Application of Geotextile Tubes to Coastal Silt Mitigation: A Case Study in Niaoyu Fishing Harbor

Abstract

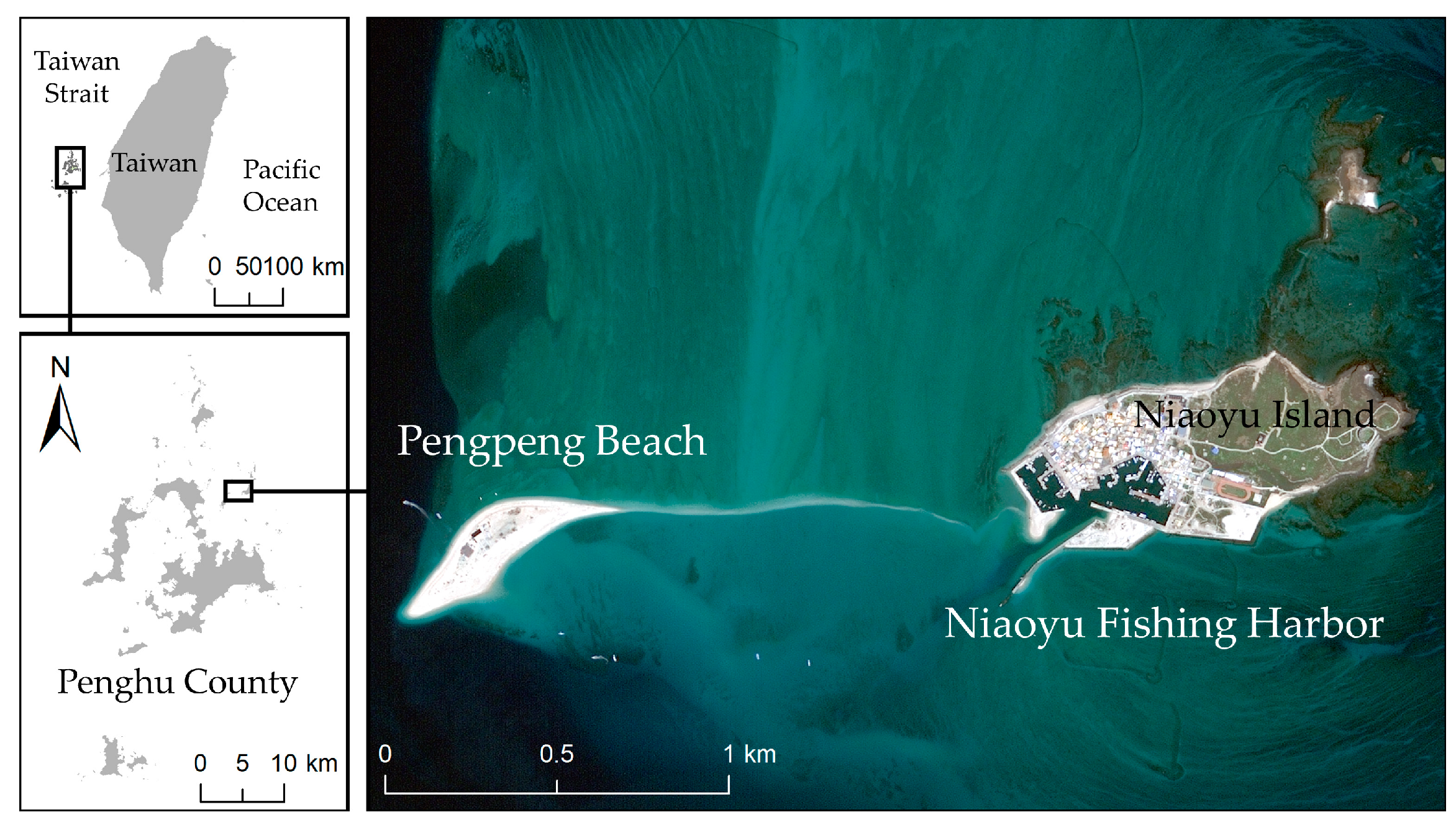

1. Introduction

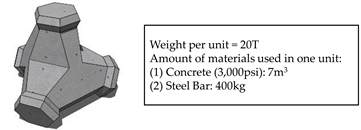

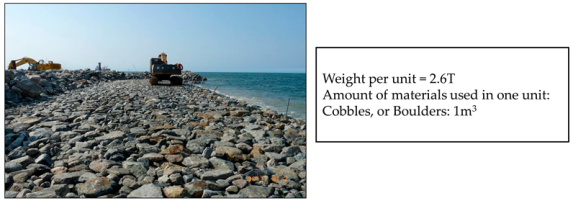

1.1. Hard Solution

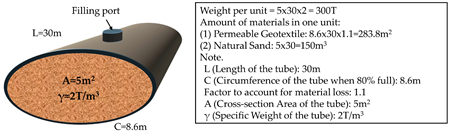

1.2. Soft Solution

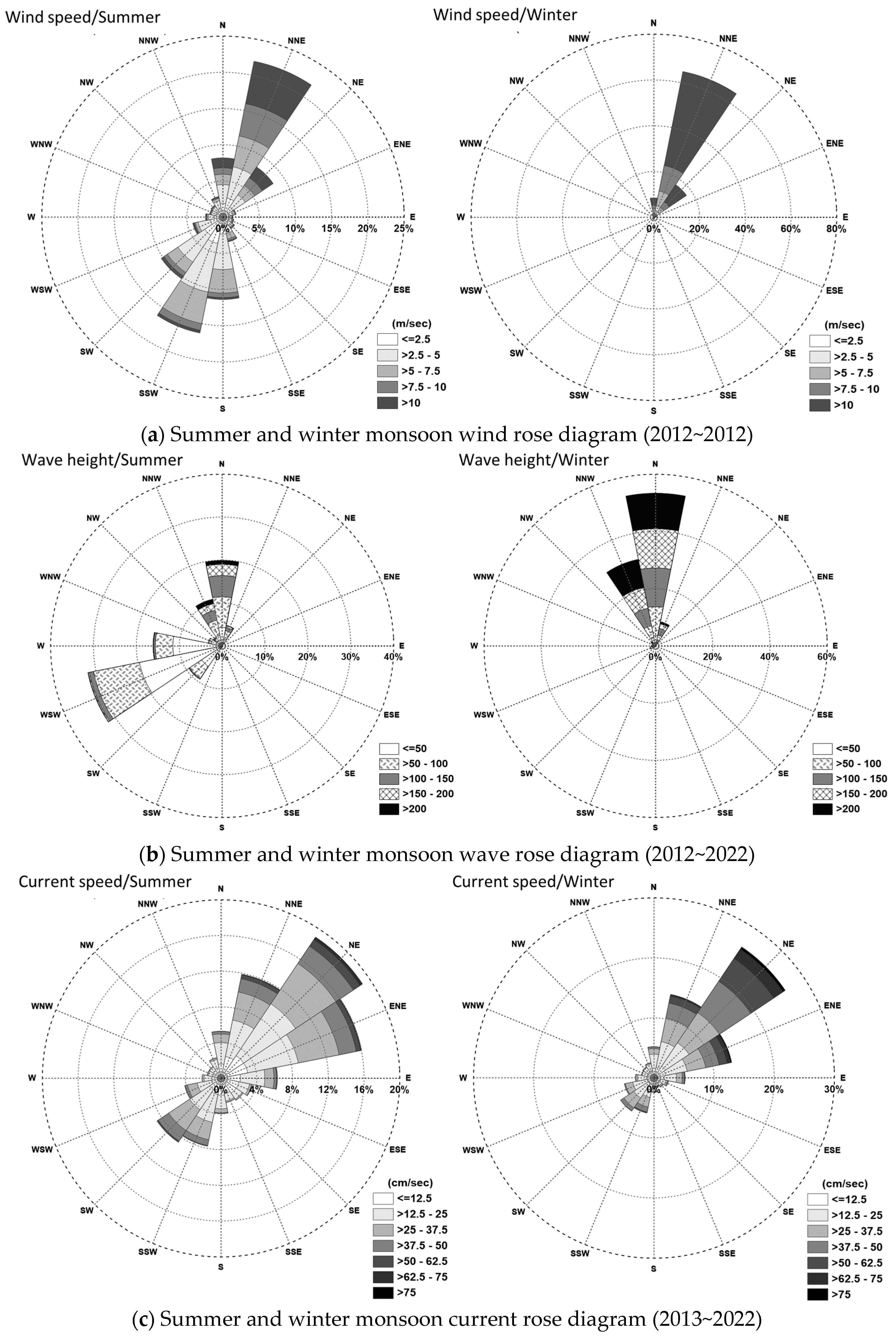

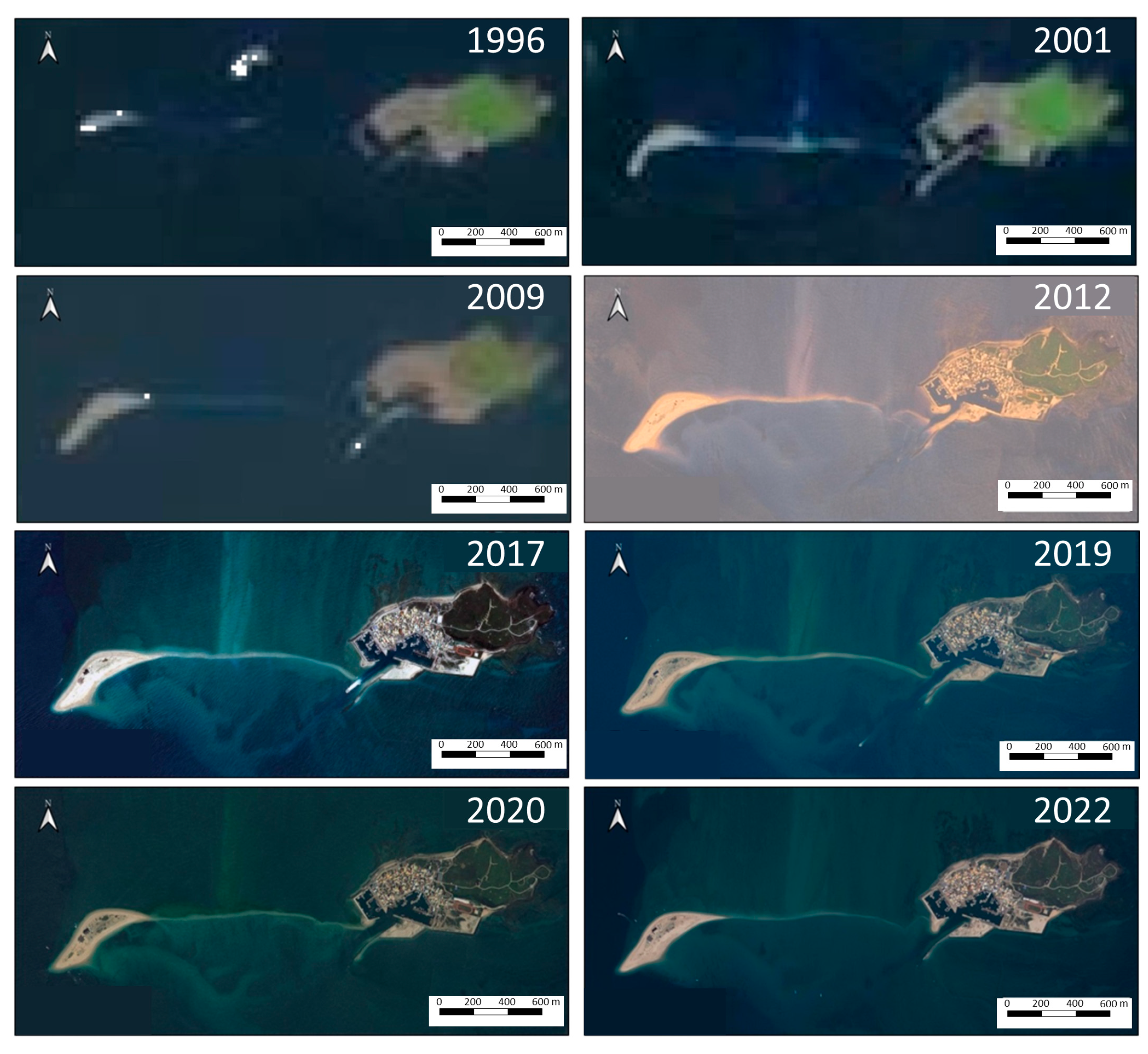

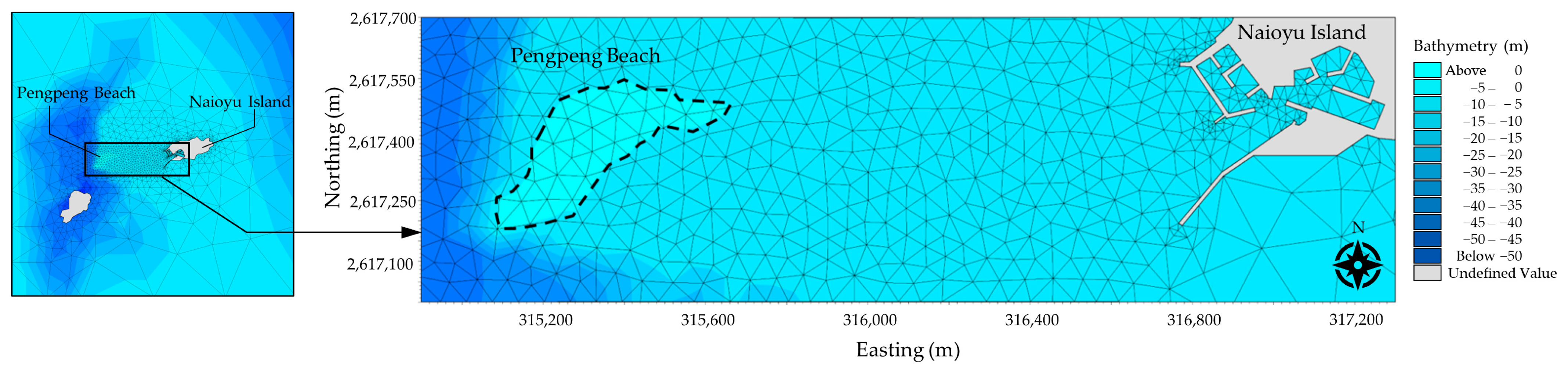

2. Study Area

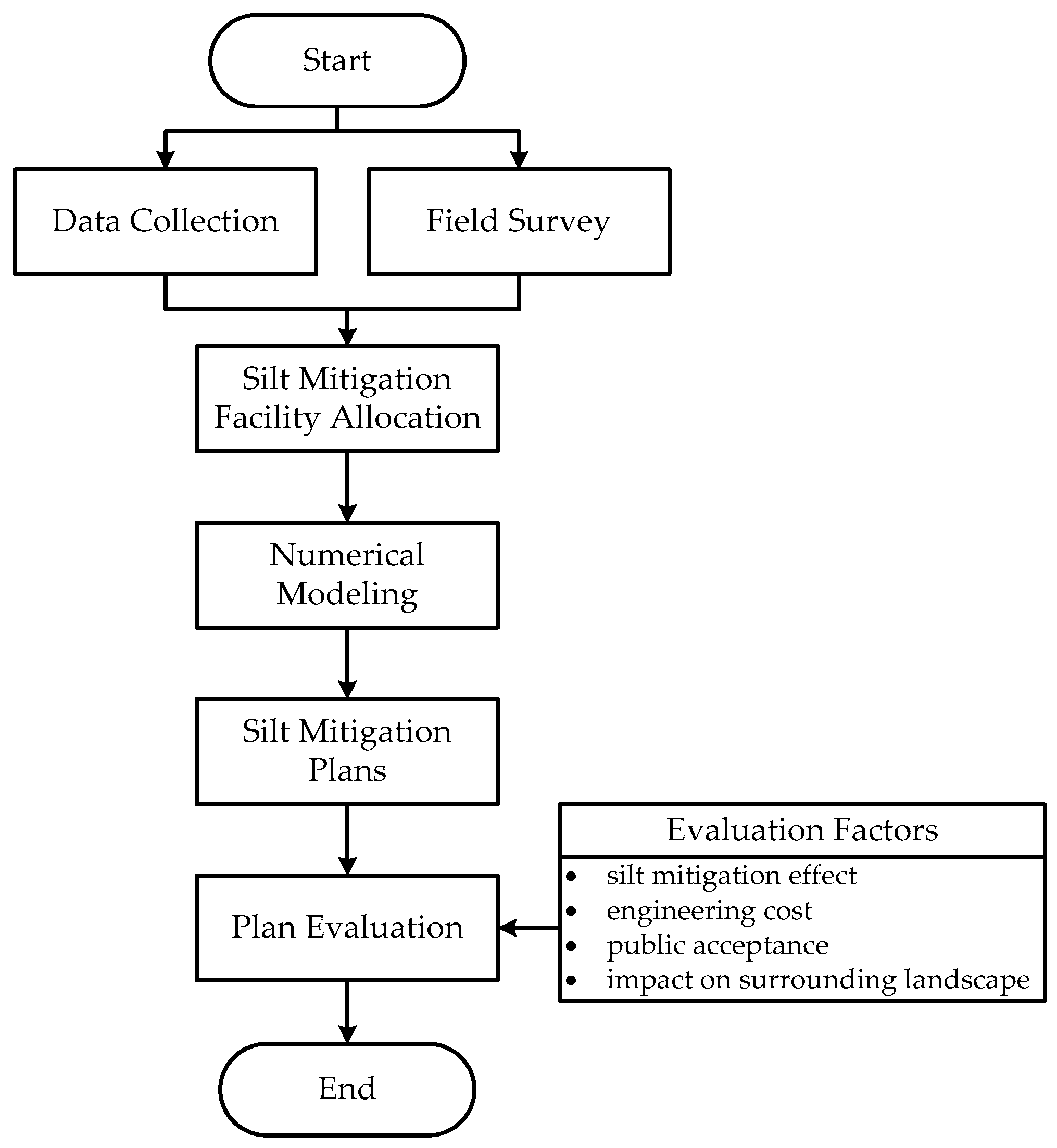

