Proposal for Implementation of Extraction Mechanism of Raw Materials during Landfill Mining and Its Application in Alternative Fuel Production

Abstract

1. Introduction

2. Materials and Methods

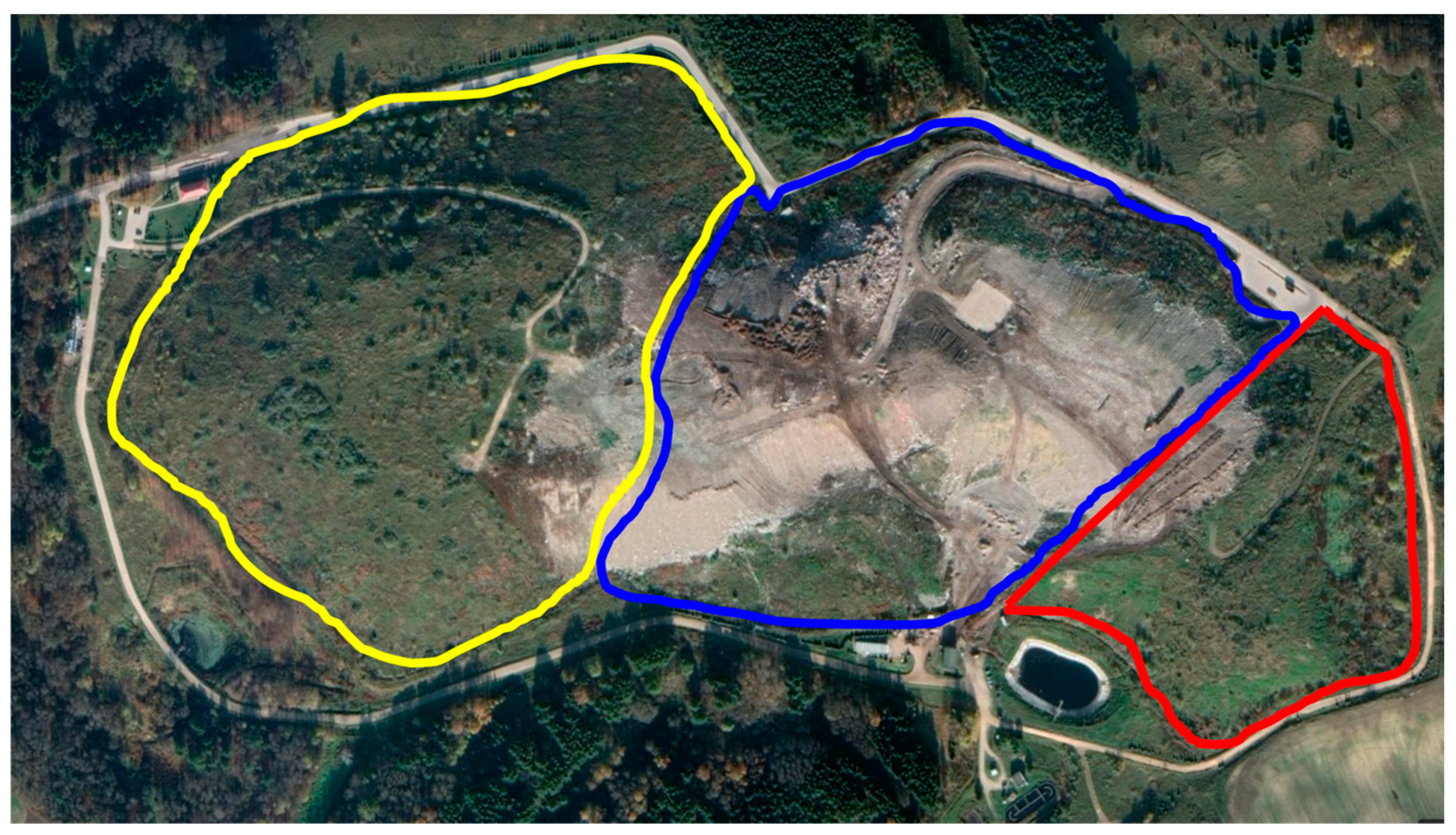

2.1. Study Area

2.2. Test Instrument

2.3. Testing LMRs

- −

- Moisture content (MC)—CEN/TS 15414-2:2010 [27];

- −

- Ash content (AC)—EN ISO 21656:2021 [28];

- −

- Volatile matter (VM)—EN ISO 18123:2015 [29];

- −

- Net calorific value (NCV)—EN ISO 21654:2021 [30];

- −

- Chlorine content (Cl)—EN 15408:2011 [31];

- −

- Mercury content (Hg)—EN 15411:2011 [32];

- −

- SEM-EDS analysis of ash;

