1. Introduction

The global transportation system is confronted with environmental challenges. According to the 2016 Climate Conference of the Parties (COP22), around 6.5 million deaths are directly or indirectly related to the air pollution each year. Furthermore, as reported in International Energy Agency 2018, the emissions from transportation sector account for 25% in global emissions, which is expected to reach 30% by 2030 and to approach 50% by 2050 if no key measures are undertaken. Moreover, among various transportation modes, road transportation has accounted for more than 70% of the total transportation volume for many years. However, its carbon emission intensity is 4 times that of railway transportation and 10 times that of waterway transportation. Therefore, optimizing the transport structure has become one of the important means of deep emission reduction in the transport sector. Many countries and agencies intend to develop multimodal transportation networks to reduce carbon emissions and contribute to achieving carbon peaking and carbon neutral statuses as soon as possible [

1]. In addition, multimodal transport can help reduce costs and improve efficiency by combining the advantages of multiple transport modes, which is also the focus of government departments and logistics enterprises. As an intensive and efficient modern intermodal transport organization mode, multimodal transport can help promote the supply-side structural reform of China’s transportation. It is also an important way to promote the high-quality development of transport and the sustainability of logistics activities [

2].

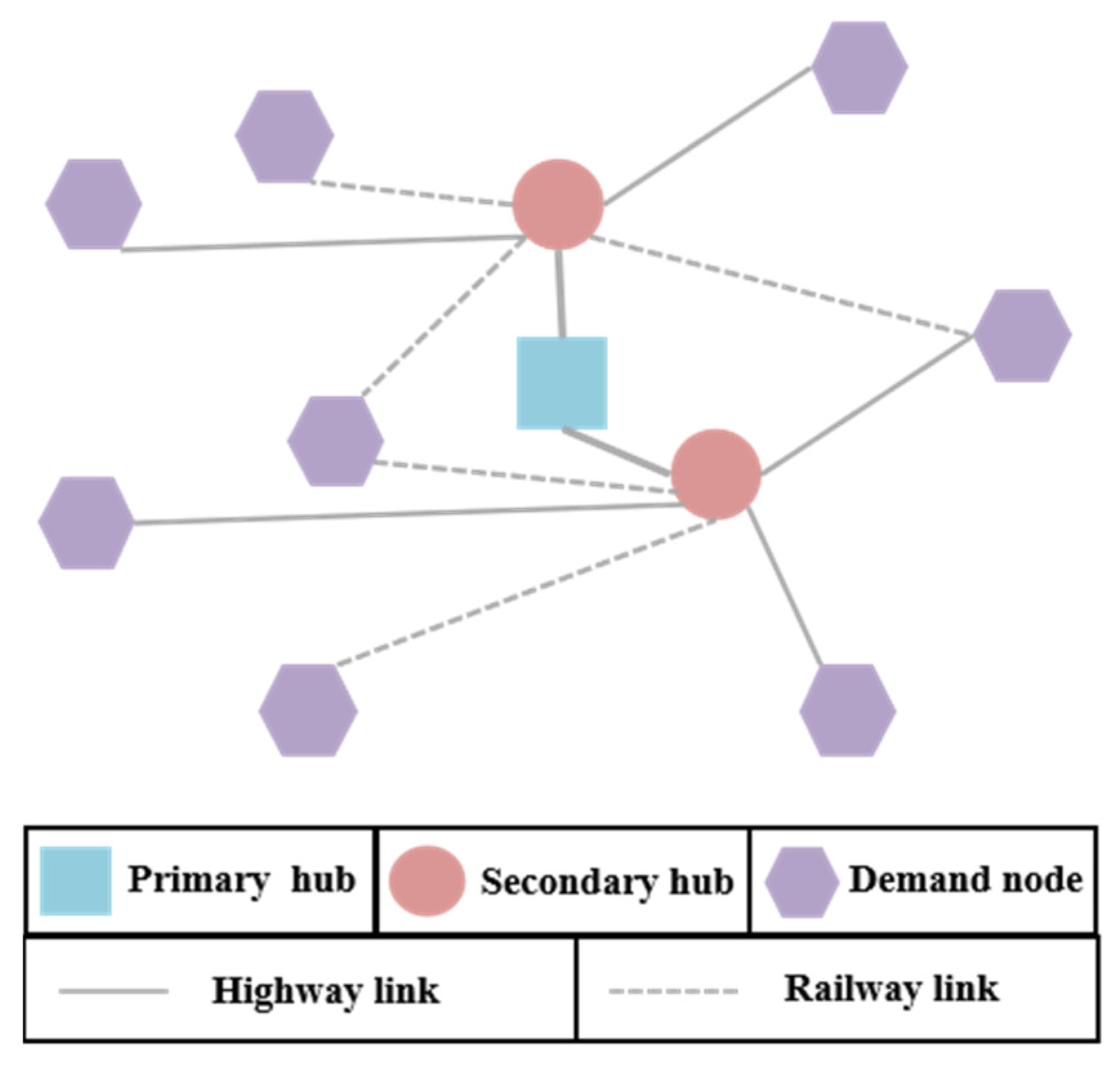

A typical multimodal transportation network is a hub-and-spoke transportation network, where the hub represents several hub nodes for gathering materials, and the spoke represents the transportation paths formed by the outward radiation from the hubs connected at the center. In the network, goods that need to be delivered are first collected at branch offices. The cargo processing operations, such as loading, unloading, sorting, etc., are carried out at hub facilities. These hub facilities are consolidation and dissemination centers. In hubs, cargos from different origins but similar destinations are collected together and re-routed according to their destinations. A package arriving at a hub can travel directly to its destination, if the destination branch office has a connection with this hub, or travel to the hub to which the destination is allocated. Due to managerial reasons, each branch office usually requires the coordination between different transportation modes. The transportation flow of the current multimodal transport network is mostly from the primary hub to the secondary hub, and then to the demand city. However, based on the actual survey, it is found that there are two outstanding problems