Algae-Powered Buildings: A Review of an Innovative, Sustainable Approach in the Built Environment

Abstract

1. Introduction

2. Microalgae and Their Intervening Role in Buildings’ Design

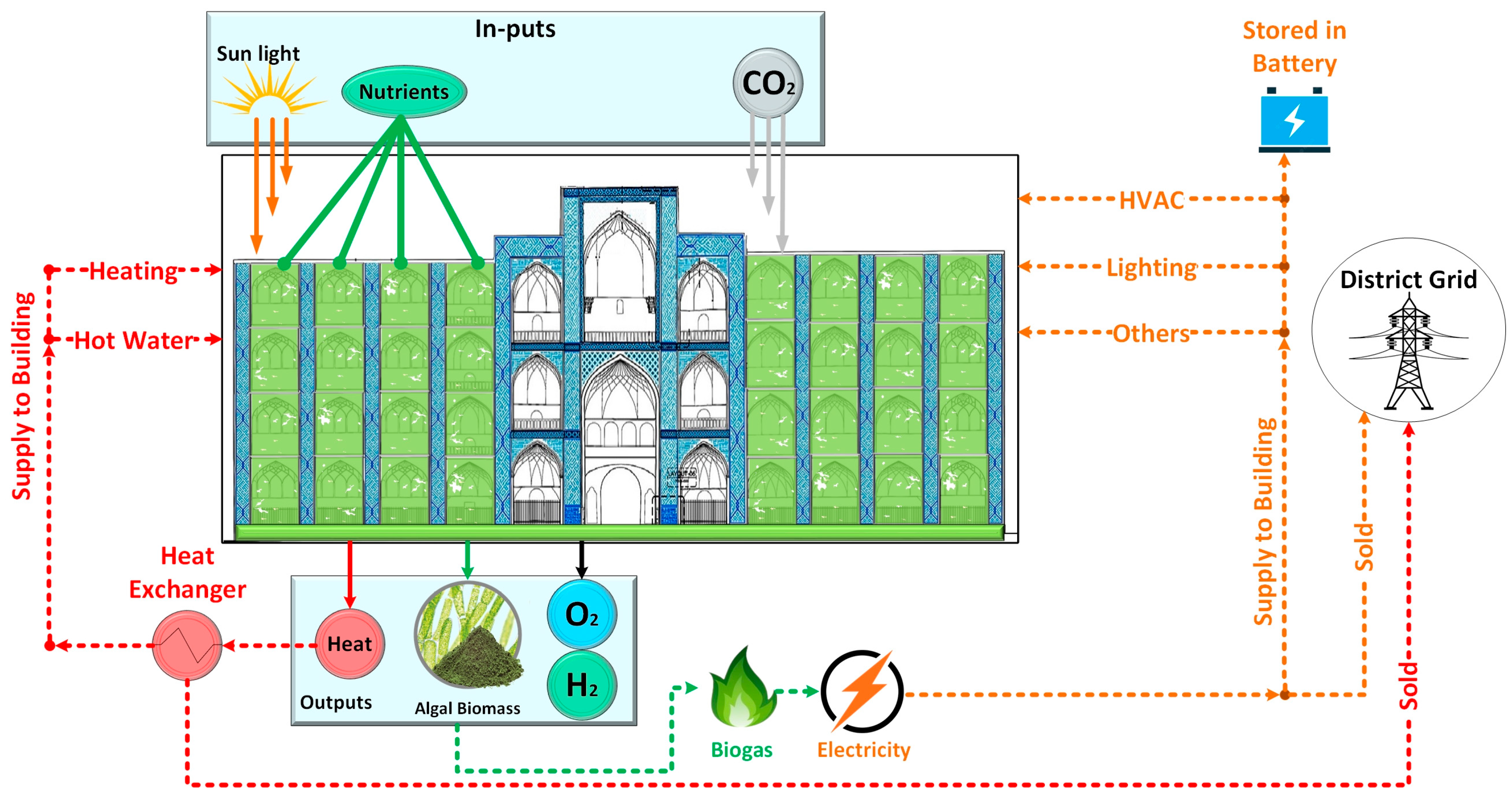

3. Façade-Integrated Algae

4. Algae-Powered Buildings: Energy Efficiency and Environmental Performance

| Recommended PBR Design Parameters | ||||||

|---|---|---|---|---|---|---|

| PBRs Type | Vertical Bubble Column | Vertical Airlift PBR | Flat Panels | Tubular PBR | Ref. | |

| Material | Glass, Low Density Polyethylene (LDPE), PVC, PMMA (poly methyl methacrylate) | Glass, LDPE, PVC, PMMA | Glass, Plexiglas, Polycarbonate, PVC, PMMA, Polyethylene, Plastic bags | Polypropylene acrylic, Polyvinylchloride, PVC, PMMA, LDPE | [74,75,76,77] | |

| PBR dimensions | Thickness/Diameter(D) | D < 20 cm | D < 20 cm | D < 7 cm | 5–9 cm | [42,76,78] |

| Height/length (H) | H < 4 m | H < 4 m | 1.5 m | 100–150 m | [42,76,78,79] | |

| Width | - | - | 10 cm | - | [78] | |

| Surface to volume ratio (S/V) | 2–8 m−1 | 2–8 m−1 | 20–80 m−1 | up to 100 m−1 | [38,77,79,80] | |

