Enhancing Biogas Production of Co-Digested Cattle Manure with Grass Silage from a Local Farm in Landshut, Bavaria, through Chemical and Mechanical Pre-Treatment and Its Impact on Biogas Reactor Hydraulic Retention Time

Abstract

1. Introduction

1.1. Lignocelluloses

1.2. Anaerobic Co-Digestion of Cattle Manure and Grass Silage

1.3. Pretreatments

1.3.1. Mechanical Pretreatment

1.3.2. Chemical Pretreatment

2. Materials and Methods

2.1. Substrate and Inoculum

2.2. Pretreatment and Gas Fermentation: Experimental Conditions and Analyzed Parameters

3. Results

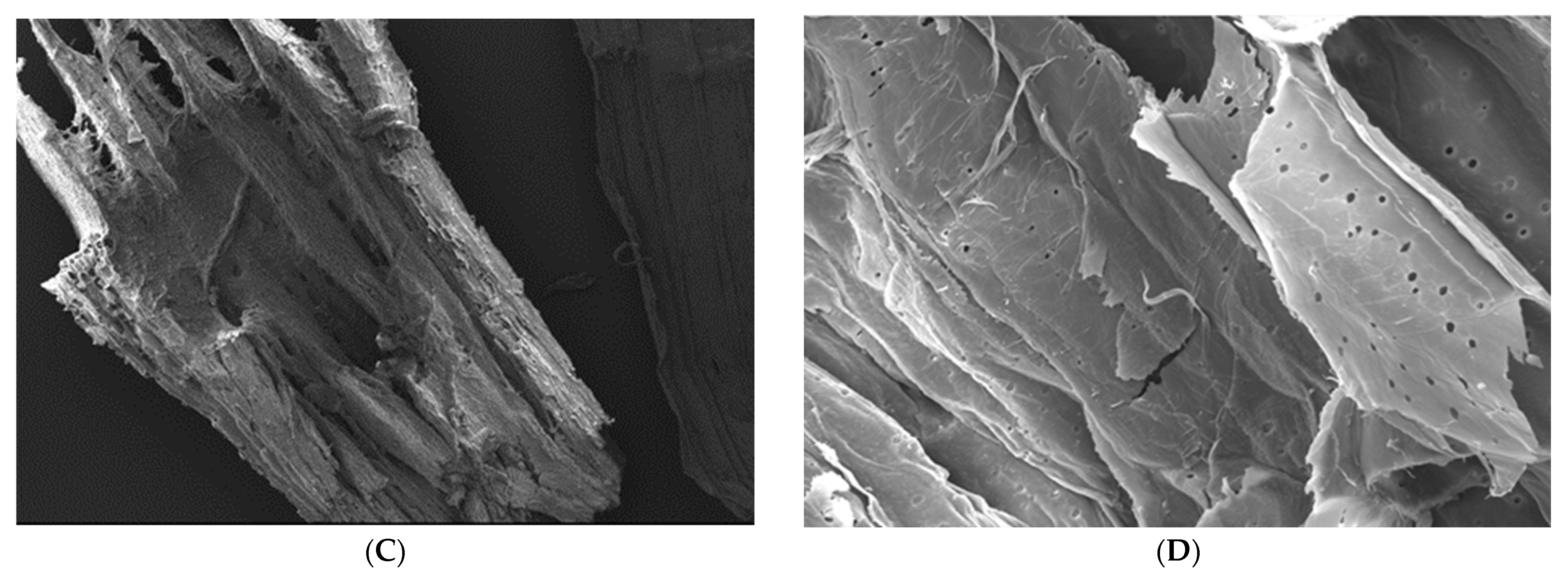

3.1. Substrate

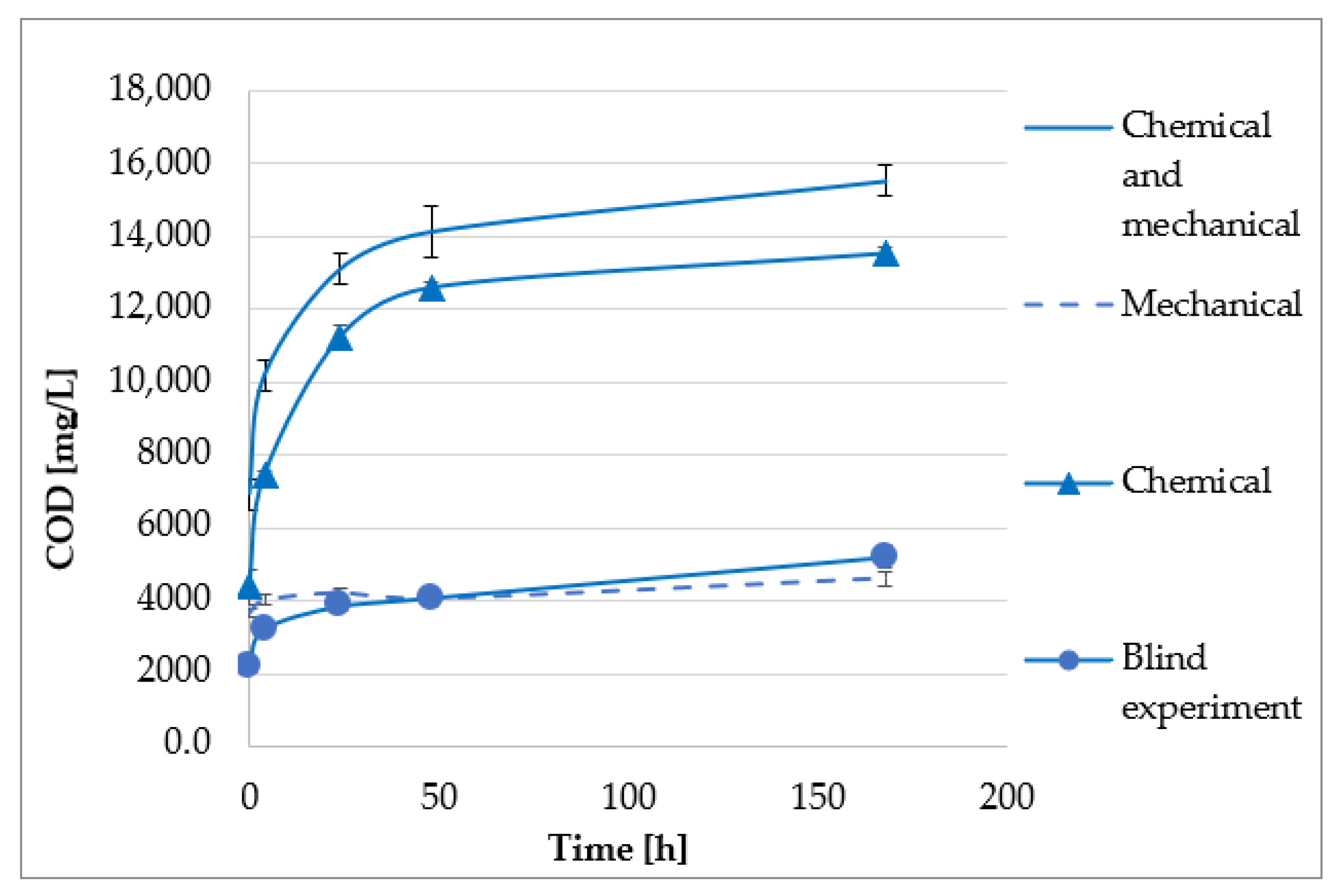

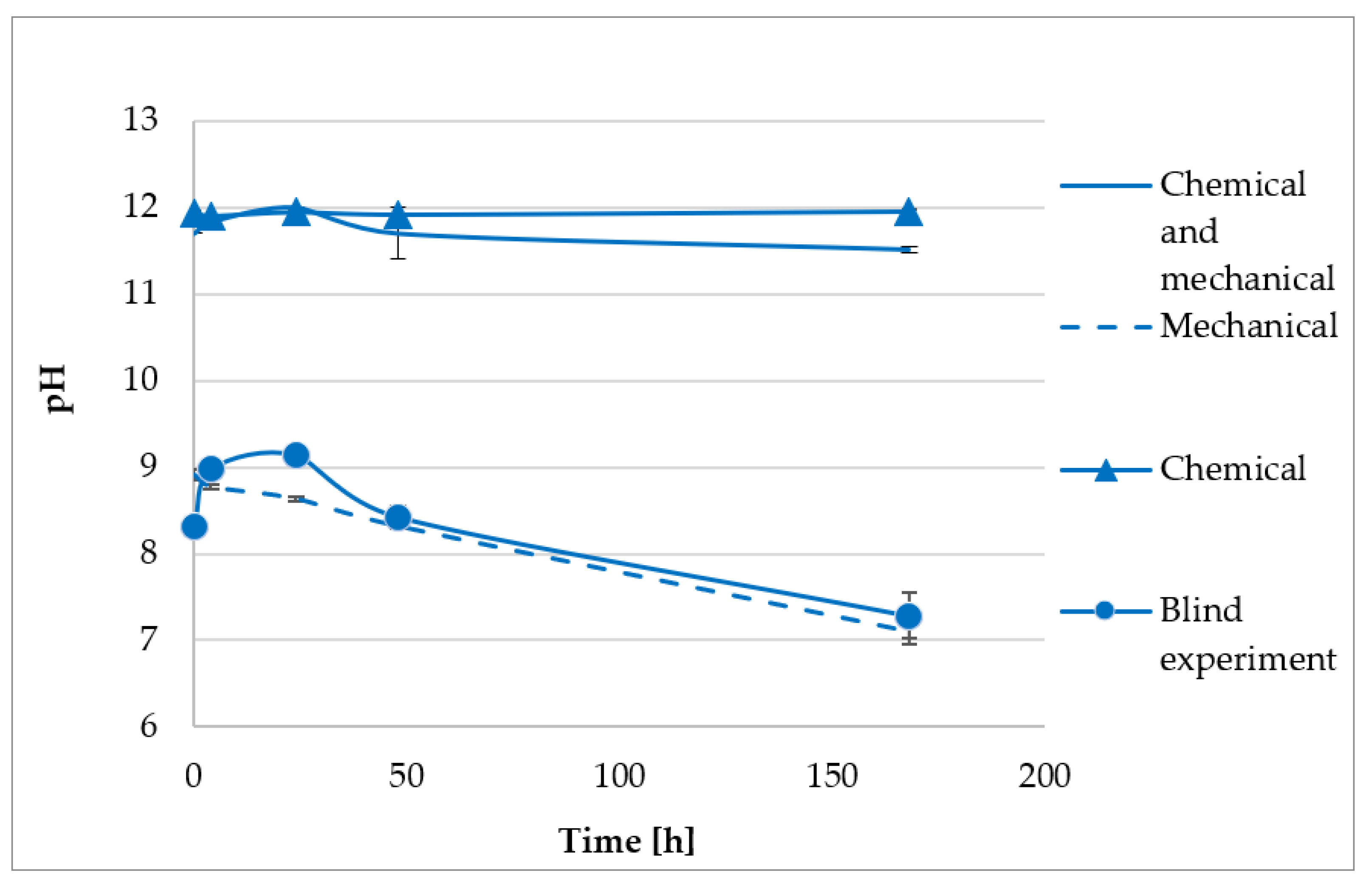

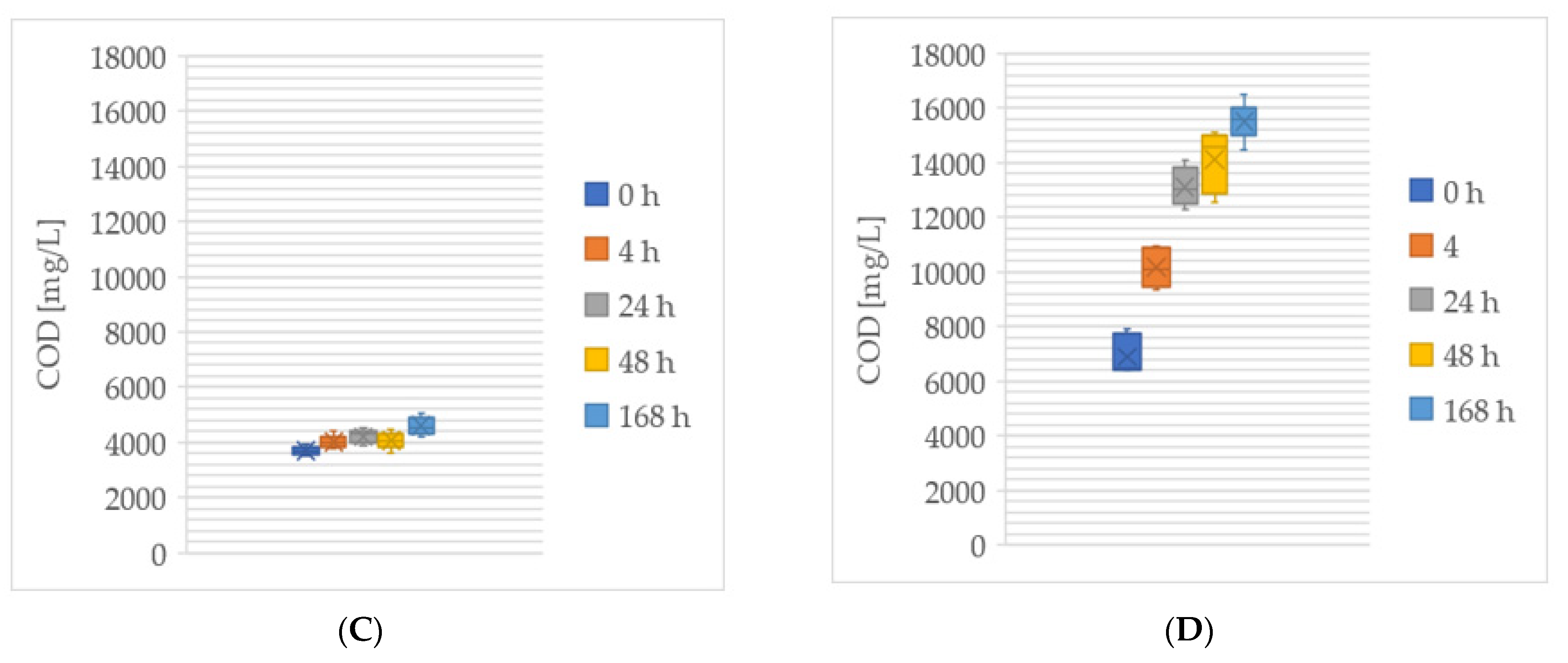

3.2. Study of the Effect of Mechanical Pre-Treatment before Shredding and Chemical NaOH Pre-Treatment

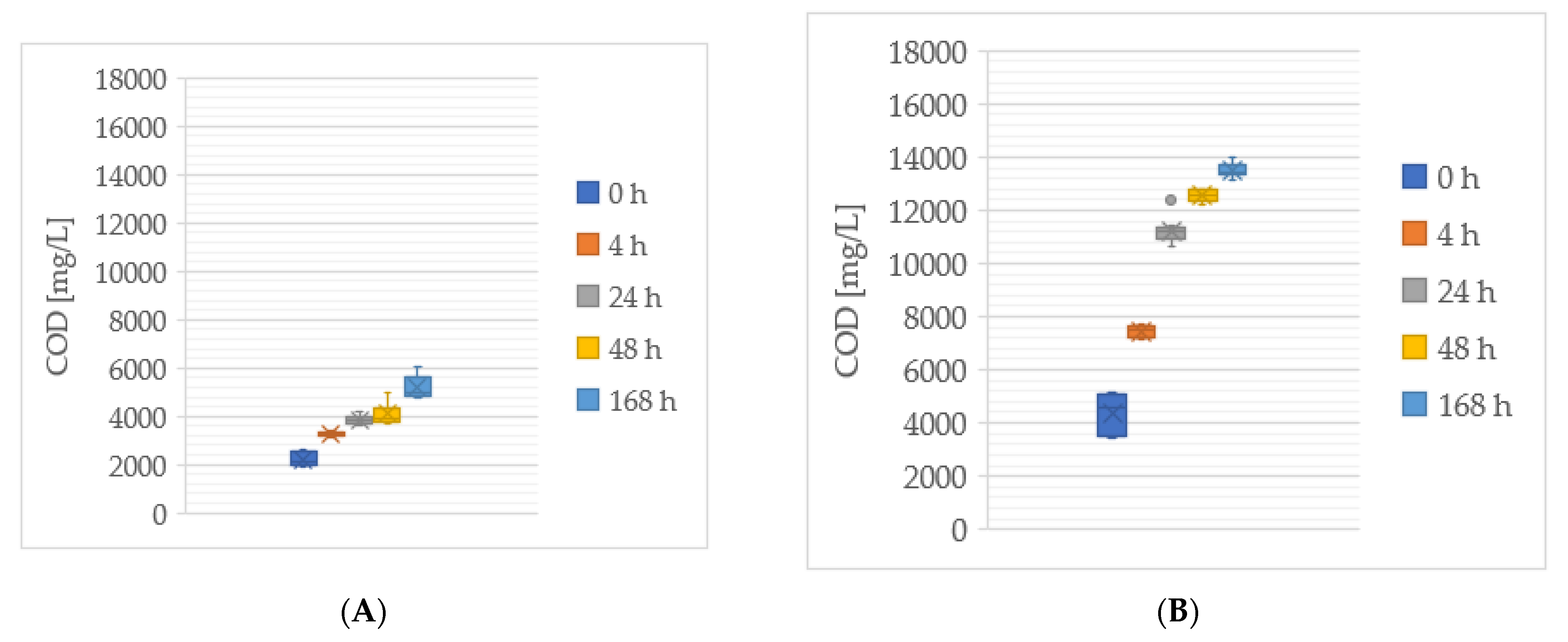

3.3. Experiments Reproducibility

3.4. Study of the Effect of NaOH Concentration on the Chemical Pretreatment with Mechanical Shredding

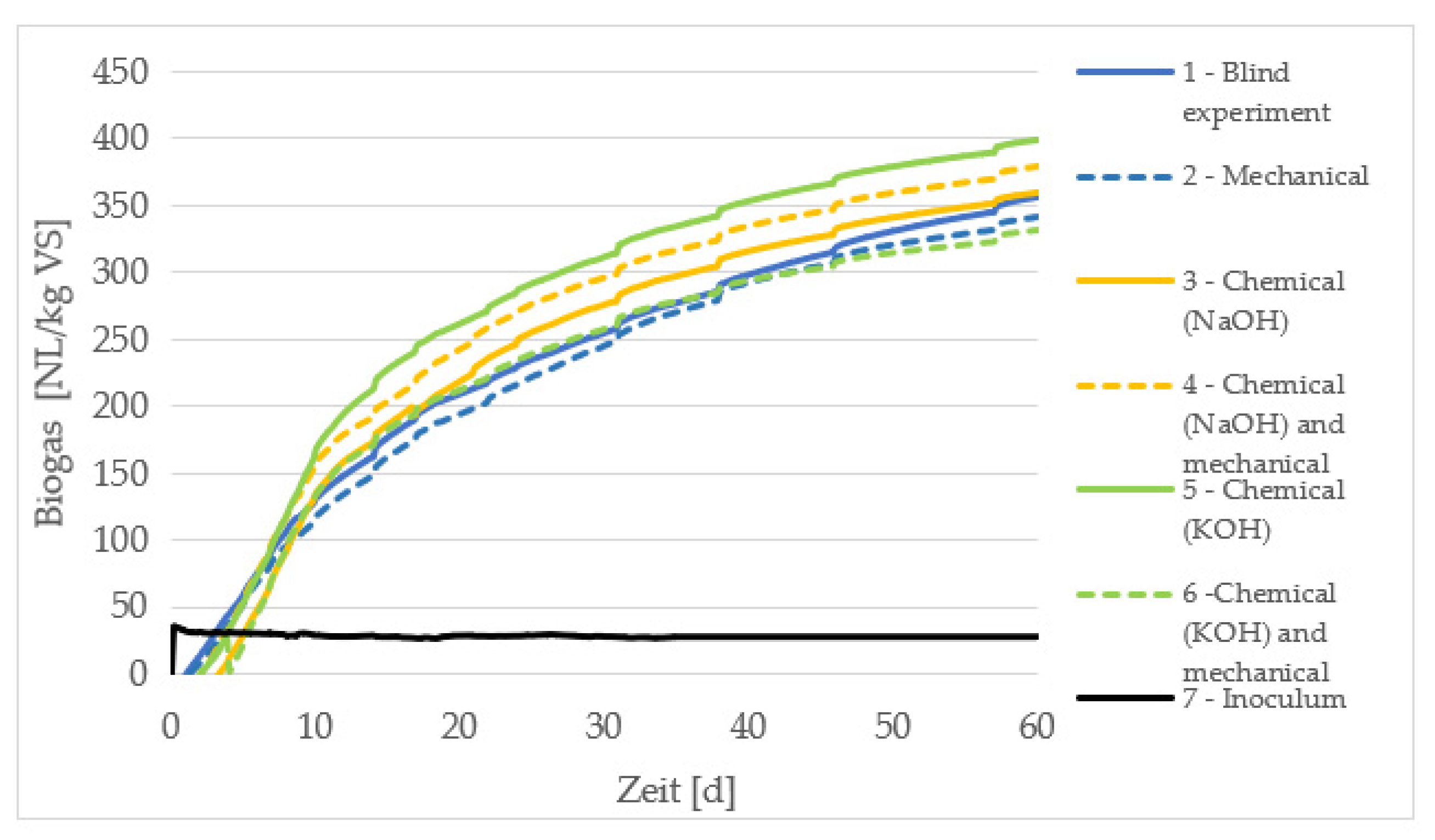

