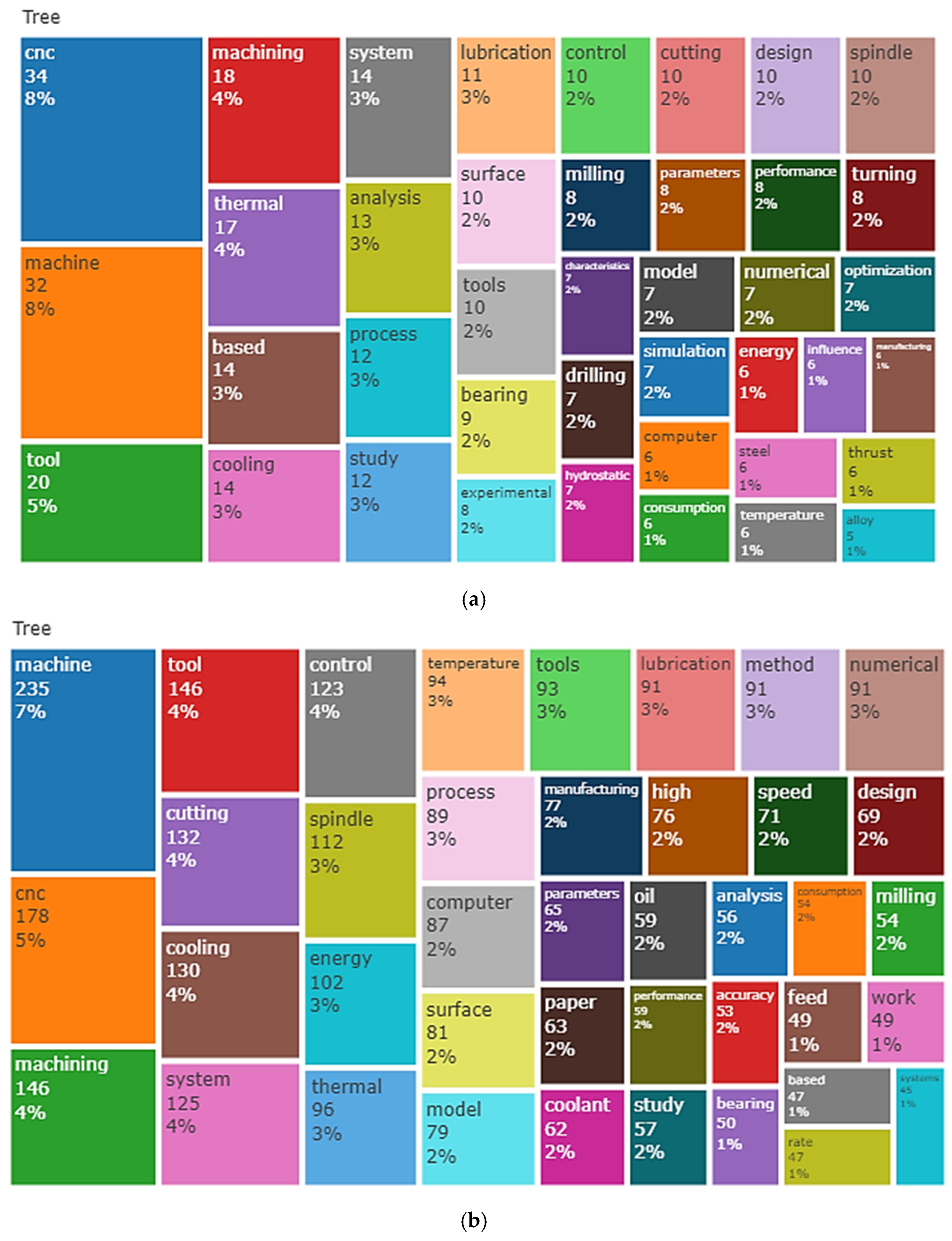

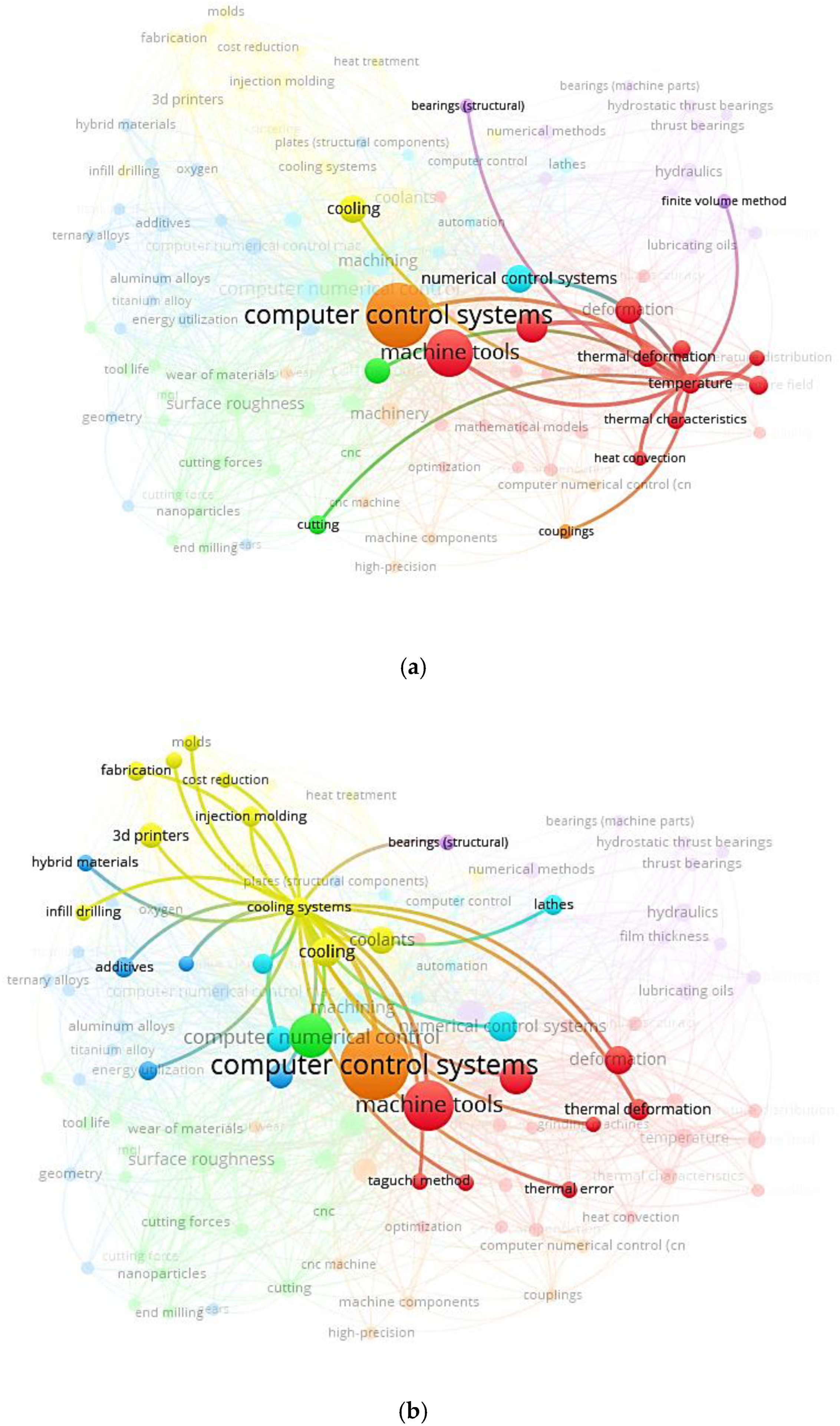

The author’s keyword of LC in the CNC MTs density map is revealed in

Figure 5. It comprises 52 author keywords out of 438, with the smallest occurrence of 2 and 39 linking. The author’s keywords are separated into 7 clusters. For example, the author’s keywords “surface roughness”, “Taguchi method”, “CNC machine tools”, “flank wear”, and “turning” displays an extreme incidence of occurrence LC in CNC MTs. The author’s keywords such as “hybrid composite”, “stir casting”, “surface integrity”, and “electrode wear rate” have fewer frequencies of occurrence. There are 39 items in total, i.e., LC in CNC MTs author keywords are divided into seven clusters:

Cluster 1 (seven items): flank wear, CNC machine, friction, slideway, sustainable manufacturing, vortex tube, wear.

Cluster 2 (seven items): CNC, cooling system, finite element analysis, hybrid manufacturing, Inconel 718, MQL, titanium alloy.

Cluster 3 (seven items): hydrostatic bearing, lubrication, machine tool, motorized spindle, spindle system, temperature field, thermal deformation,

Cluster 4 (six items): CNC machine tools, error compensation, machine learning, machine tools, prediction model, thermal error.

Cluster 5 (five items): cutting forces, machining, minimum quantity lubrication, tool life, turning process.

Cluster 6 (four items): optimization, Taguchi method, tool wear, turning.

Cluster 7 (three items): cutting force, end milling, surface roughness.

A word cloud is a visual representation of text data that displays the most frequently occurring words in a dataset as larger and bolder, while less common words appear smaller and faded. Word clouds allow users to quickly identify the most commonly occurring words in large text data. This can help researchers and analysts gain insights into the main themes or topics discussed within the text. Word clouds are easy to interpret, using visual cues to represent data. This makes it easy for non-experts to understand and draw conclusions from the data quickly. Word clouds can communicate complex ideas or concepts visually. This makes it easier to communicate findings to a broader audience, including non-experts. Word clouds can be used as a tool for content analysis, allowing researchers to identify the most frequently occurring themes, topics, or ideas within a large dataset. Word clouds can stimulate creativity by encouraging users to think about new and innovative ways to represent data visually. This can lead to new insights and discoveries that might not have been apparent from a simple text-based analysis.

Figure 6 depicts a word cloud of LC in CNC MTs author keywords and the link between author keywords published by authors and published journals. It visually represents the most frequently used words in an author’s work. The words are typically displayed in different sizes, with LC’s most frequently used words in CNC MTs appearing in the largest font.

Figure 6a can quickly identify themes and topics that the author frequently writes about. Surface roughness, temperature field, thermal deformation, motorized spindle, and titanium alloy have the largest font, so they have a greater appearance. Error compensation, additive manufacturing, finite element method, energy consumption, and cutting forces have the smallest font size and a lesser appearance.

Figure 6b depicts the relationship between the author’s keywords utilized by the authors and published journals. The author keywords surface roughness, cutting forces, and end milling are utilized by Sarhan and Hamdi and published in

The International Journal of Advanced Manufacturing Technology. The author’s keyword temperature field was used by Liu and Wang and published in

Advanced Materials Research.

