Effect of Warm Mix Asphalt (WMA) Antistripping Agent on Performance of Waste Engine Oil-Rejuvenated Asphalt Binders and Mixtures

Abstract

1. Introduction

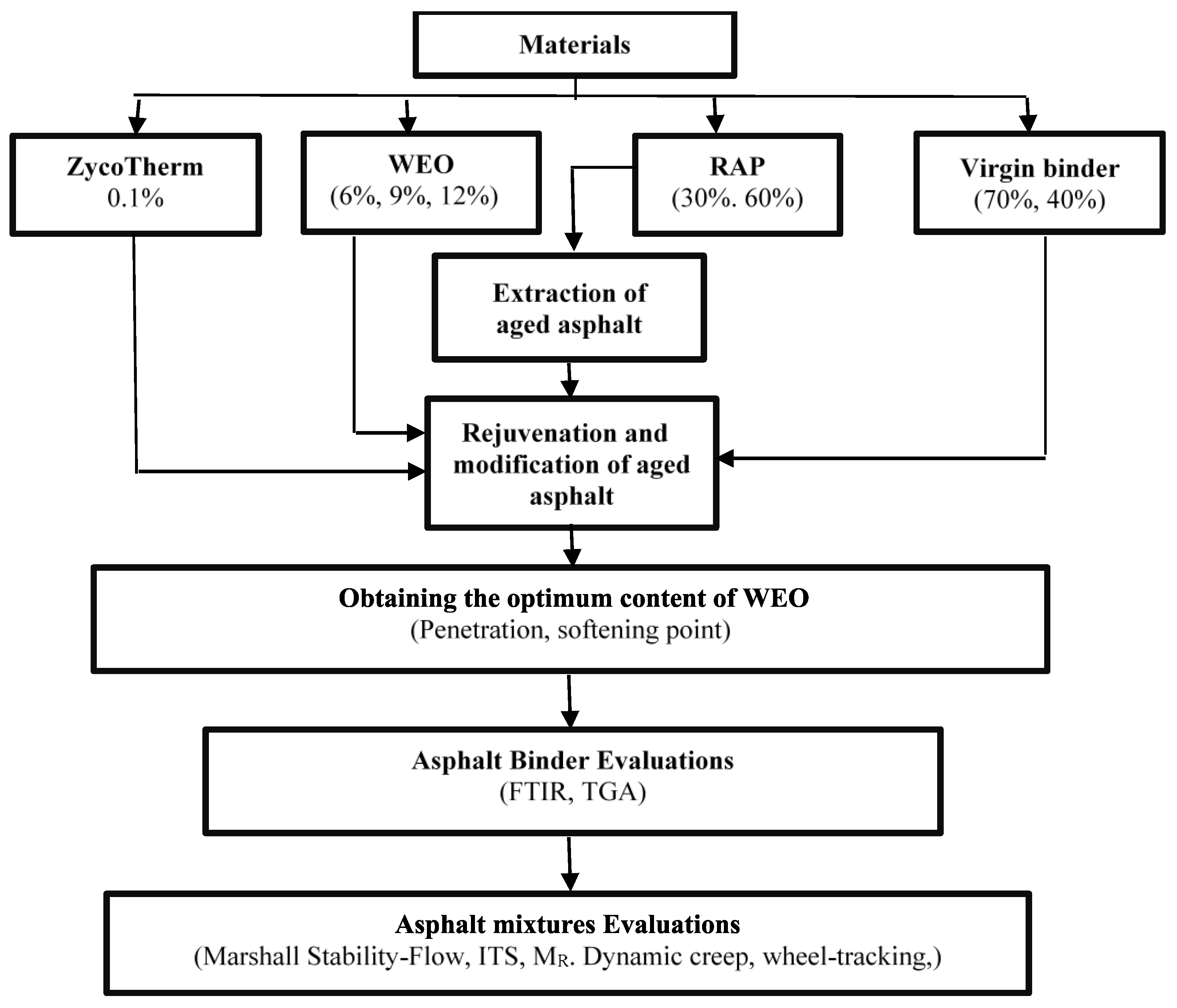

2. Materials, Sample Preparation and Methods

2.1. Materials

2.1.1. Virgin Asphalt Binder and Aggregate

2.1.2. Waste Engine Oil (WEO) and Antistripping Additive

2.1.3. Recycled Asphalt Pavement (RAP)