in this two-layer transport network. First, with the development of the economy, some secondary hubs in the transport network struggle to meet the growing demand for freight transportation due to limitations of the capacity and the hub location. The material handling capacity of the whole network is obviously limited for this reason. Secondly, the transportation distance from some secondary hubs to the demand cities is too long, which makes it impossible to meet users’ variable demands promptly and the growing freight demand of primary hubs. Therefore, it is imperative to build new secondary hubs to expand the transportation network. Most of the existing research on hub location is based on a new multimodal transport network, while the expansion of new secondary hubs based on the existing multimodal transport network is more suitable for practical applications. Furthermore, the consideration of carbon emissions is believed to further promote the development of green transportation and expand the research on low-carbon optimization at the strategic level. Thus, in this study, we focused on the hierarchical multimodal hub location problem with carbon emissions based on a typical hub-and-spoke network. The problem aims to expand secondary hubs on the original intermodal network and decide their locations, the modes of the transportation links and the distribution of cargo flow, with the objective of minimizing transport time, transport cost and carbon emission cost. The main contributions of this study are summarized as follows.

A mixed integer non-linear programming (MINLP) novel model is proposed to simultaneously optimize the location of newly-built secondary hubs (i.e., secondary hubs) and the modes of the transportation links while considering practical issues, such as cargo handling capacity, cargo clearing and carbon emission;

Due to the complexity of the study problem (consisting of sets of potential secondary hubs and transportation modes), a tangible adaptive genetic algorithm (AGA) is developed to solve the problem efficiently;

Based on the proposed model and the case study from real world, the result and sensitivity analyses investigate the relationship between some important input parameters and output variables, which may help decision makers to further assess its performance.

The remainder of this paper is organized as follows.

Section 2 provides an overview of the related work from existing research.

Section 3 introduces the background information and states the formulation of the proposed model. The developed AGA is detailed in

Section 4.

Section 5 covers the case study from the real world, where the experimental results and sensitivity analysis are discussed.

Section 6 provides a discussion of the implications and limitations of the study.

Section 7 concludes our work and discusses some possible directions for future study.