3.2. Analysis of Index Keywords: LC in CNC MTs

Index keywords, also known as index terms or descriptors, are words or phrases used to describe the content of a document or article. They are used to organize and categorize information, making it easier for users to find relevant information. Index keywords are typically chosen by the author or editor of a document and are used in search engines, databases, and library catalogues, to help users find relevant information.

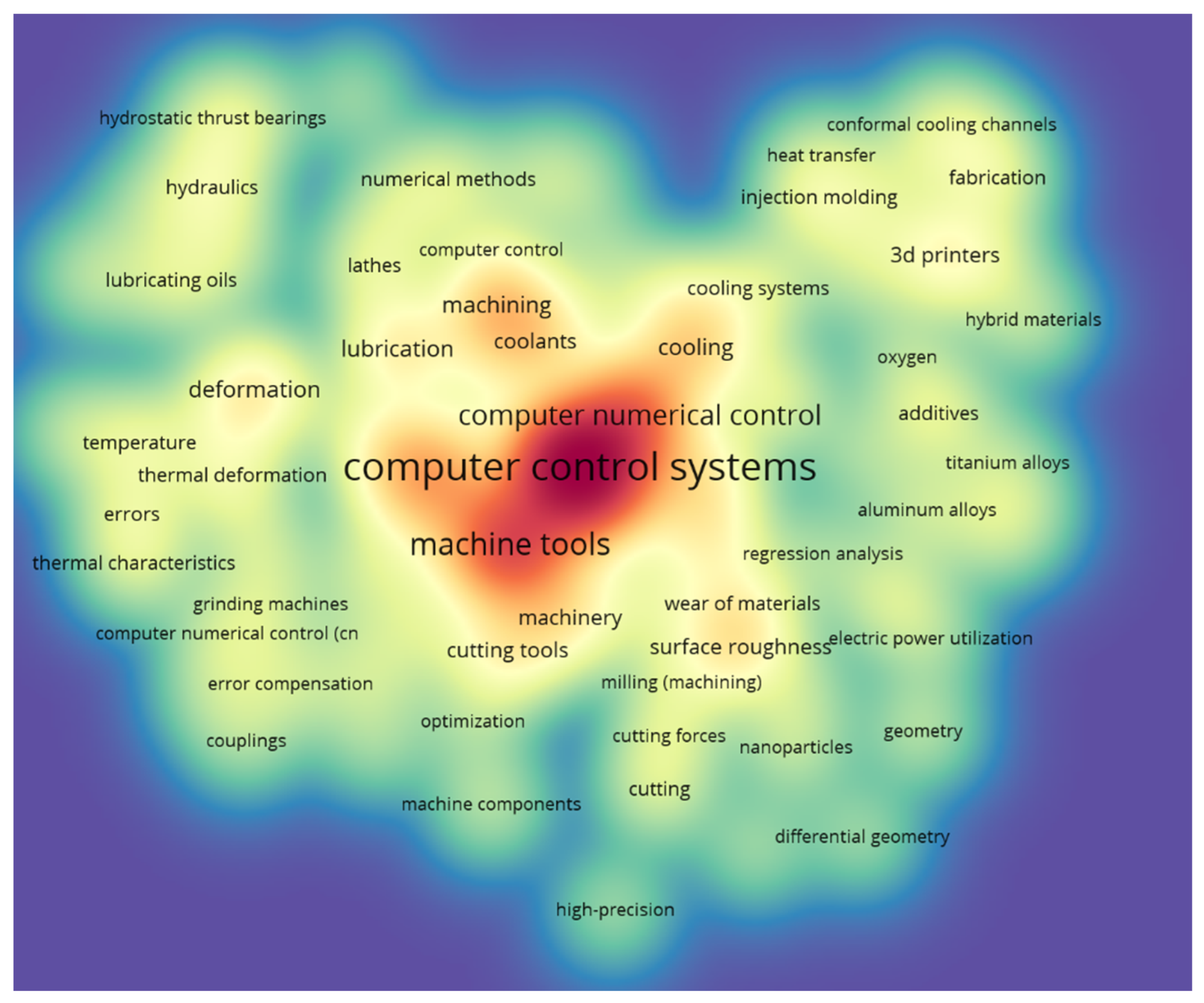

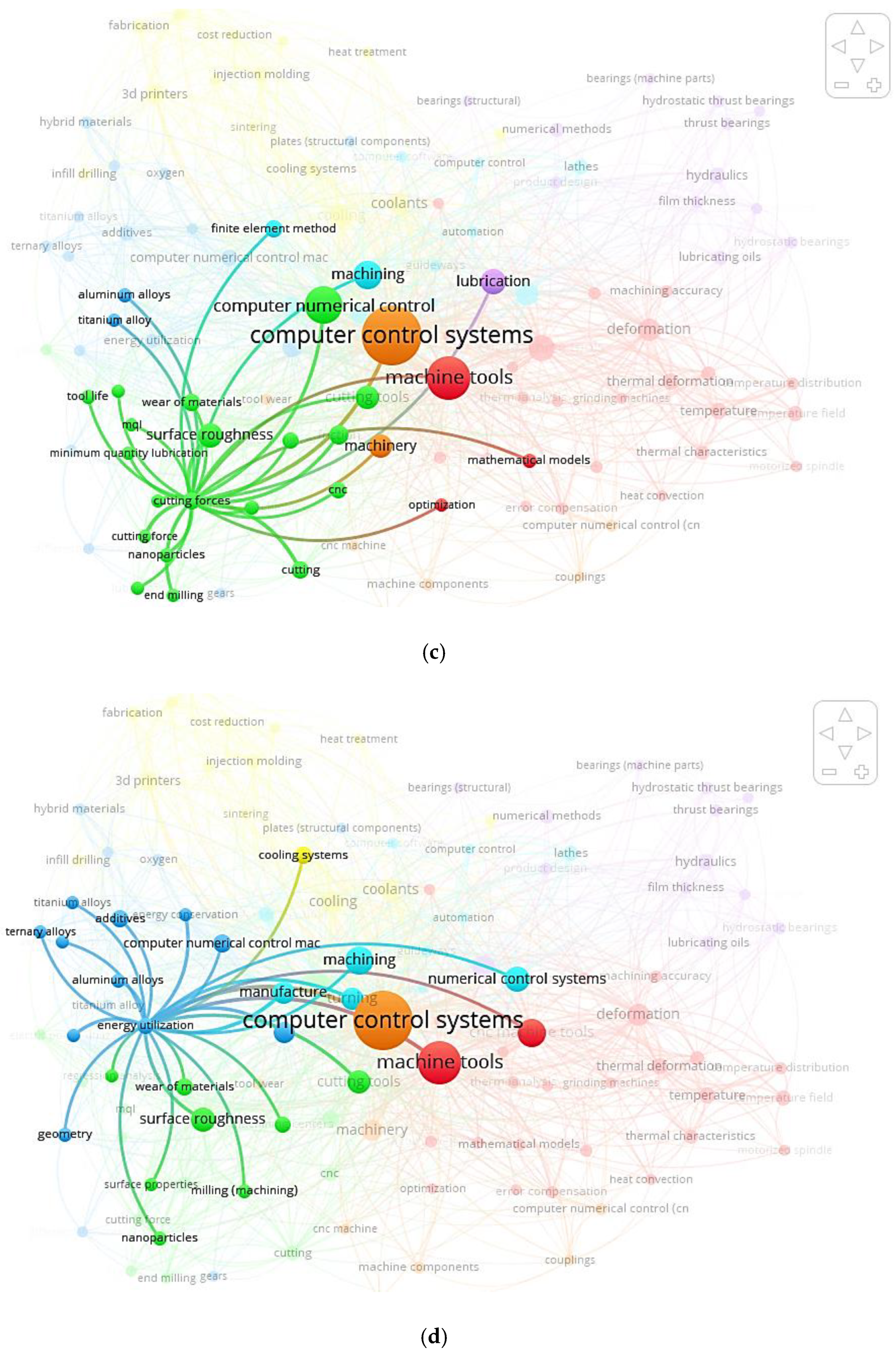

The density plot containing index terms is shown in

Figure 7. It involves LC in CNC MTs 93 index keywords out of 1245, with the lowest incidence of3. The 93 LC in CNC MTs index keywords is divided into 6 clusters.

Cluster 1 (22 items): 3D printers, additives, aluminum alloys, computer numerical control machining, conformal cooling channel, cooling, cooling systems, cost reduction, energy conservation, fabrication, heat transfer, hybrid materials infill drilling, injection molding, microstructure, molds, oxygen, sintering, temperature measurement, ternary alloys, titanium alloys, vanadium alloys.

Cluster 2 (20 items): CNC machine tools, computer simulation, deformation, error compensation, errors, grinding (machining), grinding machines, heat convection, machining accuracy, material removal rate, mathematical models, neural networks, optimization, Taguchi methods, temperature, temperature distribution, temperature sensors, thermal characteristics, thermal deformation, thermo analysis.

Cluster 3 (15 items): Automation, computer control, computer software, coolants, finite element method, fits and tolerances, guideways, lathes, lubrication, machinery, machining, manufacture numerical control systems, precision engineering, turning.

Cluster 4 (14 items): computer numerical control machines, cutting, cutting forces, cutting tools, electric power utilization, energy utilization, friction, machining centers, milling (machining), nanoparticles, regression analysis, surface properties, surface roughness, wear of materials.

Cluster 5 (13 items): bearings (machine parts), bearings (structural), computer numerical control, film thickness, finite volume method, hydraulics, hydrostatic bearings, hydrostatic thrust bearing, lubricating oils, numerical methods, plates (structural components), product design, thrust bearings.

Cluster 6 (9 items): computer control systems, computer numerical control (CNC) machine tool, couplings, machine components, differential geometry, gears, geometry, high-precision, machine tools.

Figure 8 depicts a word cloud of LC in CNC MTs index keywords and links between index keywords published by authors and nations. It is a graphical depiction of the words frequently appearing in an author’s work. The terms are often presented in various sizes, with the most commonly used word, LC in CNC MTs, appearing in the biggest type.

Figure 8a can quickly identify themes and topics of index keywords. For example, computer control systems, computer numerical control, machine tools, and numerical control systems have the largest font, so they have a greater appearance.

On the other hand, conformal cooling channels, cooling systems, temperature, energy utilization, cutting forces, and thermal characteristics have the smallest font size and a lesser appearance.

Figure 8b depicts the relationship between the index keywords utilized by the authors and published journals. For example, the index keywords computer control systems, deformation, machine tools, and CNC machine tools were utilized by authors such as Zhang Y., Dai Y., Li Z., Liu C., Wang S., and Li M, and belong to China.

