Energy Efficiency Management in Small and Medium-Sized Enterprises: Current Situation, Case Studies and Best Practices

Abstract

1. Introduction

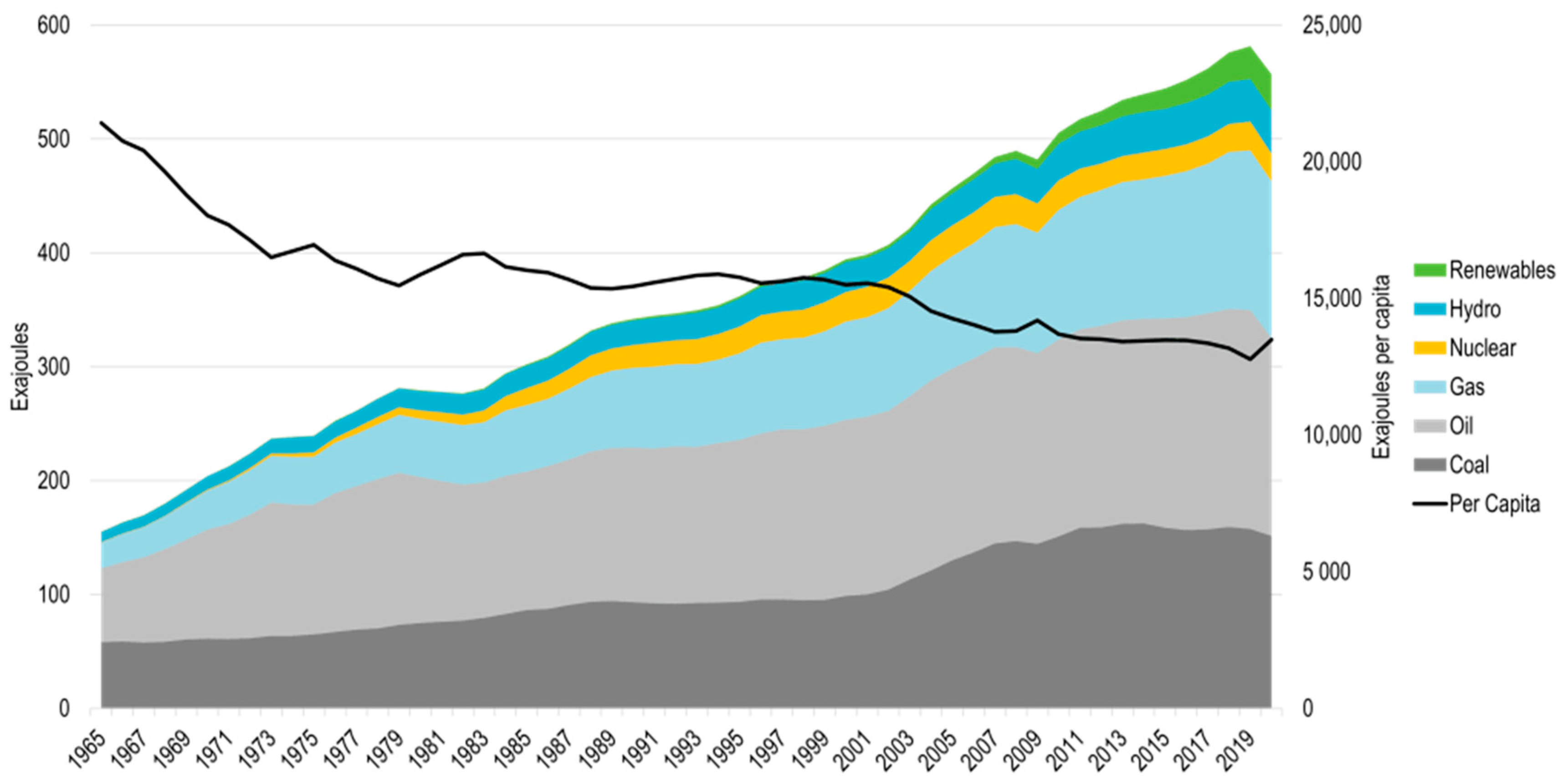

2. The Big Picture: The World Energy System

3. Energy Footprint as a Benchmarking Practice towards Energy Efficiency Targets

4. Energy Management in SMEs

- Measure energy consumption: A key component in identifying improvement opportunities is to perform a comprehensive energy analysis. The main parts of such an energy analysis include collecting energy consumption data of the equipment employed within the examined facility, as well as examining the most energy-intensive processes and operations so to be able to identify their energy consumption pattern and demand and evaluate their contribution to total energy usage. In this context, the installation of appropriate energy metering and monitoring equipment is crucial in order to track and set up the energy usage baseline of the examined facility.

- Fix the basics: Having carried out an energy audit or a similar energy analysis, organizations usually apply passive measures to improve their energy efficiency, such as implementing high-efficiency technologies and solutions for motors, lighting, and heating, as well as ventilation and air conditioning (HVAC) systems.