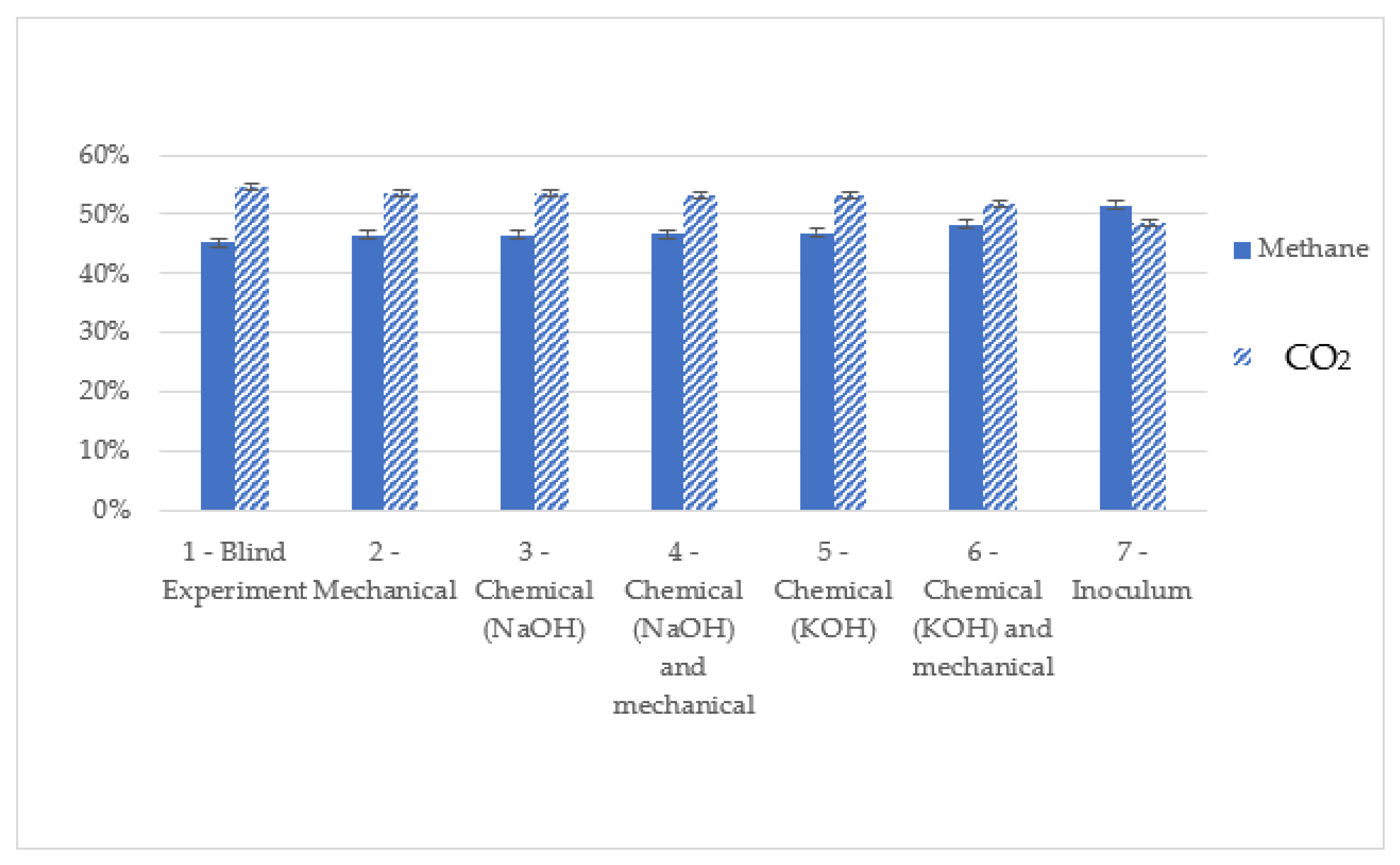

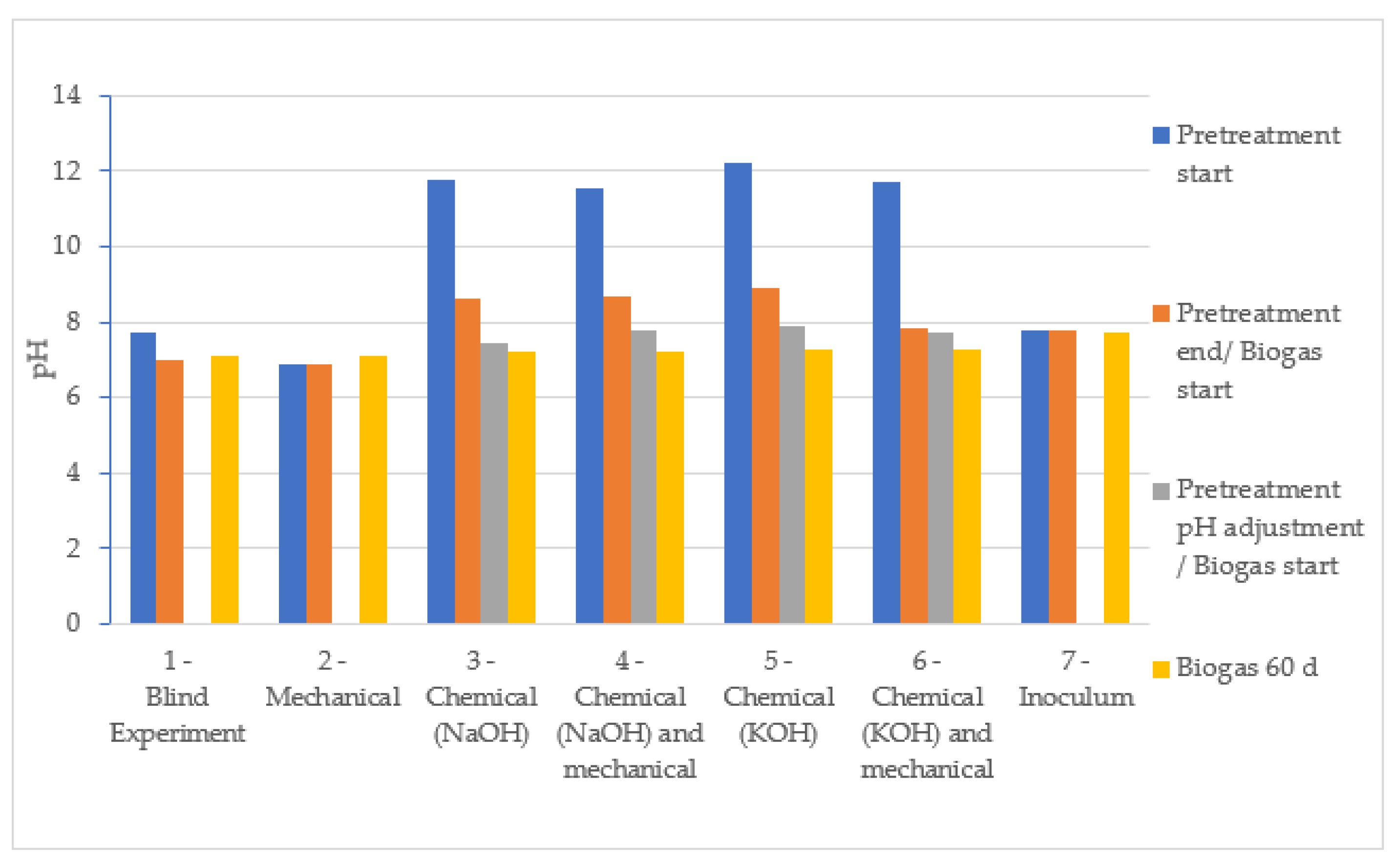

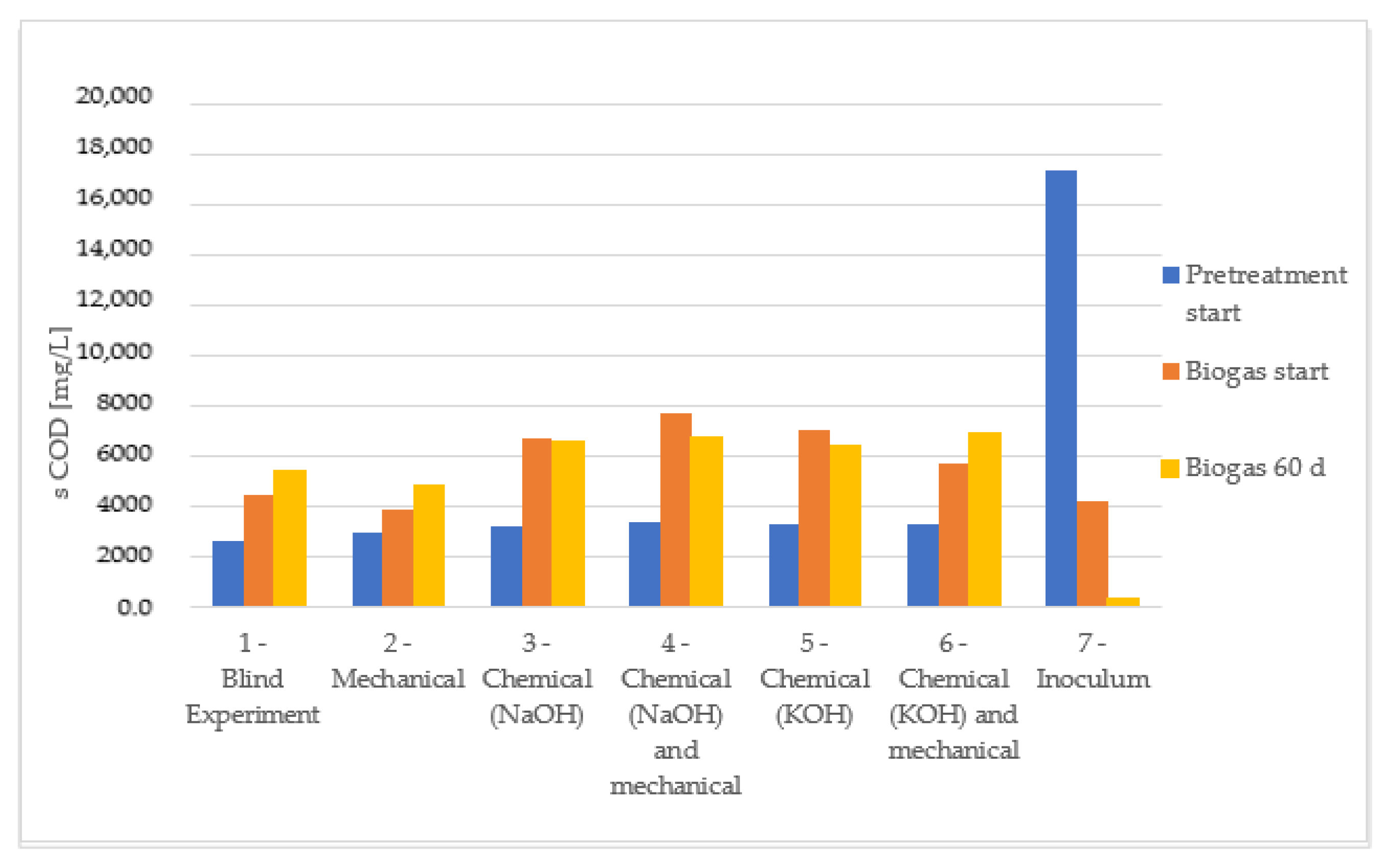

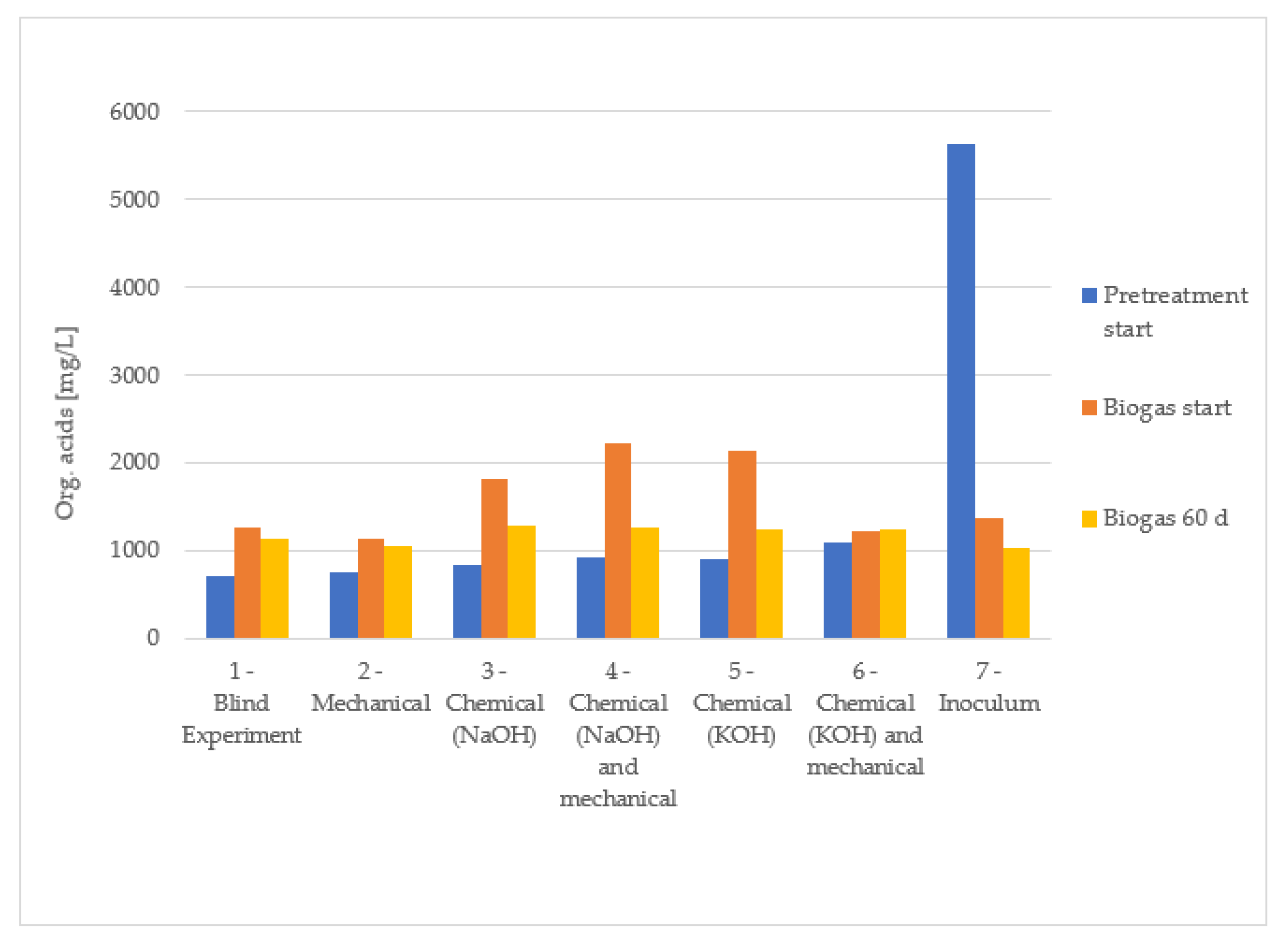

3.5. Study of Biogas Production with Mechanical and Chemical NaOH and KOH Pretreatments

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Federal Ministry for Economic Affairs and Energy. Integrated National Energy and Climate Plan (NECP). In Pursuant to the Regulation of the European Parliament and of the Council on the Governance of the Energy Union and Climate Action, as at 10.06.2020; Federal Ministry for Economic Affairs and Energy: Berlin, Germany, 2020. [Google Scholar]

- Dar, R.A.; Parmar, M.; Dar, E.A.; Sani, R.K.; Phutela, U.G. Biomethanation of agricultural residues: Potential, limitations and possible solutions. Renew. Sustain. Energy Rev. 2021, 135, 110217. [Google Scholar] [CrossRef]

- Brodeur, G.; Yau, E.; Badal, K.; Collier, J.; Ramachandran, K.B.; Ramakrishnan, S. Chemical and physicochemical pretreatment of lignocellulosic biomass: A review. Enzym. Res. 2011, 2011, 787532. [Google Scholar] [CrossRef]

