Development of a Benefit Assessment Matrix for Nanomaterials and Nano-enabled Products—Toward Safe and Sustainable by Design

Abstract

1. Introduction

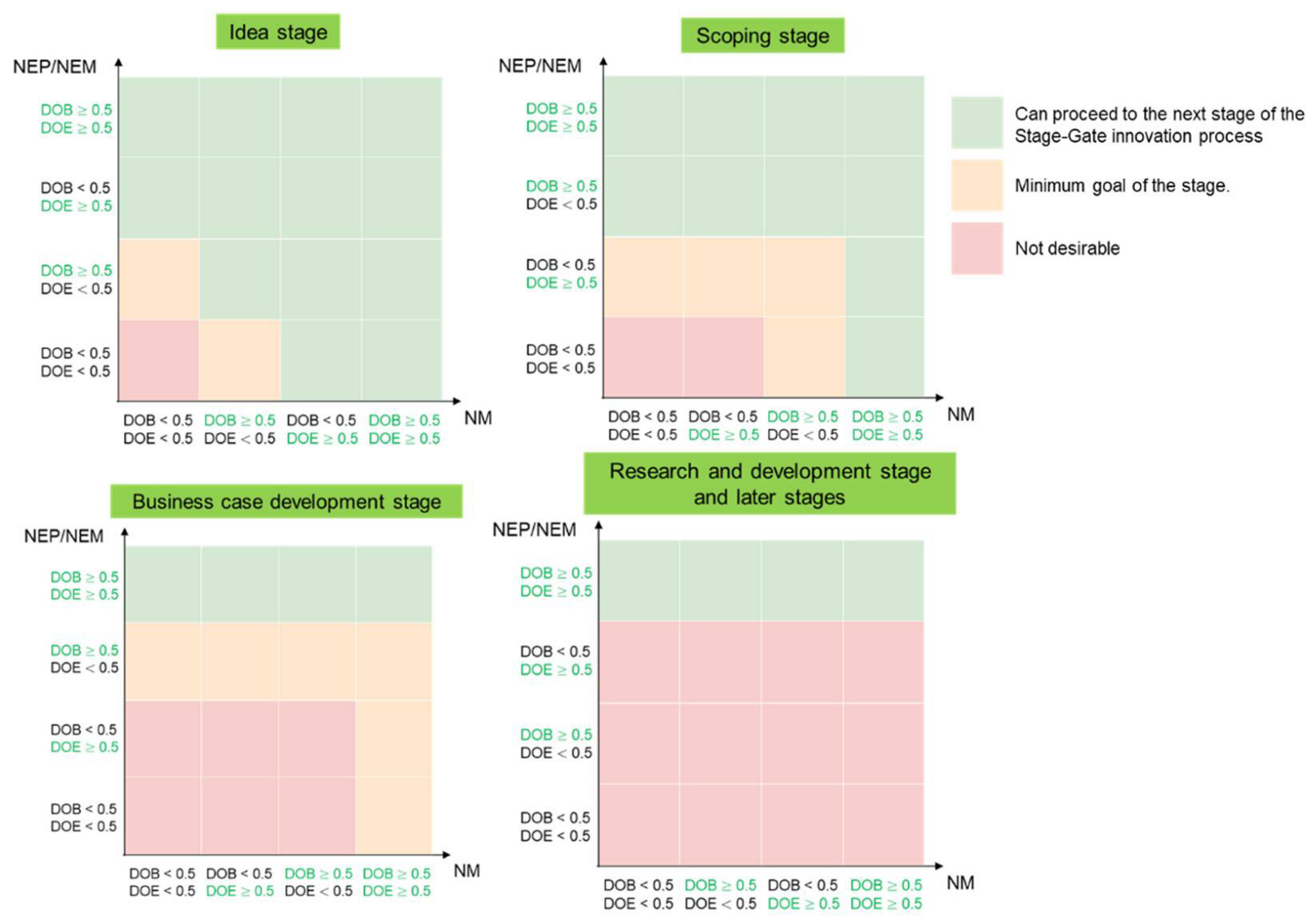

2. Scope and Domain of Applicability of the BAM

3. Overview of the BAM

3.1. Overview of Benefit Indicators

- (i)

- A company develops, produces and sells specific nanomaterials or formulations containing or combined with them (suspensions, composites, coatings, etc.) or other nanoscale structures, such as nanoporous materials or nanoscale layers, membranes or fibers: BAM for nanomaterials.