3. Methods

3.1. Field Survey and Data Collection and Analysis

3.2. Numerical Modeling

3.2.1. Bathymetry and Computational Grid Configuration

3.2.2. Spectral Wind Wave Model

3.2.3. Boundary Conditions

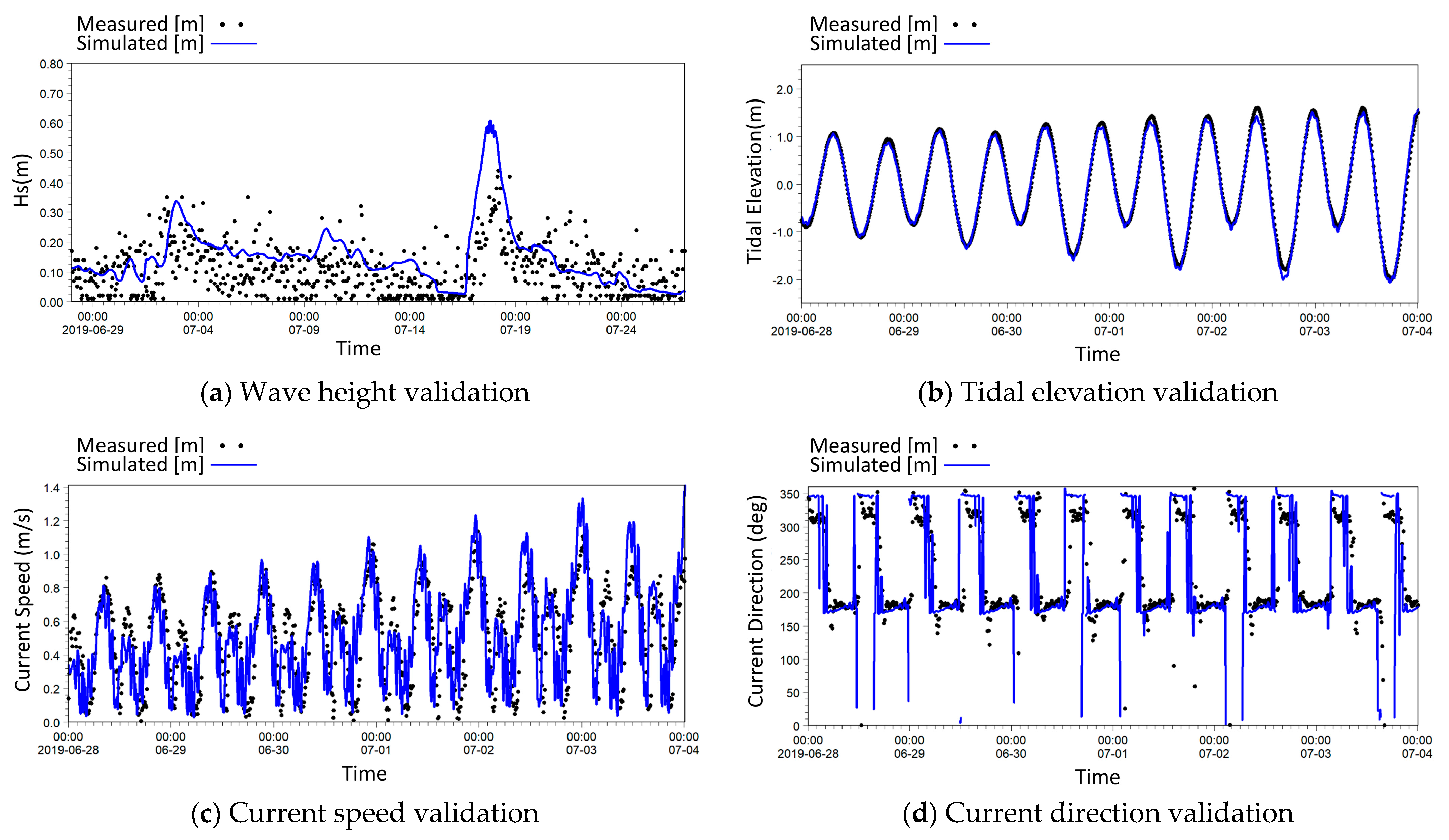

3.2.4. Model Validation

3.2.5. Short-Term Erosion Trend Numerical Modeling

3.3. Silt Mitigation Measures

3.4. Engineering Costs Estimation

4. Results

4.1. Silt Trap Facilities Allocation

4.1.1. Near Pengpeng Beach (x = 315,000~315,500 m)

