Research on Construction Waste Recycling Subsidy Model Considering Contractor’s Environmental Awareness

Abstract

1. Introduction

- (1)

- What is the performance of the recycling rate, manufacturer’s profit, consumer surplus, and social welfare when the government provides subsidy to the contractor?

- (2)

- How do recycling costs and contractors’ environmental awareness influence government and manufacturer decisions?

2. Literature Review

2.1. Construction Waste Recycling Management under Government Regulation

2.2. Decision-Making Behaviors of Stakeholders in the Reclamation of Construction Waste

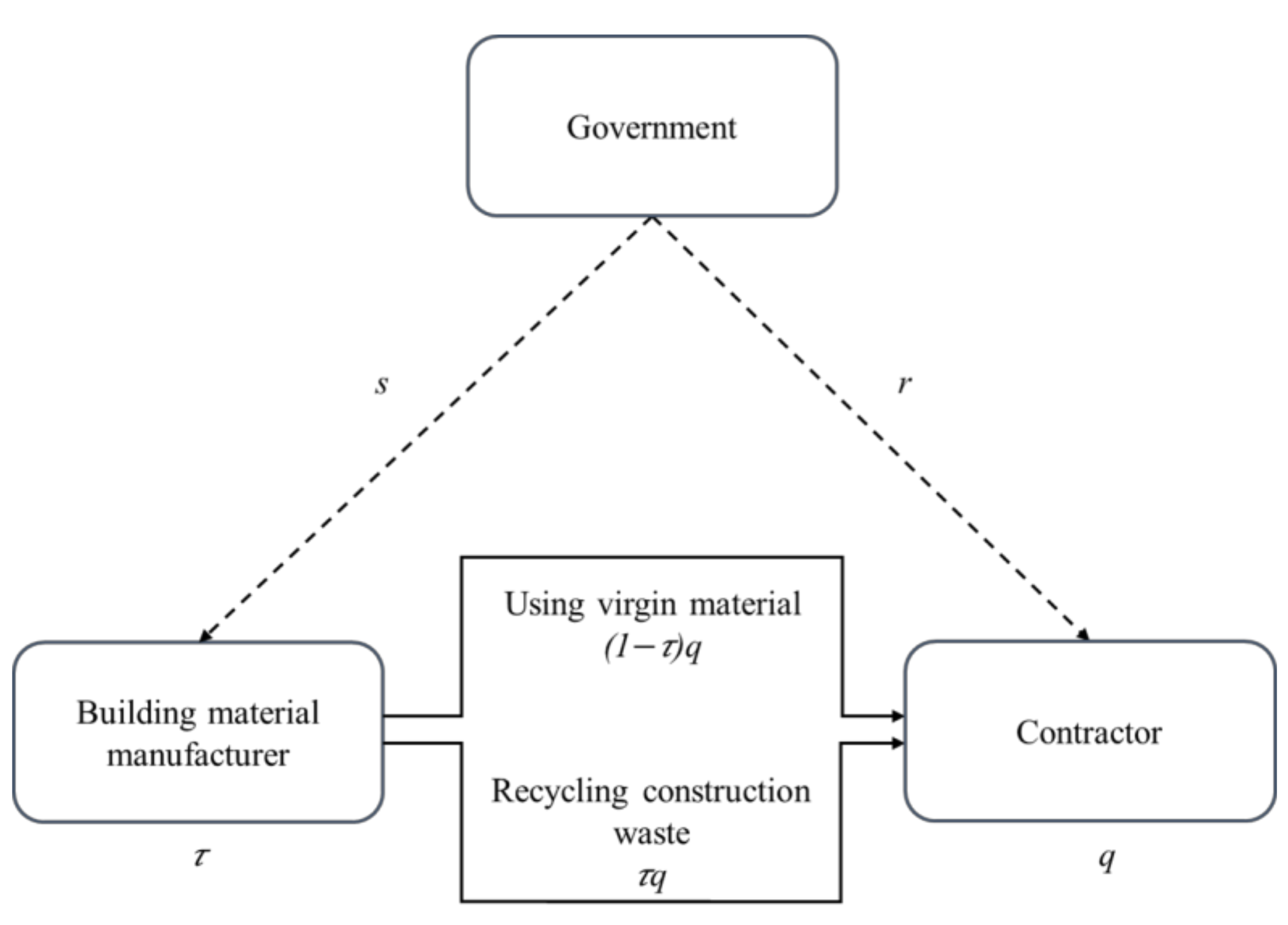

3. Problem Description

3.1. Symbol Description

3.2. Model Assumptions

- 1.

- Considering the feasibility of problem solving, this paper does not consider the competition problem, and only one manufacturer and one contractor are considered.

- 2.

- The shortage and inventory problems of construction materials are not considered, and only a single cycle of the construction materials supply chain is considered.

- 3.

- Referring to the existing literature, the consumer surplus is assumed to be as follows: , where is the traditional consumer surplus [26,27]. In addition, is added to reflect the environmental awareness of the contractor, and the larger the contractor’s environmental awareness, the more sensitive the contractor is to environmentally unfriendly behavior.

- 4.

- The manufacturer’s unit production cost is . The additional cost to be paid for recycling compared to virgin materials is [28], where is the construction waste recycling cost coefficient, the larger the , the higher the cost of recycling.

- 5.

- When the government subsidizes the contractor, the amount of subsidy received by the contractor is based on the purchase price, i.e., ; when the government subsidizes the manufacturer, the amount of subsidy received by the manufacturer is based on the cost of recycling, i.e., .

4. Model Solving

4.1. Benchmark Model without Subsidy (Model A)

4.2. Contractor Subsidy Model (Model B)

4.3. Manufacturer Subsidy Model (Model C)

5. Model Comparison and Parameter Analysis

5.1. Model Comparison

5.2. Parameter Analysis

- (1)

- ;

- (2)

- (3)

- (4)

- (5)

- (6)

- (1)

- (2)

- (3)

- (4)

- (5)

- (6)

- (7)