- −

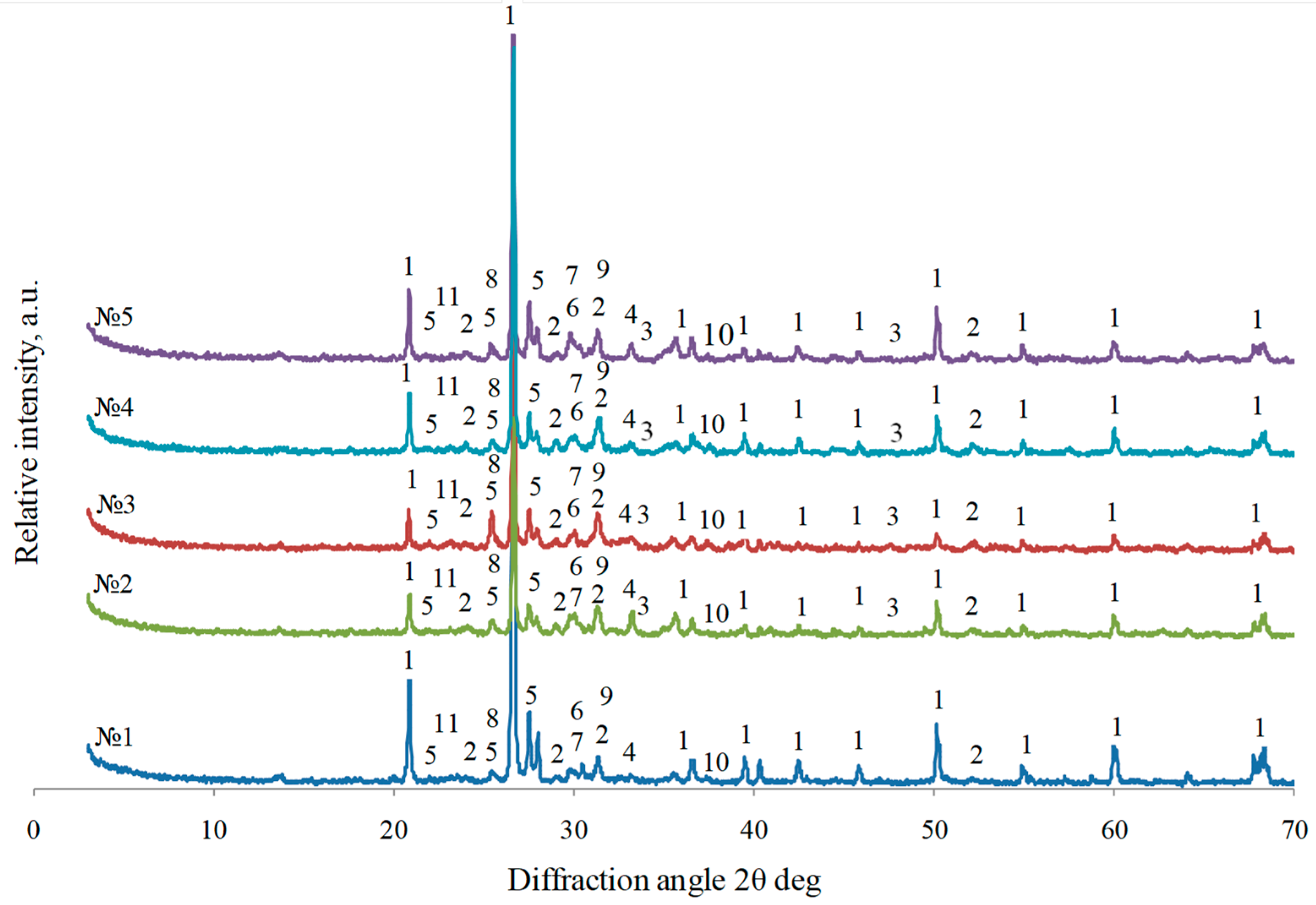

- XRD–Rietveld refinement analysis was carried out on a BRUKER D8 ADVANCE diffractometer with CuKα radiation at 40 kV in a 2Θ (5°÷70°) interval at a scanning step 0.02° and with the Topas program;

- −

- The ash morphology and elemental analysis were investigated using scanning electron microscopy equipped with an energy-dispersive spectroscopy detector (SEM-EDS). The analyzed samples were passed through sieves and then dried at 40 °C. Before the morphological observation, the ash specimens were coated using gold (Au) to obtain SEM images. SEM observation of samples was performed on a ZEISS EVO MA10 microscope at an accelerating voltage of 20 kV. The Bruker AXSX Flash 6/10 Detector can display all elements present in the specimen at an overall accuracy of about 1% and detection sensitivity down to 0.1% by weight;

- −

- The quantity element analysis of LMRs was performed using an ICP-OES, Optima 8000 (Perkin Elmer). The samples (0.4–0.5 g) were mineralized with 8 mLof concentrated nitric acid, 1 mLof hydrofluoric acid and 3 mLof hydrogen peroxide at 800 W, 6 MPa and pRate: 50 kPa · s−1 (Multivalve 3000). After the mineralization, the solution was poured into 50 mL flasks and diluted to 50 mL using deionized water. A quantitative analysis mode was used for the data acquisition of the samples. The scanning of every sample during element analysis was repeated three times to gather reasonably good results. Analysis was made in four replicates of each sample.

