1. The Significance of Professional Construction Reform

Driven by artificial intelligence, big data, and industrial Internet technologies, the steel industry is developing rapidly toward being green and intelligent. It is now in the critical period of institutional transformation and upgrading, which generates the urgent need of high-end intelligent manufacturing technology research and development practitioners who can adapt to the demand. The automation and intelligence of iron and steel metallurgical equipment carry a big weight in national intelligent manufacturing, and talents provide an important support for development. It is urgent to cultivate talent teams that can adapt to the intelligent upgrading of the iron and steel industry.

The Ministry of Education has established an intelligent manufacturing engineering major to meet the development needs of various industries. As a new engineering major, the intelligent manufacturing engineering major focuses on many approaches, such as inheritance and innovation, intersection and integration, coordination and sharing, etc., to cultivate diversified and innovative outstanding engineering talents in the future [

1]. New engineering talents are required not only to have solid basic knowledges of natural and engineering science, but also to receive engineering practice training and have the ability to analyze and solve complex engineering problems [

2]. Renewing the concept of talent training, restructuring the training objectives and knowledge structure, and changing the training methods are the essential connotation of the new engineering talent training model [

3].

A local university with characteristics of the steel industry has applied for the approval of the intelligent manufacturing engineering specialty for industry needs. As a university with industry characteristics, in the development of the establishment of the intelligent manufacturing engineering major, there are some problems, such as difficulty in implementing concepts, weakness of the school foundation, and high homogeneity in development. It has become a major obstacle to the development of local universities with the industry background.

Under this background, this paper presents the construction of the talent training mode of the new intelligent manufacturing engineering major taking Wuhan University of Science and Technology as an example. The construction of a new professional talent training method for the intelligent manufacturing engineering major is discussed. The goal of talent training is to cultivate high-quality engineering and technical personnel who can adapt to the green and intelligent development needs of steel and other industries. Ulteriorly, through training, they can be full of innovative spirit and practical ability, and can engage in system design and manufacturing, engineering development, scientific research, and production management in the field of intelligent manufacturing engineering. The research of this paper could provide references for the construction of the intelligent manufacturing engineering major in local universities with other industry backgrounds.

The steel industry is a process-oriented industry with large volumes and a high degree of automation. In recent years, the supply-side structural reform has been gradually deepening. The steel industry, especially, is in a critical period of structural transformation and upgrading. On the other hand, modern information technology is making rapid progress, such as industrial Internet, big data, artificial intelligence, and cloud computing, etc., which has a significant and profound impact on the development of the steel industry.

Moreover, the steel industry is practicing and presenting green development, promoting the green development of the steel ecosystem with technological revolutions, and realizing high-quality development constrained by green obligations. Through introductions of new energy-saving and environmental-friendly technologies, new processes, and new equipment, the steel industry gradually builds a garden-like factory.

It requires a higher quality of employees to substantially improve the intelligent and green levels of the steel industry. The current talent team structure has made it difficult to meet the needs of the transformation and upgrading of the steel industry. The high-end technology research and development talents who can adapt to the green and intelligent development needs of steel and other industries are lacking, which makes it difficult to meet the demand. Meanwhile, the talent training system of the steel industry in China lags behind the global frontier. It does not meet the demands for intelligent manufacturing talents in the transformation and upgrading of the steel industry with the current professional structure, talent training program, practice system, and teaching resources, all of which do not match.

Some serious problems of disconnects between the talent supply and the strong industry demand are gradually unfolding. These problems have greatly affected the pace of transformation and upgrading of the steel industry. It is necessary to explore the reform of the training mode of talents in intelligent manufacturing engineering, to meet the requirements of intelligent and green developments. The basic theories and expertise are cultivated in the intelligent manufacturing engineering major, which are oriented to the requirements of intelligent and green development of the steel industry. High-quality engineering and technical talents are engaged in engineering-related fields, such as design and manufacturing, engineering development, scientific research, and production management, etc.