2.2. Sample Preparation

2.3. Testing Methods

2.3.1. Fourier Transform Infrared (FTIR) Spectroscopy

2.3.2. Thermogravimetric (TG) Analysis

2.3.3. Marshall Stability and Flow Test

2.3.4. Indirect Tensile Strength (ITS) Test

2.3.5. Resilient Modulus (MR) Test

2.3.6. Dynamic Creep Test

2.3.7. Aggregate Coating Test

2.3.8. Rutting Resistance Test

3. Results and Discussion

3.1. Physical and Chemical Evaluations of Asphalt Binder Samples

3.1.1. Penetration and Softening Point

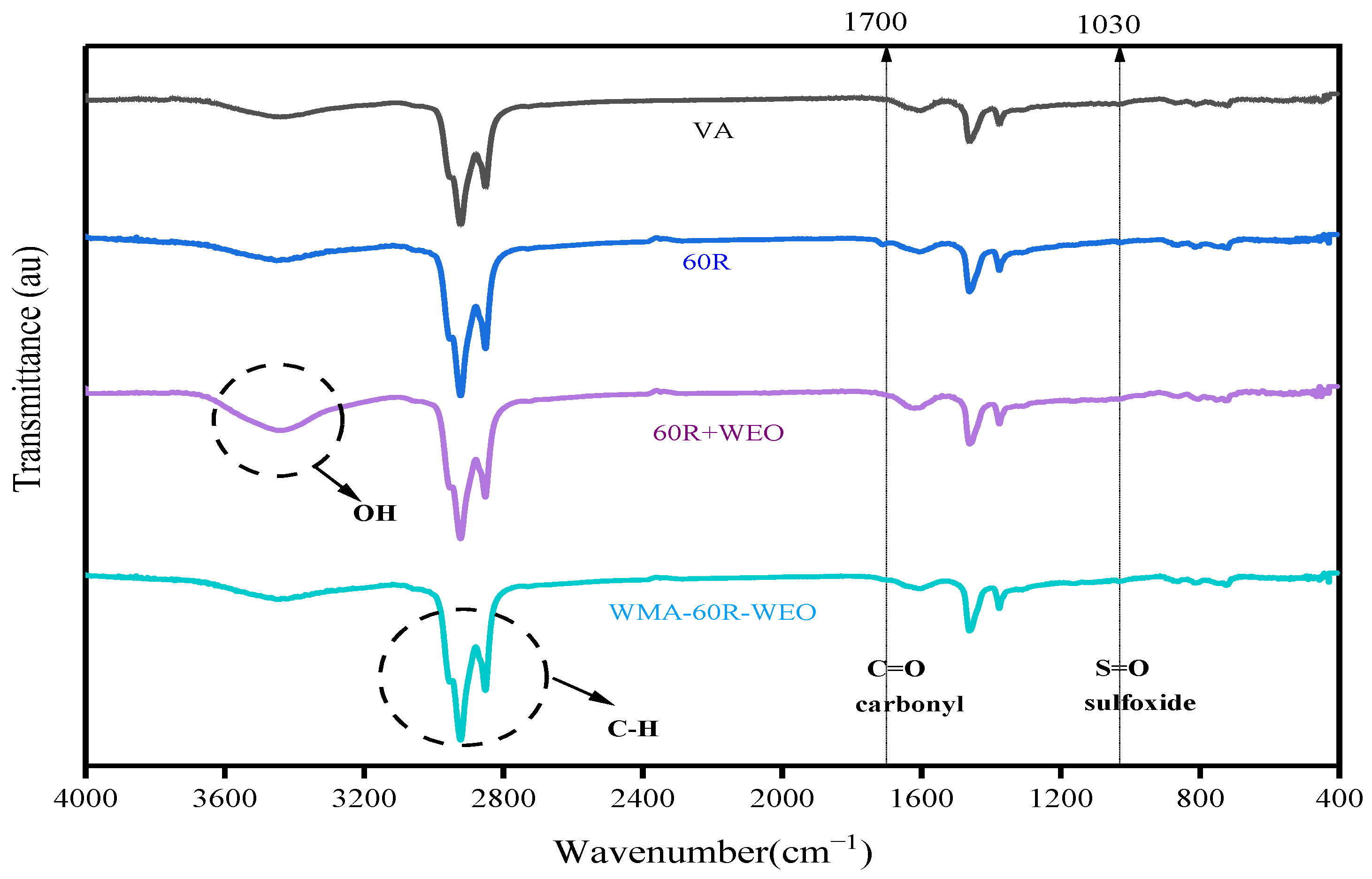

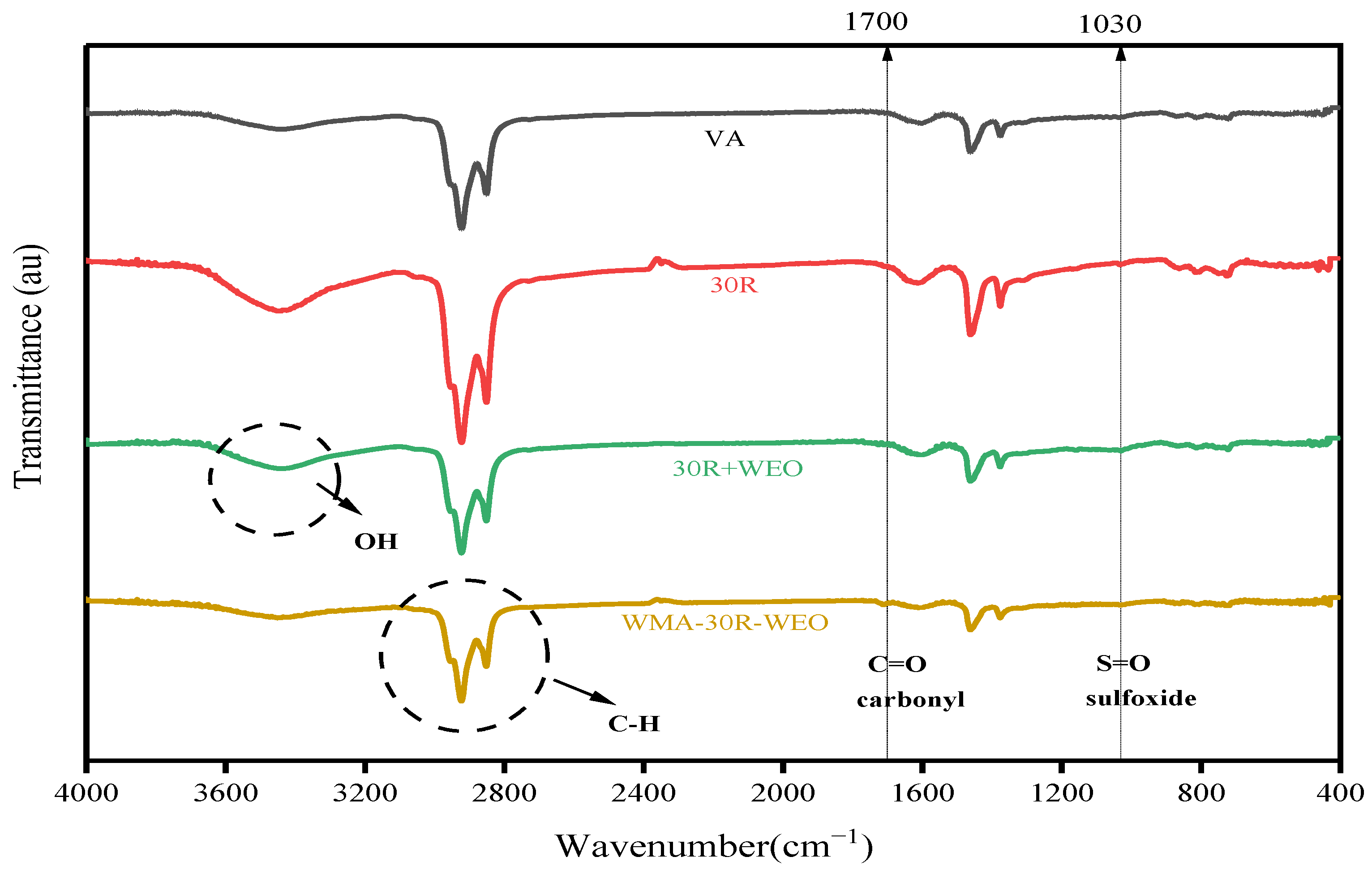

3.1.2. FTIR Results

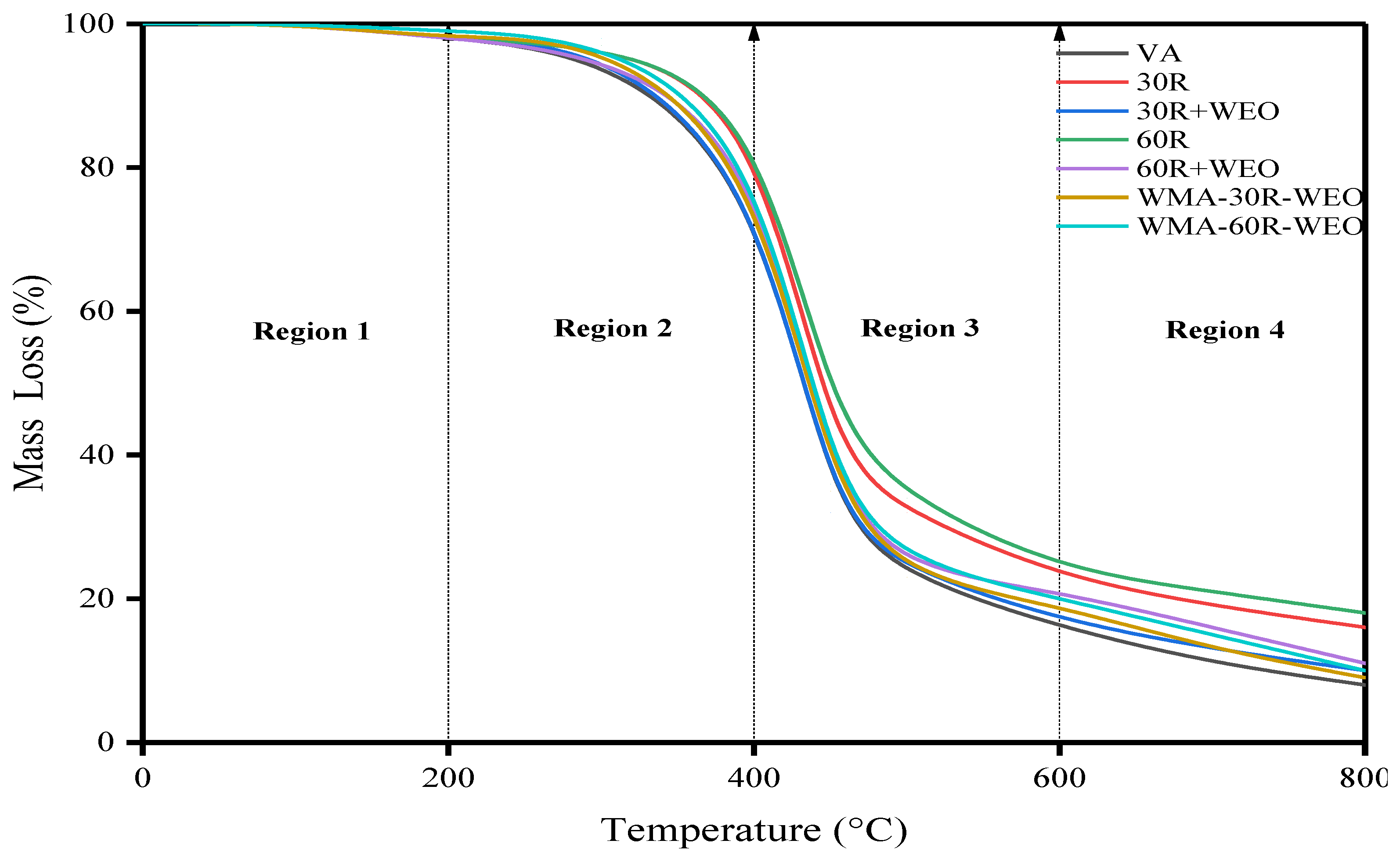

3.1.3. TG Analysis

3.2. Asphalt Mixtures’ Evaluations

3.2.1. Marshall Stability and Flow Test

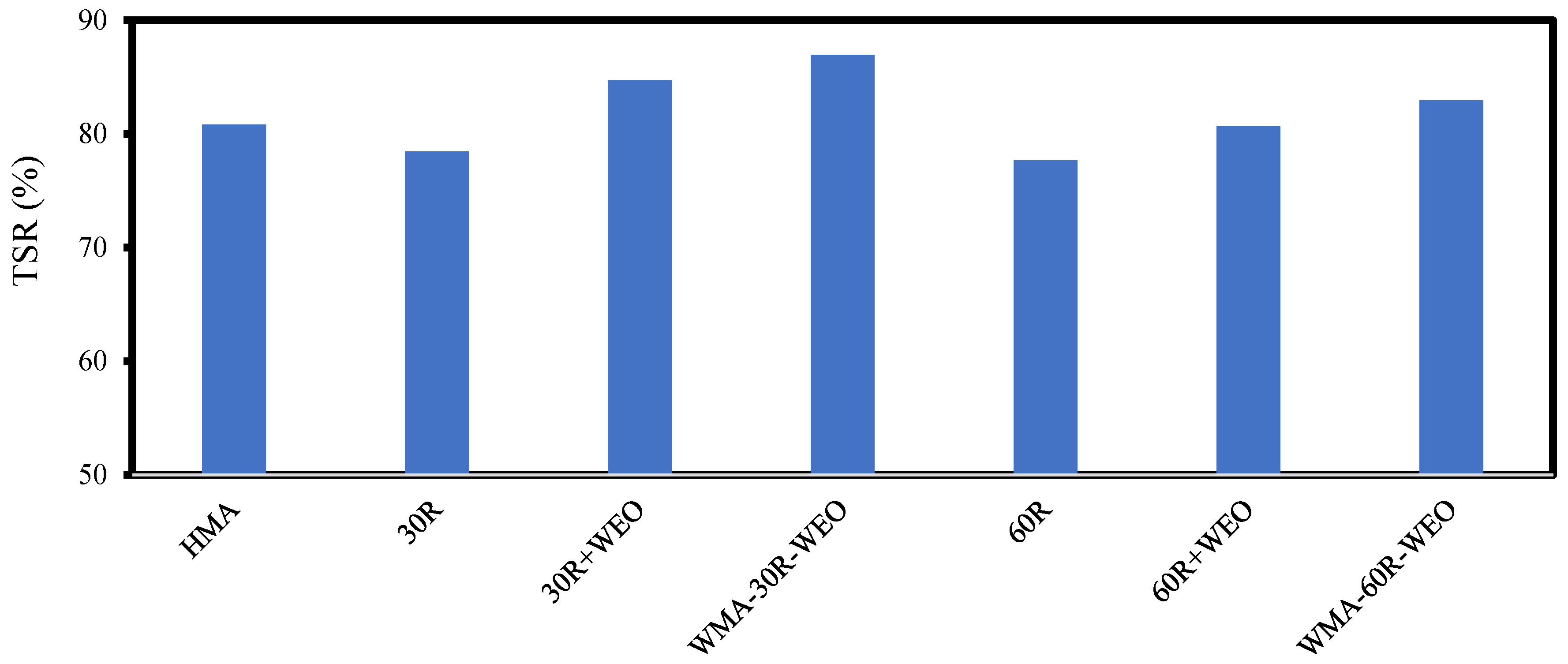