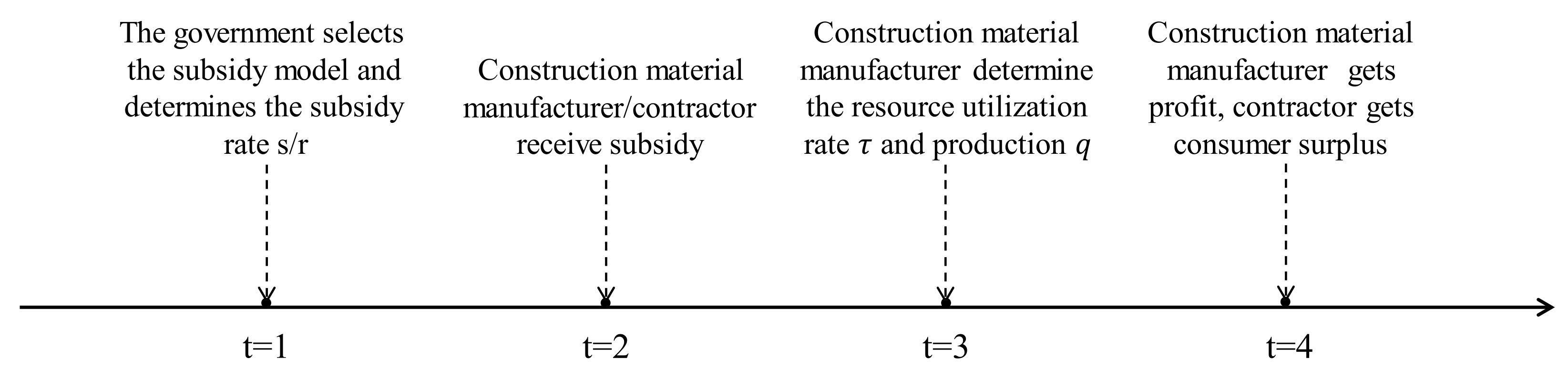

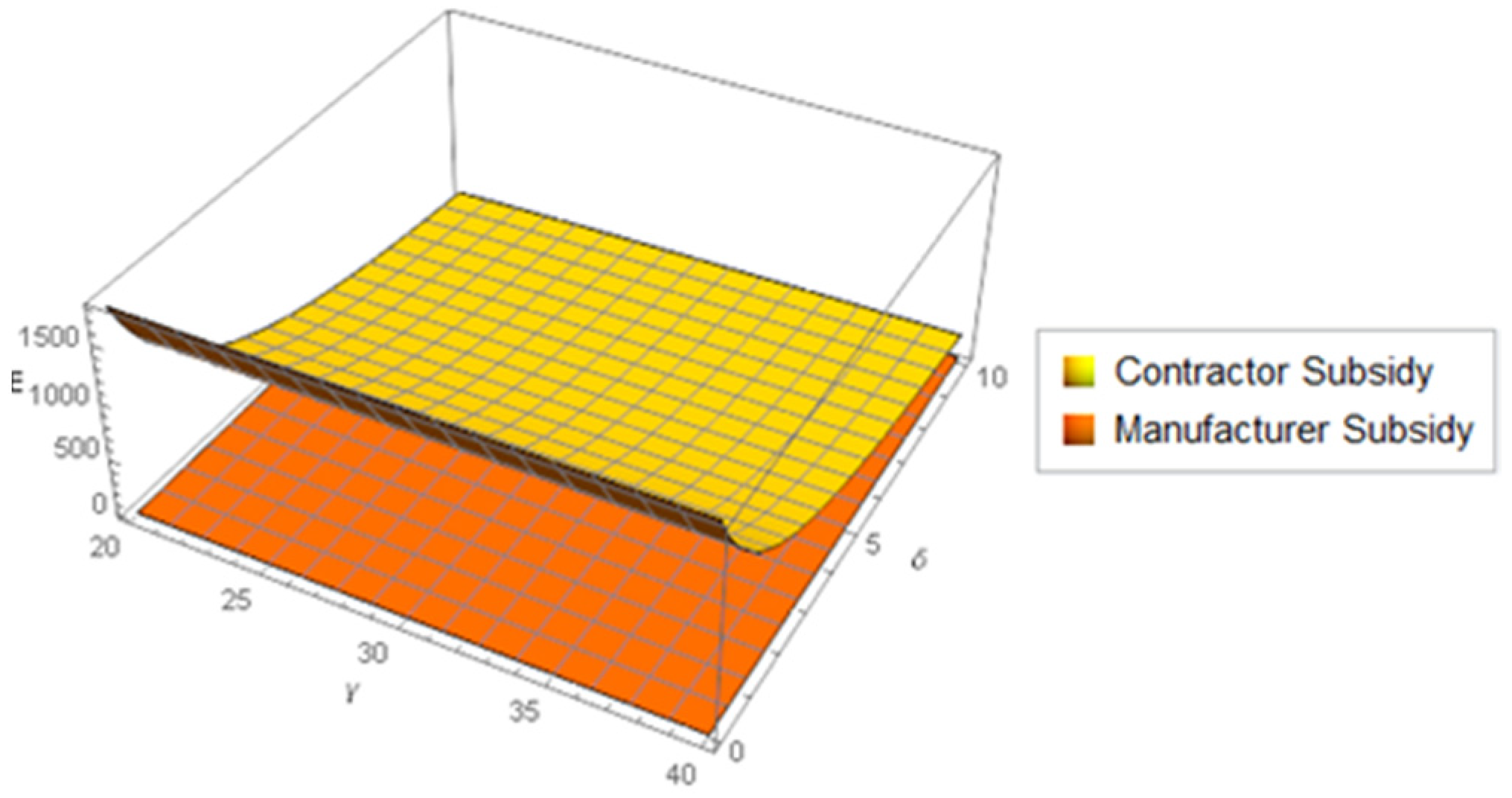