- Automate: Apart from taking passive energy efficiency measures, organizations should also adopt active energy management policies in order to further improve their energy efficiency performance and promote continuous energy efficiency enhancement and cost savings over time. A typical example of active energy management measures is the implementation of controllers, timers, sensors, etc. HVAC or lighting systems, for instance, are equipped with such automatic equipment in order to maintain room temperature at an optimum level or to turn on the lights of a room during working hours only or whenever the room is occupied.

- Monitor and control: In addition to the application of energy efficiency measures that help to manage energy-intensive operations and processes within the facility, employees’ awareness through training and information, as well as their commitment to a behavior driven by energy efficiency principles, is a decisive factor in the efforts of organizations to continuously improve their energy efficiency and reduce their operational cost. Policies that could definitely contribute to this direction are the installation of monitoring and control systems and the frequent conduction of energy audits and energy efficiency analysis, as well as the implementation of an appropriate and preferably custom-made Energy Management System (EMS).

5. Energy Consumption for Various SME Sectors

- Number of SMEs in each one the different sectors considered;

- Size of individual SMEs in the sector;

- Overall energy consumption in the sector;

- Corresponding energy efficiency;

- Potential for energy efficiency improvements in the sector.

6. Case Studies of SMEs That Improved Their Energy Efficiency

6.1. Chemicals Industry Sector

6.2. Food and Beverage Sector

6.3. Metal Manufacturing Industry Sector

6.4. Construction Sector

6.5. Miscellaneous Sectors

7. Best Practices for Energy Efficiency Improvement

7.1. Awareness of Energy Savings and Energy Efficiency Improvements

7.2. Measures Related to Operational Processes and Maintenance

- Maintenance activities should be carried out by specialized and experienced technical staff. There should be sufficient time to complete the relevant maintenance work according to relevant quality standards. Following a maintenance routine and a mid-term schedule is of outmost importance. In the case of replacement activities, the spare parts to be used should be the most modern and efficient ones.

- In the case of recurring plant failures, it should be ensured that the root causes are identified. For this purpose, experiments and tests should be conducted, and everyone must contribute to uncover them. It is very important to ensure that any root cause should be addressed effectively without causing another failure elsewhere in the facility.

- During the installation of new equipment or machinery, it must be ensured that all the relevant parts and components are installed properly following the guidelines of the manual(s) provided by the manufacturer. Additionally, the actual installation should be reviewed carefully before handover in order to ensure that it is as per design.

- Regarding equipment size, it should be ensured that equipment specifications meet the operational requirements and match the actual demand without excess capacity.

- Regarding equipment operation, it should be verified that the relevant machinery can be turned off easily and safely when it is not being used. Facility and equipment safety rules should be strictly followed. There should be safety valves and appropriate protective devices that “guarantee” the safety of the facility and the installed machinery. The ability to also restart the facility’s operation at short notice is very important for achieving improved energy efficiency.

- If there is a variety of available machines, one should choose to use the ones that exhibit the highest efficiency. It is evident, therefore, that production managers, supervisors, and/or staff should be aware and have good knowledge of the minimum, normal, and maximum operating conditions of all the available equipment.

- Production processes should be designed in such a way so as to minimize idle time of machinery. Moreover, there should be an effort to stop machines’ operation as soon as possible and start them as late as possible. Production processes should be carefully monitored and reviewed, aiming at identifying potential for efficiency improvement.

- It should be ensured that all thermal and electrical insulation is in good condition, minimizing heat losses and eliminating electricity leakages.

7.3. Measures Related to the Thermal Insulation of Buildings

- Windows present a common source of heat losses in buildings. For that reason, their frames should be regularly checked and maintained in good condition in order to ensure that they can be closed tightly and are draught-proof. Single-glazed windows should be replaced with double- or, if it is possible, with triple-glazed ones. The application of proper shading systems could also prevent building spaces from overheating.

- Like windows, doors could also be tested in order to ensure that they are draught-proof and can be closed tightly. The replacement of the existing doors with thicker ones and the implementation of self-closing mechanisms could also help to control the temperature of internal spaces consuming less energy.

- Walls and roofs should be regularly checked in order to spot existing gaps or holes which should be repaired/closed by applying appropriate filling materials. Additionally, dedicated audits could be carried out in order to explore the potential of reducing thermal losses through the application of proper thermal insulation.

7.4. Measures Related to the Heating and Cooling of Facilities

- Appropriate control systems that regulate room temperature should be employed. Office temperature, for instance, during winter months (heating operation) is recommended to be set to 19 °C. Obviously, it could be set lower than 19 °C in corridors, storerooms, and areas of higher physical activity. In the summer (cooling operation), the corresponding air temperature is recommended not be lower than 24 °C. Regarding cooling temperatures, there is an empirical rule according to which an increase in the set cooling air temperature by 1 °C will result in an increase in energy consumption on the order of 3% by the chiller.

- Cooling systems release/reject heat to the environment, namely to ambient air. It is evident, therefore, that in order for cooling systems to operate efficiently, they should have good and unobstructed access to ambient air. Thus, the positioning of cooling units with respect to existing furniture, equipment, and/or machinery is very important. Space restrictions and/or poor engineering judgment might result in positioning cooling units close to hot air exhausts or in a way that they have restricted ambient air flow, inevitably lowering the overall efficiency of the system. Facility space arrangement should cater to cooling systems to have unobstructed access to the coolest possible ambient air.