2. Problems in Professional Development

The steel industry is undergoing transformation and upgrading presently. Its production mode is evolving towards a fully Internet-based collaborative intelligent manufacturing system, accelerating cross-border integration, and building a novel industrial ecology. There is an urgent need to construct a multi-level intelligent manufacturing talent team. As a university with advantages and characteristics in the steel industry, Wuhan University of Science and Technology should orient to the major strategic needs of the country, promote the reform of discipline structures and organizational models, provide intelligent manufacturing and innovative talents for the development of the steel industry, and focus on solving the following problems.

2.1. Mismatch between the Current Discipline Structures and the Demands of Intelligent Manufacturing Talents in the Transformation and Upgrading of the Steel Industry

With the continuous advancement of China’s national strategies, such as “Made in China 2025”, “Internet +”, and “The Belt and Road Initiative”, etc., vigorous promotion of intelligent manufacturing is required in the process of industrial transformation and upgrading in the steel industry. It needs to be constructed with the digital, intelligent, smart steel industry in mind, and must apply digital and intelligent systems. An integrated platform for design, manufacturing, and service are built. The design visualization, manufacturing digitalization, and remote service are promoted.

Whether it is the reshaping of the connotation of traditional engineering majors, or the establishment and development of emerging engineering majors, its service orientations are always the regional industrial layout and structural optimization [

4]. In the focus of innovation and development of the intelligent manufacturing equipment, it is required to promote the integrated innovation of intelligent manufacturing of complete sets of equipment, such as intelligent steel making, intelligent continuous casting, and intelligent rolling. It has become an important task and mission of engineering colleges and universities to cultivate engineering and technological talents in the field of intelligent manufacturing [

5]. The traditional discipline structures cannot meet the novel demands for intelligent manufacturing talents in the transformation and upgrading of the steel industry. Based on industry characteristics and regional economic development, majors in the field of intelligent manufacturing, which is integrated with multiple disciplines such as machinery, information, computer, automation, etc., are actively laid out, set up, and constructed.

2.2. Incompatibility between the Current Talent Training Mode and the Requirements of Intelligent Manufacturing Talents in the Steel Industry

Modern science and technology have been developing rapidly. Facing such fierce international competition, characterized by innovation and technological upgrading, it is very important to enhance the independent innovation ability of scientific and technological talents [

6]. In the process of building an innovative country, talents with independent innovation capabilities play a pivotal role [

7]. Contemporary college students are the backbone of national construction and development, and the cultivation of their independent innovation ability should be an important task of quality education in colleges and universities [

8].

Among the key common technological innovation directions of intelligent manufacturing, there needs to be a breakthrough in new sensor technology, modular/embedded control system design technology, advanced control and optimization technology of steel production, collaborative technology of steel production systems, fault diagnosis and health maintenance technology, special processing technology and precision manufacturing technology, steel surface defect recognition technology, steel production line modeling and simulation technology, steel industry Internet, steel production process artificial intelligence, and other key common technologies for cultivating multidisciplinary cross-compound engineering and scientific talents.

The current talent training mode is based on a specific discipline talent training method, using a traditional curriculum teaching system, a single subject faculty. What is more, the innovation and entrepreneurship education have not been well integrated into the training process, and the industry–university–research platform is not yet sound. It cannot adapt to the new requirements for the cultivation of intelligent manufacturing talents in the steel industry. Although the outstanding engineer education and training program has achieved remarkable results in university–enterprise cooperative education and engineering teacher team construction, it still needs to be based on serving the transformation and upgrading of the steel industry, and further promote the innovation of the multidisciplinary cross-integrated intelligent manufacturing talent training mode.

2.3. Incongruity between the Current Practice System and Teaching Resources and the Requirements of Intelligent Manufacturing Talents in the Steel Industry

The steel industry is an important basic and pillar industry of the national economy. It is important to accelerate the development of intelligent manufacturing, for promoting the supply-side structural reform of the steel industry, creating new competitive advantages in the manufacturing industry, and realizing a strong manufacturing country. It is necessary to grasp the macro policy orientation, give full play to the advantages of collaborative innovation, and take the road of international competition.

