Rheological Characterization of Ground Tire Rubber Modified Asphalt Binders with Parallel Plate and Concentric Cylinder Geometries

Abstract

:1. Introduction

2. Objectives and Scope

3. Materials and Methods

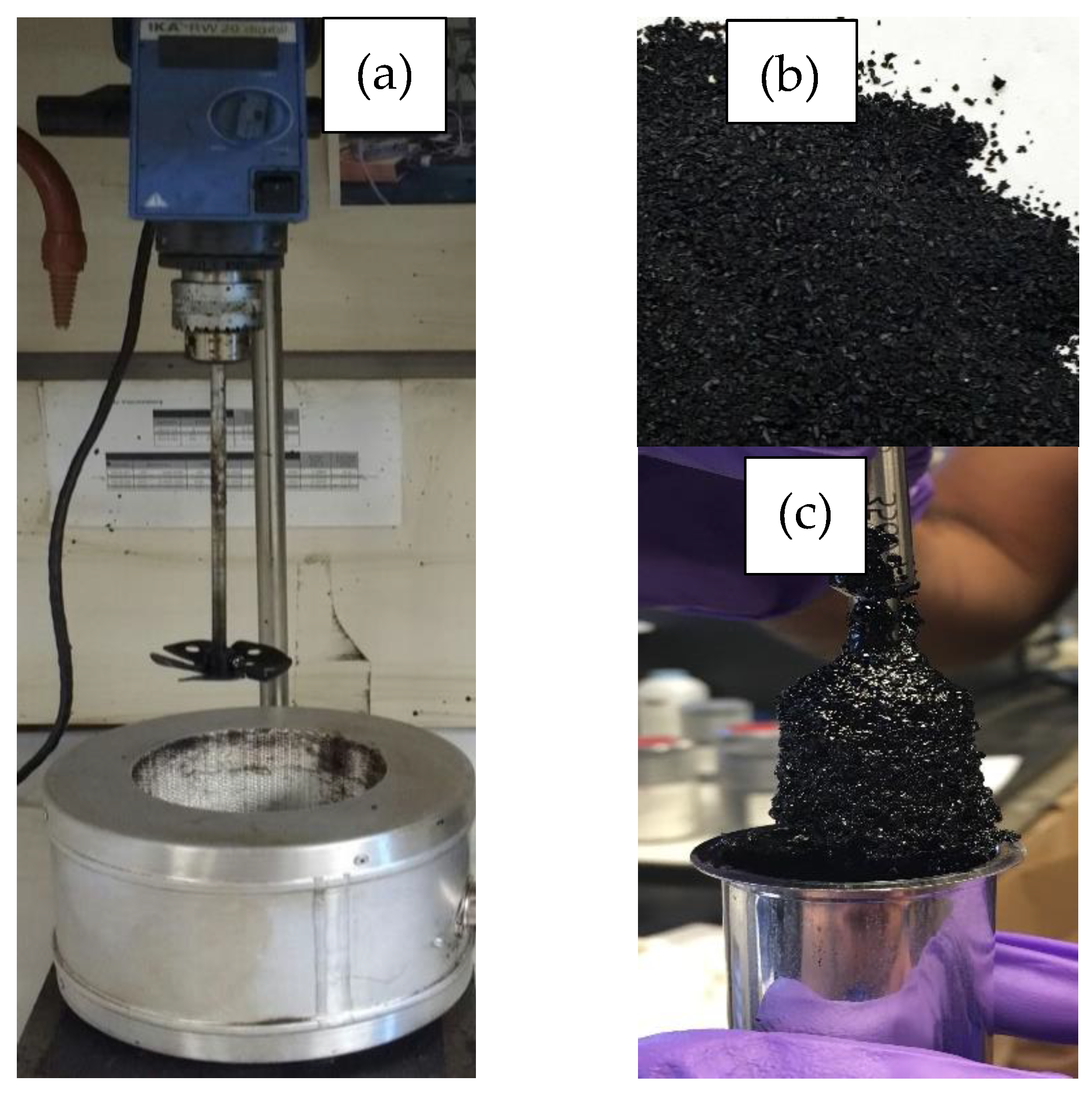

Ground Tire Rubber Modification Process

4. Tests, Results, and Discussion

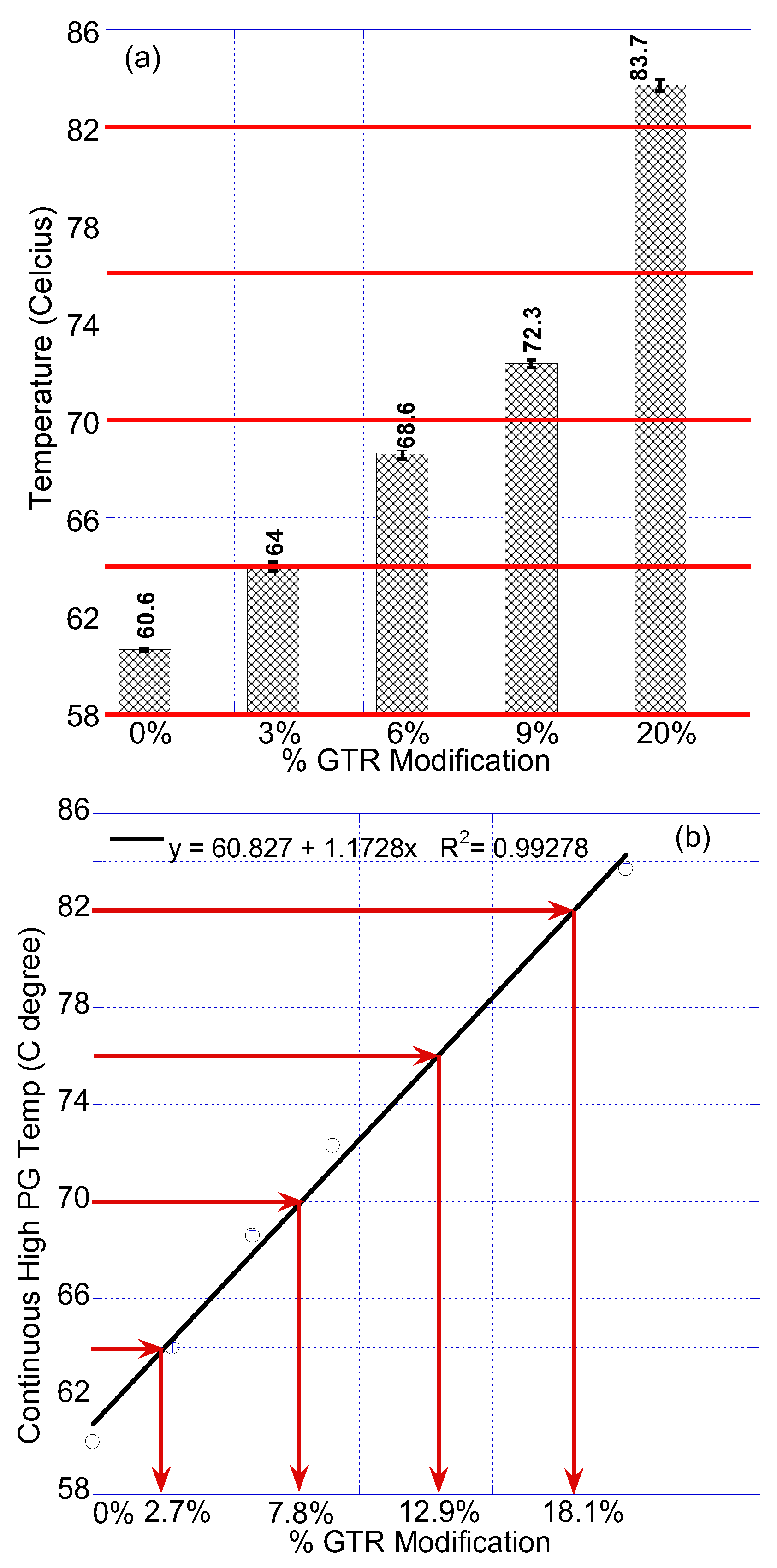

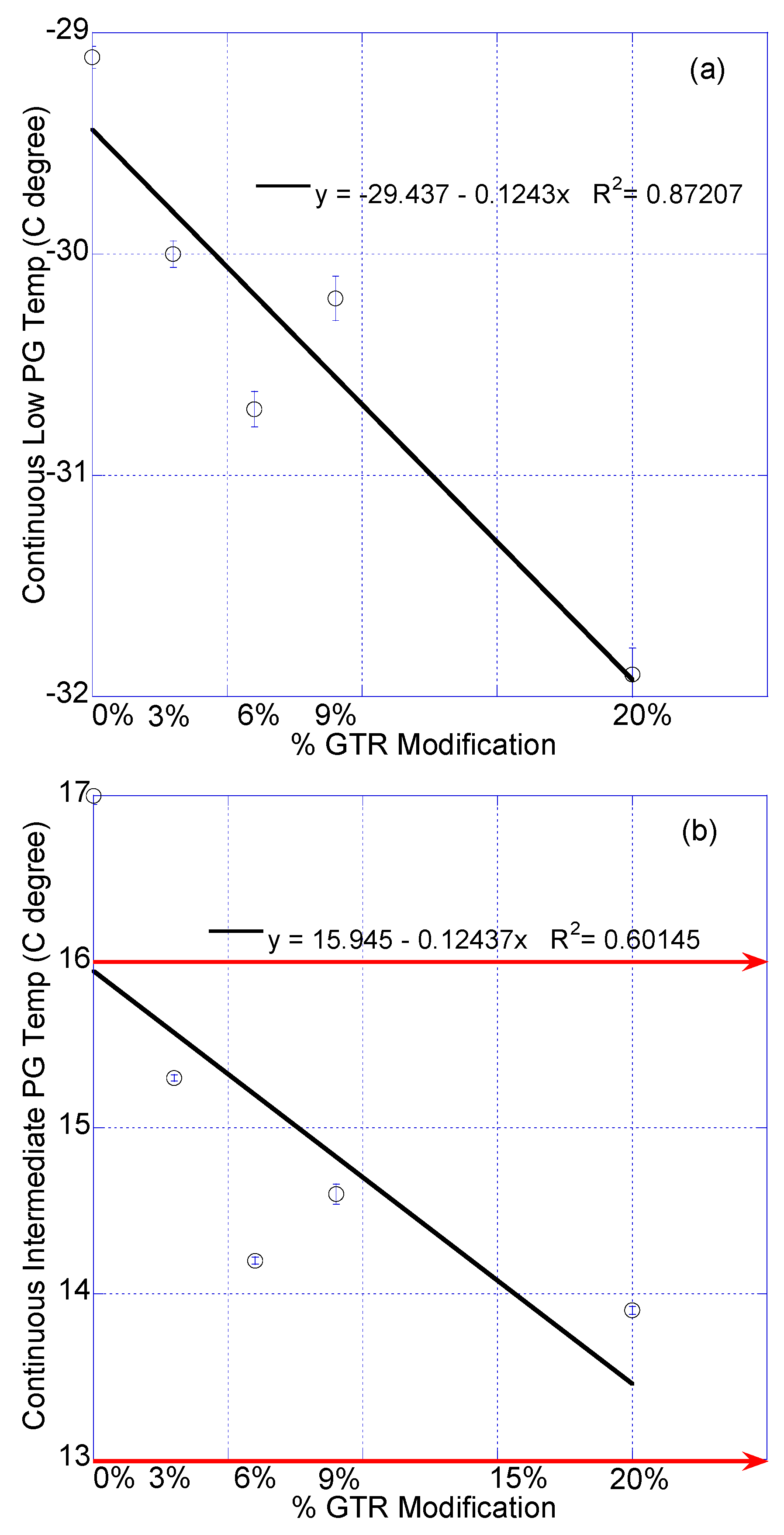

4.1. Continuous High-, Intermediate-, and Low-Performance Grade Tests and Results

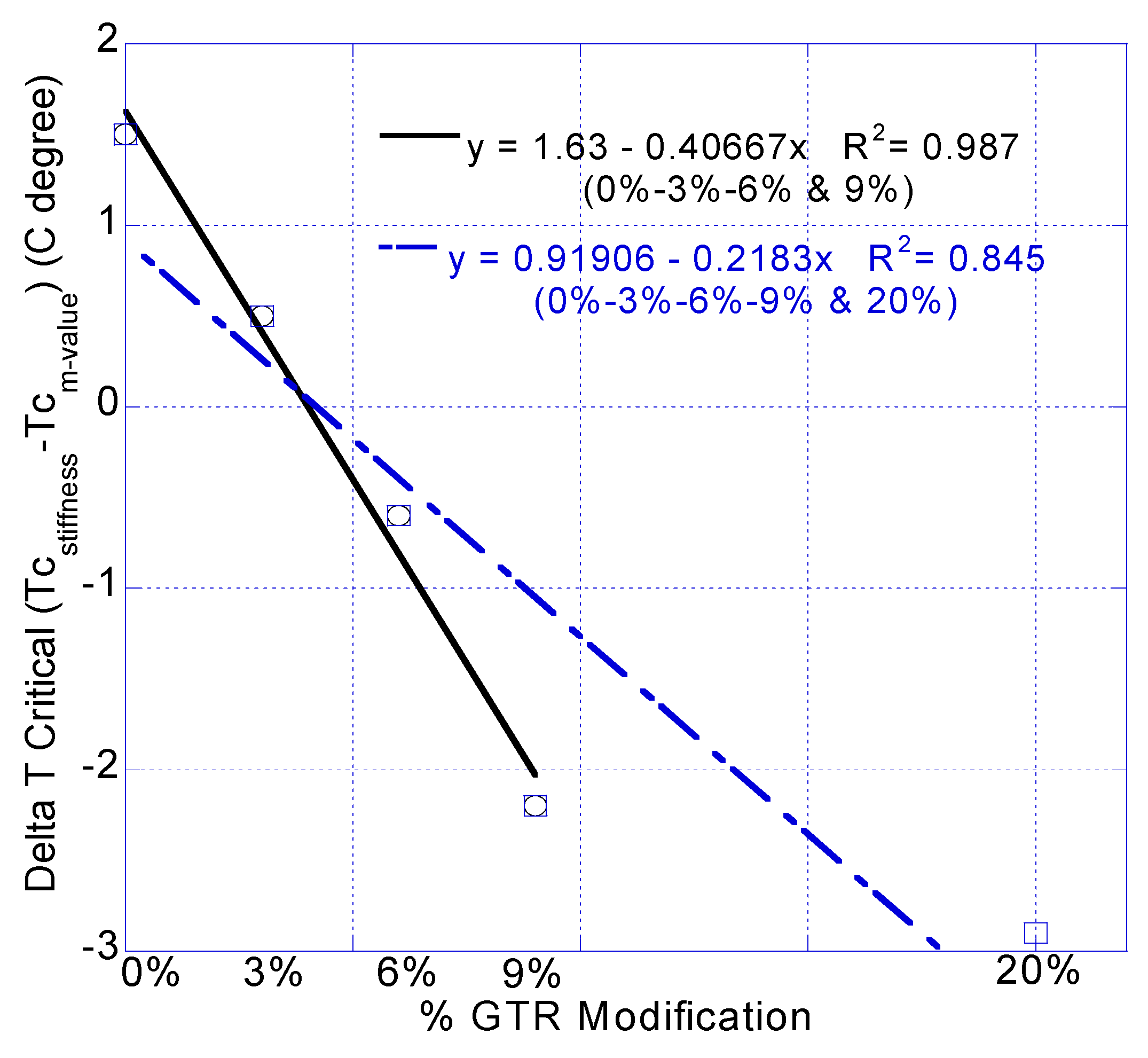

4.2. Delta T Critical (Delta Tc or ΔTc) Analysis

4.3. Fatigue Cracking Resistance Test and Results

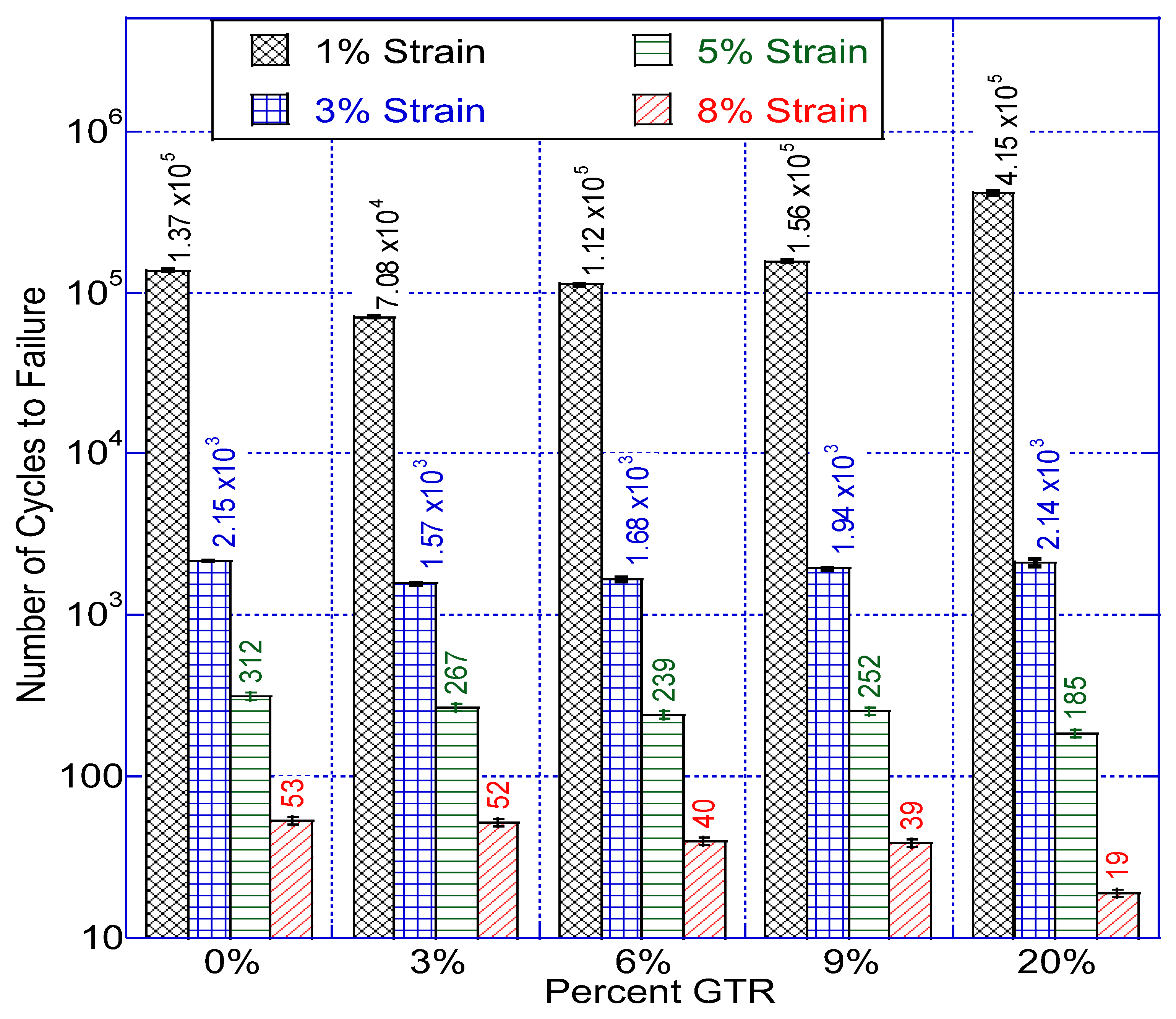

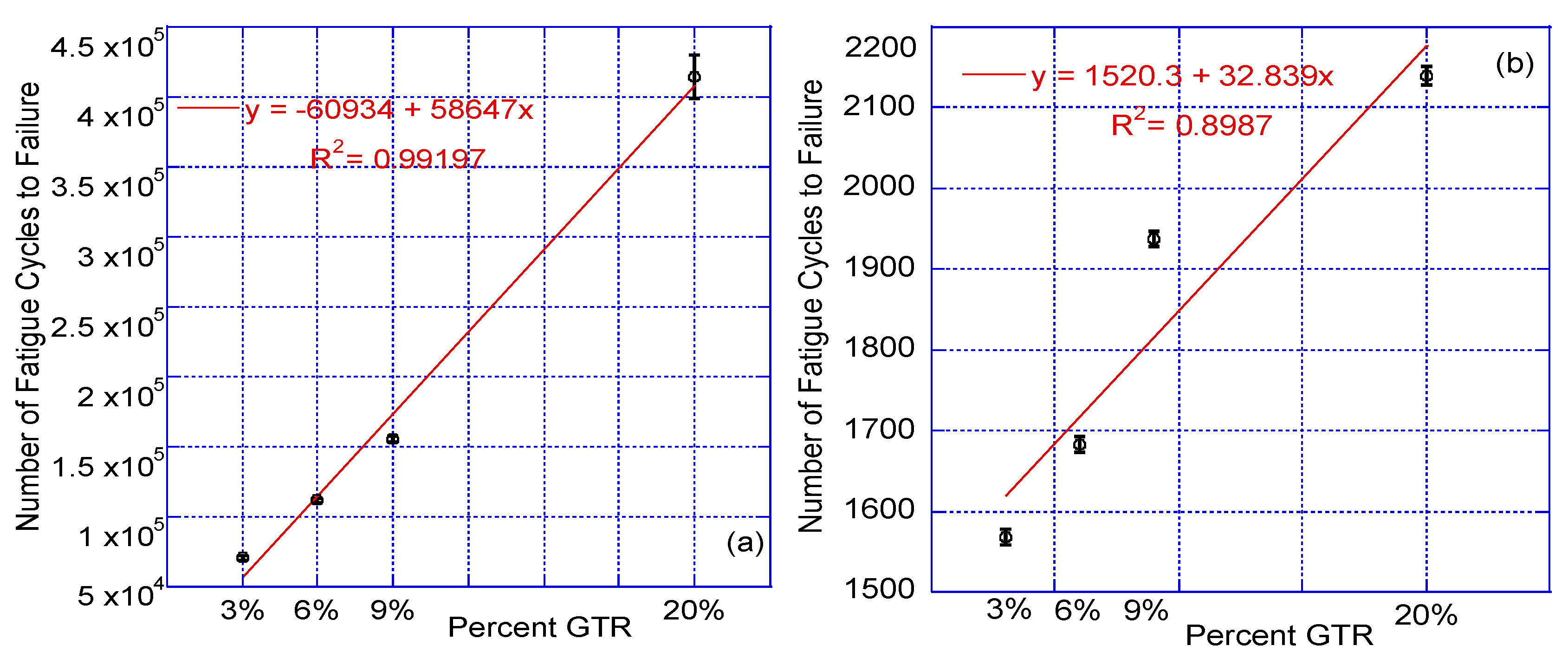

4.4. MSCR Rutting Resistance Test Results with Parallel Plate and Concentric Cylinder Geometries

- ➢

- Standard Traffic: S-grade, which occurs when 2.0 kPa−1 < Jnr@3.2kPa < 4.5 kPa−1;

- ➢

- Heavy Traffic: H-grade, which occurs when 1.0 kPa−1 < Jnr@3.2kPa < 2.0 kPa−1;

- ➢

- Very Heavy Traffic: V-grade, which occurs when 0.5 kPa−1 < Jnr@3.2kPa < 1.0 kPa−1;

- ➢

- Extremely Heavy Traffic: E-grade, which occurs when Jnr@3.2kPa < 0.5 kPa−1.