7.5. Measures Related to the Lighting of Facilities

- There are sensors and automatic devices that can identify human presence in a room/space of a building or a facility. Such devices could be deployed to turn on the lights of the corresponding room/space only when the room/space is occupied.

- There are standards and norms that specify the lighting level in a room/space according to the activity that is being carried out in the room/space. In order to achieve energy savings, overlamping should be avoided.

- All incandescent lightbulbs should be replaced by more energy-efficient LED lighting in order to save energy.

- It is often highlighted that company spaces do not exploit natural lighting to its full potential. Designing spaces in such a way so as to use natural light from windows and/or skylights at its maximum has almost no cost, mitigating at the same time electricity demand for artificial lighting. This is why objects that block windows, e.g., filing cabinets, should be relocated, while the space arrangement should always aim at maximizing the use of natural light, e.g., working desks should be positioned near windows.

7.6. Optimal Water Chemistry as a Measure for Energy Efficiency Improvement

7.7. Measures Related to Process Design and Energy Supply

7.8. Renewable Sources and Energy Storage

7.9. Combined Heat and Power (CHP)

7.10. Heat Recovery

7.11. Waste Heat to Power

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- A European Green Deal | European Commission. Available online: https://ec.europa.eu/info/strategy/priorities-2019-2024/european-green-deal_en (accessed on 23 September 2022).

- European Parliament. Council of the European Union Directive 2018/2002 Amending Directive 2012/27/EU on Energy Efficiency. Off. J. Eur. Union 2018, 328, 210–230. [Google Scholar]

- United Nations. The Paris Agreement; United Nations: New York, NY, USA, 2015. [Google Scholar]

- European Perliament. Council of the European Union Directive 2012/27/EU on Energy Efficiency. Off. J. Eur. Union 2012, 315, 1–56. [Google Scholar]

- European Commission 2030 Climate & Energy Framework. Available online: https://climate.ec.europa.eu/eu-action/climate-strategies-targets/2030-climate-energy-framework_en (accessed on 27 September 2022).

- European Commission Fit for 55—The EU’s Plan for a Green Transition. Available online: https://www.consilium.europa.eu/en/policies/green-deal/fit-for-55-the-eu-plan-for-a-green-transition/#what (accessed on 23 January 2023).

- European Commission REPowerEU. Available online: https://ec.europa.eu/commission/presscorner/detail/en/ip_22_3131 (accessed on 23 January 2023).

- European Commission European Industrial Strategy. Available online: https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/europe-fit-digital-age/european-industrial-strategy_en (accessed on 24 January 2023).

- European Commission. Powering a Climate-Neutral Economy: An EU Strategy for Energy System Integration; European Commission: Brussels, Belgium, 2020.

- Trianni, A.; Cagno, E. Dealing with Barriers to Energy Efficiency and SMEs: Some Empirical Evidences. Energy 2012, 37, 494–504. [Google Scholar] [CrossRef]

- Southernwood, J.; Papagiannis, G.K.; Güemes, E.L.; Sileni, L. Energy Efficiency Solutions for Small and Medium-Sized Enterprises. Proceedings 2021, 19, 5019. [Google Scholar] [CrossRef]

- Department of Energy & Climate Change. The Non-Domestic National Energy Efficiency Data-Framework: Energy Statistics 2006-12; Department of Energy & Climate Change: Landon, UK, 2015.

- Calogirou, C.; Sørensen, S.Y.; Larsen, P.B.; Pedersen, K.; Kristiansen, K.R.; Mogensen, J.; Alexopoulou, S.; Papageorgiou, M. SMEs and the Environment in the European Union; Publications Office of the European Union: Luxembourg, 2010. [Google Scholar]

- IEA. Accelerating Energy Efficiency in Small and Medium-Sized Enterprises: Powering SMEs to Catalyse Economic Growth. Policy Pathway. 2015. Available online: https://c2e2.unepccc.org/wp-content/uploads/sites/3/2016/03/sme-2015.pdf (accessed on 9 December 2022).

- Trianni, A.; Cagno, E.; Farné, S. Barriers, Drivers and Decision-Making Process for Industrial Energy Efficiency: A Broad Study among Manufacturing Small and Medium-Sized Enterprises. Appl. Energy 2016, 162, 1537–1551. [Google Scholar] [CrossRef]

- Lunt, P.; Ball, P.; Levers, A. Barriers to Industrial Energy Efficiency. Int. J. Energy Sect. Manag. 2014, 8, 380–394. [Google Scholar] [CrossRef]

- Rohdin, P.; Thollander, P.; Solding, P. Barriers to and Drivers for Energy Efficiency in the Swedish Foundry Industry. Energy Policy 2007, 35, 672–677. [Google Scholar] [CrossRef]

- Cagno, E.; Worrell, E.; Trianni, A.; Pugliese, G. A Novel Approach for Barriers to Industrial Energy Efficiency. Renew. Sustain. Energy Rev. 2013, 19, 290–308. [Google Scholar] [CrossRef]

