How Natural Are the “Natural” Materials? Proposal for a Quali-Quantitative Measurement Index of Naturalness in the Environmental Sustainability Context

Abstract

1. Introduction

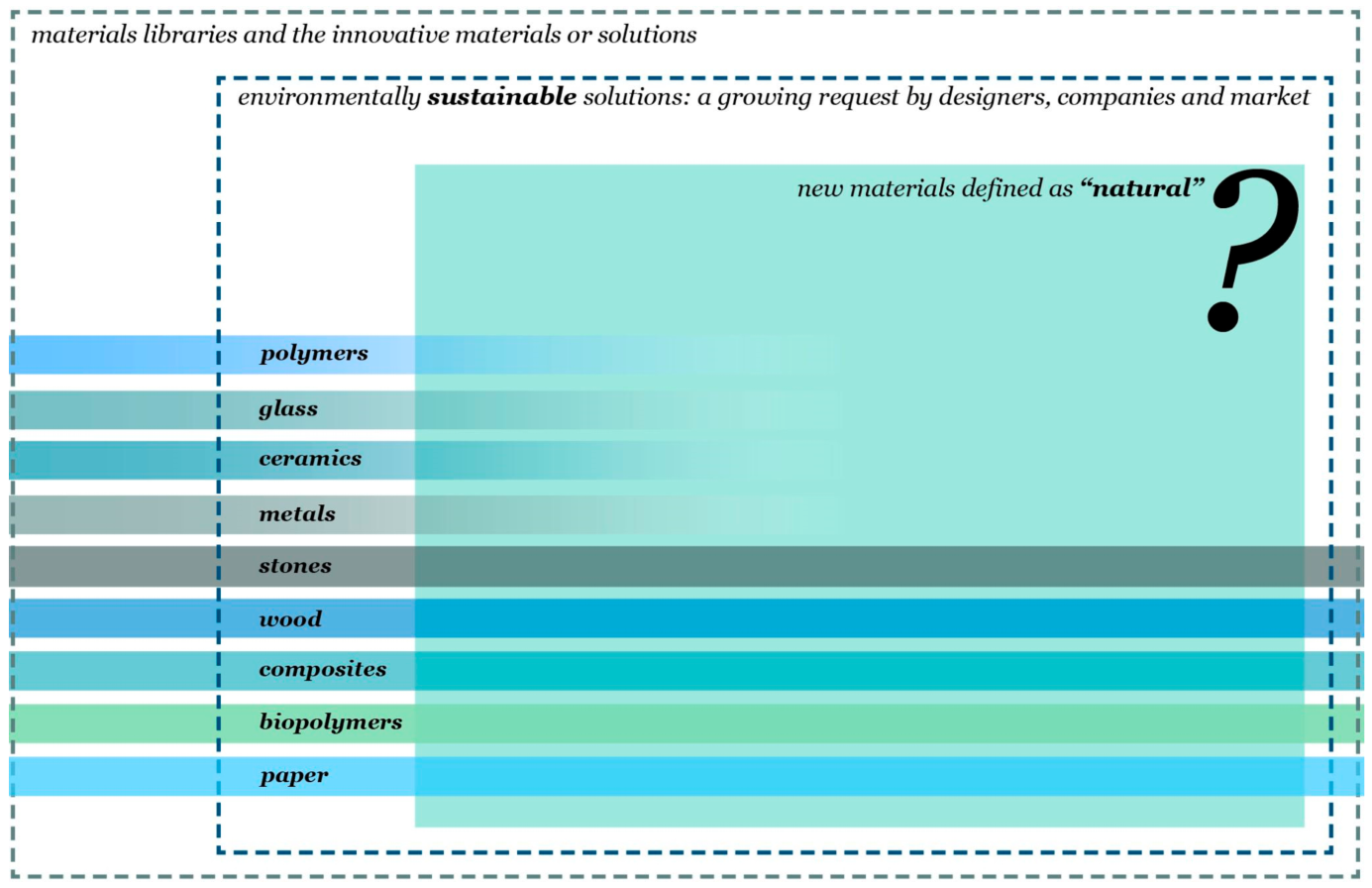

1.1. Motivation: The Overabundance of “Environmentally Sustainable” and “Natural” Materials

1.2. Significance: The “Natural” Materials Family in the Materials Libraries

1.3. Novelty: Measuring the Naturalness of Materials

2. Materials and Methods

2.1. The Source of Information: The “Natural” Materials Family in Different Materials Libraries

- The naturalness attribute is perceived in a non-homogeneous and non-consistent way when used to classify materials; for example, materials commonly recognised as “natural” such as wood or leather, are often separated from the “natural materials” family;

- The “natural” materials family comprises, in some cases, materials with a high degree of artificiality defined as “natural” by their manufacturers or because they include materials from natural resources.

