Energy Cost Assessment and Optimization of Post-COVID-19 Building Ventilation Strategies

Abstract

:1. Introduction

2. Materials and Methods

2.1. Building Simulation Details

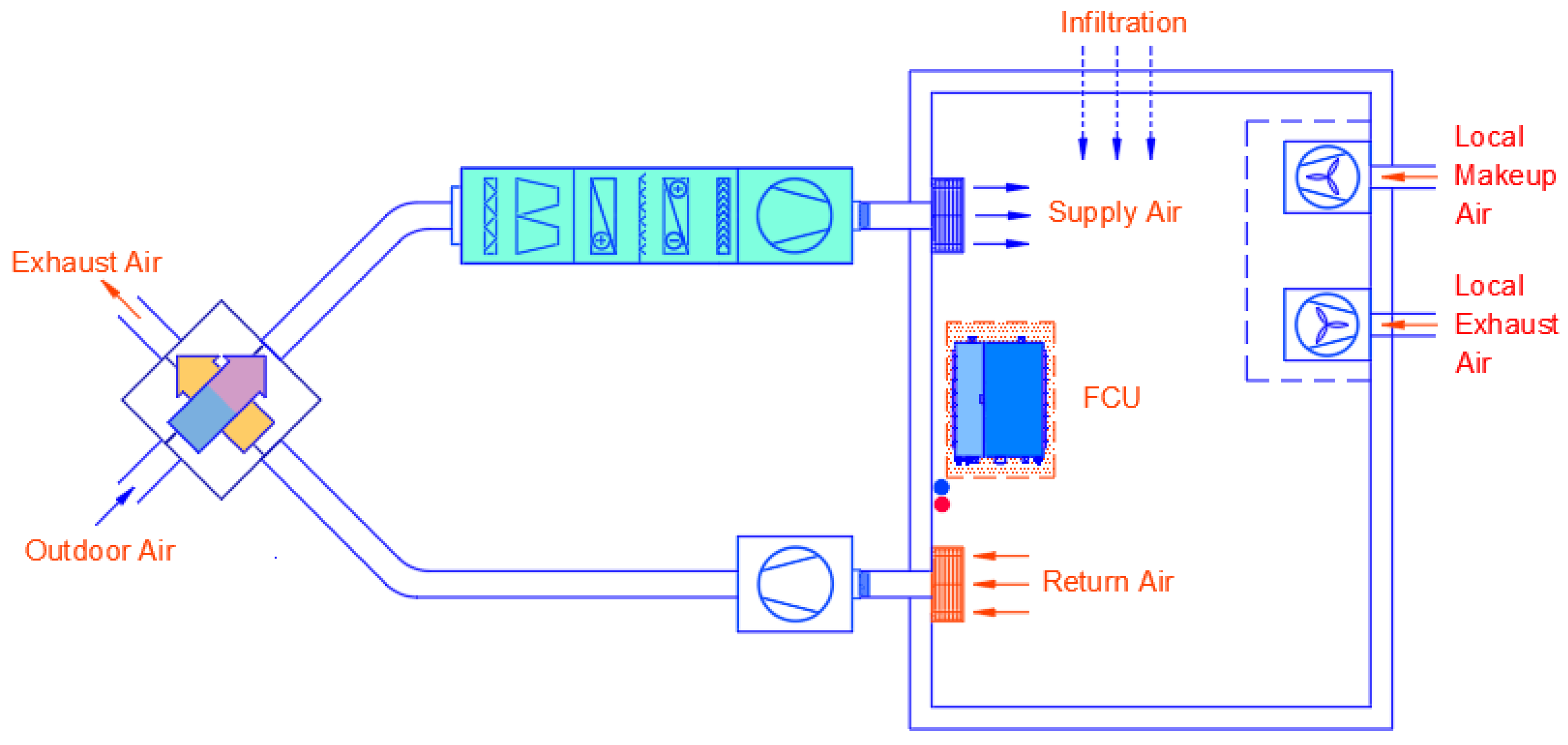

2.2. HVAC System Details and Heat Pump Submodel

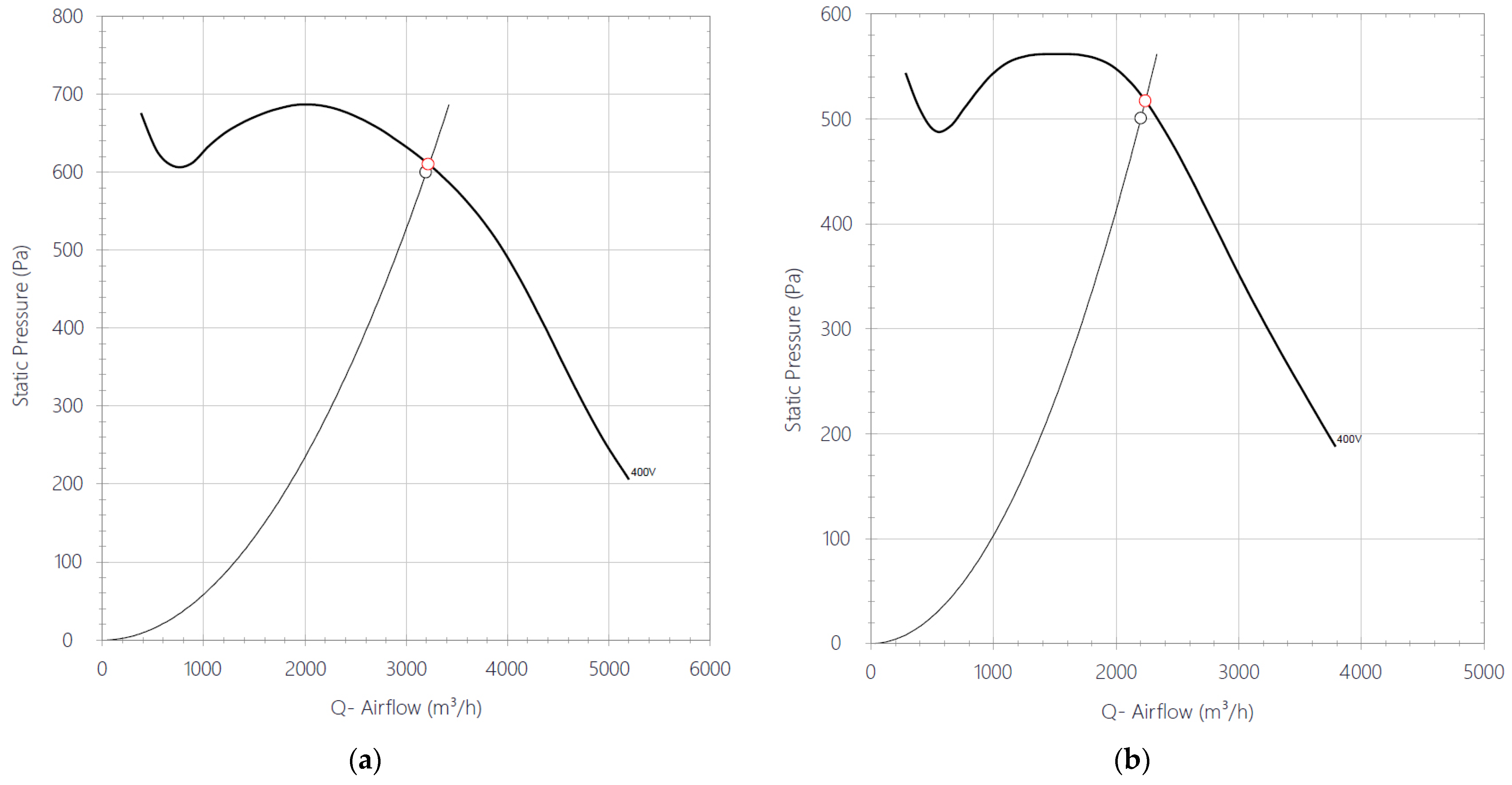

2.3. Air-Handling Units, Details of Centrifugal Fan Characteristics, Filters, Recuperators

