Polymer Banknotes: A Review of Materials, Design, and Printing

Abstract

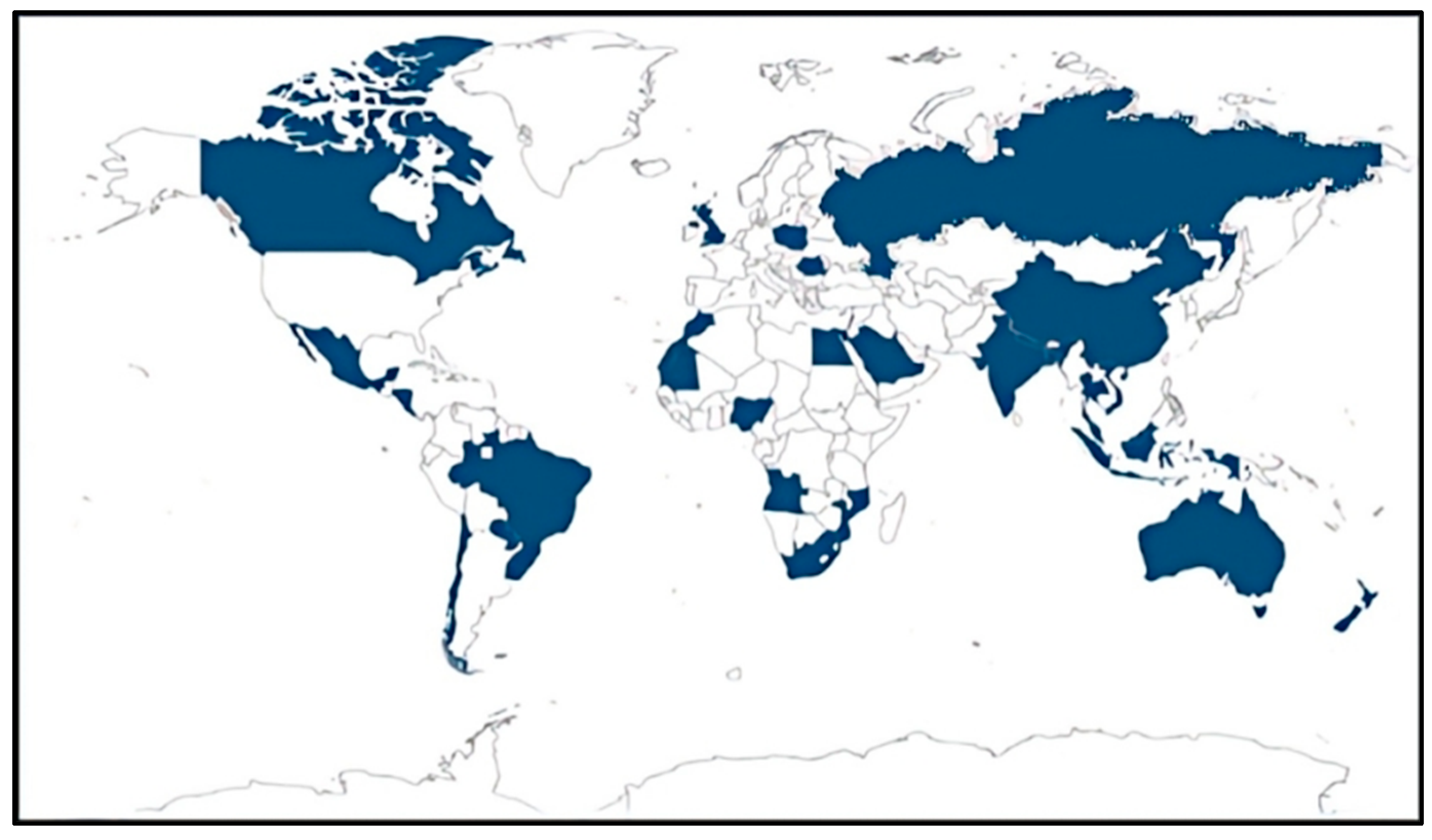

1. Introduction

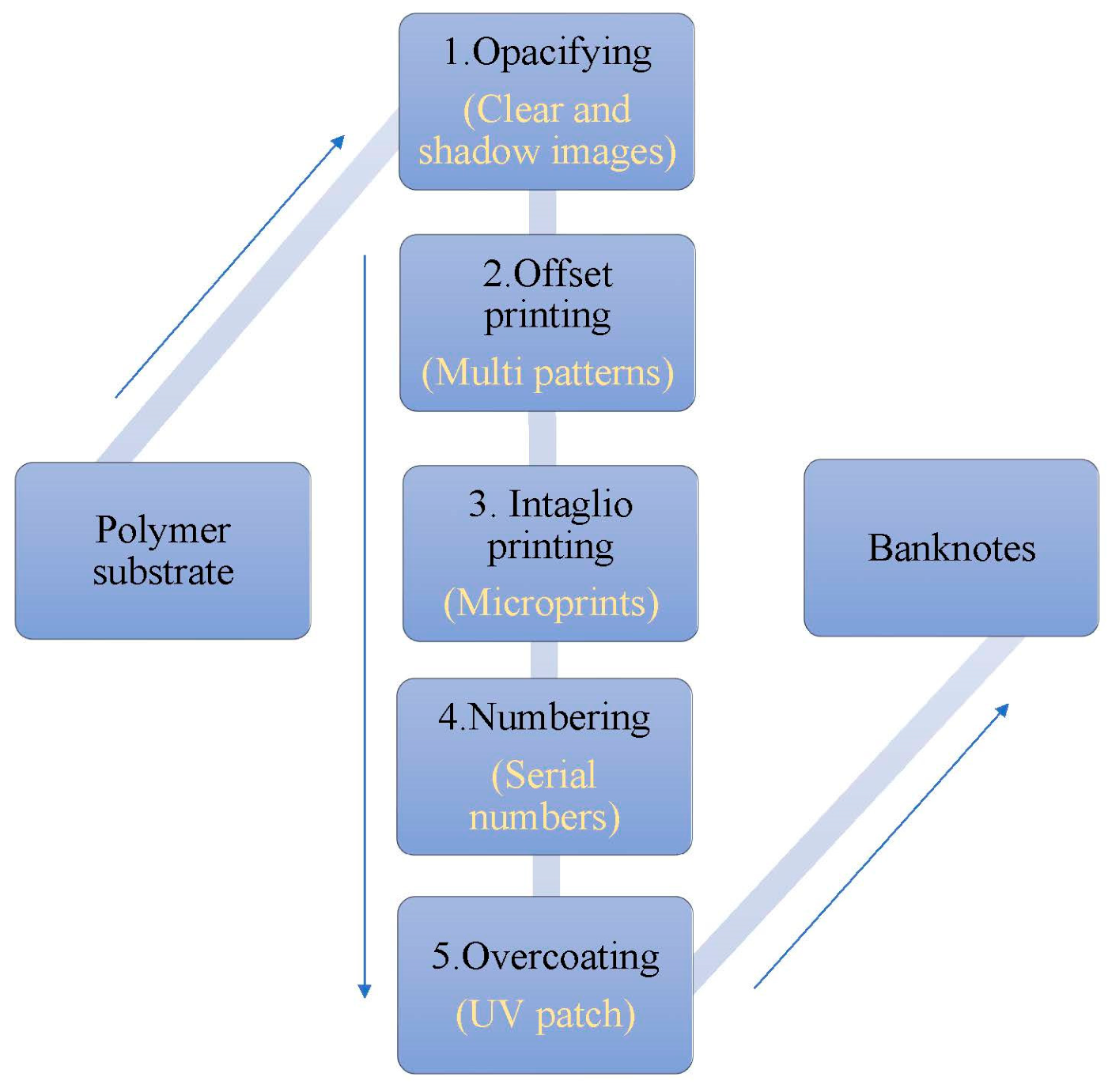

2. Materials in Polymer Banknotes

3. Polymer Banknotes Features

3.1. Transparency

3.2. Offset Printing