Under the new background, the development of steel enterprises has a series of novel characteristics: focus on planning, rational use of resources, focus on green, environmental protection, and energy saving [

9]. The current cooperative education for talent training is a passive collaborative system based on the teaching segments. It is not enough with the integration and sharing of internal resources, and the participation depth of external resources is also lacking. It cannot meet the new requirements of collaborative education for intelligent manufacturing talents in the steel industry. It must be connected with the transformation and upgrading of the steel industry and expanded across institutions of departmental and interdisciplinary professional cooperative education. Further, political–academic, industry–university, science–education, and international collaboration are promoted. The innovative talents are cultivated for intelligent manufacturing.

3. Exploration of New Model of Talent Cultivation

In view of the problems presented in the above situation, the current talent cultivation model makes it difficult to match the intelligent and green development of the steel industry, which puts forward new requirements for the talent cultivation model. Therefore, this paper focuses on exploring the talent cultivation model of intelligent manufacturing engineering that meets the requirements of intelligent and green development. Specifically, the research is carried out from the existing professional structure, talent training program, practice system, and teaching resources. The key is to implement the intelligent and green concept, knowledge, and ability training in the whole process of talent cultivation.

Talent cultivation is closely related to the situation and planning of social and economic development. Therefore, the research method design of this paper aims at the government’s innovation-driven development strategy and tries to grasp the opportunity of the current new round of industrial transformation. The design of the new cultivation model is positioned in the green and intelligent transformation and upgrading of the steel industry and the rapid development of the regional economy, which requires the training of high-quality talents in intelligent manufacturing engineering. In the design of research methods, we pay special attention to fully absorbing advanced concepts such as green manufacturing, intelligent manufacturing, digital twin, smart factory, and the achievement-oriented education concept in the main training link.

In the application practice of the new model, a multidisciplinary cross-integration professional training program is constructed, oriented towards the cultivation of the innovative ability of the intelligent manufacturing engineering major in the steel industry. Furthermore, the curriculum system, teaching content, and teaching methods are reformed based on the concept of the new model. In terms of teaching system, a modular design is carried out with the concept of green and intelligent manufacturing. A number of stereoscopic teaching resources have been constructed. These resources reflect the needs of the transformation and upgrading of the steel industry and integrate the concept of green intelligence and information digital technology to support the cultivation of innovative ability of intelligent manufacturing engineering for the steel industry.

Presently, it is necessary to strengthen the cooperation and mutual support among multiple subjects to improve the teaching effect [