2.4. Photovoltaic Installation Modeling

2.5. TRNSYS 16 Types and Simulation Details

2.6. Increased Outdoor Air Requirements during COVID-19 Episodes

3. Results and Discussion

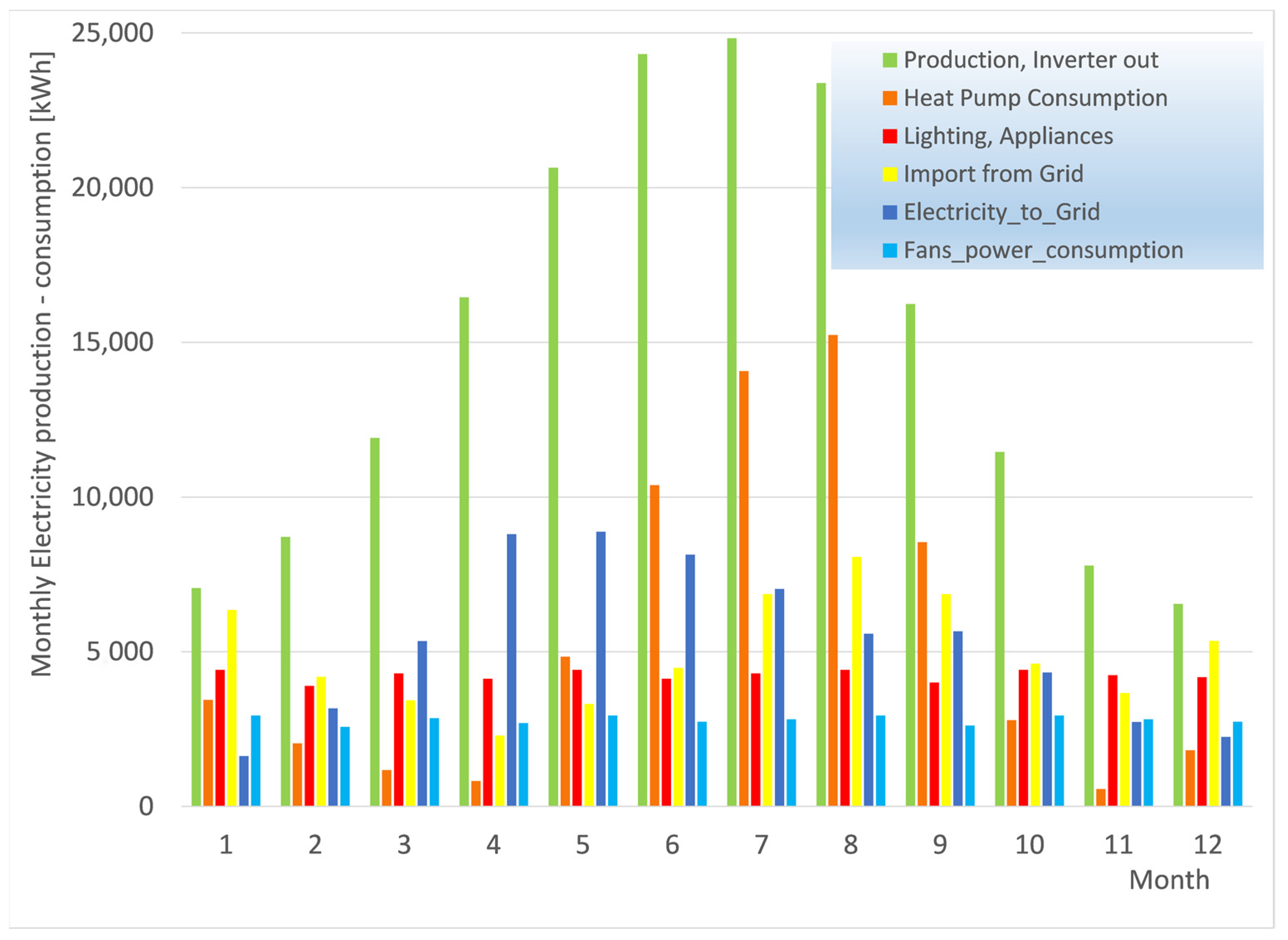

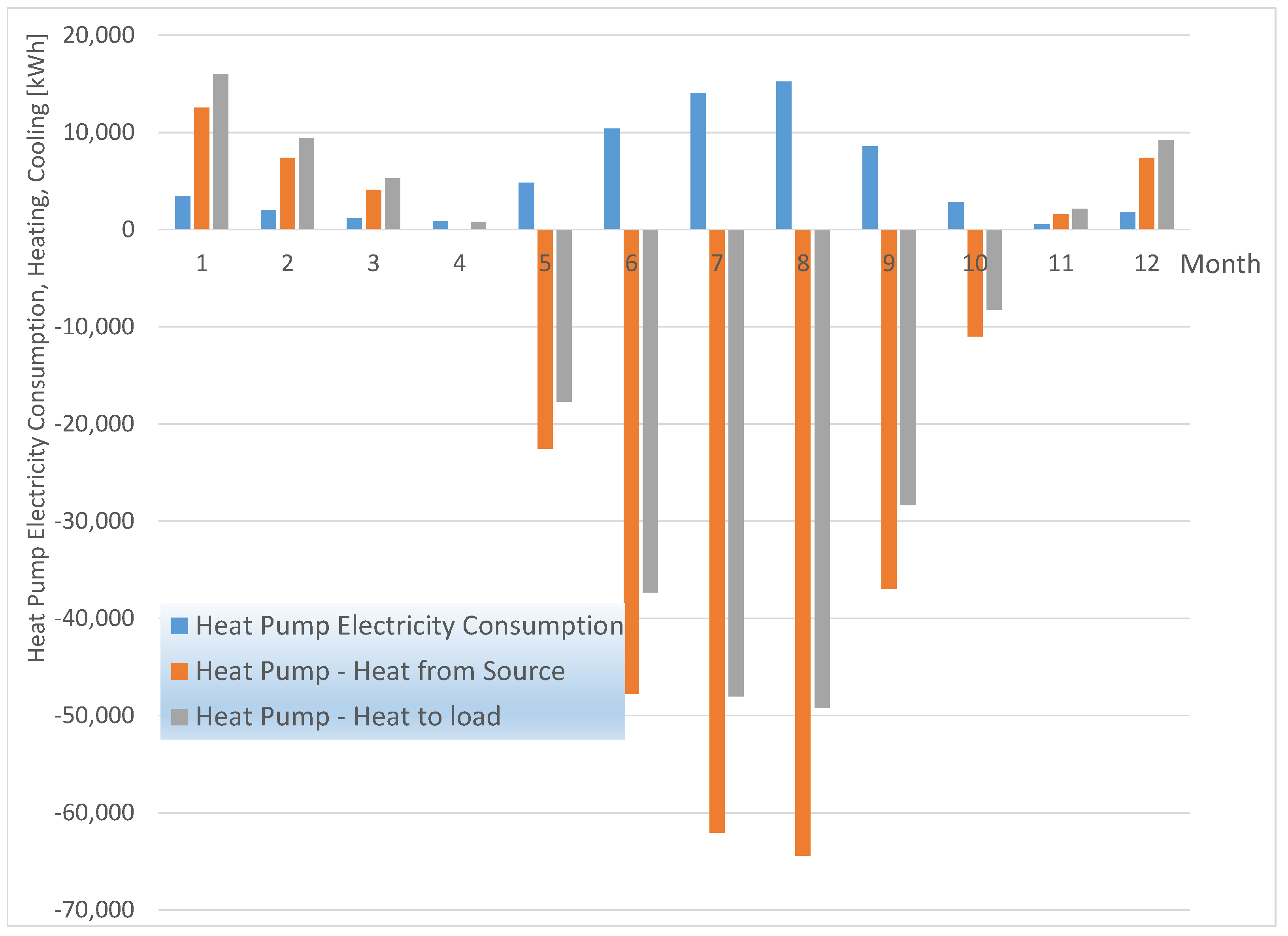

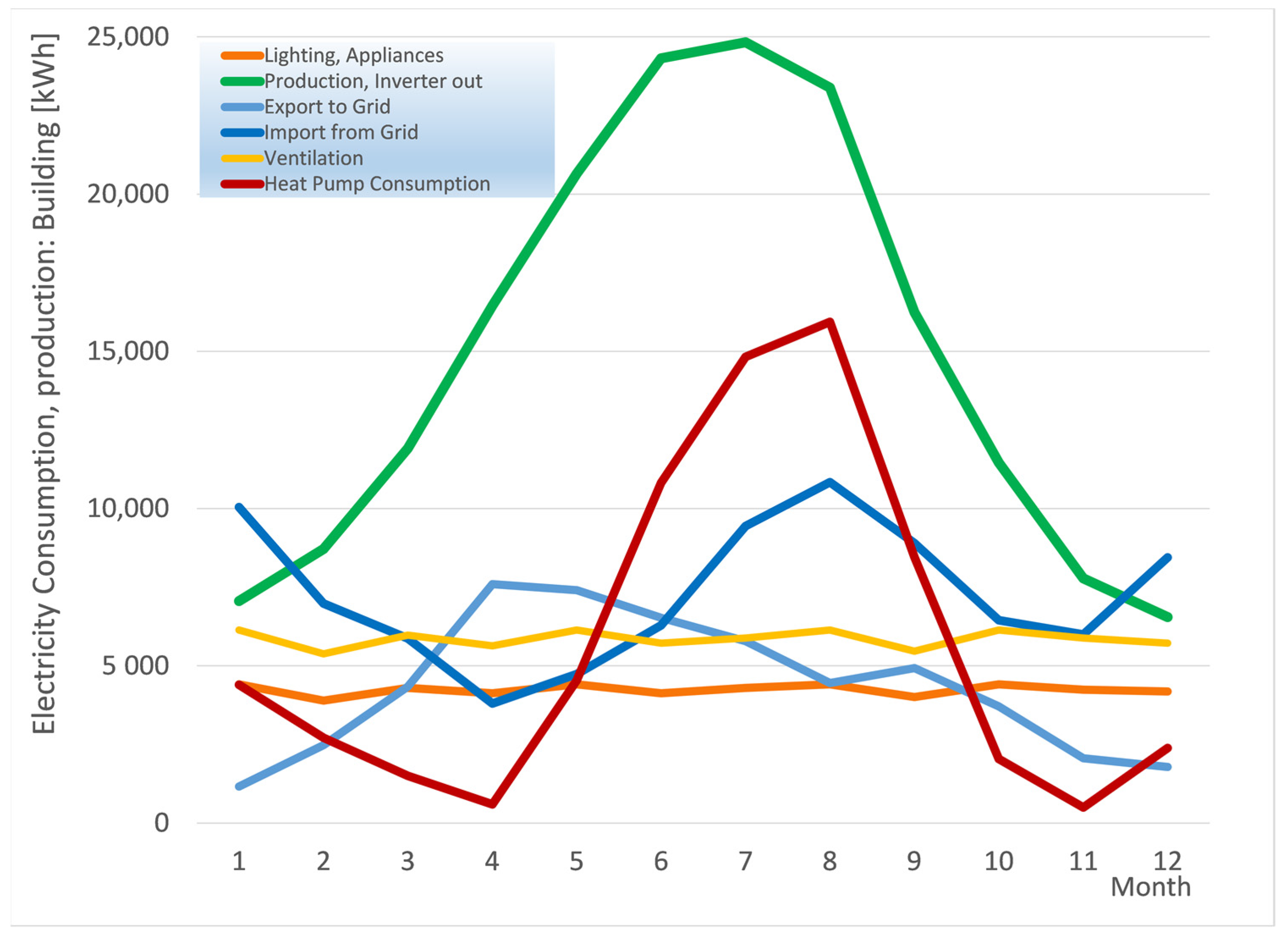

3.1. Monthly System’s Performance and Annual Summary—Baseline Building

3.2. Monthly System’s Performance—Building with Increased Ventilation