- Thollander, P.; Ottosson, M. An Energy Efficient Swedish Pulp and Paper Industry—Exploring Barriers to and Driving Forces for Cost-Effective Energy Efficiency Investments. Energy Effic. 2008, 1, 21–34. [Google Scholar] [CrossRef]

- Thollander, P.; Backlund, S.; Trianni, A.; Cagno, E. Beyond Barriers—A Case Study on Driving Forces for Improved Energy Efficiency in the Foundry Industries in Finland, France, Germany, Italy, Poland, Spain, and Sweden. Appl. Energy 2013, 111, 636–643. [Google Scholar] [CrossRef]

- Trianni, A.; Cagno, E.; Farnè, S. An Empirical Investigation of Barriers, Drivers and Practices for Energy Efficiency in Primary Metals Manufacturing SMEs. Energy Procedia 2014, 61, 1252–1255. [Google Scholar] [CrossRef]

- Bagaini, A.; Colelli, F.; Croci, E.; Molteni, T. Assessing the Relevance of Barriers to Energy Efficiency Implementation in the Building and Transport Sectors in Eight European Countries. Electr. J. 2020, 33, 106820. [Google Scholar] [CrossRef]

- Palm, J.; Backman, F. Energy Efficiency in SMEs: Overcoming the Communication Barrier. Energy Effic. 2020, 13, 809–821. [Google Scholar] [CrossRef]

- Worrell, E.; Laitner, J.A.; Ruth, M.; Finman, H. Productivity Benefits of Industrial Energy Efficiency Measures. Energy 2003, 28, 1081–1098. [Google Scholar] [CrossRef]

- Wagner, C.; Obermeyer, M.; Lüchinger, R. A Methodology for the Assessment of Multiple Benefits of Industrial Energy Efficiency Measures. SN Appl. Sci. 2020, 2, 270. [Google Scholar] [CrossRef]

- Naik, S.; Mallur, S.B. The Benefits of Energy Efficiency in Small and Medium Enterprises. IOP Conf. Ser. Mater. Sci. Eng. 2018, 376. [Google Scholar] [CrossRef]

- UNECE. Guidelines and Best Practices for Micro-, Small and Medium Enterprises in Delivering Energy-Efficient Products and in Providing Renewable Energy Equipment in the Post-COVID-19 Recovery Phase; UNECE: Geneva, Switzerland, 2021. [Google Scholar]

- Fawcett, T.; Hampton, S. Why & How Energy Efficiency Policy Should Address SMEs. Energy Policy 2020, 140. [Google Scholar] [CrossRef]

- UK Department of Energy & Climate Change. SME Guide to Energy Efficiency; UK Department of Energy & Climate Change: London, UK, 2015.

- Fleiter, T.; Schleich, J.; Ravivanpong, P. Adoption of Energy-Efficiency Measures in SMEs-An Empirical Analysis Based on Energy Audit Data from Germany. Energy Policy 2012, 51, 863–875. [Google Scholar] [CrossRef]

- Fawkes, S.; Oung, K.; Thorpe, D. Best Practices and Case Studies for Industrial Energy Efficiency Improvement; UNEP DTU Partnership: Copenhagen, Denmark, 2016. [Google Scholar]

- European Environment Agency. Overview of the European Energy System—European Environment Agency; European Environment Agency: Copenhagen, Denmark, 2015. [Google Scholar]

- Rodrigue, J.-P. Transportation and Energy. In The Geography of Transport Systems; Rodrigue, J.-P., Ed.; Routledge: New York, NY, USA, 2020. [Google Scholar]

- Grubler, A.; Johansson, T.B.; Mundaca, L.; Nakicenovic, N.; Pachauri, S.; Riahi, K.; Rogner, H.-H.; Strupeit, L.; Kolp, P.; Krey, V.; et al. Energy Primer. In Global Energy Assessment (GEA); Cambridge University Press: Cambridge, UK, 2012; pp. 99–150. [Google Scholar]

- Lewis, Y.; Cohen, B. Chapter 7: Footprint Tools. In Assessing Progress Towards Sustainability: Frameworks, Tools and Case Studies; Teodosiu, C., Fiore, S., Hospido, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 129–130. ISBN 9780323897990. [Google Scholar]

- Ewing, B.; Goldfinger, S.; Oursler, A.; Reed, A.; Moore, D.; Wackernagel, M. Ecological Footprint Atlas 2009. Carbon 2009, 2010, 113. [Google Scholar]

- Energy Efficiency | Department of Energy. Available online: https://www.energy.gov/eere/energy-efficiency (accessed on 7 June 2022).

- OECD An Introduction to Energy Management Systems: Energy Savings and Increased Industrial Productivity for the Iron and Steel Sector. 2014, 1–34. Available online: https://www.oecd.org/sti/ind/DSTI-SU-SC(2014)14-FINAL-ENG.pdf (accessed on 26 January 2023).