- Chandra, R.; Takeuchi, H.; Hasegawa, T. Methane production from lignocellulosic agricultural crop wastes: A review in context to second generation of biofuel production. Renew. Sustain. Energy Rev. 2012, 16, 1462–1476. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, L.; Liu, D. Biomass recalcitrance. Part II: Fundamentals of different pre-treatments to increase the enzymatic digestibility of lignocellulose. Biofuels Bioprod. Bioref. 2012, 6, 561–579. [Google Scholar] [CrossRef]

- Kalluri, U.C.; Yin, H.; Yang, X.; Davison, B.H. Systems and synthetic biology approaches to alter plant cell walls and reduce biomass recalcitrance. Plant Biotechnol. J. 2014, 12, 1207–1216. [Google Scholar] [CrossRef]

- Laureano-Perez, L.; Teymouri, F.; Alizadeh, H.; Dale, B.E. Understanding Factors that Limit Enzymatic Hydrolysis of Biomass. In Twenty-Sixth Symposium on Biotechnology for Fuels and Chemicals; Davison, B.H., Evans, B.R., Finkelstein, M., McMillan, J.D., Eds.; Humana Press: Totowa, NJ, USA, 2005; pp. 1081–1099. [Google Scholar]

- Ragauskas, A.J. Physicochemical Structural Changes of Cellulosic Substrates during Enzymatic Saccharification. JABB 2016, 1, 1–8. [Google Scholar] [CrossRef]

- Lange, J.-P. Lignocellulose conversion: An introduction to chemistry, process and economics. Biofuels Bioprod. Biorefining 2007, 1, 39–48. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhao, J.; Xu, F.; Li, Y. Pretreatment of lignocellulosic biomass for enhanced biogas production. Prog. Energy Combust. Sci. 2014, 42, 35–53. [Google Scholar] [CrossRef]

- Hendriks, A.T.W.M.; Zeeman, G. Pretreatments to enhance the digestibility of lignocellulosic biomass. Bioresour. Technol. 2009, 100, 10–18. [Google Scholar] [CrossRef]

- Fengel, D.; Wegener, G. Wood: Chemistry, Ultrastructure, Reactions; De Gruyter: Berlin, Germany, 1984. [Google Scholar]

- Jørgensen, H.; Kristensen, J.B.; Felby, C. Enzymatic conversion of lignocellulose into fermentable sugars: Challenges and opportunities. Biofuels Bioprod. Biorefining 2007, 1, 119–134. [Google Scholar] [CrossRef]