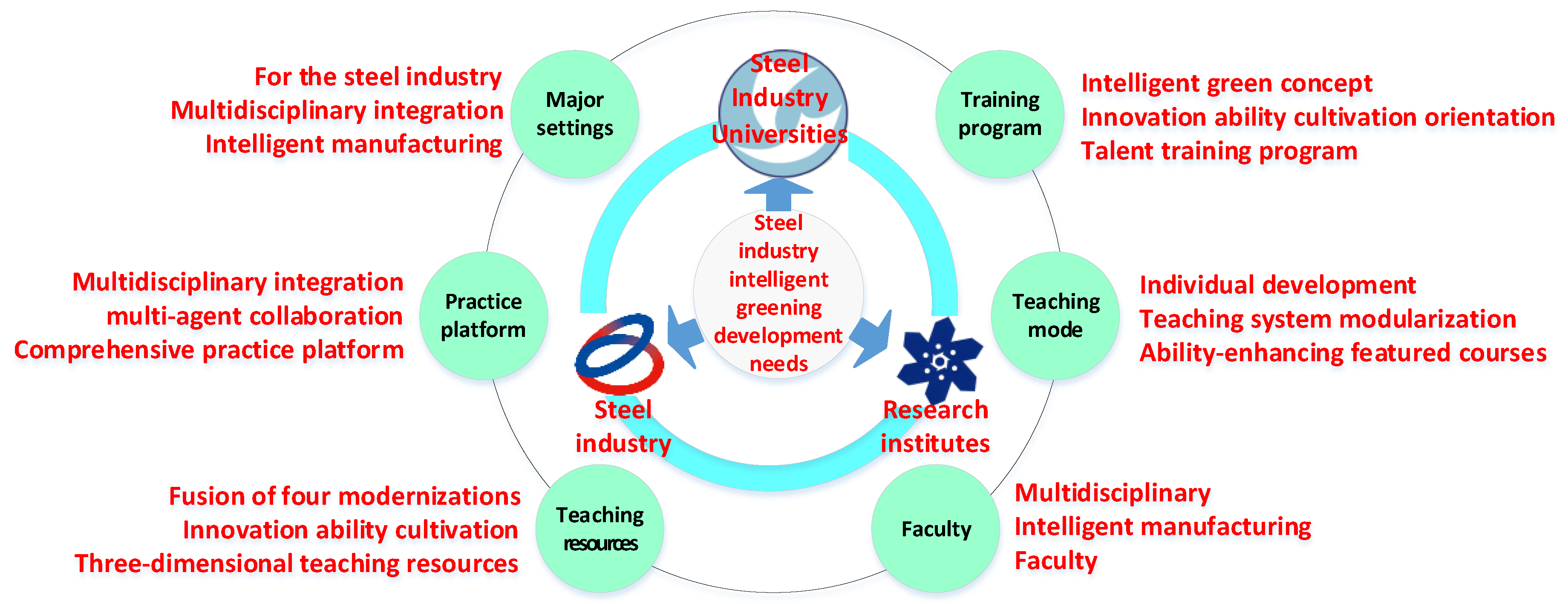

10]. A mechanism for cultivating innovative ability of students in intelligent manufacturing engineering is researched and built, in which universities, scientific research institutes, and steel enterprises cooperate with each other, as shown in

Figure 1.

In terms of practice platform construction, a project-driven independent practice teaching system and a comprehensive practice platform is built through the multi-subject collaboration of universities, research institutes, and industry companies. Combined with the transformation and upgrading needs of the steel industry, the mode of student training is promoted from classroom teaching to multi-subject collaborative training in universities, scientific research institutes, and enterprises. The all-round in-depth collaboration is carried out with training program design, teaching model innovation, practice platform construction, and teacher team guarantee.

The mechanism can strengthen the internal coupling between the scientific and technological circles and the education circles. The continuous knowledge spillover benefits and energy conversion between the industry and education circles can be utilized to improve teaching. Further, the problem of the relationship between teachers and students still being dominated by teachers can be improved to a great extent through building the learning community between teachers and students based on the close cooperation and mutual support among multiple subjects.

3.1. Reform of the Teaching Concept in the Green and Intelligent Three-Dimensional Intelligent Manufacturing Engineering

Considering the transformation and development needs of the steel industry, a knowledge system for discipline innovation training in intelligent manufacturing engineering is constructed from three dimensions: the concept and awareness of green and intelligent metallurgical production, knowledge of intelligent manufacturing engineering, and innovation ability training, as shown in

Figure 2.

In

Figure 2, the

x-axis represents literacy, philosophy, and awareness. The awareness of environmental protection, safety, service, and responsibility are cultivated, as well as the concept of intelligence and optimization, professional ethics, humanistic quality, and professionalism. It drives the establishment of a mapping with innovation awareness and capabilities.

Engineering talents must have a comprehensive and broad knowledge horizon in order to seek refinement. The y-axis represents the major knowledge dimension of intelligent manufacturing engineering. The interdisciplinary integration is emphasized. The knowledge system of intelligent manufacturing engineering is comprehensively sorted out. A large-scale engineering concept is established with organically integrating mechanics, electronics, measurement, control, and other disciplines.

The z-axis represents the ability to innovate and comprehensively apply in the field of intelligent manufacturing engineering. It covers independent learning and lifelong learning, the spirit of exploration and craftsmanship, international vision and team assistance, and active practice in pursuit of innovation. A system view is established, and fragmentation of knowledge is avoided.