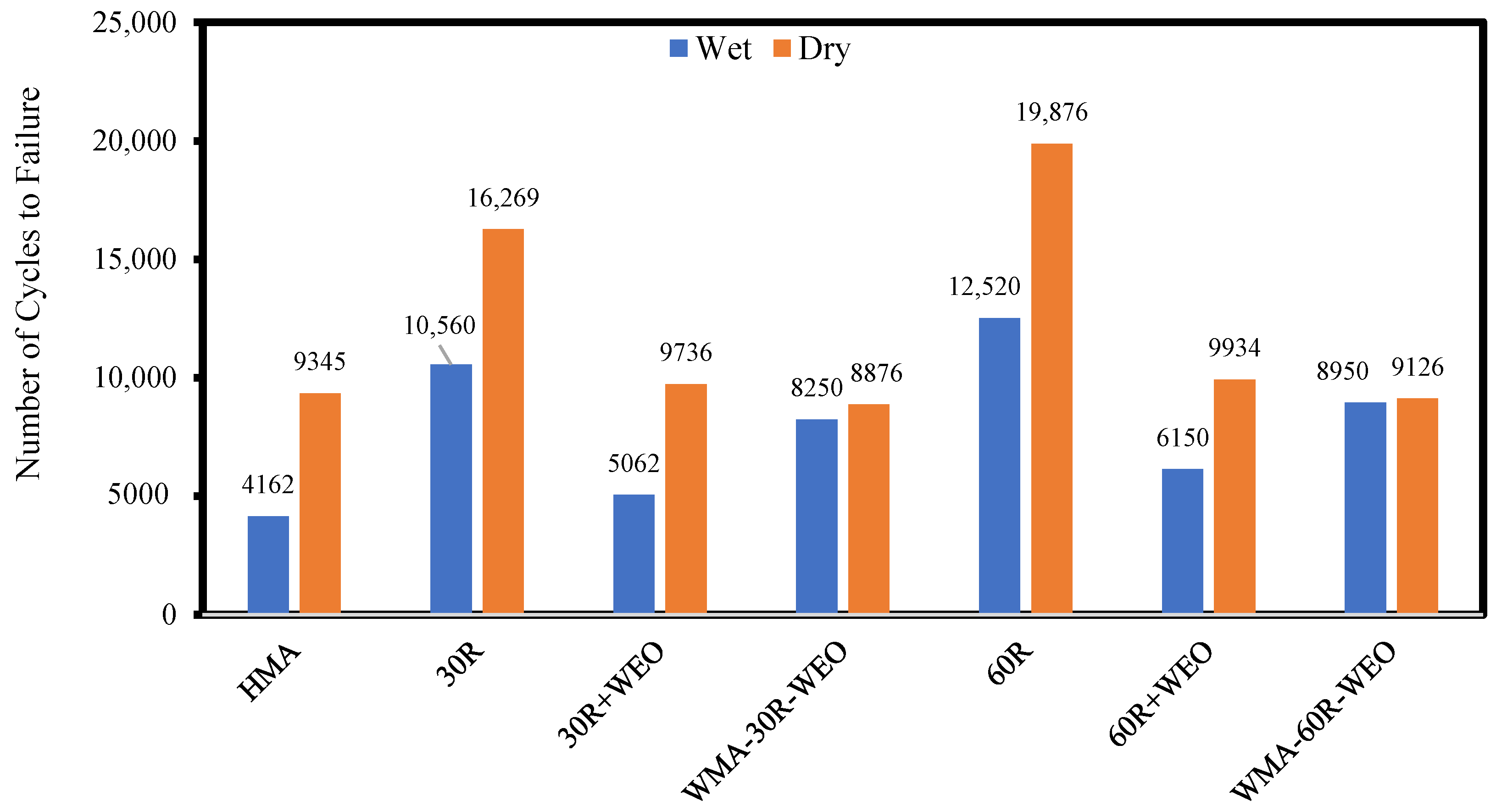

3.2.2. Indirect Tensile Strength (ITS) Test

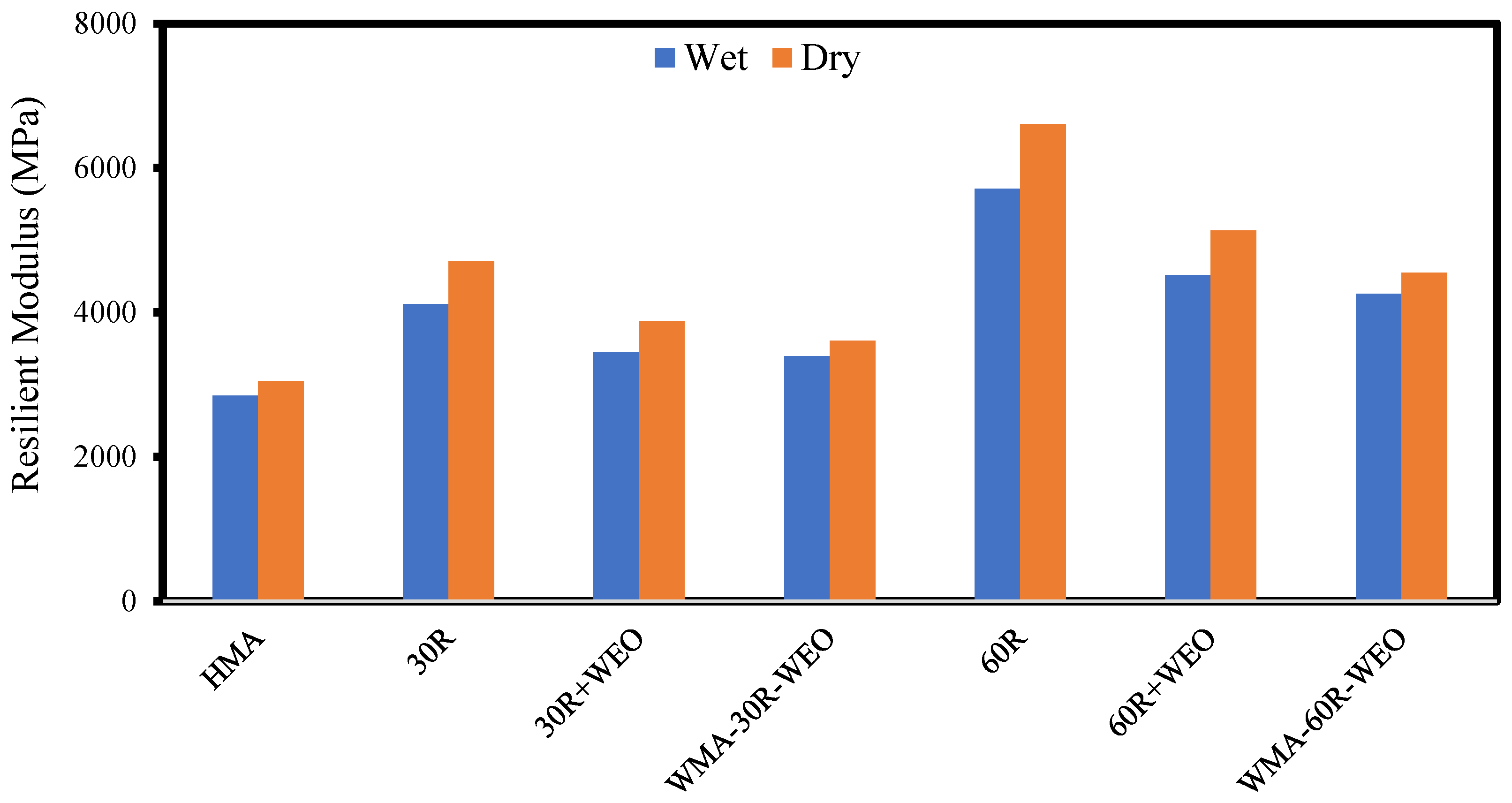

3.2.3. Resilient Modulus (MR) Test

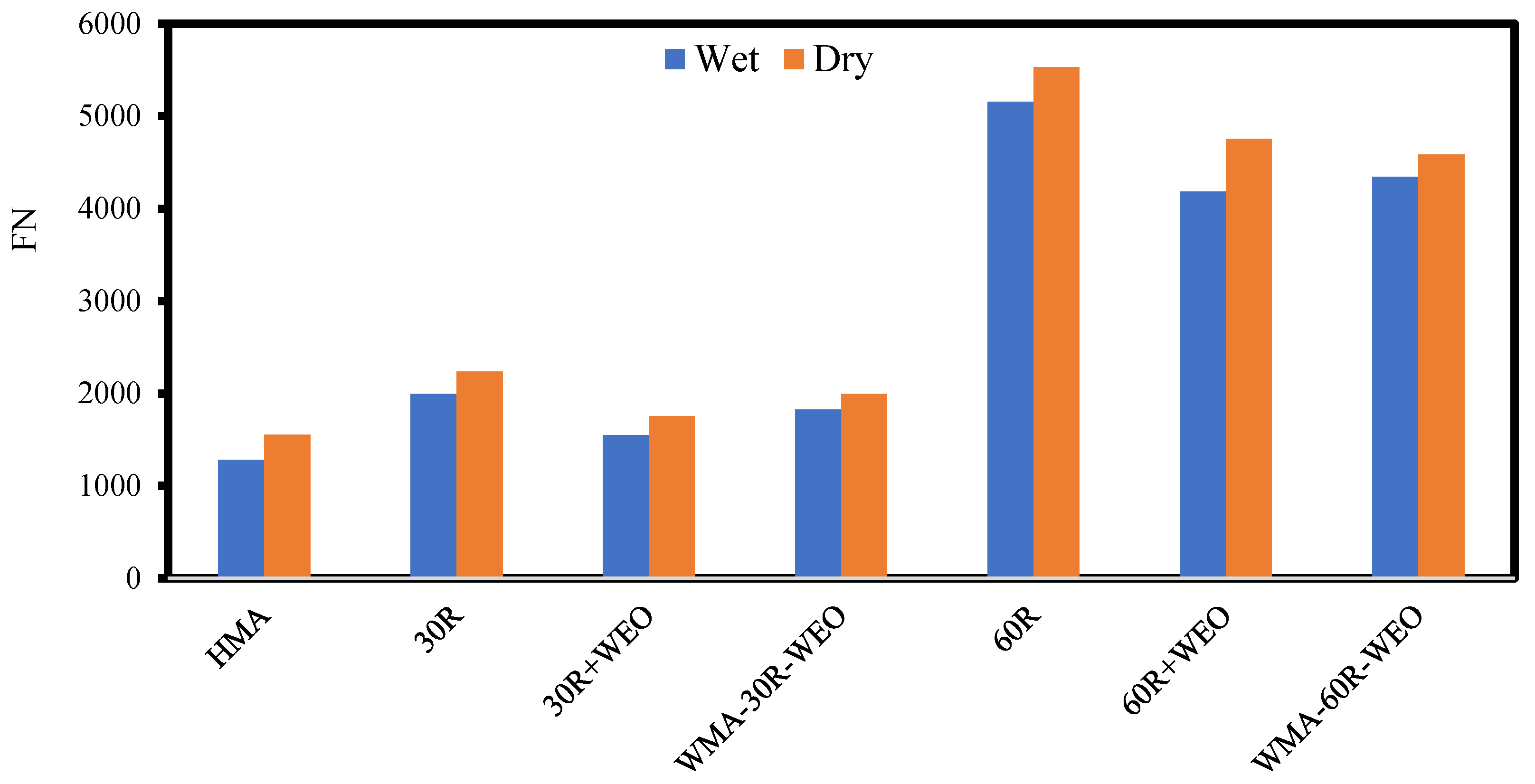

3.2.4. Dynamic Creep Test

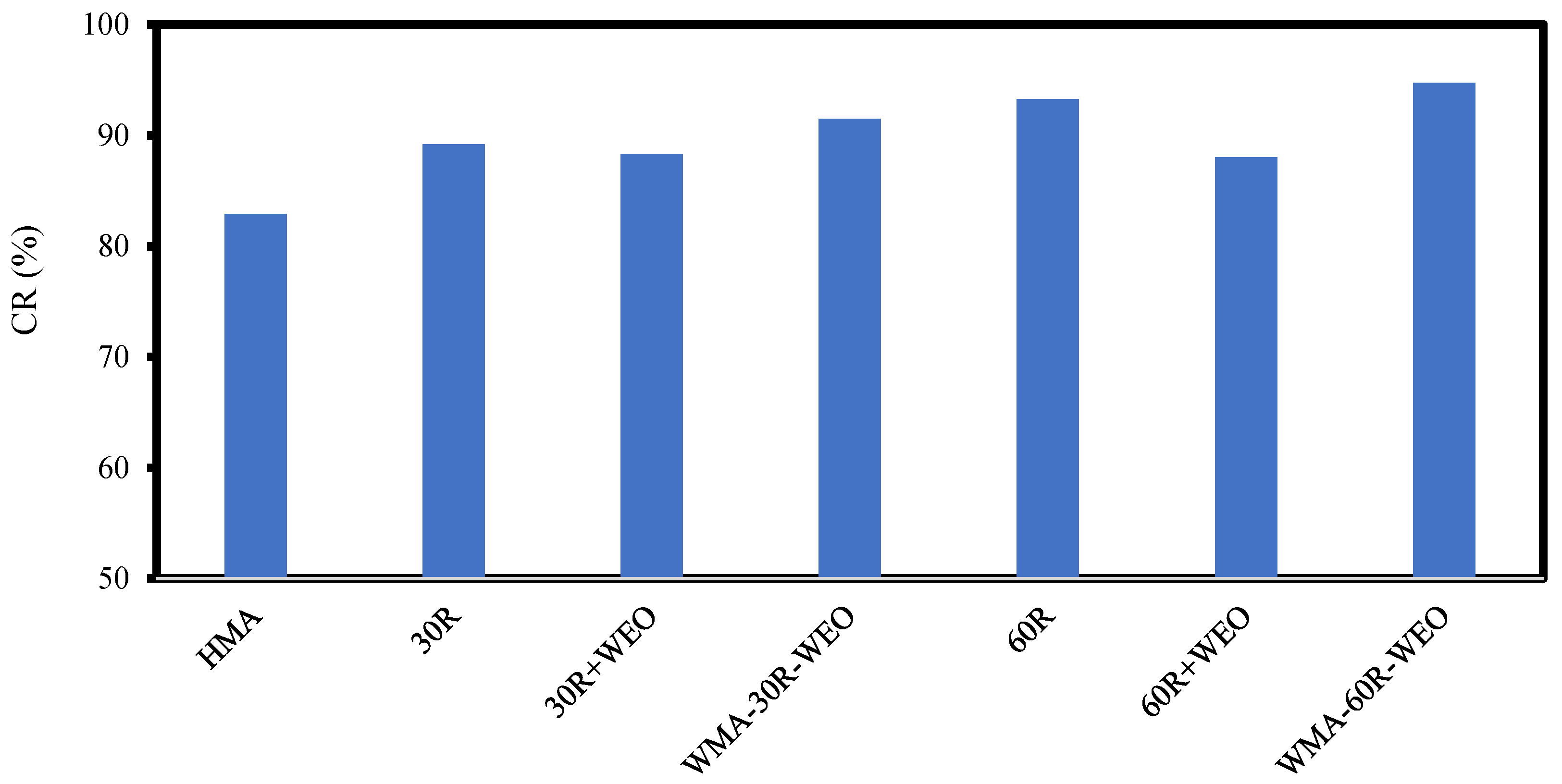

3.2.5. Aggregate Coating Test

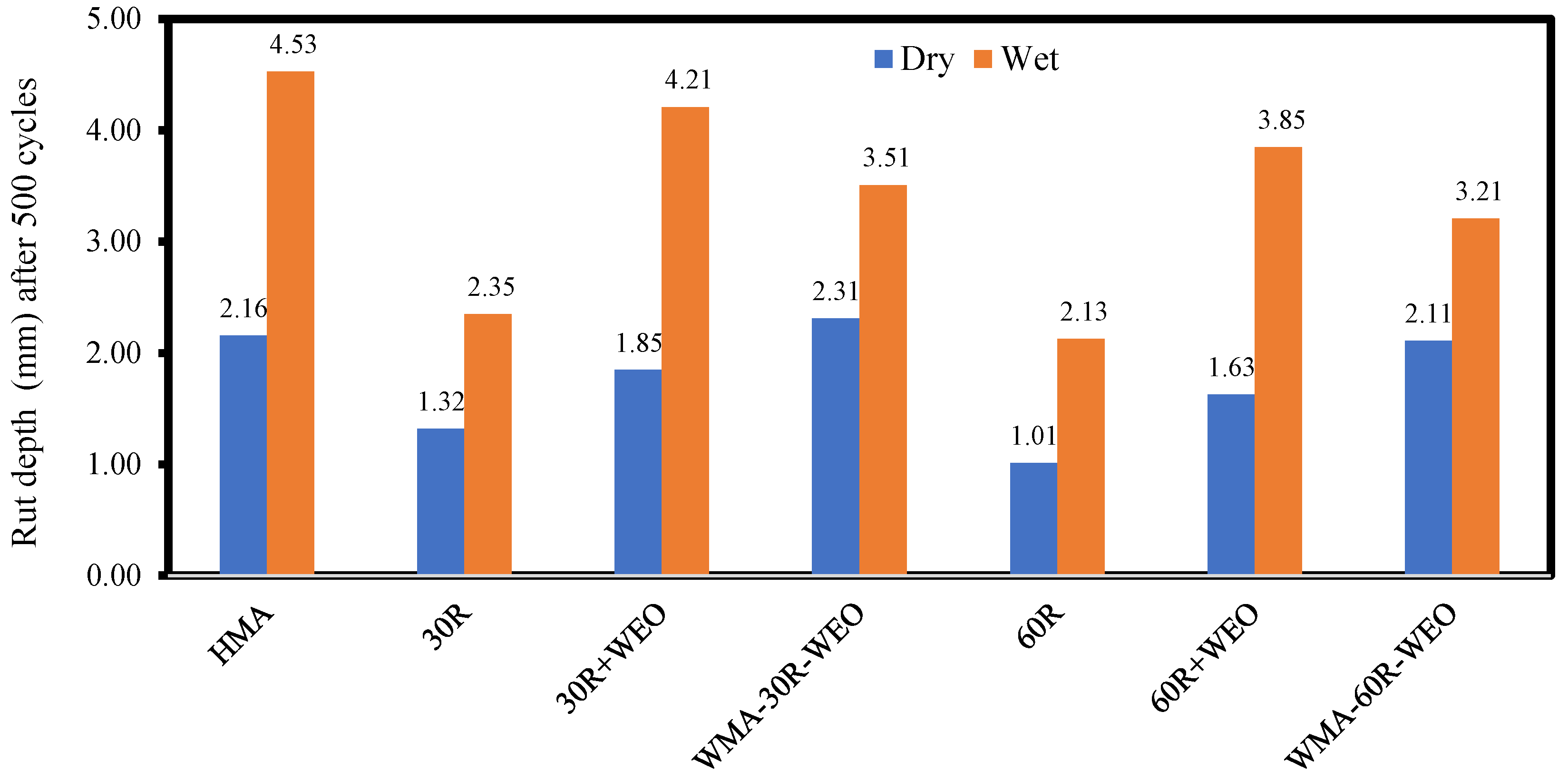

3.2.6. Wheel Tracking Test

Post-Compaction (PC)