- Tseng, Y.C.; Lee, D.S.; Lin, C.F.; Chang, C.Y. The Energy Savings and Environmental Benefits for Small and Medium Enterprises by Cloud Energy Management System. Sustainability 2016, 8, 531. [Google Scholar] [CrossRef]

- Cavicchi, C.; Oppi, C.; Vagnoni, E. Energy Management to Foster Circular Economy Business Model for Sustainable Development in an Agricultural SME. J. Clean. Prod. 2022, 368, 133188. [Google Scholar] [CrossRef]

- Kafel, P.; Nowicki, P. Circular Economy Implementation Based on ISO 14001 within SME Organization: How to Do It Best? Sustainability 2023, 15, 496. [Google Scholar] [CrossRef]

- Richert, M. An Energy Management Framework Tailor-Made for SMEs: Case Study of a German Car Company. J. Clean. Prod. 2017, 164, 221–229. [Google Scholar] [CrossRef]

- VDI. Gesellschaft Energie und Umwelt. In VDI 4602 Blatt 1—Energy Management—Fundamentals; VDI Verein Deutscher Ingenieure: Düsseldorf, Germany, 2018. [Google Scholar]

- Zhou, K.; Yang, S. 5.11 Smart Energy Management. In Comprehensive Energy Systems; Dincer, I., Ed.; Elsevier: Amsterdam, The Netherlands, 2018; Volume 5, pp. 423–456. ISBN 9780128095973. [Google Scholar]

- UNIDO What Is an Energy Management System? Available online: https://www.unido.org/stories/what-energy-management-system (accessed on 27 September 2022).

- ISO 50001; Energy Management System. ISO: Geneva, Swizerland, 2018.

- International Organization for Standardization ISO 50001:2018 Energy Management Systems—Requirements with Guidance for Use. Available online: https://www.iso.org/obp/ui/#iso:std:iso:50001:ed-2:v1:en (accessed on 27 September 2022).

- Hasan, A.S.M.M.; Trianni, A. A Review of Energy Management Assessment Models for Industrial Energy Efficiency. Energies 2020, 13, 5713. [Google Scholar] [CrossRef]

- U.S. Energy Information Administration. International Energy Outlook 2016; U.S. Energy Information Administration: Washington, DC, USA, 2016.

- Hampton, S.; Fawcett, T. Challenges of Designing and Delivering Effective SME Energy Policy. In Proceedings of the ECEEE Summer Study 2017 proceedings, Belambra Les Criques, Toulon/Hyères, France, 29 May–3 June 2017; pp. 189–199. [Google Scholar]

- Parpairi, K. Sustainability and Energy Use in Small Scale Greek Hotels: Energy Saving Strategiesand Environmental Policies. Procedia Environ. Sci. 2017, 38, 169–177. [Google Scholar] [CrossRef]

- De Bruyn, S.; Jongsma, C.; Kampman, B.; Görlach, B.; Thie, J. Energy-Intensive Industries: Challenges and Opportunities in Energy Transition; Policy Department for Economic, Scientific and Quality of Life Policies: Luxembourg, 2020. [Google Scholar]

- Fluch, J.; Brunner, C.; Grubbauer, A. Potential for Energy Efficiency Measures and Integration of Renewable Energy in the European Food and Beverage Industry Based on the Results of Implemented Projects. Energy Procedia 2017, 123, 148–155. [Google Scholar] [CrossRef]

- Constructing Excellence in the Built Evironment Constructing Excellence: The SME’ s Quick Guide to Sustainability. 2013. Available online: http://constructingexcellence.org.uk/wp-content/uploads/2014/12/SME-Guide.pdf (accessed on 26 November 2022).

- Reuter, S.; Lackner, P.; Brandl, G. Mapping SMEs in Europe. Data Collection, Analysis and Methodologies for Estimating Energy Consumptions at Country Levels. LEAP4SME Proj. D2.1. 2021. Available online: https://leap4sme.eu/wp-content/uploads/2021/07/LEAP4SME-D2.1-SME-energy-and-economic-mapping-in-Europe.pdf (accessed on 26 November 2022).

- Jabanda, R.; D’Angelo, G.; Cotrone, C.; Kyriakou, A.; Tamiakis, I.; Tinfavičienė, I.; Junevičius, G.; Nagulevičius, E.; Bacevičius, P.; Bogheanu, M.; et al. RECREATE—REinforce Competitiveness of REgionAl Transport SMEs: Transport SME Competitiveness Report. 2020. Available online: https://projects2014-2020.interregeurope.eu/fileadmin/user_upload/tx_tevprojects/library/file_1631286278.pdf (accessed on 23 November 2022).

- Bröckl, M.; Illman, J.; Oja, L.; Vehviläinen, I. Gaia Consulting Ltd. Energy Efficiency in Small and Medium Sized Enterprises; Nordic Council of Ministers: Copenhagen, Denmark, 2014. [Google Scholar]

- Eurostat Annual Enterprise Statistics for Special Aggregates of Activities. Available online: https://appsso.eurostat.ec.europa.eu/nui/show.do?dataset=sbs_na_sca_r2&lang=en (accessed on 29 September 2022).

- Eurostat Eurostat—Complete Energy Balances. Available online: https://appsso.eurostat.ec.europa.eu/nui/show.do?dataset=nrg_bal_c (accessed on 29 September 2022).