- Galkin, M.V.; Samec, J.S.M. Lignin Valorization through Catalytic Lignocellulose Fractionation: A Fundamental Platform for the Future Biorefinery. ChemSusChem 2016, 9, 1544–1558. [Google Scholar] [CrossRef] [PubMed]

- Saini, A.; Aggarwal, N.K.; Sharma, A.; Yadav, A. Prospects for Irradiation in Cellulosic Ethanol Production. Biotechnol. Res. Int. 2015, 2015, 157139. [Google Scholar] [CrossRef]

- Xu, N.; Liu, S.; Xin, F.; Zhou, J.; Jia, H.; Xu, J.; Jiang, M.; Dong, W. Biomethane Production from Lignocellulose: Biomass Recalcitrance and Its Impacts on Anaerobic Digestion. Front. Bioeng. Biotechnol. 2019, 7, 191. [Google Scholar] [CrossRef]

- Pauly, M.; Keegstra, K. Plant cell wall polymers as precursors for biofuels. Curr. Opin. Plant Biol. 2010, 13, 305–312. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, L.; Liu, D. Biomass recalcitrance. Part I: The chemical compositions and physical structures affecting the enzymatic hydrolysis of lignocellulose. Biofuels Bioprod. Bioref. 2012, 6, 465–482. [Google Scholar] [CrossRef]