5. Research Hotspots

Research hotspots are research areas currently garnering much interest; they are considered to be at the cutting edge of their respective fields, and are expected to provide new and significant discoveries. Analysis of research funding trends, publications, and citations in a certain topic might help identify hotspots. Identifying research hotspots can assist researchers, funding agencies, and industry executives in making educated decisions about where to invest time and money. Network diagrams that demonstrate links between various study topics, highlighting regions that are widely referenced or have a high degree of academic collaboration, can be used to depict research hotspots. Word clouds also represent a specific field’s most commonly used terms or phrases, offering a fast research summary.

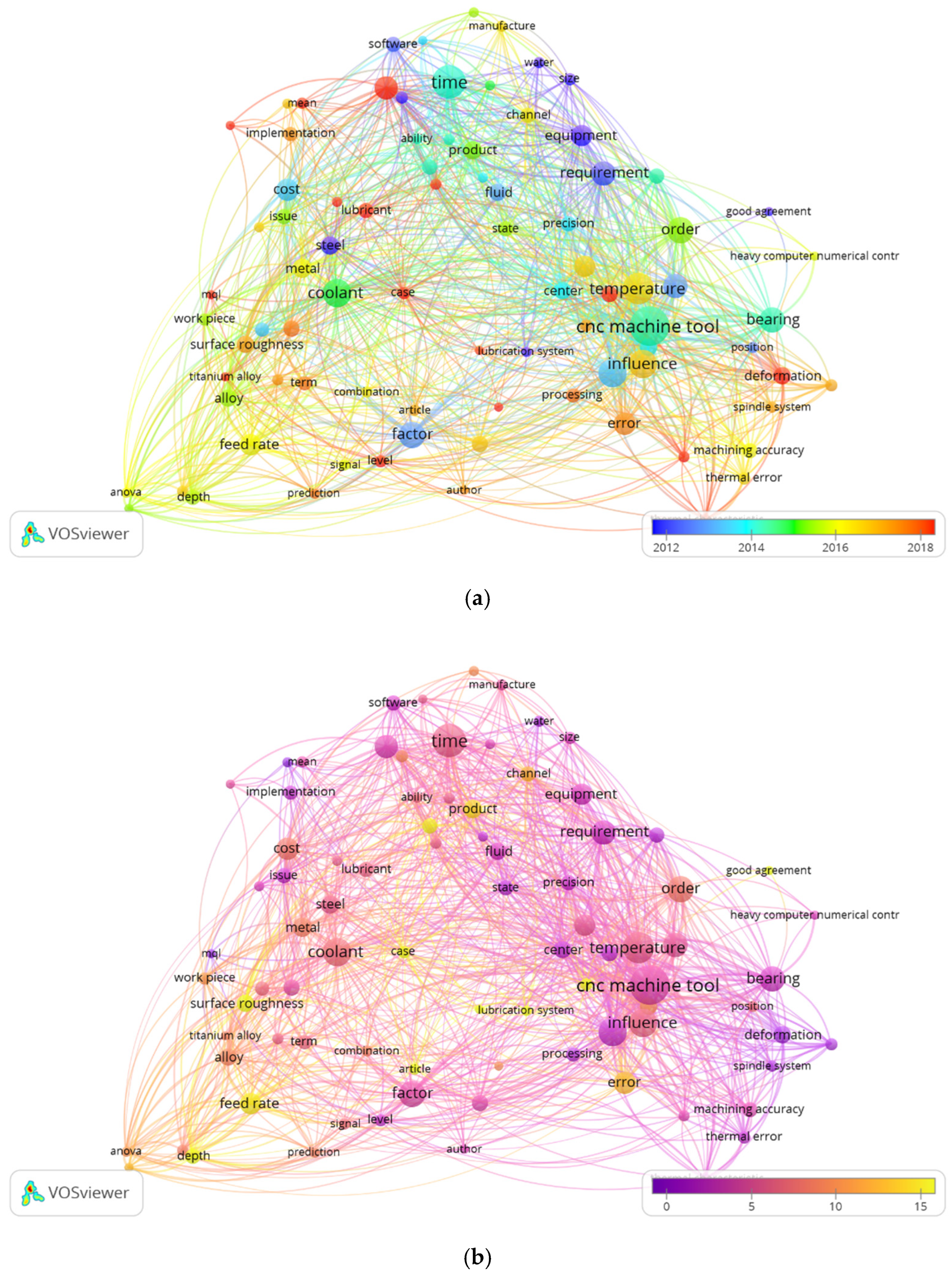

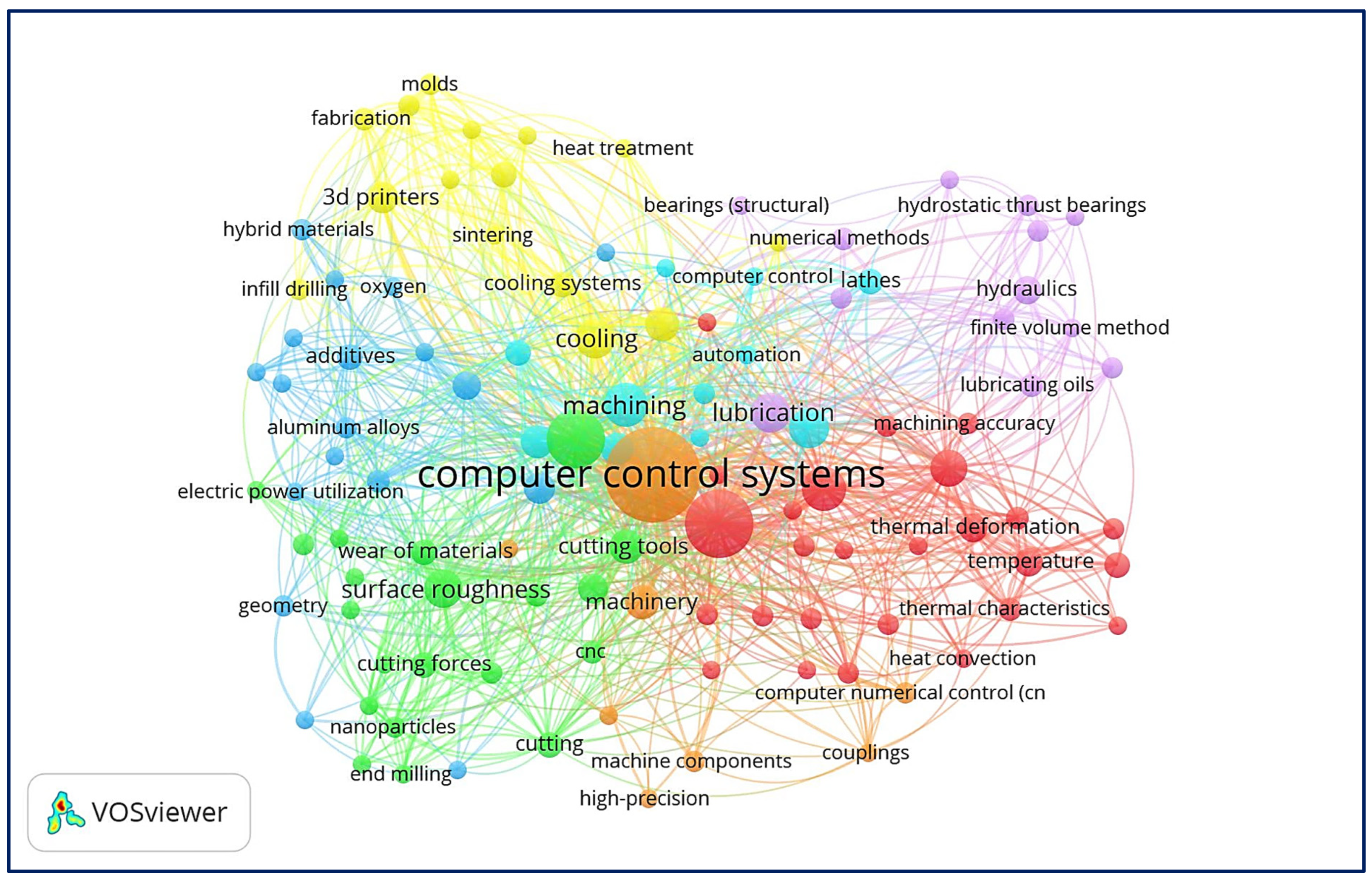

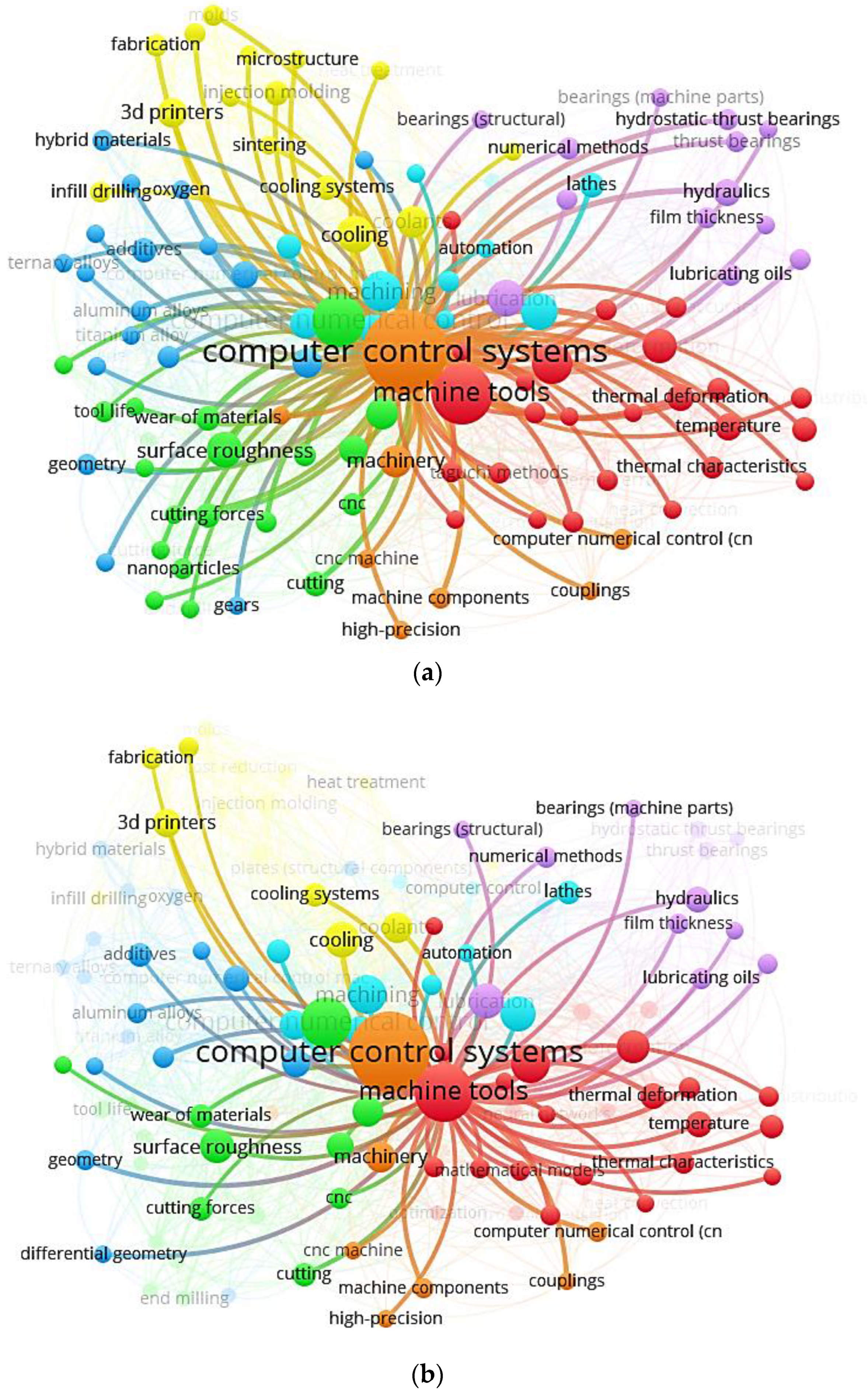

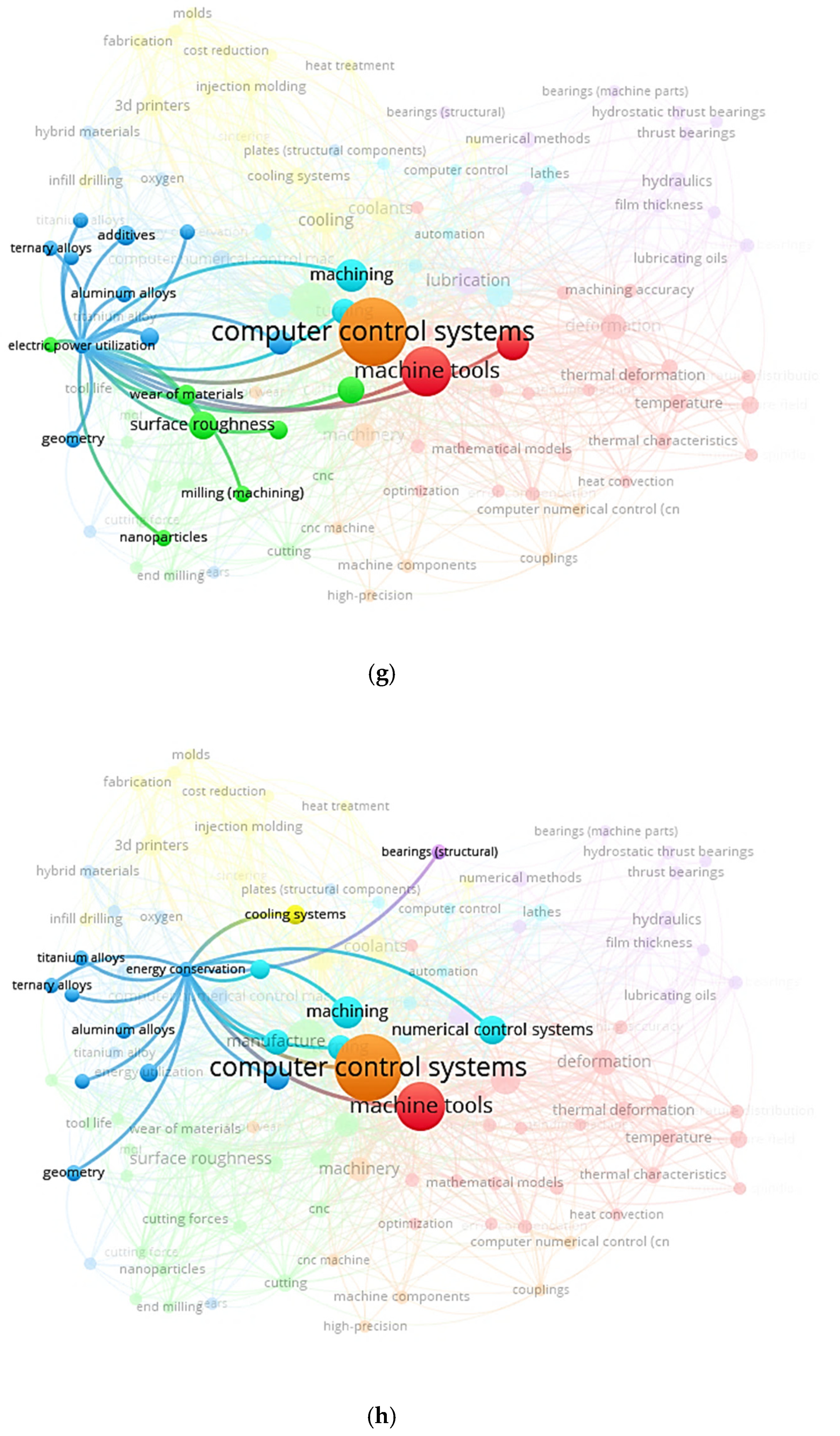

Research hotspots and gaps in LC in CNC MTs are presented while analyzing all keywords, including author and index. There are 1517 keywords from the collected data of LC in CNC MTs. The network plots of all keywords are shown in

Figure 11, with a minimum occurrence of three keywords; one hundred and eleven items appeared in the network, with division into seven clusters, with different colours. The bubble size is directly proportional to the keyword occurrence; a more significant size represents research hotspots, and a smaller size indicates research gaps. Based on this analysis,

Figure 12 depicts hotspots and

Figure 13 gaps in LC in CNC MTs.

Clusters are related articles or documents with similar characteristics or keywords. Each cluster in VOSviewer is assigned a unique color, to distinguish it from other clusters. The color of a cluster is determined using a coloring algorithm based on the modularity optimization technique. The color of a cluster is not associated with any specific meaning; it is used to differentiate between different clusters [

42]. The size of bubbles in VOSviewer represents the importance or relevance of a particular document or keyword within the network. The larger the bubble, the more important or relevant the document or keyword is. The size of a bubble is determined based on its frequency or centrality within the network. However, it is important to note that the formula used to calculate bubble size may vary, depending on the specific analysis conducted [

49].

While identifying research hotspots of LC in CNC MTs, keywords were searched to collect data for analysis, such as lubricant or lubrication or cooling or cryogenic or coolant or lubricating and computer numerical control or computer numerical control CNC machine or CNC machine tool. The searched keywords are not included in signifying research hotspots. However, these keywords can probably become research hotspots, because all collected data revolve around them. Therefore, these keywords are prominent hotspots. However, rather than these keywords, others were considered research hotspots.

Six research hotspots were identified in

Figure 11, and the highlighted views are shown in

Figure 12. It includes (a) computer control systems, (b) machine tools, (c) computer numerical control, (d) machining, (e) numerical control systems, and (f) surface roughness.

- (a)

Computer control systems

CNC MTs use computer control systems to automate the process of machining parts. These systems use a CNC program to control the movement of the MTs and input instructions such as cutting speeds, tool selections, and dimensional tolerances. The CNC program is typically written in a specialized programming language, such as G-code or M-code, and is used to control the machine’s movements by sending commands to its servo motors or stepper motors.

Computer control systems emerged as the topmost research hotspot of LC in CNC MTs and occurred 83 times, with a 463-link strength. A high-reliability computer, several trustworthy controllers, a variable speed drive unit and a software monitoring system, make up the computer control systems and belong to the index keywords of LC in CNC MTs. Computer control systems as an index keyword appeared in [