3.3. Numbering

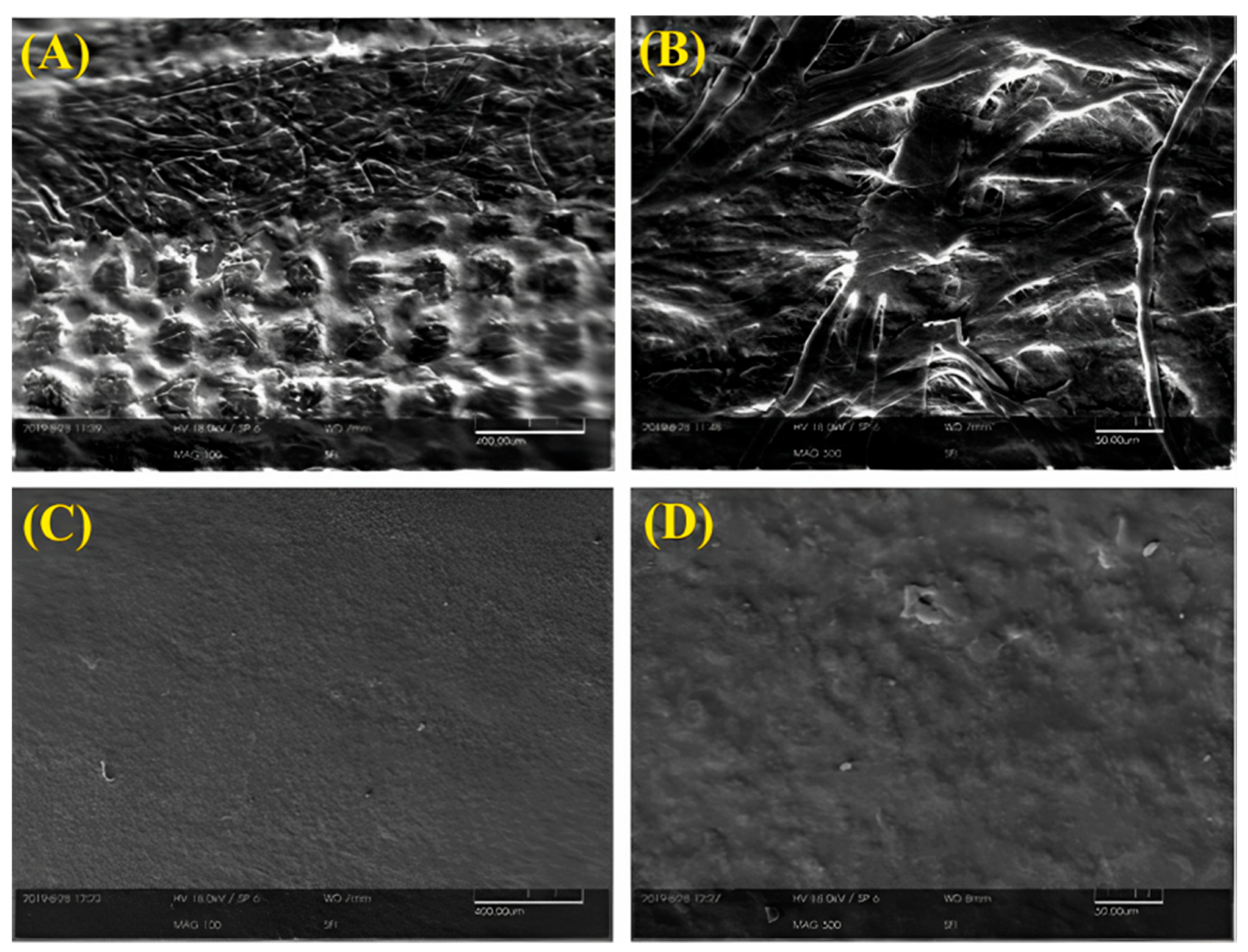

3.4. Coating

3.5. Final Banknotes

4. Design Requirements

4.1. Security

4.2. Cultural Representation

4.3. Accuracy

4.4. Banknote Equipment

4.5. Manufacturing

4.6. Accessibility

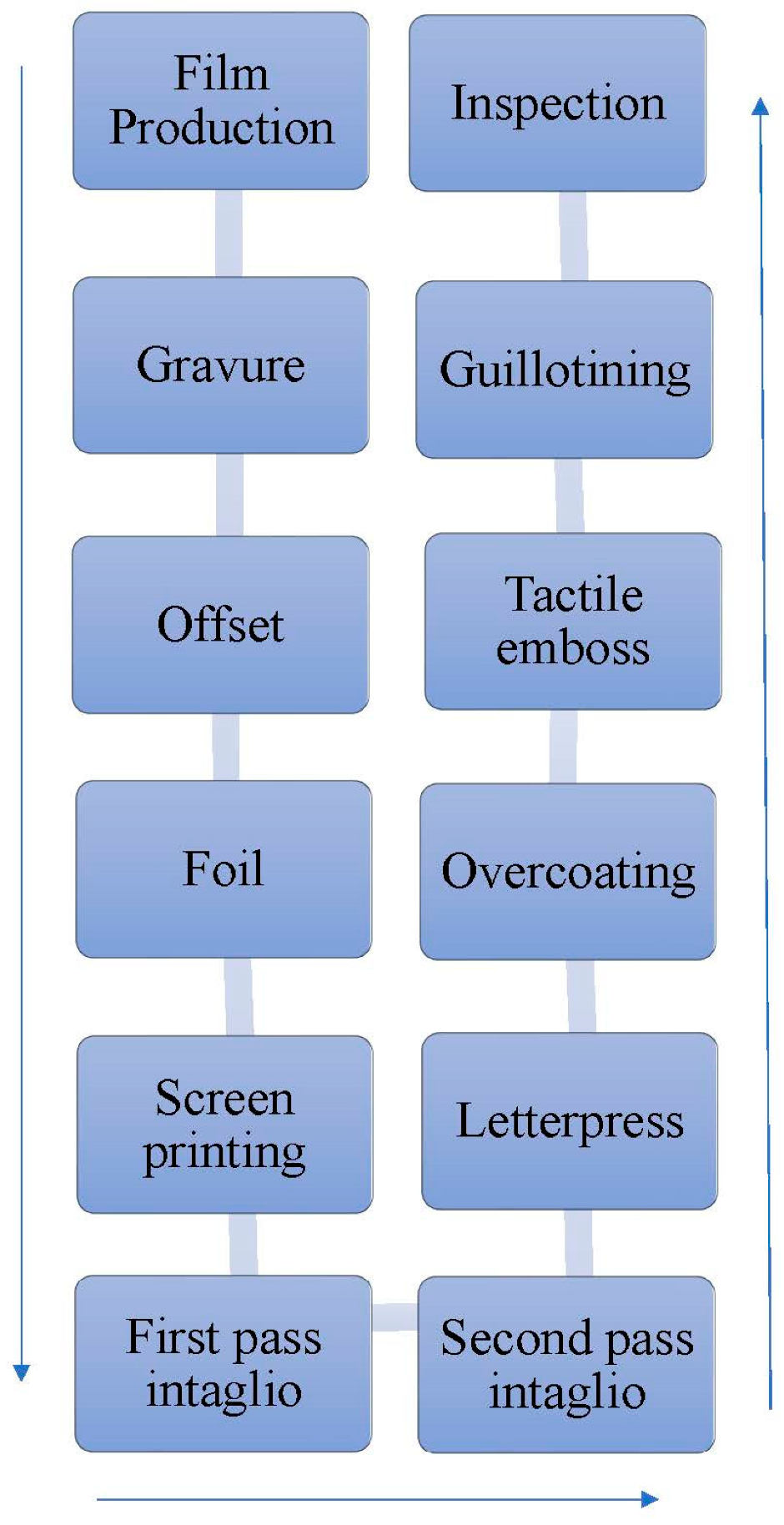