| Type of Mixing | Via gassing (Bubbling of CO2-enriched air) | Via gassing | Circulation flow, Peristaltic pumps and Via gassing | Circulation flow, Peristaltic pumps | [38,74,77,78] | |

| Oxygen mass transfer coefficient | High | High | Low | Low | [38] | |

| Risk of photo-inhibition | Low | Low | Medium | High | [38] | |

| Risk of self-shading of cells | Medium–High | Medium–High | Low (at thin panel thickness) | Low (at thin tube diameter) | [38] | |

| Risk of bio-fouling | Low | Low | High | High | [38] | |

| Investment costs | Low | Medium | Medium–High | Medium–High | [38] | |

| Space occupation | Low | Low | Medium | Medium | [38] | |

| O2 -release | Easy | Easy | Difficult | Very difficult | [38] | |

| Scalability | Difficult | Difficult | Very easy | Very easy | [38] | |

| Advantages | Compact, good mixing with low shear stress, low energy consumption, easy to sterilize, good for immobilization of algae, reduced photo-inhibition and photo-oxidation | Suitable for outdoor cultures, good light path, high biomass productivities, easy to clean up, low power consumption and shear stress, easy temperature control, low operating cost | Suitable for outdoor cultures, good biomass productivities, improvement of air residence time | [74,81] | ||

| Limitations | Construction requires sophisticated materials, stress to algal cultures, decrease of illumination surface area upon scale-up, high cleaning cost | Scale-up requires many compartments, difficulty in controlling culture temperature, some degree of wall growth, possibility of hydrodynamic stress to some algal strains | Gradients of pH, dissolved CO2 and O2 gradients, fouling, some degree of wall growth, photo limitation, high capital, and operating costs | [74,81] | ||

| Recommended Operational and Environmental Parameters | ||||||

| pH | Chlorella | 7.5–8 | [42,82,83] | |||

| Spirulina | 9 | [42,84] | ||||

| Chlorococcum | 8.0–8.5 | [42,81,84] | ||||

| Haematococcus | 7 | [42] | ||||

| Nutrients | Macro nutrients: | Phosphorus and Nitrogen | [82] | |||

| Trace metals: | Fe, Mg, B, Mo, K, Co, Zn, Mb | |||||

| Temperature | 20–30 °C | [42,81,82] | ||||

| Light intensity | 5000–10,000 Lux (100–200 μmol/(m2 × s)) | [42,82] | ||||

| Liquid velocity | 20–50 cm×s–1 | [42,81] | ||||

| Partial pressure of CO2 in gas phase | 0.2 kPa (0.076 mol × m–3) | [80,81] | ||||

| Aeration (bubble size) | 1–7 mm | [42] | ||||

5. Real-World Examples of ABT

6. Algae-Powered Buildings: Drivers and Barriers

7. The Future of PBR-Integrated Buildings

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ABT | Algae Building Technology |

| AQI | Air Quality Index |

| BIM | Building Information Modeling |

| BIQ | Bio-Intelligent Quotient |

| EUI | Energy Use Intensity |

| GHG | Green-House Gas |

| HVAC | Heating, Ventilation, and Air Conditioning |

| PBR | Photo Bio-Reactor |

| PH | Passive House |

| PV | Photovoltaic |

| ROI | Return on Investment |

| SD | System Dynamics |

| VOCs | Volatile Organic Compounds |

| WHO | World Health Organization |

| WWR | Window-to-Wall Ratio |

| ZEB | Zero Energy Building |

References

- REN21. Renewables 2014 Global Status Report; Renewable Energy Policy Network for the 21st Century: Paris, France, 2014; Available online: https://www.ren21.net/wp-content/uploads/2019/05/GSR2014_Full-Report_English.pdf (accessed on 25 December 2022).

- Lu, S.-M. A review of renewable energies in Taiwan. Int. J. Eng. Sci. Res. Technol. 2016, 5, 400–426. [Google Scholar] [CrossRef]

- Byadgi, S.A.; Kalburgi, P. Production of bioethanol from waste newspaper. Procedia Environ. Sci. 2016, 35, 555–562. [Google Scholar] [CrossRef]

- Rabbat, C.; Awad, S.; Villot, A.; Rollet, D.; Andrès, Y. Sustainability of biomass-based insulation materials in buildings: Current status in France, end-of-life projections and energy recovery potentials. Renew. Sustain. Energy Rev. 2022, 156, 111962. [Google Scholar] [CrossRef]

- Nastasi, B. Renewable energy generation and integration in Sustainable Buildings–a focus on eco-fuels. Sustain. Build. 2016, 1, 2. [Google Scholar] [CrossRef]

- Lund, H. The implementation of renewable energy systems. Lessons learned from the Danish case. Energy 2010, 35, 4003–4009. [Google Scholar] [CrossRef]

- IEA. Towards a Zero-Emission, Efficient, and Resilient Buildings and Construction Sector. Global Status Report 2017; International Energy Agency (IEA), UN Environment Programme: Paris, France, 2017; Available online: https://worldgbc.org/article/global-status-report-2017/ (accessed on 10 December 2022).