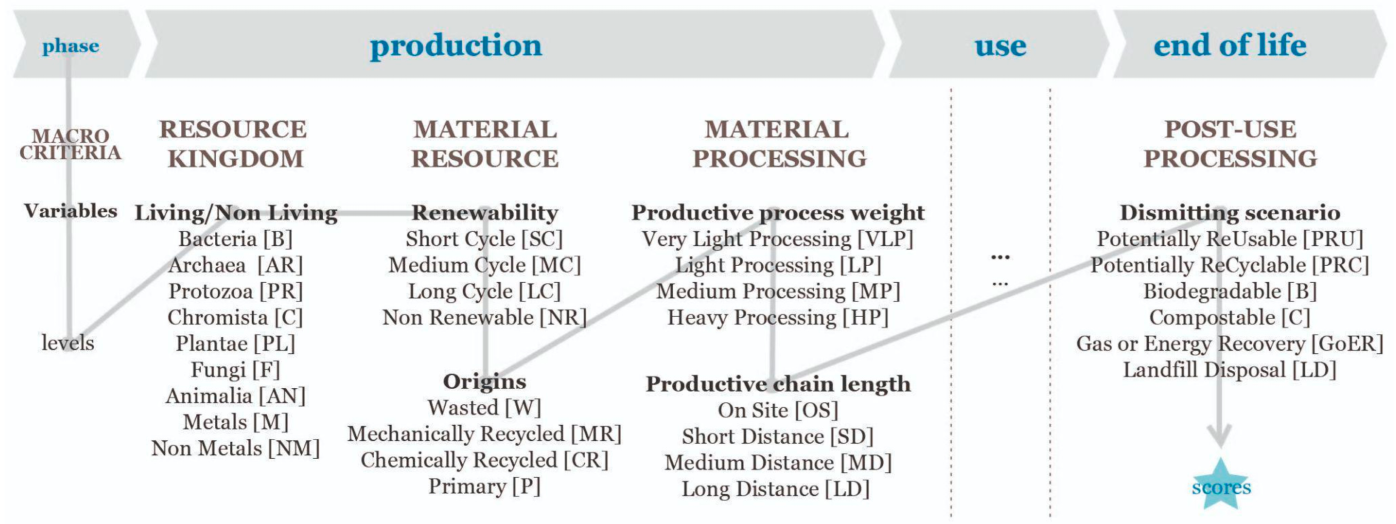

2.2. A Multicriteria Assessment Method

2.2.1. Resource Kingdom

- Bacteria [B];

- Archaea [AR];

- Protozoa [PR];

- Chromista [C];

- Plantae [PL];

- Fungi [F];

- Animalia [AN].

- Metals [M];

- Non-Metals [NM].

2.2.2. Renewability of the Resource

- Short Cycle [SC];

- Medium Cycle [MC];

- Long Cycle [LC];

- Non-Renewable [NR].

2.2.3. Origins of the Resource

2.2.4. Productive Processes Weight

- Very Light Processing [VLP]: The resource is taken directly from nature and introduced in the same configuration into the material layout; this is the case of materials that do not change their macro or micro shape during processing or that only change their shape spontaneously.

- Light Processing [LP]: The resource is usually processed with just a few traditional production processes, frequently just one, in some cases inspired by handcraft process or involving light and/or very simple technologies, such as melting, intertwining, spinning together, etc. In materials characterised by light processing, the resources are usually quite recognizable, at least with one of the five senses, because the link with their original shape is still quite strong.

- Medium Processing [MP]: The resource is processed, usually by steps, with several different technologies or with a few complex technologies; the productive process strongly affects the resource characteristics and deeply changes its mechanical properties. This approach entails a re-engineering of the material, frequently involving a natural or biologically inspired engineering approach; in this case, the resource can be recognisable, but with a completely different aspect, or it can be hidden and no longer recognizable because of the high number of undergone processes.

- High Processing [HP]: The resource is more than processed, it is entirely re-designed by a deep artificial process going back to its chemical structure; this is the case of synthetic biology, of materials created in the laboratory, generated—partially or totally—from a redesign of their intrinsic DNA, of their molecular structure.

2.2.5. Productive Chain Length

- On Site [OS]: The resource extraction site coincides with the resource processing site [38];

- Short Distance [SD]: The transformation happens in the same country of extraction as the resource;

- Medium Distance [MD]: The transformation happens in the same continent of extraction as the resource;

- Long Distance [LD]: The transformation happens on a different continent of extraction than the resource.

2.2.6. Dismitting Scenarios

- Potentially Reusable [PRU]: The material can be separated and prepared to be re-used without any other pre-processing;

- Potentially Recyclable [PRC]: The material can be reprocessed by a recycling process to recover secondary recycled material with high/low performances for the original or other purposes;

- Biodegradable [B]: The material waste can be biologically degraded by living organisms down to the base substances such as water, carbon dioxide, methane, basic elements, and biomass [42];

- Gas or Energy Recovery [GoER]: The material waste can be subject to an energy recovery treatment, through their combustion in fossil fuel power plants, or to gas recovery;

- Landfill Disposal [LD]: The only possible end of life scenario for the material is landfill.