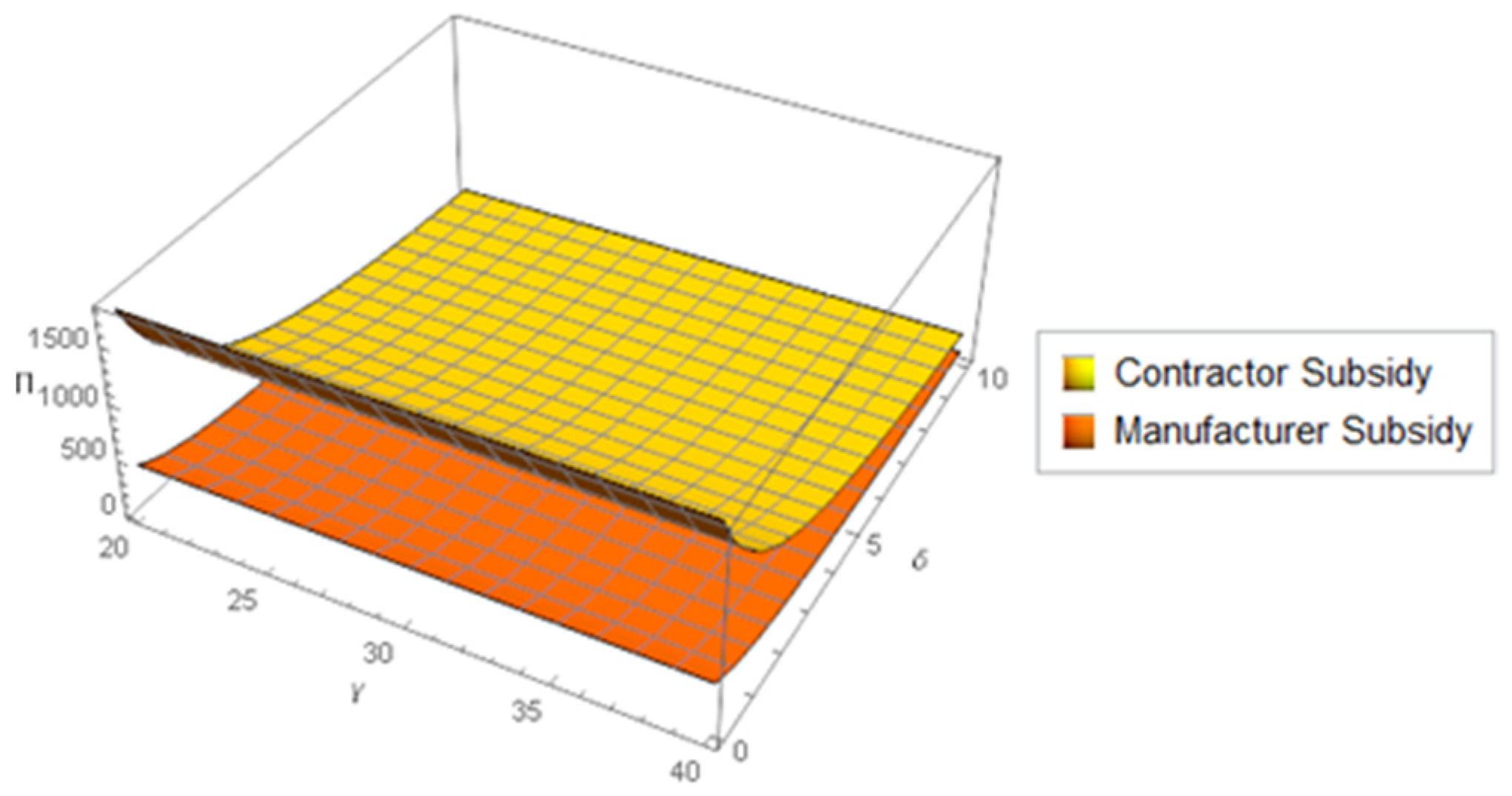

6. Numerical Analysis

7. Results & Discussion

8. Conclusions

- (1)