- Negev, E.; Yezioro, A.; Polikovsky, M.; Kribus, A.; Cory, J.; Shashua-Bar, L.; Golberg, A. Algae Window for reducing energy consumption of building structures in the Mediterranean city of Tel-Aviv, Israel. Energy Build. 2019, 204, 109460. [Google Scholar] [CrossRef]

- IEA. 2019 Global Status Report for Buildings and Construction: Towards a Zero-Emission; International Energy Agency (IEA), United Nations Environment Programme, Efficient and Resilient Buildings and Construction Sector: Nairobi, Kenya, 2019; Available online: https://wedocs.unep.org/handle/20.500.11822/30950 (accessed on 25 December 2022).

- UNEP. Buildings and Climate Change: Summary for Decision-Makers; United Nations Environment Programme; Paris, France. 2009. Available online: https://wedocs.unep.org/handle/20.500.11822/32152 (accessed on 25 December 2022).

- Yaman, Y.; Tokuç, A.; Sener, I.; Altunacar, N.; Köktürk, G.; Deniz, I.; Ezan, M. Energy Efficient Buildings with Algae. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2021; Volume 798, p. 012001. [Google Scholar] [CrossRef]

- Zeroenergyproject. What Are Zero Energy Homes? Available online: https://zeroenergyproject.com/buy/zero-energy-homes/ (accessed on 21 December 2022).

- Buildup. The BIQ House: First Algae Powered Building in the World; The European Portal for Energy Effciency in Buildings. 2015. Available online: http://www.buildup.eu/en/practices/cases/biq-house-first-algae-powered-building-world (accessed on 10 December 2022).

- Wilkinson, S.J.; Stoller, P. Algae Building Technology Energy Efficient Retrofit Potential in Sydney Housing. In International Conference on Sustainability in Energy and Buildings; Springer: Berlin/Heidelberg, Germany, 2018; pp. 311–321. [Google Scholar] [CrossRef]

- USGBC. LEED for New Construction and Major Renovation, Version 2.2; United States Green Building Council Institute: Washington, DC, USA, 2005. [Google Scholar]

- USGBC. LEED Reference Guide for Green Building Design and Construction; United States Green Building Council Institute: Washington, DC, USA, 2009. [Google Scholar]

- BREEAM. Sustainability Assessment Method. 2016. Available online: https://bregroup.com/products/breeam (accessed on 25 December 2022).

- Capeluto, I.G. The Unsustainable Direction of Green Building Codes: A Critical Look at the Future of Green Architecture. Buildings 2022, 12, 773. [Google Scholar] [CrossRef]

- Gilbert Gedeon, P. Climate Smart Brownfields Manual; The, U.S. Environmental Protection Agency (EPA): Washington, DC, USA, 2013. Available online: https://www.cedengineering.com/userfiles/Climate%20Smart%20Brownfields%20Manual%20R1.pdf (accessed on 10 December 2022).

- Wilkinson, S.; Biloria, N.; Ralph, P. The technical issues associated with algae building technology. Int. J. Build. Pathol. Adapt. 2020, 38, 673–688. [Google Scholar] [CrossRef]

- Rosillo-Calle, F.; De Groot, P.; Hemstock, S.L.; Woods, J. The Biomass Assessment Handbook: Energy for a Sustainable Environment; Routledge: Oxfordshire, UK, 2015. [Google Scholar] [CrossRef]

- L.E.K. Advanced Biofuels Study-Strategic Directions for Australia, Appendix Report. 2011. Available online: https://www.globalccsinstitute.com/archive/hub/publications/111552/advanced-biofuels-study-appendix.pdf (accessed on 21 December 2022).

- Araji, M.T.; Shahid, I. Symbiosis optimization of building envelopes and micro-algae photobioreactors. J. Build. Eng. 2018, 18, 58–65. [Google Scholar] [CrossRef]

- Pruvost, J.; Le Gouic, B.; Lepine, O.; Legrand, J.; Le Borgne, F. Microalgae culture in building-integrated photobioreactors: Biomass production modelling and energetic analysis. Chem. Eng. J. 2016, 284, 850–861. [Google Scholar] [CrossRef]

- Dincer, I.; Colpan, C.O.; Ezan, M.A. Environmentally-Benign Energy Solutions; Springer Nature: Berlin, Germany, 2019. [Google Scholar] [CrossRef]

- Perini, K.; Rosasco, P. Is greening the building envelope economically sustainable? An analysis to evaluate the advantages of economy of scope of vertical greening systems and green roofs. Urban For. Urban Green. 2016, 20, 328–337. [Google Scholar] [CrossRef]

- Perini, K.; Ottelé, M.; Fraaij, A.; Haas, E.; Raiteri, R. Vertical greening systems and the effect on air flow and temperature on the building envelope. Build. Environ. 2011, 46, 2287–2294. [Google Scholar] [CrossRef]

- Talaei, M.; Mahdavinejad, M.; Azari, R. Thermal and energy performance of algae bioreactive façades: A review. J. Build. Eng. 2020, 28, 101011. [Google Scholar] [CrossRef]

- Elrayies, G.M. Microalgae: Prospects for greener future buildings. Renew. Sustain. Energy Rev. 2018, 81, 1175–1191. [Google Scholar] [CrossRef]

