A Comprehensive In Situ Investigation on the Reinforcement of High-Filled Red Soil Using the Dynamic Compaction Method

Abstract

:1. Introduction

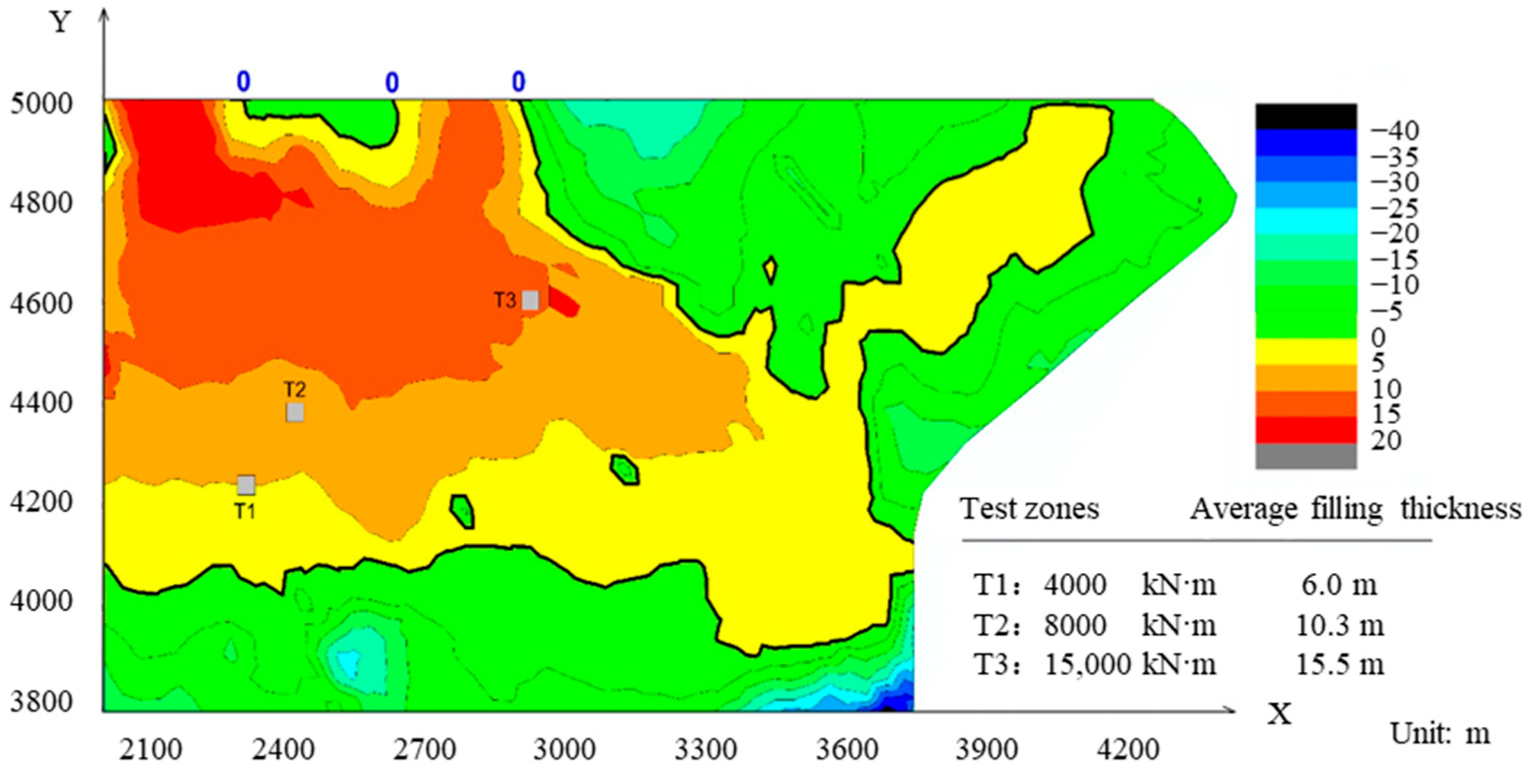