5. Discussion

6. Conclusions

- The aging during the modification process (A-0% samples) resulted in a change in the PG of the original binder from 58–28 to 58–22. While it improved the CHPG by 1.8 °C, it worsened both CIPG and CLPG by 0.9 °C and 2.2 °C, respectively.

- A linear correlation with R2 of 0.993 was established between CHPG and percent GTR modifications. The 3% GTR modifications achieved a one-grade bump while 9% and 20% GTR modifications accomplished two-grade and four-grade bumps. Similar to the linear correlation of CHPG, linear correlations between percent GTR and CIPG-CLPG were established as well. While the relationship for CLPG had an R2 equal to 0.872, it was 0.6 for CIPG.

- The ΔTc parameter reduced as the artificial aging and percent GTR modification increased. Strong linear correlations between ΔTc and percent GTR modifications with R2 value up to 0.987 were established.

- Based on the LAS test results, as the GTR percentage increased, the fatigue life of the asphalt binders enhanced considerably at lower strain levels and worsened at higher strain levels. The improvements compared to the original binder either were insignificantly small or did not exist.

- At regional high-temperature measurements, all modifications reduced the nonrecoverable creep compliance values compared to the neat binder. Compared to the original binder with no modifications, which was at the H-traffic level, both 9% and 20% GTR modifications achieved two grade bumps and reached the E-traffic level.

- Although the percent recovery values obtained with CC geometries were slightly higher than ones acquired with PP testing geometries, the difference between nonrecoverable creep compliance values was insignificant. A linear correlation between PP and CC geometries was established with R2 equal to 0.98 (0.993 with zero intercepts), implying either testing geometry can be used to determine the nonrecoverable creep compliance.

- Only 20% of GTR modifications tested with PP and CC geometries and 9% of GTR modifications tested with CC geometry were able to pass the AASHTO M322-elastic curve. This indicates that low-percent GTR modifications do not provide enough elasticity to the asphalt binder. Moreover, the type of testing geometry may have an impact on the selection decision of the GTR-modified asphalt binders.