- Oncel, S.S.; Şenyay Öncel, D. Bioactive façade system symbiosis as a key for eco-beneficial building element. In Environmentally-Benign Energy Solutions; Springer: Berlin/Heidelberg, Germany, 2020; pp. 97–122. [Google Scholar]

- Sayre, R. Microalgae: The potential for carbon capture. Bioscience 2010, 60, 722–727. [Google Scholar] [CrossRef]

- Meier, L.; Barros, P.; Torres, A.; Vilchez, C.; Jeison, D. Photosynthetic biogas upgrading using microalgae: Effect of light/dark photoperiod. Renew. Energy 2017, 106, 17–23. [Google Scholar] [CrossRef]

- Ashour, M.; Omran, A.M.M. Recent Advances in Marine Microalgae Production: Highlighting Human Health Products from Microalgae in View of the Coronavirus Pandemic (COVID-19). Fermentation 2022, 8, 466. [Google Scholar] [CrossRef]

- Ilvitskaya, S.; Chistyakova, A. Microalgae in architecture as an energy source. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; Volume 944, p. 012010. [Google Scholar] [CrossRef]

- Frederiksen, P.; Bogers, M. Editorial: Bio-energy landscapes. Biomass Bioenergy 2013, 55, 1–2. [Google Scholar] [CrossRef]

- Cervera Sardá, R.; Vicente, C.A. Case studies on the architectural integration of photobioreactors in building facades. In Nano and Biotech Based Materials for Energy Building Efficiency; Springer: Berlin/Heidelberg, Germany, 2016; pp. 457–484. [Google Scholar]

- Tredici, M.R.; Bassi, N.; Prussi, M.; Biondi, N.; Rodolfi, L.; Chini Zittelli, G.; Sampietro, G. Energy balance of algal biomass production in a 1-ha “Green Wall Panel” plant: How to produce algal biomass in a closed reactor achieving a high Net Energy Ratio. Appl. Energy 2015, 154, 1103–1111. [Google Scholar] [CrossRef]

- Koller, M. Design of Closed Photobioreactors for Algal Cultivation. In Algal Biorefineries: Volume 2: Products and Refinery Design; Prokop, A., Bajpai, R.K., Zappi, M.E., Eds.; Springer International Publishing: Berlin, Germany, 2015; pp. 133–186. [Google Scholar]

- Prokop, A.; Bajpai, R.K.; Zappi, M.E. Algal Biorefineries: Volume 2: Products and Refinery Design; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar] [CrossRef]

- Yulistyorini, A. A mini review on the integration of resource recovery from wastewater into sustainability of the green building through phycoremediation. In AIP Conference Proceedings; AIP Publishing LLC: Baltimore, MD, USA, 2017; Volume 1887, p. 020048. [Google Scholar] [CrossRef]

- Mahdavinejad, M.; Zia, A.; Larki, A.N.; Ghanavati, S.; Elmi, N. Dilemma of green and pseudo green architecture based on LEED norms in case of developing countries. Int. J. Sustain. Built Environ. 2014, 3, 235–246. [Google Scholar] [CrossRef]

- Kim, K.H. Microalgae Building Enclosures: Design and Engineering Principles; Routledge: Oxfordshire, UK, 2022. [Google Scholar] [CrossRef]

- Talaei, M.; Mahdavinejad, M.; Zarkesh, A.; Motevali Haghighi, H. A Review on Interaction of Innovative Building Envelope Technologies and Solar Energy Gain. Energy Procedia 2017, 141, 24–28. [Google Scholar] [CrossRef]

- Talaei, M.; Mahdavinejad, M.; Azari, R.; Haghighi, H.M.; Atashdast, A. Thermal and energy performance of a user-responsive microalgae bioreactive façade for climate adaptability. Sustain. Energy Technol. Assess. 2022, 52, 101894. [Google Scholar] [CrossRef]

- Hanafi, W.H.H. Bio-algae: A study of an interactive facade for commercial buildings in populated cities. J. Eng. Appl. Sci. 2021, 68, 37. [Google Scholar] [CrossRef]

- Schleicher, S. Bio-Inspired Compliant Mechanisms for Architectural Design: Transferring Bending and Folding Principles of Plant Leaves to Flexible Kinetic Structures; Universität Stuttgart: Stuttgart, Germany, 2015. [Google Scholar]

- Kim, T.-R.; Han, S.-H. Analysis for Energy Efficiency of the Algae Façade-Focused on Closed Bioreactor System. KIEAE J. 2014, 14, 15–21. [Google Scholar] [CrossRef]

- ArchDaily. Green Loop Tower—Infux Studio. 2011. Available online: https://www.archdaily.com/191229/algae-green-loop-influx-studio (accessed on 21 November 2022).

- Archinect. Process Zero: Ideas Competition for Metropolis Magazine|Sean E Williams. Available online: https://archinect.com/sewilliams/project/processzero-ideas-competition-for-metropolis-magazine (accessed on 15 November 2022).

- Benetton-Group. AlgaeBRA. Ecologicstudio. 2011. Available online: https://www.ecologicstudio.com/projects/algaebra (accessed on 14 November 2022).