- Green Revolution—Medium-Sized Companies Show the Way. Lessons from Two Spanish Companies in the Chemical Industry. Available online: https://ee-ip.org/en/article/green-revolution-medium-sized-companies-show-the-way-lessons-from-two-spanish-companies-in-the-chemical-industry-5777 (accessed on 3 June 2022).

- Wärme Verbindet | Energie-Atlas Bayern. Available online: https://www.energieatlas.bayern.de/energieatlas/praxisbeispiele/details,95 (accessed on 29 September 2022).

- Energiesparen Beim Bierbrauen | Energie-Atlas Bayern. Available online: https://www.energieatlas.bayern.de/energieatlas/praxisbeispiele/details,909 (accessed on 29 September 2022).

- EquiTherm Spart Energie Beim Bierbrauen | Energie-Atlas Bayern. Available online: https://www.energieatlas.bayern.de/energieatlas/praxisbeispiele/details,257 (accessed on 29 September 2022).

- Bäckerei: Kleine Maßnahmen, Große Wirkung | Energie-Atlas Bayern. Available online: https://www.energieatlas.bayern.de/energieatlas/praxisbeispiele/details,37 (accessed on 29 September 2022).

- Kannan, R.; Boie, W. Energy Management Practices in SME—Case Study of a Bakery in Germany. Energy Convers. Manag. 2003, 44, 945–959. [Google Scholar] [CrossRef]

- Cooremans, C. Competitiveness Benefits of Energy Efficiency: A Conceptual Framework. Proc. Eceee Summer Study 2015, 123–131. [Google Scholar]

- Lighting Upgrades Helped This Bakery Shine | Save on Energy | Case Study. Available online: https://saveonenergy.ca/For-Your-Small-Business/Small-business-Case-Studies/Cupcakes-of-Westdale-Village (accessed on 6 June 2022).

- Crittenden, P. Promoting Energy Efficiency in Small and Medium Sized Enterprises (SMEs) and Waste Heat Recovery Measures in India; Sustainable Business Pty Ltd: New Delhi, India, 2015. [Google Scholar]

- IPCC. 2006 IPCC Guidelines for National Greenhouse Gas Inventories; IPCC: Geneva, Switzerland, 2006. [Google Scholar]

- Coffee Roaster Serves up Energy Savings | Save on Energy | Case Study. Available online: https://saveonenergy.ca/For-Your-Small-Business/Small-business-Case-Studies/Reunion-Island (accessed on 29 September 2022).

- Fatima, Z.; Oksman, V.; Lahdelma, R. Enabling Small Medium Enterprises (SMEs) to Become Leaders in Energy Efficiency Using a Continuous Maturity Matrix. Sustainability 2021, 13, 10108. [Google Scholar] [CrossRef]

- König, W.; Löbbe, S.; Büttner, S.; Schneider, C. Establishing Energy Efficiency—Drivers for Energy Efficiency in German Manufacturing Small- and Medium-Sized Enterprises. Energies 2020, 13, 5144. [Google Scholar] [CrossRef]

- Fernandes, M.; Nunes, C.; Gomes, P. Medidas Transversais de Eficiência Energética Para a Indústria; Direção-Geral de Energia e Geologia: Lisbon, Portugal, 2016.

- The Business Case for Power Management | ENERGY STAR. Available online: https://www.energystar.gov/products/low_carbon_it_campaign/business_case (accessed on 22 November 2022).

- Oliveira, M.C.; Vieira, S.M.; Iten, M.; Matos, H.A. Optimisation of Water-Energy Networks in Process Industry: Implementation of Non-Linear and Multi-Objective Models. Front. Chem. Eng. 2022, 3. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, Y.; Feng, X. A Framework for Design and Operation Optimization for Utilizing Low-Grade Industrial Waste Heat in District Heating and Cooling. Energies 2021, 14, 2190. [Google Scholar] [CrossRef]

- Oliveira, M.C.; Iten, M.; Matos, H.A. Review on Water and Energy Integration in Process Industry: Water-Heat Nexus. Sustainability 2022, 14, 7954. [Google Scholar] [CrossRef]

- Food and Beverage | Energy.Gov.Au. Available online: https://www.energy.gov.au/business/industry-sector-guides/manufacturing/food-and-beverage (accessed on 23 November 2022).

- Royo, P.; Acevedo, L.; Ferreira, V.J.; García-Armingol, T.; López-Sabirón, A.M.; Ferreira, G. High-Temperature PCM-Based Thermal Energy Storage for Industrial Furnaces Installed in Energy-Intensive Industries. Energy 2019, 173, 1030–1040. [Google Scholar] [CrossRef]

- Oliveira, M.C.; Iten, M.; Fernandes, U. Modelling of a Solar Thermal Energy System for Energy Efficiency Improvement in a Ceramic Plant. Sustain. Energy Dev. Innov. 2022, 825–831. [Google Scholar] [CrossRef]

- U.S. Department of Energy—Office of Energy Efficiency & Renewable Energy. Overview of CHP Technologies; U.S. Department of Energy—Office of Energy Efficiency & Renewable Energy: Washington, DC, USA, 2017.