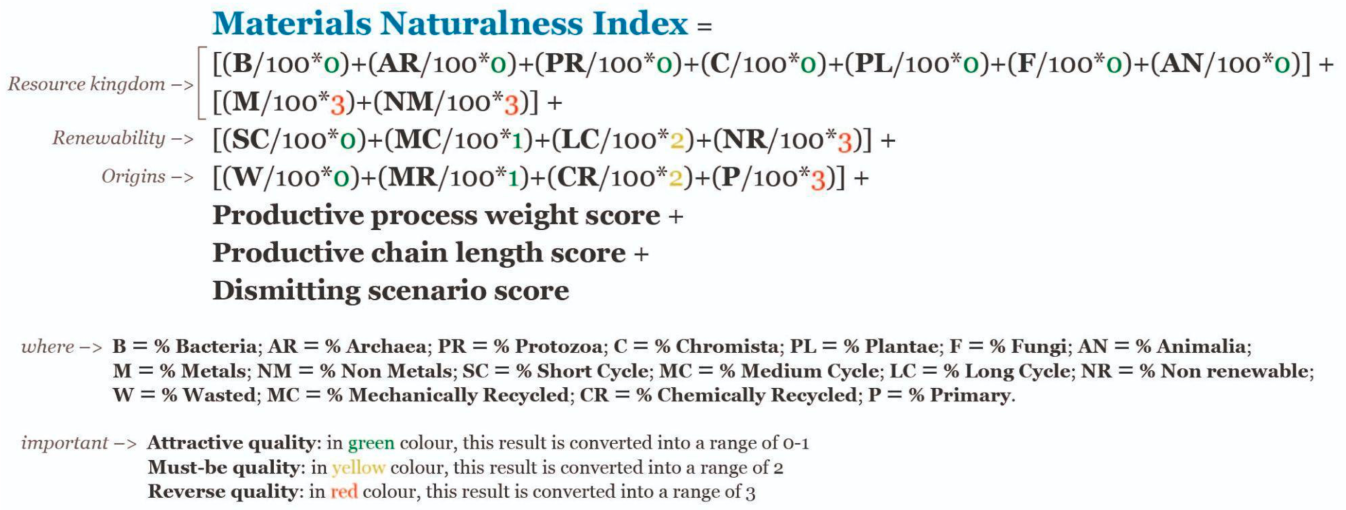

2.3. Data Analysis

- Attractive quality: If the analysed material fulfils the quality, this result is converted into a range of 0–1 (excellent; in green colour in Appendix A);

- Must-be quality: If the analysed material fulfils the quality, this result is converted into 2 (good; in yellow colour in Appendix A);

- Reverse quality: If the analysed material fulfils the quality, this result is converted into 3 (poor; in red colour in Appendix A).

2.4. A First Run of the Assessment: The Implementation on Several “Natural” Materials

3. Results

3.1. The Materials Naturalness Index

- Excellent value (of Material Naturalness): The analysed material was assessed with a value ranging from 0 to 6 (the evaluation is placed in the area with a light green background in the figure);

- Good value (of Material Naturalness): The analysed material was assessed with a value ranging from 7 to 12 (the evaluation is placed in the area with a light yellow background in the figure);

- Poor value (of Material Naturalness): The analysed material was assessed with a value ranging from 13 to 18 (the evaluation is placed in the area with a light red background in the figure).

3.2. The Analysed Materials in Relation to the “Natural” Materials Family

4. Discussion

4.1. A Comparison between MN Index and Other Studies Assessing the Material Naturalness

4.2. The Impact of the MN Index on the Design Process, and the Adoption by Its Actors

- From the designers’ perspective, using the MN Index, the designer is aided in choosing the best materials through a method that is coherent with the Life Cycle Approach but agile and easily usable during the design process. Specifically, it can be adopted in the meta-design phase to choose the most appropriate material for a sustainable project. In fact, according to recent approaches to design culture, selecting suitable materials for a product should be done as early as in the meta-design stage because this supports its technical functions and shapes its personality [57]. However, the index can also be adopted to validate the designer’s choices based on material technical, sensory, and environmental properties: the solutions can either be rejected or accepted by checking the naturalness level. Moreover, the MN index avoids using a priori preconceptions about materials’ sustainable impact (e.g., biomaterials, materials from renewable resources) regarding sustainability and artificiality, interpreted as opposed to naturalness.

- From the material libraries’ perspective, the classification of materials and their organisation in families represents a complex challenge. Through the analysis presented in this study, the “natural” term was proved needing to be considered as an attribute rather than as a family. This attribute, in fact, was demonstrated to be transversal to all material families; therefore, a new classification re-collocating the currently so-labelled “natural materials” could be proposed, as well as a new layer of investigation of materials, adopting the proposed method.

- From the material producers’ perspective, the MN index can also lead them to a reflection, especially on the use—and, frequently, abuse—of the naturalness attribute, often assumed as a marketing strategy. In fact, reflecting on the real variables that concretely lead to a higher degree of naturalness could help producers making the process being more “light”, where possible, as well as meeting the wishes of the designer and, consequently, of the final consumer, for a truly more responsible production.

4.3. Future Challenges and Applications for the MN Index

5. Conclusions

- The index allows overcoming the subjectivity and randomness with which the “natural” attribute is used in the world of materials;

- As it is based on the least number of parameters necessary for the evaluation of naturalness, it is easier to apply than a complete LCA;

- Designers could, therefore, independently evaluate the naturalness of materials starting from objective evidence and pursuing a critical point of view not influenced by marketing claims.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Attractive Quality, Must-Be Quality, Reverse Quality—Theory of Attractive Quality [Kano, Seraku, Takahashi, Tsuji, 1984] | ||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SOURCE | MATERIAL DESCRI-PTIONS | MACRO-CRITERIA | RESOURCE KINGDOM | MATERIAL RESOURCE | MATERIAL PROCESSING | POST-USE PROCESSING | Materials Naturalness Index (MN Index) | |||||||||||||||||

| VARIA- BLES | Living [L;0] | Non Living [NL;3] | Renewability | Origins | Productive Process Weight | Productive Chain Length | Dismitting Scenario | |||||||||||||||||

| LEVELS | Bacteria [B]/Archaea [AR]/Protozoa [PR]/Chromista [C]/Plantae [PL]/Fungi [F]/Animalia [AN] | Minerals | Short Cycle [SC;0]/Medium Cycle [MC;1]/Long Cycle [LC;2]/Non Renewable [NR;3] | Wasted [W;0]/Mechanically Recycled [MR;1]/Chemically Recycled [CR;2]/Primary [P;3] | Very Light Processing [VLP = 0]/Light Processing [LP = 1]/Medium Processing [MP = 2]/Heavy Processing [HP = 3] | On Site [OS = 0]/Short Distance [SD = 1]/Medium Distance [MD = 2]/Long Distance [LD = 3] | Potentially ReUsable [PRU = 0]/Potentially ReCyclable [PRC = 1]/Biodegradable [B = 2]/Compostable [C = 2]/Gas or Energy Recovery [GoER = 2] /Landfill Disposal [LD = 3] | |||||||||||||||||