4.1.2. At the Niaoyu Harbor Entrance and Its Navigation Channel (x = 316,700~317,200 m)

4.1.3. At the South and North Sides of Niaoyu Island

4.2. Silt Mitigation Plans

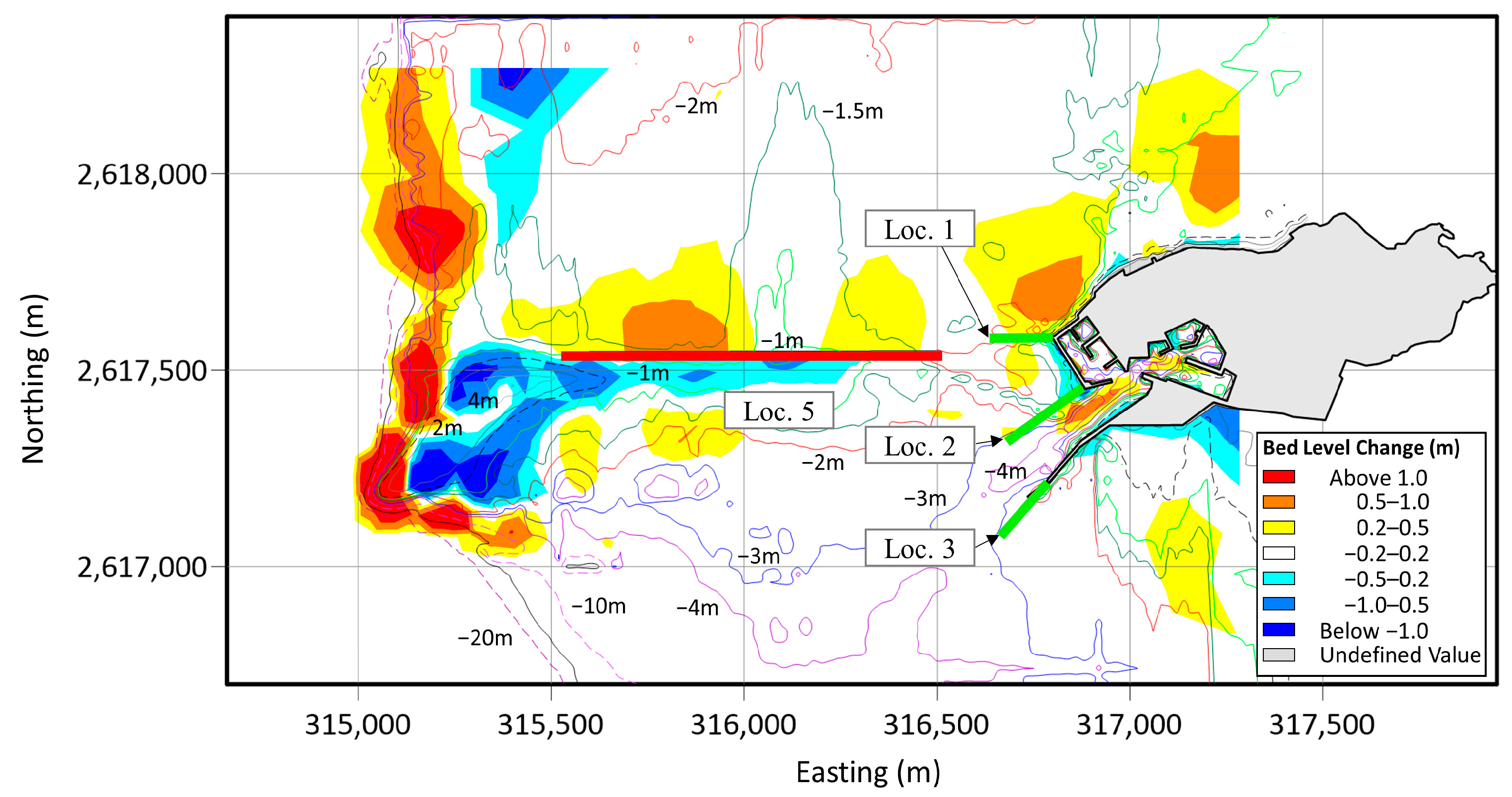

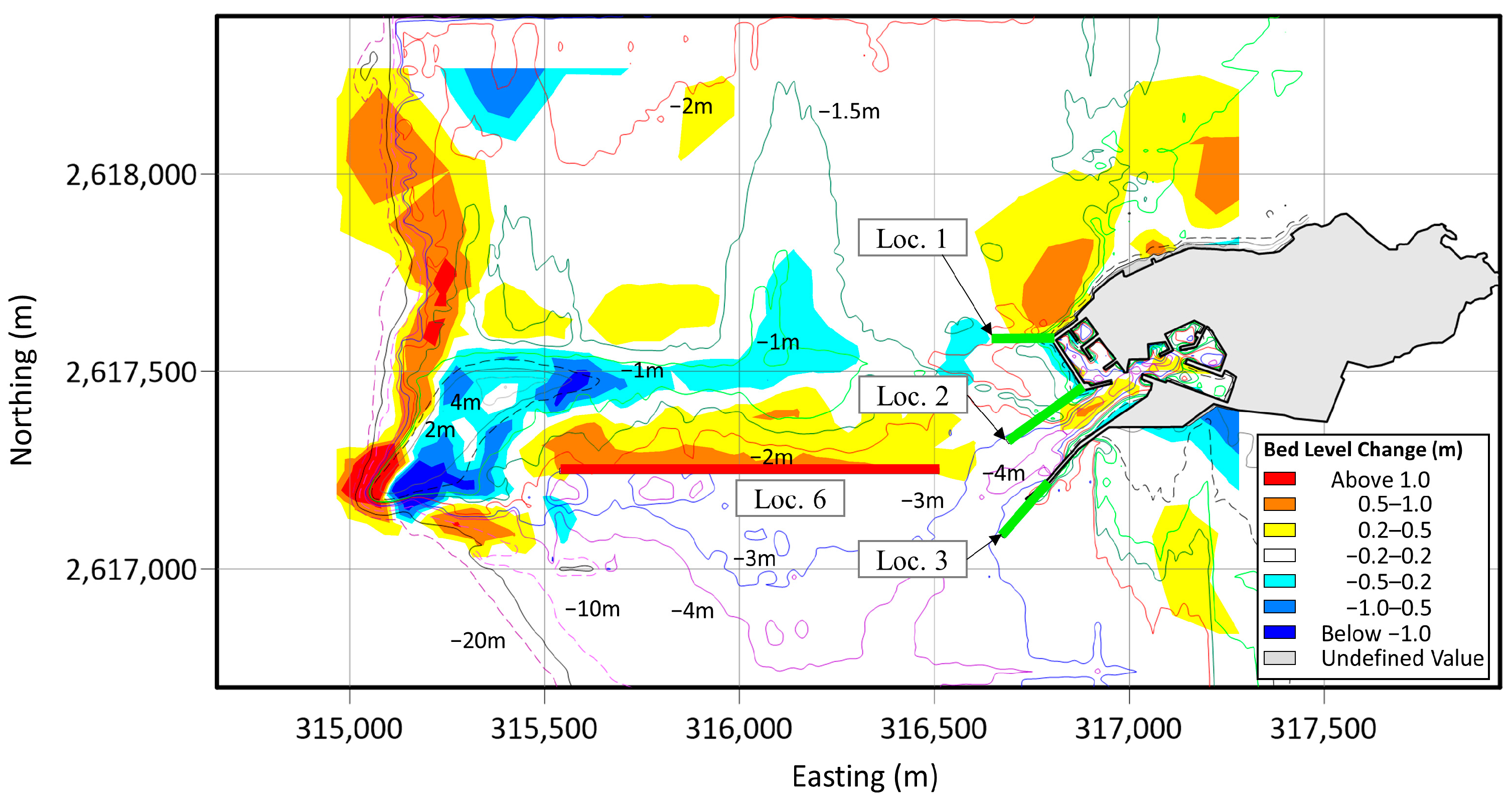

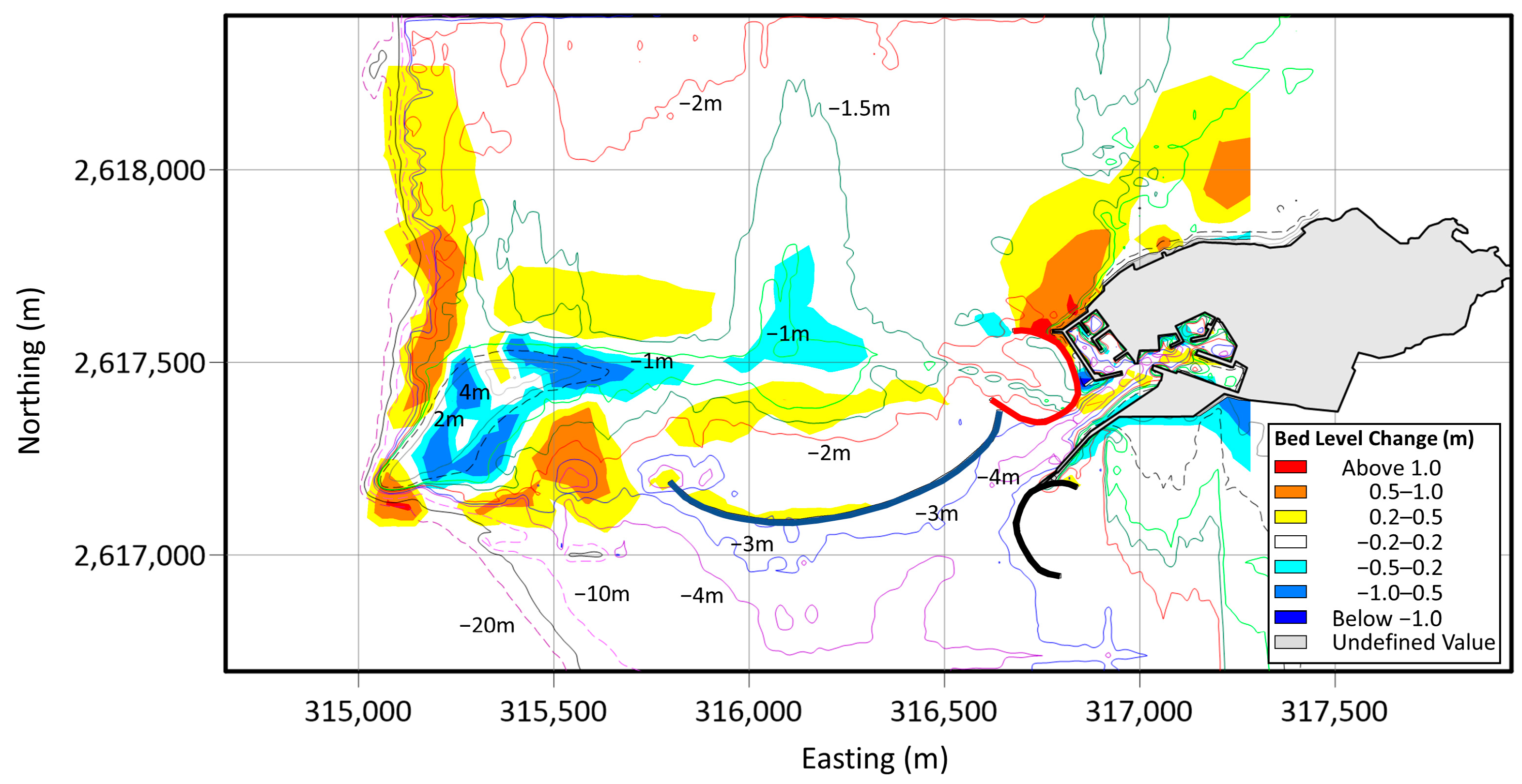

4.2.1. Mitigation Plan 0

4.2.2. Mitigation Plan 1 (Combination of Setup #1, #3, and #4)

4.2.3. Mitigation Plan 2 (Combination of Setup #2, #3, and #4)

4.3. Mitigation Plan Evaluation

4.3.1. Silt Mitigation Efficiency