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kaloush, K.E.; Biligiri, K.P. Asphalt-Rubber Standard Practice Guide; Links: West Devon, UK, 2011. [Google Scholar]

- Kocak, S. Interaction between Recycled Tire Rubber, Polymers, and High Amount of Reclaimed Asphalt Pavements. Ph.D. Dissertation, Michigan State University, East Lansing, MI, USA, 2016. [Google Scholar]

- Picado-Santos, L.G.; Capitao, S.D.; Neves, J.M.C. Crumb rubber asphalt mixtures: A literature review. Constr. Build. Mater. 2020, 247, 118577. [Google Scholar] [CrossRef]

- Riekstins, A.; Haritonovs, V.; Straupe, V. Economic and environmental analysis of crumb rubber modified asphalt. Constr. Build. Mater. 2022, 335, 127468. [Google Scholar] [CrossRef]

- Behnood, A.; Modiri, G.M. Morphology, rheology, and physical properties of polymer-modified asphalt binders. Eur. Polym. J. 2019, 112, 766–791. [Google Scholar] [CrossRef]

- Bahia, H.U.; Davies, R. Effect of crumb rubber modifiers on performance related properties of asphalt binders. J. Assoc. Asph. Paving Technol. 1994, 63, 414–449. [Google Scholar]

- Roque, R.; Birgisson, B.; Drakos, C.; Sholar, G. Guidelines for Use of Modified Binders; Project No: 4910-4504-964-12; Florida Department of Transportation: Tallahassee, FL, USA, 2005. [Google Scholar]

- Willis, R.J. Use of ground tire rubber in a dense-graded asphalt mixture on US 231 in Alabama: A case study. In Proceedings of the 2013 Airfield and Highway Pavement Conference, Los Angeles, CA, USA, 9–12 June 2013. [Google Scholar]

- Kocak, S.; Kutay, M.E. Fatigue performance assessment of recycled tire rubber modified asphalt mixtures using viscoelastic continuum damage analysis and AASHTOW are pavement ME design. Constr. Build. Mater. 2020, 248, 118658. [Google Scholar] [CrossRef]

- Behnood, A.; Olek, J. Rheological properties of asphalt binders modified with styrene-butadiene-styrene (SBS), ground tire rubber (GTR), or polyphosphoric acid (PPA). Constr. Build. Mater. 2017, 151, 464–478. [Google Scholar] [CrossRef]

- Global Tire Recycling Market Analysis 2025. Opportunity, Demand, Growth and Forecast 2017–2025 Edition 2020. Available online: https://www.goldsteinresearch.com/report/global-tire-recycling-industry-market-trends-analysis (accessed on 1 January 2023).