2.4. Energy Potential of Combustible Fractions

2.5. Development and Calculation of SRF Production Line

3. Results

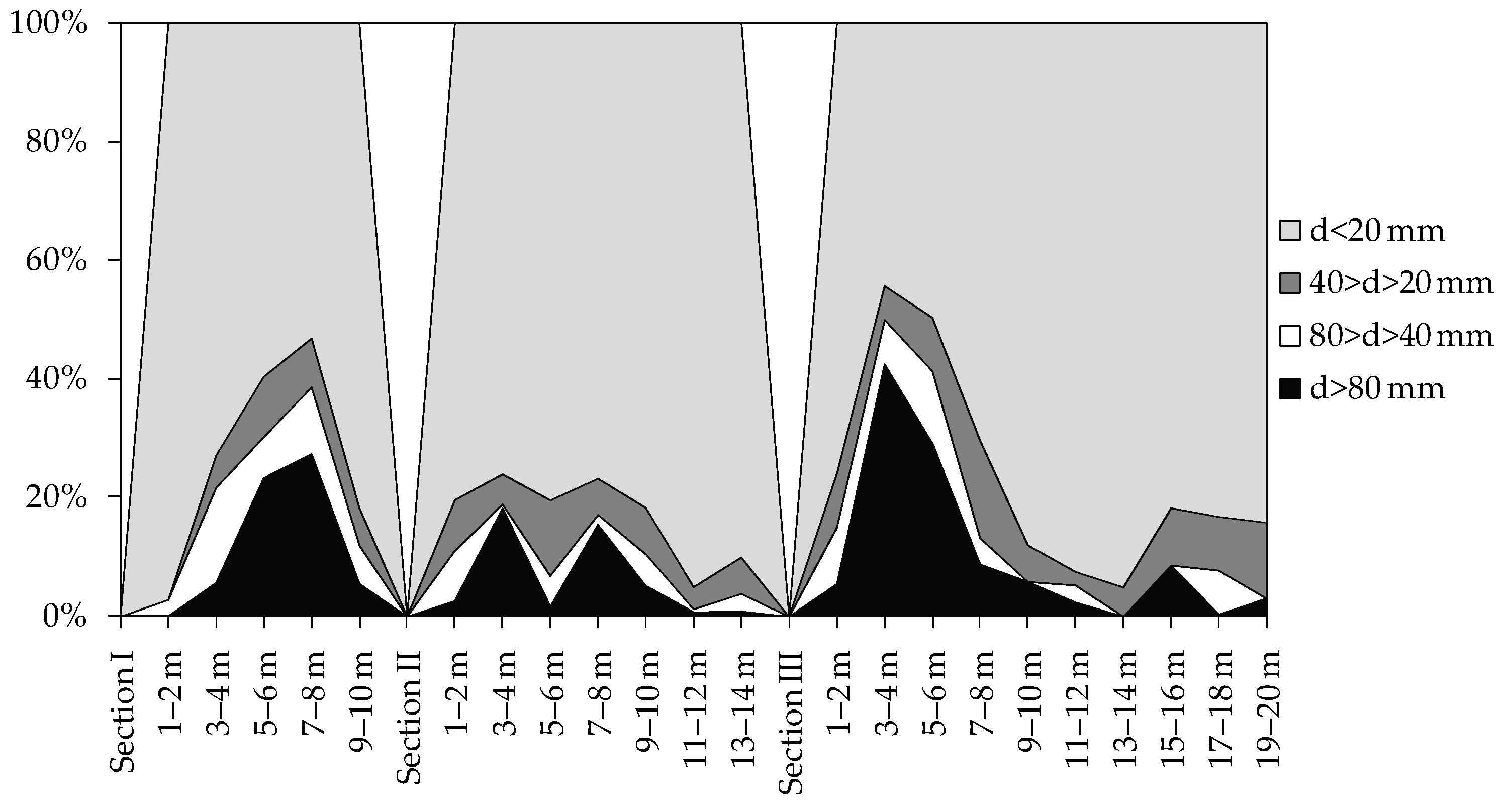

3.1. Granulometric and Morphological Analysis

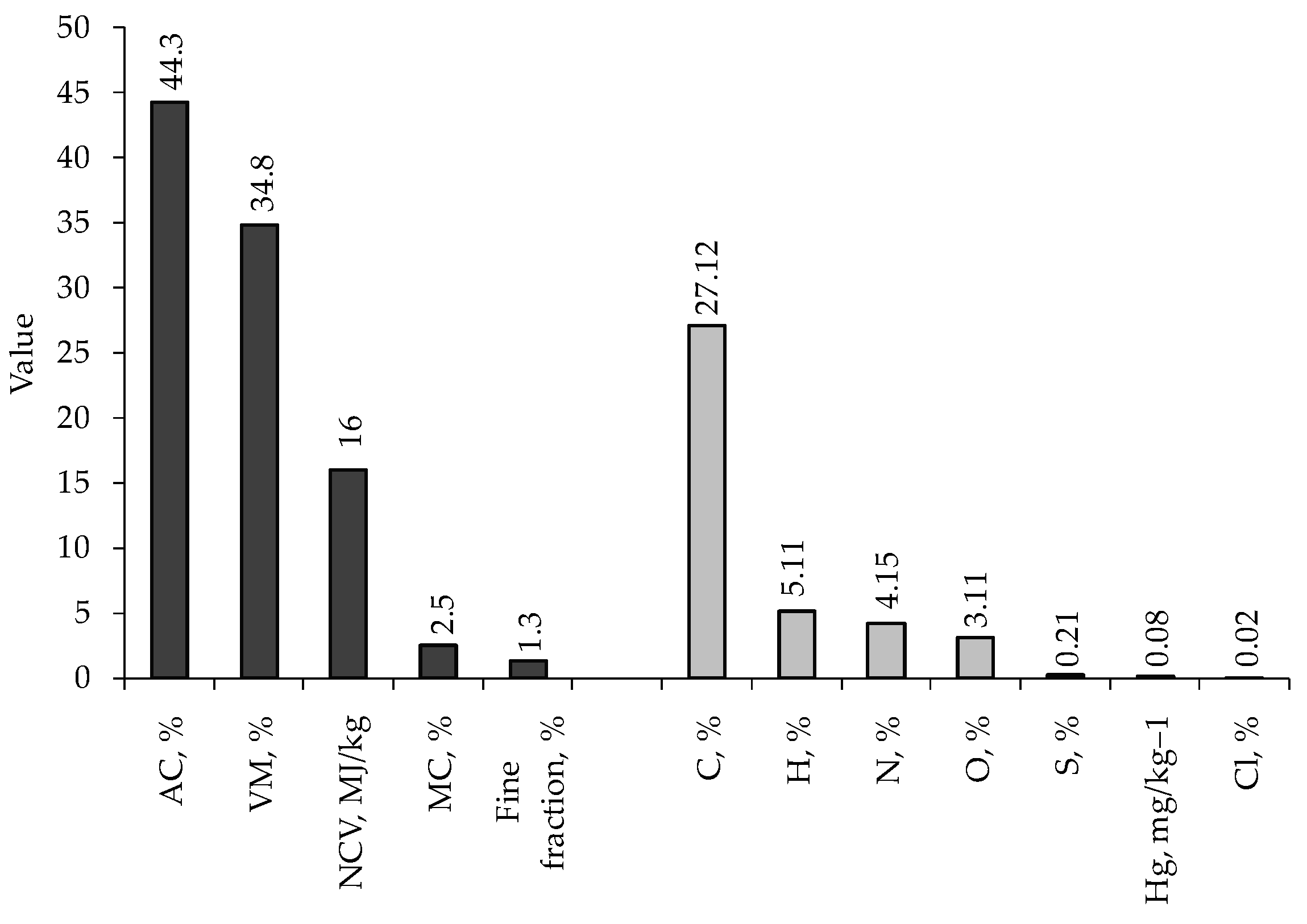

3.2. Physicochemical Properties of Potential Fuel

3.3. Development of Concept for SRF Production Line

4. Discussion

5. Conclusions

- (1)

- The extracting of energy-intensive raw materials from landfills is feasible, and it allows us to develop a mechanism for SRF production, which complies with the EU standard;

- (2)

- The mechanism for the production of SRF may, in principle, consist of two technological stages.

