Numerical Simulation of Steel Fiber Pull-Out Process Based on Cohesive Zone Model and Unified Phase-Field Theory

Abstract

1. Introduction

2. Theoretical Basis and Main Equations

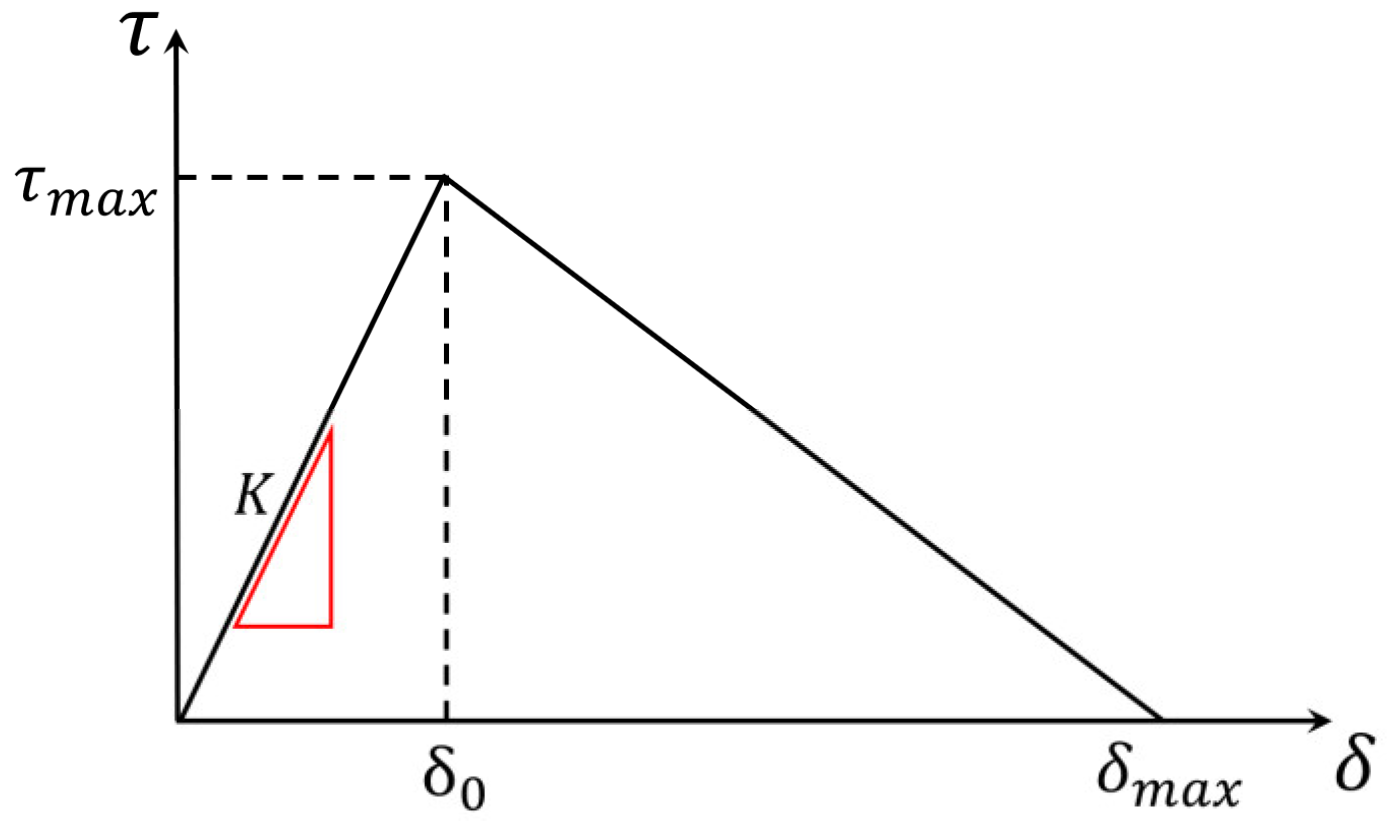

2.1. Cohesive Zone Model

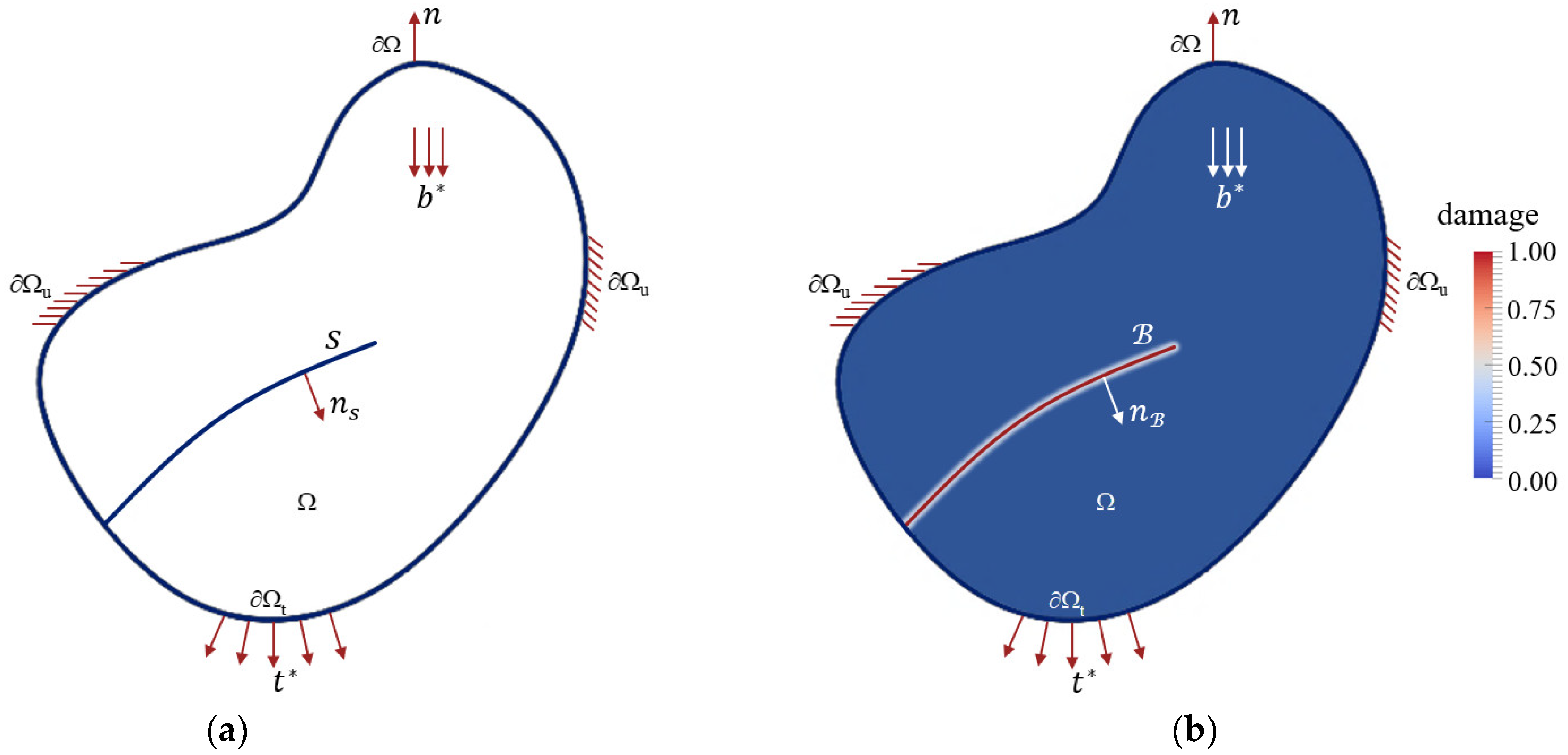

2.2. Unified Phase-Field Theory

2.2.1. Constitutive Relation and Damage Evolution Law

- (1)

- Constitutive relation

- (2)

- Damage evolution law

2.2.2. Phase-Field Regularized Cohesive Zone Model

2.2.3. Numerical Implementation

- (1)

- Governing equations

- (2)

- Finite element discretization

- (3)