- Fernández-Cegrí, V.; La Angeles De Rubia, M.; Raposo, F.; Borja, R. Effect of hydrothermal pretreatment of sunflower oil cake on biomethane potential focusing on fibre composition. Bioresour. Technol. 2012, 123, 424–429. [Google Scholar] [CrossRef] [PubMed]

- Sambusiti, C.; Ficara, E.; Malpei, F.; Steyer, J.P.; Carrère, H. Benefit of sodium hydroxide pretreatment of ensiled sorghum forage on the anaerobic reactor stability and methane production. Bioresour. Technol. 2013, 144, 149–155. [Google Scholar] [CrossRef] [PubMed]

- Xu, P.; Cheng, S.; Han, Y.; Zhao, D.; Li, H.; Wang, Y.; Zhang, G.; Chen, C. Natural Variation of Lignocellulosic Components in Miscanthus Biomass in China. Front. Chem. 2020, 8, 595143. [Google Scholar] [CrossRef]

- Guan, R.; Li, X.; Wachemo, A.C.; Yuan, H.; Liu, Y.; Zou, D.; Zuo, X.; Gu, J. Enhancing anaerobic digestion performance and degradation of lignocellulosic components of rice straw by combined biological and chemical pretreatment. Sci. Total Environ. 2018, 637–638, 9–17. [Google Scholar] [CrossRef] [PubMed]