2. Site Description and Subsoil Conditions

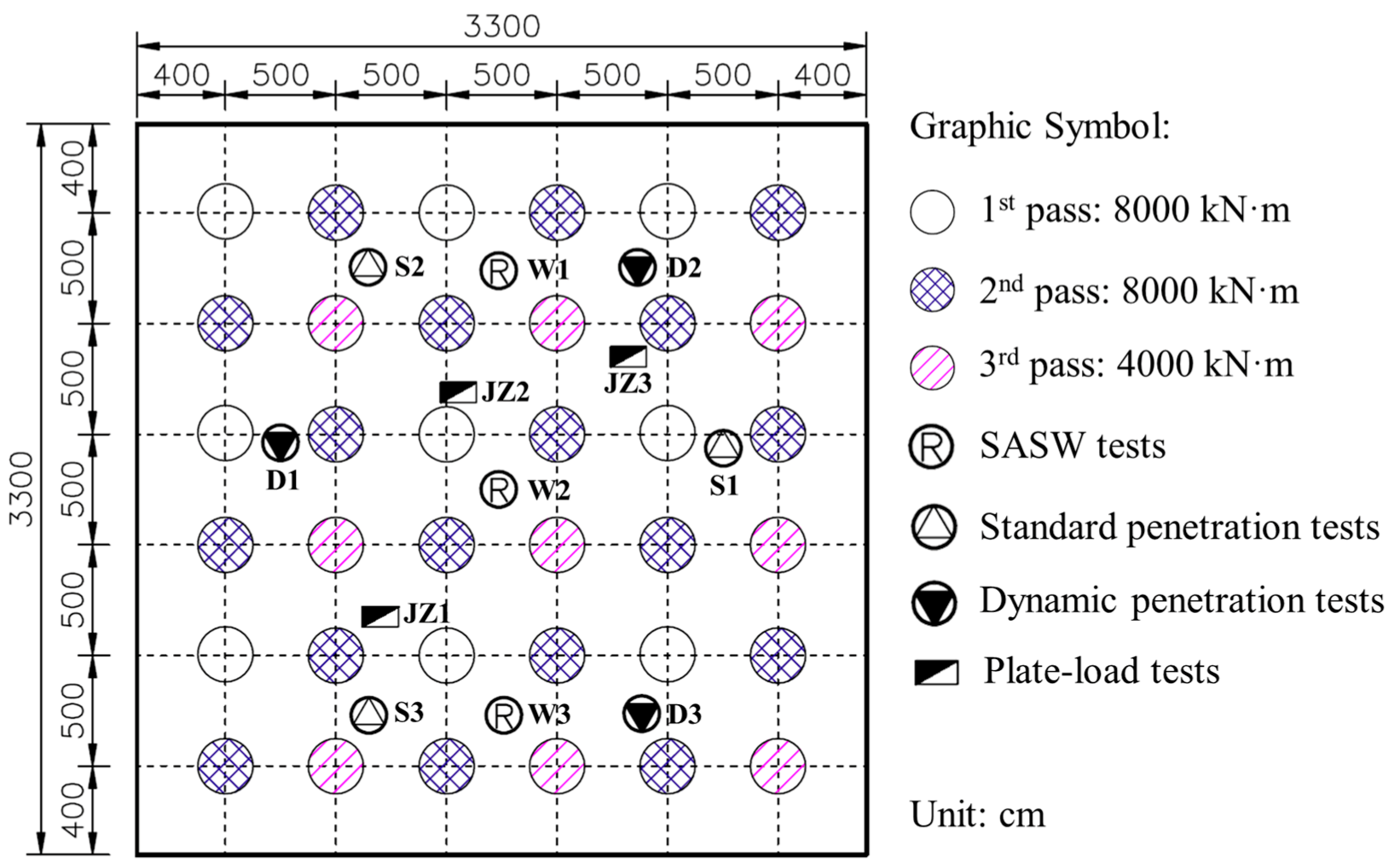

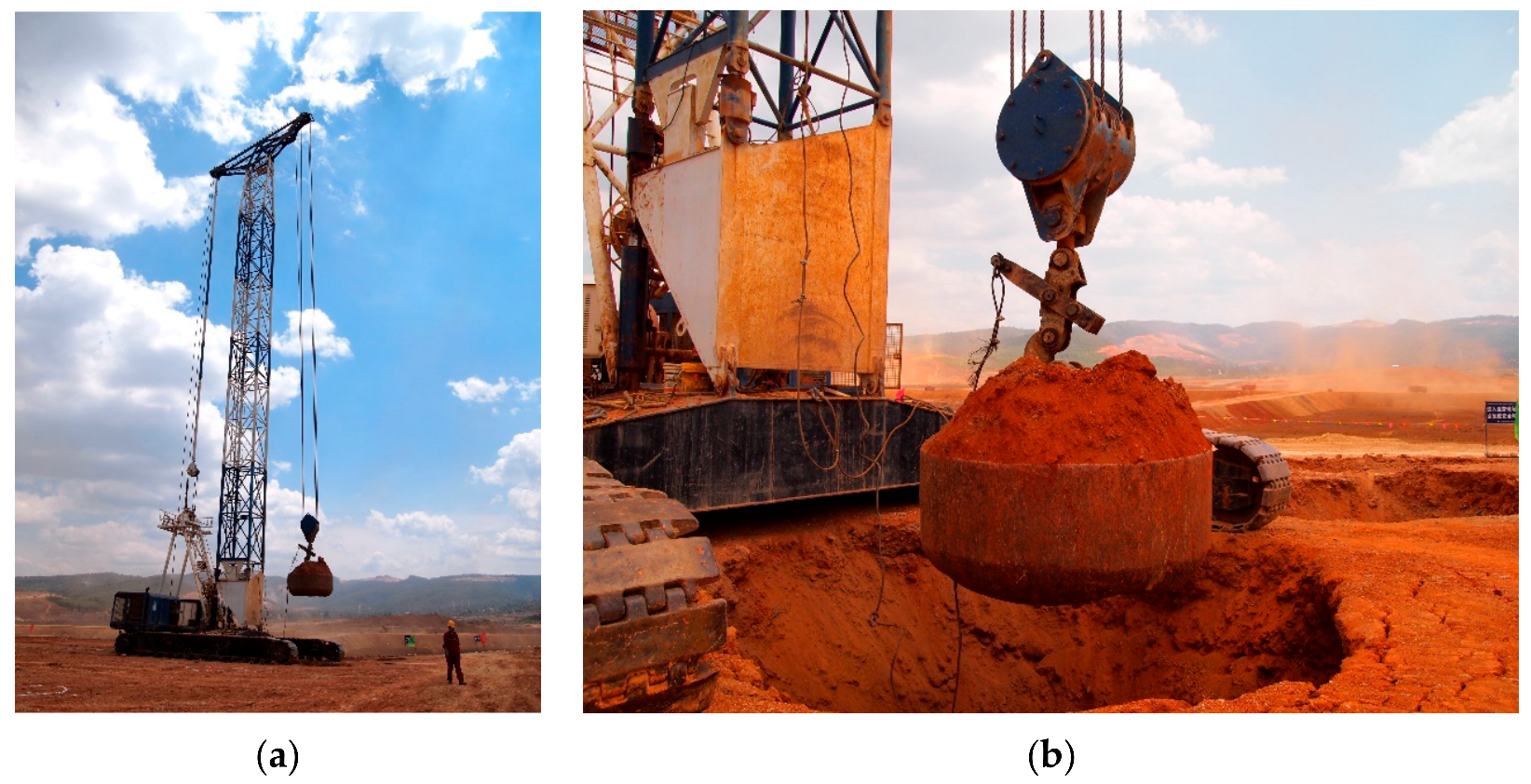

3. Test Procedure

4. Test Results

4.1. Crater Depth and Ground Settlement Monitoring