- (ii)

- A company produces or buys these specific nanomaterials, nanomaterial formulations or nanoscale structured materials and integrates them into their own products: BAM for nano-enabled products.

- (iii)

- A company uses nanomaterials during its product manufacturing process (e.g., a catalyst), but the nanomaterial does not appear in the finished product: BAM for nano-enabled manufacturing.

3.2. Scoring System

3.3. Scoring Assessment

4. BAM Examples Using Three Case Studies

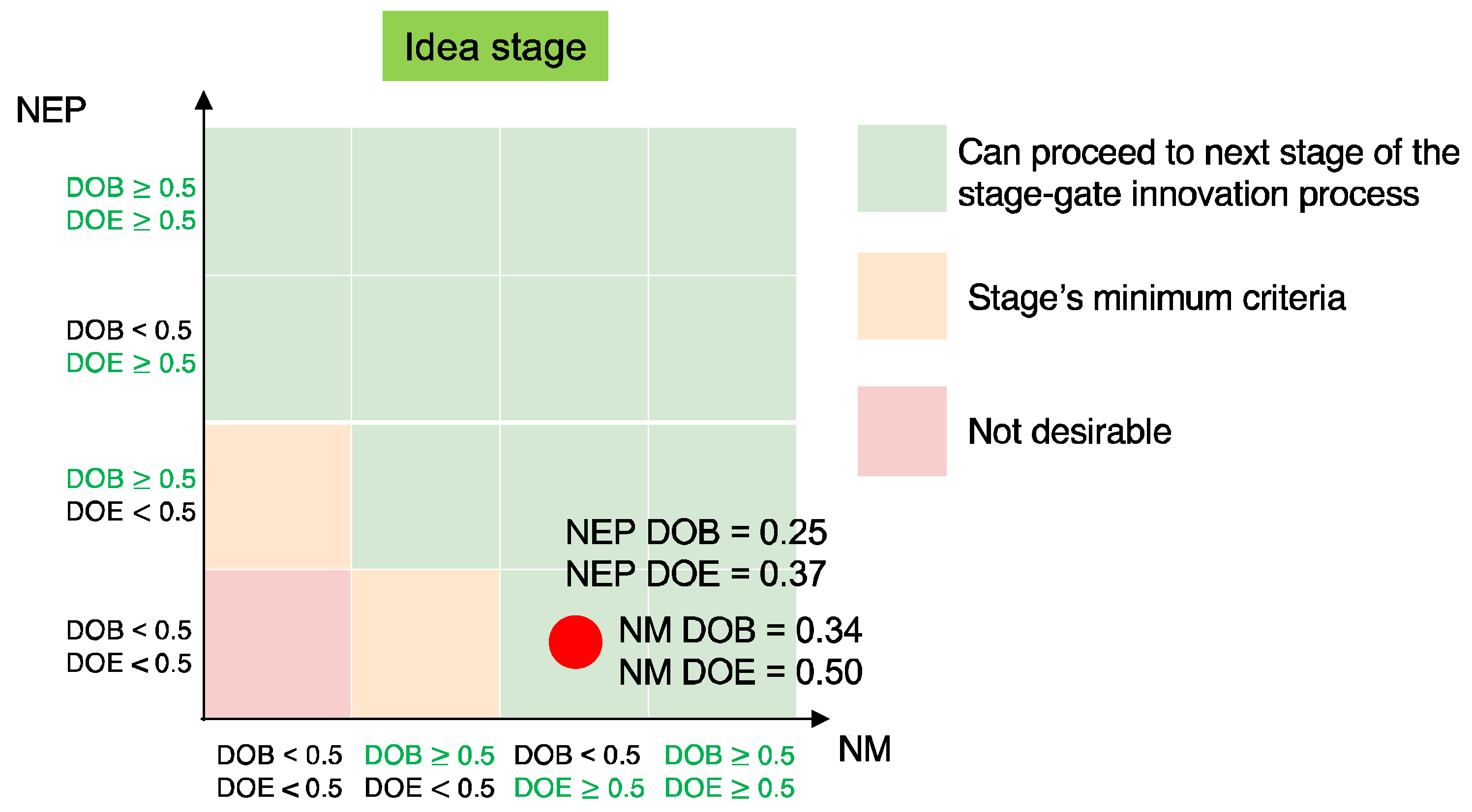

4.1. Nanocomposite: Polymer Car Part Incorporating Nanoclay

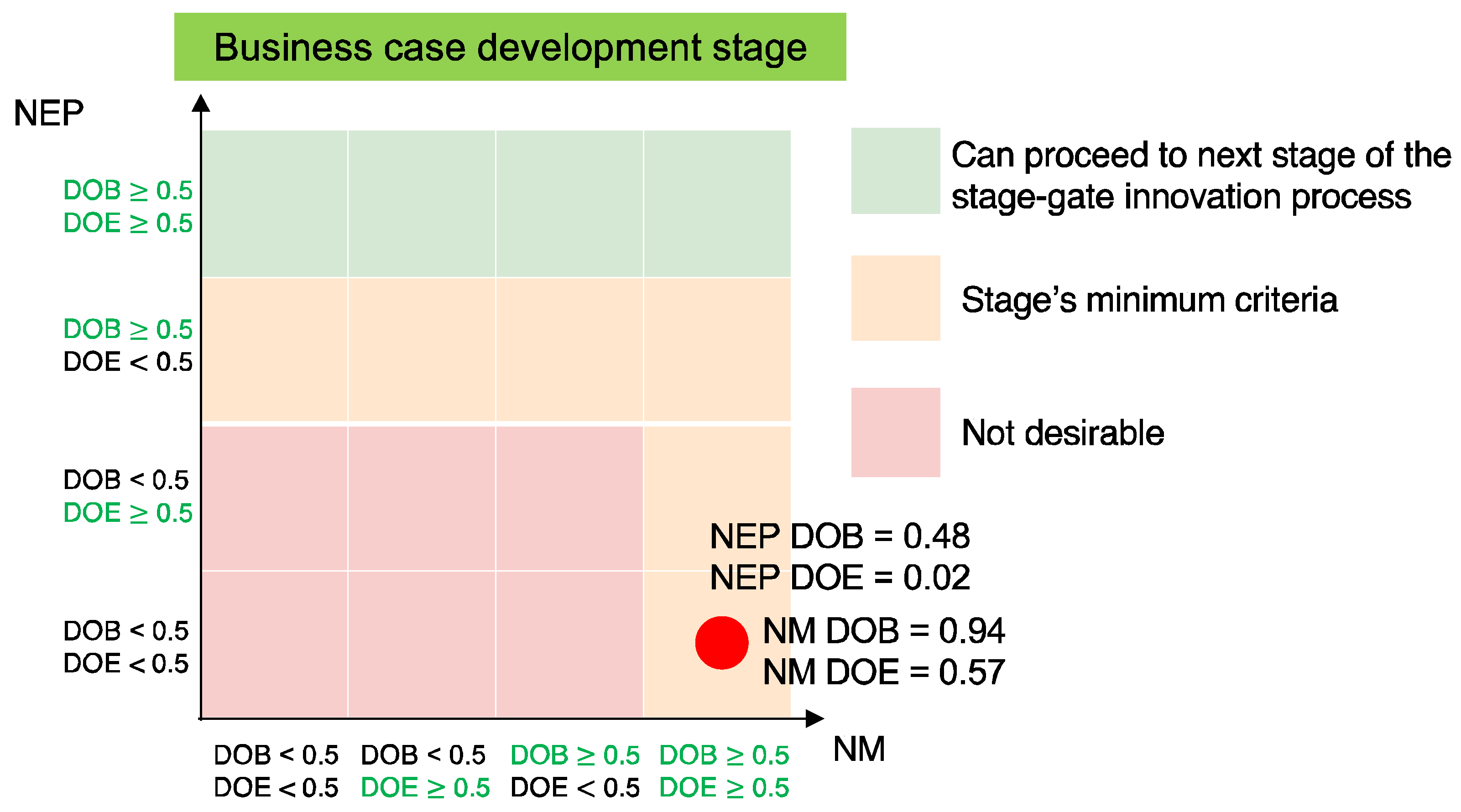

4.2. Nano-TiO2-Enabled Paint for Outdoor Facades

4.3. Nano-Ag-treated Antimicrobial T-Shirt

5. Conclusions and Recommendations

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Moloi, M.S.; Lehutso, R.F.; Erasmus, M.; Oberholster, P.J.; Thwala, M. Aquatic Environment Exposure and Toxicity of Engineered Nanomaterials Released from Nano-Enabled Products: Current Status and Data Needs. Nanomaterials 2021, 11, 2868. [Google Scholar] [CrossRef] [PubMed]