- (3)

- the first stage can be performed at the territory of the landfill, including the removal of the fine fraction, inert materials and bulky waste via primary sieving;

- (4)

- The secondary stage can be performed by using an existing MBT facility and may include the additional removal of the fine fraction and prohibited materials via secondary sieving, extraction of metals, shredding and drying;

- (5)

- The LMR coarse fraction includes combustible fractions, such as soft plastics, wood, hard plastics, paper, rubber and other burnable components, representing the total combustible fraction;

- (6)

- Extracting LMRs for SRF production is suitable for up to a 10 m landfill depth;

- (7)

- Obtained SRF by classification characteristics (caloricity, chlorine and mercury content) will belong to class III based on the main parameters;

- (8)

- Based on X-ray diffraction analysis results, the ash, which can beobtained after the incineration of the produced SRF, has a crystalline structure and contains Ca-, Na-, K-, Fe- and Si-bearing phases and corresponds to the clinker-forming minerals; it was confirmed that this SRF can be used as replacement fuel during the clinker firing process;

- (9)

- The use of obtained SRF as a replacement fuel in the cement industry would be economically feasible and more environmentally friendly due to reductions (10–20%) in coal import with a subsequent saving of costs and greenhouse emissions;

- (10)

- This would bring Lithuania closer to a circular economy by using formerly disposed materials at landfills and converting them into energy resources.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AC | Ash content |

| Cl | Chlorine content |

| EU | European Union |

| Hg | Mercury content |

| LFM | Landfill mining |

| LMRs | Landfill Mined Residues |

| LFM | Landfill mining |

| MBT | Mechanical biological treatment |

| MC | Moisture content |

| MSW | Municipal solid waste |

| NCV | Net calorific value |

| RDF | Refuse-derived fuel |

| SEM | Scanning electron microscopy |

| SEM-EDS | Scanning electron microscopy-energy dispersive X-ray spectroscopy |

| SRF | Solid recovered fuel |

| VM | Volatile matter |

| XRD | X-Ray diffraction |

References

- EU Council Directive 1999/31/EC of 26 April 1999 on the Landfill of Waste. Available online: http://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex:31999L0031 (accessed on 8 November 2017).

- EC, Waste Policy Review-Environment-European Commission. Available online: http://ec.europa.eu/environment/waste/target_review.htm (accessed on 8 November 2017).

- Eurelco, European Parliament Votes YES to Include ELFM in the EU Landfill Directive Eurelco. Available online: https://www.eurelco.org/single-post/2017/03/15/European-Parliament-votes-YES-toinclude-Enhanced-Landfill-Mining-in-the-EU-Landfill-Directive (accessed on 2 May 2017).

- COST Mining the European Anthroposphere (MINEA). Available online: http://www.cost.eu/COST_Actions/ca/CA15115 (accessed on 8 November 2017).

- Ragazzi, M.; Fedrizzi, S.; Rada, E.C.; Ionescu, G.; Ciudin, R.; Cioca, L.I. Experiencing Urban Mining in an Italian Municipality towards a Circular Economy vision. Energy Procedia 2017, 119, 192–200. [Google Scholar] [CrossRef]

- Singh, A.; Chandel, M.K. Effect of ageing on waste characteristics excavated from an Indian dumpsite and its potential valorization. Process Saf. Environ. Protec. 2020, 134, 24–35. [Google Scholar] [CrossRef]

- Yi, S. Resource recovery potentials by landfill mining and reclamation in South Korea. J. Environ. Manag. 2019, 242, 178–185. [Google Scholar] [CrossRef] [PubMed]

- Lokahita, B.; Samudro, G.; Huboyo, H.S.; Aziz, M.; Takahashi, F. Energy recovery potential from excavating municipal solid waste dumpsite in Indonesia. Energy Procedia 2019, 158, 243–248. [Google Scholar] [CrossRef]

- Johansson, N.; Krook, J.; Eklund, M. The institutional capacity for a resource transition—A critical review of Swedish governmental commissions on landfill mining. Environ. Sci. Policy 2017, 70, 46–53. [Google Scholar] [CrossRef]

- Parrodi, J.C.H.; Höllen, D.; Pomberger, R. Case study on enhanced landfill mining at Mont-Saint Guibert landfill in Belgium: Mechanical processing of fine fractions for material and energy recovery. Detritus 2019, 8, 62–78. [Google Scholar] [CrossRef]

- Takeda, C.M.; Leme, M.A.D.G.; Romeiro, D.C.; Silva, K.G.; Miguel, M.G. Variation of the Gravimetric Composition of Landfilled Municipal Solid Waste Over the Time in a Developing Country. Int. J. Environ. Res. 2022, 16, 83. [Google Scholar] [CrossRef]

- Jagodzińska, K.; Zaini, I.N.; Svanberg, R.; Yang, W.; Jönsson, P.G. Pyrolysis of excavated waste from landfill mining: Characterisation of the process products. J. Clean. Prod. 2021, 279, 123541. [Google Scholar] [CrossRef]

- Márquez, A.J.C.; Filho, P.C.C.; Rutkowski, E.W.; Isaac, R.D.L. Landfill mining as a strategic tool towards global sustainable development. J. Clean. Prod. 2019, 226, 1102–1115. [Google Scholar] [CrossRef]

