Bioethanol Production from Waste and Nonsalable Date Palm (Phoenix dactylifera L.) Fruits: Potentials and Challenges

Abstract

1. Introduction

- (a)

- sufficiency of the raw material supply and adequacy of active component content;

- (b)

- availability and maturity of the conversion and production technology; and

- (c)

- versatility of the product to society’s demand.

2. Scenario of Date Palm Fruit Production and Waste Generation in Qatar

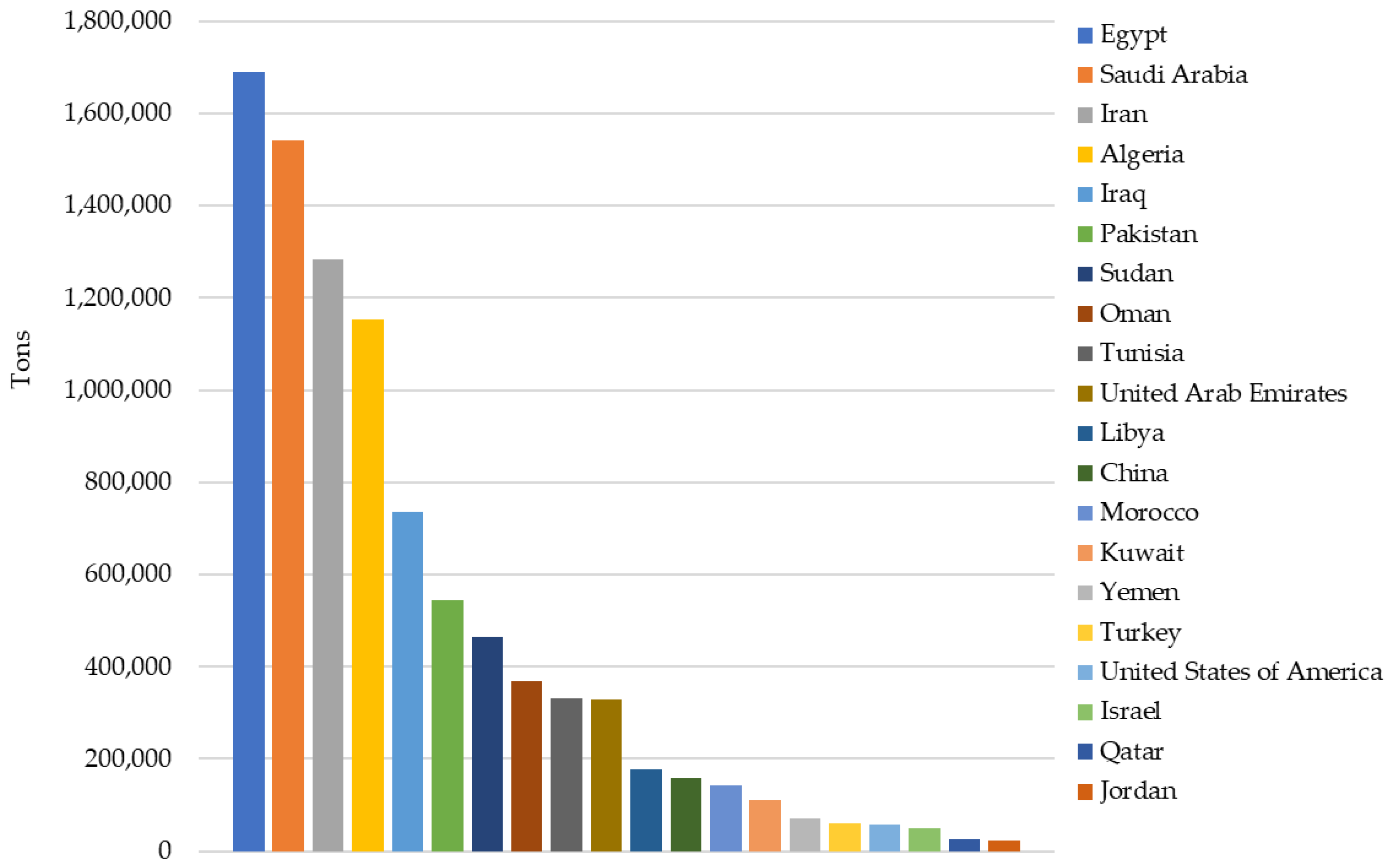

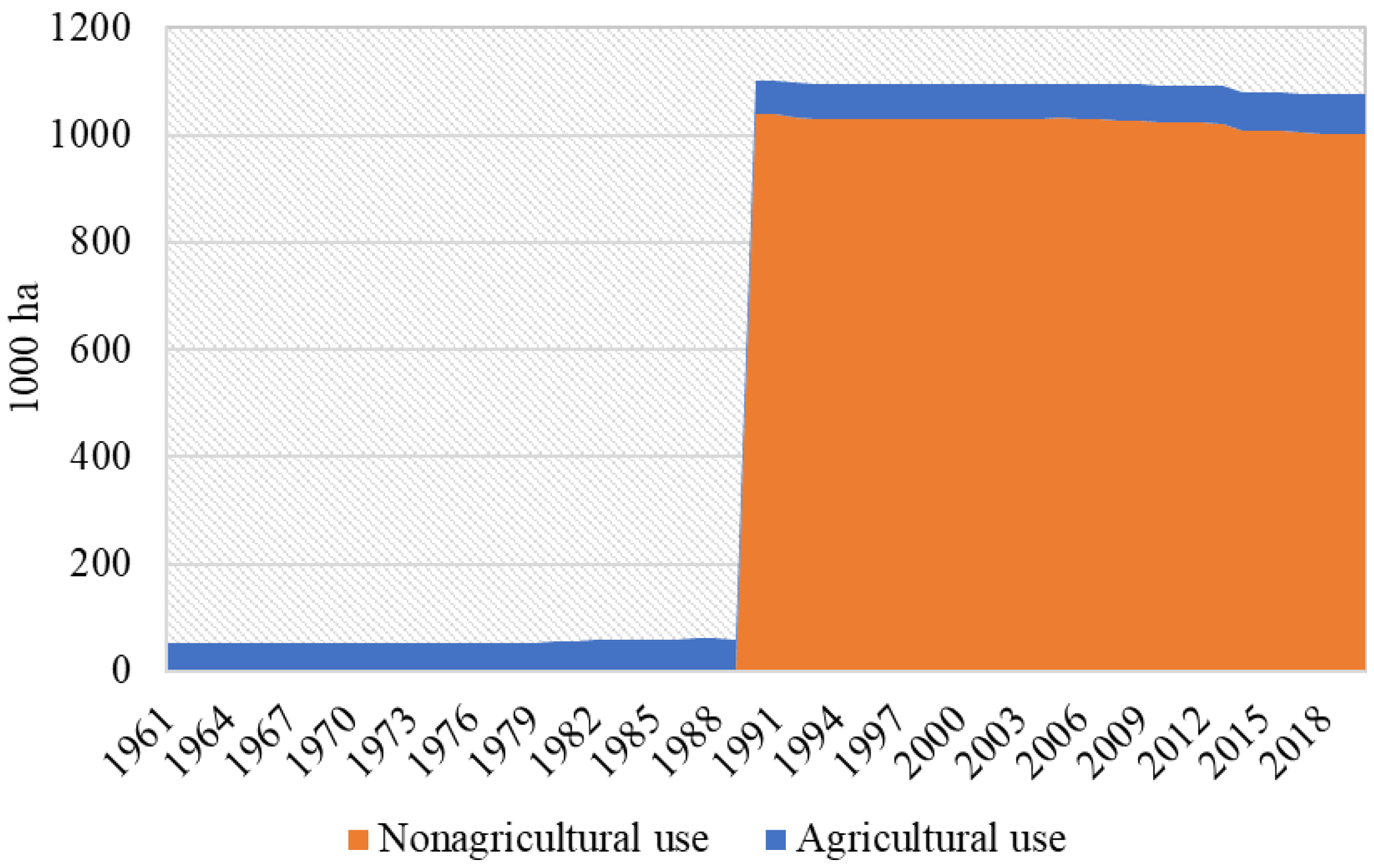

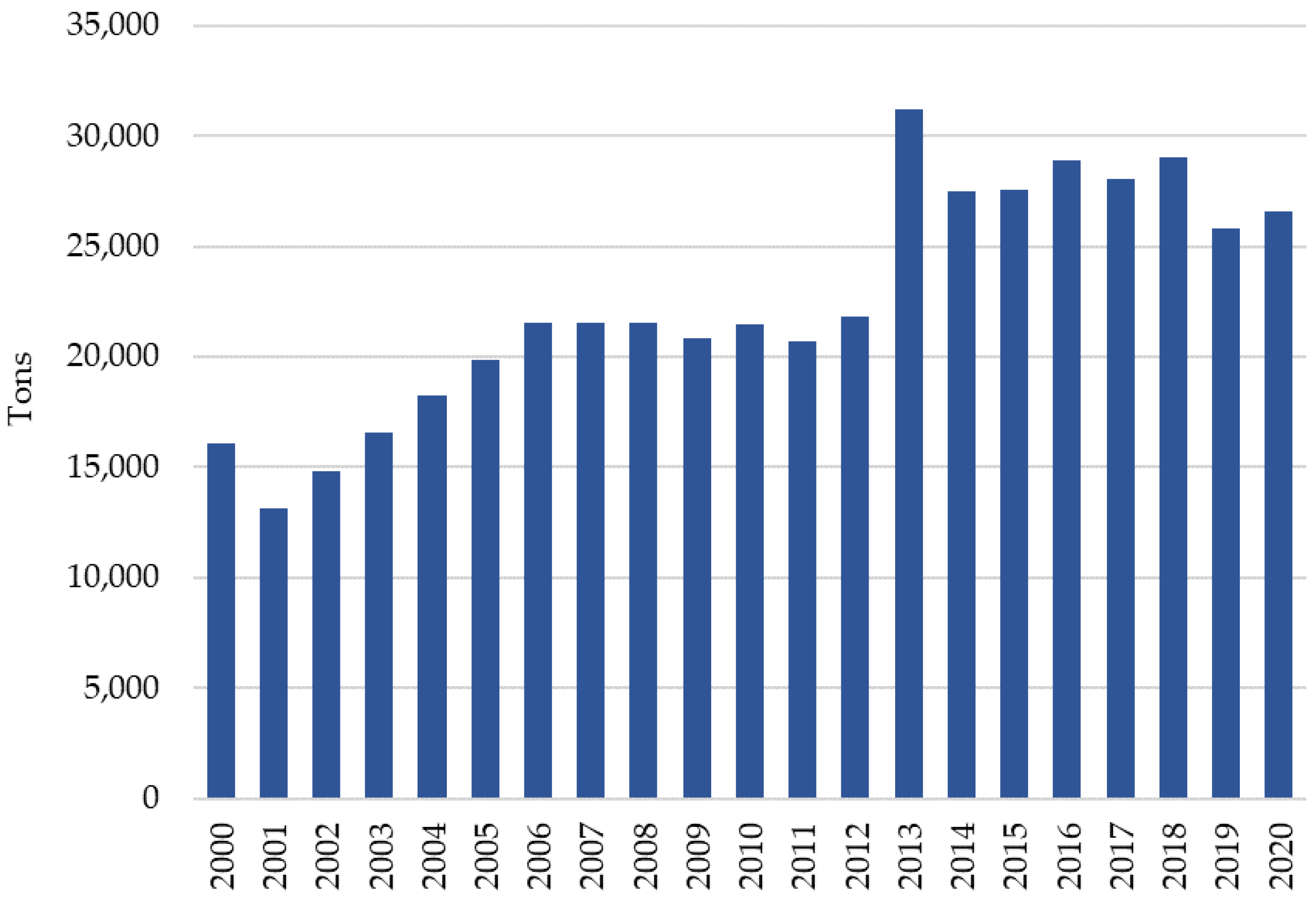