- Bano, S.; Ganie, A.S.; Sultana, S.; Sabir, S.; Khan, M.Z. Fabrication and Optimization of Nanocatalyst for Biodiesel Production: An Overview. Front. Energy Res. 2020, 8, 350. [Google Scholar] [CrossRef]

- Som, C.; Zondervan-van den Beuken, E.; Van Harmelen, T.; Güttinger, J.; Bodmer, M.; Brouwer, D.; Buist, H.E.; Carroll, R.; Coll, C.; Fransman, W.; et al. LICARA Guidelines for the Sustainable Competitiveness of Nanoproducts; Empa: Dübendorf, Switzerland, 2014. [Google Scholar]

- Bickel, M.; Som, C. Nano Textiles-Grundlagen und Leitprinzipien zur effizienten Entwicklung Nachhaltiger Nanotextilien. Empa: Dübendorf, Switzerland; TVS Textilverband: Zürich. Switzerland, 2011. [Google Scholar]

- Wiechers, J.W.; Kelly, C.L.; Blease, T.G.; Dederen, J.C. Formulating for Efficacy. Int. J. Cosmet. Sci. 2004, 26, 173–182. [Google Scholar] [CrossRef] [PubMed]

- European Commission Regulation (EU) No 528/2012 of the European Parliament and of the Council of 22 May 2012 Concerning the Making Available on the Market and Use of Biocidal Products; OJ L 167 2012; European Commission: Brussels, Belgium, 2012.

- European Commission Regulation (EC) No 1107/2009 of the European Parliament and of the Council of 21 October 2009 Concerning the Placing of Plant Protection Products on the Market and Repealing Council Directives 79/117/EEC and 91/414/EEC; L 309/1 2009; European Commission: Brussels, Belgium, 2009.

- Manfredi, S.; Ciacci, L.; Nuss, P.; Manfredi, S. Material Flow Analysis of Aluminium, Copper, and Iron in the EU-28; Publications Office of the European Union: Luxembourg, 2018; ISBN 9789279857447. [Google Scholar]

- RIVM NANoREG Results Repository. Available online: https://www.rivm.nl/en/international-projects/nanoreg (accessed on 4 May 2022).

- Noorlander, C.; Sips, A.; Sabella, S.; Wickson, F.; Salverda, J.; Prina-Mello, A. Comparison on Toxicity Testing in Drug Development and in Present MNMs Safety Testing. NANoREG Deliverable D6.03. 2014. Available online:https://www.rivm.nl/sites/default/files/2019-01/NANoREG_D6_03_DR_Comparison_on_toxicity_testing_in_drug_development_and_in_present_MNMs_safety_testing.pdf (accessed on 27 January 2023).