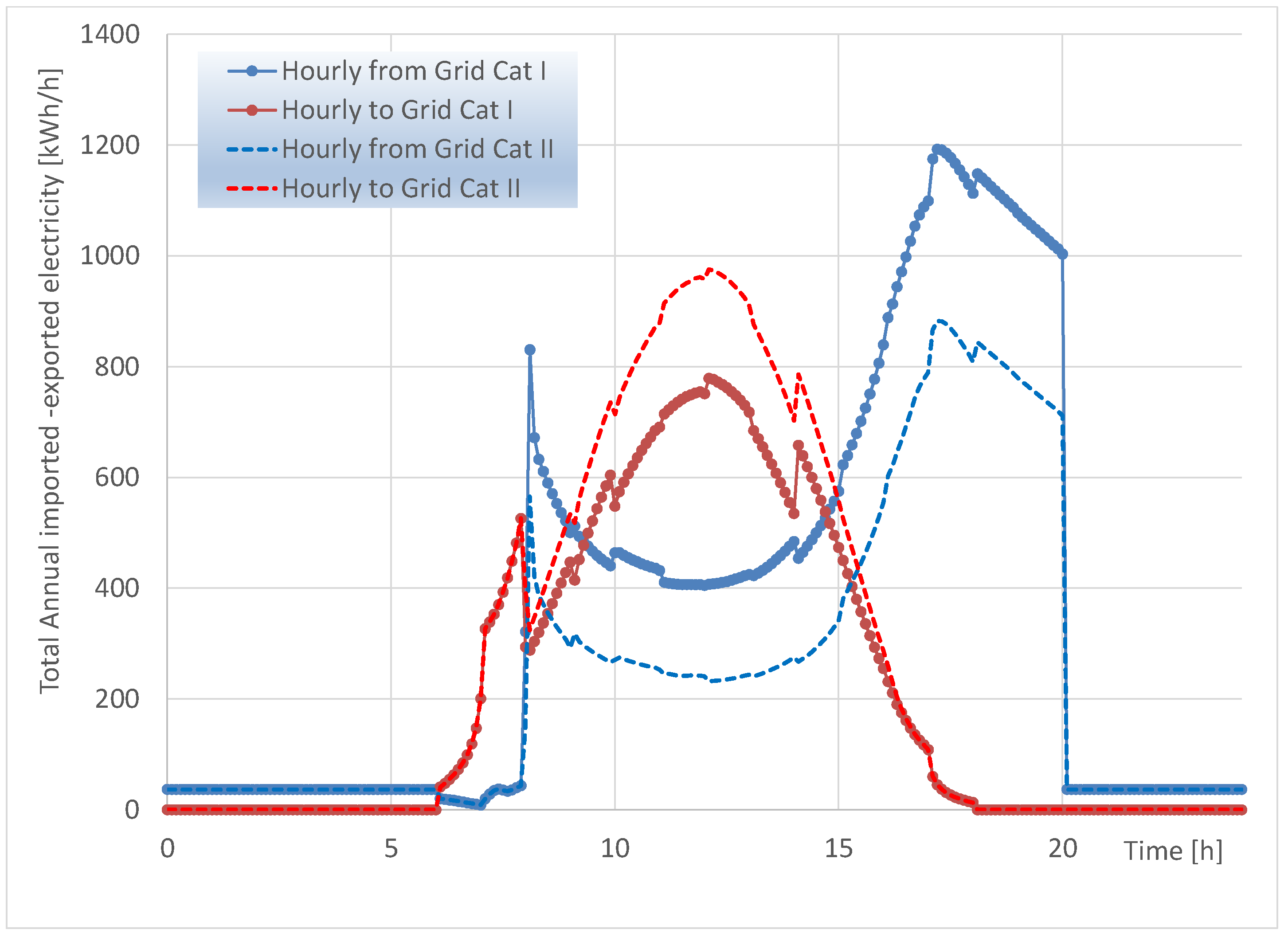

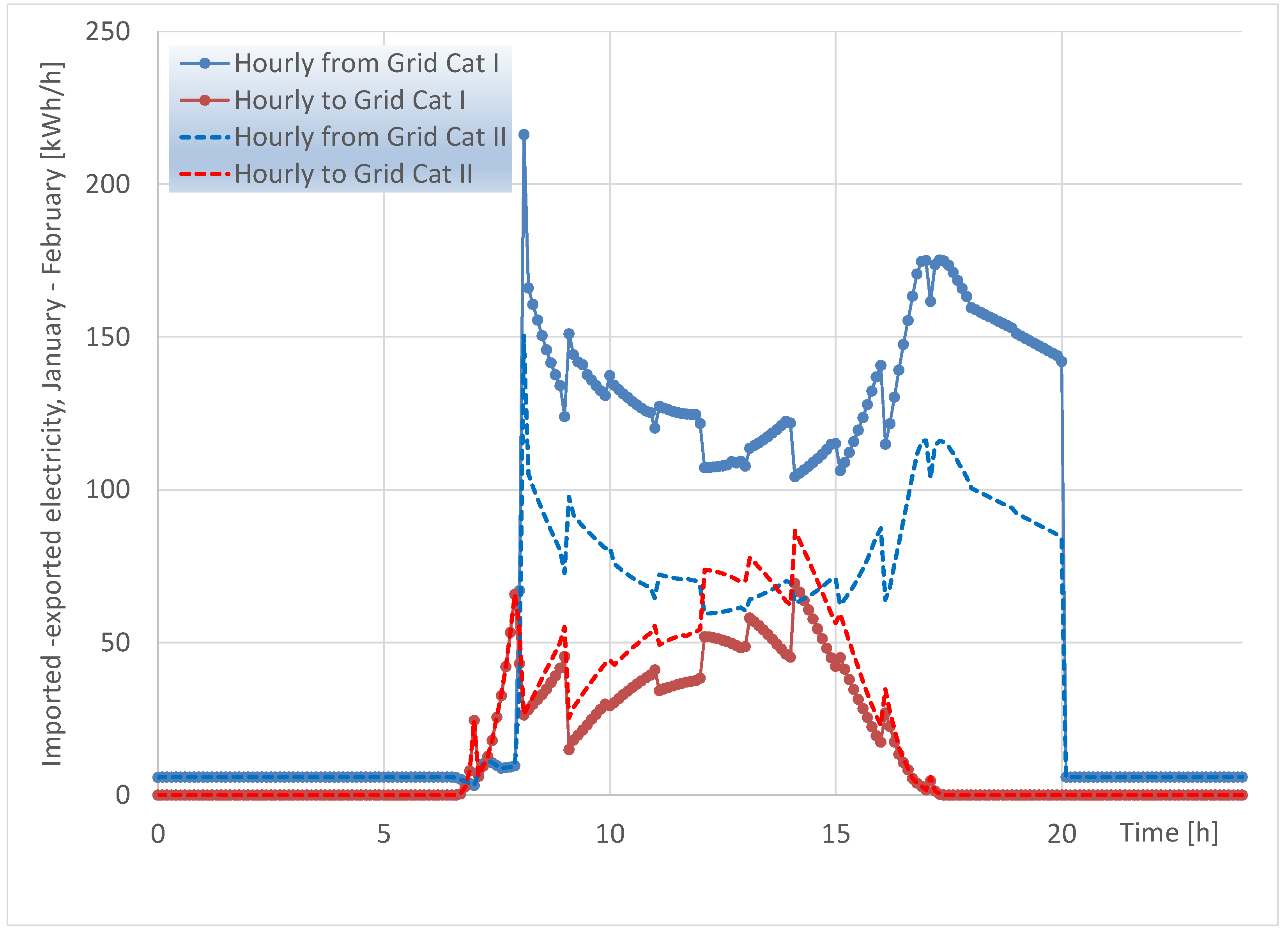

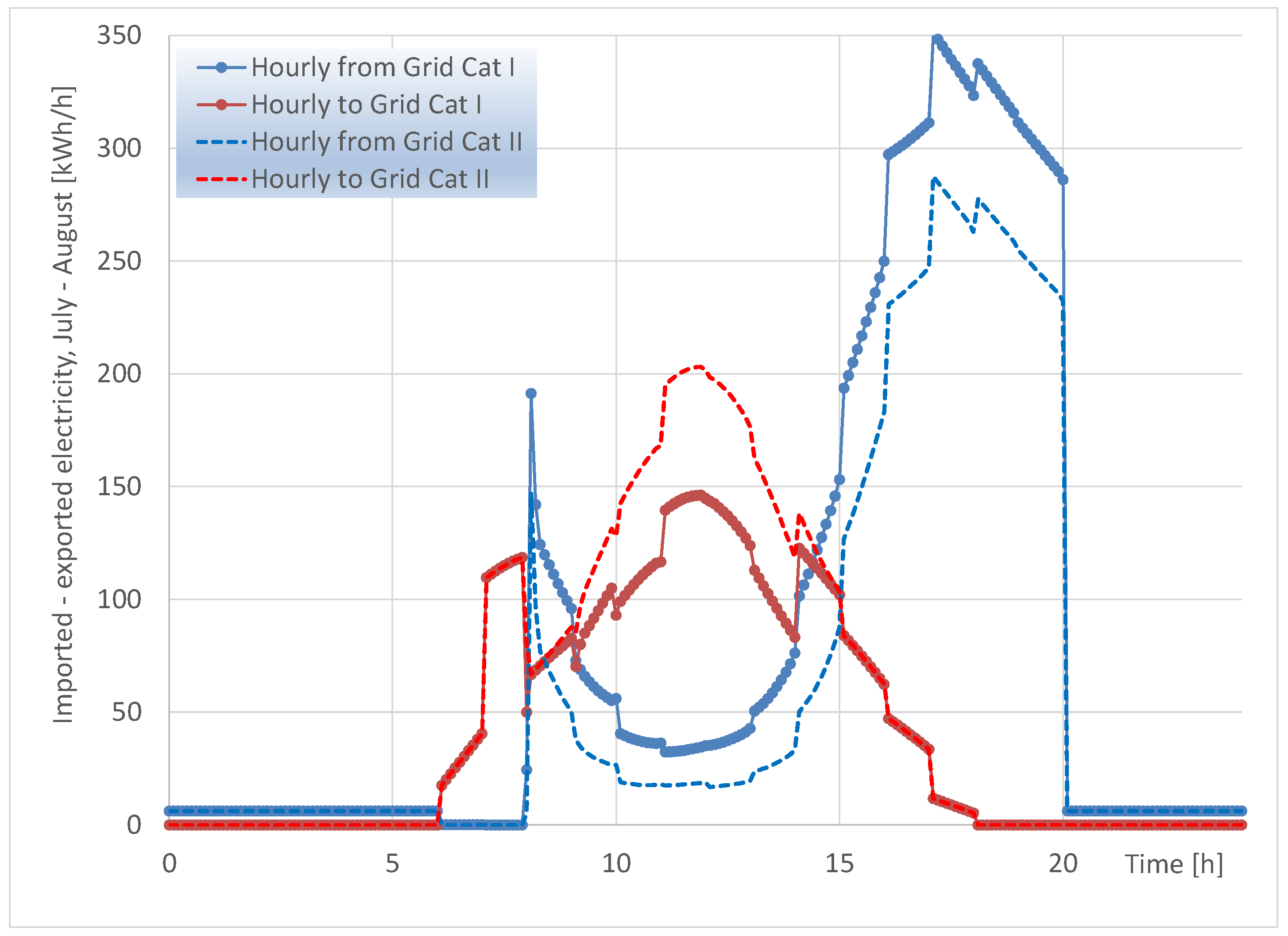

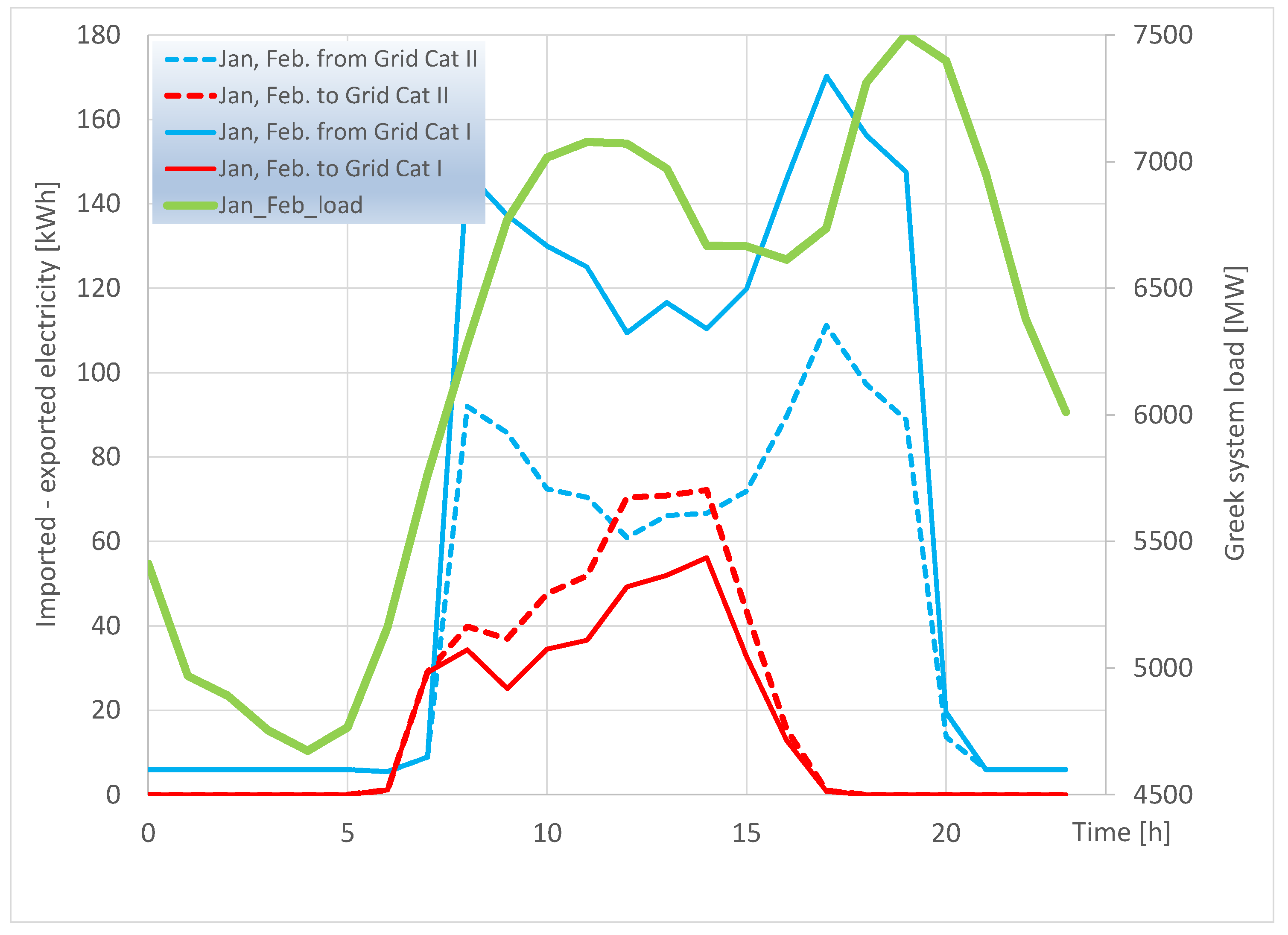

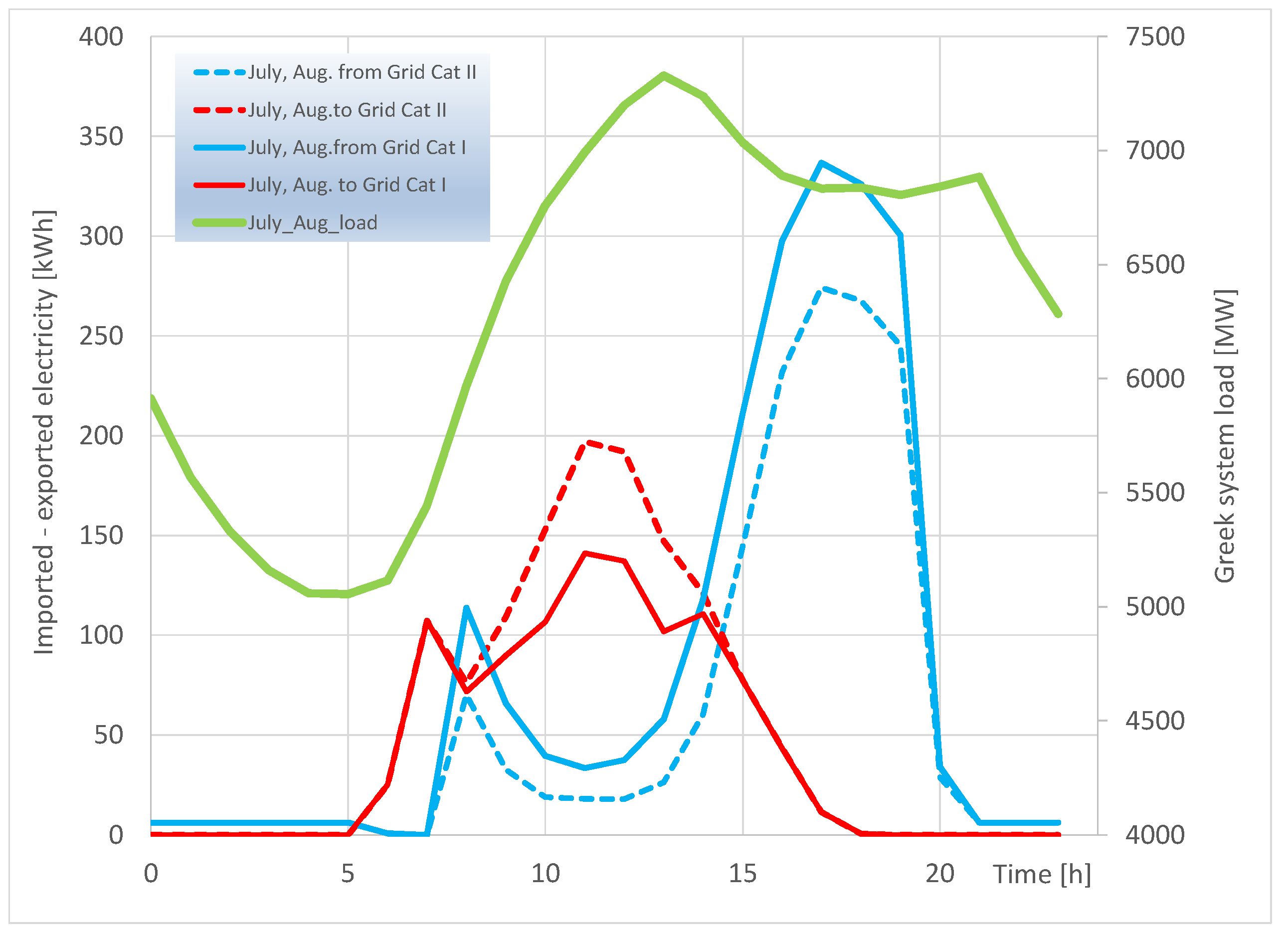

3.3. Comparative Performance of the Building with Category I–II Ventilation Requirements

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Shell Type | Layers | U (W/m2K) |

|---|---|---|