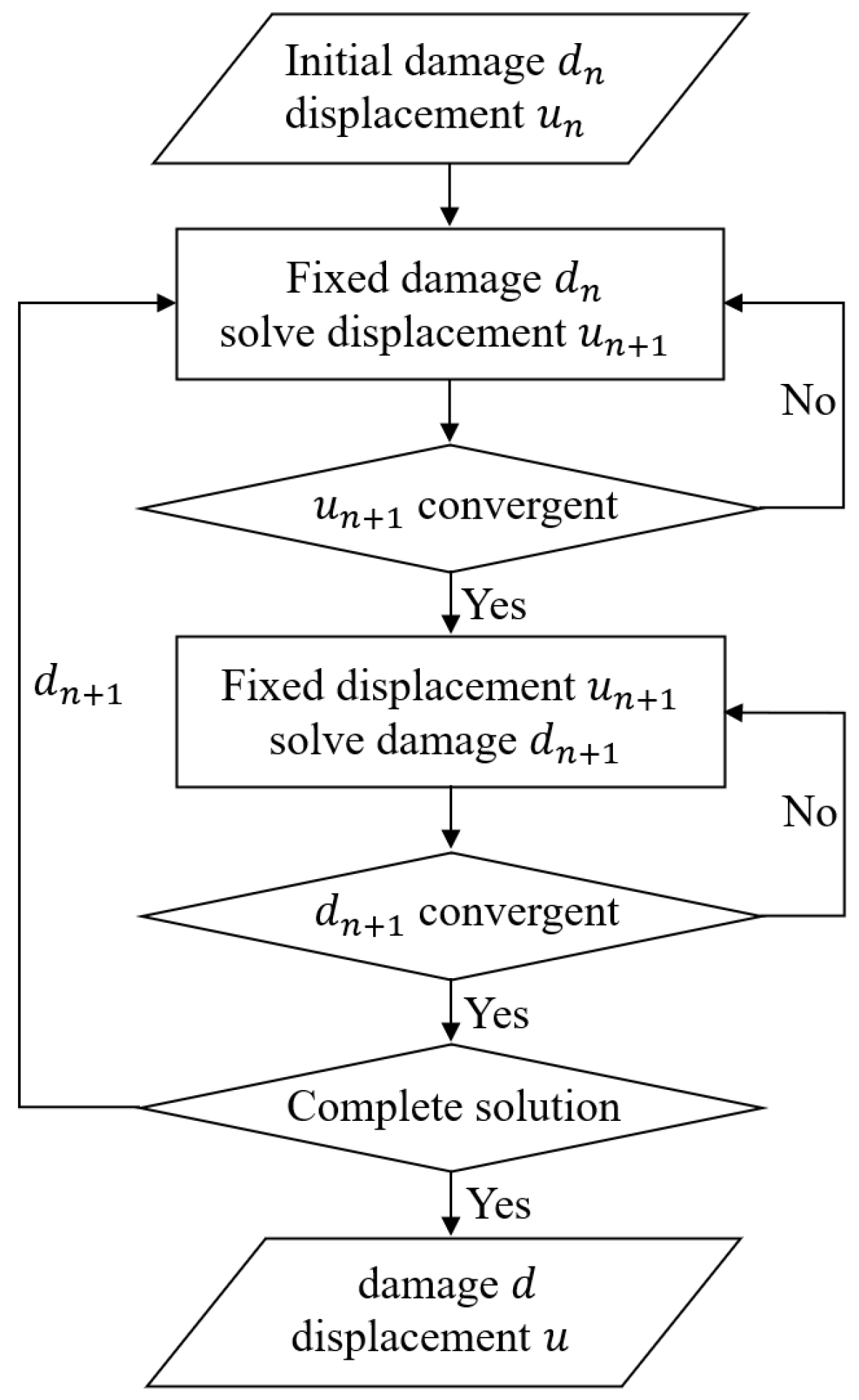

- Solving algorithm

3. Establishment and Verification of Numerical Calculation Model for Steel Fiber Pull-Out

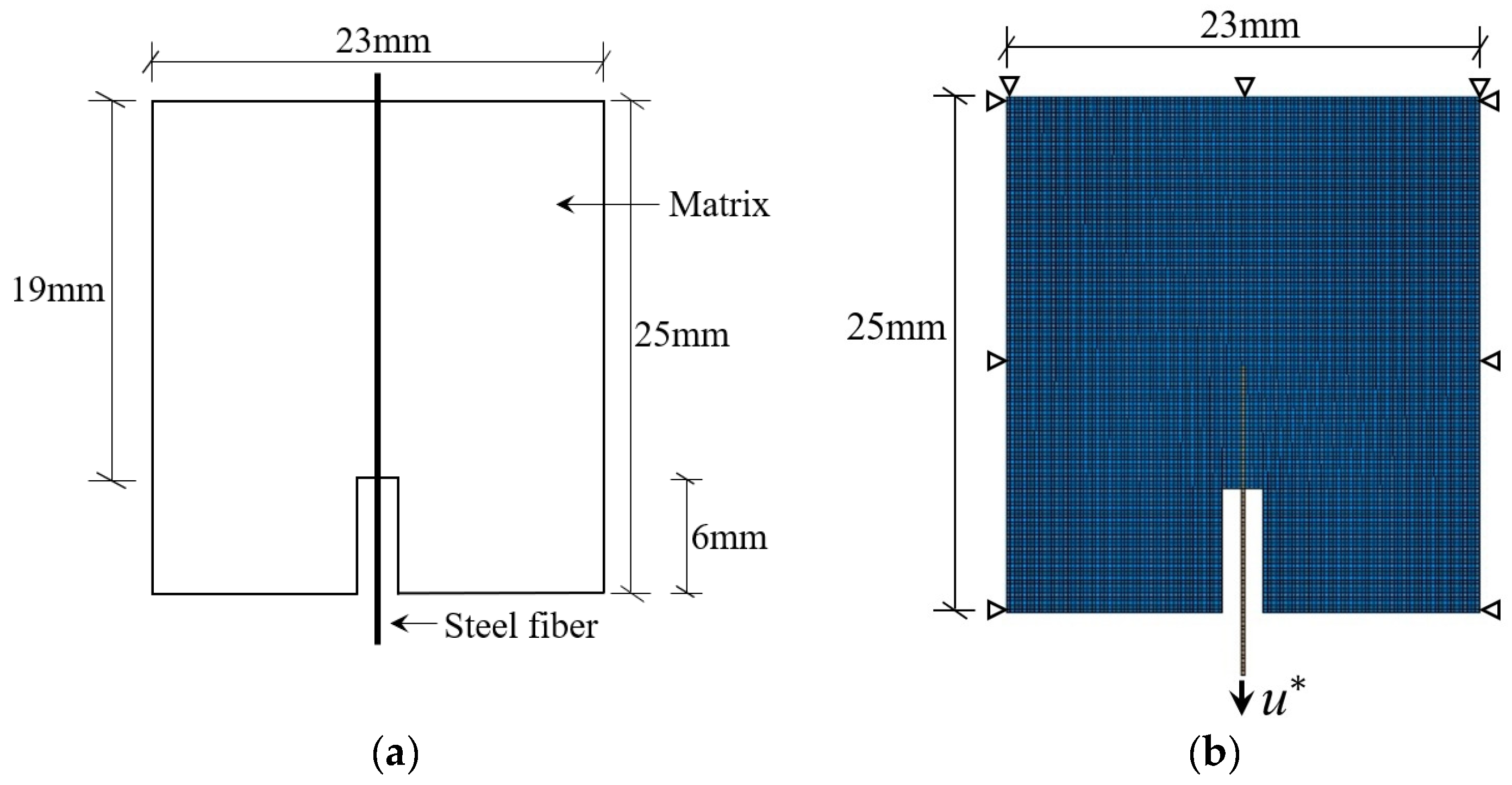

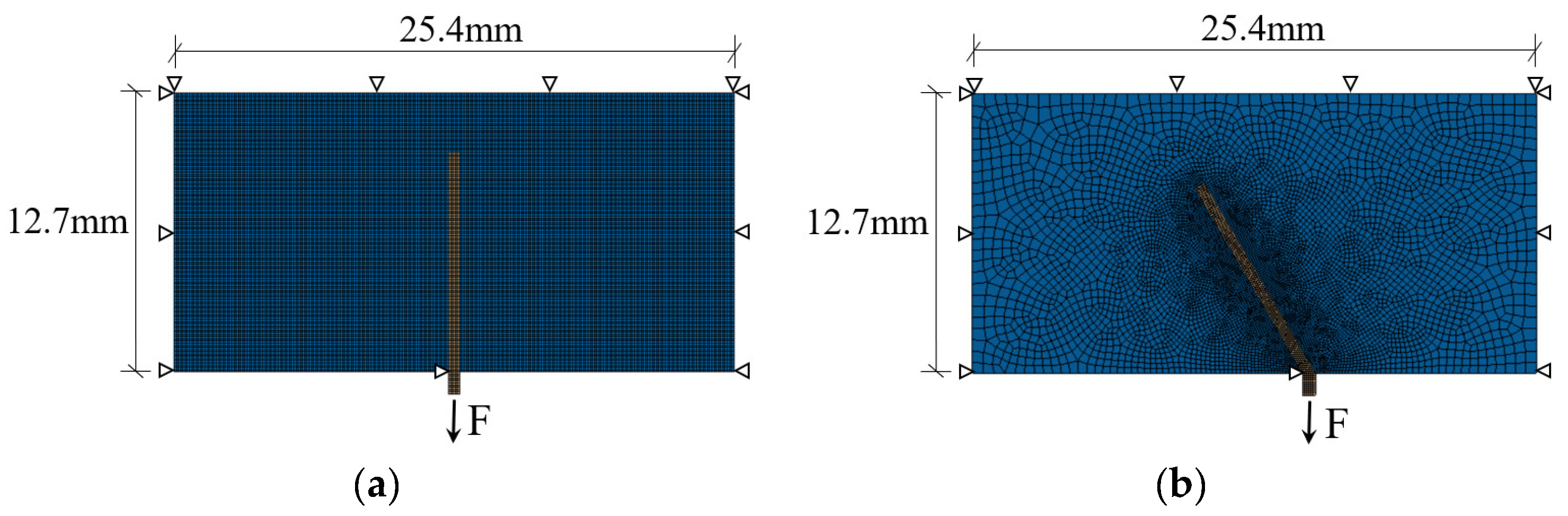