- Dezeen. FSMA Tower Algae Kyscraper by Dave Edwards. 2012. Available online: https://www.dezeen.com/2012/08/01/fsma-tower-by-dave-edwards/ (accessed on 17 November 2022).

- Estudiodinamik. Alga Therapeia Research Center by Judit Aragonés Balboa. 2011. Available online: https://www.estudiodinamik.com/en/portfolio/alga-therapeia-centro-termal-donosti-pais-vasco/ (accessed on 15 November 2022).

- Internationale-Bauausstellung-Hamburg. Smart Material Houses, BIQ. 2013. Available online: https://www.internationale-bauausstellung-hamburg.de/en/projects/the-building-exhibition-within-the-building-exhibition/smart-material-houses/biq/projekt/biq.html (accessed on 16 November 2022).

- Öncel, S.; Köse, A.; Öncel, D. Façade integrated photobioreactors for building energy efficiency. In Start-Up Creation; Elsevier: Amsterdam, The Netherlands, 2016; pp. 237–299. [Google Scholar]

- XTUArchitects. In Vivo Tower in Paris—XTU Architects. 2016. Available online: https://www.xtuarchitects.com/alguesens-xtu (accessed on 19 November 2022).

- XTUArchitects. French Dream Tower—XTU Architects. 2018. Available online: https://www.xtuarchitects.com/xtu-les-concours#/french-dream-towers-hangzhou-china/ (accessed on 18 November 2022).

- Uooustudio. Algae Tower, Photo-Bio-Reactor Facade, Australia. 2020. Available online: https://uooustudio.com/algae-tower (accessed on 21 November 2022).

- Hasnan, M.T.I.M.T.; Zaharin, P.M.B. Exploration of Microalgae Photobioreactor (PBR) in Tropical Climate Building Envelope. Environ.-Behav. Proc. J. 2020, 5, 263–278. [Google Scholar] [CrossRef]

- Trombadore, A.; Paludi, B.; D’Ostuni, M. Adaptive Design of Green Facades and Vertical Farm: Examples of Technological Integration of Microalgae for Energy Production in Resilient Architecture. In the Importance of Greenery in Sustainable Buildings; Springer: Berlin/Heidelberg, Germany, 2022; pp. 273–294. [Google Scholar]

- Clarke, D.; Marlow, A. Mind the gaps: Passive House from the inside. Sanctuary Mod. Green Homes 2018, 1, 62–66. [Google Scholar]

- Passive-House-Institute. Passive House Requirements. 2015. Available online: https://passiv.de/en/02_informations/02_passive-house-requirements/02_passive-house-requirements.htm (accessed on 10 December 2022).

- Coltgroup. Solar-Leaf Bioreactor Façade. Available online: https://www.colt-info.de/Downloads.html?file=files/colt/pdf/sonnenschutz/colt-solarleaf-bioreactor-facade.pdf (accessed on 21 December 2022).

- Al Dakheel, J.; Tabet Aoul, K. Building Applications, Opportunities and Challenges of Active Shading Systems: A State-of-the-Art Review. Energies 2017, 10, 1672. [Google Scholar] [CrossRef]

- Biloria, N.; Thakkar, Y. Integrating algae building technology in the built environment: A cost and benefit perspective. Front. Archit. Res. 2020, 9, 370–384. [Google Scholar] [CrossRef]

- Shipeng, L.; Castro-Lacouture, D. Holistic Modeling of Microalgae for Powering Residential Communities. Energy Procedia 2016, 88, 788–793. [Google Scholar] [CrossRef]

- Chang, S.; Castro-Lacouture, D.; Dutt, F.; Yang, P.P.-J. Framework for evaluating and optimizing algae façades using closed-loop simulation analysis integrated with BIM. Energy Procedia 2017, 143, 237–244. [Google Scholar] [CrossRef]

- ASHRAE-Standards-Committee. Standard 90.1-2019. Energy Standard for Buildings Except Low-Rise Residential Buildings; ASHRAE: Atlanta, GA, USA, 2019. [Google Scholar]

- Umdu, E.S.; Kahraman, İ.; Yildirim, N.; Bilir, L. Optimization of microalgae panel bioreactor thermal transmission property for building façade applications. Energy Build. 2018, 175, 113–120. [Google Scholar] [CrossRef]

- Kim, K.-H. A feasibility study of an algae façade system. In Proceedings of International Conference on Sustainable Building Asia (SB13); Sustainable Building Research Center; Seoul, Republic of Korea, 2013; Volume 8. [Google Scholar]

- Martokusumo, W.; Koerniawan, M.D.; Poerbo, H.W.; Ardiani, N.A.; Krisanti, S.H. Algae and building façade revisited. a study of façade system for infill design. J. Archit. Urban. 2017, 41, 296–304. [Google Scholar] [CrossRef]

- Wilkinson, S.; Stoller, P.; Ralph, P.; Hamdorf, B. The Feasibility of Algae Building Technology in Sydney. In City of Sydney Environmental Performance Grant 2015; University of Technology Sydney: Ultimo, NSW, Australia, 2016. [Google Scholar] [CrossRef]

- Wong, J.K.W.; Zhou, J. Enhancing environmental sustainability over building life cycles through green BIM: A review. Autom. Constr. 2015, 57, 156–165. [Google Scholar] [CrossRef]

- Sterman, J. System Dynamics: Systems Thinking and Modeling for a Complex World. 2002. Available online: http://hdl.handle.net/1721.1/102741/ (accessed on 20 November 2022).