50] and is the most cited of the 85 times in papers published in 2013 and work related to achieving superior quality and minimizing friction at the contact. The ordinary mineral oil was mixed with nanoparticles at various concentrations, and the cutting force and Ra were diminished by 21.99% and 46.32%, respectively, compared to conventional lubrication systems in CNC end milling [

50]. The next most cited of the 72 works related to Ra modelling [

51]. A unique concept for modelling and compensating was implemented to reduce the temperature-dependent positioning inaccuracy of MTs [

52]. A CNC-picture monitoring system was used to gauge the dimensions and sphericity of the hole throughout peck drilling [

53]. The innovative fuzzy-logic-based method was used to assess the machining performance while milling the Al alloy, by adding SiO

2 nanoparticles to the lubricant. From the experimental findings, the suggested fuzzy model demonstrated high levels of trustworthiness and accuracy for cutting force of 96.19%, cutting temperature of 98.27%, and Ra of 91.37% [

54]. Most recent work includes evaluating the impact of the solid lubricant on the performance of dry machining while turning, and self-lubricant coatings are applied to cutting inserts. The work solutions allow the possible application of TiSiN(Ag) coatings for dry machining of the TiAl6V4 aerospace alloy [

55].

The keyword which most emerged next, with an occurrence of 42 and a 232-link strength of LC in CNC MTs. Machine tools is found as an author and index keyword by [

52] and in other works [

53,

56,

57,

58].

Figure 12b shows it is strongly connected with computer control systems.

This is the next research hotspot, with an occurrence of 31 and a 165-link strength of LC in CNC MTs. Computer numerical control as an index keyword is utilized by [

50,

51,

53,

54,

56]. The designs of tests were used to optimize the CNC end-milling variables for aluminium alloy. A mathematical prediction model was evaluated for the groove difference and roughness [

59]. A CNC framework incorporated with ultrasonic additive manufacturing technologies uses sporadic subtractive operations. The subtractive techniques were employed for net reshaping and introducing internal features as the component was constructed. The CNC architecture also manages the motion of the welding process [

60]. The several kinds of coatings that have lately been employed in turning difficult-to-machine materials were addressed in a survey. The coatings’ interactions with turned surfaces, the wear patterns during material turning, a correlation between these wear processes, and the expected lifespan of the coated tool, were also given. Alternatives to the current turning process techniques under certain lubrication conditions are more environmentally friendly [

61]. Some other works utilized computer numerical control as a keyword [

62,

63,

64].

The term machining comes out as e the next most productive research hotspot, with an occurrence of 18 and a 87-link strength of LC in CNC MTs. Although the authors utilized the term machining in the title, abstract, and author keywords, it also appears in index keywords. The most cited article [

50] of 85 citations utilized the machining term in the title, abstract and as a keyword, and Ooi et al. [

54], Soshi et al. [

58]. Sousa et al. [

61] presented a comprehensive review while considering turning operations, including coatings. The thermal modelling for deep grinding on CNC machines has established a hypothetical equation for the burn threshold. The film boiling of the operation coolant influences the burn threshold in high-efficiency deep grinding, and the critical heat flux rises with the rate at which a given material is removed [

65]. Paras et al. [

63] utilized nano lubricants while considering power, tool life and quality features in the milling operation. The need for fast, highly precise machines has grown substantially, and the primary obstacles to enhancing CNC MTs’ accuracy are thermal motion errors, accounting for up to 70% of all machining errors. Thermal sensors were consequently installed at various locations of the MTs cooling system to monitor temperature variations [

66]. Zhang et al. [

67] offered an essential theoretical foundation for developing hydrostatic guide rails in actual engineering practice, and a dissertation of fundamental conceptual value for enhancing the machining correctness of numerical control machines and the overall CNC apparatus. The primary objective was to increase cutting stiffness [

67].