2.1. Date Production in Qatar

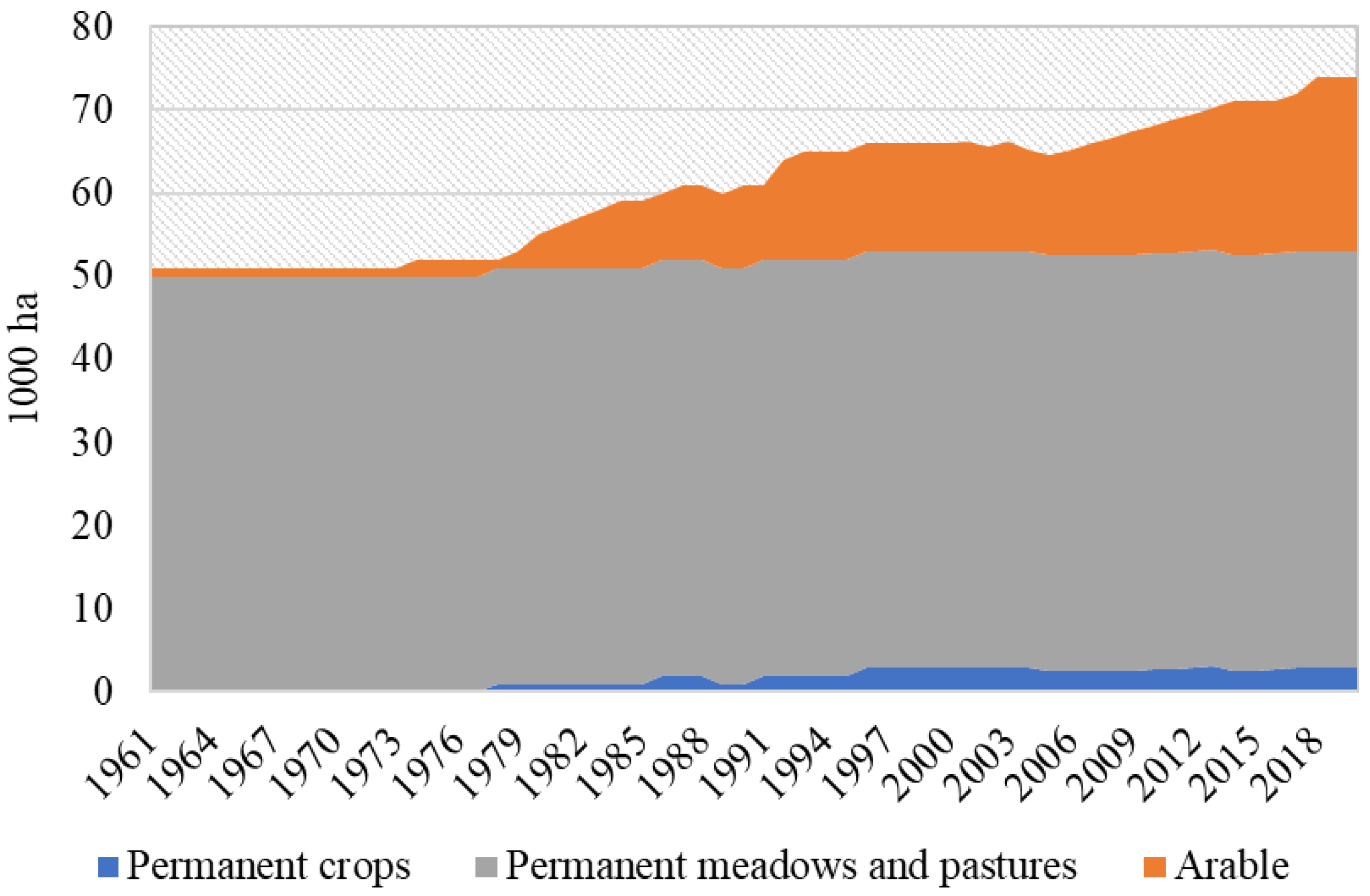

2.2. Agricultural Challenges in Date Production

- a.

- Low-yielding date cultivars, especially among old date palm trees.

- b.

- Low date fruit quality and long fruit generation time.

- c.

- Increased number of non-productive male plants in the field.

- d.

- Inability to distinguish date palm varieties.

- e.

- Low resistance to diseases and pests.

- f.

- Low tolerance to soil and water salinity.

- g.

- Low response to fertilizers.

- h.

- Insufficient good water quality and irrigation system.