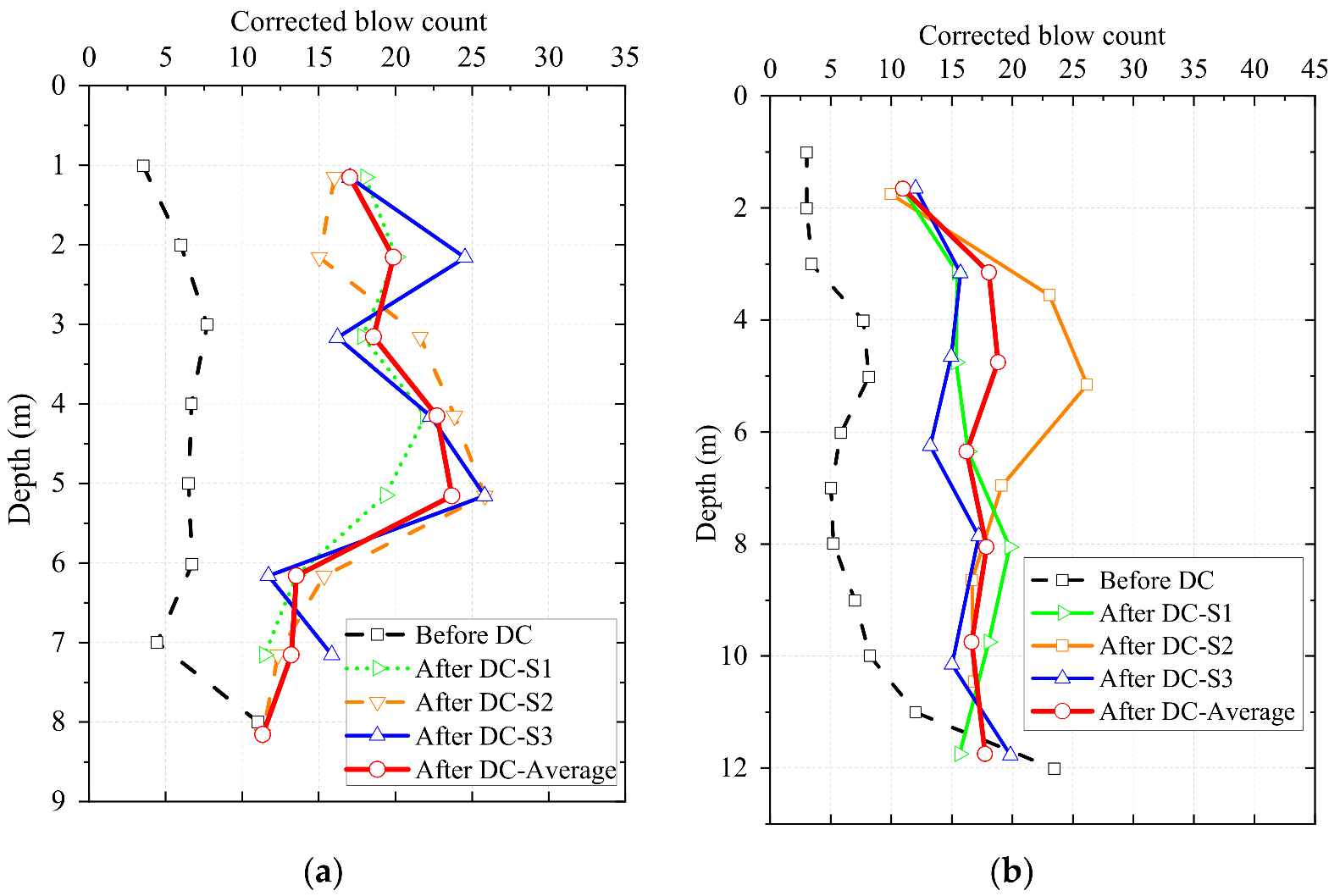

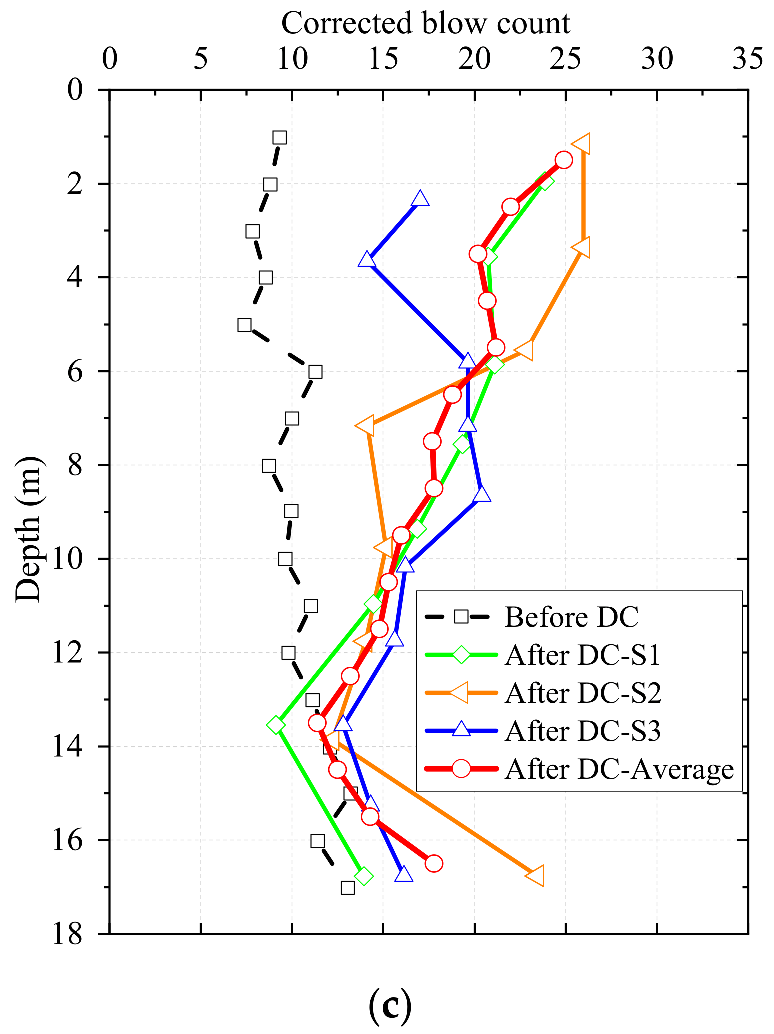

4.2. Standard Penetration Test

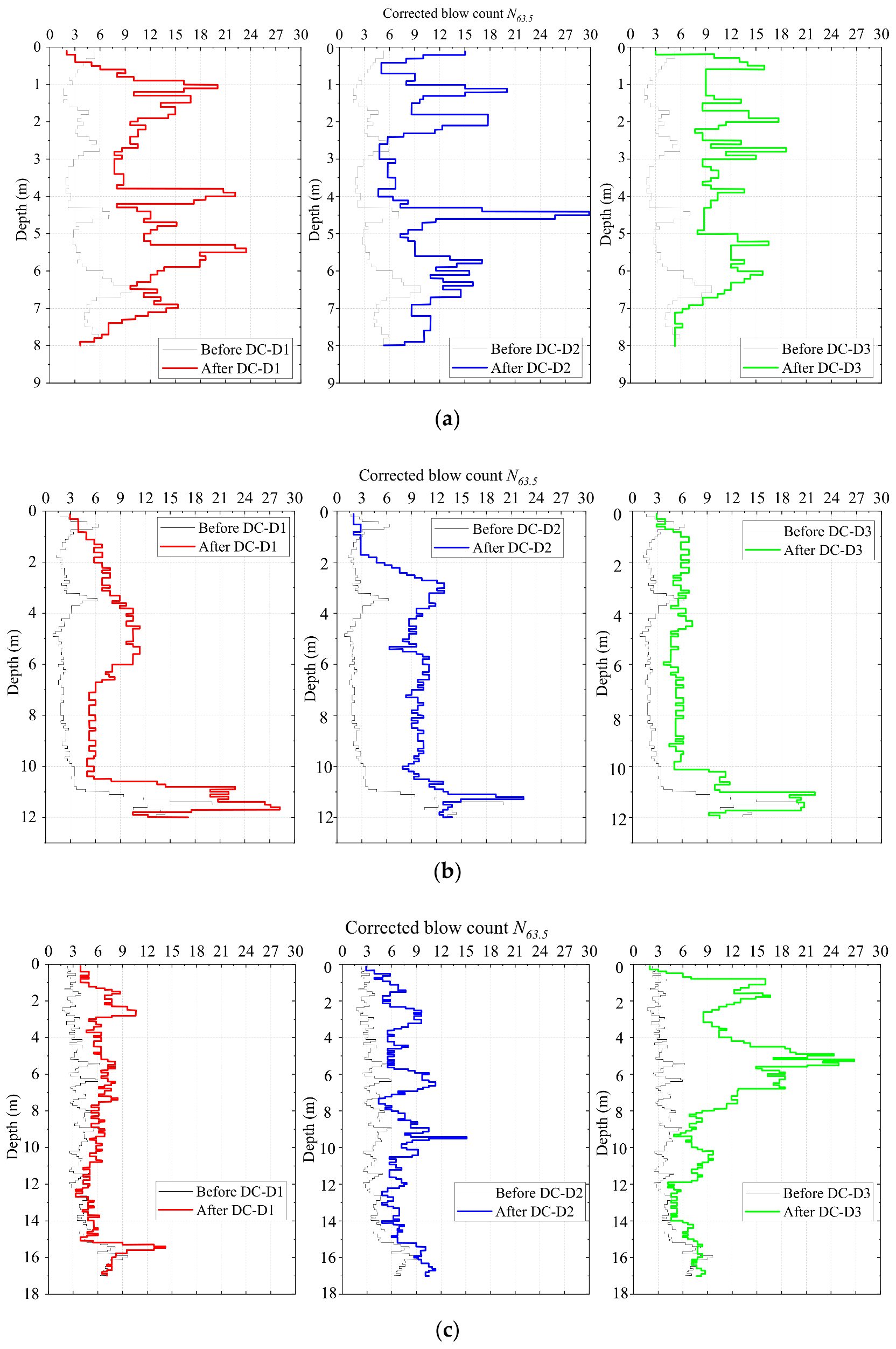

4.3. Dynamic Penetration Test