- Micheletti, C.; Roman, M.; Tedesco, E.; Olivato, I.; Benetti, F. Implementation of the NANoREG Safe-by-Design Approach for Different Nanomaterial Applications. In Proceedings of the Journal of Physics: Conference Series; Institute of Physics Publishing: Bristol, UK, 2017; Volume 838, p. 012019. [Google Scholar]

- Sørensen, S.N.; Baun, A.; Burkard, M.; Maso, M.D.; Hansen, S.F.; Harrison, S.; Hjorth, R.; Lofts, S.; Matzke, M.; Nowack, B.; et al. Evaluating Environmental Risk Assessment Models for Nanomaterials According to Requirements along the Product Innovation Stage-Gate Process. Environ. Sci. Nano 2019, 6, 505–518. [Google Scholar] [CrossRef]

- Soeteman-Hernandez, L.G.; Apostolova, M.D.; Bekker, C.; Dekkers, S.; Grafström, R.C.; Groenewold, M.; Handzhiyski, Y.; Herbeck-Engel, P.; Hoehener, K.; Karagkiozaki, V.; et al. Safe Innovation Approach: Towards an Agile System for Dealing with Innovations. Mater. Today Commun. 2019, 20, 100548. [Google Scholar] [CrossRef]

- European Commission; Joint Research Centre; Caldeira, C.; Farcal, R.; Moretti, C.; Mancini, L.; Rauscher, H.; Riego Sintes, J.; Sala, S.; Rasmussen, K. Safe and Sustainable by Design Chemicals and Materials: Review of Safety and Sustainability Dimensions, Aspects, Methods, Indicators, and Tools; Publications Office of the European Union: Luxembourg, 2022. [Google Scholar]

- Salieri, B.; Barruetabeña, L.; Rodríguez-Llopis, I.; Jacobsen, N.R.; Manier, N.; Trouiller, B.; Chapon, V.; Hadrup, N.; Jiménez, A.S.; Micheletti, C.; et al. Integrative Approach in a Safe by Design Context Combining Risk, Life Cycle and Socio-Economic Assessment for Safer and Sustainable Nanomaterials. NanoImpact 2021, 23, 100335. [Google Scholar] [CrossRef]

- O’Brien, N.; Cummins, E. Development of a Three-Level Risk Assessment Strategy for Nanomaterials. In Nanomaterials: Risks and Benefits; Linkov, I., Steevens, J., Eds.; NATO Science for Peace and Security Series C: Environmental Security; Springer: Dordrecht, The Netherlands, 2009. [Google Scholar]

- Sun, Y.-D.; Chen, Z.-M.; Wei, H.; Liu, C. Nanotechnology Challenge: Safety of Nanomaterials and Nanomedicines. Nanotechnology 2007, 7, 17–31. [Google Scholar]

- Van Harmelen, T.; Zondervan-van den Beuken, E.K.; Brouwer, D.H.; Kuijpers, E.; Fransman, W.; Buist, H.B.; Ligthart, T.N.; Hincapié, I.; Hischier, R.; Linkov, I.; et al. LICARA NanoSCAN—A Tool for the Self-Assessment of Benefits and Risks of Nanoproducts. Environ. Int. 2016, 91, 150–160. [Google Scholar] [CrossRef]

- RIVM Introduction Safe Innovation Approach (SIA) Toolbox|RIVM. Available online: https://www.rivm.nl/en/international-projects/nanoregii/introduction-sia-toolbox (accessed on 12 October 2022).