3.1. Model Building

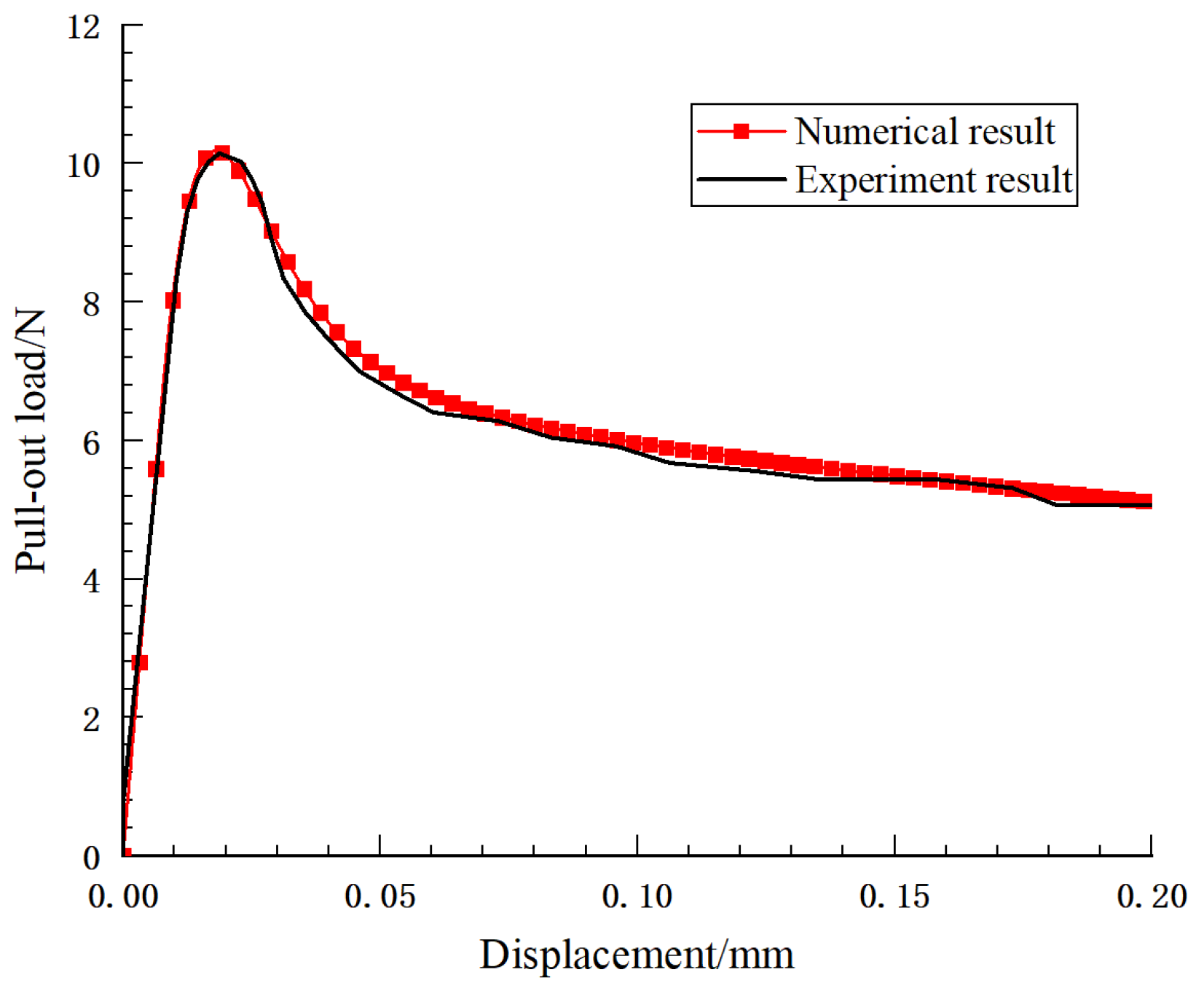

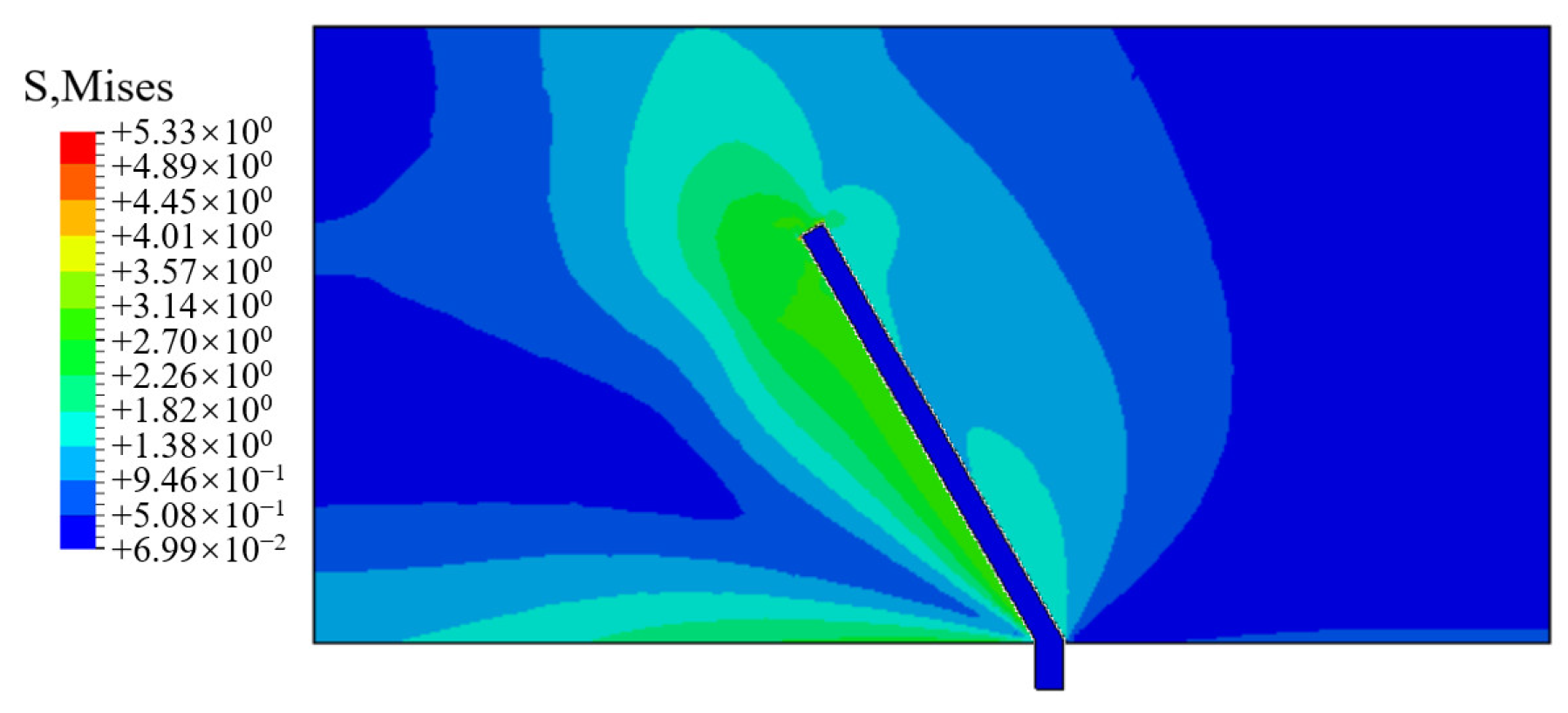

3.2. Model Validation and Analysis

4. Effects of Different Factors on the Mechanical Properties of Steel Fiber Pull-Out

