Impact of Smoking Technology on the Quality of Food Products: Absorption of Polycyclic Aromatic Hydrocarbons (PAHs) by Food Products during Smoking

Abstract

1. Introduction

- RQ1: How do smoking methods and raw materials affect the various products smoked for sustainable development?

- RQ2: How does the change in the saturation of a smoked product with polycyclic aromatic hydrocarbons absorbed from smoke correlate with its safety for consumption?

2. State of the Art

2.1. Smoking Technologies Characteristics

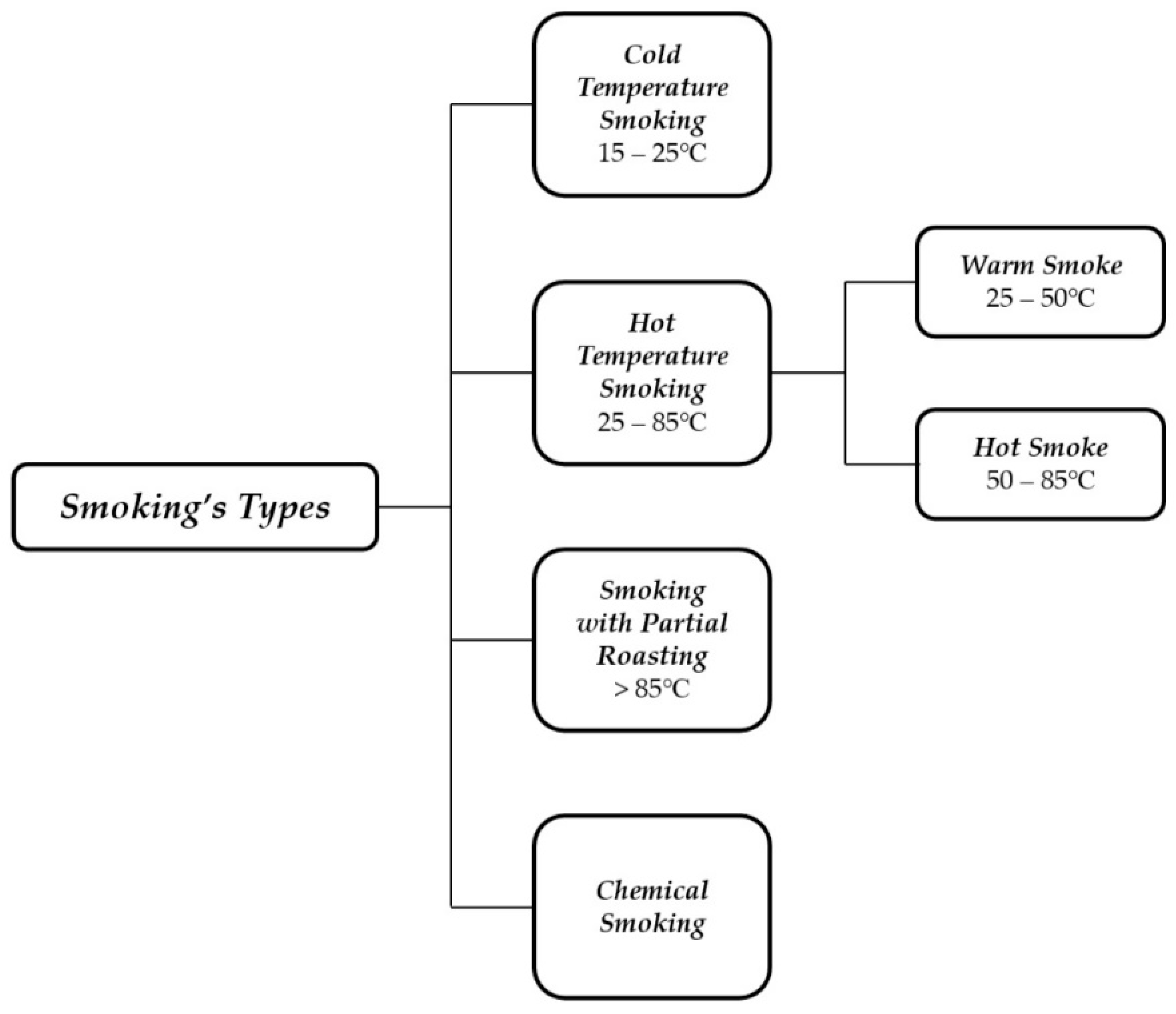

2.1.1. Smoking Methods

2.1.2. Pre-Smoking Treatment

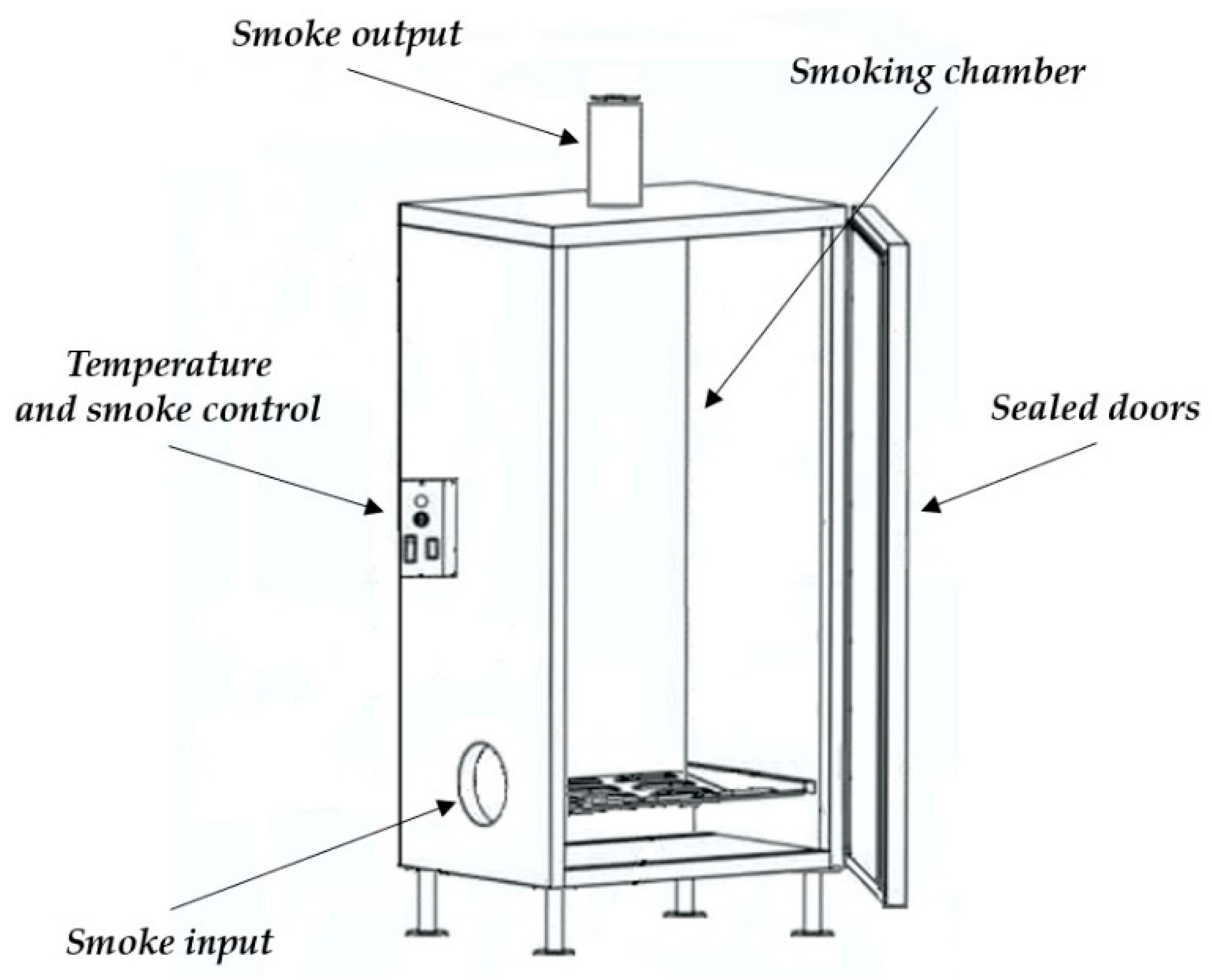

2.1.3. Smokehouses and Smoking Chambers

2.2. Smoke Characteristics

2.2.1. Selection of Smoke-Forming Raw Material

2.2.2. Smoke Production Methods

2.3. Smoking Specificity of Selected Food

2.3.1. Smoking Fish

2.3.2. Smoking Meat

2.3.3. Smoking Cheese

3. Results and Discussion

3.1. Characteristics of Chemical Compounds Found in Smoked Products

3.2. Absorption of PAHs by Popular Smoked Products