| Metals [M]/Non Metals [NM] | ||||||||||||||||||||||||

| B | AR | PR | C | PL | F | AN | M | NM | SC | MC | LC | NR | W | MR | CR | P | ||||||||

| 1 | MATto | biologically engineered banana leaf veneers | 100 | 100 | 100 | 1 | 1 | 2 | 4 | |||||||||||||||

| 2 | MATto | paper replacing up to 15% of virgin tree pulp with organic residues | 100 | 100 | 15 | 85 | 1 | 1 | 1 | 6 | ||||||||||||||

| 3 | MATto | innovative natural textile made from pineapple leaf fibre | 100 | 100 | 70 | 30 | 2 | 2 | 2 | 7 | ||||||||||||||

| 4 | Sustainable Material Library | non-wowen basalt fabric | 100 | 100 | 100 | 2 | 3 | 3 | 17 | |||||||||||||||

| 5 | Materfad | organic refuse biocompound | 100 | 100 | 100 | 2 | 1 | 2 | 5 | |||||||||||||||

| 6 | MATto | thin natural stone veneer over a cotton fleece | 5 | 95 | 5 | 95 | 100 | 2 | 2 | 3 | 16 | |||||||||||||

| 7 | MATto | steel panels that house stabilized lichens | 10 | 90 | 10 | 90 | 90 | 10 | 2 | 1 | 3 | 13 | ||||||||||||

| 8 | MATto | expanded insulation corkboard | 100 | 100 | 100 | 0 | 1 | 1 | 3 | |||||||||||||||

| 9 | MATto | innovative biological and healthy yarn obtained from milk | 65 | 35 | 100 | 35 | 65 | 3 | 2 | 0 | 7 | |||||||||||||

| 10 | MATto | fibre by a blend of Chitosan (from crab shells) and viscose | 95 | 5 | 100 | 5 | 95 | 3 | 2 | 0 | 8 | |||||||||||||

| 11 | Materfad | sheet of material from bacteria | 50 | 50 | 100 | 100 | 0 | 0 | 2 | 2 | ||||||||||||||

| 12 | MATto | alpine herb and flower veneers bonded with bio-resins | 100 | 100 | 100 | 1 | 0 | 2 | 6 | |||||||||||||||

| 13 | Materfad | cellulose fibre from Bamboo | 100 | 100 | 50 | 50 | 3 | 2 | 1 | 8 | ||||||||||||||

| 14 | Sustainable Material Library | fibre produced exclusively from wood and seaweed | 100 | 100 | 100 | 3 | 1 | 1 | 9 | |||||||||||||||

| 15 | Materfad | recycled textile waste and mycelium as a binding agent | 95 | 5 | 5 | 95 | 95 | 5 | 1 | 0 | 3 | 6 | ||||||||||||

| 16 | MATto | very thin flexible sandstone | 15 | 85 | 15 | 85 | 100 | 1 | 2 | 3 | 14 | |||||||||||||

| 17 | MATto | salmon skin leather | 100 | 100 | 100 | 1 | 0 | 1 | 2 | |||||||||||||||

| 18 | MATto | paper from algae of the Venice lagoon | 100 | 100 | 30 | 70 | 1 | 1 | 1 | 4 | ||||||||||||||

| 19 | MATto | biopolymer from PLA | 100 | 100 | 100 | 3 | 2 | 2 | 10 | |||||||||||||||

| 20 | Materfad | eco-leather from spoiled fruit and vegetables | 100 | 100 | 100 | 0 | 0 | 1 | 1 | |||||||||||||||

| 21 | Materfad | silk-like yarn from repurposed citrus juice by-products | 100 | 100 | 100 | 3 | 0 | 1 | 4 | |||||||||||||||

| 22 | Materfad | bio plastic composed of lignin, cellulose fibres, and natural additives | 100 | 100 | 100 | 1 | 2 | 3 | 7 | |||||||||||||||

| 23 | Materfad | floor covering of linseed oil, wood flour and mineral fillers | 100 | 30 | 70 | 51 | 49 | 2 | 2 | 3 | 9 | |||||||||||||

| 24 | Sustainable Material Library | high-performing insulation material from the ocean | 100 | 100 | 100 | 0 | 1 | 2 | 3 | |||||||||||||||

| 25 | Materfad | flexible foams from algae biomass | 100 | 100 | 100 | 2 | 1 | 2 | 8 | |||||||||||||||

| 26 | Materfad | sound insulating material from sheep wool | 100 | 100 | 100 | 0 | 1 | 1 | 2 | |||||||||||||||

| 27 | MATto | recycled aluminum tiles for floorings | 100 | 100 | 100 | 2 | 2 | 1 | 11 | |||||||||||||||

| 28 | MATto | recycled leather | 10 | 90 | 10 | 90 | 90 | 10 | 1 | 2 | 1 | 6 | ||||||||||||

| 29 | Sustainable Material Library | recycled polyamide for textile applications | 100 | 100 | 100 | 3 | 3 | 1 | 14 | |||||||||||||||

| 30 | Sustainable Material Library | bioplastic made from eggs | 100 | 100 | 100 | 1 | 1 | 2 | 4 | |||||||||||||||