| Roof insulation | Reinforced concrete slab, extruded polystyrene, lightweight concrete, ceramic tiles | 0.272 |

| Concrete column | Reinforced concrete, extruded polystyrene | 0.324 |

| Outside wall | Ceramic brick, extruded polystyrene, ceramic brick | 0.319 |

| Floor insulation | Reinforced concrete slab, extruded polystyrene | 0.443 |

| Heating Mode: Ground Loop Water Temperature [°C] | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 18.0 | 15.0 | 13.0 | 10.0 | 8.5 | 7.0 | 4.5 | 2.0 | 0.0 | ||||

| kW thermal | 271.4 | 255.4 | 241.9 | 228.8 | 216.0 | 209.7 | 193.2 | 183.0 | 173.0 | |||

| KW | 46.8 | 45.6 | 44.8 | 44 | 43.2 | 42.8 | 42 | 41.6 | 41.2 | |||

| COP | 5.8 | 5.6 | 5.4 | 5.2 | 5 | 4.9 | 4.6 | 4.4 | 4.2 | |||

| Cooling Mode: Ground Loop Water Temperature [°C] | ||||||||||||

| 20 | 25 | 30 | 35 | 40 | 45 | |||||||

| kW thermal | 201.6 | 198.9 | 196.1 | 194.2 | 185.6 | 177.8 | ||||||

| kW | 48 | 51 | 53 | 55.5 | 58 | 63.5 | ||||||

| COP | 4.2 | 3.9 | 3.7 | 3.5 | 3.2 | 2.8 | ||||||

References

- European_Commission. Nearly Zero-Energy Buildings. 2022. Available online: https://energy.ec.europa.eu/topics/energy-efficiency/energy-efficient-buildings/nearly-zero-energy-buildings_en (accessed on 30 January 2023).