3.2. Reform of the Talent Training Curriculum System Based on the Green and Intelligent Teaching Concept

Facing the needs of the core competitiveness of intelligent manufacturing engineering talents in the transformation and upgrading of the steel industry, focusing on the three dimensions of literacy, knowledge, and ability shown in

Figure 2, based on the general intelligent manufacturing engineering training program, the talent training objective is upgraded, and the concept of green and intelligent development is absorbed. The deep integration of knowledge and technology with the literacy–knowledge–ability requirements of the intelligent manufacturing engineering is promoted, in which the knowledge includes the metallurgical scientific content, metallurgical process mechanism, metallurgical process equipment technology, and steel industry culture. The talent training programs and systems of multidisciplinary and interdisciplinary integration in intelligent manufacturing engineering are formulated for the adaption to the transformation and upgrading of the steel industry, highlighting the green and intelligent teaching concept, and cultivating innovation ability as the orientation, as shown in

Figure 3.

The training program reform focuses on the following three aspects:

(1) Enhance frontier cognition and overall thinking

Frontier technology courses are added to theoretical courses, including 3D printing technology and application, advanced manufacturing technology, and artificial intelligence and its application. The production sites of many steel industry enterprises and intelligent manufacturing enterprises have been used for the internship practice, including Wuhan Iron and Steel Corporation, Wuhan Marine Machinery Plant, National Innovation Institute of Digital Design and Manufacturing, etc. In addition to extracurricular tutoring, industry experts are invited to give lectures on the frontiers of intelligent manufacturing disciplines, which are included in extracurricular credits. It is comprehensively cultivated for the forward-looking conception of the development of intelligent manufacturing engineering technology and for insight into the transformation of the steel industry.

(2) Broaden and optimize the knowledge structure

In accordance with the ideas of green and intelligent manufacturing, aiming at the design, manufacture, management, and other industrial needs of advanced steel production process equipment, the course system and teaching content are reconstructed. It not only corresponds to the goal of talent training, but also meets the needs of new technology development. The course categories are reclassified. The course study process relationships are optimally designed. The course modules are refactored. The specific ideas include the following: Based on the three-dimensional design of literacy–knowledge–ability, the courses are divided into cognitive, comprehension, application, and innovation course modules. The obsolete courses are deleted. The new courses are added. The course structures are optimized. The new technologies are used to upgrade and transform traditional classic course contents. More interdisciplinary compulsory courses and elective courses are added.

With optimizing the curriculum system of intelligent manufacturing engineering, the traditional course teaching contents are updated, transformed, and upgraded. The emerging technologies are increased in the field of intelligent manufacturing engineering. The cross-disciplinarity is highlighted. The three-dimensional teaching resources are constructed, in which many core courses have built online MOOCs based on the national online course platform.

(3) Improve practical application and innovation capability

Focusing on the goal of cultivating the innovative ability of talents in intelligent manufacturing engineering, many courses are added, such as big data technology and application, digital image processing, mathematical modeling practice, advanced manufacturing technology, comprehensive intelligent manufacturing, etc. It strengthens the application of modern computer software and other tools and trains students to be good at discovering, independently learning from available resources, and effectively using modern tools in the practical application of intelligent manufacturing engineering.

Further, in order to cultivate innovative ability in solving intelligent manufacturing engineering problems, effectively improve the ability to propose new theoretical methods, and design new solutions and develop new equipment systems for specific problems, the practical teaching platform is planned and constructed. The practical teaching conditions are strengthened. The practical courses are reformed. The engineering practice project content is integrated into theoretical and practical courses. In addition to the curriculum, innovative competitions with multiple tracks, multiple layers, wide directions, and serialization have been set up. Through participating in practical project training, the quality improvement of research and innovation ability is strengthened.