5. Production Stages

- I.

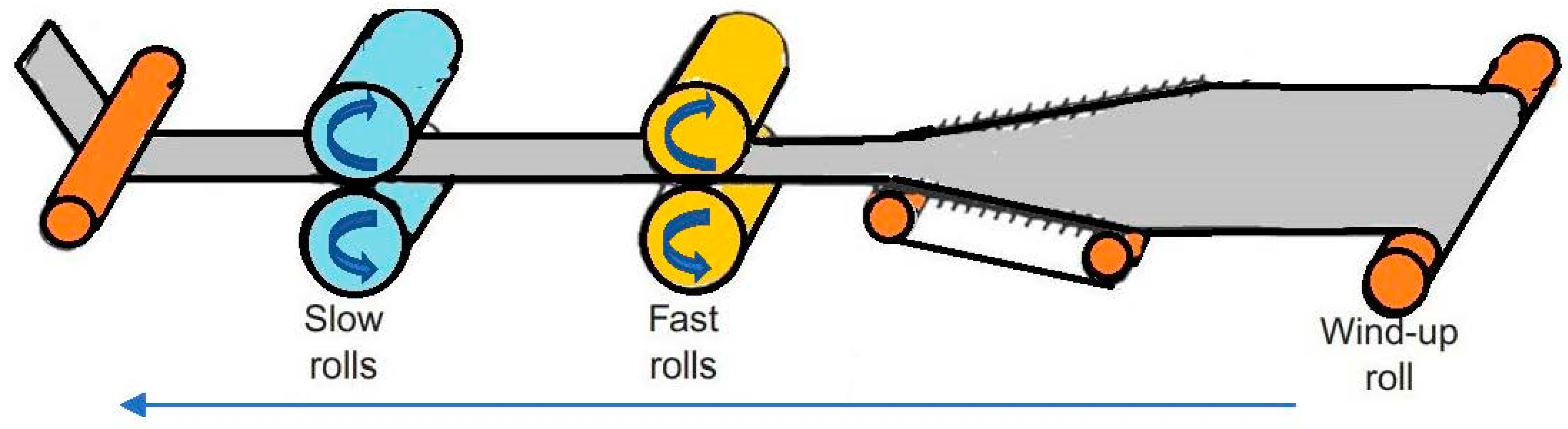

- Polymer substrate production: In the process of producing banknotes in Australia and New Zealand, transparent plastic beads are first melted and turned into a large bubble by the blowing process.