| 31 | Material District | perforated poplar wood veneers | 100 | 100 | 100 | 0 | 1 | 1 | 6 | |||||||||||||||

| 32 | Circular Material Library | activated charcoal by upcycling non-edible food waste | 60 | 40 | 40 | 60 | 60 | 40 | 3 | 2 | 2 | 10 | ||||||||||||

| 33 | Circular Material Library | textiles made by discarded wool from factory floor offcuts, deadstock yarn and post-consumer textiles waste | 100 | 100 | 100 | 1 | 2 | 1 | 5 | |||||||||||||||

| 34 | Circular Material Library | clay plaster for interior walls and ceilings | 4 | 6 | 90 | 4 | 96 | 100 | 2 | 2 | 2 | 15 | ||||||||||||

| 35 | Circular Material Library | natural dye derived from bacteria and other microorganisms | 100 | 100 | 100 | 2 | 1 | 2 | 8 | |||||||||||||||

| 36 | Circular Material Library | precast concrete created by employing microorganisms to grow the bio cement | 15 | 85 | 15 | 85 | 85 | 15 | 0 | 1 | 0 | 7 | ||||||||||||

| 37 | Circular Material Library | mimicry inspired vegan leather built on a formula of 8+ bio-based ingredients | 5 | 5 | 80 | 10 | 90 | 10 | 100 | 1 | 2 | 2 | 10 | |||||||||||

| 38 | Sustainable Material Library | oyster shell powder | 100 | 100 | 100 | 2 | 1 | 2 | 6 | |||||||||||||||

| 39 | Make it London | bio-based leather from chitin from shellfish waste and discarded coffee grounds | 30 | 30 | 40 | 100 | 100 | 1 | 1 | 2 | 4 | |||||||||||||

| 40 | Make it London | recycled plastics from marine debris collected from the bottom of the ocean | 100 | 100 | 100 | 3 | 2 | 1 | 14 | |||||||||||||||

| 41 | Make it London | high performance cement mixed ultra-fine aggregates from recycled glass and polymers | 100 | 100 | 50 | 50 | 2 | 2 | 3 | 15 | ||||||||||||||

| 42 | Make it London | tree-free mineral-based paper | 25 | 75 | 25 | 75 | 75 | 25 | 3 | 2 | 2 | 13 | ||||||||||||

| 43 | Make it London | paper board made from 100% recycled materials | 100 | 100 | 100 | 1 | 1 | 1 | 4 | |||||||||||||||

| 44 | Make it London | concrete made of hemp shiv and lime binder | 30 | 70 | 30 | 70 | 30 | 70 | 1 | 0 | 1 | 8 | ||||||||||||

| 45 | Make it London | water-based, modified gypsum composite | 100 | 100 | 100 | 1 | 1 | 1 | 11 | |||||||||||||||

| 46 | Material District | vegan coated fabric | 75 | 25 | 75 | 25 | 100 | 1 | 2 | 2 | 7 | |||||||||||||

| 47 | Material District | gypsum boards with fibrous reinforcement | 100 | 100 | 100 | 2 | 2 | 3 | 16 | |||||||||||||||

| 48 | Material District | panel from silkworm cocoons | 100 | 100 | 100 | 0 | 0 | 1 | 1 | |||||||||||||||

| 49 | Material District | 100% merino wool | 100 | 100 | 100 | 0 | 0 | 0 | 3 | |||||||||||||||

| 50 | Material District | cork fabric | 100 | 100 | 100 | 2 | 1 | 1 | 5 | |||||||||||||||

| 51 | Material District | durable surface made of recycled content | 25 | 75 | 100 | 75 | 25 | 1 | 2 | 3 | 11 | |||||||||||||

| 52 | Material District | textile fibre made from chemically recycled domestic cotton waste | 100 | 100 | 100 | 2 | 1 | 0 | 5 | |||||||||||||||

| 53 | Material District | cow stomach leather | 100 | 100 | 100 | 2 | 2 | 1 | 5 | |||||||||||||||

| 54 | Material District | sheep/cow/donkey dung paper | 25 | 75 | 100 | 100 | 0 | 0 | 1 | 1 | ||||||||||||||

| 55 | Material District | bonded leather by scraps | 25 | 55 | 20 | 55 | 25 | 20 | 80 | 20 | 2 | 1 | 1 | 6 | ||||||||||

| 56 | Material District | recycled wood chips terrazzo | 80 | 20 | 10 | 80 | 10 | 90 | 10 | 1 | 1 | 1 | 5 | |||||||||||

| 57 | Material District | decorative wood panels | 90 | 10 | 100 | 100 | 0 | 1 | 1 | 6 | ||||||||||||||

| 58 | Material District | high-density panel - freeform fiberboard | 80 | 20 | 80 | 20 | 80 | 20 | 1 | 1 | 2 | 6 | ||||||||||||

| 59 | Material District | rice husk, salt and mineral oil composite | 60 | 40 | 60 | 40 | 2 | 2 | 1 | 7 | ||||||||||||||

| 60 | Material District | cement bonded particle board | 63 | 37 | 10 | 63 | 27 | 100 | 3 | 2 | 1 | 12 | ||||||||||||

References

- Bontempi, E.; Sorrentino, G.P.; Zanoletti, A.; Alessandri, I.; Depero, L.E.; Caneschi, A. Sustainable Materials and their Contribution to the Sustainable Development Goals (SDGs): A Critical Review Based on an Italian Example. Molecules 2021, 26, 1407. [Google Scholar] [CrossRef] [PubMed]