- McElvery, R. Is the road to sustainable asphalt paved with tires. Am. Chem. Soc. CS Cent. Sci. 2020, 6, 2120–2122. [Google Scholar] [CrossRef]

- Valentini, F.; Pegoretti, A. End-of-life options of tyres. A review. Adv. Ind. Eng. Polym. Res. 2022, 5, 203–213. [Google Scholar] [CrossRef]

- CalRecycle. Tire Management. 2022. Available online: https://calrecycle.ca.gov/tires/ (accessed on 1 January 2023).

- Kocak, S.; Kutay, M.E. Relationship between material characteristics of asphalt mixtures and highway noise. Transp. Res. Rec. 2012, 2295, 35–43. [Google Scholar] [CrossRef]

- Xu, L.; Ni, H.; Zhang, Y.; Sun, D.; Zheng, Y.; Hu, M. Porous asphalt mixture use asphalt rubber binders: Preparation and noise reduction evaluation. J. Clean. Prod. 2022, 376, 134119. [Google Scholar] [CrossRef]

- Noel, B. Five Major Benefits of Rubber Modified Asphalt. 2022. Available online: https://www.forconstructionpros.com/asphalt/article/22458257 (accessed on 1 January 2023).

- Buttlar, W.G.; Rath, P. State of Knowledge Report on Rubber Modified Asphalt; US Tire Manufacturing Association: Washington, DC, USA, 2021. [Google Scholar]

- Calabi-Floody, A.; Mignolet-Garrido, C.; Valdes-Vidal, G. Study of the effect of the use of asphalt binders modified with polymer fibres from end-of-life tyres (ELT) on the mechanical properties of hot mix asphalt at different operating temperatures. Materials 2022, 15, 7578. [Google Scholar] [CrossRef] [PubMed]

- Kocak, S.; Kutay, M.E. Use of crumb rubber in lieu of binder grade bumping for mixture with high percentage of reclaimed asphalt pavement. Road Mater. Pavement Des. 2017, 18, 116–129. [Google Scholar] [CrossRef]

- Papagiannakis, A.T. A Review of Crumb-Rubber Modified Asphalt Concrete Technology; Research Project T9902-09 Rubber-Asphalt Study; Washington State Transportation Center: Pullman, WA, USA, 1995. [Google Scholar]

- Hassan, N.A.; Airey, G.D.; Jaya, R.P.; Mashros, N.; Aziz, M. A review of crumb rubber modification in dry mixed rubberised asphalt mixtures. J. Teknol. 2014, 70, 127–134. [Google Scholar]

- Nuha, S.M.; Asim, H.A.; Mohamed, R.K.; Mahrez, A. An overview of crumb rubber modified asphalt. Int. J. Phys. Sci. 2012, 7, 166–170. [Google Scholar]

- Xia, C.; Chen, M.; Geng, J.; Liao, X.; Chen, Z. Swelling and degradation characteristics of crumb rubber modified asphalt during processing. Math. Probl. Eng. 2021, 2021, 6682905. [Google Scholar] [CrossRef]

- Kocak, S.; Kutay, M.E. Effect of devulcanized rubber modification on performance grade, fatigue cracking resistance and rutting resistance of asphalt binders. J. Mater. Civ. Eng. 2021, 33. [Google Scholar] [CrossRef]

- Kocak, S.; Kutay, M.E. Combined effect of SBS and devulcanized rubber (DVR) modification on performance grade and fatigue cracking resistance of asphalt binders. In 8th RILEM International Conference on Mechanisms of Cracking and Debonding in Pavements; Springer: Berlin/Heidelberg, Germany, 2016; Volume 13, pp. 269–274. [Google Scholar]

- Zeng, Z.A.; Underwood, B.S.; Castorena, C. Low-temperature performance grade characterisation of asphalt binder using the dynamic shear rheometer. Int. J. Pavement Eng. 2022, 23, 811–823. [Google Scholar] [CrossRef]

- Anderson, R.M.; King, G.N.; Hanson, D.I.; Blankenship, P.B. Evaluation of the relationship between asphalt binder properties and non-load related cracking. J. Assoc. Asph. Paving Technol. 2021, 80, 615–664. [Google Scholar]

- Federal Highway Administration (FHWA). Technical Brief on Delta Tc Binder Specification Parameter; FHWA-HIF-21-042:29; Federal Highway Administration (FHWA): Washington, DC, USA, 2021. [Google Scholar]

- Asphalt Institute (AI). State -of-the-Knowledge: Use of the Delta Tc Parameter to Characterize Asphalt Binder Behavior; AI-IS-240; Asphalt Institute (AI): Lexington, AL, USA, 2019. [Google Scholar]

- Reinke, G. The relationship of binder delta Tc (ΔTc) and other binder properties to mixture fatigue and relaxation. In Proccedings of the Binder ETC Meeting, Fall River, MA, USA, 10 May 2018. [Google Scholar]