- Jaffar, M.; Pang, Y.; Yuan, H.; Zou, D.; Liu, Y.; Zhu, B.; Korai, R.M.; Li, X. Wheat straw pretreatment with KOH for enhancing biomethane production and fertilizer value in anaerobic digestion. Chin. J. Chem. Eng. 2016, 24, 404–409. [Google Scholar] [CrossRef]

- Mading Makur, M.; Duraisamy, R.; Birhanu, T. Clarifying Capacity of Eco-Friendly Nano Cao and Okra(AbelmoschusEsculentus) Extract on the Processing of Sugarcane Juice: A Review. IRJST 2019, 1, 21–30. [Google Scholar] [CrossRef]

- Alonso-Pippo, W.; Luengo, C.A.; Felfli, F.F.; Garzone, P.; Cornacchia, G. Energy recovery from sugarcane biomass residues: Challenges and opportunities of bio-oil production in the light of second generation biofuels. J. Renew. Sustain. Energy 2009, 1, 63102. [Google Scholar] [CrossRef]

- Maciej, W.; Maria, S.B. The quantity and quality of methanogenic microorganisms based on rRNA analysis and their relation to methane production. Afr. J. Microbiol. Res. 2013, 7, 3389–3395. [Google Scholar] [CrossRef]

- Croce, S.; Wei, Q.; D’Imporzano, G.; Dong, R.; Adani, F. Anaerobic digestion of straw and corn stover: The effect of biological process optimization and pre-treatment on total bio-methane yield and energy performance. Biotechnol. Adv. 2016, 34, 1289–1304. [Google Scholar] [CrossRef]

- Lebuhn, M.; Munk, B.; Effenberger, M. Agricultural biogas production in Germany—From practice to microbiology basics. Energy Sustain. Soc. 2014, 4, 1–21. [Google Scholar] [CrossRef]

- Bah, H.; Zhang, W.; Wu, S.; Qi, D.; Kizito, S.; Dong, R. Evaluation of batch anaerobic co-digestion of palm pressed fiber and cattle manure under mesophilic conditions. Waste Manag. 2014, 34, 1984–1991. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhang, S.; Song, J.; Sheng, C.; Shang, Z.; Wang, R.; Wang, X.; Yang, G.; Feng, Y.; Ren, G. Strategies to improve production of biomethane from organic wastes with anaerobic co-digestion: A systematic review. Biofuels Bioprod. Biorefining 2022, 16, 1388–1411. [Google Scholar] [CrossRef]

- Mata-Alvarez, J.; Macé, S.; Llabrés, P. Anaerobic digestion of organic solid wastes. An overview of research achievements and perspectives. Bioresour. Technol. 2000, 74, 3–16. [Google Scholar]

- Shen, X.; Sun, R. Recent advances in lignocellulose prior-fractionation for biomaterials, biochemicals, and bioenergy. Carbohydr. Polym. 2021, 261, 117884. [Google Scholar] [CrossRef]

- Cirne, D.G.; Lehtomäki, A.; Björnsson, L.; Blackall, L.L. Hydrolysis and microbial community analyses in two-stage anaerobic digestion of energy crops. J. Appl. Microbiol. 2007, 103, 516–527. [Google Scholar] [CrossRef]

- Pang, Y.Z.; Liu, Y.P.; Li, X.J.; Wang, K.S.; Yuan, H.R. Improving Biodegradability and Biogas Production of Corn Stover through Sodium Hydroxide Solid State Pretreatment. Energy Fuels 2008, 22, 2761–2766. [Google Scholar] [CrossRef]

- Tsapekos, P.; Kougias, P.G.; Angelidaki, I. Biogas production from ensiled meadow grass; effect of mechanical pretreatments and rapid determination of substrate biodegradability via physicochemical methods. Bioresour. Technol. 2015, 182, 329–335. [Google Scholar] [CrossRef] [PubMed]

- Bruni, E.; Jensen, A.P.; Angelidaki, I. Comparative study of mechanical, hydrothermal, chemical and enzymatic treatments of digested biofibers to improve biogas production. Bioresour. Technol. 2010, 101, 8713–8717. [Google Scholar] [CrossRef] [PubMed]

- Wei, Y.; Li, X.; Yu, L.; Zou, D.; Yuan, H. Mesophilic anaerobic co-digestion of cattle manure and corn stover with biological and chemical pretreatment. Bioresour. Technol. 2015, 198, 431–436. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Jahng, D. Enhanced anaerobic digestion of piggery wastewater by ammonia stripping: Effects of alkali types. J. Hazard. Mater. 2010, 182, 536–543. [Google Scholar] [CrossRef]

- Wetter, C.; Merbecks, R.; Florack, M.; Tiemann, M. Untersuchungen der Potentiellen Gasausbeute von Gärsubstraten für Biogasanlage mit Hilfe des OxiTop Control-Messsystem; Applikationsbericht für WTW.; Fachhochschule Münster: Münster, Germany, 2007. [Google Scholar]

- DIN 38414-8:1985; Schlamm und Sedimente (Gruppe S): Bestimmung des Faulverhantens. German Institute for Standardisation Registered Society (DIN e.V.): Berlin, Germany, 1985.

- Langhans, G.; Scholwin, F.; Nelles, M. (Eds.) Handbuch zur Bilanzierung von Biogasanlagen für Ingenieure—Band I.; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2020. [Google Scholar]

- VDI 4630:2016-11; Fermentation of Organic Materials. Characterisation of the Substrate, Sampling, Collection of Material Data, Fermentation Test. VDI-Society of Process Engineering and Chemical Engineering: Düsseldorf, Germany, 2016.

- Bayerische Landesanstalt für Landwirtschaft (LfL). Anleitung zur Probenahme von Wirtschaftsdüngern; Interreg Baltic Sea Region: Rostock, Germany, 2019. [Google Scholar]

- Ferreira, L.C.; Nilsen, P.J.; Fdz-Polanco, F.; Pérez-Elvira, S.I. Biomethane potential of wheat straw: Influence of particle size, water impregnation and thermal hydrolysis. Chem. Eng. J. 2014, 242, 254–259. [Google Scholar] [CrossRef]

- Wichern, M.; Gehring, T.; Fischer, K.; Andrade, D.; Lübken, M.; Koch, K.; Gronauer, A.; Horn, H. Monofermentation of grass silage under mesophilic conditions: Measurements and mathematical modeling with ADM 1. Bioresour. Technol. 2009, 100, 1675–1681. [Google Scholar] [CrossRef]

- Schwarz, B. Final Report Utilisation of Straw-Based Energy Pellets and Poultry Manure in Biogas Plants with Self-Sustaining Digestate Upgrading—STEP, 2019; Strom-Forschung: Juelich, Germany, 2019. [Google Scholar]

- Wirtschaftlichkeit von Biogasanlagen—Opus4. Available online: https://opus4.kobv.de/opus4-slbp/frontdoor/deliver/index/docId/1301/file/biogas07.pdf (accessed on 19 January 2023).