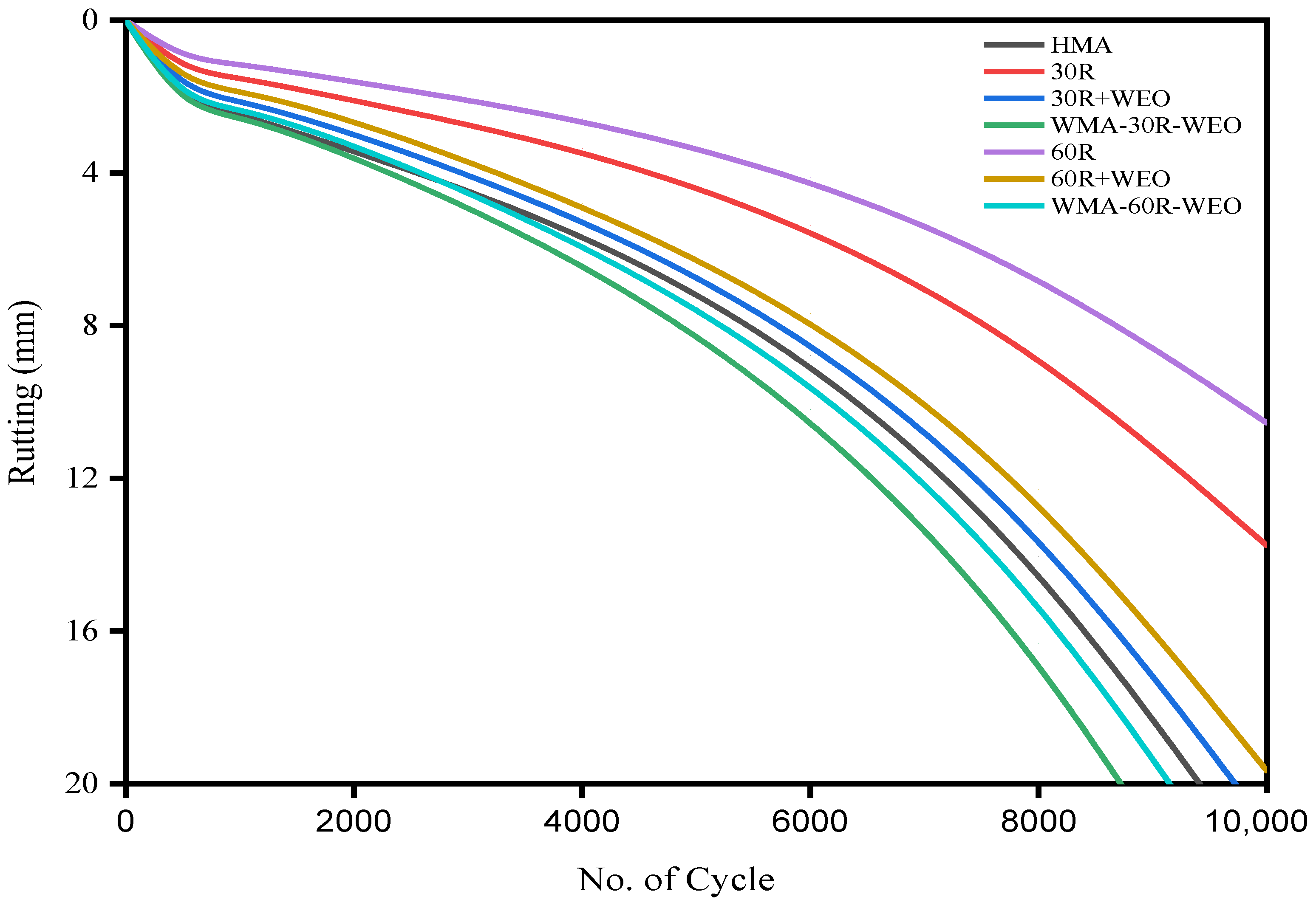

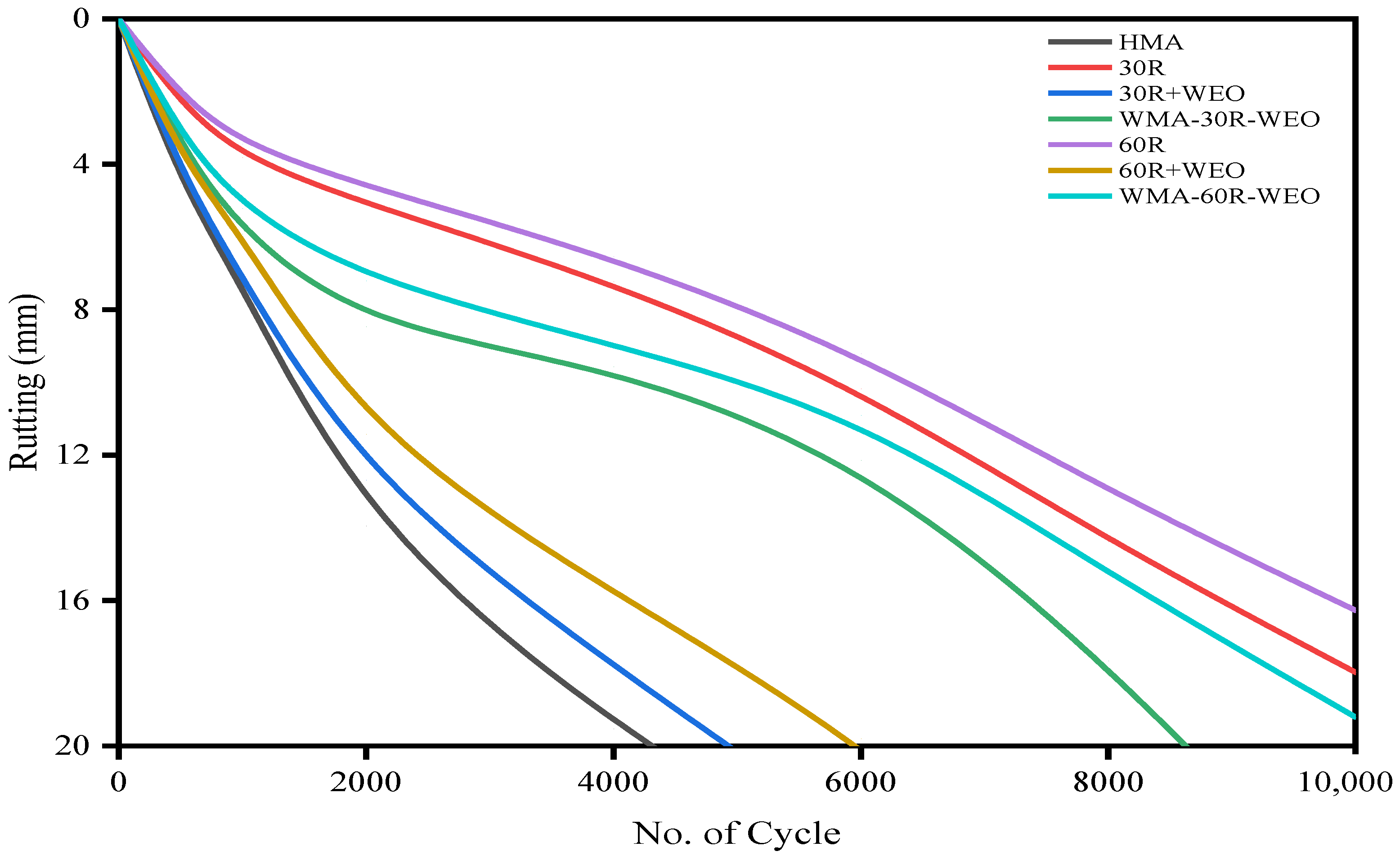

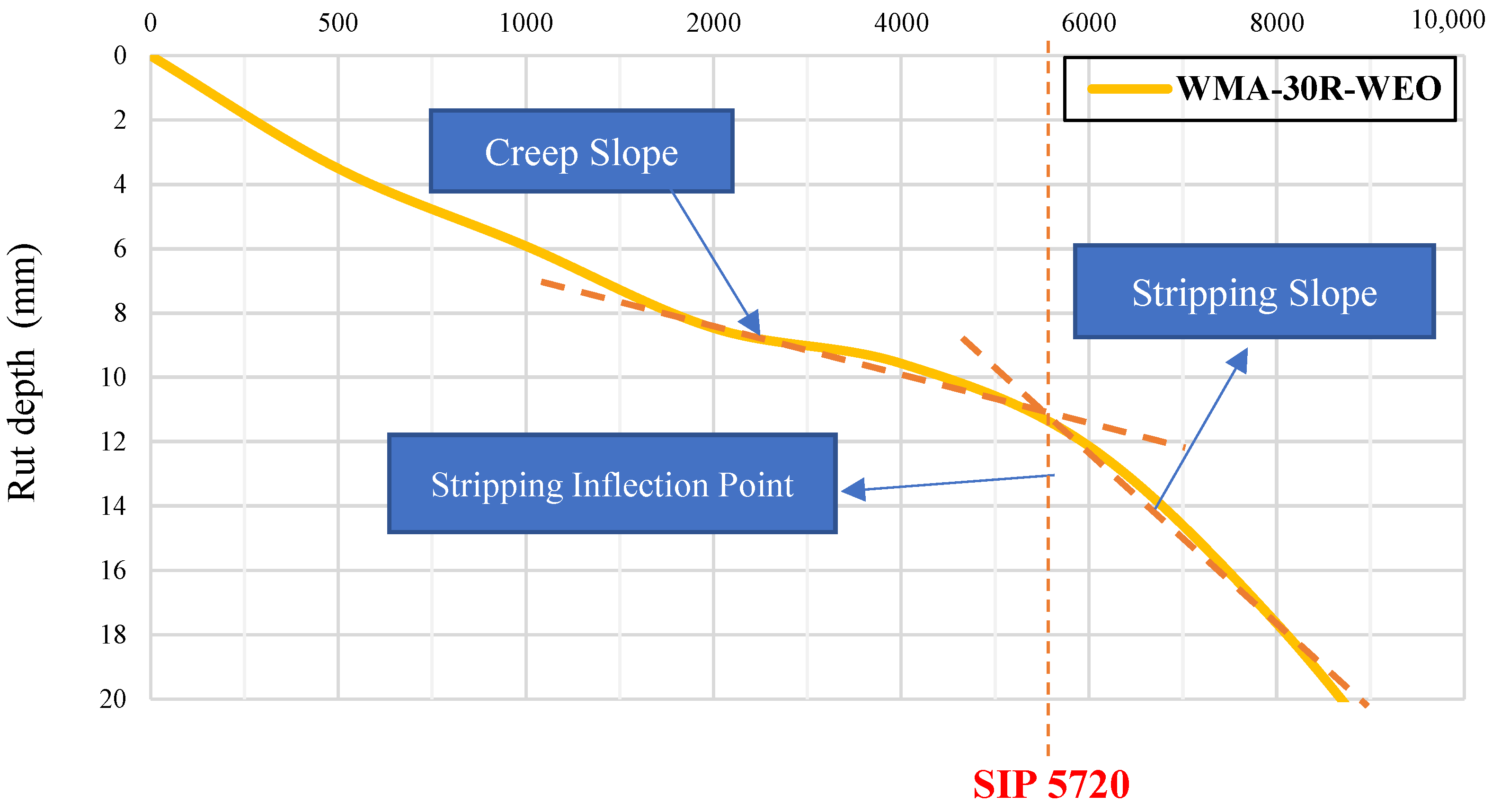

Rutting Depth Versus Load Cycle

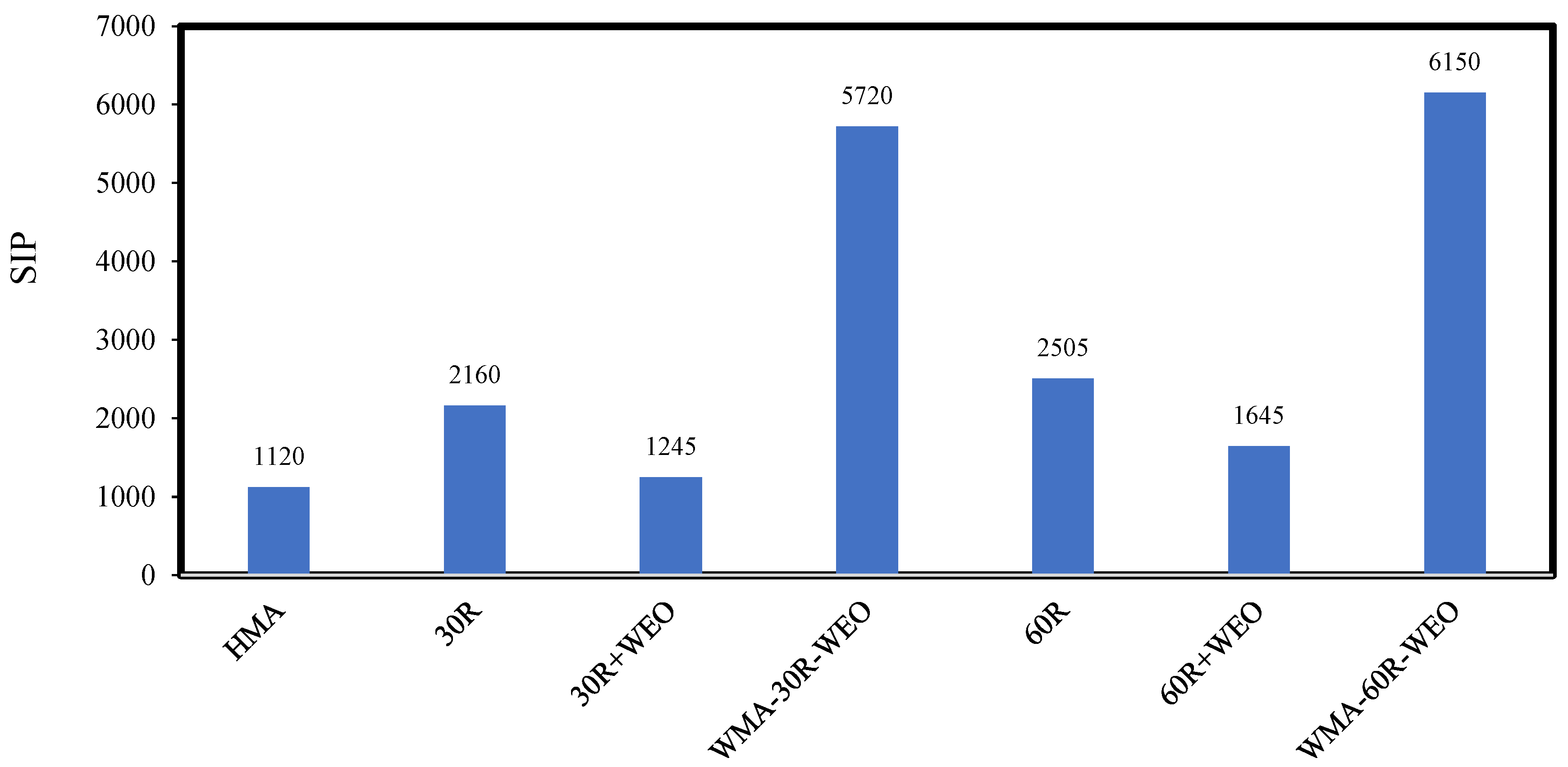

Stripping Inflection Point (SIP)

4. Conclusions

- FTIR showed that the water-sensitive functional group (carboxylic acids and Si-OH compounds) vanished when the WEO-rejuvenated binders were modified with ZycoTherm, indicating that ZycoTherm works adequately as an antistripping agent. TG analysis also revealed that the additions of ZycoTherm and WEO did not affect the thermal stability of the blended binders.

- The addition of ZycoTherm to rejuvenated mixtures was found to increase the stability and decrease the flow of mixtures, which indicates a better adhesion and thus enhances the binder–aggregate mechanical interlocking.

- Mixtures containing ZycoTherm have relatively higher ITS, TSR, MR and RMR values. The decrease in viscosity of the rejuvenated binders modified with ZycoTherm allows the binder to penetrate the pore on the aggregate external morphology. Furthermore, lower mixing temperatures in the WMA mixtures lead to less aging and therefore lower possibility of cracking and moisture intrusion to the binder–aggregate bond during the conditioning phase.

- The results revealed that ZycoTherm has a positive impact on the rutting resistance in the presence of moisture. This may be attributed to the fact that the modified samples exhibited a high coating percentage, which impedes water infiltration to disrupt the binder–aggregate interface.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- El-labbad, E.M.; Heneash, U.; El-Badawy, S.M. Investigation of Waste Electrical Power Plant Oil as a Rejuvenating Agent for Reclaimed Asphalt Binders and Mixtures. Materials 2022, 15, 4811. [Google Scholar] [CrossRef] [PubMed]

- Saberi, S.S.; Mohamed, A.; Eltwati, A.S. Mechanical and Physical Properties of Recycled Concrete Aggregates for Road Base Materials. J. Phys. Conf. Ser. 2021, 1973, 012236. [Google Scholar] [CrossRef]

- Maciejewski, K.; Ramiączek, P.; Remisova, E. Effects of Short-Term Ageing Temperature on Conventional and High-Temperature Properties of Paving-Grade Bitumen with Anti-Stripping and WMA Additives. Materials 2021, 14, 6229. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Ren, Q.; Qian, Z.; Wang, X. Evaluating the effects of high RAP content and rejuvenating agents on fatigue performance of fine aggregate matrix through DMA flexural bending test. Materials 2019, 12, 1508. [Google Scholar] [CrossRef] [PubMed]

- Enieb, M.; Hasan Al-Jumaili, M.A.; Eedan Al-Jameel, H.A.; Eltwati, A.S. Sustainability of using reclaimed asphalt pavement: Based-reviewed evidence. J. Phys. Conf. Ser. 2021, 1973, 012242. [Google Scholar] [CrossRef]

- Eltwati, A.; Enieb, M.; Ahmeed, S.; Zaid, A.-S.; Mohamed, A. Effects of waste engine oil and crumb rubber rejuvenator on the performance of 100% RAP binder. J. Innov. Transp. 2022, 3, 8–15. [Google Scholar] [CrossRef]