- EU. Directive 2010/31/EU of the European Parliament and of the Council of 19 May 2010 on the Energy Performance of Buildings; EU: Maastricht, The Netherlands, 2010. [Google Scholar]

- BPIE. Nearly Zero: A Review of EU Member State Implementation of New Build Requirements; BPIE: Brussels, Belgium, 2021. [Google Scholar]

- Lebrouhi, B.E.; Schall, E.; Lamrani, B.; Chaibi, Y.; Kousksou, T. Energy Transition in France. Sustainability 2022, 14, 5818. [Google Scholar] [CrossRef]

- Bottarelli, M.; González Gallero, F.J. Energy Analysis of a Dual-Source Heat Pump Coupled with Phase Change Materials. Energies 2020, 13, 2933. [Google Scholar] [CrossRef]

- Stamatellos, G.; Zogou, O.; Stamatelos, A. Energy Analysis of a NZEB Office Building with Rooftop PV Installation: Exploitation of the Employees’ Electric Vehicles Battery Storage. Energies 2022, 15, 6206. [Google Scholar] [CrossRef]

- Stamatellos, G.; Zogou, O.; Stamatelos, A. Interaction of a House’s Rooftop PV System with an Electric Vehicle’s Battery Storage and Air Source Heat Pump. Solar 2022, 2, 186–214. [Google Scholar] [CrossRef]

- NN. ANSI/ASHRAE Standard 62.1-2004; Ventilation and Acceptable Indoor Air Quality: Atlanta, GA, USA, 2004; p. 44. [Google Scholar]

- ANSI/ASHRAE. ASHRAE Standard 62.1-2022; Ventilation and Acceptable Indoor Air Quality (ANSI Approved): Atlanta, GA, USA, 2022. [Google Scholar]

- ASHRAE. ASHRAE 62.1-2022 Document History. 2022. Available online: https://www.techstreet.com/ashrae/standards/ashrae-62-1-2022?product_id=2501063 (accessed on 30 January 2023).

- Mokhtari, R.; Jahangir, M.H. The effect of occupant distribution on energy consumption and COVID-19 infection in buildings: A case study of university building. Build. Environ. 2021, 190, 107561. [Google Scholar] [CrossRef] [PubMed]

- Lu, J.; Gu, J.; Li, K.; Xu, C.; Su, W.; Lai, Z.; Zhou, D.; Yu, C.; Xu, B.; Yang, Z. COVID-19 Outbreak Associated with Air Conditioning in Restaurant, Guangzhou, China, 2020. Emerg. Infect. Dis. J. 2020, 26, 1628. [Google Scholar] [CrossRef]

- Dao, H.T.; Kim, K.-S. Behavior of cough droplets emitted from Covid-19 patient in hospital isolation room with different ventilation configurations. Build. Environ. 2022, 209, 108649. [Google Scholar] [CrossRef]

- Xie, X.; Li, Y.; Chwang, A.T.Y.; Ho, P.L.; Seto, W.H. How far droplets can move in indoor environments–revisiting the Wells evaporation–falling curve. Indoor Air 2007, 17, 211–225. [Google Scholar] [CrossRef]

- Guo, M.; Xu, P.; Xiao, T.; He, R.; Dai, M.; Miller, S.L. Review and comparison of HVAC operation guidelines in different countries during the COVID-19 pandemic. Build. Environ. 2021, 187, 107368. [Google Scholar] [CrossRef]

- AE. AE-A-Series EV Charger. Available online: https://www.ae-electronics.com/ (accessed on 30 January 2023).

- Hamdani, H.; Sabri, F.S.; Harapan, H.; Syukri, M.; Razali, R.; Kurniawan, R.; Irwansyah, I.; Sofyan, S.E.; Mahlia, T.M.I.; Rizal, S. HVAC Control Systems for a Negative Air Pressure Isolation Room and Its Performance. Sustainability 2022, 14, 11537. [Google Scholar] [CrossRef]

- Zheng, W.; Hu, J.; Wang, Z.; Li, J.; Fu, Z.; Li, H.; Jurasz, J.; Chou, S.K.; Yan, J. COVID-19 Impact on Operation and Energy Consumption of Heating, Ventilation and Air-Conditioning (HVAC) Systems. Adv. Appl. Energy 2021, 3, 31. [Google Scholar] [CrossRef]

- Alonso, A.; Llanos, J.; Escandón, R.; Sendra, J.J. Effects of the COVID-19 Pandemic on Indoor Air Quality and Thermal Comfort of Primary Schools in Winter in a Mediterranean Climate. Sustainability 2021, 13, 2699. [Google Scholar] [CrossRef]

- Fageha, M.K.; Alaidroos, A.; Fageha, M.K.; Alaidroos, A. Performance Optimization of Natural Ventilation in Classrooms to Minimize the Probability of Viral Infection and Reduce Draught Risk. Sustainability 2022, 14, 14966. [Google Scholar] [CrossRef]

- Sha, H.; Zhang, X.; Qi, D. Optimal control of high-rise building mechanical ventilation system for achieving low risk of COVID-19 transmission and ventilative cooling. Sustain. Cities Soc. 2021, 74, 103256. [Google Scholar] [CrossRef]

- Wang, J.; Huang, J.; Feng, Z.; Cao, S.-J.; Haghighat, F. Occupant-density-detection based energy efficient ventilation system: Prevention of infection transmission. Energy Build. 2021, 240, 110883. [Google Scholar] [CrossRef]

- EPA. Ventilation and Coronavirus (COVID-19). 2022. Available online: https://www.epa.gov/coronavirus/ventilation-and-coronavirus-covid-19 (accessed on 30 January 2023).

- Mohammadi, M.; Calautit, J.; Mohammadi, M.; Calautit, J. Impact of Ventilation Strategy on the Transmission of Outdoor Pollutants into Indoor Environment Using CFD. Sustainability 2021, 13, 10343. [Google Scholar] [CrossRef]

- Pampati, S.; Rasberry, C.N.; McConnell, L. Ventilation Impriesovement Strategies among K–12 Public Schools—The National School COVID-19 Prevention Stud. MMWR Morb. Mortal. Wkly. Rep. 2022, 71, 770. [Google Scholar] [CrossRef] [PubMed]

- Marotta, A.; Porras-Amores, C.; Rodríguez Sánchez, A. Resilient Built Environment: Critical Review of the Strategies Released by the Sustainability Rating Systems in Response to the COVID-19 Pandemic. Sustainability 2021, 13, 11164. [Google Scholar] [CrossRef]

- REHVA. Health-based target ventilation rates and design method for reducing exposure to airborne respiratory infectious diseases. In REHVA Proposal for Post COVID Target Ventilation Rates; REHVA: Brussels, Belgium, 2022. [Google Scholar]

- EN 16798-1:2019; Energy Performance of Buildings-Ventilation for Buildings-Part 1: Indoor Environmental Input Parameters for Design and Assessment of Energy Performance of Buildings Addressing Indoor Air Quality, Thermal Environment, Lighting and Acoustics. CEN: Brussels, Belgium, 2019.