- Zhang, X. Microalgae Removal of CO2 from Flue Gas; IEA Clean Coal Centre: Paris, France, 2015; Available online: https://usea.org/sites/default/files/042015_Microalgae%20removal%20of%20CO2%20from%20flue%20gas_ccc250.pdf (accessed on 22 November 2022).

- Qiu, F. Algae Architecture. Delft University of Technology. 2014. Available online: http://resolver.tudelft.nl/uuid:b0b6e05d-49d8-4cc0-9e28-f510b0a8b215 (accessed on 22 November 2022).

- Hijazi, R.; Mounsef, J.R.; Kanaan, H.Y. Design Considerations for Photo-Bioreactors: A Review. In Proceedings of the 2020 5th International Conference on Renewable Energies for Developing Countries (REDEC), Marrakech, Morocco, 29–30 June 2020; pp. 1–7. [Google Scholar] [CrossRef]

- Acién, F.G.; Molina, E.; Reis, A.; Torzillo, G.; Zittelli, G.C.; Sepúlveda, C.; Masojídek, J. 1—Photobioreactors for the production of microalgae. In Microalgae-Based Biofuels and Bioproducts; Gonzalez-Fernandez, C., Muñoz, R., Eds.; Woodhead Publishing: Cambridge, UK, 2017; pp. 1–44. [Google Scholar]

- Acién Fernández, F.G.; Fernández Sevilla, J.M.; Molina Grima, E. Photobioreactors for the production of microalgae. Rev. Environ. Sci. Bio/Technol. 2013, 12, 131–151. [Google Scholar] [CrossRef]

- Sirohi, R.; Kumar Pandey, A.; Ranganathan, P.; Singh, S.; Udayan, A.; Kumar Awasthi, M.; Hoang, A.T.; Chilakamarry, C.R.; Kim, S.H.; Sim, S.J. Design and applications of photobioreactors- a review. Bioresour. Technol. 2022, 349, 126858. [Google Scholar] [CrossRef] [PubMed]

- Posten, C. Design principles of photo-bioreactors for cultivation of microalgae. Eng. Life Sci. 2009, 9, 165–177. [Google Scholar] [CrossRef]

- Huang, Q.; Jiang, F.; Wang, L.; Yang, C. Design of Photobioreactors for Mass Cultivation of Photosynthetic Organisms. Engineering 2017, 3, 318–329. [Google Scholar] [CrossRef]

- Ahmad, I.; Abdullah, N.; Koji, I.; Yuzir, A.; Eva Muhammad, S. Evolution of Photobioreactors: A Review based on Microalgal Perspective. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1142, 012004. [Google Scholar] [CrossRef]

- Malapascua, J.; Ranglová, K.; Masojídek, J. Photosynthesis and growth kinetics of Chlorella vulgaris R-117 cultured in an internally LED-illuminated photobioreactor. Photosynthetica 2019, 57, 103–112. [Google Scholar] [CrossRef]

- Ismaiel, M.M.S.; El-Ayouty, Y.M.; Piercey-Normore, M. Role of pH on antioxidants production by Spirulina (Arthrospira) platensis. Braz. J. Microbiol. 2016, 47, 298–304. [Google Scholar] [CrossRef]

- Zhang, X. Visit to World First Algal House at BIQ in Hamburg; International Centre for Sustainable Carbon: London, UK, 2014; Available online: https://www.sustainable-carbon.org/blogs/visit-to-world-first-algal-house-at-biq-in-hamburg/ (accessed on 10 December 2022).

- Arup. SolarLeaf, Hamburg. Worldwide First Façade System to Cultivate Micro-Algae to Generate Heat and Biomass as Renewable Energy Sources. 2015. Available online: https://www.arup.com/projects/solar-leaf (accessed on 10 December 2022).

- Arup. World’s First Microalgae Façade Goes ‘Live’, by Marina Miceli. 2013. Available online: https://www.arup.com/news-and-events/worlds-first-microalgae-facade-goes-live (accessed on 10 December 2022).

- Landers, J. German Building to Test Algae-Filled Facade as Source of Shade and Energy. Civ. Eng. Mag. Arch. 2013, 83, 36–37. [Google Scholar] [CrossRef]

- Pruvost, J.; Gouic, B.L.; Legrand, J. Symbiotic Integration of Photobioreactors In A Factory Building Façade for Mutual Benefit Between Buildings and Microalgae Needs. In 21st International Congress of Chemical and Process Engineering, CHISA 2014 and 17th Conference on Process Integration, Modelling and Optimisation for Energy Saving and Pollution Reduction, PRES 2014; CHISA: Prague, Czech Republic, 2014; Volume 4, p. 2184. [Google Scholar] [CrossRef]

- Ecologicstudio. PhotoSynthetica Curtain. 2019. Available online: https://www.ecologicstudio.com/projects/photo-synth-etica (accessed on 21 November 2022).

- Sayigh, A.; Trombadore, A. The Importance of Greenery in Sustainable Buildings; Springer: Berlin/Heidelberg, Germany, 2022. [Google Scholar] [CrossRef]

- Ecologicstudio. AirBubble. 2018. Available online: https://www.ecologicstudio.com/projects/airbubble-playground-and-exhibition (accessed on 22 November 2022).