- II.

- Film production: Bubble walls are compressed together and cooled to form polyethylene multilayer polymer films [24].

- III.

- Inking: Special colors are used to create a matte film, except for the brown areas to create clear windows before they reach the sheet.

- IV.

- Offset: Background colors and patterns are printed on both sides of the polymer sheet simultaneously on the printing machine once. These machines can print up to 8000 sheets per hour.

- V.

- Foil: Multiple security features are applied in the top–down window as a continuous bar. This is the first unique method for new banknotes.

- VI.

- Screen printing: The effect of rotating color on a screen printing process using variable optical ink is applied in the second unique process [27].

- VII.

- The first stage of 3D printing: The main design elements, such as portraits and narrative elements, are printed using printing machines. In this process, the ink is transferred to high-pressure sheets in the form of engraved metal sheets.

- VIII.

- The second stage of 3D printing: Separate prints are required for each side of the sheet. An updated print result is an important feature of Australian cash. Some small and large features are also produced during this process.

- IX.

- Serial number: The serial number is added to the sheets by the printing process.

- X.

- Coating: A protective coating is used for the flexible printing process (flexography) in the form of banknotes. This coating helps the durability and cleanliness of the plastic cash.

- XI.

- Coating: The touch function is employed in the final printing process for a new generation of banknotes. The touch function was created to assist visually handicapped people in identifying different currencies. This number is composed of several numbers on the long edges of the alphabet adjacent to the top–down window.

- XII.

- Cutting: Printed sheets are cut individually.

- XIII.