- Grobe, A. Verantwortlicher Umgang mit Nanotechnologien–Bericht und Empfehlungen der NanoKommission 2011; Bundesministerium für Umwelt, Naturschutz und Reaktorsicherheit (BMU): Berlin, Germany, 2010. [Google Scholar]

- Krishna, M.G.; Vinjanampati, M.; Purkayastha, D.D. Metal Oxide Thin Films and Nanostructures for Self-Cleaning Applications: Current Status and Future Prospects. EPJ Appl. Phys. 2013, 62, 30001. [Google Scholar] [CrossRef]

- Khurana, C.; Vala, A.K.; Andhariya, N.; Pandey, O.P.; Chudasama, B. Antibacterial Activity of Silver: The Role of Hydrodynamic Particle Size at Nanoscale. J. Biomed. Mater. Res. A 2014, 102, 3361–3368. [Google Scholar] [CrossRef]

- Adesina, A.A. Industrial Exploitation of Photocatalysis: Progress, Perspectives and Prospects. Catal. Surv. Asia 2004, 8, 265–273. [Google Scholar] [CrossRef]

- Roucoux, A.; Schulz, J.; Patin, H. Reduced Transition Metal Colloids: A Novel Family of Reusable Catalysts? Chem. Rev. 2002, 102, 3757–3778. [Google Scholar] [CrossRef]

- Roes, A.L.; Marsili, E.; Nieuwlaar, E.; Patel, M.K. Environmental and Cost Assessment of a Polypropylene Nanocomposite. J. Polym. Environ. 2007, 15, 212–226. [Google Scholar] [CrossRef]

- Hischier, R.; Nowack, B.; Gottschalk, F.; Hincapie, I.; Steinfeldt, M.; Som, C. Life Cycle Assessment of Façade Coating Systems Containing Manufactured Nanomaterials. J. Nanoparticle Res. 2015, 17, 1–13. [Google Scholar] [CrossRef]

- Walser, T.; Demou, E.; Lang, D.J.; Hellweg, S. Prospective Environmental Life Cycle Assessment of Nanosilver T-Shirts. Environ. Sci. Technol. 2011, 45, 4570–4578. [Google Scholar] [CrossRef]

- Nahin, A.M.; Asrafuzzaman; Amin, K.F. Life-Cycle Assessment of Polymer Nanocomposites. In Advanced Polymer Nanocomposites; Woodhead Publishing: Sawston, UK, 2022; pp. 145–167. [Google Scholar]

- Isaifan, R.J.; Samara, A.; Suwaileh, W.; Johnson, D.; Yiming, W.; Abdallah, A.A.; Aïssa, B. Improved Self-Cleaning Properties of an Efficient and Easy to Scale up TiO2 Thin Films Prepared by Adsorptive Self-Assembly. Sci. Rep. 2017, 7, 9466. [Google Scholar] [CrossRef]

- Miyoshi, A.; Miyoshi, A.; Kato, K.; Yokoi, T.; Wiesfeld, J.J.; Nakajima, K.; Yamakara, A.; Maeda, K. Nano: Vs. Bulk Rutile TiO2: N,F in Z-Scheme Overall Water Splitting under Visible Light. J. Mater. Chem. A Mater. 2020, 8, 11996–12002. [Google Scholar] [CrossRef]

- Krifa, M.; Prichard, C. Nanotechnology in textile and apparel research—An overview of technologies and processes. J. Text. Inst. 2020, 111, 1778–1793. [Google Scholar] [CrossRef]

- Heine, E.; Knops, H.G.; Schaefer, K.; Vangeyte, P.; Moeller, M. Antimicrobial Functionalisation of Textile Materials. In Multifunctional Barriers for Flexible Structure; Duquesne, S., Magniez, C., Camino, G., Eds.; Materials Science; Springer: Berlin/Heidelberg, Germany, 2007; Volume 97. [Google Scholar]

- Windler, L.; Height, M.; Nowack, B. Comparative Evaluation of Antimicrobials for Textile Applications. Environ. Int. 2013, 53, 62–73. [Google Scholar] [CrossRef]

- Gottardo, S.; Mech, A.; Drbohlavová, J.; Małyska, A.; Bøwadt, S.; Riego Sintes, J.; Rauscher, H. Towards safe and sustainable innovation in nanotechnology: State-of-play for smart nanomaterials. NanoImpact 2021, 21, 100297. [Google Scholar] [CrossRef]