2.3. Date Palm Fruit Waste Sources

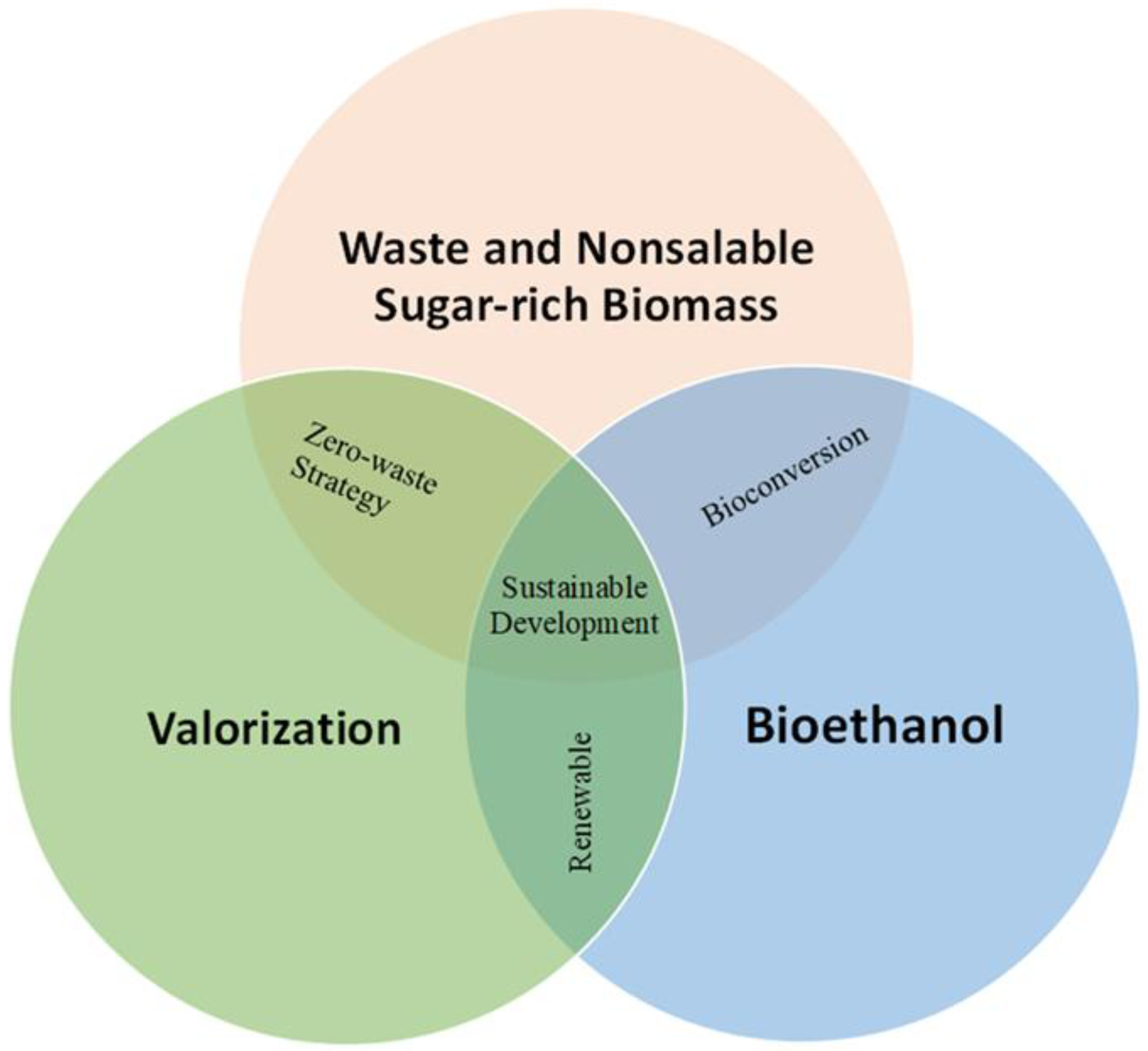

3. Valorization of Waste Date Fruits and Bioethanol Production

3.1. Valorization of Waste Date Palm Fruits

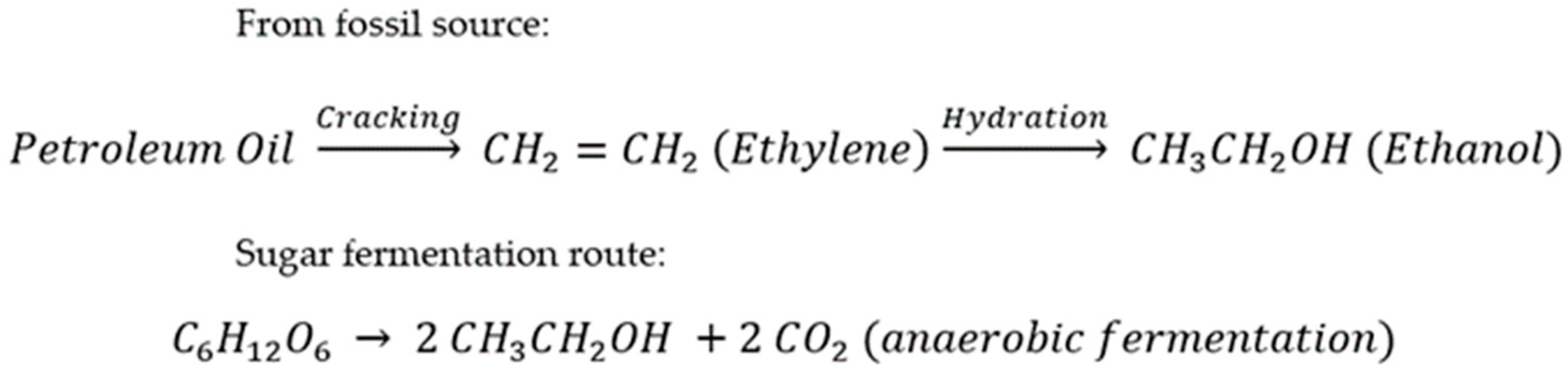

3.2. Bioethanol Production from Date Fruits

3.3. Advances in Ethanol Production from Fruit Waste

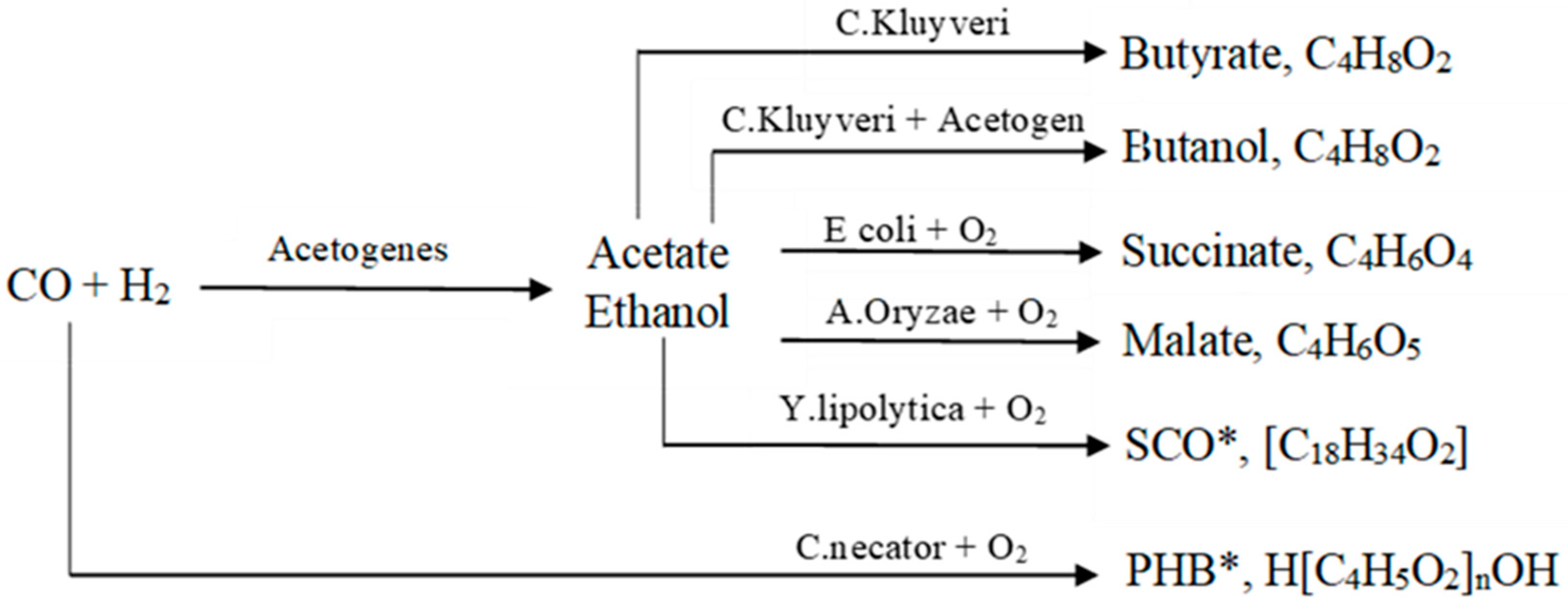

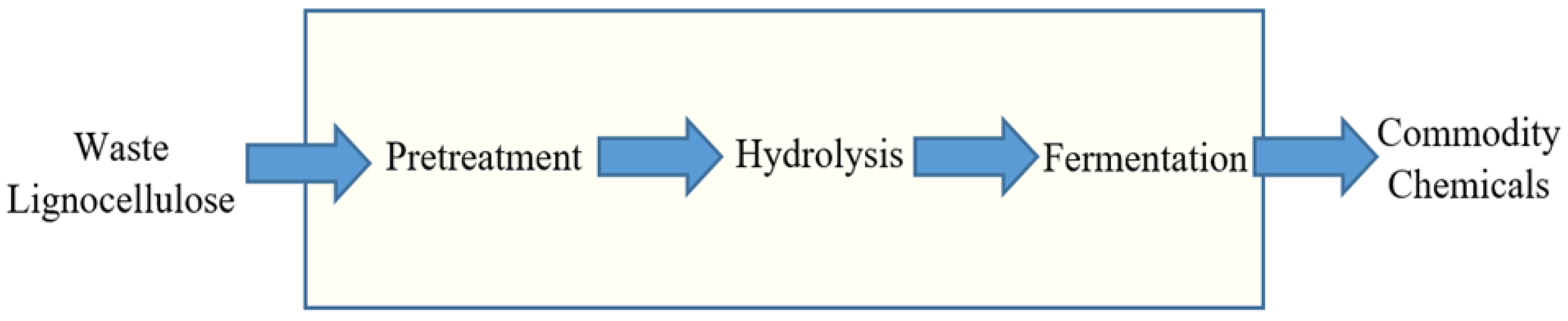

4. Sustainability in Bulk Chemical Production through Bioconversion and Uses of Ethanol

4.1. Sustainability in Bulk Chemicals Production through Bioconversion

4.2. Uses of Ethanol

5. Synthesis and Discussion

6. Conclusions and Future Prospective

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tengberg, M. Beginnings and early history of date palm garden cultivation in the Middle East. J. Arid Environ. 2012, 86, 139–147. [Google Scholar] [CrossRef]

- FAOSTAT. 2020. Available online: https://www.fao.org/faostat/en/#rankings/countries_by_commodity (accessed on 12 September 2022).