3.3. Establishing a Four-Level, Three-Theme, Multidisciplinary Integration Intelligent Manufacturing Engineering Innovation Practice Platform

Relying on the national-level mechanical experiment teaching demonstration center, scientific research laboratory, school–enterprise practice platform, etc., many provincial, ministerial, and school high-level practice platforms have been integrated, such as the key laboratory of metallurgical equipment of the Ministry of Education, the key laboratory of mechanical transmission and manufacturing of Hubei Province, the precision manufacturing research institute, the green manufacturing research institute, the energy saving and emission reduction center, engineering training center, etc. Focusing on the concepts of green and intelligent manufacturing, a practical platform for cultivating innovative capabilities in intelligent manufacturing engineering is created, which covers four levels of “discipline cognition, professional understanding, comprehensive application, exploration and innovation” and three themes of “cultural quality, engineering quality, and scientific research quality”, as shown in

Figure 4.

The intelligent manufacturing engineering innovation practice platform relies on the above four learning levels. It pays attention to the intersection between various related disciplines and the integration between related engineering technologies. Facing the above three training themes, a project-based integrated practice teaching method is designed, and the ability to solve engineering problems and innovation ability in practice are improved. The innovative practice platform and teaching methods of engineering practice do not simply emphasize innovation but focus on improving the innovative ability of students. In terms of the practical operation mechanism of engineering practice, the method of substituting indoctrination teaching with self-directed learning is particularly emphasized. Through project-based integrated practical teaching, a new window of independent learning is opened.

Independent topic selection: In the topic selection process, students design the topic independently, and then the tutor chooses it. Students independently carry out literature reviews, broaden the vision of academic literature reading in the field of intelligent manufacturing engineering, stimulate the creativity of thinking, drive ideological exploration, and enrich the harvest of intelligent manufacturing engineering practice.

Independent team formation: The project research process is also the training of teamwork ability. In the research of intelligent manufacturing engineering projects, through independent team formation, students are allowed to independently evaluate the optimal combination of the knowledge structure of team members, build communication channels independently, and improve communication skills and team cooperation abilities.

Independent management: Independent management is an important ability to solve complex engineering problems and carry out innovative activities. It plays an important role in the project research process. Through reasonable design and coordination with team behaviors in engineering practice, the autonomy of students is given full play, the team initiative is mobilized, the independent management ability of students is cultivated, and the independent management and operation system of students is built in the practice of intelligent manufacturing engineering.

Independent innovation: Students can participate in tutor projects or subject competition projects and can also design their own works. In the process, the tutor encourages students to put forward bold and even risky innovative ideas. Students grasp research hotspots through literature study and academic exchanges and understand some important principles and key technologies. In the process of project participation, the knowledge system is constantly improved to ensure the implementation of innovative behaviors and the realization of innovative works. The tutor demonstrates the selected topic, revises and supplements the contents, and guides and helps the process, so as to support the smooth development of the project research.

3.4. Building a Stereoscopic Teaching Resource Library That Embodies the Concept of Green and Intelligent Manufacturing, and Integrates New Methods and Technologies

Guided by the concept of green manufacturing and intelligent manufacturing, innovative education, teaching methods, and technologies are integrated. Furthermore, advanced scientific and technological achievements are also absorbed in the green and intelligent development of the steel industry. On this basis, a stereoscopic teaching resource library is built, which includes learning resources, learning scenarios, teaching materials, and teaching cases, as shown in

Figure 5. The main construction ideas and measures include the following.

These include relying on the construction of national and provincial online and offline course teaching resources, such as mechanical principles, hydraulic transmission, and mechanical manufacturing, as well as the construction of online courses, such as mechanical manufacturing technology, engineering project management, and mechanical engineering testing technology, and multi-level learning resources are enriched, such as MOOCs, videos, animation, virtual simulation experiments, shared courseware, online question database, etc.

Combined with the needs of the steel industry and regional economic development, and in accordance with the steel intelligent manufacturing engineering education system, interdisciplinary teaching resources are opened up. The contents of multidisciplinary teaching resources are expanded. Oriented by the learning effect, knowledge materials are integrated, including steel industry intelligence, industrial Internet materials, industrial big data, digital twins, etc [

11]. Diversified subject teaching contents are designed. The engineering application and innovation abilities of students are cultivated.