- Jouhara, H.; Khordehgah, N.; Almahmoud, S.; Delpech, B.; Chauhan, A.; Tassou, S.A. Waste Heat Recovery Technologies and Applications. Therm. Sci. Eng. Prog. 2018, 6, 268–289. [Google Scholar] [CrossRef]

- Oliveira, M.C.; Iten, M.; Cruz, P.L.; Monteiro, H. Review on Energy Efficiency Progresses, Technologies Waste Heat Recovery. Energies 2020, 13, 6096. [Google Scholar] [CrossRef]

- Castro Oliveira, M.; Iten, M.; Matos, H.A. Simulation and Assessment of an Integrated Thermal Processes and Organic Rankine Cycle (ORC) System with Modelica. Energy Rep. 2022, 8, 764–770. [Google Scholar] [CrossRef]

| Policy | Contextualization |

|---|---|

| Paris Agreement [3] | It is a worldwide agreement set to promote practices considering the requirement to limit global warming up to 2 °C and (if possible) to 1.5 °C. In the scope to achieve the aims of this agreement, all the involved countries are set to submit comprehensive national climate action plans. Although all these are not sufficient in terms of the establishment of specific measures to be practiced (such as the ones related to the decarbonization of the energy systems), the agreement traces a way for further action. |

| 2012 Energy Efficiency Directive (and 2018 Amendment) [2,4] | It sets a list of rules and obligations that must be followed by EU Member States for the achievement of 2020 and 2030 targets. In relation to energy consumption targets and savings for the reference year of 2030, it is set to promote:

|

| 2030 Climate and Energy Framework [5] | It is set to establish major targets and policy objectives for the 2021–2030 period, namely:

|

| European Green Deal [1] | It is a roadmap for the 2019–2024 period set to promote the aims of the 2050 long-term strategy (near-zero GHG emissions in 2050). In relation to energy efficiency improvement and clean energy transition promotion, it is set to accomplish the following:

|

| Fit for 55 Package [6] | It is a set of policy proposals to achieve the climate target of reducing EU emissions by at least 55% by 2030 towards the long-term objective of climate-neutral EU. The main objectives of Fit for 55 package are as follows:

|

| REPowerEU [7] | It is an EU strategy initiated to reduce the dependence on imported fossil fuels and tackle the climate crisis. These specific policies set to be met by 2030:

|

| European Industrial Strategy [8] | It is a policy package for the green and digital transition of the European industrial sector towards global competitiveness. Based on the lessons learned from the COVID-19 pandemic, the EU proposed the following policy actions:

|

| EU Strategy for Energy System Integration [9] | It is a strategy which was elaborated considering the combination of the aims of both the European Green Deal and the EU long-term strategy until 2050. It is divided into three main pillars, and The 1st Pillar (Energy Efficiency and Circular Economy Nexus) deals with the following:

|

| Industry Grouping | Representative Industries |

|---|---|

| Energy-intensive manufacturing | |

| Food | Food, beverage, and tobacco manufacturing |

| Pulp and paper | Paper manufacturing, printing, and related support activities |

| Basic chemicals | Inorganic chemicals, organic chemicals (e.g., ethylene propylene), resins, and agricultural chemicals; includes chemical feedstocks |

| Refining | Petroleum refineries and cola products manufacturing, including coal and natural gas used as feedstocks |

| Iron and steel | Iron and steel manufacturing, including coke ovens |

| Nonferrous metals | Primarily aluminum and other nonferrous metals, such as copper, zinc, and tin |

| Nonmetallic minerals | Primarily cement and other nonmetallic minerals such as glass, lime, gypsum, and clay products |

| Nonenergy-intensive manufacturing | |

| Other chemicals | Pharmaceuticals (medicinal and botanical), paint and coatings, adhesives, detergents, and other miscellaneous chemical products, including chemical feedstocks |

| Other industrials | All other industrial manufacturing, including metal-based durables (fabricated metal products, machinery, computer and electronic products, transportation equipment, and electrical equipment) |

| Nonmanufacturing | |

| Agriculture, forestry, and fishing | Agriculture, forestry, and fishing |

| Mining | Coal mining, oil and natural gas extraction, and mining of metallic and nonmetallic minerals |

| Construction | Construction of buildings (residential and commercial), heavy and civil engineering construction, industrial construction, and specialty trade contractors. |

| Sector | Level of Energy Consumption per Enterprise | Level of Energy Efficiency | Energy Efficiency Improvement Potential |

|---|---|---|---|

| Food, Beverage, and Tobacco | Medium | High | Medium |

| Chemical and Metal Production | High | High | High |

| Construction | Low | Medium | High |

| Agriculture and Forestry | Low | Low | High |

| Transport, Storage, and Communication | High | Low | High |

| Sector | Case Study | Implemented Measures | Savings |

|---|---|---|---|

| Chemical industry | SATECMA plant [60] |

| 20% in total energy |

| Chemical plant in UK [13] | Elimination of leakages associated with the supply of gas in boilers | 30% in total energy | |