4.3.2. Engineering Costs

4.3.3. Public Acceptance

4.3.4. Impact on the Surrounding Landscape

4.4. Mitigation Plan Selection

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| |||||

| Item | Material | Unit | Amount | Unit CO2 Emissions (kg) | Total CO2 Emissions (kg) |

|---|---|---|---|---|---|

| Armor Block | Concrete (3000 psi) | m3 | 7 | 253.7 1 | 1775.8 |

| Rebar | kg | 400 | 0.97 2 | 388.0 | |

| Unit Weight (T) | 20 | ||||

| CO2 Emissions (kg/T) | 108.2 | ||||

| |||||

| Item | Material | Unit | Amount | Unit CO2 Emissions (kg) | Total CO2 Emissions (kg) |

|---|---|---|---|---|---|

| Geotextile Tube | Permeable Geotextile | m2 | 283.8 | 2.5 3 | 709 |

| Fill Material | Natural Sand | m3 | 150 | 0 | 0 |

| Unit Weight (T) | 300 | ||||

| CO2 Emissions (kg/T) | 2.4 | ||||

| |||||

| Item | Material | Unit | Amount | Unit CO2 Emissions (kg) | Total CO2 Emissions (kg) |

|---|---|---|---|---|---|

| Riprap | Cobbles or Boulders | m3 | 1 | 72.3 4 | 72.3 |

| Unit Weight (T) | 2.6 | ||||

| CO2 Emissions (kg/T) | 27.8 | ||||

References

- Chien, A.; Wu, S.; Tseng, F.; Tang, A. Geotextile Tubes Application on Beach Nourishment in UAE. Int. J. Environ. Sci. Dev. 2014, 5, 506–509. [Google Scholar] [CrossRef]

- Tsai, C.-C.; Chen, Y.-M.; Tsai, C.-J.; Chang, M.-W.; Chen, Y.-S. Breakwater made of geotextile tubes in Ras Al-Khaimah City, UAE. In Proceedings of the 37th Ocean Engineering Conference in Taiwan, Taichung, Taiwan, 12–13 November 2015; Volume 1, pp. 505–510. [Google Scholar]