- The recycling rate under the contractor subsidy is lower than that under the manufacturer subsidy because the recycling rate when the government subsidizes the contractor does not depend on the subsidy, so the subsidy does not directly incentivize waste recycling, while the recycling under the manufacturer subsidy is directly incentivized by the government subsidy.

- (2)

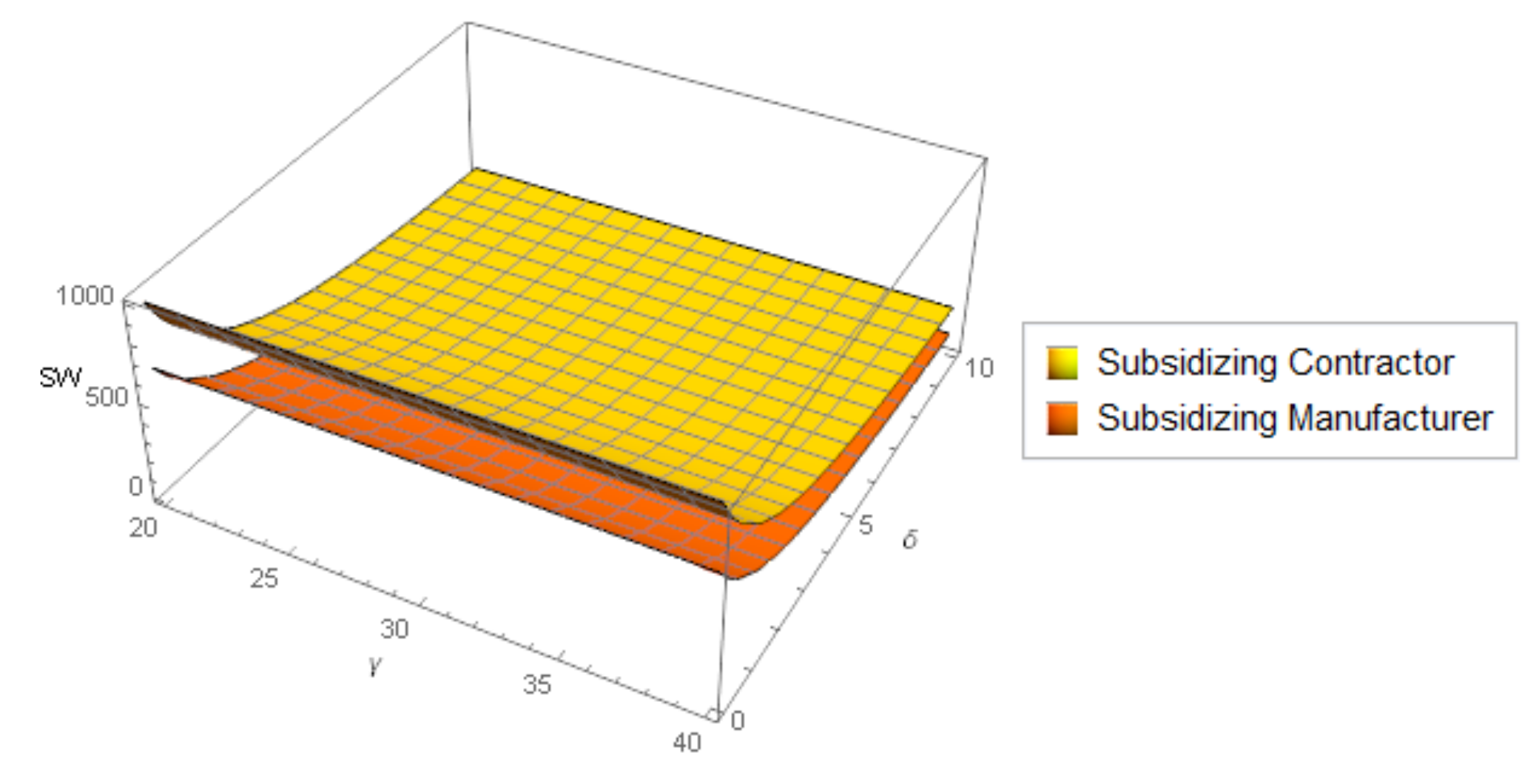

- Manufacturer profits, consumer surplus, and social welfare are greater when the government subsidizes the contractor than when it subsidizes the manufacturer, so both manufacturers and contractors prefer the contractor subsidy model.

- (3)

- There is free-riding behavior by manufacturers in the contractor subsidy model, when manufacturers will capture government subsidies through the price mechanism, making government subsidy expenditures increase.

- (4)

- As contractors’ environmental awareness increases and manufacturers pay more attention to construction waste recycling, the waste recycling rate will increase, while manufacturers’ profits, consumer surplus, and social welfare will decrease.

- (5)

- As the cost of waste recycling increases, the waste recycling rate decreases, at which time the changes in manufacturer profits, consumer surplus, and social welfare are affected by the pattern of government subsidies and the level of recycling costs.

- (1)

- For the government, there are differences in the implementation effects of different subsidy models. If the contractor is subsidized, higher social welfare can be obtained, but at this time, the resource utilization rate of waste is reduced and the government spends more on subsidies; the opposite is true if the manufacturer is subsidized. Therefore, the government should implement the subsidy policy that depends on the specific situation of the government, when the government budget is limited, it should consider the manufacturer subsidy policy, while when the government is more concerned about social welfare, the contractor subsidy policy should be used.