6. Security Factor

6.1. Optical Membrane Security Assembly with Focused Sensors

6.2. Benefits of Using Sensors and Optical Membranes

6.3. Authentication and Security Warning Signs

6.4. Membrane Lasers

7. Effects of Polymer Banknotes

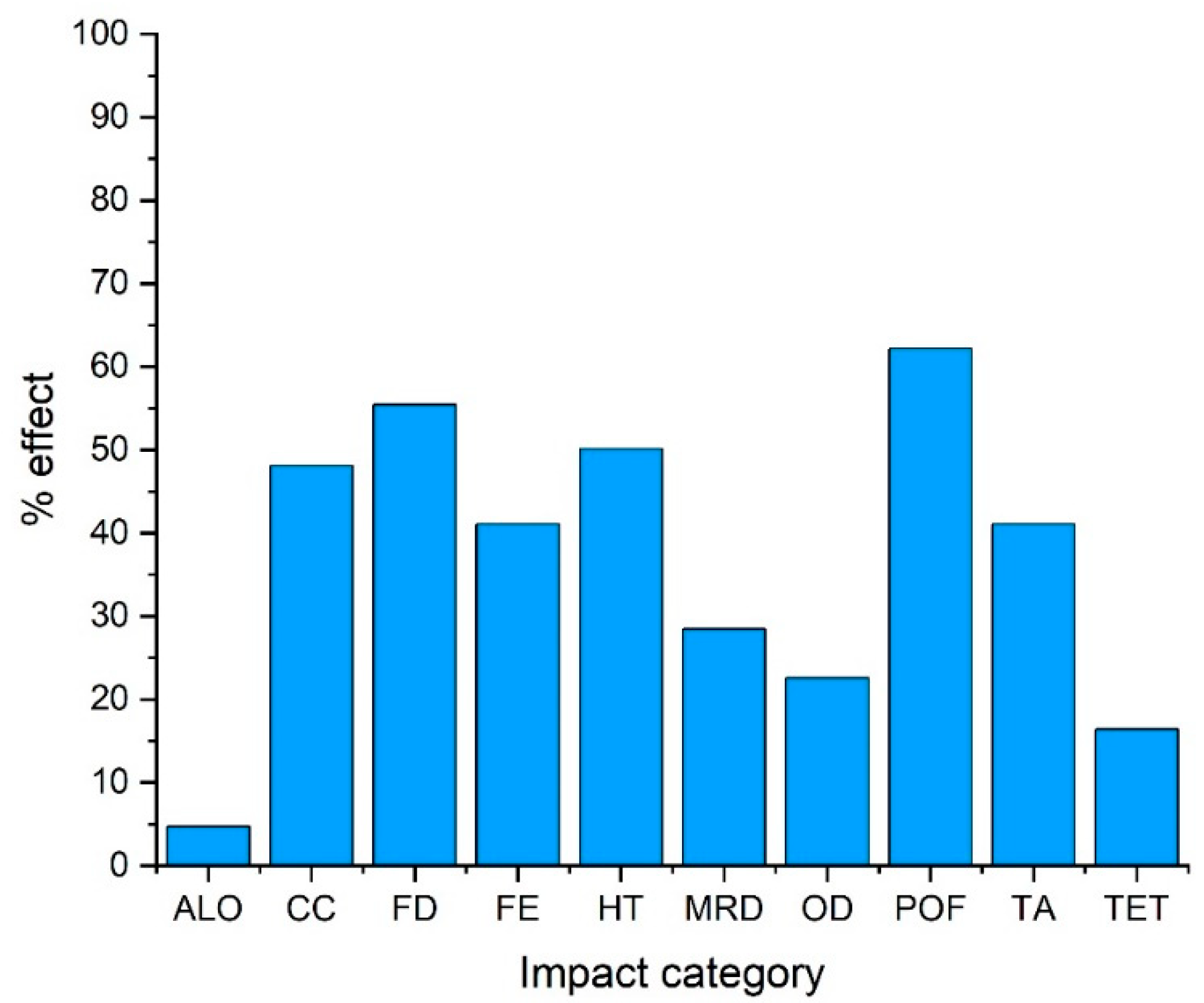

7.1. Environmental Effects

7.2. Effect on Customer Behaviour

8. Comparison between Paper-Based Banknotes and Polymer Banknotes Properties

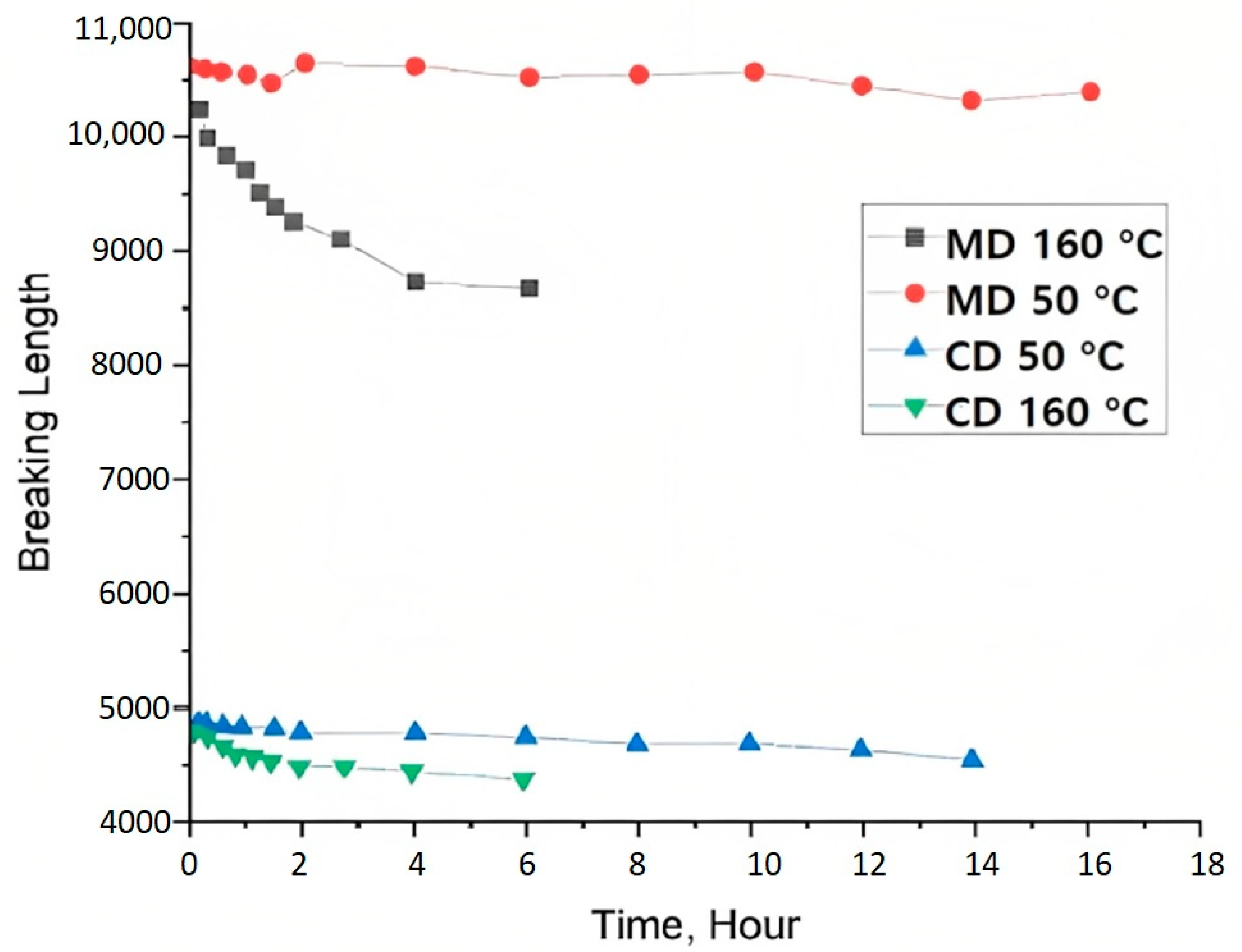

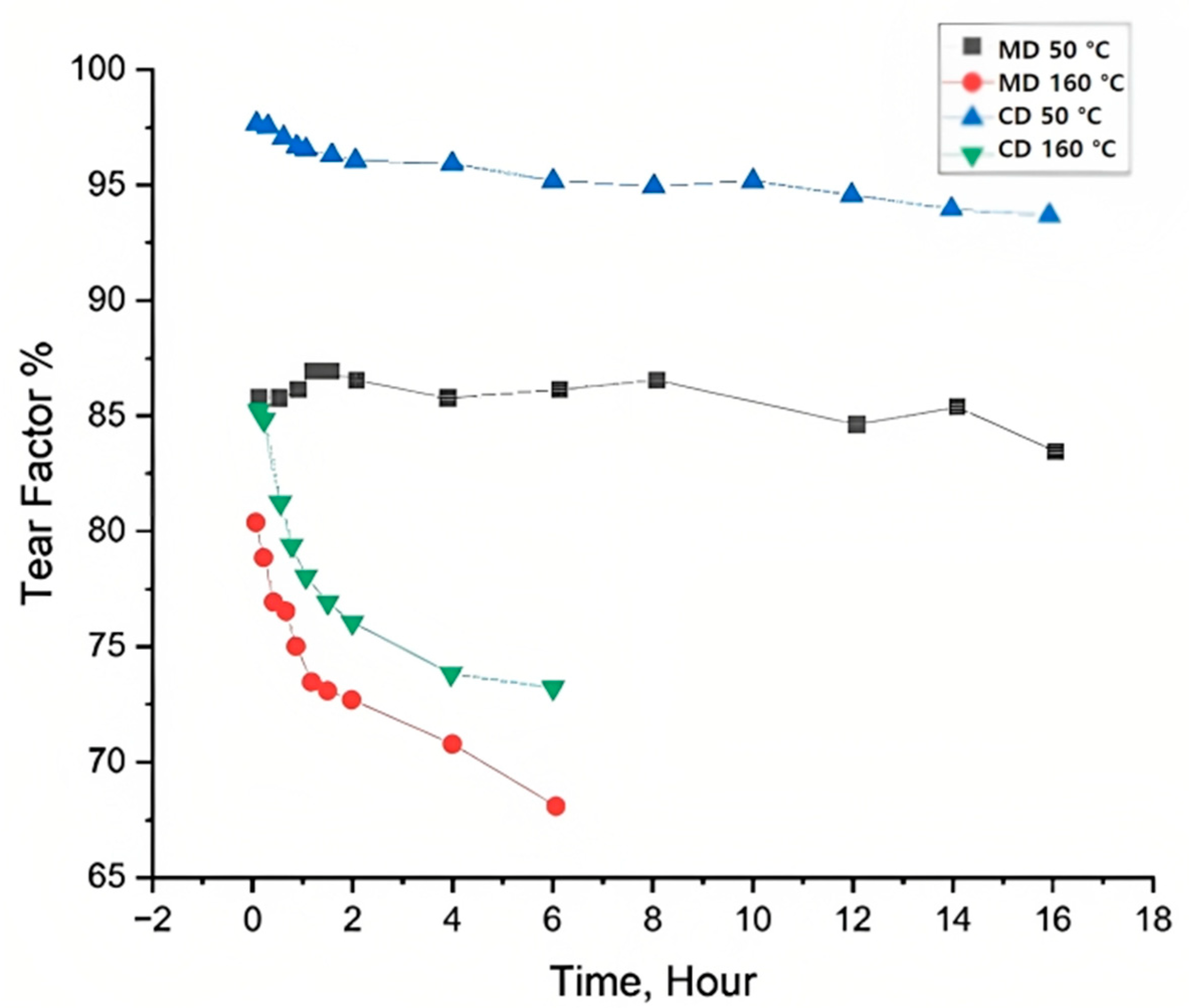

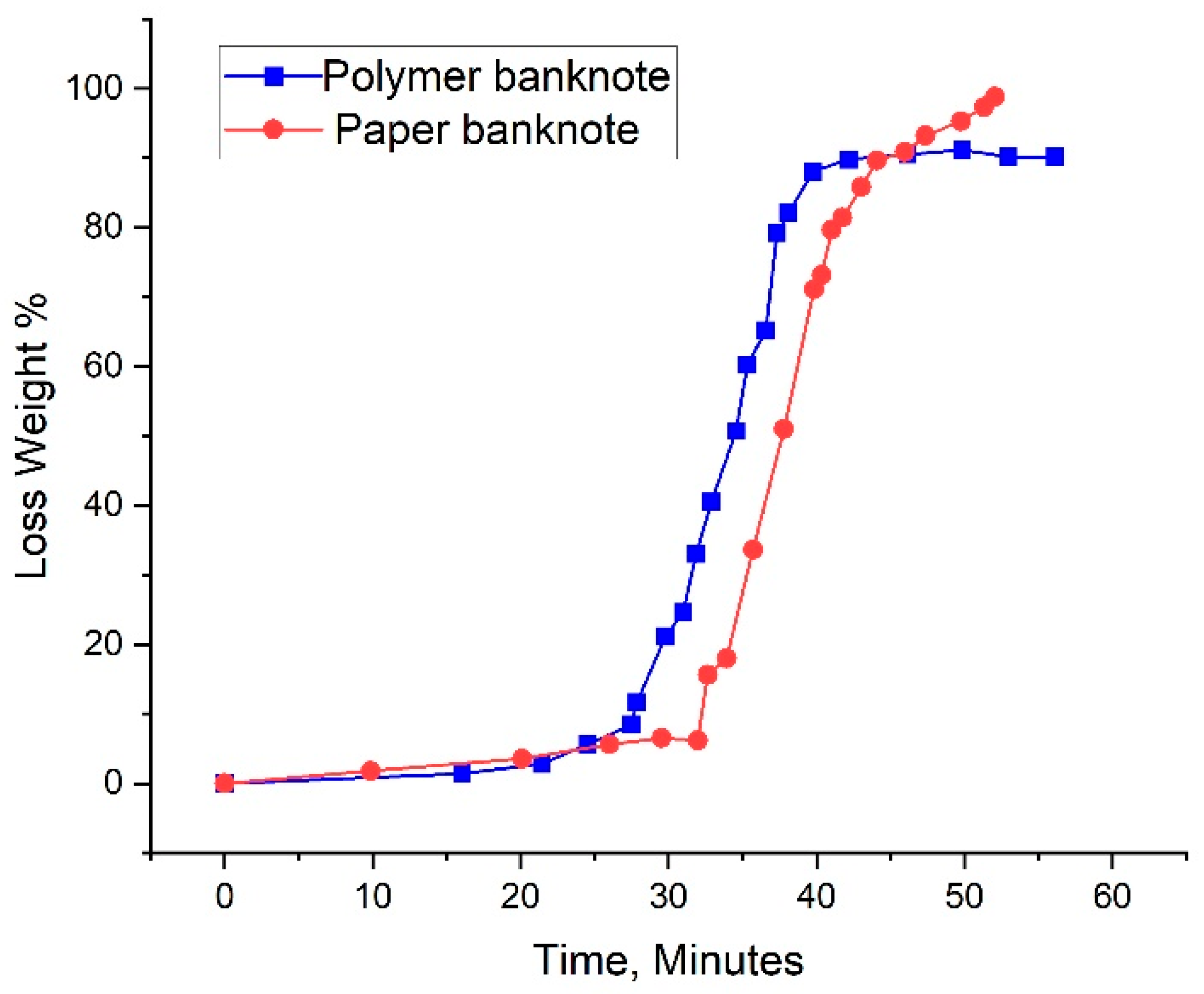

8.1. Ageing Effect on Mechanical and Thermal Behaviour

8.2. Breaking Length as a Mechanical Behaviour

8.3. Tear Factor as a Mechanical Behaviour

8.4. Thermal Stability of Paper and Synthesis Polymer Banknotes

8.5. Trace Evidence Dynamics of Cocaine

9. Conclusions

10. Suggestions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Solomon, D.; Spurling, T. The Plastic Banknote: From Concept to Reality; CSIRO Publishing: Melbourne, VIC, Australia, 2014; Available online: https://www.publish.csiro.au/book/6490 (accessed on 7 February 2023).

- Rogers, J.A.; Someya, T.; Huang, Y. Materials and Mechanics for Stretchable Electronics. Science 2010, 327, 1603–1607. [Google Scholar] [CrossRef] [PubMed]

- Available online: https://www.royaldutchkusters.com/blog/the-five-pros-and-cons-of-polymer-banknotes (accessed on 8 February 2023).