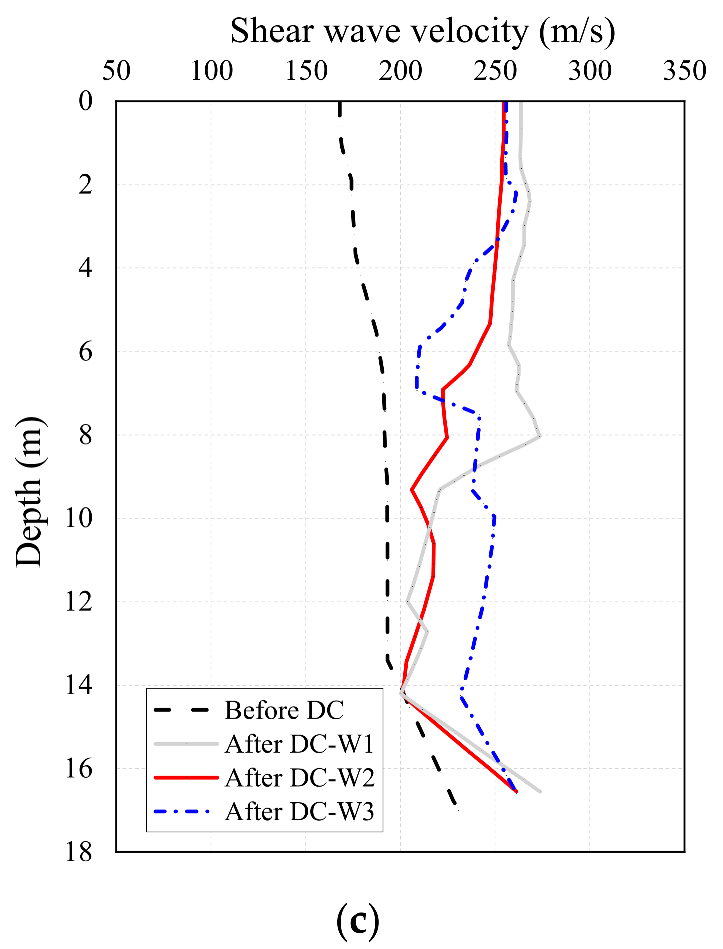

4.4. Surface Wave Velocity Test

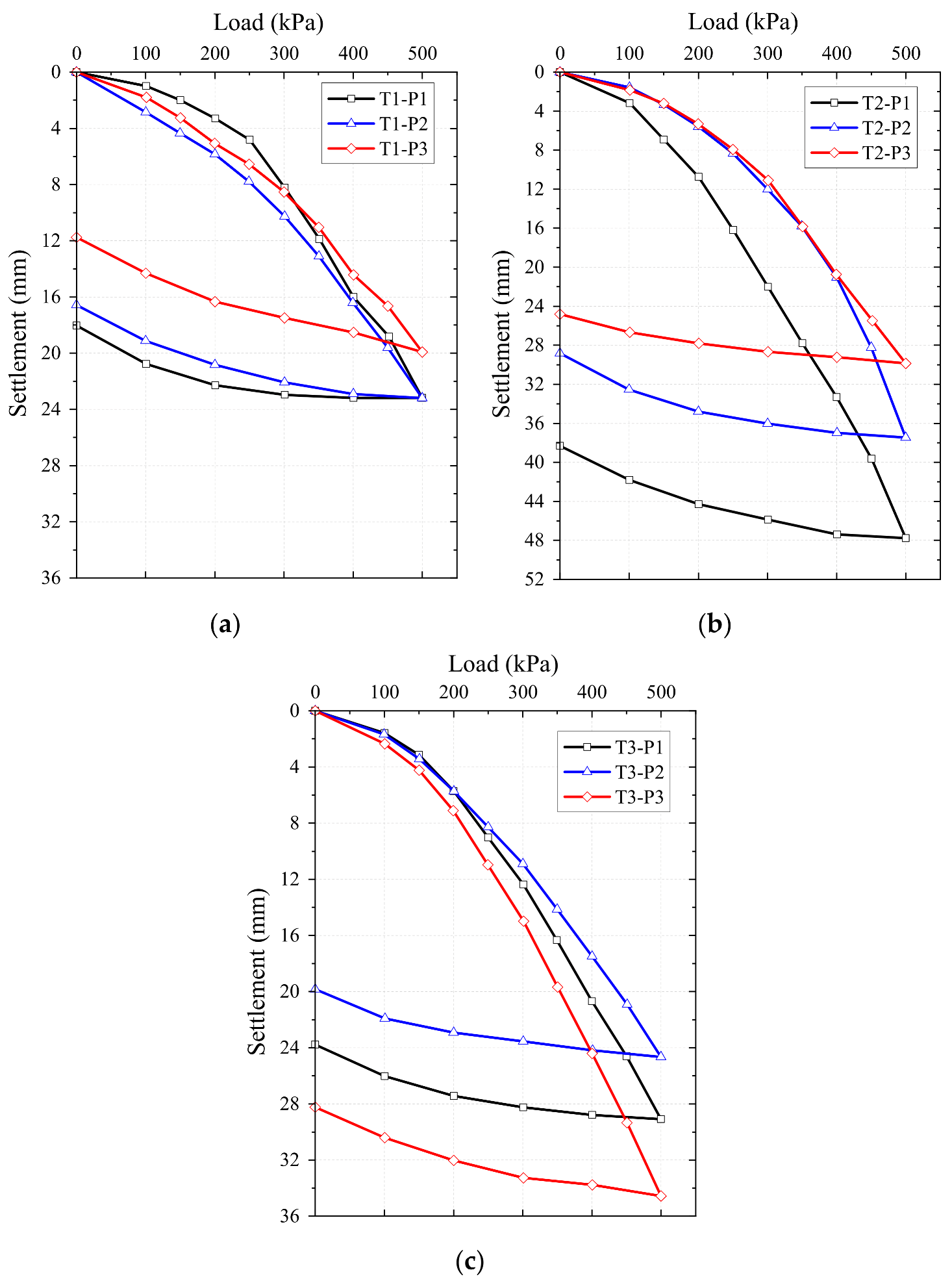

4.5. Plate-Load Test

5. Discussion

6. Conclusions

- (1)

- The DC method is effective in reinforcing super-high-filled red soil, with the characteristic values of ground bearing capacity reached 250 kPa in all three test zones, meeting the design requirement of 160 kPa;

- (2)