- Al-Saffar, Z.H.; Yaacob, H.; Katman, H.Y.; Mohd Satar, M.K.; Bilema, M.; Putra Jaya, R.; Eltwati, A.S.; Radeef, H.R. A Review on the Durability of Recycled Asphalt Mixtures Embraced with Rejuvenators. Sustainability 2021, 13, 8970. [Google Scholar] [CrossRef]

- Al-Saffar, Z.H.; Yaacob, H.; Al Jawahery, M.S.; Yousif, S.T.; Satar, M.K.I.M.; Jaya, R.P.; Radeef, H.R.; Eltwati, A.S.; Shaffie, E. Extraction and Characterisation of Maltene from Virgin Asphalt as a Potential Rejuvenating Agent. Sustainability 2023, 15, 909. [Google Scholar] [CrossRef]

- Brasileiro, L.; Moreno-Navarro, F.; Tauste-Martínez, R.; Matos, J.; Rubio-Gámez, M.D. Reclaimed Polymers as Asphalt Binder Modifiers for More Sustainable Roads: A Review. Sustainability 2019, 11, 646. [Google Scholar] [CrossRef]

- Joumblat, R.; Al Basiouni Al Masri, Z.; Al Khateeb, G.; Elkordi, A.; El Tallis, A.R.; Absi, J. State-of-the-Art Review on Permanent Deformation Characterization of Asphalt Concrete Pavements. Sustainability 2023, 15, 1166. [Google Scholar] [CrossRef]

- Pasandín, A.R.; Pérez, I.; Gómez-Meijide, B. Performance of High Rap Half-Warm Mix Asphalt. Sustainability 2020, 12, 10240. [Google Scholar] [CrossRef]

- Jing, F.; Wang, R.; Zhao, R.; Li, C.; Cai, J.; Ding, G.; Wang, Q.; Xie, H. Enhancement of Bonding and Mechanical Performance of Epoxy Asphalt Bond Coats with Graphene Nanoplatelets. Polymers 2023, 15, 412. [Google Scholar] [CrossRef] [PubMed]

- Shoukat, T.; Yoo, P.J. Rheology of Asphalt Binder Modified with 5W30 Viscosity Grade Waste Engine Oil. Appl. Sci. 2018, 8, 1194. [Google Scholar] [CrossRef]

- Al-Saffar, Z.H.; Yaacob, H.; Mohd Satar, M.K.I.; Saleem, M.K.; Jaya, R.P.; Lai, C.J.; Shaffie, E. Evaluating the Chemical and Rheological Attributes of Aged Asphalt: Synergistic Effects of Maltene and Waste Engine Oil Rejuvenators. Arab. J. Sci. Eng. 2020, 45, 8685–8697. [Google Scholar] [CrossRef]

- Wang, F.; Fang, Y.; Chen, Z.; Wei, H. Effect of waste engine oil on asphalt reclaimed properties. AIP Conf. Proc. 2018, 1973, 020012. [Google Scholar] [CrossRef]

- Su, N.; Xiao, F.; Wang, J.; Cong, L.; Amirkhanian, S. Productions and applications of bio-asphalts—A review. Constr. Build. Mater. 2018, 183, 578–591. [Google Scholar] [CrossRef]

- Jia, X.; Huang, B.; Bowers, B.F.; Zhao, S. Infrared spectra and rheological properties of asphalt cement containing waste engine oil residues. Constr. Build. Mater. 2014, 50, 683–691. [Google Scholar] [CrossRef]

- Jahanbakhsh, H.; Karimi, M.M.; Naseri, H.; Nejad, F.M. Sustainable asphalt concrete containing high reclaimed asphalt pavements and recycling agents: Performance assessment, cost analysis, and environmental impact. J. Clean. Prod. 2020, 244, 118837. [Google Scholar] [CrossRef]

- Eltwati, A.S.; Enieb, M.; Al-Saffar, Z.H.; Mohamed, A. Effect of glass fibers and waste engine oil on the properties of RAP asphalt concretes. Int. J. Pavement Eng. 2022, 23, 5227–5238. [Google Scholar] [CrossRef]

- Babangida Attahiru, Y.; Mohamed, A.; Eltwati, A.; Burga, A.A.; Ibrahim, A.; Nabade, A.M. Effect of waste cooking oil on warm mix asphalt block pavement—A comprehensive review. Phys. Chem. Earth Parts A/B/C 2023, 129, 103310. [Google Scholar] [CrossRef]