For complex engineering scenarios under specific working conditions, especially for practical segments such as course experiments, course design, and graduation design, such as topology optimization design of complex aeronautical structural parts, multi-robot detection-processing integrated system design, complex surface multi-degree-of-freedom processing trajectory planning, etc., combined with virtual simulation technology and field practice experiments, immersive and imaginative video and animation teaching scenes are designed. They enhance engineering site experience, promote the understanding and mastery of students of complex engineering problems in specific scenarios, and train engineering practice ability.

In view of the problems, such as abstract and fragmented course content and similar and single teaching design, advanced concepts and outcome-based education (OBE) are fully absorbed, including system engineering, digital twins, and smart manufacturing. The traditional teaching modes are reformed. The roles of teachers and students in the teaching process are adjusted. A combination of case teaching and online and offline discussions is adopted. The knowledge-instilling classroom is modified into a smart flipped classroom that mixes online and offline. It highlights the role of teachers as leaders and allows students to learn fully independently.

Most of the resources require students to log in to the resource management system through their accounts for learning. For example, the virtual simulation teaching platform we built can be used by students to conduct virtual simulation experiments online. There are also some published on open websites, such as the “Mechanical Manufacturing Foundation”, “Mechanical Manufacturing Technology”, and “Hydraulic Transmission”. The teaching videos and resources of such courses, constructed based on the concept of green manufacturing and intelligent manufacturing, are published on the open website.

4. Conclusions

After exploring the construction of intelligent manufacturing engineering for the green and intelligent upgrading of the steel industry, a basically complete teaching system has been formed. The training of students in intelligent manufacturing engineering is carried out in Wuhan University of Science and Technology. The new major of intelligent manufacturing engineering has been established in the local university with a distinctive industry background. It firmly grasps the new engineering teaching concept, “output-oriented”, takes students as the center, reverse-designs the curriculum system, and continuously improves it. In the continuous deepening and implementation, it focuses on the following items.

(1) Facing the development needs of intelligent transformation and upgrading of characteristic industries, according to the green and intelligent teaching concept, the multidisciplinary integration of intelligent manufacturing engineering is set up, the discipline construction goals are formulated, and the talent training standards are determined.

(2) Guided by the cultivation of innovative ability of intelligent manufacturing engineering in characteristic industries, a talent training plan for multidisciplinary integration is formulated. The curriculum system, teaching content, and teaching methods are reformed. A number of industry–university–research comprehensive practice platforms for intelligent manufacturing in characteristic industries are built. An international evaluation and continuous improvement system for the quality of talent training is established.

(3) Facing the intelligent transformation and upgrading of characteristic industries, the out-campus and on-campus practice and teaching bases are optimized and shared. A comprehensive practice platform for multidisciplinary integration is built, including mechanical or near-mechanical majors, such as intelligent manufacturing engineering, mechanical engineering, mechatronic engineering, measurement and control technology and instruments, and industrial engineering, etc. Industry–university–research collaboration programs are coordinated and promoted. A project-driven autonomous practice teaching system is constructed. The engineering ability and innovation ability of students are cultivated.

(4) Based on the innovative ability training system of intelligent manufacturing engineering, a number of stereoscopic teaching resources have been constructed. It embodies the transformation and upgrading of characteristic industries, integrates the green and intelligent concept and information and digital technology, and cultivates the professional innovation ability of intelligent manufacturing engineering for characteristic industries. These curriculum resources have obtained some certifications or rewards. For example, “Mechanical Principle” is certified as a “National First-Cass Courses”; “Mechanical Manufacturing Foundation”, “Hydraulic Transmission”, “Industrial Engineering Foundation” and so on are certified as “Provincial onal First-Cass Courses”. The structural balance, content sharing, continuous improvement, and optimization of teaching resources are realized. Personalized learning is enabled. It provides strong support for improving the innovation capability of intelligent manufacturing engineering.