2. Literature Review

The hub location problem is an important branch of the transportation network, which has attracted the attention of many scholars. For the classical hub-and-spoke networks, its hub location problem was first proposed by O’kelly [

3]. In addition, two heuristic algorithms based on the enumeration method were designed to solve this problem [

4]. O’kelly and Lao [

5] also developed a zero-one linear programming model to solve the transportation mode selection of hub-and-spoke multimodal networks. Campbell [

6,

7] realized the single allocation and multi allocation between hubs and demand nodes based on the study of O’kelly et al., and defined four discrete hub location problems: the P-hub median problem, the uncapacitated hub location problem, the P-hub center problem and the hub covering problem. Scholars have conducted extensive research based on the model proposed by Campbell [

8,

9,

10,

11,

12,

13]. Some studies have expanded the hub location problem by, for example, considering capacity constraints [

14], budget constraints [

15], dual decision-makers [

16], traffic congestion [

17], etc., to achieve more practical applications. Other researches focused on the exploration of solutions to hub location problems, such as analytic hierarchy process (AHP) decision-making [

18], multi-criteria decision-making [

19], improved or hybrid methods based on genetic algorithm [

14,

20], tabu search algorithm [

21], benders decomposition [

15] and other meta heuristics.

The introduction of hub nodes in multimodal transport network was first proposed by Slack and has been proved to improve the efficiency and reduce the cost of freight transport [

22]. Therefore, the hub location problem of multimodal transport has become particularly fundamental and important. He et al. [

23] developed an improved MIP heuristic, which combines branch-and-bound, Lagrangian relaxation and linear programming relaxation to obtain competitive results for the intermodal hub location problem. Considering the multi-cycle scenario and the uncertainty of freight demand, Benedyk et al. [

24] proposed a scenario-based mixed integer dynamic capacitated intermodal facility location model, which aims to minimize the total cost of transportation, congestion, handling, empty container repositioning and investment cost, to help decision-makers with national or regional intermodal facility investment planning. Rothenbacher et al. [

25] developed an arc-based model to solve the hub location problem of the road–rail intermodal transport network, and designed a branch-and-price-and-cut algorithm. Zhang et al. [

26] applied road–rail intermodal transportation to the supply chain design of forest-delivered biofuel, and established a mixed integer programming model for strategic and tactical decisions, including the location decision of storage yards. They also verified the effectiveness and economy of road–rail multimodal transport compared with single transport mode through a case study. Fortuhi and Huynh [

27] addressed a multi-period intermodal transport expansion location problem by modeling a robust path-based mixed integer program and developing a hybrid simulated annealing algorithm. Fazayeli et al. [

28] integrated the freight transport route optimization into the intermodal location problem, taking into account both the time windows and uncertain demands of customers. A mixed integer fuzzy mathematical model was proposed and solved by a two-stage genetic algorithm. Kumar et al. [

29] evaluated the sustainability of multimodal transport candidate locations from five dimensions of society, technology, economy, environment and politics through the TOPSIS method, and verified the proposed framework through the dedicated freight corridor of India. Real et al. [

30] optimized the location of the hub and the fleet size of heterogeneous vehicle when designing multimodal transport network, and proposed two algorithms based on the adaptive large neighborhood search as solution methods. Zukhruf et al. [

31] presented an integrated restoration model for a multimodal transportation network disrupted by a catastrophic disaster, which determined the road network and multimodal terminals to be restored. In addition, the model was solved by the designed particle swarm optimization and greedy heuristic algorithm.

With the development of green transportation, some scholars also pay attention to carbon emissions in the research of multimodal transport. Sedehzadeh et al. [

32] proposed a multi-modal tree hub location problem considering energy consumption, and constructed a double objective function model including energy consumption and cost. A triangular fuzzy approach is adopted to cope with the uncertainty of parameters, and a multi-objective imperialist competitive algorithm is designed to obtain the Pareto-optimal solution of the model. According to the emission limit of freight orders through intermodal transportation network, Heinold et al. [

33] proposed a MIP formulation to make decisions on the optimized order routing, transportation mode selection and emission allocation. Wang et al. [

34] presented an integrated production and distribution model for multimodal transport considering the uncertain delay of marine arrival, and designed an improved multiple heterogeneous coded genetic algorithm. They also analyzed the impact of different operation strategies on carbon emissions. Qi et al. [

35] studied a multi-commodity flow service selection problem under the Belt and Road Initiative and multimodal transport, and formulated a mathematical model considering the transportation costs, in-transit inventory costs and carbon emission costs. The case study showed the impact of carbon emissions on route selection. Wang et al. [

36] regarded the energy consumption and emission reduction as one of the efficiency evaluation indicators of multimodal transport, and decide the route selection of multimodal transport based on the evaluation results. Demir et al. [

37] considered environmental factors in intermodal freight transportation planning, developed a bi-objective model to minimize costs and carbon emissions simultaneously, and obtained the Pareto optimal solution of the model through the ε-constraint method.