- Isigonis, P.; Hristozov, D.; Benighaus, C.; Giubilato, E.; Grieger, K.; Pizzol, L.; Semenzin, E.; Linkov, I.; Zabeo, A.; Marcomini, A. Risk Governance of Nanomaterials: Review of Criteria and Tools for Risk Communication, Evaluation, and Mitigation. Nanomaterials 2019, 9, 696. [Google Scholar] [CrossRef] [PubMed]

- Som, C.; Nowack, B.; Krug, H.; Wick, P. Towards the development of decision supporting tools that can be used for safe production and use of nanomaterials. Acc. Chem. Res. 2013, 46, 863–872. [Google Scholar] [CrossRef] [PubMed]

| Life-Cycle Stage | Functional Benefit | Health Benefit | Environmental Benefit | |

|---|---|---|---|---|

| Direct | Indirect | Direct | Indirect | |||

| Nanomaterial | Production | Not applicable | Indirect | Indirect |

| Nano-enabled manufacturing | Manufacturing | Direct | Indirect | Indirect |

| Nano-enabled product | Manufacturing | Not applicable | Indirect | Indirect |

| Use | Direct | Direct/Indirect | Direct/Indirect | |

| EoL | Not applicable | Indirect | Indirect |

| Life-Cycle Stage | Category of Benefit | Benefit Indicator | Description |

|---|---|---|---|

| Nanomaterial production | Indirect | Energy consumption | Nanomaterial production process consumes less energy than the reference material |

| Water consumption | Nanomaterial production process consumes less water than the reference material | ||

| Raw material consumption | Nanomaterial production process consumes fewer raw materials than the reference material | ||

| Greenhouse gas emission | Nanomaterial production process produces less greenhouse gas or has a lower carbon footprint than the reference material | ||

| Emission of pollutants | Nanomaterial production process emits fewer pollutants than the reference material | ||

| Waste volume | Nanomaterial production process produces less waste than the reference material | ||

| Hazardous waste | Nanomaterial production process produces less hazardous waste than the reference material | ||

| Safe(r) handling | Nanomaterial production process is safer than the reference material’s process | ||

| Nano-enabled manufacturing | Direct | Environmental protection | The main goals of using nanomaterials during the manufacturing process are protecting the environment or reducing negative environmental impacts |

| Health protection | The main goal of using nanomaterials during the manufacturing process is to avoid any adverse effects on human health | ||

| Functionality | Using nanomaterials has a functional benefit on the manufacturing process | ||

| Indirect | Energy consumption | Using nanomaterials during the manufacturing process consumes less energy than the reference manufacturing process | |

| Water consumption | Using nanomaterials during the manufacturing process consumes less water than the reference manufacturing process | ||

| Raw material consumption | Using nanomaterials during the manufacturing process consumes fewer raw materials than the reference manufacturing process | ||

| Greenhouse gas emission | Using nanomaterials during the manufacturing process produces less greenhouse gas than the reference manufacturing process | ||

| Emission of pollutants | Using nanomaterials during the manufacturing process emits fewer pollutants than the reference manufacturing process | ||

| Waste volume | Using nanomaterials during the manufacturing process produces less waste than the reference manufacturing process | ||

| Hazardous waste | Using nanomaterials during the manufacturing process produces less hazardous waste than the reference manufacturing process | ||

| Safe(r) handling | Using nanomaterials during the manufacturing process is safer than the reference manufacturing process | ||

| Manufacturing NEPs | Indirect | Energy consumption | Manufacturing the NEP consumes less energy than manufacturing the reference product |

| Water consumption | Manufacturing the NEP consumes less water than manufacturing the reference product | ||

| Raw material consumption | Manufacturing the NEP consumes fewer raw materials than manufacturing the reference product | ||

| Greenhouse gas emission | Manufacturing the NEP emits less greenhouse gas than manufacturing the reference product | ||

| Emission of pollutants | Manufacturing the NEP emits fewer pollutants than manufacturing the reference product | ||

| Waste volume | Manufacturing the NEP produces less waste than manufacturing the reference product | ||

| Hazardous waste | Manufacturing the NEP produces less hazardous waste than manufacturing the reference product | ||