- Martinez-Soto, A.; Calabi-Floody, A.; Valdes-Vidal, G.; Hucke, A.; Martinez-Toledo, C. Life Cycle Assessment of Natural Zeolite-Based Warm Mix Asphalt and Reclaimed Asphalt Pavement. Sustainability 2023, 15, 1003. [Google Scholar] [CrossRef]

- Manfro, A.L.; Staub de Melo, J.V.; Villena Del Carpio, J.A.; Broering, W.B. Permanent deformation performance under moisture effect of an asphalt mixture modified by calcium carbonate nanoparticles. Constr. Build. Mater. 2022, 342, 128087. [Google Scholar] [CrossRef]

- Enieb, M.; Cengizhan, A.; Karahancer, S.; Eltwati, A. Evaluation of Physical-Rheological Properties of Nano Titanium Dioxide Modified Asphalt Binder and Rutting Resistance of Modified Mixture. Int. J. Pavement Res. Technol. 2022. [Google Scholar] [CrossRef]

- Mirzababaei, P. Effect of zycotherm on moisture susceptibility of Warm Mix Asphalt mixtures prepared with different aggregate types and gradations. Constr. Build. Mater. 2016, 116, 403–412. [Google Scholar] [CrossRef]

- Caputo, P.; Abe, A.A.; Loise, V.; Porto, M.; Calandra, P.; Angelico, R.; Oliviero Rossi, C. The Role of Additives in Warm Mix Asphalt Technology: An Insight into Their Mechanisms of Improving an Emerging Technology. Nanomaterials 2020, 10, 1202. [Google Scholar] [CrossRef] [PubMed]

- Ayazi, M.J.; Moniri, A.; Barghabany, P. Moisture susceptibility of warm mixed-reclaimed asphalt pavement containing Sasobit and Zycotherm additives. Pet. Sci. Technol. 2017, 35, 890–895. [Google Scholar] [CrossRef]

- Sukhija, M.; Prasad, A.N.; Saboo, N.; Mashaan, N. Assessment of Virgin Binder-Blended Rejuvenators and Antistripping Agents for Hot Recycled Asphalt Mixture. Int. J. Pavement Res. Technol. 2022. [Google Scholar] [CrossRef]

- Yousefi, A.A.; Haghshenas, H.F.; Shane Underwood, B.; Harvey, J.; Blankenship, P. Performance of warm asphalt mixtures containing reclaimed asphalt pavement, an anti-stripping agent, and recycling agents: A study using a balanced mix design approach. Constr. Build. Mater. 2023, 363, 129633. [Google Scholar] [CrossRef]

- Ameri, M.; Vamegh, M.; Chavoshian Naeni, S.F.; Molayem, M. Moisture susceptibility evaluation of asphalt mixtures containing Evonik, Zycotherm and hydrated lime. Constr. Build. Mater. 2018, 165, 958–965. [Google Scholar] [CrossRef]

- Sani, A.; Mohd Hasan, M.R.; Shariff, K.A.; Jamshidi, A.; Ibrahim, A.H.; Poovaneshvaran, S. Engineering and microscopic characteristics of natural rubber latex modified binders incorporating silane additive. Int. J. Pavement Eng. 2020, 21, 1874–1883. [Google Scholar] [CrossRef]

- ASTM D5/D5M-20; Standard Test Method for Penetration of Bituminous Materials. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D36/D36M-14; Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus). ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM E1131-08; Standard Test Method for Compositional Analysis by Thermogravimetry. ASTM International: West Conshohocken, PA, USA, 2014.

- AASHTO T283; Standard Method of Test for Resistance of Compacted Bituminous Mixture to Moisture Induced Damage. AASHTO Standards: Washington, DC, USA, 2014.

- AASHTO T322; Standard Method of Test for Determining the Creep Compliance and Strength of Hot-Mix Asphalt (HMA) Using the Indirect Tensile Test Device. AASHTO Standards: Washington, DC, USA, 2011.

- ASTM D7369-20; Standard Test Method for Determining the Resilient Modulus of Bituminous Mixtures by Indirect Tension Tes. ASTM International: West Conshohocken, PA, USA, 2020.

- Ameri, M.; Kouchaki, S.; Roshani, H. Laboratory evaluation of the effect of nano-organosilane anti-stripping additive on the moisture susceptibility of HMA mixtures under freeze–thaw cycles. Constr. Build. Mater. 2013, 48, 1009–1016. [Google Scholar] [CrossRef]

- Witczak, M.W. Specification Criteria for Simple Performance Tests for Rutting NCHRP Rep. 580, Project 9–19; Transportation Research Board: Washington, DC, USA, 2007; Volume 580. [Google Scholar]

- AASHTO T195; Standard Method of Test for Determining Degree of Particle Coating of Asphalt Mixtures. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2011.

- Eltwati, A.S.; Enieb, M.; Mohamed, A.; Al-Saffar, Z.H.; Al-Jumaili, M.A. A laboratory study of the effect of fiberglass additive on the behavioural properties of RAP asphalt mixtures. J. Phys. Conf. Ser. 2021, 1973, 012241. [Google Scholar] [CrossRef]

- Mamun, A.; Al-Abdul Wahhab, H. Evaluation of waste engine oil-rejuvenated asphalt concrete mixtures with high RAP content. Adv. Mater. Sci. Eng. 2018, 2018, 7386256. [Google Scholar] [CrossRef]

- Leng, Z.; Sreeram, A.; Padhan, R.K.; Tan, Z. Value-added application of waste PET based additives in bituminous mixtures containing high percentage of reclaimed asphalt pavement (RAP). J. Clean. Prod. 2018, 196, 615–625. [Google Scholar] [CrossRef]

- Cong, P.; Chen, B.; Zhao, H. Coupling effects of wasted cooking oil and antioxidant on aging of asphalt binders. Int. J. Pavement Res. Technol. 2020, 13, 64–74. [Google Scholar] [CrossRef]

- Mannan, U.A.; Ahmad, M.; Tarefder, R.A. Influence of moisture conditioning on healing of asphalt binders. Constr. Build. Mater. 2017, 146, 360–369. [Google Scholar] [CrossRef]

- Eltwati, A.; Al-Saffar, Z.; Mohamed, A.; Rosli Hainin, M.; Elnihum, A.; Enieb, M. Synergistic effect of SBS copolymers and aromatic oil on the characteristics of asphalt binders and mixtures containing reclaimed asphalt pavement. Constr. Build. Mater. 2022, 327, 127026. [Google Scholar] [CrossRef]

- Pradhan, S.K.; Sahoo, U.C. Influence of softer binder and rejuvenator on bituminous mixtures containing reclaimed asphalt pavement (RAP) material. Int. J. Trans. Sci. Technol. 2022, 11, 46–59. [Google Scholar] [CrossRef]

- Elkashef, M.; Williams, R.C.; Cochran, E. Thermal stability and evolved gas analysis of rejuvenated reclaimed asphalt pavement (RAP) bitumen using thermogravimetric analysis–Fourier transform infrared (TG–FTIR). J. Therm. Anal. Calorim. 2018, 131, 865–871. [Google Scholar] [CrossRef]

- Taherkhani, H.; Noorian, F. Comparing the effects of waste engine and cooking oil on the properties of asphalt concrete containing reclaimed asphalt pavement (RAP). Road Mater. Pavement Des. 2020, 21, 1238–1257. [Google Scholar] [CrossRef]

- Katla, B.; Raju, S.; Waim, A.R.; Danam, V.A. Utilization of Higher Percentages of RAP for Improved Mixture Performance by Adopting the Process of Fractionation. Int. J. Pavement Res. Technol. 2022, 15, 349–366. [Google Scholar] [CrossRef]

- Pradhan, S.K.; Sahoo, U.C. Evaluation of recycled asphalt mixtures rejuvenated with Madhuca longifolia (Mahua) oil. Int. J. Pavement Res. Technol. 2021, 14, 43–53. [Google Scholar] [CrossRef]

- El-Shorbagy, A.M.; El-Badawy, S.M.; Gabr, A.R. Investigation of waste oils as rejuvenators of aged bitumen for sustainable pavement. Constr. Build. Mater. 2019, 220, 228–237. [Google Scholar] [CrossRef]

- Mirzababaei, P.; Moghadas Nejad, F.; Naderi, K. Effect of liquid silane-based anti-stripping additives on rheological properties of asphalt binder and hot mix asphalt moisture sensitivity. Road Mater. Pavement Des. 2020, 21, 570–585. [Google Scholar] [CrossRef]

- Wang, W.; Shen, A.; Yang, X.; Guo, Y.; Zhao, T. Surface free energy method for evaluating the effects of anti-stripping agents on the moisture damage to asphalt mixtures. J. Adhes. Sci. Technol. 2020, 34, 1947–1970. [Google Scholar] [CrossRef]

- Chaturabong, P.; Bahia, H.U. Effect of moisture on the cohesion of asphalt mastics and bonding with surface of aggregates. Road Mater. Pavement Des. 2018, 19, 741–753. [Google Scholar] [CrossRef]

- Ameli, A.; Norouzi, N.; Khabbaz, E.H.; Babagoli, R. Influence of anti stripping agents on performance of binders and asphalt mixtures containing Crumb Rubber and Styrene-Butadiene-Rubber. Constr. Build. Mater. 2020, 261, 119880. [Google Scholar] [CrossRef]

- Goli, H.; Latifi, M. Evaluation of the effect of moisture on behavior of warm mix asphalt (WMA) mixtures containing recycled asphalt pavement (RAP). Constr. Build. Mater. 2020, 247, 118526. [Google Scholar] [CrossRef]

- Song, W.; Huang, B.; Shu, X. Influence of warm-mix asphalt technology and rejuvenator on performance of asphalt mixtures containing 50% reclaimed asphalt pavement. J. Clean. Prod. 2018, 192, 191–198. [Google Scholar] [CrossRef]

- Abed, A.H.; Qasim, Z.I.; Al-Mosawe, H.; Norri, H.H. The effect of hybrid anti-stripping agent with polymer on the moisture resistance of hot-mix asphalt mixtures. Cogent Eng. 2019, 6, 1659125. [Google Scholar] [CrossRef]

- Mullapudi, R.S.; Karanam, G.D.; Kusam, S.R. Influence of chemical characteristics of RAP binders on the mechanical properties of binders and mixes. Int. J. Pavement Res. Technol. 2019, 12, 632–637. [Google Scholar] [CrossRef]