- (2)

- Resourcefulness costs and contractors’ environmental awareness influence government and manufacturers’ decisions in different ways. Therefore, the government should understand the environmental awareness of contractors and evaluate the recycling cost of manufacturers before formulating a subsidy policy to promote construction waste recycling.

- (3)

- The environmental awareness of contractors creates public pressure on manufacturers and will promote waste recycling by manufacturers, which also indicates that in addition to increasing the recycling rate through policy measures, the government can also draw contractors’ attention to the environment.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| contractor | construction contractor |

| manufacturer | building materials manufacturer |

References

- Zheng, L.; Wu, H.; Zhang, H.; Duan, H.; Wang, J.; Jiang, W.; Dong, B.; Liu, G.; Zuo, J.; Song, Q. Characterizing the Generation and Flows of Construction and Demolition Waste in China. Constr. Build. Mater. 2017, 136, 405–413. [Google Scholar] [CrossRef]

- Guangzhou Urban Management Committee Guangzhou Housing and Urban-Rural Development Committee Guangzhou Finance Bureau Notice on the Issuance of “Trial Measures for the Management of Financial Subsidy Funds for Comprehensive Utilization of Construction Waste in Guangzhou”—Guangzhou Municipal People’s Government Portal. Available online: https://www.gz.gov.cn/gfxwj/sbmgfxwj/gzscsglhzhzfj/content/post_5486460.html (accessed on 22 November 2022).

- Shanghai Construction Waste Disposal Management Regulations” (Shanghai Government Order No. 57). Available online: https://www.shanghai.gov.cn/nw42535/20200823/0001-42535_53874.html (accessed on 22 November 2022).