- Pariona, A. Leading Countries Growing Dates (Fresh Date Palm Fruits)—WorldAtlas. 2017. Available online: https://www.worldatlas.com/articles/world-leading-countries-growing-fresh-dates.html (accessed on 14 September 2022).

- Dhehibi, B.; Ben Salah, M.; Frija, A. Date Palm Value Chain Analysis and Marketing Opportunities for the Gulf Cooperation Council (GCC) Countries. In Agricultural Economics-Current Issues; IntechOpen: London, UK, 2019. [Google Scholar] [CrossRef]

- Surkatti, R.; Ibrahim, M.H.; El-Naas, M.H. Date pits activated carbon as an effective adsorbent for water treatment. In Sorbents Materials for Controlling Environmental Pollution; Elsevier: Amsterdam, The Netherlands, 2021; pp. 135–161. [Google Scholar] [CrossRef]

- Hossain, M.Z.; Waly, M.I.; Singh, V.; Sequeira, V.; Rahman, M.S. Chemical composition of date-pits and its potential for developing value-added product—A review. Pol. J. Food Nutr. Sci. 2014, 64, 215–226. [Google Scholar] [CrossRef]

- Muhammed, N.H.; Ahmed, O.E.; Ahmed, T.A.; Al-Yafai, M.S. Date palm status and perspective in qatar. In Date Palm Genetic Resources and Utilization; Springer: Berlin/Heidelberg, Germany, 2015; Volume 2, pp. 323–351. [Google Scholar] [CrossRef]

- FAOSTAT. 2020. Available online: https://www.fao.org/faostat/en/#country/179 (accessed on 22 September 2022).

- WITS World Integrated Trade Solution Fruit, Edible; Dates, Fresh or Dried Exports to Qatar|2019. 2019. Available online: https://wits.worldbank.org/trade/comtrade/en/country/All/year/2019/tradeflow/Exports/partner/QAT/product/080410 (accessed on 14 September 2022).

- Ataullah, S. 82 Percent Self-Sufficiency in Dates Production. 2022. Available online: https://thepeninsulaqatar.com/article/02/08/2022/82-percent-self-sufficiency-in-dates-production (accessed on 13 September 2022).

- Taghizadeh-Alisaraei, A.; Motevali, A.; Ghobadian, B. Ethanol production from date wastes: Adapted technologies, challenges, and global potential. Renew. Energy 2019, 143, 1094–1110. [Google Scholar] [CrossRef]

- Al-Dous, E.K.; George, B.; Al-Mahmoud, M.E.; Al-Jaber, M.Y.; Wang, H.; Salameh, Y.M.; Al-Azwani, E.K.; Chaluvadi, S.; Pontaroli, A.C.; Debarry, J.; et al. De novo genome sequencing and comparative genomics of date palm (Phoenix dactylifera). Nat. Biotechnol. 2011, 29, 521–527. [Google Scholar] [CrossRef]

- Amery, H.A. Ethical and Cultural Dimensions of Water Reuse: Islamic Perspectives. In Urban Water Reuse Handbook; CRC Press: Boca Raton, FL, USA, 2015; pp. 311–320. [Google Scholar] [CrossRef]

- Ahmed, Z.F.R.; Kaur, N.; Hassan, F.E. Ornamental Date Palm and Sidr Trees: Fruit Elements Composition and Concerns Regarding Consumption. Int. J. Fruit Sci. 2022, 22, 17–34. [Google Scholar] [CrossRef]

- Bashir, K.; Seki, M.; Nishizawa, N.K. The transport of essential micronutrients in rice. Mol. Breed. 2019, 39, 168. [Google Scholar] [CrossRef]

- Salama, K.F.; Randhawa, M.A.; Al Mulla, A.A.; Labib, O.A. Heavy metals in some date palm fruit cultivars in Saudi Arabia and their health risk assessment. Int. J. Food Prop. 2019, 22, 1684–1692. [Google Scholar] [CrossRef]

- Abdulaal, W.H.; Zeyadi, M.; Baothman, O.A.S.; Zamzami, M.A.; Choudhry, H.; Almulaiky, Y.Q.; Saleh, R.M.; Mohamed, S.A. Investigation of antioxidant and detoxifying capacities of some date cultivars (Phoenix dactylifera L.) irrigated with sewage water. RSC Adv. 2017, 7, 12953–12958. [Google Scholar] [CrossRef]

- Cohen, Y.; Slavkovic, F.; Birger, D.; Greenberg, A.; Sadowsky, A.; Ish-Shalom, M.; Benita, M.; Ticuchinski, T.; Avnat, Y.; Kamenetsky, R. Fertilization and fruit setting in date palm: Biological and technological challenges. In InXXIX International Horticultural Congress on Horticulture: Sustaining Lives, Livelihoods and Landscapes (IHC2014): International Symposia on the Physiology of Perennial Fruit Crops and Production Systems and Mechanisation, Precision Horticulture and Robotics; International Society for Horticultural Science: Leuven, Belgium, 2016; Available online: https://www.researchgate.net/publication/311663324_Fertilization_and_fruit_setting_in_date_palm_biological_and_technological_challenges (accessed on 30 September 2022).

- Nourani, A.; Pegna, F.G.; Romano, A. Mechanically assisted harvesting of dry and semi-dry dates of average to low quality. J. Agric. Environ. Int. Dev. 2021, 115, 85–96. [Google Scholar] [CrossRef]

- Sadeq, M. Community identity and economy in Qatar prior to the oil industry, based on archaeological evidence: An interdisciplinary research study. Arab World Geogr. 2017, 20, 109–129. [Google Scholar] [CrossRef]

- Shaaban, S.; Nasr, M. Toward Three R’s Agricultural Waste in MENA: Reduce, Reuse, and Recycle; Springer: Berlin/Heidelberg, Germany, 2020; pp. 337–353. [Google Scholar] [CrossRef]

- Hamada, J.S.; Hashim, I.B.; Sharif, F.A. Preliminary analysis and potential uses of date pits in foods. Food Chem. 2002, 76, 135–137. [Google Scholar] [CrossRef]

- El-Naas, M.H.; Al-Zuhair, S.; Alhaija, M.A. Removal of phenol from petroleum refinery wastewater through adsorption on date-pit activated carbon. Chem. Eng. J. 2010, 162, 997–1005. [Google Scholar] [CrossRef]

- Chandrasekaran, M.; Bahkali, A.H. Valorization of date palm (Phoenix dactylifera) fruit processing by-products and wastes using bioprocess technology—Review. Saudi J. Biol. Sci. 2013, 20, 105–120. [Google Scholar] [CrossRef] [PubMed]

- Oladzad, S.; Fallah, N.; Mahboubi, A.; Afsham, N.; Taherzadeh, M.J. Date fruit processing waste and approaches to its valorization: A review. Bioresour. Technol. 2021, 340, 125625. [Google Scholar] [CrossRef]