- The improvement depths of T1 and T2 meet the required improvement depths of 6 m and 10 m, respectively, while T3 falls short of the 15 m requirement due to the presence of a weak interlayer;

- (3)

- The empirical correction factor (n) values for T1, T2 and T3 are 0.324, 0.357 and 0.344, respectively, indicating that a larger overall energy input should be considered when applying the DC method to reinforce high-filled red soil in order to achieve the desired improvement depth. Overall, these findings provide valuable insights for the effective application of the DC method to improve the bearing capacity of high-filled red soil.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhao, G.Q.; Yang, Y.Y.; Zhang, H.Q.; Zhang, G.L. A case study integrating field measurements and numerical analysis of high-fill slope stabilized with cast-in-place piles in Yunnan, China. Eng. Geol. 2019, 253, 160–170. [Google Scholar] [CrossRef]

- Feng, S.J.; Du, F.L.; Shi, Z.M.; Shui, W.H.; Tan, K. Field study on the reinforcement of collapsible loess using dynamic compaction. Eng. Geol. 2015, 185, 105–115. [Google Scholar] [CrossRef]

- Mei, Y.; Hu, C.M.; Wang, X.Y. Experimental Research on Deep Collapsible Loess Foundation Treatment By Dynamic Compaction Under Super High Fill. Adv. Civ. Eng. 2013, 256–259, 129–138. [Google Scholar] [CrossRef]

- Liang, Y.; Shui, W.; Lu, S. Field practice and ground settlement behaviors of a land creation case in loess area of China. B Eng. Geol. Environ. 2022, 81, 462. [Google Scholar] [CrossRef]

- Zhu, C.H.; Li, N. Ranking of influence factors and control technologies for the post-construction settlement of loess high-filling embankments. Comput. Geotech. 2020, 118, 103320. [Google Scholar] [CrossRef]

- Wei, Y.M.; Liu, X.J.; Zhao, C.Y.; Tomas, R.; Jiang, Z. Observation of Surface Displacement Associated with Rapid Urbanization and Land Creation in Lanzhou, Loess Plateau of China with Sentinel-1 SAR Imagery. Remote Sens. 2021, 13, 3472. [Google Scholar] [CrossRef]

- Zhang, H.X.; Zeng, R.Q.; Zhang, Y.; Zhao, S.F.; Meng, X.M.; Li, Y.X.; Liu, W.C.; Meng, X.P.; Yang, Y.P. Subsidence monitoring and influencing factor analysis of mountain excavation and valley infilling on the Chinese Loess Plateau: A case study of Yan’an New District. Eng. Geol. 2022, 297, 106482. [Google Scholar] [CrossRef]

- Zhu, C.H.; Zhou, X.S.; Wang, S.H. Foundation Treatment Assessment and Postconstruction Settlement Prediction of a Loess High Fill Embankment: A Case Study. Shock Vib. 2020, 2020, 8864690. [Google Scholar] [CrossRef]

- Xua, W.J.; Xu, Q.; Hu, R.L. Study on the shear strength of soil-rock mixture by large scale direct shear test. Int. J. Rock Mech. Min. 2011, 48, 1235–1247. [Google Scholar]

- Athanasiu, C.; Simonsen, A.S.; Soereide, O.K.; Tistel, J. Elastic and creep settlements of rock fills. In Proceedings of the 16th International Conference on Soil Mechanics and Geotechnical Engineering, Osaka, Japan, 12–16 September 2005; Volumes 1–5, pp. 1837–1843. [Google Scholar]

- Charles, J.A.; Watts, K.S. The assessment of the collapse potential of fills and its significance for building on fill. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1996, 119, 15–28. [Google Scholar] [CrossRef]

- Li, S.; Jianie, Y.C.; Ho, I.H.; Ma, L.; Yu, B.T.; Wang, C.D. Evolution of Load Reduction for High-Filled Cut-and-Cover Tunnels Subjected to Soil Creep. Int. J. Geomech. 2021, 21, 04021172. [Google Scholar] [CrossRef]

- Li, S.; Jianie, Y.; Ho, I.H.; Ma, L.; Ning, G.X.; Wang, C.D. Long-term behavior of earth pressure around a high-filled cut-and-cover tunnel. Geomech. Eng. 2021, 26, 311–321. [Google Scholar]

- Eslami, A.; Ahmadnezhad, M.; Kenarsari, A.E.; Rezazadeh, S. Experimental study on stiffness properties of non-engineered clay and granular fills. Arab. J. Geosci. 2015, 8, 3065–3075. [Google Scholar] [CrossRef]

- Li, Z.Q.; Qi, S.W.; Qi, Z.Y.; Zhang, L.X.; Hou, X.K. Microstructural insight into the characteristics and mechanisms of compaction during natural sedimentation and man-made filling on the Loess Plateau. Environ. Earth Sci. 2021, 80, 668. [Google Scholar] [CrossRef]

- Jia, M.C.; Zhao, Y.; Zhou, X.J. Field Studies of Dynamic Compaction on Marine Deposits. Mar. Georesour. Geotec. 2016, 34, 313–320. [Google Scholar] [CrossRef]

- Feng, S.J.; Shui, W.H.; Gao, L.Y.; He, L.J.; Tan, K. Field studies of the effectiveness of dynamic compaction in coastal reclamation areas. B Eng. Geol. Environ. 2010, 69, 129–136. [Google Scholar] [CrossRef]

- Mayne, P.W.; Jones, J.S.; Dumas, J.C. Ground Response to Dynamic Compaction. J. Geotech. Eng.-ASCE 1984, 110, 757–774. [Google Scholar] [CrossRef]

- Mei, Y.; Zhang, S.M.; Hu, C.M.; Wang, X.Y.; Yuan, Y.L.; Zhao, L.J.; Zhou, D.B. Field test study on dynamic compaction in treatment of a deep collapsible loess foundation. B Eng. Geol. Environ. 2021, 80, 8059–8073. [Google Scholar] [CrossRef]