From the above studies, fewer scholars have studied multimodal networks similar to this study, where new secondary hubs were established to extend the original network. Moreover, in addition to Sedehzadeh et al. [

32], most studies consider carbon emission factors at the operational level (such as the routing problem) of multimodal transport, rather than at the strategic level (such as the location problem). In addition, most optimization objective functions are formulated to explore the impact between economic cost and carbon emission cost. However, little attention has been paid to the impact of carbon emissions on time efficiency pursued by customers. Therefore, in this study, we focused on siting new secondary hubs based on existing multimodal networks. Strategic location problem takes into account carbon emission factors. In addition, transportation time and total cost, including carbon emission cost, are comprehensively considered in the objective function. Our study makes up for the environment-friendly multimodal transport strategic planning. In addition, genetic algorithm has shown good performance in solving various facility location problems [

38,

39,

40], and has also been selected as the solution heuristic for this study. Combined with the characteristics of the research problem, an adaptive genetic algorithm is designed to solve the proposed hierarchical multimodal hub location problem.

4. Solution Algorithm

The proposed model consisting of seven binary decision variables is combinatorial, for which the solution can be optimized with commercial solvers only for small cases. Hence, a tangible adaptive genetic algorithm (AGA) is developed to search the solution. AGA is expected to improve the traditional GA by adaptively adjusting the crossover and mutation probabilities. In addition, a real number coding method was designed to jointly optimize the location of newly-built secondary hubs, the hubs to clear the cargo and the modes of the transportation links. The flow chart of the proposed AGA is illustrated in

Figure 3. The AGA starts by randomly initializing a group of the population. Each individual in the population is tested by the constraints’ sorting and has a fitness value. Then, the evolution process is applied to search for the optimal solution. A group of individuals pass through tournament selection, crossover, mutation and fitness evaluation, which are discussed next. Note that in the proposed AGA, the crossover rate and mutation rate are reset in every iteration. This process is repeated until the stopping criteria is met.

4.1. Initialization

4.1.1. Chromosome Coding

As is shown in

Figure 4, there is a sample network containing seven nodes besides one primary hub, among which 1, 2, 3, 4, 5, 6, 7 8 are demand nodes (1 and 2 are selected as the candidate secondary hubs, while 7 and 8 are the existing secondary hubs). The number of newly-built secondary hubs is set as one. Thus, the sample chromosome can be divided into three parts, which consists of seven demand nodes including two candidate secondary hubs, two existing secondary hubs and five demand nodes. The first part is to select the best location of newly-built secondary hubs from candidate hubs. The second part is to choose the transportation modes for links and the third part is to select the hubs to clear the cargo. Each gene contains two terms. The upper one is real-coded, representing the node in the network. The lower one is randomly initialized between 0 and 1 to assist the genetic process.

4.1.2. Chromosome Decoding

The decoding process is illustrated in

Figure 5. In step 1, two randomly initialized numbers for two candidate secondary hubs are compared with 0.5 in the first part. If it is larger than 0.5, the corresponding node will be selected to build the new secondary hub. Step 2 is to select the transportation node. Seven randomly initialized numbers for seven nodes are compared with 0.5 in the second part. If it is larger than 0.5, the railway is employed to its in-flow link. If not, the highway is employed. Step 3 and 4 are to allocate demand nodes and secondary hubs, which are discussed next. Step 5 is to select the hubs to clear the cargo of all nodes. Similar to step 2, seven randomly initialized numbers for seven nodes are compared with 0.5 in the third part. If it is larger than 0.5, the cargo of the corresponding node is cleared at the primary hub. If not, the corresponding cargo is cleared at secondary hubs.

Figure 6 details steps 3 and 4. The node allocating process starts from demand node

. If demand node

is selected to build the new secondary hub, secondary hub

will be allocated to the primary hub. If not, we will find secondary hub

which is the closest to demand node

. If the remaining cargo handling capacity of secondary hub

is larger than the cargo demand of node

, node

will be allocated to hub

. If not,

. Then, the remaining cargo handling capacity of secondary hub

is updated. This process is repeated until all demand nodes are allocated.

4.1.3. Population Initialization

The chromosome length is determine based on the number of candidate hubs, the number of demand cities and the number of existing secondary hubs. A reasonable population size () is set based on the length of the chromosome, and individuals are randomly generated. All individuals must satisfy relevant constraints after chromosome decoding.