- Jafari, M.; Babazadeh, A. Evaluation of polyphosphoric acid-modified binders using multiple stress creep and recovery and linear amplitude sweep tests. Road Mater. Pavement Des. 2016, 17, 859–876. [Google Scholar] [CrossRef]

- Xie, W.; Castorena, C.; Wang, C.; Kim, Y. A framework to characterize the healing potential of asphalt binder using the linear amplitude sweep test. Constr. Build. Mater. 2017, 154, 771–779. [Google Scholar] [CrossRef]

- Safaei, F.; Castorena, C. Temperature effects of linear amplitude sweep testing and analysis. Transp. Res. Rec. 2016, 2574, 92–100. [Google Scholar] [CrossRef]

- Teymourpour, P.; Bahia, H. Linear amplitude sweep test: Binder grading specification and field validation. In Proccedings of the Binder Expert Task Group Meeting, Baton Rouge, LA, USA, 16 September 2014. [Google Scholar]

- Hintz, C.; Bahia, H. Simplification of linear amplitude sweep test and specification parameter. Transp. Res. Rec. 2013, 2370, 10–16. [Google Scholar] [CrossRef]

- Liu, H.; Zeiada, W.; Al-Khateeb, G.G.; Shanableh, A.; Samarai, M. Use of the multiple stress creep recovery (MSCR) test to characterize the rutting potential of asphalt binders: A literature review. Constr. Build. Mater. 2021, 269, 121320. [Google Scholar] [CrossRef]

- D’Angelo, J.; Dongré, R. Practical use of multiple stress creep and recovery test: Characterization of styrene–butadiene–styrene dispersion and other additives in polymer-modified asphalt binders. Transp. Res. Rec. 2009, 2126, 73–82. [Google Scholar] [CrossRef]

- D’Angelo, J. The relationship of the MSCR test to rutting. Road Mater. Pavement Des. 2009, 10, 61–80. [Google Scholar] [CrossRef]

- Laukkanen, O.V.; Soenen, H.; Pellinen, T.; Heyrman, S.; Lemoine, G. Creep-recovery behavior of bituminous binders and its relation to asphalt mixture rutting. Mater. Struct. 2015, 48, 4039–4053. [Google Scholar] [CrossRef]

- Ahmed, T.A.; Hajj, E.Y.; Bahzad, D.S.; Piratheepan, M.; Warrag, A. Investigation of the rheological and bonding characteristics of crumb rubber-modified asphalt binders mixed with warm mix asphalt additive and antistrip agent. Int. J. Pavement Res. Technol. 2022, 15, 509–524. [Google Scholar] [CrossRef]

- Zhu, H.; Zhang, M.; Li, Y.; Zou, Y.; Chen, A.; Wang, F.; Liu, L.; Gu, D.; Zhou, S. Swelled mechanism of crumb rubber and technical properties of crumb rubber modified bitumen. Materials 2022, 15, 7987. [Google Scholar] [CrossRef]

- Haibin, L.; Cui, C.; Temitope, A.; Feng, Z.; Zhao, G.; Guo, P. Effect of SBS and crumb rubber on asphalt modification: A review of the properties and practical application. J. Traffic Transp. Eng. 2022, 9, 836–863. [Google Scholar]

- Ren, S.; Liu, X.; Lin, P.; Wang, H.; Fan, W.; Erkens, S. The continuous swelling-degradation behaviors and chemo-rheological properties of waste crumb rubber modified bitumen considering the effect of rubber size. Constr. Build. Mater. 2021, 307, 124966. [Google Scholar] [CrossRef]

- Ren, S.; Liu, X.; Lin, P.; Erkens, S. Influence of swelling-degradation degree on rheological properties, thermal pyrolysis kinetics, and emission components of waste crumb rubber modified bitumen. Constr. Build. Mater. 2022, 337, 127555. [Google Scholar] [CrossRef]

- Baumgardner, G.L. Delta Tc Asphalt Binder Specification Parameter, FHWA Development and Deployment of Innovative Asphalt Pavement Technologies Coop Agreement with University of Nevade, Reno; Federal Highway Administration (FHWA): Washington, DC, USA, 2021. [Google Scholar]

- Li, J.; Xiao, F.O.; Amirkhanian, S.N. Storage, fatigue and low temperature characteristics of plasma treated rubberized binders. Constr. Build. Mater. 2022, 209, 454–462. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, T.; Pei, J.; Amirkhanian, S.; Xiao, F.; Ye, Z. Fan Low temperature and fatigue characteristics of treated crumb rubber modified asphalt after a long term aging procedure. J. Clean. Prod. 2019, 234, 1262–1274. [Google Scholar] [CrossRef]

- Shi, C.; Zhou, W.; Wang, T.; Cai, X.; Wang, H.; Yang, J.; Hong, J.; Gong, M. Fatigue performance characterization of styrene-butadiene-styrene and crumb rubber composite modified asphalt binders with high crumb rubber contents. J. Clean. Prod. 2022, 331, 129979. [Google Scholar] [CrossRef]

- Niu, D.; Xie, X.; Zhang, Z.; Niu, Y.; Yang, Z. Influence of binary waste mixtures on road performance of asphalt and asphalt mixture. J. Clean. Prod. 2021, 298, 126842. [Google Scholar] [CrossRef]

- Li, F.; Zhang, X.; Wang, L.; Zhai, R. The preparation process, service performances and interaction mechanisms of crumb rubber modified asphalt (CRMA) by wet process: A comprehensive review. Constr. Build. Mater. 2022, 354, 129168. [Google Scholar] [CrossRef]

- Badri, M.R.; Alkaissi, Z.A.; Sutanto, M. Physical, rheological and morphological characterization of modified asphalt binder with differing crumb rubber contents. Mater. Today Proc. 2021, 42, 3028–3034. [Google Scholar] [CrossRef]