- Available online: https://www.rbnz.govt.nz/money-and-cash/banknotes/the-history-of-banknotes-in-new-zealand (accessed on 7 February 2023).

- Wilson, G.J. Australian polymer banknote: A review, Optical Security and Counterfeit Deterrence Techniques II. In Proceedings of the PHOTONICS WEST ‘98 ELECTRONIC IMAGING, San Jose, CA, USA, 24–30 January 1998. [Google Scholar] [CrossRef]

- Romanic, H.; Jackson, W.K. Australian Patent PCT/AU00/00629, 2000. Intaglio Contrast Effect The Intaglio Contrast Effect Works by Printing an Intaglio Design on Top of a Highly Reflective Metallic Patch. When the Intaglio Design Is Viewed at Different Angles the Colour Becomes Brighter and More enhancedwo2000076784a1—Security Document or Device Having an Intaglio Contrast Effect, Google Patents. Google. 2000. Available online: https://patents.google.com/patent/WO2000076784A1/en (accessed on 7 February 2023).

- Available online: https://en.wikipedia.org/wiki/Polymer_banknote (accessed on 7 February 2023).

- Spencer, C. Paying with Polymer: Developing Canada’s New Bank Notes, Bank of Canada Review, Spring. 2011, pp. 37–45. Available online: https://www.bankofcanada.ca/wp-content/uploads/2011/06/spencer.pdf (accessed on 7 February 2023).

- Han, T.-H.; Lee, Y.; Choi, M.-R.; Woo, S.; Bae, S.-H.; Hong, B.H.; Ahn, J.-H.; Lee, T.-W. Extremely efficient flexible organic light-emitting diodes with modified graphene anode. Nat. Photon 2012, 6, 105–110. [Google Scholar] [CrossRef]

- White, M.S.; Kaltenbrunner, M.; Głowacki, E.D.; Gutnichenko, K.; Kettlgruber, G.; Graz, I.; Aazou, S.; Ulbricht, C.; Egbe, D.A.M.; Miron, M.C.; et al. Ultrathin, highly flexible and stretchable PLEDs. Nat. Photon 2013, 7, 811–816. [Google Scholar] [CrossRef]

- Kaltenbrunner, M.; Sekitani, T.; Reeder, J.; Yokota, T.; Kuribara, K.; Tokuhara, T.; Drack, M.; Schwödiauer, R.; Graz, I.; Bauer-Gogonea, S.; et al. An ultra-lightweight design for imperceptible plastic electronics. Nature 2013, 499, 458–463. [Google Scholar] [CrossRef]

- International Monetary Fund Bosnia and Herzegovina: Financial Sector Assessment Program-Detailed Assessment of Observance of the CPMI-IOSCO Principles for Financial Market Infrastructures. IMF Staff. Ctry. Rep. 2015, 15, 1. [CrossRef]

- Xia, R.; Heliotis, G.; Bradley, D.D.C. Fluorene-based polymer gain media for solid-state laser emission across the full visible spectrum. Appl. Phys. Lett. 2003, 82, 3599–3601. [Google Scholar] [CrossRef]

- Available online: https://www.imf.org/external/pubs/ft/fandd/2016/06/pdf/currency.pdf (accessed on 7 February 2023).

- Hardwick, B.; Jackson, W.; Wilson, G.; Mau, A.W.H. Advanced Materials for Banknote Applications. Adv. Mater. 2001, 13, 980–984. [Google Scholar] [CrossRef]

- Bengiat, R.; Liptz, Y.; Rajs, N.; Bentolila, A.; Levin-Elad, M. Time is Money or Money is Time? A Rapid Operational Sequence for Detecting Fingermarks on Polymer Banknotes. J. Forensic Sci. 2020, 65, 1465–1473. [Google Scholar] [CrossRef]

- Vásquez-Garay, F.; Carrillo-Varela, I.; Vidal, C.; Reyes-Contreras, P.; Faccini, M.; Mendonça, R.T. A Review on the Lignin Biopolymer and Its Integration in the Elaboration of Sustainable Materials. Sustainability 2021, 13, 2697. [Google Scholar] [CrossRef]

- Jones, N.; Kelly, M.; Stoilovic, M.; Lennard, C.; Roux, C. The development of latent fingerprints on polymer banknotes. J. Forensic Identif. 2003, 53, 50–77. Available online: https://researchprofiles.canberra.edu.au/en/publications/the-development-of-latent-fingerprints-on-polymer-banknotes (accessed on 7 February 2023).

- Marabello, D.; Benzi, P.; Lombardozzi, A.; Strano, M. X-ray Powder Diffraction for Characterization of Raw Materials in Banknotes. J. Forensic Sci. 2017, 62, 962–970. [Google Scholar] [CrossRef] [PubMed]

- McClintock, R.; Whymark, R. Bank of England Notes: The Switch to Polymer, Bank of England Quarterly Bulletin, Q 1. 2016, pp. 23–32. Available online: https://www.bankofengland.co.uk/-/media/boe/files/quarterly-bulletin/2016/boe-notes-the-switch-to-polymer.pdf?la=enandhash=9F33836E77E82605F6CAF7E928E0BDBD70B734C3 (accessed on 7 February 2023).

- Scotcher, K.; Bradshaw, R. The analysis of latent fingermarks on polymer banknotes using MALDI-MS. Sci. Rep. 2018, 8, 1–13. [Google Scholar] [CrossRef] [PubMed]

- International Monetary Fund Report to the Executive Boards of the IMF and the World Bank on the New CPSS-IOSCO Principles for Financial Market Infrastructures. Policy Pap. 2012, 2012. [CrossRef]

- Karnutsch, C.; Pflumm, C.; Heliotis, G.; Demello, J.C.; Bradley, D.D.C.; Wang, J.; Weimann, T.; Haug, V.; Gartner, C.A.; Lemmer, U. Improved organic semiconductor lasers based on a mixed-order distributed feedback resonator design. Appl. Phys. Lett. 2007, 90, 131104. [Google Scholar] [CrossRef]

- Chen, Y.; Herrnsdorf, J.; Guilhabert, B.J.E.; Kanibolotsky, A.L.; Mackintosh, A.R.; Wang, Y.; Pethrick, R.A.; Gu, E.; Turnbull, G.A.; Skabara, P.J.; et al. Laser action in a surface-structured free-standing membrane based on a π-conjugated polymer-composite. Org. Electron. 2011, 12, 62–69. [Google Scholar] [CrossRef]

- Reserve Bank of New Zealand: Bulletin. Available online: https://www.rbnz.govt.nz/money-and-cash/banknotes (accessed on 7 February 2023).