- Dino, G.A.; Rossetti, P.; Perotti, L.; Alberto, W.; Sarkka, H.; Coulon, F.; Wagland, S.; Griffiths, Z.; Rodeghiero, F. Landfill mining from extractive waste facilities: The importance of a correct site characterisation and evaluation of the potentialities. a case study from Italy. Resour. Policy. 2018, 55, 50–61. [Google Scholar] [CrossRef]

- Frank, R.R.; Cipullo, S.; Garcia, J.; Davies, S.; Wagland, S.T.; Villa, R.; Trois, C.; Coulon, F. Compositional and physicochemical changes in waste materials and biogas production across 7 landfill sites in UK. Waste Manag. 2017, 63, 11–17. [Google Scholar] [CrossRef] [PubMed]

- López, C.G.; Ni, A.; Hernández Parrodi, J.C.; Küppers, B.; Raulf, K.; Pretz, T. Characterization of landfill mining material after ballistic separation to evaluate material and energy recovery potential. Detritus 2019, 8, 5–23. [Google Scholar] [CrossRef]

- Zhang, P.; Chai, J.; Cao, J.; Qin, Y.; Dang, M.; Wang, T. Analysis of the existence form of landfill leachate water level and its development pattern under the condition of considering internal source water: A case study. Environ. Sci. Pollut. Res. 2022, 30, 9820–9840. [Google Scholar] [CrossRef] [PubMed]

- Hossain, S.; DeVries, B. Resource Recovery and Sustainable Material Management through Landfill Mining. In Proceedings of the 3rd Global Landfill Mining Conference and Exhibition, London, UK, 17–18 November 2014; p. 30. [Google Scholar]

- Kieckhäfer, K.; Breitenstein, A.; Spengler, T.S. Material flow-based economic assessment of landfill mining processes. Waste Manag. 2017, 60, 748–764. [Google Scholar] [CrossRef] [PubMed]

- Krook, J.; Baas, L. Getting serious about mining the technosphere: A review of recent landfill mining andurban mining research. J. Clean. Prod. 2013, 55, 1–9. [Google Scholar] [CrossRef]

- Kara, M. Environmental and economic advantages associated with the use of RDF in cement kilns. Resour. Conserv. Recycl. 2012, 68, 21–28. [Google Scholar] [CrossRef]

- Hemidat, S.; Saidan, M.; Al-Zu’bi, S.; Irshidat, M.; Nassour, A.; Nelles, M. Potential Utilization of RDF as an Alternative Fuel to be Used in Cement Industry in Jordan. Sustainability 2019, 11, 5819. [Google Scholar] [CrossRef]

- Dace, E.; Blumberga, D. An assessment of the potential of refuse-derived fuel in Latvia. Manag. Environ. Qual. 2012, 23, 503–516. [Google Scholar] [CrossRef]

- Garces, D.; Diaz, E.; Ordonez, S.; Gonzalez-LaFuente, J.M. Evaluation of the potential of different high calorific waste fraction for the preparation of solid recovered fuels. Waste Manag. 2016, 47, 164–173. [Google Scholar] [CrossRef]

- Somani, M.; Datta, M.; Ramana, G.V.; Hölzle, I.; Sundaram, R.; Sreekrishnan, T.R. Effect of depth of landfill on the characteristics of soil-like material of aged waste: A case study of Bhalswa dumpsite, India. J. Mater. Cycles Waste Manag. 2022, 24, 1902–1912. [Google Scholar] [CrossRef]

- Cheela, V.R.; John, M.; Dubey, B. Quantitative determination of energy potential of refuse-derived fuel from the waste recovered from Indian landfill. Sustain. Environ. Res. 2021, 31, 1–9. [Google Scholar] [CrossRef]

- CEN/TS 15414-2:2010; Solid Recovered Fuels—Determination of Moisture Content Using the Oven Dry Method—Part 2: Determination of Total Moisture Content by a Simplified Method. Management Centre: Brussels, Belgium, 2010. Available online: https://standards.iteh.ai/catalog/standards/sist/58032711-f7e5-46ea-a696-4e4bbe46e359/sist-ts-cen-ts-15414-2-2010 (accessed on 12 March 2004).

- EN ISO 21656:2021; Solid recovered fuels—Determination of Ash Content. CEN-CENELEC Management Centre: Brussels, Belgium, 2021. Available online: https://standards.iteh.ai/catalog/standards/sist/49d4536a-b804-4991-833d-cd8aa8e87ae1/sist-en-iso-21656-2021 (accessed on 12 March 2004).

- EN ISO 18123:2015; Solid BioFuels—Determination of the Content of Volatile Matter (ISO 18123:2015). CEN-CENELEC Management Centre: Brussels, Belgium, 2015. Available online: https://standards.iteh.ai/catalog/standards/sist/3e8c87a2-6cf4-412a-9512-b56b10a054fb/sist-en-iso-18123-2016 (accessed on 12 March 2004).

- EN ISO 21654:2021; Solid Recovered Fuels—Determination of Calorific Value. CEN-CENELEC Management Centre: Brussels, Belgium, 2021. Available online: https://standards.iteh.ai/catalog/standards/sist/059c7d2c-79e2-4a57-89a6-8d50a6f3d3b2/sist-en-iso-21654-2021 (accessed on 12 March 2004).

- EN 15408:2011; Solid Recovered Fuels—Methods for the Determination of Sulphur (S), Chlorine (Cl), Fluorine (F) and Bromine (Br) Content. Management Centre: Brussels, Belgium, 2011. Available online: https://standards.iteh.ai/catalog/standards/sist/230b887f-d469-4668-8ffedce61f6f1431/sist-en-15408-2011 (accessed on 12 March 2004).

- EN 15411:2011; Solid Recovered Fuels—Methods for the Determination of the Content of Trace Elements (As, Ba, Be, Cd, Co, Cr, Cu, Hg, Mo, Mn, Ni, Pb, Sb, Se, Tl, V and Zn). Management Centre: Brussels, Belgium, 2021. Available online: https://standards.iteh.ai/catalog/standards/sist/6c0486af-f647-499d-8d40-a00375df5c67/sist-en-15411-2011 (accessed on 12 March 2004).