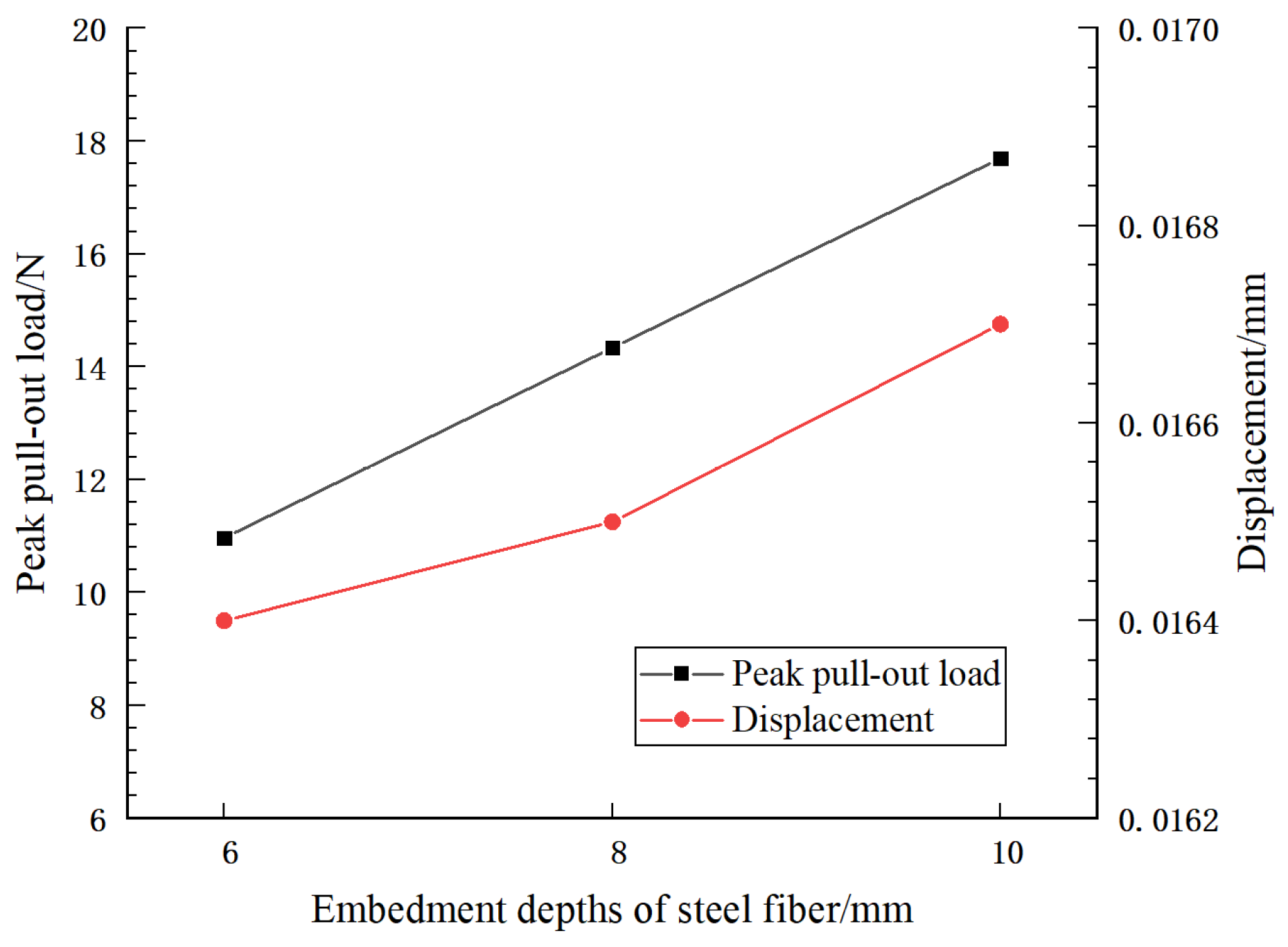

4.1. Effect of Steel Fiber Embedment Depth

4.2. Effect of Length–Diameter Ratio of Steel Fiber

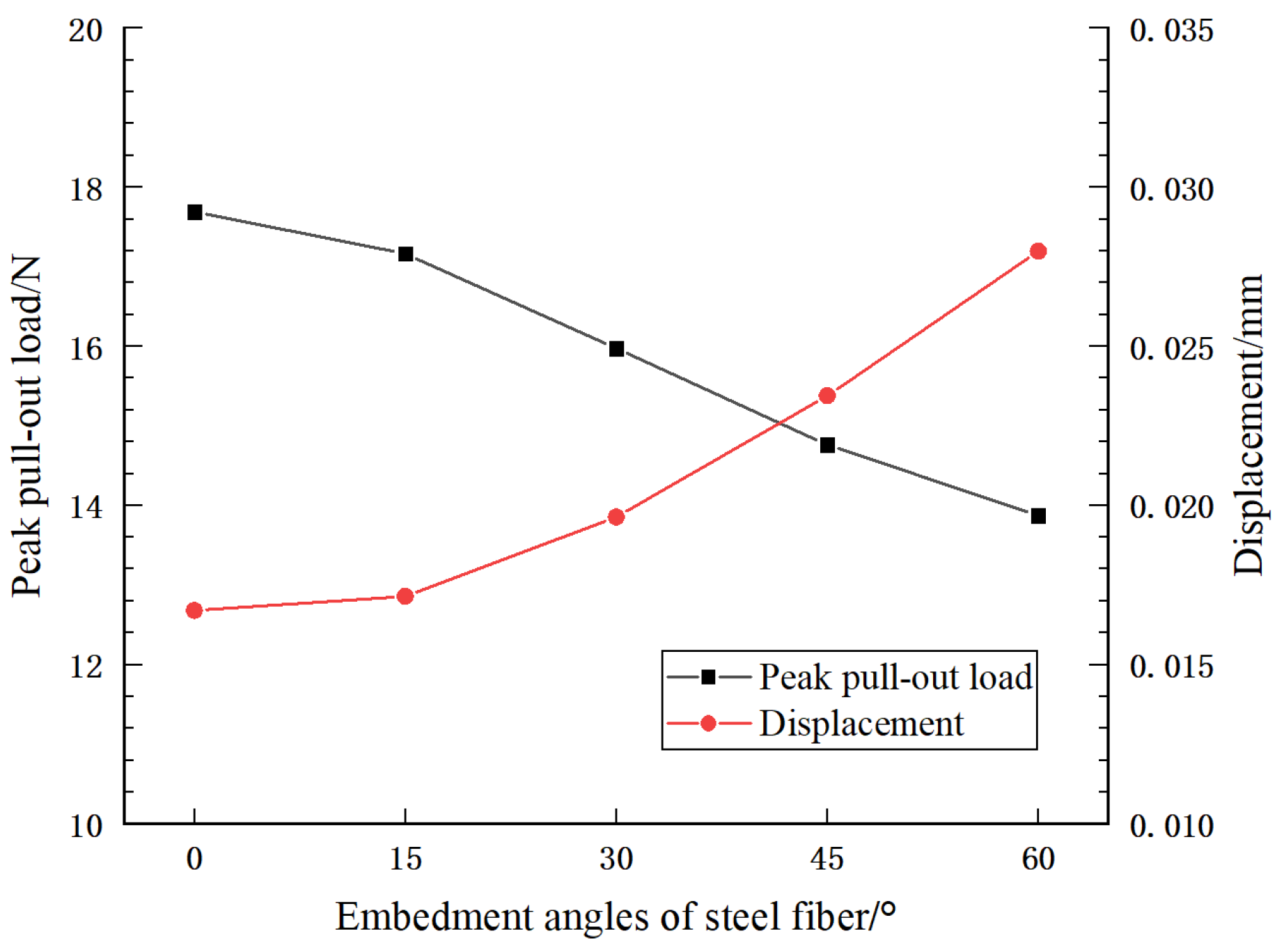

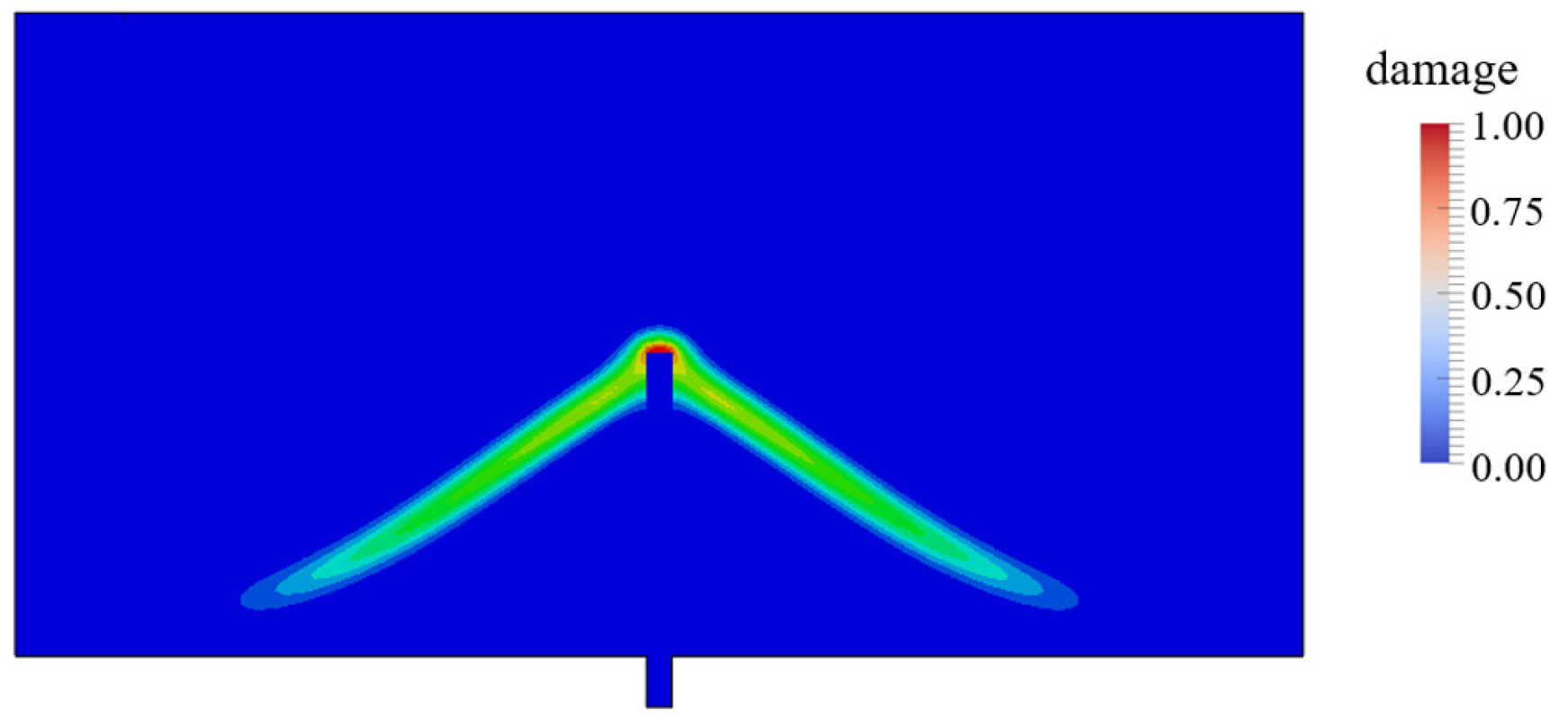