4.2. Fitness Evaluation

In order to evaluate the fitness of each individual, two contrary objectives (e.g., total time T and total cost C) in the proposed model are normalized by Equation (27).

,

and

denote the fitness, maximum fitness and minimum fitness of total time T, respectively.

,

and

represent the fitness, maximum fitness and minimum fitness of total cost C, respectively.

and

are the weights of total time and total cost, respectively.

4.3. Selection

Tournament selection is employed to yield new population in the proposed AGA, which is detailed as follows.

Step 1: N is set as the number of the selected individuals in each iteration;

Step 2: N individuals are selected from the population. The individual with the highest fitness is kept while the rest N-1 individuals are put back to the population;

Step 3: Step 2 is repeated until the number of kept individuals reaches the preset population size.

4.4. Crossover and Mutation

Multi-point crossover and single-point mutation are employed in the proposed AGA. In each iteration, the crossover rate

and mutation rate

are adjusted by the hyperbolic function, which is a probabilistic nonlinear method to adjust parameters [

41,

42]. As shown in Equations (28) and (29),

denotes average fitness of the individual in each iteration.

is an exogenous auxiliary adaptive parameter. A larger

indicates more probability of crossover and mutation in the genetic process.

4.5. Stopping Criterion

Setting a maximum number of iterations is a common algorithm termination criterion. In this study, the AGA terminates when it iterates for times; otherwise, it continues to iterate to find the optimal solution.

6. Discussion

The model proposed in this paper effectively solves the problem of extending secondary hubs in the existing network consisting of primary hub, secondary hub and demand side. The model has the potential to be reproduced for solving the network expansion siting and traffic distribution problems in all similar three-level networks. In practice, this study will make a great contribution to the expansion of the waterless ports as the secondary hub has the capacity to support the construction of the port’s collection and distribution system and to strengthen the port’s agglomeration and radiation capacity. Furthermore, this study can provide a relevant theoretical basis for the research on the location of distribution centers in the three-level logistics distribution network, where goods are usually transported from the warehouse to the distribution center and then to the customer point.

Moreover, the consideration of carbon emissions in the model and the corresponding carbon tax sensitivity analysis results provide insights to government departments and managers of multimodal transport companies:

(1) For government departments, the regulation of carbon tax will directly affect the network structure of freight transportation. For the decarbonized and stable development of national freight transportation, government departments should actively encourage transportation companies to expand their hub network. Reasonable transportation hub layout and well-developed hub channel will promote multimodal transport enterprises to adopt low-carbon transportation mode;

(2) For the managers of transportation enterprises, this study brought new inspiration from the perspective of low carbon. The consideration of carbon emission cost can increase the transportation time and affect the efficiency of freight transportation. From the perspective of the demand customer, managers need to build more hubs to mitigate the impact of low-carbon and inefficient transportation modes on customers. Therefore, how to balance the interests of enterprises and customers is worth thinking about by managers.

The model assumptions proposed in this study also make the model have some limitations in practical application. The secondary hub is usually located at the intersection of the railway and the highway in the inland economic center city. It is a natural logistics hub with convenient cargo handling, temporary storage and transportation. This study only focused on the functions of the secondary hubs for collecting and distributing goods and customs declaration; it ignored the hub channel between them. The transportation modes and networks among the primary hub, secondary hub and demand points are also relatively simple. In practice, there are various ways to transfer from the primary hub to the demand cities, such as multiple transfers through the secondary hub, transfer between the demand cities, etc. When the primary hub is close to the demand city, goods can also be directly transported from the primary hub to the demand city. Combining various real-world scenarios, the proposed model needs to be extended to further meet the complex traffic network environment.