- Eboh, F.C.; Ahlström, P.; Richards, T. Estimating the specific chemical energy of municipal solid waste. Energy Sci. Eng. 2016, 4, 217–231. [Google Scholar] [CrossRef]

- Reinhart, D.R. Determining the Chemical Composition of Solid Waste Problem Statement; Georgia Institute of Technology: Atlanta, Georgia, 2004. [Google Scholar]

- The World Bank. Municipal Solid Waste Incineration; The World Bank: Washington, DC, USA, 1999. [Google Scholar]

- Jani, Y.; Kaczala, F.; Marchand, C.; Hogland, M.; Kriipsalu, M.; Hogland, W.; Kihl, A. Characterisation of excavated fine fraction and waste composition from a Swedish landfill. Waste Manag. Res. 2016, 34, 1292–1299. [Google Scholar] [CrossRef] [PubMed]

- Quaghebeur, M.; Laenen, B.; Geysen, D.; Nielsen, P.; Pontikes, Y.; van Gerven, T.; Spooren, J. Characterization of landfilled materials: Screening of the enhanced landfill mining potential. J. Clean. Prod. 2013, 55, 72–83. [Google Scholar] [CrossRef]

- European Commission. Methodology for the Analysis of Solid Waste (SWA-Tool) User Version. In Project: SWA-Tool, Development of a Methodological Tool to Enhance the Precision & Comparability of Solid Waste Analysis Data: SWA-Tool Consortium. Available online: https://www.wien.gv.at/meu/fdb/pdf/swa-tool-759-ma48.pdf (accessed on 12 March 2004).

- EN 15411:2011; Solid Recovered Fuels—Determination of Particle Size Distribution—Part 1: Screen Method for Small Dimension Particles. Management Centre: Brussels, Belgium, 2021. Available online: https://standards.iteh.ai/catalog/standards/sist/f5ff81d1-a55c-4ea4-b69e-971e75839527/sist-en-15415-1-2011 (accessed on 12 March 2004).

- Pecorini, I.; Iannelli, R. Characterization of Excavated Waste of Different Ages in View of Multiple Resource Recovery in Landfill Mining. Sustainability 2020, 12, 1780. [Google Scholar] [CrossRef]

- García, J.; Davies, S.; Villa, R.; Gomes, D.M.; Coulon, F.; Wagland, S.T. Compositional analysis of excavated landfill samples and the determination of residual biogas potential of the organic fraction. Waste Manag. 2016, 55, 336–344. [Google Scholar] [CrossRef]

- ERFO. The Role of SRF in a Circular Economy. Retrieved from 1048. Available online: https://www.erfo.info/images/PDF/The_role_of_SRF_in_a_Circular_Economy.pdf (accessed on 29 April 2019).

- Abilmagzhanov, A.Z.; Ivanov, N.S.; Kholkin, O.S.; Adelbaev, I.E. Assessment of the Energetical and Biological Characteristics of Municipal Solid Waste from One of the Largest Landfills in Kazakhstan. Recycling 2022, 7, 80. [Google Scholar] [CrossRef]

- Vollprecht, D.; Hernández Parrodi, J.C.; Lucas, H.; Pomberger, R. Case study on enhanced landfill mining at montsaintguibert landfill in Belgium: Mechanical processing, physico-chemical and mineralogical characterisation of fine fractions <4.5 mm. Detritus 2020, 10, 26–43. [Google Scholar] [CrossRef]

- Council Decision 2003/33/EC Establishing Criteria and Procedures for the Acceptance of Waste at Landfills Pursuant to Article 16 of an Annex II to Directive 1999/31/EC. Available online: https://www.ecolex.org/details/legislation/council-decision-200333ec-establishing-criteria-and-procedures-for-the-acceptance-of-waste-at-landfills-pursuant-to-article-16-of-and-annex-ii-to-directive-199931ec-lex-faoc039228/ (accessed on 19 December 2002).

- 2014/955/EU: Commission Decision of 18 December 2014 amending Decision 2000/532/EC on the list of waste pursuant to Directive 2008/98/EC of the European Parliament and of the Council Text with EEA relevance. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=OJ:L:2014:370:FULL&from=EN (accessed on 30 December 2014).

- Neehaul, N.; Jeetah, P.; Deenapanray, P. Energy recovery from municipal solid waste in Mauritius: Opportunities and challenges. Environ. Dev. 2020, 33, 100489. [Google Scholar] [CrossRef]

- Acha, E.; Lopez-Urionabarrenechea, A.; Delgado, C.; Martinez-Canibano, L.; Perez-Martinez, B.B.; Serras-Malillos, A.; María Caballero, B.; Unamunzaga, L.; Dosal, E.; Montes, N.; et al. Combustion of a Solid Recovered Fuel (SRF) Produced from the Polymeric Fraction of Automotive Shredder Residue (ASR). Polymers 2021, 13, 3807. [Google Scholar] [CrossRef]

- Jagodzinska, K.; Lopez, C.G.; Yang, W.; Jonsson, P.G.; Pretz, T.; Raulf, K. Characterisation of excavated landfill waste fractions to evaluate the energy recovery potential using Py-GC/MS and ICP techniques. Res. Conser. Recyc. 2021, 168, 105446. [Google Scholar] [CrossRef]

- Goli, V.S.N.S.; Singh, D.N.; Baser, T. A critical review on thermal treatment technologies of combustible fractions from mechanical biological treatment plants. J. Environ. Chem. Eng. 2021, 9, 105643. [Google Scholar] [CrossRef]

- Jones, P.T.; Geysen, D.; Tielemans, Y.; Van Passel, S.; Pontikes, Y.; Blanpain, B.; Quaghebeur, M.; Hoekstra, N. Enhanced Landfill Mining in view of multiple resource recovery: A critical review. J. Clean. Prod. 2013, 55, 45–55. [Google Scholar] [CrossRef]