- Fernandes, S.R.M.; Silva, H.M.R.D.; Oliveira, J.R.M. Developing enhanced modified bitumens with waste engine oil products combined with polymers. Constr. Build. Mater. 2018, 160, 714–724. [Google Scholar] [CrossRef]

- Guo, M.; Liu, H.; Jiao, Y.; Mo, L.; Tan, Y.; Wang, D.; Liang, M. Effect of WMA-RAP technology on pavement performance of asphalt mixture: A state-of-the-art review. J. Clean. Prod. 2020, 266, 121704. [Google Scholar] [CrossRef]

- Li, H.; Zhang, F.; Feng, Z.; Li, W.; Zou, X. Study on waste engine oil and waste cooking oil on performance improvement of aged asphalt and application in reclaimed asphalt mixture. Constr. Build. Mater. 2021, 276, 122138. [Google Scholar] [CrossRef]

- Khani Sanij, H.; Afkhamy Meybodi, P.; Amiri Hormozaky, M.; Hosseini, S.H.; Olazar, M. Evaluation of performance and moisture sensitivity of glass-containing warm mix asphalt modified with zycothermTM as an anti-stripping additive. Constr. Build. Mater. 2019, 197, 185–194. [Google Scholar] [CrossRef]

- Eltwati, A.; Mohamed, A.; Hainin, M.R.; Jusli, E.; Enieb, M. Rejuvenation of aged asphalt binders by waste engine oil and SBS blend: Physical, chemical, and rheological properties of binders and mechanical evaluations of mixtures. Constr. Build. Mater. 2022, 346, 128441. [Google Scholar] [CrossRef]

- Baldi-Sevilla, A.; Montero, M.L.; Aguiar-Moya, J.P.; Loria-Salazar, L.G.; Bhasin, A. Influence of bitumen and aggregate polarity on interfacial adhesion. Road Mater. Pavement Des. 2017, 18, 304–317. [Google Scholar] [CrossRef]

- Cong, P.; Guo, X.; Ge, W. Effects of moisture on the bonding performance of asphalt-aggregate system. Constr. Build. Mater. 2021, 295, 123667. [Google Scholar] [CrossRef]

- Han, Y.; Jiang, J.; Ni, F.; Dong, Q.; Zhao, X. Effect of cohesive and adhesive parameters on the moisture resistance of thin friction course (TFC) with varying mix design parameters. Constr. Build. Mater. 2020, 258, 119420. [Google Scholar] [CrossRef]

- Syed, I.A.; Mannan, U.A.; Tarefder, R.A. Comparison of rut performance of asphalt concrete and binder containing warm mix additives. Int. J. Pavement Res. Technol. 2019, 12, 162–169. [Google Scholar] [CrossRef]

- Fakhri, M.; Hosseini, S.A. Laboratory evaluation of rutting and moisture damage resistance of glass fiber modified warm mix asphalt incorporating high RAP proportion. Constr. Build. Mater. 2017, 134, 626–640. [Google Scholar] [CrossRef]

- Omar, H.A.; Yusoff, N.I.M.; Mubaraki, M.; Ceylan, H. Effects of moisture damage on asphalt mixtures. J. Traffic Trans. Eng. (Engl. Ed.) 2020, 7, 600–628. [Google Scholar] [CrossRef]

- Chen, A.; Hu, Z.; Li, M.; Bai, T.; Xie, G.; Zhang, Y.; Li, Y.; Li, C. Investigation on the mechanism and performance of asphalt and its mixture regenerated by waste engine oil. Constr. Build. Mater. 2021, 313, 125411. [Google Scholar] [CrossRef]

- Fernandes, S.R.; Silva, H.M.; Oliveira, J.R. Recycled stone mastic asphalt mixtures incorporating high rates of waste materials. Constr. Build. Mater. 2018, 187, 1–13. [Google Scholar] [CrossRef]

- Ren, S.; Liu, X.; Fan, W.; Qian, C.; Nan, G.; Erkens, S. Investigating the effects of waste oil and styrene-butadiene rubber on restoring and improving the viscoelastic, compatibility, and aging properties of aged asphalt. Constr. Build. Mater. 2021, 269, 121338. [Google Scholar] [CrossRef]

- Zhang, Y.; Bahia, H.U. Effects of recycling agents (RAs) on rutting resistance and moisture susceptibility of mixtures with high RAP/RAS content. Constr. Build. Mater. 2021, 270, 121369. [Google Scholar] [CrossRef]

- Lv, Q.; Lu, J.; Tang, X.; Hu, Y.; Yan, C. Evaluation of the moisture resistance of rubberized asphalt using BBS/UTM bonding test, TSR and HWT test. Constr. Build. Mater. 2022, 340, 127831. [Google Scholar] [CrossRef]

- Zhang, J.; Huang, W.; Zhang, Y.; Yan, C.; Lv, Q.; Guan, W. Evaluation of the terminal blend crumb rubber/SBS composite modified asphalt. Constr. Build. Mater. 2021, 278, 122377. [Google Scholar] [CrossRef]

- Walubita, L.F.; Fuentes, L.; Prakoso, A.; Rico Pianeta, L.M.; Komba, J.J.; Naik, B. Correlating the HWTT laboratory test data to field rutting performance of in-service highway sections. Constr. Build. Mater. 2020, 236, 117552. [Google Scholar] [CrossRef]

- Doyle, J.D.; Howard, I.L. Rutting and moisture damage resistance of high reclaimed asphalt pavement warm mixed asphalt: Loaded wheel tracking vs. conventional methods. Road Mater. Pavement Des. 2013, 14, 148–172. [Google Scholar] [CrossRef]

- Padhan, R.K.; Mohanta, C.; Sreeram, A.; Gupta, A. Rheological evaluation of bitumen modified using antistripping additives synthesised from waste polyethylene terephthalate (PET). Int. J. Pavement Eng. 2020, 21, 1083–1091. [Google Scholar] [CrossRef]

| Property | Units | Base Binder | Aged Binder | Standard |

|---|---|---|---|---|

| Penetration (25 °C, 10 g, 5 s) | 0.1 mm | 67 | 20.1 | ASTM-D5 |

| Softening point (R&B) | °C | 50.5 | 66.80 | ASTM-D36 |

| Ductility (25 °C, 5 cm/mm) | cm | 117 | 9.30 | ASTM-D113 |

| Kinematic viscosity (135 °C) | Pa.s | 0.51 | 3.52 | ASTM-D4402 |

| Specific gravity | - | 1.02 | 1.10 | ASTM-D70 |

| Mixture ID | Type of Binder |

|---|---|

| HMA | Hot mix asphalt mixture containing virgin binder (VA) and aggregate |

| 30R | HMA containing 30% RAP |

| 30R+WEO | 12%WEO Rejuvenated HMA containing 30% RAP |

| WMA-30R-WEO | 12%WEO Rejuvenated HMA containing 30% RAP and 0.1% ZycoTherm |

| 60R | HMA containing 30% RAP |

| 60R+WEO | 12%WEO Rejuvenated HMA containing 60% RAP |

| WMA-60R-WEO | 12%WEO Rejuvenated HMA containing 60% RAP and 0.1% ZycoTherm |

| Mixture ID | Weight of Different Mixes’ Content (grams) | ||||

|---|---|---|---|---|---|

| RAP | Fresh Agg. | Fresh Bit. | WEO | ZycoTherm | |

| HMA | -- | 1140 | 60 | -- | -- |

| 30R | 360 | 798 | 42 | -- | -- |

| 30R+WEO | 360 | 798 | 42 | 2.16 | -- |

| WMA-30R-WEO | 360 | 798 | 42 | 2.16 | 0.06 |

| 60R | 720 | 456 | 24 | -- | -- |

| 60R+WEO | 720 | 456 | 24 | 4.32 | -- |

| WMA-60R-WEO | 720 | 456 | 24 | 4.32 | 0.06 |

| Mixture ID | Optimal Binder Content% | Mixes’ Properties | |||

|---|---|---|---|---|---|

| Air Voids in Total Volume% | Stability (kN) Min 8.83 kN | Flow (mm) (2–4 mm) | Marshall Quotient (kN/mm) (2.95–4.91) | ||

| Reference Mix | 5.0 | 4.00 | 15.49 | 3.50 | 4.43 |

| 30R | 5.0 | 4.10 | 24.05 | 3.25 | 7.40 |

| 30R+WEO | 5.0 | 4.14 | 16.15 | 3.95 | 4.09 |

| WMA-30R-WEO | 5.0 | 4.18 | 17.56 | 3.85 | 4.56 |

| 60R | 5.0 | 3.95 | 26.37 | 2.95 | 8.94 |

| 60R+WEO | 5.0 | 4.16 | 17.82 | 3.84 | 4.64 |

| WMA-60R-WEO | 5.0 | 4.20 | 18.23 | 3.79 | 4.81 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Eltwati, A.; Putra Jaya, R.; Mohamed, A.; Jusli, E.; Al-Saffar, Z.; Hainin, M.R.; Enieb, M. Effect of Warm Mix Asphalt (WMA) Antistripping Agent on Performance of Waste Engine Oil-Rejuvenated Asphalt Binders and Mixtures. Sustainability 2023, 15, 3807. https://doi.org/10.3390/su15043807

Eltwati A, Putra Jaya R, Mohamed A, Jusli E, Al-Saffar Z, Hainin MR, Enieb M. Effect of Warm Mix Asphalt (WMA) Antistripping Agent on Performance of Waste Engine Oil-Rejuvenated Asphalt Binders and Mixtures. Sustainability. 2023; 15(4):3807. https://doi.org/10.3390/su15043807

Chicago/Turabian StyleEltwati, Ahmed, Ramadhansyah Putra Jaya, Azman Mohamed, Euniza Jusli, Zaid Al-Saffar, Mohd Rosli Hainin, and Mahmoud Enieb. 2023. "Effect of Warm Mix Asphalt (WMA) Antistripping Agent on Performance of Waste Engine Oil-Rejuvenated Asphalt Binders and Mixtures" Sustainability 15, no. 4: 3807. https://doi.org/10.3390/su15043807

APA StyleEltwati, A., Putra Jaya, R., Mohamed, A., Jusli, E., Al-Saffar, Z., Hainin, M. R., & Enieb, M. (2023). Effect of Warm Mix Asphalt (WMA) Antistripping Agent on Performance of Waste Engine Oil-Rejuvenated Asphalt Binders and Mixtures. Sustainability, 15(4), 3807. https://doi.org/10.3390/su15043807