- Silva, A.; Rosano, M.; Stocker, L.; Gorissen, L. From waste to sustainable materials management: Three case studies of the transition journey. Waste Manag. 2017, 61, 547–557. [Google Scholar] [CrossRef] [PubMed]

- Hofmann, M.; Hofmann, H.; Hagelüken, C.; Hool, A. Critical raw materials: A perspective from the materials science community. Sustain. Mater. Technol. 2018, 17, e00074. [Google Scholar] [CrossRef]

- Helbig, C.; Kolotzek, C.; Thorenz, A.; Reller, A.; Tuma, A.; Schafnitzel, M.; Krohns, S. Benefits of resource strategy for sustainable materials research and development. Sustain. Mater. Technol. 2017, 12, 1–8. [Google Scholar] [CrossRef]

- Arif, Z.U.; Khalid, M.Y.; Sheikh, M.F.; Zolfagharian, A.; Bodaghi, M. Biopolymeric sustainable materials and their emerging applications. J. Environ. Chem. Eng. 2022, 10, 108159. [Google Scholar] [CrossRef]

- de Freitas Netto, S.V.; Sobral, M.F.F.; Ribeiro, A.R.B.; da Luz Soares, G.R. Concepts and forms of greenwashing: A systematic review. Environ. Sci. Eur. 2020, 32, 19. [Google Scholar] [CrossRef]

- Rozin, P.; Fischler, C.; Shields-Argelès, C. European and American perspectives on the meaning of natural. Appetite 2012, 59, 448–455. [Google Scholar] [CrossRef]

- Overvliet, K.E.; Karana, E.; Soto-Faraco, S. Perception of naturalness in textiles. Mater. Des. 2016, 90, 1192–1199. [Google Scholar] [CrossRef]

- Sérgio, M.C.; Nascimento, A.M.A.; Gegenfurtner, K.R. Naturalness and aesthetics of colors—Preference for color compositions perceived as natural. Vis. Res. 2021, 185, 98–110. [Google Scholar]

- Allione, C.; De Giorgi, C.; Lerma, B.; Petruccelli, L. From ecodesign products guidelines to materials guidelines for a sustainable product. Qualitative and quantitative multicriteria environmental profile of a material. Energy 2012, 39, 90–99. [Google Scholar] [CrossRef]

- Lerma, B. Materials in sustainable design. Characteristics and potential of materials for low environmental impact design. In Towards Conscious Design. Research, Environmental Sustainability, Local Development Project; Ceppa, C., Lerma, B., Eds.; Società Editrice Umberto Allemandi & C.: Torino, Italy, 2014; pp. 46–57. [Google Scholar]

- Peters, S. Material Revolution II: New Sustainable and Multi-Purpose Materials for Design and Architecture, 1st ed.; Birkhauser: Basel, Switzerland, 2014; pp. 1–223. [Google Scholar]

- Vezzoli, C. The “material” side of design for sustainability. In Materials Experience: Fundamentals of Materials and Design, 1st ed.; Karana, E., Pedgley, O., Rognoli, V., Eds.; Butterworth-Heinemann: Oxford, UK, 2014; pp. 105–121. [Google Scholar]

- Whalen, K.; Peck, D. In the Loop—Sustainable, Circular Product Design and Critical Materials. Int. J. Autom. Technol. 2014, 8, 664–676. [Google Scholar] [CrossRef]

- Wilkes, S.; Wongsriruksa, S.; Howes, P.; Gamester, R.; Witchel, H.; Conreen, M.; Laughlin, Z.; Miodownik, M. Design tools for interdisciplinary translation of material experiences. Mater. Des. 2016, 90, 1228–1237. [Google Scholar] [CrossRef]

- Marschallek, B.E.; Jacobsen, T. Classification of material substances: Introducing a standards-based approach. Mater. Des. 2020, 193, 108784. [Google Scholar] [CrossRef]

- De Giorgi, C.; Lerma, B.; Dal Palù, D. The Material Side of Design. The Future Material Design Cultures; Società Editrice Umberto Allemandi & C.: Torino, Italy, 2020; pp. 1–144. [Google Scholar]

- Fazil, A.; Pedgley, O. Sample Libraries to Expedite Materials Experience for Design: A Survey of Global Provision. Mater. Des. 2016, 90, 1207–1217. [Google Scholar]

- Pimonenko, T.; Bilan, Y.; Horák, J.; Starchenko, L.; Gajda, W. Green brand of companies and greenwashing under sustainable development goals. Sustainability 2020, 12, 1679. [Google Scholar] [CrossRef]

- Seeram, R.; Rajan, J. Addressing sustainability gaps. Sci. Total Environ. 2022, 806, 151208. [Google Scholar]

- De Jong, M.D.; Harkink, K.M.; Barth, S. Making green stuff? Effects of corporate greenwashing on consumers. J. Bus. Technol. Commun. 2018, 32, 77–112. [Google Scholar] [CrossRef]

- Goodman, T.; Montgomery, R.; Bialek, A.; Forbes, A.; Rides, M.; Whitaker, T.A.; Overvliet, K.; Mcglone, F.; van der Heijden, G. The measurement of naturalness (MONAT). In Proceedings of the 12th IMEKO TC1 & TC7 Joint Symposium on Man Science & Measurement, Annecy, France, 3–5 September 2008. [Google Scholar]

- Karana, E. Characterization of ‘natural’ and ‘high-quality’ materials to improve perception of bio-plastics. J. Clean. Prod. 2012, 37, 316–325. [Google Scholar] [CrossRef]