- Gao, Z.; Du, Y.; Lai, Y.; Huang, X. Reinforcement effect of broken stone fills under dynamic consolidation. In CICTP 2012: Multimodal Transportation Systems—Convenient, Safe, Cost-Effective, Efficient; American Society of Civil Engineers (ASCE): Beijing, China, 2012; pp. 2976–2985. [Google Scholar]

- Dou, J.Z.; Chen, J.J.; Wang, W. Method for Estimating the Degree of Improvement in Soil between Adjacent Tamping Locations under Dynamic Compaction. Int. J. Geomech. 2019, 19, 04019134. [Google Scholar] [CrossRef]

- Jia, M.C.; Cheng, J.X.; Liu, B.; Ma, G.Q. Model tests of the influence of ground water level on dynamic compaction. B Eng. Geol. Environ. 2021, 80, 3065–3078. [Google Scholar] [CrossRef]

- Yao, Z.Y.; Zhou, C.; Lin, Q.; Yao, K.; Satchithananthan, U.; Lee, F.H.; Tang, A.M.; Jiang, H.; Pan, Y.T.; Wang, S.T. Effect of dynamic compaction by multi-point tamping on the densification of sandy soil. Comput. Geotech. 2022, 151, 104949. [Google Scholar] [CrossRef]

- Mollamahmutoglu, M.; Avci, E. Dynamic compaction experience in alluvial soils of Carsamba (Turkey). Maejo Int. J. Sci. Tech. 2018, 12, 206–220. [Google Scholar]

- Zhou, C.; Yang, C.J.; Qi, H.; Yao, K.; Yao, Z.Y.; Wang, K.; Ji, P.; Li, H. Evaluation on Improvement Zone of Foundation after Dynamic Compaction. Appl. Sci. 2021, 11, 2156. [Google Scholar] [CrossRef]

- Fu, J. Field test on 30,000 kN m ultra high energy level dynamic compaction on large thickness gravel foundation. In Proceedings of the 16th Asian Regional Conference on Soil Mechanics and Geotechnical Engineering, Taipei, Taiwan, 14–18 October 2020. [Google Scholar]

- Nian, T.; Shui, W.; Li, H.; Yang, Q.; Wang, Y. Field tests of high energy dynamic compaction on foundation backfilled by crushed stone in coastal area. Chin. J. Geotech. Eng. 2010, 32, 1029–1034. [Google Scholar]

- Fu, J.; Zhang, R.; Liu, A. Filed test on 25,000 kN m ultra high energy level dynamic consolidation on large thickness gravel foundation. In IOP Conference Series: Materials Science and Engineering; IOP Publishing Ltd.: Singapore, 2018. [Google Scholar]

- Feng, S.J.; Shui, W.H.; Tan, K.; Gao, L.Y.; He, L.J. Field Evaluation of Dynamic Compaction on Granular Deposits. J. Perform. Constr. Fac. 2011, 25, 241–249. [Google Scholar] [CrossRef]

- Feng, S.; Tan, K.; Shui, W.; Zhang, Y. Densification of desert sands by high energy dynamic compaction. Eng. Geol. 2013, 157, 48–54. [Google Scholar] [CrossRef]

- Feng, S.; Du, F.; Chen, H.X.; Mao, J. Centrifuge modeling of preloading consolidation and dynamic compaction in treating dredged soil. Eng. Geol. 2017, 226, 161–171. [Google Scholar] [CrossRef]

- Hu, X.Q.; Gao, Z.Y.; Liu, F.Y.; Tao, Y.; Xu, D.H.; Du, Y.G.; Gou, C.F.; Li, M.F. The optimal combination form of vacuum pre-loading combined with electro-osmosis and with dynamic compaction method on the improvement of dredged slurry. Mar. Georesour. Geotec. 2021, 39, 1192–1204. [Google Scholar] [CrossRef]

- Yuan, H.; Liu, M.; Li, W.; Wang, Y. Dynamic Compaction Model Tests for the Characteristics of Red Clay Under equal Energy Level. Geotech. Geol. Eng. 2018, 36, 1873–1883. [Google Scholar] [CrossRef]

- YS/T 5209-2018; Technical Specification for Dynamic Compaction Foundation. China Planning Press: Beijing, China, 2019. (In Chinese)

- Jia, M.C.; Liu, B.; Zhou, X.J. Field Test Study of High Energy Dynamic Compaction on Marine Silty Fine Sand Deposits with Soft Interlayers. J. Build. Constr. 2019, 40, 240–246. [Google Scholar]

- GB 50007-2011; Code for Design of Building Foundation. China Architecture and Building Press: Beijing, China, 2012. (In Chinese)

- Menard, L.; Broise, Y. Theoretical and Practical Aspects of Dynamic Consolidation. Geotechnique 1975, 25, 3–18. [Google Scholar] [CrossRef]

- Lukas, R.G. Dynamic Compaction for Highway Construction. Design and Construction Guidelines; Rep. No. FHWA/RD-86/133; U.S. Federal Highway Administration: Washington, DC, USA, 1986; Volume 1, pp. 204–219. [Google Scholar]

- Rollins, K.M.; Rogers, G.W. Mitigation Measures for Small Structures on Collapsible Alluvial Soils. J. Geotech. Eng. 1994, 120, 1533–1553. [Google Scholar] [CrossRef]