- Zeinelabdeen, M.A.; Abasaeed, A.E.; Gaily, M.H.; Sulieman, A.K.; Putra, M.D. Coproduction of Fructose and Ethanol from Dates by S. cerevisiae ATCC 36859. Int. J. Chem. Mol. Eng. 2013, 7, 417–420. [Google Scholar]

- El-Sohaimy, S.A.; Hafez, E.E. Biochemical and nutritional characterizations of date palm fruits (Phoenix dactylifera L.). J. Appl. Sci. Res. 2010, 6, 1060–1067. [Google Scholar]

- Elguerrouj, M.; Paquot, M.; Robert, C.; Benjouad, A.; Bouakka, M.; Hakkou, A. Physico-chemical composition of two varieties of moroccan palm date fruit. Asian J. Chem. 2011, 23, 1932–1936. [Google Scholar]

- Elhussieny, N.I.; Bakri, M.M.; Ganash, M.; Ghany, T.M.A. Chemical mutagenesis of saccharomyces cerevisiae for enhancing bioethanol production with fermentation at very high sugar concentration. BioResources 2020, 15, 1354–1369. [Google Scholar] [CrossRef]

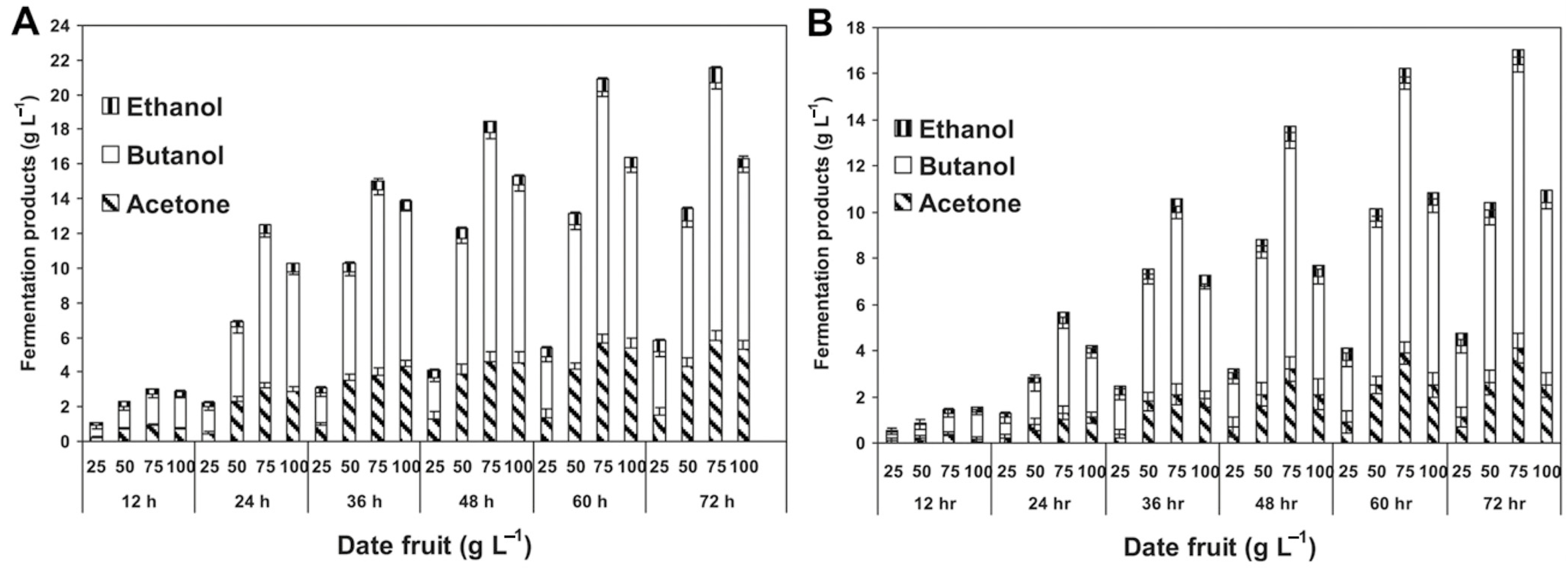

- Abd-Alla, M.H.; Elsadek El-Enany, A.W. Production of acetone-butanol-ethanol from spoilage date palm (Phoenix dactylifera L.) fruits by mixed culture of Clostridium acetobutylicum and Bacillus subtilis. Biomass Bioenergy 2012, 42, 172–178. [Google Scholar] [CrossRef]

- Ahmad, A.; Naqvi, S.A.; Jaskani, M.J.; Waseem, M.; Ali, E.; Khan, I.A.; Faisal Manzoor, M.; Siddeeg, A.; Aadil, R.M. Efficient utilization of date palm waste for the bioethanol production through Saccharomyces cerevisiae strain. Food Sci. Nutr. 2021, 9, 2066–2074. [Google Scholar] [CrossRef]