The U-shaped milling grooves were observed to have superior temperature regulation to the straight cooling channels. With U-shaped milling grooves, the core and cavity temperature distributions were more even than with straight cooling channels [

68]. The primary factors that determine a motorized spindle’s performance and impact CNC MTs’ machining precision are its thermal properties. Therefore, to enhance a motorized spindle’s thermal properties, it is crucial to forecast its thermal field while operating precisely. Zhang et al. [

69] presented the finite element model and considered how the LC system variables affected the surface temperature of the motorized spindle. According to the data, the relative mean prediction error is 1.5% when the spindle is spinning at 10,000 rpm, and 3.6% when it is spinning at 15,000 rpm. The suggested model can accurately predict the motorized spindle’s temperature field [

35]. To decrease tooth-surface flaws and enhance the quality of the tooth-surface topography, a technique of shaving operation for gears was devised. On a CNC MT, machining trials for gears were carried out using shaving cutters with axial grooves. The findings significantly impacted the way of lubricating and activating the spiroid face gears [

70].

A sizable component of production- and manufacturing-workshop servicing involves MTs lubrication systems. Automatic lubrication systems provide a healthier, more regular, and time-appropriate monitoring method for MT lubrication by eliminating the need for reckless manual lubrication. Classical automatic lubrication systems, however, come with built-in technical, economic and environmental issues. The innovative automatic-lubrication-control system in the CNC MT guideways was presented by Sparham et al. [

71]. Temperature signals from delicate sensing devices put in the MT guideways, with the signals representing the friction, wear, and loading conditions, can be used for failure identification and correction in the LC network [

71].

To meet the criteria for the transmission and structure of CNC MTs for high-speed machining, a high-rotation unit powered by an integrated motor was devised by Zhang et al. [

72]. The spindle motor was cooled using an oil–water heat-exchange system. The spindle bearings were also lubricated and kept cold using an oil–air lubricator. To balance the spindle, various unusual structures were finally chosen [

72]. Temperature gradients develop, due to resistance to heat movement within and between an MT and the workpiece from both internal and external heating systems. This results in linear expansion and the distortion of the MT’s structural components. The influence of extension and compression on the spatial location of the tool and workpiece, which results in thermal errors on the workpiece, was determined by the connection of the structural parts. Temperature gradients significantly affect machining accuracy, and shift and change shape during the machining process, according to measurements on various MTs [

73]. White et al. [

73] examined connectivity and MT architecture. They demonstrated that the location and intensity of thermal gradients significantly influenced the comparative mobility of the tool and workpiece. Additionally, a vertical-machining centre’s findings indicate that an effective thermal-distortion prediction requires information [

73]. Mohammadi et al. [

74] looked for a real-time technique to track the electrical outflows in a CNC MT. This technique segmented MT into modules and took readings of the user’s power, the temperature at the pump’s inlet and outlet, the current, and the motors’ speed. A Sankey chart was used for the depiction, which makes it simple to comprehend the energetic flows in the MT [

74].

Zhang et al. [

75] used finite element analysis to simulate the features of rotating speed on the pressure and flow arenas of the oil pad, which is a technique of resolving complex engineering glitches by breaking them down into smaller, simpler problems that can be solved using mathematical equations. The study found that the pressure in all recesses declines with the rotation speed. This is likely due to the increased fluid flow and movement that occurs as the rotation speed upsurges, which causes the pressure to decrease. Wang et al. [

76] used a combination of electrical discharge and computer-controlled movement to deposit the alloy onto the substrate. The microstructure of the deposited coatings was found to change as the number of layers increased. Specifically, the coatings start as a body-centred cubic solid solution and then transform into an amorphous phase. The study suggested that the process effectively produces medium-entropy-alloy coatings with high hardness and unique microstructure properties on titanium alloy substrates. The study also provided insight into the effect of layer number on the microstructure and hardness of the coatings. Shen et al. [

70] also worked on numerical control systems. Shen et al. [

77] used a hybrid procedure for creating lubricant grooves on linear guides. They proposed combining laser ablation and CNC machining to create precise and consistent lubricant grooves. The results show that the hybrid process can produce lubricant grooves with high precision and surface quality while being more efficient and cost-effective than traditional machining methods. As a result, the process can be applied in the aerospace, automotive and manufacturing industries, where lubricant grooves are necessary, and is a valuable resource for researchers and engineers working in precision manufacturing and lubrication technology.

Lee et al. [

78] presented a study on the microscopic analyses of the electrical conductivity of micromachined-folded waveguides for terahertz vacuum electron devices. The authors focused on the relationship between the Ra of the waveguide and its electrical conductivity. The results show a strong correlation between the Ra of the waveguide and its electrical conductivity. Therefore, controlling the Ra of the waveguide is crucial for achieving high electrical conductivity in terahertz vacuum electron devices. They also proposed a method of surface treatment to reduce Ra and increase conductivity.

Sheng et al. [

79] studied the thermal characteristics of the spindle system of a c CNC MT using theoretical analysis and experimental measurements, and investigated the thermal behaviour of the spindle system, identifying the key factors that affect its thermal performance. The spindle system’s thermal performance was affected by several factors, including the spindle speed, the power of the spindle motor, and the cooling system. An efficient cooling system is crucial for maintaining the thermal stability of the spindle system and ensuring accurate machining. The study makes a valuable contribution to the field of CNC MTs by providing a better understanding of the thermal characteristics of the spindle system and the key factors that affect its performance.

Weng et al. [

80] studied the couple-bearing force of magnetic-liquid suspension guideways with complex constraints. The benefits of using magnetic-liquid suspension systems in transportation technology were discussed, such as their ability to provide levitation and guidance for high-speed trains. However, the guide-way and magnetic sources are often complex and multi-faceted in real-world applications. This complexity can lead to a non-uniform and unstable suspension, which can negatively impact the performance and safety of the transportation system.

Carvalho et al. [

81] reviewed the prior research on using grammatical evolution (GE) for modelling EC on a CNC MT. First, they presented the increasing importance of energy efficiency in manufacturing, particularly in CNC MT. They described GE as a method for automatically generating mathematical models, and noted that it had been successfully applied in various fields, such as optimization, control, and prediction. Finally, the authors used GE to model energy consumption in manufacturing systems. However, they noted that these studies have primarily focused on predicting energy consumption in specific manufacturing processes. They also highlighted the fact that these studies had used GE to model the energy consumption of CNC MT under different operating conditions, such as varying cutting parameters and tool wear. The review revealed that GE could generate accurate models of energy consumption in CNC MTs, and that these models could capture the complex relationships between energy consumption and operating conditions. However, the review pointed out limitations, in that research focused mainly on individual machines and processes, and did not consider the entire factory or production line.

Sayuti et al. [

50] explored the possessions of carbon onion nanolubrication on cutting force and Ra in machining aerospace duralumin. The machining of aerospace materials such as duralumin can be challenging, due to their high hardness and strength, and results in high cutting forces and poor Ra. The use of lubricants in machining can help to reduce cutting forces and improve surface quality, but traditional lubricants have limitations, such as poor thermal stability and poor lubrication at high temperatures. The authors proposed carbon onion nanolubrication as a new lubrication system that uses carbon onions, which are spherical carbon structures, as lubricant particles were shown to have excellent thermal stability and good lubrication properties at high temperatures. Kurra et al. [

51] presented a new method for modelling and optimizing Ra in single-point incremental forming. It can effectively reduce Ra in single-point incremental forming. Ooi et al. [

54] explored the effects of nano-suspended lubrication on Ra and tool wear in the precise machining of aerospace aluminium. The nano-suspended lubrication system maintained its lubricating properties even at high cutting speeds and temperatures.

The internal cooling channels fabricated via SLM had a lower flow rate and cooling performance than those fabricated via the conventional drilling process. However, the Ra of the internal cooling channels fabricated via SLM was higher than those fabricated via the conventional drilling process. Therefore, optimizing internal cooling channels is needed to fully understand this technology’s potential [

62]. A sustainable machining of AISI 1045 steel revealed a reduction in EC and improved Ra by using high-performance cutting tools, optimizing cutting parameters, and recycling CFs [

64].

Sparham et al. [

71] investigated precision machining and oil consumption in CNC MT guideways. The system utilizes sensors to monitor the lubrication needs of the machine and automatically dispenses the appropriate amount of lubricant. The results revealed more precise machining and less oil consumption than manual lubrication. Okafor [

82] investigated the consequences of cooling and machining approaches on Ra, tool wear, and machining time, in the high-speed milling of titanium and nickel superalloys. High-speed milling is challenging, due to its high strength and hardness. These materials generate high cutting forces, temperatures, and Ra, leading to poor Ra, tool wear, and short life. The study found that high-pressure coolant and cryogenic cooling effectively reduced Ra and tool wear, while laser-assisted machining reduced machining time.