- Behmel, U.; (University of Applied Sciences Landshut, Landshut, Germany). Personal Communication, 2022.

| Biomass Resource (Plant) | Chemical Composition (w/w%) | Reference | ||

|---|---|---|---|---|

| Cellulose | Hemicellulose | Lignin | ||

| Untreated sunflower oil cake (SuOC) | 27 | 7 | 14 | [19] |

| Ensiled sorghum | 25.9 ± 1.79 | 12.9 ± 0.32 | 20.7 ± 0.32 | [20] |

| Miscanthus sinensis | 37.66 ± 3.8 | 22.94 ± 3.71 | 17.35 ± 1.29 | [21] |

| Rice Straw | 35.32 ± 0.56 | 28.92 ± 0.01 | 7.88 ± 0.20 | [22] |

| Wheat straw | 41.63 ± 0.4 | 28.29 ± 0.6 | 12.45 ± 0.3 | [23] |

| Sugarcane stalk | 5.5 | 2 | 2 | [24] |

| Sugarcane bagasse | 46 | 27 | 23 | [25] |

| Silage maize | 18.39 | 19.59 | 1.43 | [26] |

| Dry matter (%) | 16.36 |

| Residue on ignition in DM (%) | 12.04 |

| Crude fat in DM (%) | 0.98 |

| Crude protein in DM (%) | 11.40 |

| Sugar in DM (%) | 0.55 |

| Crude fibre in DM (%) | 32.98 |

| ADF in DM (%) | 49.50 |

| ADL in DM (%) | 14.90 |

| NDF in DM (%) | 60.10 |

| Hemicellulose in DM (%) | 10.60 |

| Cellulose in DM (%) | 34.60 |

| Lignin in DM (%) | 2.86 |

| Ammonium nitrogen (mg/kg) | 904.92 |

| Copper in DM (mg/kg) | 23.14 |

| Zinc in DM (mg/kg) | 125.30 |

| Calcium in DM (%) | 2.41 |

| Potassium in DM (%) | 4.31 |

| Sodium in DM (%) | 0.889 |

| Magnesium in DM (%) | 0.46 |

| Setup Vessels Repetitions | Chemical Pretreatment NaOH (0.2 M) | Mechanical Pretreatment Blender (20 s, 1000 Watt) | Average Weigh Cattle Manure Probe (g) |

|---|---|---|---|

| 1.1/1.2/1.3 | − | − | 200.54 ± 0.06 |

| 2.1/2.2/2.3 | + | − | 201 ± 3083.697 |

| 3.1/3.2/3.3 | − | + | 200.377 ± 0.173 |

| 4.1/4.2/4.3 | + | + | 200.403 ± 0.117 |

| Vessels | NaOH (0.2 M) | NaOH (0.1 M) | NaOH (0.05 M) | Schredder (20 s, 1000 Watt) | Cattle Manure (g) |

|---|---|---|---|---|---|

| A.1 | − | − | − | − | 201.77 |

| A.2 | + | − | − | − | 201.44 |

| A.3 | − | − | − | + | 200.13 |

| A.4 | + | − | − | + | 200.19 |

| B.1 | − | − | − | − | 200 |

| B.2 | − | + | − | − | 201.25 |

| B.3 | − | − | − | + | 200 |

| B.4 | − | + | − | + | 200.38 |

| C.1 | − | − | − | − | 200.78 |

| C.2 | − | − | + | − | 200.94 |

| C.3 | − | − | − | + | 201.47 |

| C.4 | − | − | + | + | 201.81 |

| Biogas Reactor | 1— Substrate without Pretreatments | 2— Substrate with Mechanical Pretreatment | 3— Chemical NaOH Pretreatment | 4—Chemical NaOH and Mechanical Pretreatment | 5— Chemical KOH Pretreatment | 6—Chemical KOH and Mechanical Pretreatment | 7—Inoculum |

|---|---|---|---|---|---|---|---|

| Fermentation batch (mL) inc. Inoculum | 477.69 | 475.85 | 480.81 | 479.06 | 476.00 | 478.11 | 471.99 |

| Vf (m) -free gas volume in the test reactor | 672.31 | 674.15 | 669.19 | 670.94 | 674.00 | 671.89 | 678.01 |

| Substrate and inoculum weight (g) | 146.96 | 146.98 | 147.19 | 147.17 | 147.22 | 147.33 | 96.97 |

| DM fermentation batch (%) | 4.32% | 4.32% | 4.33% | 4.33% | 4.33% | 4.33% | 1.97% |

| VS fermentation batch (%) | 3.43% | 3.43% | 3.43% | 3.43% | 3.43% | 3.43% | 1.45% |

| Test temperature (°C) | 37 | 37 | 37 | 37 | 37 | 37 | 37 |

| Water (g) | 335 | 335 | 335 | 335 | 335 | 335 | 375.02 |

| Cattle Manure (g) | 50 | 50 | 50 | 50 | 50 | 50 | 0 |

| Inoculum (g) | 96.96 | 96.98 | 97.19 | 97.17 | 97.22 | 97.33 | 96.97 |

| DM cattle manure (%) | 23.05% | 23.05% | 23.05% | 23.05% | 23.05% | 23.05% | 23.05% |

| DM inoculum (%) | 9.61% | 9.61% | 9.61% | 9.61% | 9.61% | 9.61% | 9.61% |

| VS cattle manure of the wet mass (%) | 19.37% | 19.37% | 19.37% | 19.37% | 19.37% | 19.37% | 19.37% |

| VS inoculum of the wet mass (%) | 7.04% | 7.04% | 7.04% | 7.04% | 7.04% | 7.04% | 7.04% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hidalgo-Sánchez, V.; Behmel, U.; Hofmann, J.; Borges, M.E. Enhancing Biogas Production of Co-Digested Cattle Manure with Grass Silage from a Local Farm in Landshut, Bavaria, through Chemical and Mechanical Pre-Treatment and Its Impact on Biogas Reactor Hydraulic Retention Time. Sustainability 2023, 15, 2582. https://doi.org/10.3390/su15032582

Hidalgo-Sánchez V, Behmel U, Hofmann J, Borges ME. Enhancing Biogas Production of Co-Digested Cattle Manure with Grass Silage from a Local Farm in Landshut, Bavaria, through Chemical and Mechanical Pre-Treatment and Its Impact on Biogas Reactor Hydraulic Retention Time. Sustainability. 2023; 15(3):2582. https://doi.org/10.3390/su15032582

Chicago/Turabian StyleHidalgo-Sánchez, Verónica, Uwe Behmel, Josef Hofmann, and María Emma Borges. 2023. "Enhancing Biogas Production of Co-Digested Cattle Manure with Grass Silage from a Local Farm in Landshut, Bavaria, through Chemical and Mechanical Pre-Treatment and Its Impact on Biogas Reactor Hydraulic Retention Time" Sustainability 15, no. 3: 2582. https://doi.org/10.3390/su15032582

APA StyleHidalgo-Sánchez, V., Behmel, U., Hofmann, J., & Borges, M. E. (2023). Enhancing Biogas Production of Co-Digested Cattle Manure with Grass Silage from a Local Farm in Landshut, Bavaria, through Chemical and Mechanical Pre-Treatment and Its Impact on Biogas Reactor Hydraulic Retention Time. Sustainability, 15(3), 2582. https://doi.org/10.3390/su15032582