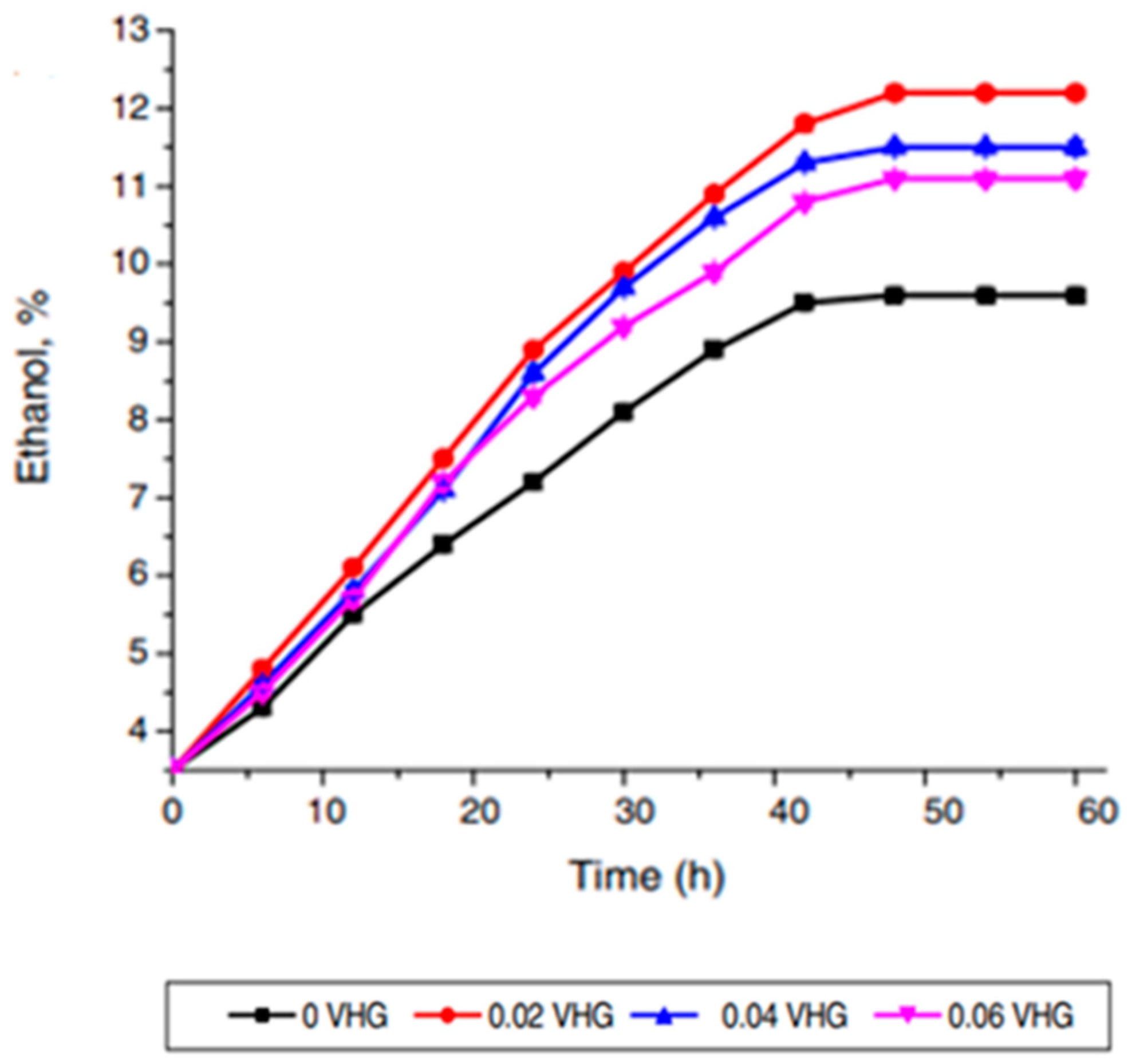

- Arshad, M.; Hussain, T.; Iqbal, M.; Abbas, M. Enhanced ethanol production at commercial scale from molasses using high gravity technology by mutant S. cerevisiae. Braz. J. Microbiol. 2017, 48, 403–409. [Google Scholar] [CrossRef] [PubMed]

- Ajit, A.; Sulaiman, A.Z.; Chisti, Y. Production of bioethanol by Zymomonas mobilis in high-gravity extractive fermentations. Food Bioprod. Process. 2017, 102, 123–135. [Google Scholar] [CrossRef]

- Cazetta, M.L.; Celligoi, M.A.P.C.; Buzato, J.B.; Scarmino, I.S. Fermentation of molasses by Zymomonas mobilis: Effects of temperature and sugar concentration on ethanol production. Bioresour. Technol. 2007, 98, 2824–2828. [Google Scholar] [CrossRef] [PubMed]

- Jacobs, C.J.; Prior, B.A.; de Kock, M.J. A rapid screening method to detect ethanol production by microorganisms. J. Microbiol. Methods 1983, 1, 339–342. [Google Scholar] [CrossRef]

- Vashisht, A.; Thakur, K.; Kauldhar, B.S.; Kumar, V.; Yadav, S.K. Waste valorization: Identification of an ethanol tolerant bacterium Acetobacter pasteurianus SKYAA25 for acetic acid production from apple pomace. Sci. Total Environ. 2019, 690, 956–964. [Google Scholar] [CrossRef]

- Hariantono, J.; Yokota, A.; Shoichi, T.; Tomita, F. Ethanol production from raw starch by simultaneous fermentation using Schizosaccharomyces pombe and a raw starch saccharifying enzyme from Corticium rolfsii. J. Ferment. Bioeng. 1991, 71, 367–369. [Google Scholar] [CrossRef]

- Bryan, W.L. Solid-state fermentation of sugars in sweet sorghum. Enzyme Microb. Technol. 1990, 12, 437–442. [Google Scholar] [CrossRef]

- Juodeikiene, G.; Cernauskas, D.; Vidmantiene, D.; Basinskiene, L.; Bartkiene, E.; Bakutis, B.; Baliukoniene, V. Combined fermentation for increasing efficiency of bioethanol production from Fusarium sp. contaminated barley biomass. Catal. Today 2014, 223, 108–114. [Google Scholar] [CrossRef]

- Jayus; Nurhayati; Mayzuhroh, A.; Arindhani, S.; Caroenchai, C. Studies on Bioethanol Production of Commercial Baker’s and Alcohol Yeast under Aerated Culture Using Sugarcane Molasses as the Media. Agric. Agric. Sci. Procedia 2016, 9, 493–499. [Google Scholar] [CrossRef]

- Boulal, A.; Kihal, M.; Khelifi, C.; Benali, B. Bioethanol production from date palm fruit waste fermentation using solar energy. Afr. J. Biotechnol. 2016, 15, 1621–1627. [Google Scholar] [CrossRef]

- Taouda, H.; Chabir, R.; Aarab, L.; Miyah, Y.; Errachidi, F. Biomass and bio-ethanol production from date extract. J. Mater. Environ. Sci. 2017, 8, 3093–3098. [Google Scholar]

- Bouaziz, F.; Ben Abdeddayem, A.; Koubaa, M.; Barba, F.J.; Ben Jeddou, K.; Kacem, I.; Ghorbel, R.E.; Chaabouni, S.E. Bioethanol Production from Date Seed Cellulosic Fraction Using Saccharomyces cerevisiae. Separations 2020, 7, 67. [Google Scholar] [CrossRef]

- Vidhya, C. Microalgae—The ideal source of biofuel. In Biofuels and Bioenergy; Elsevier: Amsterdam, The Netherlands, 2021; pp. 389–405. [Google Scholar] [CrossRef]

- Chen, H.; Fu, X. Industrial technologies for bioethanol production from lignocellulosic biomass. Renew. Sustain. Energy Rev. 2016, 57, 468–478. [Google Scholar] [CrossRef]

- Ögmundarson, Ó.; Herrgård, M.J.; Forster, J.; Hauschild, M.Z.; Fantke, P. Addressing environmental sustainability of biochemicals. Nat. Sustain. 2020, 3, 167–174. [Google Scholar] [CrossRef]

- Stoll, I.K.; Boukis, N.; Neumann, A.; Ochsenreither, K.; Zevaco, T.A.; Sauer, J. The Complex Way to Sustainability: Petroleum-Based Processes versus Biosynthetic Pathways in the Formation of C4 Chemicals from Syngas. Ind. Eng. Chem. Res. 2019, 58, 15863–15871. [Google Scholar] [CrossRef]

- Sheldon, R.A. The Road to Biorenewables: Carbohydrates to Commodity Chemicals. ACS Sustain. Chem. Eng. 2018, 6, 4464–4480. [Google Scholar] [CrossRef]

- van Haveren, J.; Scott, E.L.; Sanders, J. Bulk chemicals from biomass. Biofuels Bioprod. Biorefining 2008, 2, 41–57. [Google Scholar] [CrossRef]

- Bhetalu, A.; Ingole, N. An overview: Ethanol as Motor Fuel. J. Eng. Res. Stud. 2012, 3, 112–120. [Google Scholar]