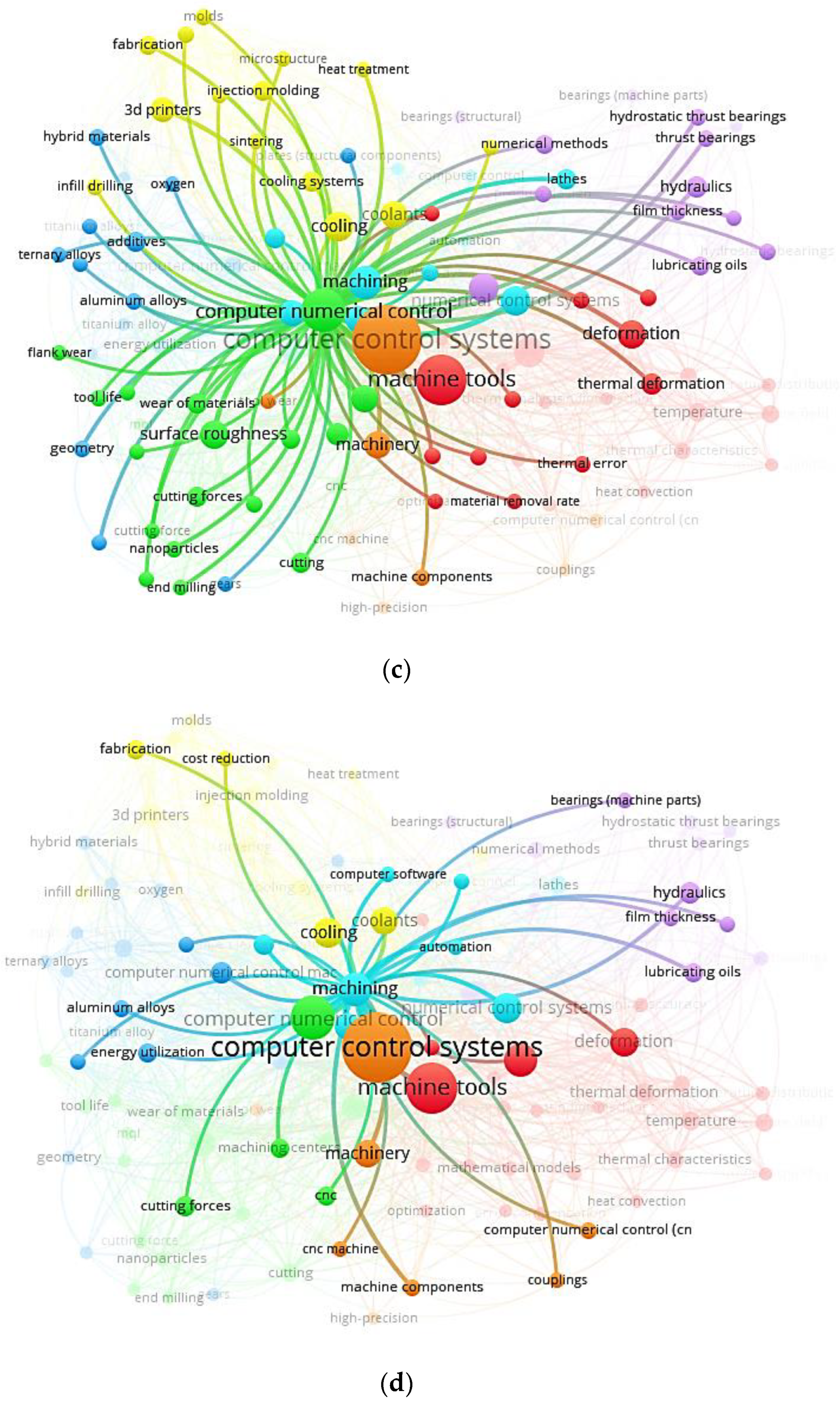

6. Research Gaps and Future Directions

VOSviewer can be a valuable tool for identifying research gaps by visually representing the structure of the research literature in a specific field. By identifying areas of the network with few connections between clusters, researchers can gain insight into the areas where new research is needed to advance the field.

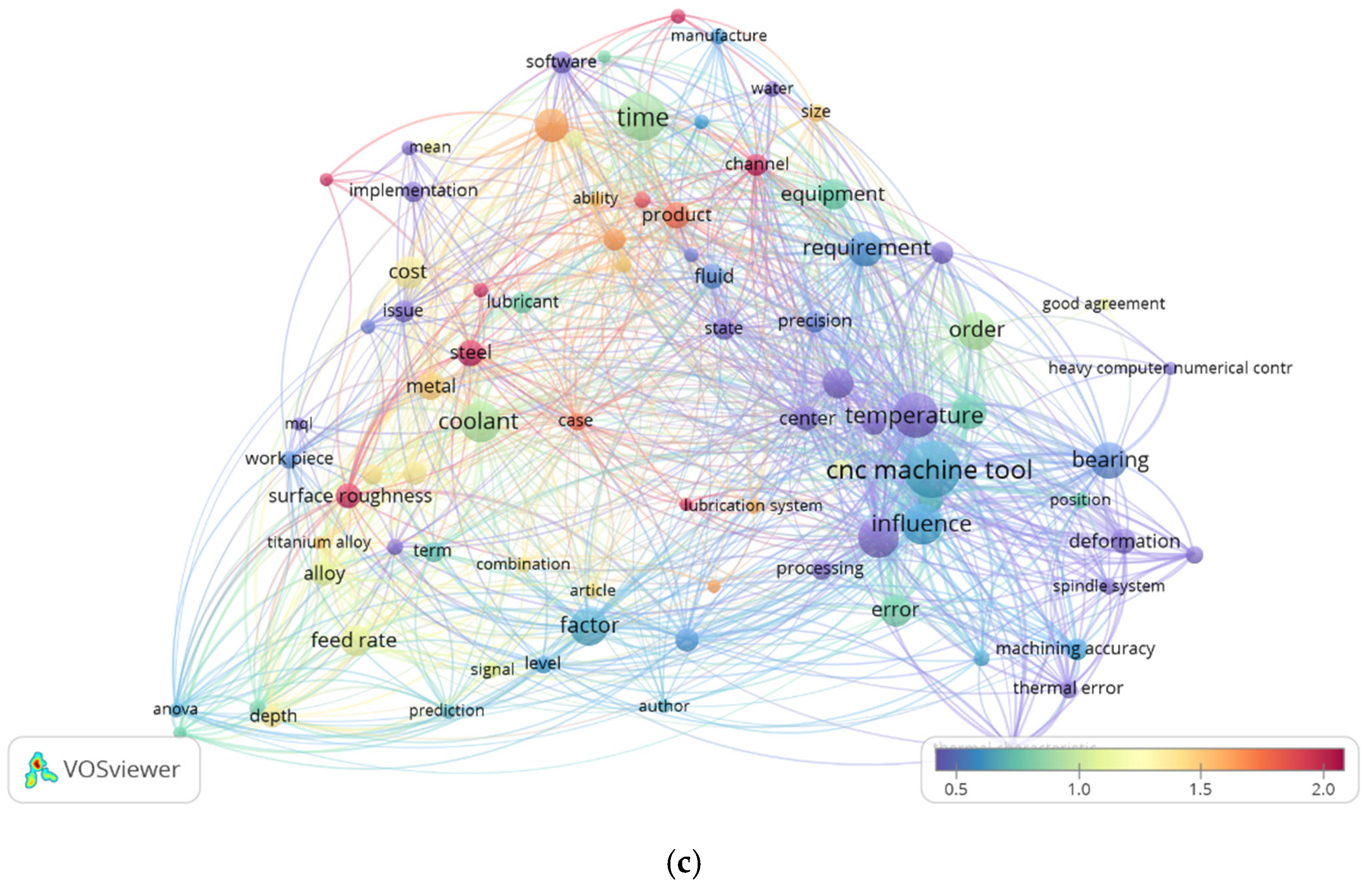

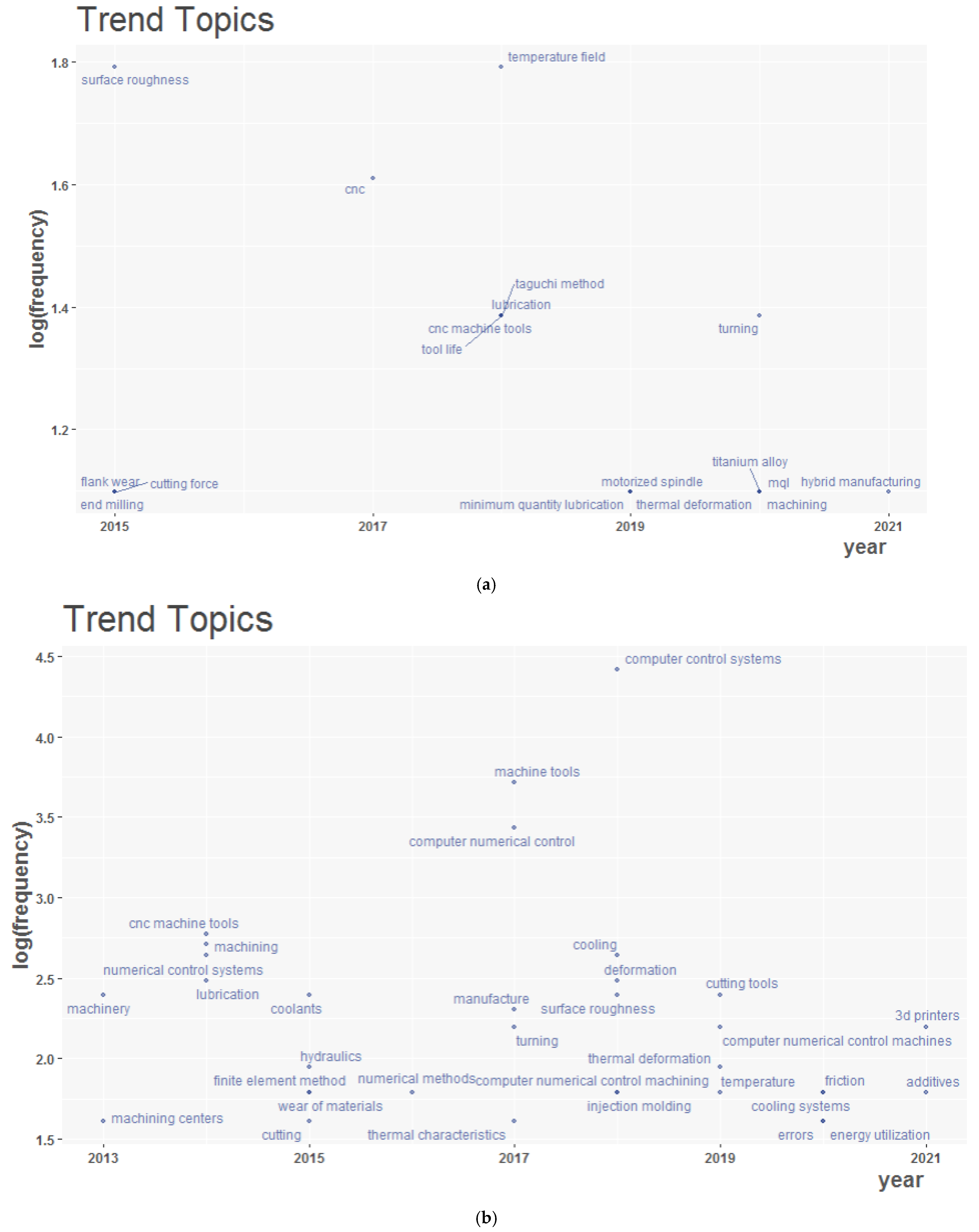

Figure 13 depicts gaps in LC in CNC MTs. It includes main gaps such as those shown in

Figure 13: (a) temperature, (b) cooling systems, (c) cutting forces, (d) energy utilization, (e) tool life, (f) nanoparticles, (g) electric-power utilization, and (h) energy conservation. These terms were identified as having the least occurrence, and some details are discussed here.