4.3. Effect of Steel Fiber Embedment Angle

4.4. Effect of Interface Properties

4.4.1. Failure of the Interface Layer between Steel Fiber and Concrete Matrix

- (1)

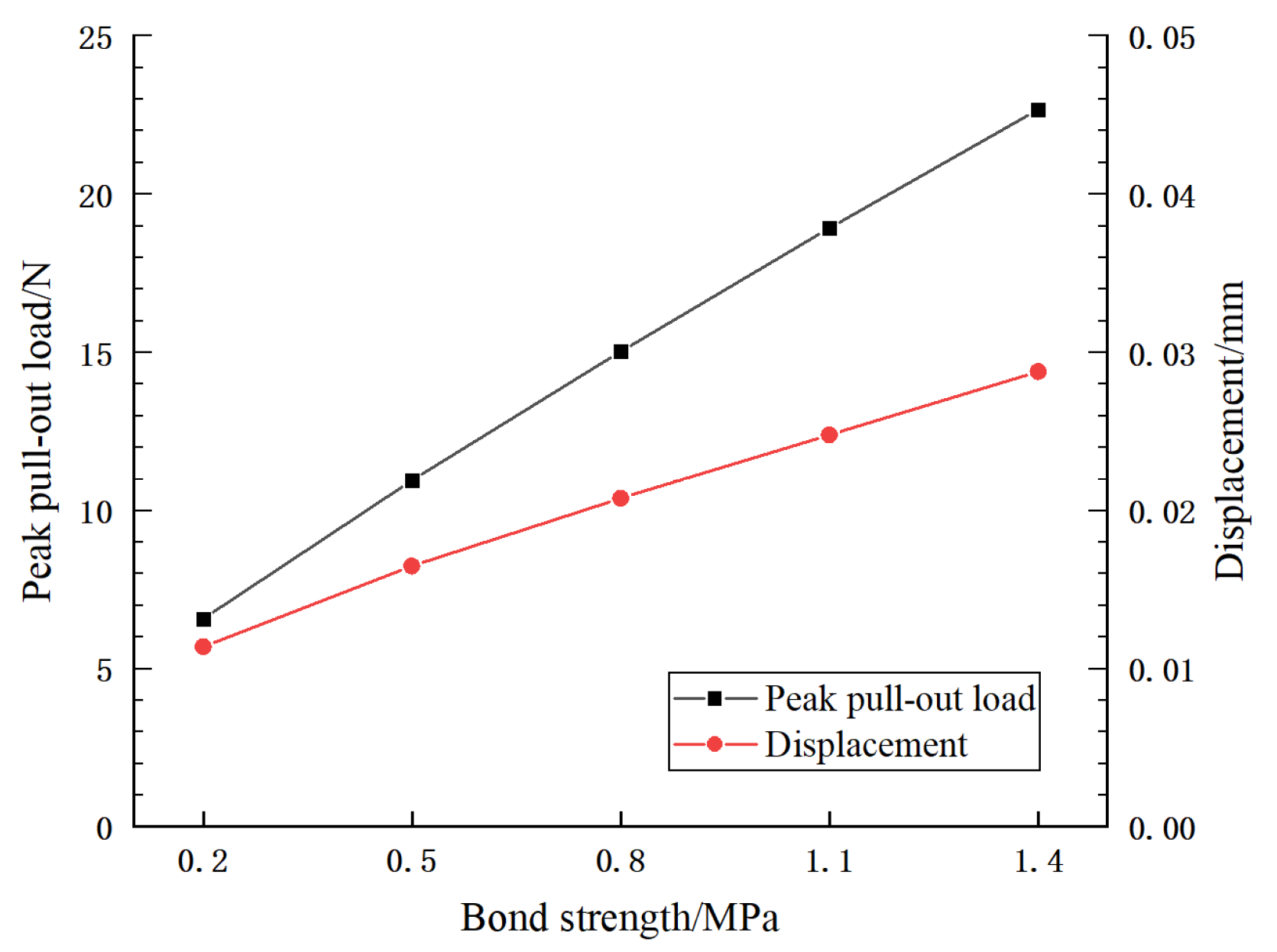

- Effect of bond strength

- (2)