- Iodice, P.; Langella, G.; Amoresano, A. Ethanol in gasoline fuel blends: Effect on fuel consumption and engine out emissions of SI engines in cold operating conditions. Appl. Therm. Eng. 2018, 130, 1081–1089. [Google Scholar] [CrossRef]

- Iodice, P.; Amoresano, A.; Langella, G. A review on the effects of ethanol/gasoline fuel blends on NOX emissions in spark-ignition engines. Biofuel Res. J. 2021, 8, 1465–1480. [Google Scholar] [CrossRef]

- Straathof, A.J.J.; Bampouli, A. Potential of commodity chemicals to become bio-based according to maximum yields and petrochemical prices. Biofuels Bioprod. Biorefining 2017, 11, 798–810. [Google Scholar] [CrossRef]

- Bušić, A.; Marđetko, N.; Kundas, S.; Morzak, G.; Belskaya, H.; Šantek, M.I.; Komes, D.; Novak, S.; Šantek, B. Bioethanol Production from Renewable Raw Materials and Its Separation and Purification: A Review. Food Technol. Biotechnol. 2018, 56. [Google Scholar] [CrossRef] [PubMed]

- L’OREAL. Alcohol in Cosmetics. Loreal. 2022. Available online: https://inside-our-products.loreal.com/ingredients/alcohol-cosmetics (accessed on 13 September 2022).

- European Medicines Agency. Medicines Agency. Information for the Package Leaflet Regarding Ethanol Used as An excipient in Medicinal Products for Human Use. Committee for Medicinal Products for Human Use (CHMP). 2018. Available online: https://www.ema.europa.eu/en/documents/scientific-guideline/information-package-leaflet-regarding-ethanol-used-excipient-medicinal-products-human-use_en.pdf (accessed on 17 September 2022).

- Hikmawanti, N.P.E.; Fatmawati, S.; Asri, A.W. The Effect of Ethanol Concentrations as The Extraction Solvent on Antioxidant Activity of Katuk (Sauropus androgynus (L.) Merr.) Leaves Extracts. IOP Conf. Ser. Earth Environ. Sci. 2021, 755, 012060. [Google Scholar] [CrossRef]

- Anseeuw, K.; Sabbe, M.B.; Legrand, A. Methanol poisoning: The duality between ‘fast and cheap’ and ‘slow and expensive’. Eur. J. Emerg. Med. 2008, 15, 107–109. [Google Scholar] [CrossRef] [PubMed]

- Mcdonnell, G.; Russell, A.D. Antiseptics and disinfectants: Activity, action, and resistance. Clin. Microbiol. Rev. 1999, 12, 147–179. [Google Scholar] [CrossRef] [PubMed]

- Bomgardner, M.M.; Mullin, R.; Scott, A. Stepping up to the hand sanitizer shortage. CEN Glob. Enterp. 2020, 98, 12. [Google Scholar] [CrossRef]

- Globartis Qatari Pharmaceutical Company Looking for a Supplier of Ethyl Alcohol (Ethanol) 99.9%. Available online: https://globartis.com/Alcohol-Ethyl-Pharma-Qatar-Supplier-opportunity-1029 (accessed on 17 September 2022).

- Global Market Insights Hand Sanitizer Market Size By Type (Gel, Liquid, Foam), By Composition (Alcohol-based Sanitizer, Alcohol-free Sanitizer), By Distribution Channel (Retail {Pharmaceutical Stores, Supermarkets, Convenience Stores}, Online Platform), Industry Analysis Report. Available online: https://www.gminsights.com/industry-analysis/hand-sanitizer-market (accessed on 17 September 2022).

- Zohri, A.-N.A.; Etnan, M.M. Ethanol Production from Dates in Saudi Arabia on Industrial Scale. Mycobiology 2000, 28, 76–81. [Google Scholar] [CrossRef]

- Yang, D.; Yang, H. Effects of ethanol on gelation of iota-carrageenan. LWT 2020, 126, 109281. [Google Scholar] [CrossRef]

- Zhang, M.; Yu, Y. Dehydration of Ethanol to Ethylene. Ind. Eng. Chem. Res. 2013, 52, 9505–9514. [Google Scholar] [CrossRef]

- Kampf, G. Efficacy of ethanol against viruses in hand disinfection. J. Hosp. Infect. 2017, 98, 331–338. [Google Scholar] [CrossRef]

| Date Cultivar | Agwa | Anbar | Safawi | |||

|---|---|---|---|---|---|---|

| HM | MW | SW | MW | SW | MW | SW |

| Cr | 0.9087 | 0.9836 | 0.3407 | 0.4799 | 0.0188 | 0.1100 |

| Cu | 1.4668 | 1.5334 | 0.2543 | 0.4466 | 0.4785 | 0.5113 |

| Fe | 17.917 | 20.565 | 16.342 | 17.958 | 14.94 | 16.077 |

| Mn | 2.4299 | 3.2355 | 0.2076 | 0.4997 | 0.7985 | 1.25 |

| Pb | 1.122 | 1.459 | 1.148 | 1.48 | 0.903 | 0.982 |

| Zn | 0.0723 | 0.0986 | 0.0967 | 0.1234 | 0.1025 | 0.1153 |

| Bulk Chemicals | Bio-Based Feedstocks |

|---|---|

| Ethylene | sucrose/sugar |

| Ethanol | sucrose/sugar |

| ethylene glycol | glycerine |

| 1,4-butanediol | glycerine |

| Benzene | lignin |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Castillo, A.B.; Cortes, D.J.D.; Sorino, C.F.; Soriño, C.K.P.; El-Naas, M.H.; Ahmed, T. Bioethanol Production from Waste and Nonsalable Date Palm (Phoenix dactylifera L.) Fruits: Potentials and Challenges. Sustainability 2023, 15, 2937. https://doi.org/10.3390/su15042937

Castillo AB, Cortes DJD, Sorino CF, Soriño CKP, El-Naas MH, Ahmed T. Bioethanol Production from Waste and Nonsalable Date Palm (Phoenix dactylifera L.) Fruits: Potentials and Challenges. Sustainability. 2023; 15(4):2937. https://doi.org/10.3390/su15042937

Chicago/Turabian StyleCastillo, Azenith B., Dan Jerry D. Cortes, Caesar F. Sorino, Christian Kim P. Soriño, Muftah H. El-Naas, and Talaat Ahmed. 2023. "Bioethanol Production from Waste and Nonsalable Date Palm (Phoenix dactylifera L.) Fruits: Potentials and Challenges" Sustainability 15, no. 4: 2937. https://doi.org/10.3390/su15042937

APA StyleCastillo, A. B., Cortes, D. J. D., Sorino, C. F., Soriño, C. K. P., El-Naas, M. H., & Ahmed, T. (2023). Bioethanol Production from Waste and Nonsalable Date Palm (Phoenix dactylifera L.) Fruits: Potentials and Challenges. Sustainability, 15(4), 2937. https://doi.org/10.3390/su15042937