- (a)

Temperature

Feng et al. [

52] proposed a method for modelling and compensating for errors based on thermal-characteristic analysis; there are temperature-related errors in positioning systems. Previous studies have focused on the effects of thermal expansion on linear positioning systems, such as those used in MT or robots, and methods have relied on empirical models. However, there has been less research on the effects of temperature on rotary positioning systems, such as those used in aircraft or satellites. The proposed method involves measuring the thermal properties of the materials used in the system, and using these properties to predict the effects of temperature changes. and is suitable for both linear and rotary positioning systems. It can be easily implemented in real-world systems. It is necessary to test and validate the proposed method on various systems and operating conditions to evaluate its performance and generalizability. The grinding process is significantly influenced by temperature, with high temperatures resulting in greater grinding forces and worse surface quality. Hence, applying coolants during the grinding operation can aid in lowering temperatures and enhance the workpiece’s surface condition. The significance of temperature in the grinding process and the necessity for additional study of cooling techniques was emphasized. In addition, advanced methods such as artificial intelligence and finite element analysis may enhance grinding-process control, leading to better surface quality and a lower burn threshold [

65].

By lowering friction and heat generation during milling, nanolubrication can enhance the machining process. Implementing fuzzy logic in machining control can aid in optimizing machining settings and enhance workpiece surface quality. It has been recommended that more research be done on how temperature affects machining processes and how nanolubrication is used in various temperature ranges. Using cutting-edge methods such as AI and machine learning (ML) to understand better and manage the machining process can lead to improved surface quality, longer tool life, and less heat damage [

54]. Thermal fluctuations throughout the machining process result in spindle faults and worse machining precision. Applying thermal-compensation techniques in CNC MTs can help lower thermal mistakes and increase machining accuracy. The significance of temperature in the CNC MTs was emphasized as the necessity for additional study of thermal-compensation techniques. According to the authors, using cutting-edge methods like AI and finite element analysis may help to increase the management of thermal mistakes in CNC machining, leading to increased machining accuracy.

The temperature greatly impacts the injection-moulding process; high temperatures enhance the cycle time, lower the quality of the parts, and accelerate the wear on the mould. In injection moulding, different cooling techniques, such as air and water cooling, can help to lower temperatures and enhance the quality of the moulded components. Therefore, it is necessary to look into how U-shaped milling grooves affect cooling effectiveness and moulded-part quality. Advanced techniques such as simulation and optimization are desired to improve the understanding and control of the cooling process in injection moulding [

68]. The functionality of motorized spindles is significantly influenced by temperature, with extreme temperatures resulting in shorter spindle life and reduced precision. Hence, using advanced forecasting models, including empirical models and finite element analysis, to predict the temperature field of motorized spindles, can assist in identifying and preventing thermal problems. To forecast the temperature field of a motorized spindle, the authors devised a hybrid prediction model that incorporates finite element analysis and empirical models. In addition, the authors recommended validating the proposed hybrid prediction model’s design and looking into cutting-edge methods such as AI and ML to increase the precision and efficacy of temperature prediction in motorized spindles [

69]. The effectiveness of CNC MTs highlights the significance of good lubrication and the requirement for effective lubrication control systems. The suggested automated lubrication control system might work well for increasing machining accuracy and minimizing oil usage in CNC MT guideways. In addition, AI and ML could help increase CNC MT performance and optimize the lubrication control system [

71].

Cooling systems are crucial for CNC grinding MTs, as they remove heat produced during the grinding operation and guard against thermal damage to the machine and workpiece. The reliability of CNC grinding machines was examined, due to the use of cooling techniques such as air, water, and oil. It was suggested that fault tree analysis be utilized to gauge how reliable a CNC grinding machine’s cooling system is. In addition, it was recommended that more research be carried out, to determine the impacts of temperature and environment on the cooling system’s reliability and to investigate the adoption of cutting-edge approaches to optimize the cooling system and boost the dependability of CNC grinding MTs [

83]. A CNC lathe-spindle system’s cooling channels may be designed better, according to Yang and Lee, who suggested employing optimization analysis. Investigating the effects of various coolant flow rates, temperatures, and environments on the cooling system’s performance is necessary. It is also necessary to investigate the use of cutting-edge methodologies such as simulation and computational fluid dynamics to improve the performance of CNC lathes and optimize cooling-system design. Optimization analysis may be useful for optimizing the design of cooling channels in CNC lathe-spindle systems [

84]. Energy use in CNC MTs is heavily influenced by cooling systems, with efficient cooling systems resulting in lower energy use. The authors suggested utilizing genetic programming’s grammatical evolution approach to model energy use in a CNC MT. Advanced techniques are recommended to optimize cooling systems, improve energy efficiency and reduce energy consumption in CNC machines [

81].

According to Feng et al. [

85], effective cooling in moulds is crucial, since it significantly impacts the manufacturing process’s productivity and quality. According to the review, moulds employ various cooling methods, including conventional straight, serpentine, and conformal cooling channels. Conformal cooling channels, which fit the mould’s contour, are very useful for increasing cooling effectiveness. The different techniques, such as milling, electrochemical machining, and additive manufacturing, utilized to create conformal cooling channels, were examined. In addition, the most recent developments in the subject were emphasized, including creating novel materials and coatings to increase thermal conductivity and using computer-aided design and modelling tools to optimize the design of conformal cooling channels. However, the authors stated that further study is needed to create more advanced manufacturing processes and materials and to increase simulation tools’ accuracy and reliability. In addition, more comprehensive testing is required to fully comprehend the potential benefits of conformal cooling channels, including cost savings and greater productivity.

Cutting forces are critical in machining, because they greatly influence the surface quality and process productivity. Coolants, CFs, and lubricants are some of the ways that have been utilized to lower cutting forces. The authors [

50] concentrated on applying carbon onion nanolubrication systems, which successfully reduce cutting forces and improve surface quality. There are numerous ways to fabricate and use carbon onion nanolubrication systems and the potential processes for reducing cutting forces. Recent advances in the subject were emphasized, including the use of sophisticated characterization techniques to analyze the behaviour of carbon onion nanolubrication systems during machining, and developing novel materials and coatings to increase their performance. However, the basic methods by which carbon onion nanolubrication systems lower cutting forces and increase surface quality must be understood. Extensive testing is required to fully appreciate the potential benefits of these technologies, including cost reductions and greater productivity in milling aerospace duralumin. Salami et al. [

57] highlighted the relevance of cutting factors in machining processes and the difficulties involved with optimizing parameters for sculptured surfaces. For example, the feed rate was optimized using a genetic algorithm depending on the Ra of the machined surface. Future research topics include the need to create more complex optimization approaches that can handle numerous cutting parameters, as well as the necessity of combining cutting parameter optimization with other manufacturing processes to increase the overall efficiency of machining operations. The authors [

54] concentrated on the utilization of nano-suspended lubrication in metal cutting and the possible benefits it can offer in terms of cutting forces and Ra, arguing that more studies are required to establish a deeper understanding of the mechanisms of nano-suspended lubrication and its effects on cutting forces and Ra in various machining operations. Furthermore, combining modern measuring techniques and sensors with fuzzy-logic-based models may aid in predicting cutting forces in machining processes. The authors [

61] examined numerous research on coated tools in turning operations, such as the impact of coatings on cutting forces, tool wear, Ra, and tool life. They also examined the limits of these researchers as well as the difficulties associated with employing coated tools in turning operations. They proposed that combining modern measuring techniques and sensors with numerical models might enhance cutting-force prediction in turning operations. Furthermore, many lubrication circumstances provide a more ecological option than traditional turning process methods; using coated tool inserts under these conditions is a current hot-study issue, since there is an emphasis on selecting more environment-conscious machining solutions.

Recently, there has been a surge of interest in using nano lubricants and laser surface texturing to improve tool life and reduce power consumption and Ra in milling operations. These technologies can greatly increase milling operations’ productivity and cost, rendering them an appealing solution for many industries. Nanoparticles in lubricants have been proven to enhance tool life and minimize power consumption in milling operations by decreasing friction and wear between the tool and the workpiece. This is due to the lubricant’s nanoparticles’ ability to build a protective coating on the tool’s surface, lowering the heat generated during the milling operation. Furthermore, nano lubricants can increase surface polish by minimizing burr development. Laser surface texturing is a method of creating a pattern of micro-features on the surface of an object using a laser. Lowering the cutting force necessary to remove material from the workpiece can increase tool life and power usage. However, more studies are needed to thoroughly comprehend these technologies’ possible advantages and limits and the best circumstances for their application. Nonetheless, the future of this technology seems bright in the realm of manufacturing, particularly for cutting difficult-to-machine materials and lowering energy usage. Nano lubricants and laser surface texturing are projected to become increasingly common, as the demand for energy-efficient and sustainable production grows [

63].

Sustainable machining is a new discipline that tries to lessen the environmental implications of MT energy usage. The theory behind sustainable machining is that by enhancing MT energy efficiency it is feasible to mitigate the environmental problems connected with energy usage. Sustainable machining on AISI 1045 steel machining was conducted to investigate the possibilities for energy savings and their environmental consequences. Compared to conventional machining procedures, sustainable techniques such as high-speed and cryogenic machining have been proven to cut energy usage by up to 50%. Furthermore, sustainable machining may minimize heat, noise, and vibration, positively influencing the environment. Minimizing energy usage reduces greenhouse gas emissions and the carbon footprint of the industrial process. Sustainable machining techniques are projected to become increasingly common, as the demand for energy-efficient and sustainable production grows. Furthermore, new sustainable machining processes, such as hybrid and precision machining, will be critical to improving the performance of these technologies [

64].

Machining activities account for a large portion of manufacturing energy consumption, and lowering energy usage in these operations can result in considerable cost savings. Zebala et al. [

86] described a technique for minimizing power consumption during turning Ti6Al4V titanium alloy, which involves managing the breakability of the turning chips. The power consumption is lowered when the chips are fragmented into little bits. The unique problems of machining titanium alloys mean that they are notorious for being difficult to mill, due to their extreme strength and hardness. Although chip breakability control has been investigated in other materials, there has been little study on its application to titanium alloys. In addition, there has been limited study on the link between chip breakability and power consumption, with most studies focusing on the usage of specific cutting tools or cutting settings. More study is needed to determine whether the suggested approach applies to additional materials and industrial processes. It may also be beneficial to investigate the impact of various cutting settings on chip breakability and power consumption, to improve the machining process. The suggested method’s potential can be expanded by combining it with other energy-saving technologies, such as high-speed machining and sophisticated cutting tools.