- Damen, F.; Steenbekkers, B. Added value of physical food products as a stimulus during interviewing. Appetite 2022, 169, 105819. [Google Scholar] [CrossRef]

- Damen, F.; Verkerk, R.; Steenbekkers, B. Healthiness, naturalness and sustainability perception of adolescents toward chocolate snack bars. Br. Food J. 2022, 124, 200–218. [Google Scholar] [CrossRef]

- Barrette, M.; Dumais, D.; Auger, I.; Boucher, Y.; Bouchard, M.; Bouliane, J. Naturalness assessment performed using forestry maps to validate forest management sustainability. Ecol. Indic. 2020, 119, 106832. [Google Scholar] [CrossRef]

- Curran, M. Strengths and Limitations of Life Cycle Assessment. In Background and Future Prospects in Life Cycle Assessment. LCA Compendium. The Complete World of Life Cycle Assessment; Klöpffer, W., Ed.; Springer: Dordrecht, The Netherlands, 2014; pp. 189–206. [Google Scholar]

- Srubar, W.V., III. Engineered Living Materials: Taxonomies and Emerging Trends. Trends Biotechnol. 2021, 39, 574–583. [Google Scholar] [CrossRef] [PubMed]

- Ruggiero, M.A.; Gordon, D.P.; Orrell, T.M.; Bailly, N.; Bourgoin, T.; Brusca, R.C.; Cavalier-Smith, T.; Guiry, M.D.; Kirk, P.M.; Thuesen, E.V. A higher level classification of all living organisms. PLoS ONE 2015, 10, e0130114. [Google Scholar]

- Edens, B.; Di Matteo, I. Classification issues for mineral and energy resources. In Proceedings of the 11th London Group Meeting, Pretoria, South Africa, 26–30 March 2007; pp. 26–30. [Google Scholar]

- Boubault, A.; Maïzi, N. Devising mineral resource supply pathways to a low-carbon electricity generation by 2100. Resources 2019, 8, 33. [Google Scholar] [CrossRef]

- Oubraham, A.; Zaccour, G. A Survey of Applications of Viability Theory to the Sustainable Exploitation of Renewable Resources. Ecol. Econ. 2018, 145, 346–367. [Google Scholar] [CrossRef]

- Vezzoli, C.A. Design for Environmental Sustainability. Life Cycle Design of Products, 2nd ed.; Springer London Ltd: London, UK, 2018; pp. 1–330. [Google Scholar]

- Sassanelli, C.; Urbinati, A.; Rosa, P.; Chiaroni, D.; Terzi, S. Addressing circular economy through design for X approaches: A systematic literature review. Comput. Ind. 2020, 120, e103245. [Google Scholar] [CrossRef]

- Bontempi, E. Raw Materials and Sustainability Indicators; Springer: Cham, Switzerland, 2017; pp. 1–28. [Google Scholar]

- Thiounn, T.; Smith, R.C. Advances and approaches for chemical recycling of plastic waste. J. Polym. Sci. 2020, 58, 1347–1364. [Google Scholar] [CrossRef]

- Lerma, B.; Dal Palù, D. Natural materials. A family on the move, but where is the last stop? In Running with Scissors. In Proceedings of the 13th International Conference of the EAD, Dundee, UK, 10–12 April 2019. [Google Scholar]

- Raman, R.; Bashir, R. Biomimicry, Biofabrication, and Biohybrid Systems: The Emergence and Evolution of Biological Design. Adv. Healthc. Mater. 2017, 6, 1700496. [Google Scholar] [CrossRef]

- Rajendran, K.; Lin, R.; Wall, D.M.; Murphy, J.D. Influential Aspects in Waste Management Practices. In Sustainable Resource Recovery and Zero Waste Approaches; Taherzadeh, M.J., Bolton, K., Wong, J., Pandey, A., Eds.; Elsevier NV: Amsterdam, The Netherlands, 2019; pp. 65–78. [Google Scholar]

- Directive (EU) 2018/851 of the European Parliament and of the Council of 30 May 2018 Amending Directive 2008/98/EC on Waste. Available online: https://eur-lex.europa.eu/eli/dir/2018/851/oj (accessed on 19 January 2023).

- Moreno, M.; De los Rios, C.; Rowe, Z.; Charnley, F. A Conceptual Framework for Circular Design. Sustainability 2016, 8, 1–15. [Google Scholar] [CrossRef]

- Goswami, P.; O’Haire, T. Developments in the use of green (biodegradable), recycled and biopolymer materials in technical nonwovens. In Woodhead Publishing Series in Textiles, Advances in Technical Nonwovens; Kellie, G., Ed.; Woodhead Publishing: Sawston, UK, 2016; pp. 97–114. [Google Scholar]

- ISO 18606:2013; Packaging and the Environment—Organic Recycling. International Organization for Standardization: London, UK.

- ISO 17088:2021; Plastics—Organic Recycling—Specifications for Compostable Plastics. International Organization for Standardization: London, UK.