- Chen, Y.; Ji, C.; Wang, H.; Su, Y. Evaluation of crumb rubber modification and short-term aging on the rutting performance of bioasphalt. Constr. Build. Mater. 2018, 193, 467–473. [Google Scholar] [CrossRef]

- Zhang, L.; Xing, C.; Gao, F.; Li, T.; Tan, Y. Using DSR and MSCR tests to characterize high temperature performance of different rubber modified asphalt. Constr. Build. Mater. 2016, 127, 466–474. [Google Scholar] [CrossRef]

| Property | Value | Unit |

|---|---|---|

| Continuous High Grade | 60.1 | °C |

| Continuous Intermediate Grade | 17 | °C |

| Continuous Low Grade | −29.1 | °C |

| Viscosity at 135 °C & 170 °C | 285 & 68 | cP |

| |G*| at 10 °C & 70 °C | 3,470,167 & 238 | Pa |

| Phase Angle at 10 °C & 70 °C | 62.6 & 88.8 | degrees |

| Flash Point | 312 | °C |

| GTR 3% Original | GTR 3% RTFO-Aged | ||||||

|---|---|---|---|---|---|---|---|

| Average of Run 1 | Average of Run 2 | AVR 1 | Average of Run 1 | Average of Run 2 | AVR 1 | ||

| TC-neat (°C) | 64.28 | 63.64 | 63.96 | TC-rtfo (°C) | 64.75 | 65.01 | 64.87 |

| T1 (°C) | 64.0 | 58 | Stdev 2 | T1 (°C) | 64.0 | 64.0 | Stdev 2 |

| T2 (°C) | 70.0 | 64.0 | 0.46 | T2 (°C) | 70.0 | 70.0 | 0.17 |

| P1 (kPa) | 1.03 | 1.97 | COV 3 | P1 (kPa) | 2.4 | 2.47 | COV 3 |

| P2 (kPa) | 0.548 | 0.956 | 0.71% | P2 (kPa) | 1.2 | 1.23 | 0.26% |

| Ps (kPa) | 1.0 | 1.0 | Ps (kPa) | 2.2 | 2.2 | ||

| TC-final (°C) | 63.96 | ||||||

| GTR 3% Stiffness (S-Value) Based | GTR 3% Slope (m-Value) Based | ||||||

|---|---|---|---|---|---|---|---|

| Average of Run 1 | Average of Run 2 | AVR | Average of Run 1 | Average of Run 2 | AVR | ||

| TC-s (°C) | −20.03 | −20.04 | −20.04 | TC-m (°C) | −20.59 | −20.36 | −20.48 |

| T1 (°C) | −18 | −18 | Stdev | T1 (°C) | −18 | −18 | Stdev |

| T2 (°C) | −24 | −24 | 0.46 | T2 (°C) | −24 | −24 | 0.16 |

| P1 (MPa) | 231 | 230 | COV | P1 (MPa) | 0.319 | 0.313 | COV |

| P2 (MPa) | 501 | 503 | 1.53% | P2 (MPa) | 0.275 | 0.280 | 0.53% |

| Ps (MPa) | 300 | 300 | Ps (MPa) | 0.300 | 0.300 | ||

| TC (°C) | −20.04 | ||||||

| Modification Type | Continuous | Continuous Inter. PG (°C) | Continuous | CHPG-CLPG | |||||

|---|---|---|---|---|---|---|---|---|---|

| High PG (°C) | Low PG (°C) | ||||||||

| CH PG | Original PG | RTFO Aged | CIPG PAV Aged | CLPG | S-Based | m-Value Based | ΔTc | (°C) | |

| 0% | 60.1 | 60.1 | 61.2 | 17.0 | −29.1 | −29.1 | −30.6 | 1.5 | 89.2 |

| A-−0% | 61.9 | 61.9 | 62.5 | 17.9 | −26.9 | −28.4 | −26.9 | −1.5 | 88.8 |

| 3% GTR | 64.0 | 64.0 | 64.9 | 15.3 | −30.0 | −30.0 | −30.5 | 0.5 | 94.0 |

| 6% GTR | 68.6 | 68.6 | 69.3 | 14.2 | −30.7 | −31.3 | −30.7 | −0.6 | 99.3 |

| 9% GTR | 72.3 | 72.3 | 74.3 | 14.6 | −30.2 | −32.4 | −30.2 | −2.2 | 102.5 |

| 20% GTR | 83.7 | 83.7 | 86.4 | 13.9 | −31.9 | −34.8 | −31.9 | −2.9 | 115.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kocak, S. Rheological Characterization of Ground Tire Rubber Modified Asphalt Binders with Parallel Plate and Concentric Cylinder Geometries. Sustainability 2023, 15, 2880. https://doi.org/10.3390/su15042880

Kocak S. Rheological Characterization of Ground Tire Rubber Modified Asphalt Binders with Parallel Plate and Concentric Cylinder Geometries. Sustainability. 2023; 15(4):2880. https://doi.org/10.3390/su15042880

Chicago/Turabian StyleKocak, Salih. 2023. "Rheological Characterization of Ground Tire Rubber Modified Asphalt Binders with Parallel Plate and Concentric Cylinder Geometries" Sustainability 15, no. 4: 2880. https://doi.org/10.3390/su15042880

APA StyleKocak, S. (2023). Rheological Characterization of Ground Tire Rubber Modified Asphalt Binders with Parallel Plate and Concentric Cylinder Geometries. Sustainability, 15(4), 2880. https://doi.org/10.3390/su15042880