- Chandana, N.; Goli, V.S.N.S.; Mohammad, A.; Singh, D.N. Characterization and Utilization of Landfill-Mined-Soil-Like-Fractions (LFMSF) for Sustainable Development: A Critical Appraisal. Waste Biomass-Valorization 2020, 12, 641–662. [Google Scholar] [CrossRef]

- Hull, R.M.; Krogmann, U.; Strom, P.F. Composition and characteristics of excavated materials from a New Jersey landfill. J. Environ. Eng. 2005, 131, 478–490. [Google Scholar] [CrossRef]

- Chiou, I.-J.; Chen, C.-H. Municipal solid waste landfill age and refuse-derived fuel. Waste Manag. Res. 2020, 39, 601–606. [Google Scholar] [CrossRef] [PubMed]

- Wolfsberger, T.; Aldrian, A.; Sarc, R.; Hermann, R.; Höllen, D.; Budischowsky, A.; Zöscher, A.; Ragoßnig, A.; Pomberger, R. Landfill mining: Resource potential of Austrian landfills–Evaluation and quality assessment of recovered municipal solid waste by chemical analyses. Waste Manag. Res. J. Sustain. Circ. Econ. 2015, 33, 962–974. [Google Scholar] [CrossRef]

- Rotheut, M.; Quicker, P. Energetic utilisation of refuse derived fuels from landfill mining. Waste Manage. 2017, 62, 101–117. [Google Scholar] [CrossRef]

- Dong, T.T.T.; Lee, B.-K. Analysis of potential RDF resources from solid waste and their energy values in the largest industrial city of Korea. Waste Manag. 2009, 29, 1725–1731. [Google Scholar] [CrossRef]

- Hölzle, I. Analysing material flows of landfill mining in a regional context. J. Clean. Prod. 2019, 207, 317–328. [Google Scholar] [CrossRef]

- Bożym, M.; Klojzy-Karczmarczyk, B. Assessment of the mercury contamination of landfilled and recovered foundry waste — A case study. Open Chem. 2021, 19, 462–470. [Google Scholar] [CrossRef]

- Pitak, I.; Baltusnikas, A.; Kalpokaite-Dickuviene, R.; Kriukiene, R.; Denafas, G. Experimental study effect of bottom ash and temperature of firing on the properties, microstructure and pore size distribution of clay bricks: A Lithuania point of view. Case Stud. Constr. Mater. 2022, 17, e01230. [Google Scholar] [CrossRef]

- Götze, J.; Pan, Y.; Müller, A. Mineralogy and mineral chemistry of quartz: A review. Miner. Mag. 2021, 85, 639–664. [Google Scholar] [CrossRef]

- Yang, L.; Ying, W.; Yuqiong, Z.; Zheng, W.; Yuan, L.; Wuxing, H.; Yongfa, Z. The characteristics of mineralogy, morphology and sintering during co-combustion of Zhundong coal and oil shale. RSC Adv. 2017, 7, 51036–51045. [Google Scholar] [CrossRef]

- Kotowski, J.; Nejbert, K.; Olszewska-Nejbert, D. Rutile Mineral Chemistry and Zr-in-Rutile Thermometry in Provenance Study of Albian (Uppermost Lower Cretaceous) Terrigenous Quartz Sands and Sandstones in Southern Extra-Carpathian Poland. Minerals 2011, 11, 553. [Google Scholar] [CrossRef]

- Muhammad, M.; Fatmaliana, A.; Jalil, Z. Study of hematite mineral (Fe2O3) extracted from natural iron ore prepared by co-precipitation method. IOP Conf. Ser. Earth Environ. Sci. 2019, 348, 012135. [Google Scholar] [CrossRef]

- Boulliard, J.-C.; Gaillou, E. Twinning in “anorthoclase” megacrysts from phonolitic eruptions, Erebus volcano, Antarctica. Eur. J. Miner. 2019, 31, 99–110. [Google Scholar] [CrossRef]

- Diopside Mineral Data. Available online: https://www.mindat.org/min-1294.html (accessed on 25 January 2023).

- Hervy, M.; Remy, D.; Dufour, A.; Mauviel, G. Air-blown gasification of Solid Recovered Fuels (SRFs) in lab-scale bubbling fluidizedbed: Influence of the operating conditions and of the SRF composition. Energy Convers. Manag. 2019, 181, 584–592. [Google Scholar] [CrossRef]

- Locher, F.W. Zement—Grundlagen der Herstellung und Verwendung. Düsseldorf 522. 2000. Available online: https://www.google.ru/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&cad=rja&uact=8&ved=2ahUKEwin_Obn-Lr9AhX4g_0HHYgYD34QFnoECA0QAQ&url=https%3A%2F%2Fdownload.e-bookshelf.de%2Fdownload%2F0003%2F5106%2F68%2FL-G-0003510668-0013613454.pdf&usg=AOvVaw0-HmoVI11qP-j392H6cyQA (accessed on 24 February 2023).

- Akmenės cementas. Description of cement production technology. 2021. Available online: https://cementas.lt/en/production/description-of-cement-production-technology/ (accessed on 12 August 2014).

- Coal Marketing International (CMI). Coal Basics. Available online: http://www.coalmarketinginfo.com/coal-basics (accessed on 5 November 2012).

- Directive 2000/76/EC of the European Parliament and of the Council on the incineration of waste. Available online: https://eur-lex.europa.eu/eli/dir/2000/76/oj (accessed on 31 December 2020).

- Del Zotto, L.; Tallini, A.; Di Simone, G.; Molinari, G.; Cedola, L. Energy Enhancement of Solid Recovered Fuel within Systems of Conventional Thermal Power Generation. Energy Procedia 2015, 81, 319–338. [Google Scholar] [CrossRef]

- Organization for Economic Co-Operation and Development (OECD). Effective Carbon Rates. Available online: https://www.oecd.org/tax/tax-policy/effective-carbon-rates-2021-highlights-brochure.pdf (accessed on 5 May 2021).