| Wacker Chemie AG plant [61] |

| 421 GWh/year in steam processes 44 GWh/year in facility heating and hot water preparation | |

| Food and beverage industry | World-leading producer of Scotland’s national dish haggis [13] |

| 15% in gas bills in 2006–2008 |

| Brewery in Aying, Germany [62] |

| 20% in electricity 100 tons/year in CO2 emissions | |

| “Krones A” brewery [63] | Innovative “EquiTherm” process was developed; energy used for heating and cooling purposes was reduced via waste heat recovery, as well as freshwater | 20% in electricity 30% in thermal energy | |

| Rager bakery [64] |

| 2.5 k EUR/year | |

| Bakery in Germany [65,66] |

| ||

| Cupcakes of Westdale Village company [67] | Improvement of lighting equipment | USD 400/year in electricity bills | |

| Metal manufacturing industry | AMB Alloys Ltd. [27] | Energy efficiency improvements included a completely new production plant | 4.3 MWh/year in total energy 1.7 CO2 tons/year |

| Construction | Lagodekhautogza Ltd. [27] | This cement producing company upgraded old machinery to the most recent one Volume of production was increased by 55% | 160 MWh/year in total energy |

| “Mshenebeli 2019” [27] | This asphalt producing company substituted a natural-gas-based heat generator with a biomass-based solid-fuel heat generator | USD 126,400/year in fuel bills | |

| Miscellaneous sectors | Liquid gases company in Denmark [31] | Implementation of a technology combining an ozone unit and a sand filter which can reduce the temperature of the required cooling water | 153 MWh/year in total energy 50, 12, 20 k USD/year in process chemicals, corrosion inhibitors, and corrosion, respectively |

| Firozabad heat recovery system [68] | It is a cluster of SMEs of the glass sector in India which implemented a simple waste heat recovery system | 25–30% in total energy | |

| Druckerei Senser [69] |

| 30% in total power 25% in total electricity 20% in heating | |

| Reunion Island Coffee Roasters company [70] |

| 25% in electricity bills |

| Category | Characterization | Ref. |

|---|---|---|

| Awareness of energy efficiency improvement potential and opportunities | Measures related to the appropriate training of SMEs’ employees in order to promote their awareness of these matters and to create an energy efficiency and/or energy-saving culture within the organization | [71,72] |

| Measures related to operational processes and maintenance |

| [31,73] |

| Buildings’ energy efficiency measures | Thermal-insulation-related | [29,31,69,74] |

| ||

| HVAC Systems-related | ||

| ||

| Lightning-systems-related | ||

| ||

| Measures related to process design and energy supply |

| [76,77] |

| Renewable energy and energy storage |

| [78,79,80] |

| Combined heat and power (CHP) |

| [81] |

| Heat recovery | The aim of implementing heat recovery measures is to reduce the amount of fuel or thermal energy utilized; prerequisites for the implementation of these measures:

| [31,82] |

| Waste heat to power | It is a subset of heat-recovery-related measures set to be implemented to generated electricity, namely:

| [31,83,84] |

| Measures related to water quality | Water, which is the most common working fluid in thermal processes equipment such as boilers, heat exchangers, etc., contains impurities, mineral salts, dissolved organic matter, and microbiological organisms that adversely affect the operational efficiency of equipment. Water quality should be closely monitored and controlled in order to achieve equipment operation with low energy consumption. | [31,75] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gennitsaris, S.; Oliveira, M.C.; Vris, G.; Bofilios, A.; Ntinou, T.; Frutuoso, A.R.; Queiroga, C.; Giannatsis, J.; Sofianopoulou, S.; Dedoussis, V. Energy Efficiency Management in Small and Medium-Sized Enterprises: Current Situation, Case Studies and Best Practices. Sustainability 2023, 15, 3727. https://doi.org/10.3390/su15043727

Gennitsaris S, Oliveira MC, Vris G, Bofilios A, Ntinou T, Frutuoso AR, Queiroga C, Giannatsis J, Sofianopoulou S, Dedoussis V. Energy Efficiency Management in Small and Medium-Sized Enterprises: Current Situation, Case Studies and Best Practices. Sustainability. 2023; 15(4):3727. https://doi.org/10.3390/su15043727

Chicago/Turabian StyleGennitsaris, Stavros, Miguel Castro Oliveira, George Vris, Antonis Bofilios, Theodora Ntinou, Ana Rita Frutuoso, Catarina Queiroga, John Giannatsis, Stella Sofianopoulou, and Vassilis Dedoussis. 2023. "Energy Efficiency Management in Small and Medium-Sized Enterprises: Current Situation, Case Studies and Best Practices" Sustainability 15, no. 4: 3727. https://doi.org/10.3390/su15043727

APA StyleGennitsaris, S., Oliveira, M. C., Vris, G., Bofilios, A., Ntinou, T., Frutuoso, A. R., Queiroga, C., Giannatsis, J., Sofianopoulou, S., & Dedoussis, V. (2023). Energy Efficiency Management in Small and Medium-Sized Enterprises: Current Situation, Case Studies and Best Practices. Sustainability, 15(4), 3727. https://doi.org/10.3390/su15043727