| Safe(r) handling | Manufacturing the NEP is a safer procedure than manufacturing the reference product | ||

| Using NEPs | Direct | Environmental protection | The main goal of using the NEP is to protect the environment or reduce negative environmental impacts |

| Health protection | The main goal of using the NEP is to avoid any adverse effects on human health | ||

| Functionality | There are functional benefits to using the NEP in the manufacturing process | ||

| Indirect | Energy consumption | Using the NEP consumes less energy than using the reference product | |

| Water consumption | Using the NEP consumes less water than using the reference product | ||

| Raw material consumption | Using the NEP consumes fewer raw materials than using the reference product | ||

| Greenhouse gas emission | Using the NEP emits less greenhouse gas than using the reference product | ||

| Emission of pollutants | Using the NEP emits fewer pollutants than using the reference product | ||

| Waste volume | Using the NEP produces less waste than using the reference product | ||

| Safe(r) handling | Using the NEP is a safer procedure than using the reference product | ||

| NEP EoL | Indirect | Energy consumption | The NEP’s EoL consumes less energy than the reference product’s EoL |

| Water consumption | The NEP’s EoL consumes less water than the reference product’s EoL | ||

| Raw material consumption | The NEP’s EoL consumes fewer raw materials than the reference product’s EoL | ||

| Greenhouse gas emission | The NEP’s EoL emits less greenhouse gas than the reference product’s EoL | ||

| Emission of pollutants | The NEP’s EoL emits fewer pollutants than the reference product’s EoL | ||

| Waste volume | The NEP’s EoL produces less waste than the reference product’s EoL | ||

| Hazardous waste | The NEP’s EoL produces less hazardous waste than the reference product’s EoL | ||

| Safe(r) handling | The NEP’s EoL is a safer procedure than the reference product’s EoL |

| Probability of Achieving the Benefit (a) | Magnitude of Benefit (m) | ||

|---|---|---|---|

| Better | Same | Worse | |

| A standard procedure is implemented, and the benefit will always be achieved. | B = 1 | B = 0.5 | B = 0.01 |

| There is a correct usage or treatment, and this should be taught and implemented. | B = 0.5 | B = 0.25 | B = 0.005 |

| The benefit is only achievable theoretically. | B = 0.01 | B = 0.02 | B = 0 |

| Nanomaterial | Nano-Enabled Product | Nanomaterial-Related Enhancement | Stage of the Innovation Process | Reference Study |

|---|---|---|---|---|

| Nanoclay (Layered silicates) | Internal automobile body-panels | Improved elasticity, strength and fire-retardant properties | Idea stage (before gate 1) | [25] |

| Nano-TiO2 | Outdoor facade coatings | Self-cleaning | Business case development stage (between gates 3 and 4) | [26] |

| Nano-Ag | T-shirts | Antimicrobial activity | Scoping stage (between gates 1 and 2) | [27] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hong, H.; Som, C.; Nowack, B. Development of a Benefit Assessment Matrix for Nanomaterials and Nano-enabled Products—Toward Safe and Sustainable by Design. Sustainability 2023, 15, 2321. https://doi.org/10.3390/su15032321

Hong H, Som C, Nowack B. Development of a Benefit Assessment Matrix for Nanomaterials and Nano-enabled Products—Toward Safe and Sustainable by Design. Sustainability. 2023; 15(3):2321. https://doi.org/10.3390/su15032321

Chicago/Turabian StyleHong, Hyunjoo, Claudia Som, and Bernd Nowack. 2023. "Development of a Benefit Assessment Matrix for Nanomaterials and Nano-enabled Products—Toward Safe and Sustainable by Design" Sustainability 15, no. 3: 2321. https://doi.org/10.3390/su15032321

APA StyleHong, H., Som, C., & Nowack, B. (2023). Development of a Benefit Assessment Matrix for Nanomaterials and Nano-enabled Products—Toward Safe and Sustainable by Design. Sustainability, 15(3), 2321. https://doi.org/10.3390/su15032321