- Li, J.; Yao, Y.; Zuo, J.; Li, J. Key Policies to the Development of Construction and Demolition Waste Recycling Industry in China. Waste Manag. 2020, 108, 137–143. [Google Scholar] [CrossRef] [PubMed]

- Yuan, H.; Wang, J. A System Dynamics Model for Determining the Waste Disposal Charging Fee in Construction. Eur. J. Oper. Res. 2014, 237, 988–996. [Google Scholar] [CrossRef]

- Huang, B.; Wang, X.; Kua, H.; Geng, Y.; Bleischwitz, R.; Ren, J. Construction and Demolition Waste Management in China through the 3R Principle. Resour. Conserv. Recycl. 2018, 129, 36–44. [Google Scholar] [CrossRef]

- Jia, S.; Yan, G.; Shen, A.; Zheng, J. Dynamic Simulation Analysis of a Construction and Demolition Waste Management Model under Penalty and Subsidy Mechanisms. J. Clean. Prod. 2017, 147, 531–545. [Google Scholar] [CrossRef]

- Hu, M.; Zhou, M. Research on the Economic Benefits and Countermeasures of Construction Waste On-site Sorting during the Construction Process:A Case of Chongqing. Constr. Econ. 2018, 39, 108–113. [Google Scholar] [CrossRef]

- Chen, J.; Yuan, S. Simulating evaluation on the policies of construction and demolition waste sorting and recycling:analysis based on different subsidy amount. Urban Probl. 2017, 07, 27–34. [Google Scholar] [CrossRef]

- Liu, J.; Wang, Y.; Zhang, W.; Zheng, Z. Cost-benefit analysis of construction and demolition waste management based on system dynamics:A case study of Guangzhou. Syst. Eng. Theory Pract. 2014, 34, 1480–1490. [Google Scholar]

- Begum, R.A.; Siwar, C.; Pereira, J.J.; Jaafar, A.H. Attitude and Behavioral Factors in Waste Management in the Construction Industry of Malaysia. Resour. Conserv. Recycl. 2009, 53, 321–328. [Google Scholar] [CrossRef]

- Wu, Z.; Yu, A.T.W.; Shen, L. Investigating the Determinants of Contractor’s Construction and Demolition Waste Management Behavior in Mainland China. Waste Manag. 2017, 60, 290–300. [Google Scholar] [CrossRef]

- Liu, Y.; Bai, Y. An Exploration of Firms’ Awareness and Behavior of Developing Circular Economy: An Empirical Research in China. Resour. Conserv. Recycl. 2014, 87, 145–152. [Google Scholar] [CrossRef]

- Yuan, H.; Shen, L. Trend of the Research on Construction and Demolition Waste Management. Waste Manag. 2011, 31, 670–679. [Google Scholar] [CrossRef]

- Yau, Y. Domestic Waste Recycling, Collective Action and Economic Incentive: The Case in Hong Kong. Waste Manag. 2010, 30, 2440–2447. [Google Scholar] [CrossRef]

- Ma, L.; Zhang, L. Evolutionary Game Analysis of Construction Waste Recycling Management in China. Resour. Conserv. Recycl. 2020, 161, 104863. [Google Scholar] [CrossRef]

- Du, L.; Feng, Y.; Lu, W.; Kong, L.; Yang, Z. Evolutionary Game Analysis of Stakeholders’ Decision-Making Behaviours in Construction and Demolition Waste Management. Environ. Impact Assess. Rev. 2020, 84, 106408. [Google Scholar] [CrossRef]

- Mak, T.M.W.; Chen, P.-C.; Wang, L.; Tsang, D.C.W.; Hsu, S.C.; Poon, C.S. A System Dynamics Approach to Determine Construction Waste Disposal Charge in Hong Kong. J. Clean. Prod. 2019, 241, 118309. [Google Scholar] [CrossRef]

- Yuan, H.; Wang, Z. Promotion of Major Participants Cooperation in Construction Waste Recycling. J. Eng. Stud. 2017, 9, 181–189. [Google Scholar]

- Li, J.; He, G.; Zhong, X. Research on Policy Instruments Selection of Construction and Demolition Waste Recycling Management in Japan, Germany and Singapore. Constr. Econ. 2017, 38, 87–90. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, G. The closed-loop supply chain network decision based on corporate environmental criteria and consumer’s environmental consciousness. China Popul. Resour. Environ. 2019, 29, 71–81. [Google Scholar]