- Lin, Z.; Tseng, F.; Cheng, H.-C. Geotextile Tube solution for Dos Bocas beach erosion problem at Tabasco, Mexico. In Proceedings of the 32rd Ocean Engineering Conference in Taiwan, Keelung, Taiwan, 24 November 2010; Volume 1, pp. 629–634. [Google Scholar]

- Lim, A.L.K.; Siew, K.H. Geotextile Tube for Coastal Protection and Land Reclamation. In Scour- and Erosion-Related Issues; Reddy, C.N.V.S., Sassa, S., Eds.; Springer Singapore: Singapore, 2022; pp. 95–116. [Google Scholar]

- Kim, H.J.; Dinoy, P.R.; Kim, H.S. Tension force analysis of geotextile tubes by half cross-section test. Geotext. Geomembr. 2020, 48, 243–256. [Google Scholar] [CrossRef]

- Kim, H.J.; Dinoy, P.R. Two-dimensional consolidation analysis of geotextile tubes filled with fine-grained material. Geotext. Geomembr. 2021, 49, 1149–1164. [Google Scholar] [CrossRef]

- Kim, D.-J.; Kim, S.-C.; Lee, J.-S.; Byun, Y.-H.; Kang, B.-Y. Internal strength characterization of geotextile tube using miniature cone. Ocean. Eng. 2022, 266, 113157. [Google Scholar] [CrossRef]

- Ho, Y.-H.; Liu, C.-N.; Wang, T.-C.; Tseng, F. The case study of geotextile tube solution for tidal inlet restoration project in Tainan City. In Proceedings of the 35th Ocean Engineering Conference in Taiwan, Kaohsiung, Taiwan, 21–22 November 2013; Volume 1. [Google Scholar]

- Wu, C.-T.; Yao, W.-T.; Chan, C.-Y.; Li, J.-J.; Cheng, H.-C. Geotextile tubes application in Taichung harbor north side siltation area wind-blown sand remediation. In Proceedings of the 36th Ocean Engineering Conference in Taiwan, Hsinchu, Taiwan, 4–5 December 2014; Volume 1, pp. 591–596. [Google Scholar]

- Fowler, J.; Bagby, R.M.; Trainer, E. Dewatering sewage sludge with geotextile tubes. In Proceedings of the 49th Canadian Geotechnical Conference, St. John’s, NL, Canada, 23–25 September 1996; pp. 1–31. [Google Scholar]

- Moo-Young, H.K.; Myers, T.; Townsend, D.; Ochola, C. Contaminant migration through GeoContainers used in dredging operations. Eng. Geol. 1999, 53, 167–176. [Google Scholar] [CrossRef]

- Tseng, C.-J.; Lin, Z.; Tang, A. ACECONTAINER applied in high-polluting sludge. In Proceedings of the 33rd Ocean Engineering Conference in Taiwan, Kaohsiung, Taiwan, 1–2 December 2011; Volume 1, pp. 659–664. [Google Scholar]

- Tseng, I.-F.; Cheng, H.-C.; Lee, C.-P.; Lin, I.-F.; Lee, F.-C.; Wang, Y.-C.; Weng, J.-C. The application of geotextile tube for coastal protection. In Proceedings of the 38th Ocean Engineering Conference in Taiwan, Taipei, Taiwan, 8–9 December 2016; Volume 1, pp. 178–183. [Google Scholar]

- Qiu, J.-Q.; Tseng, I.-F.; Wang, Y.-C.; Weng, J.-C. Experimental study on geotextile tube applications for coastal protection. In Proceedings of the 40th Ocean Engineering Conference in Taiwan, Kaohsiung, Taiwan, 20–22 November 2018. [Google Scholar]

- Chang, Y.-S. Life Cycle Assessment on the Reduction of Carbon Dioxide Emission of Buildings. Ph.D. Thesis, National Cheng Kung University, Tainan City, Taiwan, 2002. [Google Scholar]

- Matsumoto, K.; Ooe, M.; Sato, T.; Segawa, J. Ocean tide model obtained from TOPEX/POSEIDON altimetry data. J. Geophys. Res. 1995, 100, 25319–25330. [Google Scholar] [CrossRef]

- NOAA National Geophysical Data Center. 2-Minute Gridded Global Relief Data (ETOPO2) v2. Available online: https://www.ncei.noaa.gov/access/metadata/landing-page/bin/iso?id=gov.noaa.ngdc.mgg.dem:301 (accessed on 11 November 2022).

- NOAA Physical Sciences Laboratory. The NCEP/NCAR Reanalysis Project. Available online: https://psl.noaa.gov/data/reanalysis/reanalysis.shtml (accessed on 11 November 2022).

| Method | Material | CO2 Emissions (kg/T) | Ratio * | Carbon Reduction Efficiency |

|---|---|---|---|---|

| Geotextile Tube | Permeable Fabric, Natural Sand | 2.4 | 1:1 | – |

| Armor Block | Concrete, Steel Bar | 108.2 | 46:1 | 97.8% |

| Riprap | Sand, Boulder | 27.8 | 12:1 | 91.3% |

| Year | Area (m2) |

|---|---|

| 1996 | 12,387 |

| 2001 | 40,509 |

| 2009 | 50,422 |

| 2012 | 64,219 |

| 2017 | 65,621 |

| 2019 | 78,192 |

| 2020 | 65,446 |

| 2022 | 65,675 |

| Setup # | Location | Breakwater Length (m) | Cross-Section Type |

|---|---|---|---|

| 1 | North side of the navigation channel (the red line in Figure 18) | 500 | Type B (Geotextile Tubes + Rock Armor) |

| 2 | Type C (Geotextile Tubes) | ||

| 3 | South side of the navigation channel (the black line in Figure 18) | 500 | Type A (Geotextile Tubes + Rock Armor) |

| 4 | South side of the Pengpeng Beach sand tail (the blue line in Figure 18) | 1000 | Type A (Geotextile Tubes + Rock Armor) |

| Cross-Section Type | Design Drawing of the Breakwater Cross-Sections |

|---|---|

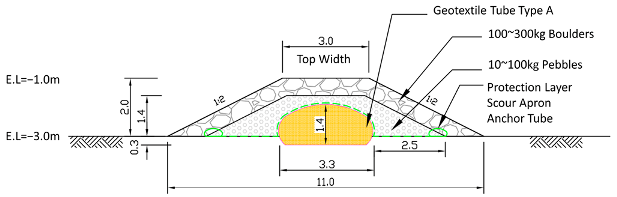

| Type A |  |

| Cross-Section Type: Geotextile Tubes + Armor Rock Levee Dimension (Height/Length): 2.0 m/3.0 m Geotextile Tube Dimension (Height/Length): 1.4 m/3.3 m | |