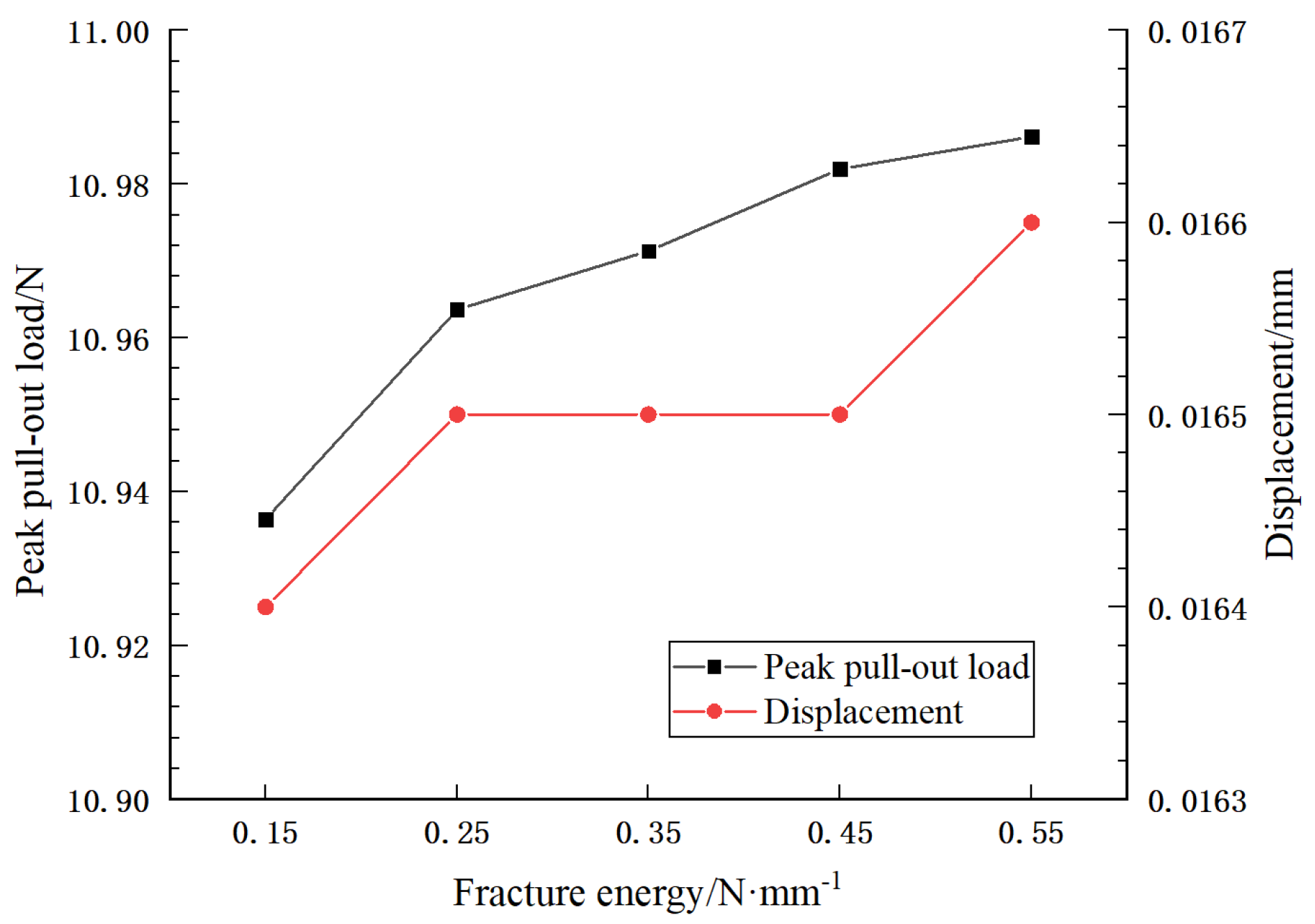

- Effect of fracture energy of the interface layer

4.4.2. Failure of the Concrete Matrix Itself

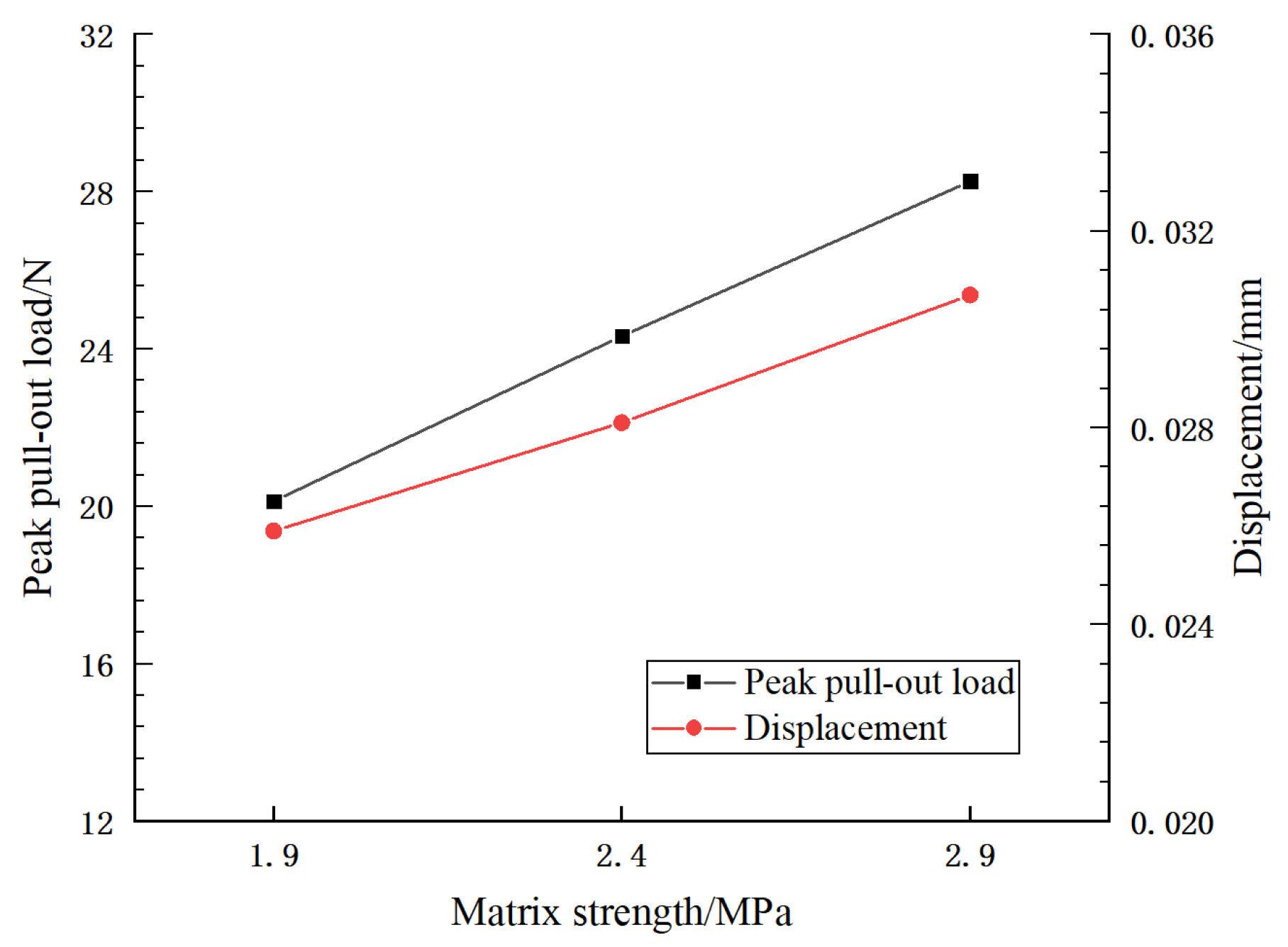

- (1)