7. Conclusions

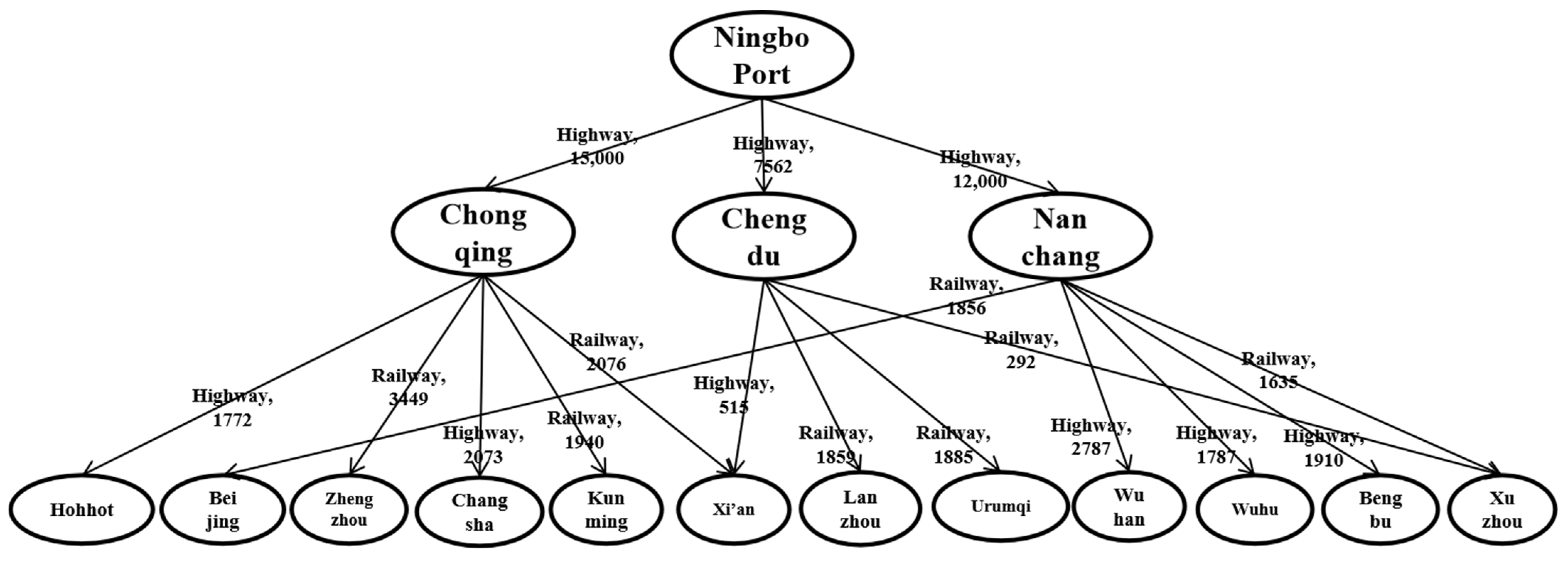

This study proposes a hierarchical multimodal transport hub location problem to expand the existing network. An innovative mixed integer nonlinear model considering carbon emissions is developed to determine the optimal location of new-built secondary hubs and the optimal transportation mode among hubs. From the perspective of logistics enterprises and customers, the minimization of total transportation cost and the minimization of transportation time are considered, respectively, and the double objective optimization is achieved by weighting method. The proposed model provides a potential reproducibility capability for the similar three-level network of “primary hubs—secondary hubs—demand cities” in different regions. A tangible adaptive genetic algorithm (AGA) is designed to solve the proposed model effectively. AGA showed better convergence performance than traditional GA and is expected to be applied to solve larger scale cases. The case study of Ningbo Port in China shows that the located secondary hubs significantly improved the current multimodal transport network. The new-built hubs have been proven to improve cargo handling capacity. Two additional hubs can handle 41.46% more cargo flow than the original network. Moreover, these new-built hubs achieve 2.35% transportation cost savings and 2.2% transportation time savings. The sensitivity analysis of carbon tax also provides the government and enterprises with insightful opinions from the perspective of low-carbon transportation. The government’s regulation of carbon tax can directly affect the network structure of cargo transportation. A higher carbon tax would prompt enterprises to choose a low-carbon transportation mode or open more secondary hubs to reduce the transit time for goods.

For further research, it would be interesting to continue the study with the created model and application. In this study, only highway and railway transportation modes are considered. In practice, other transportation modes may be required according to the characteristics of goods. In addition, in the complex transportation network, secondary hubs are connected, and some demand cities are also connected. Thus, the proposed hub location model will be further expanded to accommodate various hybrid hub-and-spoke networks. The location–routing problem of multimodal transport networks will also be studied to explore the impact of route optimization on hub location decision. In addition, some exact solution algorithms or other heuristic algorithms will be explored to find more efficient solutions for the hub location combination optimization problem.