- Kano, N.; Seraku, N.; Takahashi, F.; Tsuji, S. Attractive Quality and Must-Be Quality. J. Jpn. Soc. Qual. Control. 1984, 41, 39–48. [Google Scholar]

- Witell, L.; Löfgren, M.; Dahlgaard, J.J. Theory of attractive quality and the Kano methodology—The past, the present, and the future. Total Qual. Manag. Bus. Excell. 2013, 24, 1241–1252. [Google Scholar] [CrossRef]

- Dace, E.; Stibe, A.; Timma, L. A holistic approach to manage environmental quality by using the Kano model and social cognitive theory. Corp. Soc. Responsib. Environ. Manag. 2019, 27, 430–443. [Google Scholar] [CrossRef]

- Renetzeder, C.; Schindler, S.; Peterseil, J.; Prinz, M.A.; Mücher, S.; Wrbka, T. Can we measure ecological sustainability? Landscape pattern as an indicator for naturalness and land use intensity at regional, national and European level. Ecol. Indic. 2010, 10, 39–48. [Google Scholar] [CrossRef]

- Teixeira, F.M.; Pereira, A.F. Perception of naturalness in materials and user’s choice: Hardwood and melamine foil finished products. Strateg. Des. Res. J. 2019, 12, 361–382. [Google Scholar]

- Karana, E.; Nijkamp, N. Fiberness, reflectiveness and roughness in the characterization of natural and high quality materials. J. Clean. Prod. 2014, 68, 252–260. [Google Scholar] [CrossRef]

- Etale, A.; Siegrist, M. Food processing and perceived naturalness: Is it more natural or just more traditional? Food Qual. Prefer. 2021, 94, 104323. [Google Scholar] [CrossRef]

- Magnier, L.; Schoormans, J.; Mugge, R. Judging a product by its cover: Packaging sustainability and perceptions of quality in food products. Food Qual. Prefer. 2016, 53, 132–142. [Google Scholar] [CrossRef]

- Román, S.; Sánchez-Siles, L.M.; Siegrist, M. The importance of food naturalness for consumers: Results of a systematic review. Trends Food Sci. Technol. 2017, 67, 44–57. [Google Scholar] [CrossRef]

- Labbe, D.; Pineau, N.; Martin, N. Food expected naturalness: Impact of visual, tactile and auditory packaging material properties and role of perceptual interactions. Food Qual. Prefer. 2013, 27, 170–178. [Google Scholar] [CrossRef]

- Gebhardt, B.; Sperl, R.; Carle, R.; Müller-Maatsch, J. Assessing the sustainability of natural and artificial food colorants. J. Clean. Prod. 2020, 260, 120884. [Google Scholar] [CrossRef]

- de Haes, H.A.U.; Heijungs, R.; Suh, S.; Huppes, G. Three Strategies to Overcome the Limitations of Life-Cycle Assessment. J. Ind. Ecol. 2004, 8, 19–32. [Google Scholar] [CrossRef]

- Lerma, B.; De Giorgi, C.; Allione, C. Design and materials: Sensory Perception_Sustainability_Project; FrancoAngeli: Milano, Italy, 2013; pp. 1–177. [Google Scholar]

- Wilkes, S.E.; Miodownik, M.A. Materials library collections as tools for interdisciplinary research. Interdiscip. Sci. Rev. 2018, 43, 3–23. [Google Scholar] [CrossRef] [PubMed]

| Material Library Name | Family Organisation (and Number of Collected Items up to November 2022) | Particular Notes |

|---|---|---|

| Materfad | Natural materials, 336 (animal origins, 103; vegetal origins, 46; mineral origins, 187). | A subdivision by living kingdoms is adopted. |

| Material District | Other naturals, 685; Wood, 300; Natural stones, 72. | The “other naturals” materials family comprises bioplastics. |

| Make it London | Timber and construction boards, 25; Plastics, 8; Stones and composites, 11; Naturals and organics, 10; Paper and print, 9; Metals, 8; Textiles, 13. | Commonly considered natural materials, such as stone or wood, are ascribed into other materials families than “naturals and organics”. Furthermore, materials families and applications are mixed. |

| Circular Material Library | TechCycle, 37; BioCycle, 60. | All items are circular materials. There is no specific session dedicated to “natural” materials. In the” TechCycle” family are collected metals, plastics, etc., and in BioCycle woods, bioplastics, etc. |

| Sustainable Materials Library | Organic materials, 543 (plastic, 244; fibre, 160; natural, 32; rubber, 68; others, 39); Inorganic materials, 46 (metal, 14; mineral, 32). | There is no distinction between “natural” and other materials. All materials are brought back to nature. |

| MATto | Natural materials, 33; Wood, 90; Metals, 50; Paper, 136. | “Natural materials” include materials such as leather, cork, basalt, etc. Bioplastics are not included in the “natural materials” family. |

| Positive | Negative | |

|---|---|---|

| internal | STRENGTHS

| WEAKNESSES

|

| external | OPPORTUNITIES

| THREATS

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dal Palù, D.; Lerma, B. How Natural Are the “Natural” Materials? Proposal for a Quali-Quantitative Measurement Index of Naturalness in the Environmental Sustainability Context. Sustainability 2023, 15, 4349. https://doi.org/10.3390/su15054349

Dal Palù D, Lerma B. How Natural Are the “Natural” Materials? Proposal for a Quali-Quantitative Measurement Index of Naturalness in the Environmental Sustainability Context. Sustainability. 2023; 15(5):4349. https://doi.org/10.3390/su15054349

Chicago/Turabian StyleDal Palù, Doriana, and Beatrice Lerma. 2023. "How Natural Are the “Natural” Materials? Proposal for a Quali-Quantitative Measurement Index of Naturalness in the Environmental Sustainability Context" Sustainability 15, no. 5: 4349. https://doi.org/10.3390/su15054349

APA StyleDal Palù, D., & Lerma, B. (2023). How Natural Are the “Natural” Materials? Proposal for a Quali-Quantitative Measurement Index of Naturalness in the Environmental Sustainability Context. Sustainability, 15(5), 4349. https://doi.org/10.3390/su15054349