- Effect of tensile strength

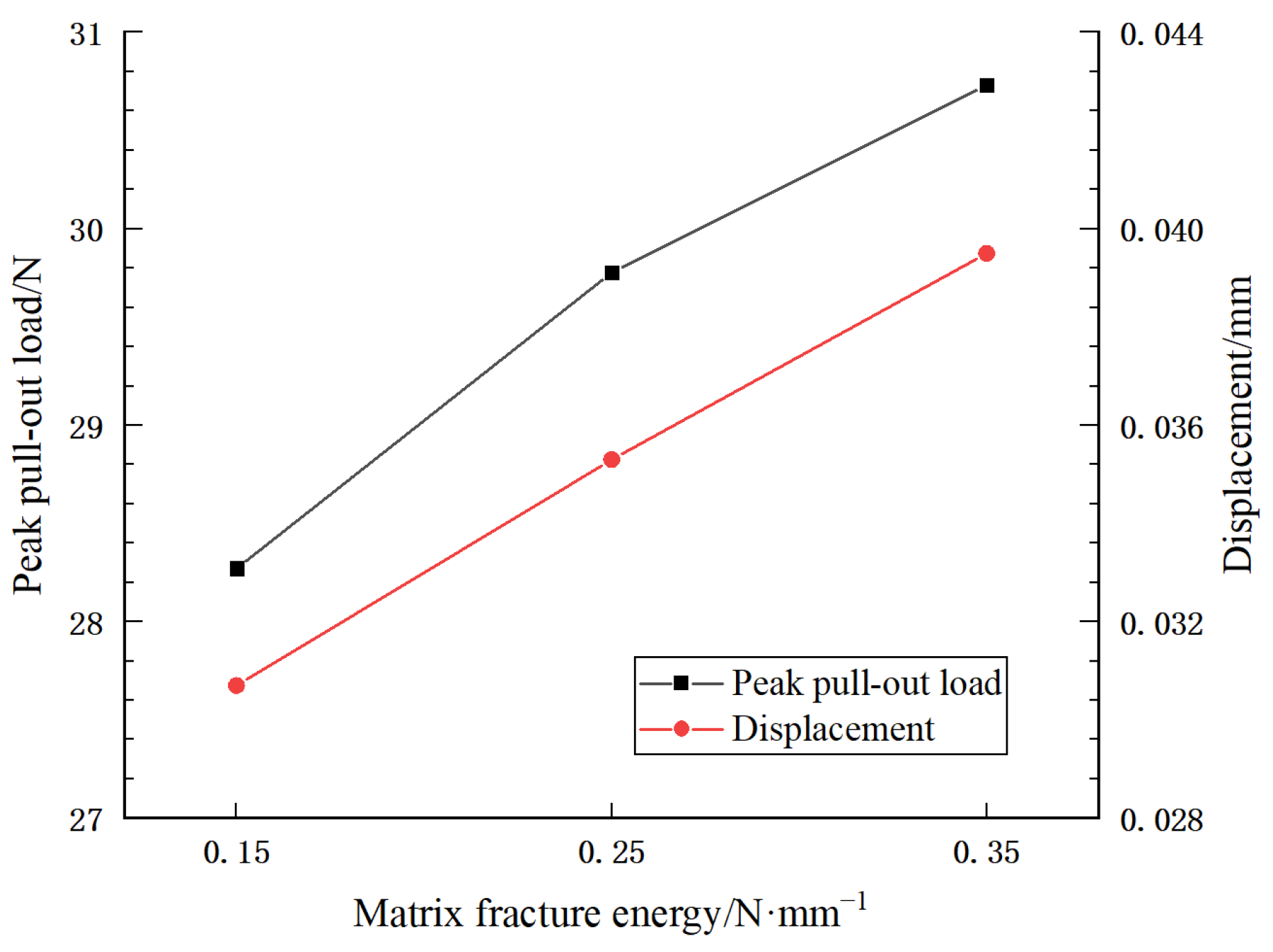

- (2)

- Effect of fracture energy of the concrete matrix

5. Conclusions

- (1)

- Based on the cohesive zone model and the unified phase-field theory, the pull-out load–displacement curve obtained by the simulation of the steel fiber pull-out test is in good agreement with the test results, which indicates that the finite element model of steel fiber pull-out established by the cohesive zone model and the phase-field regularized cohesive zone model has a certain accuracy and reliability. In addition, according to the results, the phase-field regularized cohesive zone model can represent the damage and failure evolution process of a concrete matrix intuitively and accurately.

- (2)

- By studying the influence of different factors on the pull-out mechanical properties of steel fiber, it is found that the pull-out load-bearing capacity of steel fiber when the embedment depth of steel fiber is 8mm and 10mm is increased by 30.7 and 61.37%, respectively, compared with that when the embedment depth is 6 mm. However, the pull-out load-bearing capacity of steel fiber is reduced with the increase in the length–diameter ratio and the embedment angle of the steel fiber. Therefore, these factors can be adjusted in actual projects to achieve the purpose of improving the mechanical properties of steel fiber reinforced concrete.

- (3)

- By studying the influence of interface properties on the pull-out mechanical properties of steel fiber, it is found that the bond strength of the interface layer and the strength of the concrete matrix have great influences on the pull-out mechanical properties of steel fiber. Among these influences, when the interface bond strength is 0.5~1.4 MPa, the pull-out load-bearing capacity of steel fiber is increased by 66.6~244.5% compared with 0.2 MPa; and when the matrix strength is 2.4 and 2.9 MPa, the pull-out load-bearing capacity of steel fiber is increased by 20.84 and 40.43%, respectively, compared with that when the matrix strength is 1.9 MPa. Therefore, the reinforcing effect of steel fiber on the concrete matrix can be improved by controlling the bond strength of the interface layer and the strength of the concrete matrix.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yao, J.; Zhou, Z.; Zhou, H. Steel Fiber Reinforced Concrete. In Highway Engineering Composite Material and Its Application; Springer: Singapore, 2019; pp. 51–80. ISBN 9789811360671. [Google Scholar]

- Gilbert, R.I.; Bernard, E.S. Post-cracking ductility of fibre reinforced concrete linings in combined bending and compression. Tunn. Undergr. Space Technol. 2018, 76, 1–9. [Google Scholar] [CrossRef]

- De Smedt, M.; Vrijdaghs, R.; Van Steen, C.; Verstrynge, E.; Vandewalle, L. Damage analysis in steel fibre reinforced concrete under monotonic and cyclic bending by means of acoustic emission monitoring. Cem. Concr. Compos. 2020, 114, 103765. [Google Scholar] [CrossRef]

- Abdulhameed, H.A.; Nassif, H.; Khayat, K.H. Use of Fiber-Reinforced Self-Consolidating Concrete to Enhance Serviceability Performance of Damaged Beams. Transp. Res. Rec. 2018, 2672, 45–55. [Google Scholar] [CrossRef]

- Vijayan, D.S.; Sivasuriyan, A.; Parthiban, D.; Jakimiuk, A.; Bayat, H.; Podlasek, A.; Vaverková, M.D.; Koda, E. A Comprehensive Analysis of the Use of SFRC in Structures and Its Current State of Development in the Construction Industry. Materials 2022, 15, 7012. [Google Scholar] [CrossRef]

- Naaman, A.E.; Najm, H. Bond-Slip Mechanisms of Steel Fibers in Concrete. Aci Mater. J. 1991, 88, 135–145. [Google Scholar]

- Tuyan, M.; Yazıcı, H. Pull-out behavior of single steel fiber from SIFCON matrix. Constr. Build. Mater. 2012, 35, 571–577. [Google Scholar] [CrossRef]

- Bhutta, A.; Farooq, M.; Zanotti, C.; Banthia, N. Pull-out behavior of different fibers in geopolymer mortars: Effects of alkaline solution concentration and curing. Mater. Struct. 2017, 50, 80. [Google Scholar] [CrossRef]