- Xiong, Z.; Zhang, P.; Guo, N. Impact of carbon tax and consumers’ environmental awareness on carbon emissions in supply chains. Syst. Eng. Theory Pract. 2014, 34, 2245–2252. [Google Scholar]

- Alizamir, S.; Iravani, F.; Mamani, H. An Analysis of Price vs. Revenue Protection: Government Subsidies in the Agriculture Industry. Manag. Sci. 2019, 65, 32–49. [Google Scholar] [CrossRef]

- Arya, A.; Mittendorf, B. Supply Chain Consequences of Subsidies for Corporate Social Responsibility. Prod. Oper. Manag. 2015, 24, 1346–1357. [Google Scholar] [CrossRef]

- Ingene, C.A.; Parry, M.E. Bilateral Monopoly, Identical Distributors, and Game-Theoretic Analyses of Distribution Channels. J. Acad. Mark. Sci. 2007, 35, 586–602. [Google Scholar] [CrossRef]

- Singh, N.; Vives, X. Price and Quantity Competition in a Differentiated Duopoly. RAND J. Econ. 1984, 15, 546–554. [Google Scholar] [CrossRef]

- Spence, M. Product differentiation and welfare. Am. Econ. Rev. 1976, 66, 407–414. [Google Scholar]

- Liu, T.; Zhang, J.; Hu, M. Analysis on environmental benefits of construction and demolition waste recycling: A case study in Chongqing. China Environ. Sci. 2018, 38, 3853–3867. [Google Scholar] [CrossRef]

| Symbols | Description |

|---|---|

| Parameters | |

| a | the upper limit of the price function, 0 < a |

| b | sensitivity coefficient of sales price to quantity demanded, 0 < b |

| c | unit production cost of new materials, 0 < c < a |

| γ | cost coefficient of construction waste recycling, 0 < γ |

| δ | contractor’s environmental awareness, 0 < δ |

| Decision Variables | |

| s | government subsidy rates to the manufacturer of construction materials, 0 < s |

| r | government subsidy rate to the contractor, 0 < r |

| τ | recycling rate, 0 ≤ τ < 1 |

| q | manufacturer’s production quantity, 0 < q |

| p(q) | construction material sales price, p(q) = a − bq > 0 |

| Objective function | |

| Π | profit of construction material manufacturer |

| CS | contractor’s consumer surplus |

| SW | social welfare |

| M | production volume of recycled materials, |

| N | production volume of virgin materials, |

| E | subsidy amount |

| Corner marker | |

| A | no subsidy |

| B | contractor subsidy |

| C | manufacturer subsidy |

| Model A | Model B | Model C | |

|---|---|---|---|

| - | |||

| 0 | |||

| 0 | |||

| - | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, R.; Jin, H.; Yu, M.; Yang, J.; Zhang, J. Research on Construction Waste Recycling Subsidy Model Considering Contractor’s Environmental Awareness. Sustainability 2023, 15, 2333. https://doi.org/10.3390/su15032333

Tan R, Jin H, Yu M, Yang J, Zhang J. Research on Construction Waste Recycling Subsidy Model Considering Contractor’s Environmental Awareness. Sustainability. 2023; 15(3):2333. https://doi.org/10.3390/su15032333

Chicago/Turabian StyleTan, Ruwen, Huan Jin, Minjiu Yu, Jingsong Yang, and Jing Zhang. 2023. "Research on Construction Waste Recycling Subsidy Model Considering Contractor’s Environmental Awareness" Sustainability 15, no. 3: 2333. https://doi.org/10.3390/su15032333

APA StyleTan, R., Jin, H., Yu, M., Yang, J., & Zhang, J. (2023). Research on Construction Waste Recycling Subsidy Model Considering Contractor’s Environmental Awareness. Sustainability, 15(3), 2333. https://doi.org/10.3390/su15032333