- Kunjapur, A.M.; Eldridge, R.B. Photobioreactor design for commercial biofuel production from microalgae. Ind. Eng. Chem. Res. 2010, 49, 3516–3526. [Google Scholar] [CrossRef]

- Genin, S.N.; Aitchison, J.S.; Allen, D.G. Photobioreactor-Based Energy Sources. In Nano and Biotech Based Materials for Energy Building Efficiency; Pacheco Torgal, F., Buratti, C., Kalaiselvam, S., Granqvist, C.-G., Ivanov, V., Eds.; Springer International Publishing: Berlin, Germany, 2016; pp. 429–455. [Google Scholar]

- Chew, K.W.; Khoo, K.S.; Foo, H.T.; Chia, S.R.; Walvekar, R.; Lim, S.S. Algae utilization and its role in the development of green cities. Chemosphere 2021, 268, 129322. [Google Scholar] [CrossRef] [PubMed]

- Bell, S.G.; Codd, G.A. Cyanobacterial toxins and human health. Rev. Res. Med. Microbiol. 1994, 5, 256–264. [Google Scholar] [CrossRef]

| Project | Objective and Design Data | Ref. | |

|---|---|---|---|

| Green Loop Tower, 2011 Location: Chicago, Illinois, USA Designer(s): Influx Studio |  | The concept of this building aims to showcase algae potential connection with new emerging green technologies, to create a whole new CO2 scrubbing integrated system, contributing to clean polluted air, to create energy onsite, allow food and biofuel production, and ensure wastewater treatment. PBR type: Helical tube PBR Building type: Retrofitted building | [42,48,58] |

| Process Zero, 2011 Location: Los Angeles, California, USA Designer(s): Sean Williams |  | Process Zero is a renewable energy system that includes a thin photovoltaic façade system, rooftop photovoltaics, integrated solar thermal panels, and series of transparent tubular bioreactors growing microalgae. This collection of renewable energy systems offsets the energy consumption of the building and serves as an artificial tree, absorbing CO2 for energy generation and releasing oxygen. PBR type: Modular tube panel PBR PBR façade area: 25,000 ft2 Energy production: 14 kBTU/sf/year | [42,49,58] |

| Algae BRA, 2011 Location: Tehran, Iran Designer(s): Benetton Group |  | An innovative ecological project based on natural ecosystem processes and the traditional Iranian architecture which aims to conduct solar control and screening, passive ventilation, and ground cooling by using water as thermal storage and heat regulator, biomass production, and decarbonation. PBR type: Vertical tube PBR Building type: Retrofitted building | [42,50] |

| FSMA Tower, 2011 Location: London, England Designer(s): Dave Edwards |  | Mixed-use tower enclosed with bioreactors used for CO2 sequestration and improving air quality, with algae-absorbing CO2 emissions which are also harvested as bio-methane to provide heat and power. PBR type: Flat panel PBR Building type: New building PBR façade area: 21,100–44,000 m2 Absorbed CO2: 250,000 ton/year Produced biodiesel: 450 ton/year | [51] |

| Algae Therapeia, 2011 Location: Donostia, Spain Designer(s): Aragonés Balboa, J. |  | The concept of this design aims to establish a research center of marine algae, typical of the Basque coast, for medicinal, food, and industrial applications. A PBR skin generates the necessary energy for all building operations. PBR type: Tubular PBR Building type: New building | [42,52] |

| Urbanlab, 2012 Location: Paris La Défense, France Designer(s): Axel Schonert |  | A speculative building proposal enclosed with microalgae PBR focusing on transforming algae into biofuels, coupled with wastewater treatment. PBR type: Flat panel PBR Building type: New building PBR façade area: 100,000 ft2 Microalgae yield: 150 ton/year Produced biodiesel: 70 ton/year | [42] |

| In Vivo, 2016 Location: Paris, France Designer(s): XTU Architects |  | A speculative building integrating a microalgae-producing PBR bio-façade for medical research. The heat collected by the PBRs is used for domestic hot water and heating. PBR type: Flat panel PBR Building type: New building PBR area: 100,000 ft2 (932 m2) | [55,59] |

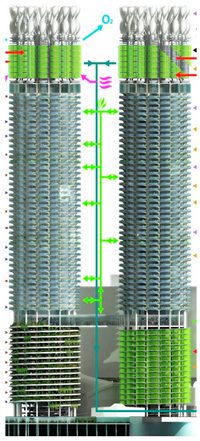

| French Dream Tower, 2018 Location: Hangzhou, China Designer(s): XTU Architects |  | The towers enclosed with PBRs for regulating solar energy and thermal insulation, acoustic insulation, and reducing the building’s carbon footprint by absorbing CO2 and releasing oxygen. PBR type: Flat panel PBR Building type: New building | [56,59] |