- Shannag, M.J.; Brincker, R.; Hansen, W. Pullout behavior of steel fibers from cement-based composites. Cem. Concr. Res. 1997, 27, 925–936. [Google Scholar] [CrossRef]

- Abu-Lebdeh Rate Effect on Pullout Behavior of Steel Fibers Embedded in Very-High Strength Concrete. Am. J. Eng. Appl. Sci. 2010, 3, 454–463. [CrossRef]

- Abu-Lebdeh, T.; Hamoush, S.; Heard, W.; Zornig, B. Effect of matrix strength on pullout behavior of steel fiber reinforced very-high strength concrete composites. Constr. Build. Mater. 2011, 25, 39–46. [Google Scholar] [CrossRef]

- Kim, J.-J.; Yoo, D.-Y. Effects of fiber shape and distance on the pullout behavior of steel fibers embedded in ultra-high-performance concrete. Cem. Concr. Compos. 2019, 103, 213–223. [Google Scholar] [CrossRef]

- Ye, D.J.; Yang, Z.J.; Liu, G.H.; Yao, Y. Analytical Solution and Experimental Verification of Pullout Force of Twisted Steel Fibers in Ultra–high Performance Concrete. J. Zhejiang Univ. (Eng. Sci.) 2018, 52, 1911–1918. (In Chinese) [Google Scholar]

- Lee, Y.; Kang, S.-T.; Kim, J.-K. Pullout behavior of inclined steel fiber in an ultra-high strength cementitious matrix. Constr. Build. Mater. 2010, 24, 2030–2041. [Google Scholar] [CrossRef]

- Wang, X.W.; Guo, R.; Tian, W.; Zhao, X. Experimental Investigation of the Bonding and Slipping Performance of the Deformed Steel-fiber. J. Hebei Univ. Technol. 2007, 36, 110–114. (In Chinese) [Google Scholar]

- Tian, W.L.; Wang, X.W.; Li, Z.X. Research on the Experiment of the Bonding Strength between Deformed Steel Fiber and Concrete. J. Build. Mater. 2007, 10, 337–341. (In Chinese) [Google Scholar]

- Shao, W.; Sun, Q.; Xu, X.; Yue, W.; Shi, D. Durability life prediction and horizontal bearing characteristics of CFRP composite piles in marine environments. Constr. Build. Mater. 2023, 367, 130116. [Google Scholar] [CrossRef]

- Wang, H.; Li, L.; Li, J.; Sun, D. Drained expansion responses of a cylindrical cavity under biaxial in situ stresses: Numerical investigation with implementation of anisotropic S-CLAY1 model. Can. Geotech. J. 2023, 60, 198–212. [Google Scholar] [CrossRef]

- Long, X. Numerical Simulation of the Fiber Pulled Out from Steel-fiber Concrete. Master's Thesis, Northeastern University, Shenyang, China, 2014. (In Chinese). [Google Scholar]

- Hsueh, C.-H. Interfacial Debonding and Fiber Pull-out Stresses of Fiber-reinforced Composites. Mater. Sci. Eng. A 1990, 123, 1–11. [Google Scholar] [CrossRef]

- Kim, J.; Baillie, C.; Mai, Y. Interfacial debonding and fibre pull-out stresses. J. Mater. Sci. 1992, 27, 3143–3154. [Google Scholar] [CrossRef]

- Huang, J.; Jiang, H.D.; Mei, M.R. Analysis of Fiber Debonding and Pull-out with Interfacial Layer. J. Yangtze River Sci. Res. Inst. 2006, 23, 61–64. (In Chinese) [Google Scholar]

- Liu, F. Study of Numerical Simulation for Steel Fiber Reinforced Concrete on Meso-Level. Master's Thesis, South China University of Technology, Guangzhou, China, 2014. (In Chinese). [Google Scholar]

- Zong, Y.W. Analysis of Interfacial Bonding Properties of Cement-based Materials with Steel Fibers Based on Cohesive Zone Model. Master's Thesis, Chongqing University, Chongqing, China, 2017. (In Chinese). [Google Scholar]

- Yang, C.C. Numerical Simulation of the Influence of Basalt Fiber on the Performance of Asphalt Mixture. Master's Thesis, Changsha University of Science & Technology, Changsha, China, 2020. (In Chinese). [Google Scholar]

- Wu, J.-Y. A geometrically regularized gradient-damage model with energetic equivalence. Comput. Methods Appl. Mech. Eng. 2018, 328, 612–637. [Google Scholar] [CrossRef]

- Zhuang, L.J. Application Study of Unified Phase Field Theory for Modeling Localized Failure in Concrete. Master's Thesis, South China University of Technology, Guangzhou, China, 2019. (In Chinese). [Google Scholar]

- Wu, J.-Y.; Qiu, J.-F.; Nguyen, V.P.; Mandal, T.K.; Zhuang, L.-J. Computational modeling of localized failure in solids: XFEM vs PF-CZM. Comput. Methods Appl. Mech. Eng. 2019, 345, 618–643. [Google Scholar] [CrossRef]

- Yang, Z.-J.; Li, B.-B.; Wu, J.-Y. X-ray computed tomography images based phase-field modeling of mesoscopic failure in concrete. Eng. Fract. Mech. 2019, 208, 151–170. [Google Scholar] [CrossRef]

- Wu, J.-Y. A unified phase-field theory for the mechanics of damage and quasi-brittle failure. J. Mech. Phys. Solids 2017, 103, 72–99. [Google Scholar] [CrossRef]

- Lu, Z.X. A Simple Review for Cohesive Zone Models of Composite Interface and Their Applications. Chin. J. Solid Mech. 2015, 36 (Suppl. S1), 85–94. (In Chinese) [Google Scholar]

- Wu, J.-Y.; Nguyen, V.P. A length scale insensitive phase-field damage model for brittle fracture. J. Mech. Phys. Solids 2018, 119, 20–42. [Google Scholar] [CrossRef]

- Wu, J.-Y.; Huang, Y. Comprehensive implementations of phase-field damage models in Abaqus. Theor. Appl. Fract. Mech. 2020, 106, 102440. [Google Scholar] [CrossRef]

- Bourdin, B.; Francfort, G.A.; Marigo, J.-J. Numerical experiments in revisited brittle fracture. J. Mech. Phys. Solids 2000, 48, 797–826. [Google Scholar] [CrossRef]

- Bourdin, B.; Francfort, G.A.; Marigo, J.J. The Variational Approach to Fracture; Springer Science & Business Media: Cham, Switzerland, 2008. [Google Scholar]

- Zhang, H.; Huang, Y.J.; Yang, Z.J.; Xu, S.L.; Chen, X.W. A discrete-continuum coupled finite element modelling approach for fibre reinforced concrete. Cem. Concr. Res. 2018, 106, 130–143. [Google Scholar] [CrossRef]

| Material | Elastic Modulus E (GPa) | Poisson’s Ratio v | Tensile Strength ft (MPa) | Fracture Energy Gc (N/mm) |

|---|---|---|---|---|

| Concrete matrix | 25 | 0.173 | 2.9 | 0.15 |

| Steel fiber | 200 | 0.3 | — | — |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, G.; Wang, H. Numerical Simulation of Steel Fiber Pull-Out Process Based on Cohesive Zone Model and Unified Phase-Field Theory. Sustainability 2023, 15, 4015. https://doi.org/10.3390/su15054015

Wu G, Wang H. Numerical Simulation of Steel Fiber Pull-Out Process Based on Cohesive Zone Model and Unified Phase-Field Theory. Sustainability. 2023; 15(5):4015. https://doi.org/10.3390/su15054015

Chicago/Turabian StyleWu, Guozheng, and Huiming Wang. 2023. "Numerical Simulation of Steel Fiber Pull-Out Process Based on Cohesive Zone Model and Unified Phase-Field Theory" Sustainability 15, no. 5: 4015. https://doi.org/10.3390/su15054015

APA StyleWu, G., & Wang, H. (2023). Numerical Simulation of Steel Fiber Pull-Out Process Based on Cohesive Zone Model and Unified Phase-Field Theory. Sustainability, 15(5), 4015. https://doi.org/10.3390/su15054015