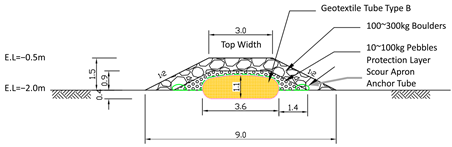

| Type B |  |

| Cross-Section Type: Geotextile Tubes + Armor Rock Levee Dimension (Height/Length): 1.5 m/3.0 m Geotextile Tube Dimension (Height/Length): 1.1 m/3.6 m | |

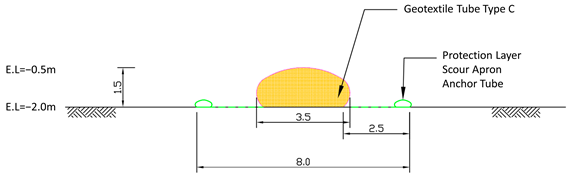

| Type C |  |

| Cross-Section Type: Geotextile Tubes Geotextile Tube Dimension (Height/Length): 1.5 m/3.5 m |

| (Setup #1): North Side of Fish Harbor (2.0 M), 500 m | |||

|---|---|---|---|

| Item Description | Unit Price | Quantity | Amount |

| 6500 NTD/m | 500 m | 3,250,000 |

| 2000 NTD/m3 | 907.5 m3 | 1,815,000 |

| 2300 NTD/m3 | 2711.5 m3 | 6,236,450 |

| 400 NTD/m2 | 6490 m2 | 2,596,000 |

| 60 NTD/m2 | 6050 m2 | 363,000 |

| 500,000 NTD/Set | 1 set | 500,000 |

| Total Cost (NTD) | 14,760,450 | ||

| NTD/m | 29,521 | ||

| (Setup #2): North Side of Fish Harbor (1.5 M), 500 m | |||

|---|---|---|---|

| Item Description and Unit Price | Unit Price | Quantity | Amount |

| 6500 NTD/m | 500 m | 3,250,000 |

| 200 NTD/m | 5580 m3 | 1,116,000 |

| 400 NTD/m2 | 2750 m3 | 1,100,000 |

| 60 NTD/m2 | 4400 m2 | 264,000 |

| 500,000 NTD/Set | 1 Set | 500,000 |

| Total Cost (NTD) | 6,230,000 | ||

| NTD/m | 12,460 | ||

| (Setup #3): North Side of Fish Harbor (1.5M), 500 m | |||

|---|---|---|---|

| Item Description and Unit Price | Unit Price | Quantity | Amount |

| 6500 NTD/m | 500 m | 3,250,000 |

| 2000 NTD/m3 | 2618 m3 | 5,236,000 |

| 2300 NTD/m3 | 3448.5 m3 | 7,931,550 |

| 400 NTD/m2 | 7700 m2 | 3,080,000 |

| 60 NTD/m2 | 6050 m2 | 363,000 |

| 500,000 NTD/Set | 1 Set | 500,000 |

| Total Cost (NTD) | 20,360,550 | ||

| NTD/m | 40,721 | ||

| (Setup #4): South Side of Pengpeng Beach (2.0 M), 1000 m | |||

|---|---|---|---|

| Item Description and Unit Price | Unit Price | Quantity | Amount |

| 6500 NTD/m | 1000 m | 6,500,000 |

| 2000 NTD/m3 | 5236 m3 | 10,472,200 |

| 2300 NTD/m3 | 6897 m3 | 15,863,100 |

| 400 NTD/m2 | 15,400 m2 | 6,160,000 |

| 60 NTD/m2 | 12,100 m2 | 7,266,000 |

| 500,000 NTD/Set | 1 Set | 500,000 |

| Total Cost (NTD) | 40,221,100 | ||

| NTD/m | 40,221 | ||

| Factor | Siltation Mitigation Efficiency | Engineering Cost | PublicAcceptance | Impact on Surrounding Landscape | Weighted Score | |

|---|---|---|---|---|---|---|

| Weight (%) | 40 | 25 | 25 | 10 | ||

| Plan 0 | Maintain Current Status | 2 | 4 | 2 | 4 | 2.7 |

| Plan 1 | Setup #1, #3 and #4 | 5 | 4 | 4 | 4 | 4.4 |

| Plan 2 | Setup #2, #3 and #4 | 5 | 4 | 4 | 4.5 | 4.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tseng, I.-F.; Hsu, C.-H.; Cheng, H.-C.; Chen, Y.-S. Application of Geotextile Tubes to Coastal Silt Mitigation: A Case Study in Niaoyu Fishing Harbor. Sustainability 2023, 15, 2024. https://doi.org/10.3390/su15032024

Tseng I-F, Hsu C-H, Cheng H-C, Chen Y-S. Application of Geotextile Tubes to Coastal Silt Mitigation: A Case Study in Niaoyu Fishing Harbor. Sustainability. 2023; 15(3):2024. https://doi.org/10.3390/su15032024

Chicago/Turabian StyleTseng, I-Fan, Chih-Hung Hsu, Heng-Chih Cheng, and Yen-Shun Chen. 2023. "Application of Geotextile Tubes to Coastal Silt Mitigation: A Case Study in Niaoyu Fishing Harbor" Sustainability 15, no. 3: 2024. https://doi.org/10.3390/su15032024

APA StyleTseng, I.-F., Hsu, C.-H., Cheng, H.-C., & Chen, Y.-S. (2023). Application of Geotextile Tubes to Coastal Silt Mitigation: A Case Study in Niaoyu Fishing Harbor. Sustainability, 15(3), 2024. https://doi.org/10.3390/su15032024