- Leonards, G.A.; Holtz, R.D.; Cutter, W.A. Dynamic Compaction of Granular Soils. J. Geotech. Eng. Div. 1980, 106, 35–44. [Google Scholar] [CrossRef]

| Layer No. | Layer Name | Average Thickness (m) | Density (g/cm3) | Moisture Content (%) | Void Ratio | SPT Blow Count | CPT Tests | Plate-Load Tests | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Tip Resistance (MPa) | Side Friction (kPa) | Modulus of Deformation (MPa) | Bearing Capacity (kPa) | |||||||

| ① | Filling soil | 11 | - | - | - | - | - | - | - | - |

| ② | Silty clay | 3.01 | 1.91 | 28.0 | 0.859 | 7.0 | 1.55 | 58 | 14.3 | 176.0 |

| ②-1 | Silty clay | 1.85 | 1.90 | 31.4 | 1.048 | 3.8 | 0.86 | 33 | 8.8 | 133.3 |

| ②-3 | Gravel | 1.80 | - | - | - | - | 3.60 | 78 | 15.3 | 189.3 |

| ②-4 | Gravelly silty clay | 1.57 | 1.89 | 30.2 | 0.780 | 7.7 | 2.20 | 80 | - | - |

| ③ | Gravelly silty clay | 1.76 | 1.90 | 30.4 | 0.793 | 7.9 | 1.80 | 90 | - | - |

| ③-1 | Organic clay | 1.91 | 1.84 | 33.7 | 0.994 | 3.3 | 0.93 | 37 | - | - |

| ③-4 | Gravel | 1.20 | - | - | - | - | 4.50 | 110 | - | - |

| ③-5 | Silty clay | 2.35 | 1.91 | 29.8 | 0.831 | 7.8 | 1.70 | 75 | - | - |

| ③-6 | Organic clay | 2.27 | 1.81 | 37.0 | 0.863 | 7.6 | 2.00 | 78 | - | - |

| ④ | Silty clay | 3.40 | 1.85 | 33.9 | 0.919 | 11.4 | 2.10 | 95 | 14.7 | 208.7 |

| Testing Zone | Tamping Pass | Energy Level (kN·m) | Spacing (m) | Stop Criterion | Ironing DC Energy (kN·m) | Improvement Requirement | ||

|---|---|---|---|---|---|---|---|---|

| Improvement Depth (m) | Bearing Capacity (kPa) | Compression Modulus (MPa) | ||||||

| T1 | First pass | 4000 | 6.0 | s < 10 cm | 1500 | 6.0 | ≥160 | ≥10 |

| Second pass | 4000 | 6.0 | ||||||

| T2 | First pass | 8000 | 10.0 | s < 20 cm | 2000 | 10.0 | ≥160 | ≥10 |

| Second pass | 8000 | 10.0 | s < 20 cm | |||||

| Third pass | 4000 | 10.0 | s < 10 cm | |||||

| T3 | First pass | 15,000 | 10.0 | s < 25 cm | 2000 | 15.0 | ≥160 | ≥10 |

| Second pass | 15,000 | 10.0 | s < 20 cm | |||||

| Third pass | 8000 | 10.0 | s < 20 cm | |||||

| Test Zone | Tamping Pass | Energy Level (kN·m) | Blow Counts per Pass | Cumulative Crater Depth of Single DC Point (m) | Average Settlement after DC (m) | ||

|---|---|---|---|---|---|---|---|

| Range | Average | Range | Average | ||||

| T1 | First pass | 4000 | 12–15 | 14 | 3.12–4.84 | 3.98 | 0.66 |

| Second pass | 4000 | 12–13 | 13 | 2.42–3.44 | 2.93 | ||

| T2 | First pass | 8000 | 10–15 | 13 | 3.79–6.17 | 4.98 | 0.52 |

| Second pass | 8000 | 8–19 | 14 | 5.17–5.82 | 5.50 | ||

| Third pass | 4000 | 8–11 | 10 | 1.85–2.56 | 2.21 | ||

| T3 | First pass | 15,000 | 14–16 | 15 | 3.37–5.60 | 4.67 | 0.94 |

| Second pas | 15,000 | 11–14 | 13 | 3.47–5.71 | 9.18 | ||

| Third pass | 8000 | 8–10 | 9 | 1.57–3.00 | 2.29 | ||

| Test Zone | Improvement Depth (m) | Empirical Coefficient | |||

|---|---|---|---|---|---|

| SPT | DPT | SASW | Preferred Values | ||

| T1 | 7.0 | 7.5 | 8.0 | 7.0 | 0.324 |

| T2 | 11.0 | 11.5 | 11.0 | 11.0 | 0.357 |

| T3 | 13.0 | 12.5 | 13.0 | 12.5 | 0.344 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Du, F.; Liang, Y.; Gao, W.; Zhang, G.; Sheng, Z.; Chen, X. A Comprehensive In Situ Investigation on the Reinforcement of High-Filled Red Soil Using the Dynamic Compaction Method. Sustainability 2023, 15, 4756. https://doi.org/10.3390/su15064756

Wang L, Du F, Liang Y, Gao W, Zhang G, Sheng Z, Chen X. A Comprehensive In Situ Investigation on the Reinforcement of High-Filled Red Soil Using the Dynamic Compaction Method. Sustainability. 2023; 15(6):4756. https://doi.org/10.3390/su15064756

Chicago/Turabian StyleWang, Lei, Fenglei Du, Yonghui Liang, Wensheng Gao, Guangzhe Zhang, Zhiqiang Sheng, and Xiangsheng Chen. 2023. "A Comprehensive In Situ Investigation on the Reinforcement of High-Filled Red Soil Using the Dynamic Compaction Method" Sustainability 15, no. 6: 4756. https://doi.org/10.3390/su15064756

APA StyleWang, L., Du, F., Liang, Y., Gao, W., Zhang, G., Sheng, Z., & Chen, X. (2023). A Comprehensive In Situ Investigation on the Reinforcement of High-Filled Red Soil Using the Dynamic Compaction Method. Sustainability, 15(6), 4756. https://doi.org/10.3390/su15064756