It is stated that CNC MTs are widely employed in industry and that their energy consumption might be high. The complexity of the systems, the high number of variables, and the need to balance energy efficiency with performance are among the issues involved with improving the control of CNC MTs to minimize energy consumption. The emphasis is on particular approaches, such as sophisticated control algorithms or the optimization of cutting parameters, although there has been little study on applying genetic programming for this purpose. The primary goal was to reduce energy use during idle times rather than during milling. The methods required to balance energy efficiency and performance apply to a wide spectrum of CNC MTs [

81]. Zhou et al. [

87] developed a novel model based on power-consumption measurements of CNC MTs under various operating scenarios, such as idle time, cutting time, and quick traverse time, and compared its performance to earlier models. There are difficulties in precisely predicting the energy consumption of CNC MTs, such as system complexity and the necessity to account for changing operation circumstances. Previous research has concentrated on establishing models for calculating the energy consumption of CNC MTs, but there is a scarcity of actual data to validate these models. A summary of the suggested new empirical model for predicting CNC MT standby and auxiliary power consumption was presented. The model is based on measurements of the power consumption of CNC MTs under various operating settings and accounts for the MTs’ various components. Additional characteristics, such as machine size, tooling, and material qualities, might be added to the suggested model to improve it. Furthermore, the potential of the suggested model may be expanded by merging it with other energy-saving technologies, such as real-time monitoring and machine learning, to improve forecast accuracy and enable the dynamic management of MT’s energy usage.

Nanoparticles have recently been an important research topic because of their unique features and potential for various uses. One study area is their use in lubrication for accurate machining, such as in the aerospace sector. When compared to standard lubricants, the nanoparticles provided improved lubrication and cooling. Furthermore, the study’s use of fuzzy logic allowed for the adjusting of the nanoparticle concentration in the lubricant, which increased machining performance even further. Future research on this topic might focus on creating new nanoparticles with improved lubricating and cooling qualities, and investigating the use of nanoparticles in other forms of precision machining [

54]. The nanoparticles have been explored as lubricants for several materials, but there has been little study on their usage in aerospace-duralumin machining. The suggested approach was used to machine aerospace duralumin AL-2017-T4, utilizing carbon onion nanoparticles as a lubricant. The suggested method’s application to different materials and production processes must be researched. The potential of the suggested technology may be expanded by adjusting the nanoparticle concentration, cutting tool type, and cutting parameters [

50]. Nanoparticles have received much attention, because of their unique features that make them suited for various applications, including lubrication. Nanoparticles, sometimes known as nano lubricants, have been discovered to improve performance and efficiency in several machining operations. Future studies on this topic might concentrate on producing novel nano lubricants with improved qualities for machining operations and investigating the application of nano lubricants in other machining processes. Furthermore, more research should be undertaken on the cost-effectiveness of employing nano lubricants in milling, as well as the environmental impact of their use [

63].

The electric power utilization in milling activities is energy-intensive and can result in high costs and environmental implications. Nano lubricants and laser surface texturing may be viable techniques for enhancing the electric power use, efficiency, and quality of milling operations, but further study is required to appreciate their potential advantages and limits [

29] fully. Using electric power in turning activities can be energy-intensive, resulting in high costs and environmental implications. Cryogenic treatment is chilling a material to extremely low temperatures, often less than −180 °C, to improve its mechanical characteristics. It has been observed that cryogenic treatment of tungsten carbide inserts increases their strength, hardness, and wear resistance, resulting in longer tool life and lower power usage. Turning nodular cast iron with cryogenically treated tungsten carbide inserts resulted in higher cutting performance, decreased Ra, and extended tool life, according to experimental results and performance analyses. To create appropriate cryogenic-therapy regimens and understand their potential advantages and limits, it is necessary to understand the underlying processes [

49] completely. Rather than requiring hefty physical devices or the usage of actual materials, virtual laboratories may offer students a simulated environment for learning and practising CNC machining and automation skills. This can result in economic savings, as well as a lower environmental impact. Virtual laboratories might also provide students with a safe and controlled setting for experimentation and learning, eliminating the chance of harm or equipment failure. Virtual 3-D laboratories may be likely to decrease energy use and the carbon emissions associated with real equipment, while offering a safe and regulated setting for experimentation, learning, and practice [

88].

Energy conservation in CNC MTs is a key topic of study and development, since these machines are often energy-intensive and can consume a large amount of energy in a production plant. Several solutions for lowering the energy consumption of CNC machine tools have been presented and explored in the literature. To decrease the energy required to remove material, one option is to optimise the cutting conditions [

89]. This may be accomplished by employing sophisticated cutting-tool materials and coatings, and optimised cutting-tool geometries. Another strategy is to apply sophisticated control techniques, such as adaptive control, to maximise machine performance in real time, while reducing energy usage [

90]. Another strategy is to employ energy-efficient drive technologies, such as servo motors, energy-saving modes and power management systems. When the machine is not in use or is operating at low loads, these technologies can automatically turn it off or minimise its power usage. Another strategy is to employ modern cooling systems, such as high-efficiency ones, to lower the energy required to cool the machine. This may be accomplished by utilising high-efficiency cooling pumps, heat exchangers, and cooling fluids. Further studies are necessary to create effective control mechanisms for specific materials such as Ti6Al4V titanium alloy [

86,

91].

Li et al. [

92] looked at the literature on energy conservation and the strategic development of dual-driving electric spindles. Spindle systems account for a significant portion of energy usage in CNC MTs. Fresh patents on the design and modelling of dual-driving electric spindles, an alternative to classic spindle systems that might save energy, were highlighted. Dual-driving electric spindles are spindle systems that employ two motors, one for primary spindle rotation and one for auxiliary rotation, allowing for more efficient energy consumption. The investigation also uncovered the usage of simulation tools to evaluate the effectiveness of dual-driving electric spindles and find possible energy savings. Depending on the exact design and control technique, dual-driving electric spindles can save up to 50% more energy than traditional spindle systems. The authors conclude the paper by stating that while dual-driving electric spindles show promise for decreasing energy usage in CNC MTs, additional research is required to create appropriate designs and control systems. Furthermore, there is a gap in implementing these spindles in real-world applications and analysing their long-term energy savings.

7. Remarks on Current Trends, the Future, and the Conclusions

7.1. Trending Topics, and Future Directions in LC in CNC MTs

A trending topic in

Figure 14 is a graph visually representing the most popular or frequently discussed topics on LC in CNC MTs. The graphs in

Figure 14a,b shows the number of mentions or the level of engagement with each topic over a specific period for the author and index keywords, respectively. They can be used to identify trends and patterns in the data and to gain insights into what researchers are talking about and what issues are gaining attention on LC in CNC MTs.

Based on the author’s keywords for 2015 to 2021, it was analyzed that surface roughness, flank wear and cutting force played a crucial role up to 2015. In 2017, CNC was on-trend, followed by a temperature study in CNC MTs and lubrication and cooling, employing the Taguchi method. From 2018 onwards, minimum quantity lubrication (MQL) and thermal deformation have come into a trend in the research of LC in CNC MTs. From 2020–2021 onwards, the main trend is hybrid manufacturing and titanium alloys, considering LC in CNC MTs; refer to

Figure 14a.

Furthermore, the transformative trends in the development of LC in CNC MTs were scrutinized utilizing index keywords for 2013–2021. During this period, major developments were observed from 2014 to 2019. In 2014, CNC MTs, machining, numerical control systems and lubrication took their place in LC in CNC MTs. Numerical control systems and lubrication play a crucial role in ensuring CNC machines’ accurate, efficient, and reliable operation. Without proper numerical control systems and lubrication, CNC MTs would experience more wear and tear, resulting in lower precision and a shorter lifespan, which is why these are more trending topics and CNC MTs are becoming an integral part of machining. In 2021 and onwards, 3D printers, additives and energy utilization are on-trend; refer to

Figure 14b.

A few recent trends in LC in CNC MTs aim to improve the performance and efficiency of the machines. First, minimal quantity lubrication (MQL) is a method of lubrication that uses small amounts of lubricant, typically delivered through a fine mist or aerosol. MQL is becoming increasingly popular in CNC MTs, because it reduces the amount of lubricant required, which can lead to cost savings and a reduction in environmental impact. Second, closed-loop lubrication systems use sensors to monitor the lubrication levels and automatically adjust the flow of lubricant to the machine components, as needed. This can help to reduce waste and improve the consistency of lubrication. Third, high-pressure coolant systems use pumps to deliver coolant directly to the cutting tool. This can improve the cooling efficiency and reduce the heat generated during the cutting process. Finally, in-process monitoring and control use sensors and data analysis to monitor the machine’s performance, detect potential issues and adjust the lubrication and cooling systems accordingly. This can help improve machine uptime and prolong the machine’s life. Overall, the trend in LC in CNC MTs is focused on reducing waste, improving efficiency, and increasing the machine’s lifespan.

Several potential research directions for LC in CNC MTs aim to improve the performance and efficiency of the machines. These include developing more efficient and environmentally friendly lubricants. Researchers are working on developing lubricants with lower viscosity and requiring less frequent re-application, reducing the amount of lubricant required and the environmental impact. In addition, researchers are looking into alternative coolants, such as water-based or bio-based, which may have a lower environmental impact and be more energy-efficient. Research is being carried out to develop real-time monitoring and control systems that can detect potential issues with the lubrication and cooling systems and adjust them accordingly, improving the machine’s performance and lifespan. Finally, research is being carried out on developing intelligent lubrication and cooling systems that use ML algorithms to optimize the LC processes for specific applications and conditions. Researchers are exploring using nanoparticles as lubricants to reduce friction, heat, and wear in CNC MTs. Overall, the future research directions in LC in CNC MTs are focused on increasing efficiency, reducing waste, and improving the environmental impact of these systems.

Energy conservation in CNC MTs is a crucial area of study and development, due to the energy-intensive nature of these machines. Various solutions have been proposed in the literature to lower energy consumption, such as optimizing cutting conditions, applying sophisticated control techniques, using energy-efficient drive technologies, and employing modern cooling systems. In addition, dual-driving electric spindles, which employ two motors for more efficient energy consumption, have also been explored as a potential solution, with some studies indicating energy savings of up to 50% compared to traditional spindle systems. However, further research is needed to develop appropriate designs and control systems for these spindles and to analyze their long-term energy savings in real-world applications.

Electric power utilization in milling and turning activities can result in high costs and environmental implications. Techniques such as nano lubricants, laser surface texturing, and the cryogenic treatment of tungsten carbide inserts have been proposed as potential solutions to enhance electric power use, efficiency, and quality of milling operations. However, more research is needed to understand their potential advantages and limitations fully. Another approach is to use virtual laboratories for learning and practising CNC machining and automation skills, which can result in economic savings and a lower environmental impact while providing a safe and controlled setting for experimentation and learning. Virtual 3-D laboratories can also decrease energy use and carbon emissions associated with real equipment.