- Stamatellos, G.; Zogou, O.; Stamatelos, A. Energy Performance Optimization of a House with Grid-Connected Rooftop PV Installation and Air Source Heat Pump. Energies 2021, 14, 740. [Google Scholar] [CrossRef]

- Zogou, O.; Stamatelos, A. Optimization of thermal performance of a building with ground source heat pump system. Energy Convers. Manag. 2007, 48, 2853–2863. [Google Scholar] [CrossRef]

- Zogou, O.; Stamatelos, A. Application of Building Energy Simulation in the Sizing and Design Optimization of an Office Building and Its HVAC Equipment; Chapter 11 in Energy and Buildings: Efficiency, Air Quality, and Conservation; Utrick, J.B., Ed.; Nova Science Publishers: Hauppauge, NY, USA, 2009. [Google Scholar]

- Safa, A.A.; Fung, A.S.; Kumar, R. Heating and cooling performance characterisation of ground source heat pump system by testing and TRNSYS simulation. Renew. Energy 2015, 83, 565–575. [Google Scholar] [CrossRef]

- Neymark, J.; Judkoff, R.; Knabec, G.; Lec, H.-T.; Duerig, M.; Glasse, A.; Zweifele, G. Applying the building energy simulation test (BESTEST) diagnostic method to verification of space conditioning equipment models used in whole-building energy simulation programs. Energy Build. 2002, 34, 917–931. [Google Scholar] [CrossRef]

- Standard 140-2001; Standard Method of Test for the Evaluation of Building Energy Analysis Computer Programs. ASHRAE: Atlanta, GA, USA, 2001.

- Component Libraries for TRNSYS, Version 2.0. User’s Manual; TESS: Madison, WI, USA, 2004; Available online: http://www.tess-inc.com/services/software (accessed on 30 January 2023).

- S&P. EasyVent Fan Selection Tool. Available online: https://easyvent.solerpalau.com/ (accessed on 30 January 2023).

- De Soto, W.; Klein, S.A.; Beckman, W.A. Improvement and validation of a model for photovoltaic array performance. Sol. Energy 2006, 80, 78–88. [Google Scholar] [CrossRef]

- Sharp. 415Wp/Mono NUJC415 Data Sheet. Available online: https://docs.aws.sharp.eu/Marketing/Datasheet/2208_NUJC_415_HC-Mono_Datasheet_EN.pdf (accessed on 30 January 2023).

- Chen, C.-Y.; Chen, P.-H.; Chen, J.-K.; Su, T.-C. Recommendations for ventilation of indoor spaces to reduce COVID-19 transmission. J. Formos. Med. Assoc. 2021, 120, 2055–2060. [Google Scholar] [CrossRef]

- EU. COMMISSION RECOMMENDATION (EU) 2016/1318 of 29 July 2016 on Guidelines for the Promotion of Nearly Zero-Energy Buildings and Best Practices to Ensure That, by 2020, All New Buildings Are Nearly Zero-Energy Buildings; Official Journal of the European Union: Brussels, Belgium, 2016. [Google Scholar]

- Sang, J.; Liu, X.; Liang, C.; Feng, G.; Li, Z.; Wu, X.; Song, M. Differences between design expectations and actual operation of ground source heat pumps for green buildings in the cold region of Northern China. Energy 2022, 252, 124077. [Google Scholar] [CrossRef]

- Huang, S.; Zhu, K.; Dong, J.; Li, J.; Kong, W.; Jiang, Y.; Fang, Z. Heat transfer performance of deep borehole heat exchanger with different operation modes. Renew. Energy 2022, 193, 645–656. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Y.; You, S.; Zheng, X.; Wei, S. Operation optimization of the coaxial deep borehole heat exchanger coupled with ground source heat pump for building heating. Appl. Therm. Eng. 2022, 213, 118656. [Google Scholar] [CrossRef]

- Awbi, H. Ventilation Systems: Design and Performance; Taylor and Francis: Abingdon, UK, 2008. [Google Scholar]

- Ren, J.; Wang, Y.; Liu, Q.; Liu, Y. Numerical Study of Three Ventilation Strategies in a prefabricated COVID-19 inpatient ward. Build. Environ. 2021, 188, 107467. [Google Scholar] [CrossRef]

| Category | Explanation | |

|---|---|---|

| I | High level of expectation: recommended for spaces occupied by very sensitive, fragile persons with special requirements: handicapped, sick, very young children, elderly persons | 1 |

| II | Normal level of expectation: should be used for new buildings and renovations | 0.7 |

| III | An acceptable, moderate level of expectation: may be used for existing buildings | 0.4 |

| PV Module Parameter | Value | Comments |

|---|---|---|

| ISC at STC | 13.87 A | Short circuit current |

| VOC at STC | 38.08 V | Open circuit voltage |

| IMPP at STC | 13.18 A | Current at max power point |

| VMPP at STC | 31.49 V | Voltage at max power point |

| Temp. coefficient of ISC (STC) | 0.054%/K | αISC |

| Temp. coefficient of VOC (STC) | −0.262%/K | βVOC |

| Number of cells wired in series | 2 strings × 60 | modules |

| Module temperature at NOCT | 315.5 K | |

| Ambient temperature at NOCT | 293 K | |

| Module area | 1.95 m2 | |

| Module efficiency | 21.25% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stamatellou, A.-M.; Zogou, O.; Stamatelos, A. Energy Cost Assessment and Optimization of Post-COVID-19 Building Ventilation Strategies. Sustainability 2023, 15, 3422. https://doi.org/10.3390/su15043422

Stamatellou A-M, Zogou O, Stamatelos A. Energy Cost Assessment and Optimization of Post-COVID-19 Building Ventilation Strategies. Sustainability. 2023; 15(4):3422. https://doi.org/10.3390/su15043422

Chicago/Turabian StyleStamatellou, Antiopi-Malvina, Olympia Zogou, and Anastassios Stamatelos. 2023. "Energy Cost Assessment and Optimization of Post-COVID-19 Building Ventilation Strategies" Sustainability 15, no. 4: 3422. https://doi.org/10.3390/su15043422

APA StyleStamatellou, A.-M., Zogou, O., & Stamatelos, A. (2023). Energy Cost Assessment and Optimization of Post-COVID-19 Building Ventilation Strategies. Sustainability, 15(4), 3422. https://doi.org/10.3390/su15043422