- Available online: https://www.rbnz.govt.nz/hub/-/media/project/sites/rbnz/files/publications/bulletins/2014/2014dec77-7.pdf?sc_lang=en (accessed on 7 February 2023).

- Karl, M.; Whitworth, G.L.; Schubert, M.; Dietrich, C.P.; Samuel, I.D.W.; Turnbull, G.A.; Gather, M.C. Optofluidic distributed feedback lasers with evanescent pumping: Reduced threshold and angular dispersion analysis. Appl. Phys. Lett. 2016, 108, 261101. [Google Scholar] [CrossRef]

- Finger, N.; Schrenk, W.; Gornik, E. Analysis of TM-polarized DFB laser structures with metal surface gratings. IEEE J. Quantum Electron. 2000, 36, 780–786. [Google Scholar] [CrossRef]

- Amarasinghe, D.; Ruseckas, A.; Vasdekis, A.E.; Turnbull, G.A.; Samuel, I.D.W. High-Gain Broadband Solid-State Optical Amplifier using a Semiconducting Copolymer. Adv. Mater. 2009, 21, 107–110. [Google Scholar] [CrossRef]

- Singh, N. Polymer Banknotes—A Viable Alternative to Paper Banknotes. Asia Pac. Bus. Rev. 2008, 4, 42–50. [Google Scholar] [CrossRef]

- Delori, F.C.; Webb, R.H.; Sliney, D.H. Maximum permissible exposures for ocular safety (ANSI 2000), with emphasis on ophthalmic devices. J. Opt. Soc. Am. A 2007, 24, 1250–1265. [Google Scholar] [CrossRef]

- Available online: https://www.romania-insider.com/fingerprint-biggest-forger-plastic-banknotes (accessed on 7 February 2023).

- Nada, A.M.A.; El-Kady, A.; Simonian, M.; Basalah, G.; Ahmed Goher, R. Thermal Behavior of Natural and Synthetic Polymer Banknotes. First Arab International Conference of Forensic Science and Forensic Medicine. Arab J. Forensic Sci. Forensic Med. 2015, 1, 143–148. [Google Scholar]

- Karl, M.; Glackin, J.M.E.; Schubert, M.; Kronenberg, N.M.; Turnbull, G.A.; Samuel, I.D.W.; Gather, M.C. Flexible and ultra-lightweight polymer membrane lasers. Nat. Commun. 2018, 9, 1525. [Google Scholar] [CrossRef] [PubMed]

- Luján-Ornelas, C.; Sternenfels, U.M.D.C.; Güereca, L.P. Life cycle assessment of Mexican polymer and high-durability cotton paper banknotes. Sci. Total Environ. 2018, 630, 409–421. [Google Scholar] [CrossRef] [PubMed]

- Xanthos, M. Recycling of the #5 Polymer. Science 2012, 337, 700–702. [Google Scholar] [CrossRef]

- Orabi, M.M.A. Would Polymer Banknotes (Plastic Money) Influence Customer Intention to Buy? An Empirical Study from Jordan. J. Asian Financ. Econ. Bus. 2022, 9, 355–361. [Google Scholar] [CrossRef]

- Amaral, M.; Gibson, A.; Morgan, R. Trace evidence dynamics of cocaine on banknotes: A comparison study of paper and polymer banknotes. Sci. Justice 2022, 62, 221–228. [Google Scholar] [CrossRef]

- Tran, T.K.P. Unemployment and Shadow Economy in ASEAN Countries. J. Asian Financ. Econ. Bus. 2021, 8, 41–46. [Google Scholar] [CrossRef]

- Luong, T.T.H.; Nguyen, T.M.; Nguyen, T.A.N. Rule of Law, Economic Growth and Shadow Economy in Transition Countries. J. Asian Financ. Econ. Bus. 2020, 7, 145–154. [Google Scholar] [CrossRef]

- Duong, D.V.N.A.M.T.H. Shadow Economy, Corruption and Economic Growth: An Analysis of BRICS Countries. J. Asian Financ. Econ. Bus. 2021, 8, 665–672. [Google Scholar] [CrossRef]

| England | U.A.E | Canada | Australia | Vietnam |

| Egypt | Angola | Mexico | New Zealand | Romania |

| India | Albania | Sri Lanka | South Africa | Thailand |

| Islands | Chile | Nicaragua | Lebanon | Nicaragua |

| Israel | Brazil | Singapore | Uruguay | Northern Ireland |

| China | Philippine | Honduras | Guatemala | Indonesia |

| Solomon | Scotland | Nepal | Libya | Paraguay |

| Saudi Arabia | Haiti | Kuwait | Morocco | Namibia |

| Russia | Brunei | Poland | Nigeria | Maldives |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rafiei, A.; Karimi, A.; Bodaghi, M. Polymer Banknotes: A Review of Materials, Design, and Printing. Sustainability 2023, 15, 3736. https://doi.org/10.3390/su15043736

Rafiei A, Karimi A, Bodaghi M. Polymer Banknotes: A Review of Materials, Design, and Printing. Sustainability. 2023; 15(4):3736. https://doi.org/10.3390/su15043736

Chicago/Turabian StyleRafiei, Amirmohammad, Amirhossein Karimi, and Mahdi Bodaghi. 2023. "Polymer Banknotes: A Review of Materials, Design, and Printing" Sustainability 15, no. 4: 3736. https://doi.org/10.3390/su15043736

APA StyleRafiei, A., Karimi, A., & Bodaghi, M. (2023). Polymer Banknotes: A Review of Materials, Design, and Printing. Sustainability, 15(4), 3736. https://doi.org/10.3390/su15043736