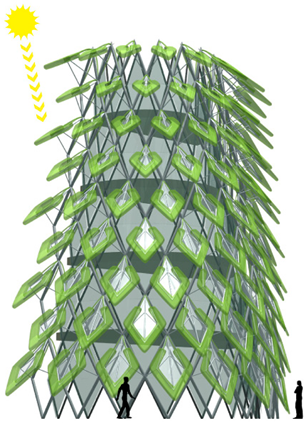

| Algae Tower, 2020 Location: Melbourne, Australia Designer(s): UOOU Studio |  | The façade system acts as a large-scale PBR transforming a classic façade shading system in an “artificial-leaves-canopy”. The canopy protects the building from direct solar radiation, generates energy, and absorbs CO2. PBR type: Artificial-leaves-canopy | [57] |

| Influencing Factor | Influential Factors |

|---|---|

| Thermal insulation | PBR material PBR size Building WWR Algae type Culture medium density |

| Shading | PBR size Orientation Surface to volume ratio Culture medium density |

| Biomass production | Regional climatic conditions Algae type Surface to volume ratio Inclination degree Orientation Material thickness Building aspect ratio |

| Project | Location | Year | Designer(s) | Objective | Data | Ref. | |

|---|---|---|---|---|---|---|---|

| BIQ Building | Hamburg, Germany | 2013 | Splitterwerk Architects | The first and most well-known actual enclosed PBR building that uses algal biomass to produce heat and energy, control light and provide shade, sequestrate carbon, and improve building energy savings. | PBR Type: Flat panel (24-L capacity) Number of PBR modules: 129 (2.5 × 0.7 m) PBR façade area: 2500 ft2 Sequestered CO2: 16 kg/day Biomass production: 30 kWh/m2/year Heat production: 150 kWh/m2/year Cost of PBR’s installation: USD 2300 to USD 3200 | [45,53,59,88] |

| CSTB prototype | Champs-sur-Marne, France | 2014 | XTU Architects | Microalgae curtain wall system that is integrated with PBRs with the aim of growing biomass, protecting the apartments from both sun and noise, carbon sequestration, and air quality improvement. | PBR type: Flat panel PBR PBR façade area: 200 m2 | [54] |

| SYMBIO2 | Nantes, France | 2014 | XTU Architects | The project aims to demonstrate the economic and technical feasibility of simultaneous microalgae production and flue gas partial treatment in a waste processing plant. | PBR type: Flat panel PBR PBR façade area: 300 m2 Biomass production: 0.7–1 ton/year Sequestered CO2: 1–1.8 ton/year | [36,89] |

| PhotoSynthetica | Dublin, Ireland | 2018 | ecoLogicStudio | The curtains capture CO2 from the atmosphere, store is via algae and transform into reusable biomass. | PBR type: Curtain module Sequestered CO2: 1 kg/day Number of PBR modules: 16 (2 × 7 m) | [90,91] |

| AirBubble | Warsaw, Poland | 2018 | ecoLogicStudio | The world’s first biotechnological playground integrated with air-purifying microalgae. The white bubbling noise of the algae gardening system masks the surrounding urban noise to provide a calming atmosphere in which to play and interact. | PBR type: Glass algae reactors Number of PBR modules: 52 Total volume of microalgae: 520 L Flow of polluted air: 200 L/min | [92] |

| Microalgae Ivy | Charlotte, NC, USA | 2021 | EcoClosure + UNC Charlotte | A full-scale prototype to retrofit low-performing window for biomass production and CO2 reduction. | Full-scale prototype dimension: (8 × 12 feet) Biomass production: 200 kg/year | [42] |

| Advantages | |

| ➢ | Energy savings due to promoting natural cooling process, improving thermal insulation capacity, transmitting natural light; inside the building, and providing shades; |

| ➢ | Capturing airborne pollutants and reducing noise; |

| ➢ | Reducing CO2 levels and enjoying the benefits of low-carbon economy; |

| ➢ | Providing aesthetic variation and creating visual interest; |

| ➢ | Production of biofuels and other high-value bio-products; |

| ➢ | Wastewater treatment. |

| Disadvantages | |

| ➢ | High costs; |

| ➢ | Health and safety concerns due to odors and toxins may produce by algae; |

| ➢ | Requiring highly efficient and specialized maintenance; |

| ➢ | Unknown durability of technology and long ROI; |

| ➢ | Guidelines needed; |

| ➢ | Technology complexity. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sedighi, M.; Pourmoghaddam Qhazvini, P.; Amidpour, M. Algae-Powered Buildings: A Review of an Innovative, Sustainable Approach in the Built Environment. Sustainability 2023, 15, 3729. https://doi.org/10.3390/su15043729

Sedighi M, Pourmoghaddam Qhazvini P, Amidpour M. Algae-Powered Buildings: A Review of an Innovative, Sustainable Approach in the Built Environment. Sustainability. 2023; 15(4):3729. https://doi.org/10.3390/su15043729

Chicago/Turabian StyleSedighi, Mahsa, Peiman Pourmoghaddam Qhazvini, and Majid Amidpour. 2023. "Algae-Powered Buildings: A Review of an Innovative, Sustainable Approach in the Built Environment" Sustainability 15, no. 4: 3729. https://doi.org/10.3390/su15043729

APA StyleSedighi, M., Pourmoghaddam Qhazvini, P., & Amidpour, M. (2023). Algae-Powered Buildings: A Review of an Innovative, Sustainable Approach in the Built Environment. Sustainability, 15(4), 3729. https://doi.org/10.3390/su15043729