—Section I;

—Section I;  —Section II;

—Section II;  —Section III.

—Section III.

| Parameters | Sections Landfill | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Section I | Section II | Section III | ||||||||||||||||||||

| Depth of Drilling, m | ||||||||||||||||||||||

| 1–2 | 3–4 | 5–6 | 7–8 | 9–10 | 1–2 | 3–4 | 5–6 | 7–8 | 9–10 | 11–12 | 13–14 | 1–2 | 3–4 | 5–6 | 7–8 | 9–10 | 11–12 | 13–14 | 15–16 | 17–18 | 19–20 | |

| Cl, % | 1.87 | 0.25 | 0.24 | 4.32 | 0.96 | 0.33 | 0.31 | 1.8 | 0.25 | 0.16 | 0.25 | 0.94 | 0.469 | 0.4 | 0.07 | 0.09 | 0.29 | 0.11 | 0.96 | 1.46 | 0.09 | 0.27 |

| Hg, mg/kg−1 | 0.02 | 0.03 | 0.11 | 0.05 | 0.09 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | – | – | 0.30 | 0.07 | 0.04 | 0.03 | 0.02 | – | – | – | – | – |

| № | Minerals | Section Landfill | ||||

|---|---|---|---|---|---|---|

| №1 | №2 | №3 | ||||

| Drilling Depth, m | ||||||

| 1–10 | 1–10 | 11–14 | 1–10 | 11–20 | ||

| Value, % | ||||||

| 1 | Quartz | 72.23 | 36.32 | 38.66 | 45.77 | 49.40 |

| 2 | Akermanite | 5.35 | 9.21 | 7.23 | 7.77 | 11.28 |

| 3 | Perovskite | - | 1.87 | 0.54 | 1.26 | 0.99 |

| 4 | Hematite | 0.60 | 1.85 | 13.39 | 3.11 | 1.51 |

| 5 | Microcline | 3.19 | 5.44 | 4.63 | 6.60 | 2.74 |

| 6 | Diopside | 2.12 | 3.21 | 9.44 | 1.53 | 2.06 |

| 7 | Wollastonite | 0.54 | 5.85 | 3.63 | 1.94 | 1.09 |

| 8 | Anhydrite | 1.43 | 6.68 | 2.35 | 2.37 | 1.61 |

| 9 | Lisetite | 4.85 | 3.42 | 3.20 | 3.19 | 3.76 |

| 10 | Augite | 1.20 | 3.97 | 4.53 | 10.84 | 6.28 |

| 11 | Anorthite | 1.73 | 4.92 | 2.74 | 8.84 | 8.53 |

| Amorphous | 6.75 | 17.26 | 9.66 | 6.78 | 10.96 | |

| Oxides | CaO | CO2 | SiO2 | Al2O3 | Fe2O3 | MgO | K2O | SO3 | TiO2 | Na2O | P2O5 | Mn2O3 | Cr2O3 | ZnO |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Quantity in ash, % | Section I, depth 1–10 m | |||||||||||||

| 23.02 | 57.33 | 8.05 | 4.04 | 2.63 | 2.32 | 0.44 | 0.92 | 0.36 | 0.49 | 0.33 | - | - | - | |

| Section II, depth 1–10 m | ||||||||||||||

| 32.82 | 25.64 | 18.97 | 3.53 | 4.08 | 5.22 | 0.59 | 3.69 | 3.45 | 1.06 | 0.9 | - | - | - | |

| Section II, depth 11–14 m | ||||||||||||||

| 33.08 | 16.24 | 22.13 | 8.75 | 11.55 | 2.94 | 0.23 | 1.47 | 1.47 | 1.19 | 0.9 | - | - | - | |

| Section III, depth 1–10 m | ||||||||||||||

| 22.28 | 23.0 | 25.5 | 9.28 | 10.4 | 3.93 | 0.54 | 1.36 | 0.21 | 1.59 | 0.62 | 0.11 | 0.13 | - | |

| Section III, depth 11–20 m | ||||||||||||||

| 30.32 | 7.49 | 24.49 | 17.19 | 7.6 | 4.4 | 0.61 | 1.53 | 2.21 | 2.06 | 1.4 | - | - | 0.63 | |

| Quantity in clinker, % | 42.5 | 34.5 | 14.0 | 3.5 | 1.8 | 1.0 | 0.7 | 0.5 | 0.2 | 0.1 | 0.08 | 0.05 | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pitak, I.; Denafas, G.; Baltušnikas, A.; Praspaliauskas, M.; Lukošiūtė, S.-I. Proposal for Implementation of Extraction Mechanism of Raw Materials during Landfill Mining and Its Application in Alternative Fuel Production. Sustainability 2023, 15, 4538. https://doi.org/10.3390/su15054538

Pitak I, Denafas G, Baltušnikas A, Praspaliauskas M, Lukošiūtė S-I. Proposal for Implementation of Extraction Mechanism of Raw Materials during Landfill Mining and Its Application in Alternative Fuel Production. Sustainability. 2023; 15(5):4538. https://doi.org/10.3390/su15054538

Chicago/Turabian StylePitak, Inna, Gintaras Denafas, Arūnas Baltušnikas, Marius Praspaliauskas, and Stasė-Irena Lukošiūtė. 2023. "Proposal for Implementation of Extraction Mechanism of Raw Materials during Landfill Mining and Its Application in Alternative Fuel Production" Sustainability 15, no. 5: 4538. https://doi.org/10.3390/su15054538

APA StylePitak, I., Denafas, G., Baltušnikas, A., Praspaliauskas, M., & Lukošiūtė, S.-I. (2023). Proposal for Implementation of Extraction Mechanism of Raw Materials during Landfill Mining and Its Application in Alternative Fuel Production. Sustainability, 15(5), 4538. https://doi.org/10.3390/su15054538