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bax, M.-L.; Aubry, L.; Ferreira, C.; Daudin, J.-D.; Gatellier, P.; Rémond, D.; Santé-Lhoutellier, V. Cooking temperature is a key determinant of in vitro meat protein digestion rate: Investigation of underlying mechanisms. J. Agric. Food Chem. 2012, 60, 2569–2576. [Google Scholar] [CrossRef] [PubMed]

- Bhat, Z.F.; Morton, J.D.; Bekhit, A.E.; Kumar, S.; Bhat, H.F. Thermal processing implications on the digestibility of meat, fish and seafood proteins. Compr. Rev. Food Sci. Food Saf. 2021, 20, 4511–4548. [Google Scholar] [CrossRef] [PubMed]

- Singh, L.; Varshney, J.G.; Agarwal, T. Polycyclic Aromatic hydrocarbons’ formation and occurrence in processed food. Food Chem. 2016, 199, 768–781. [Google Scholar] [CrossRef] [PubMed]

- Goñi, S.M.; Salvadori, V.O. Prediction of cooking times and weight losses during meat roasting. J. Food Eng. 2010, 100, 1–11. [Google Scholar] [CrossRef]

- Racovita, R.C.; Secuianu, C.; Ciuca, M.D.; Israel-Roming, F. Effects of smoking temperature, smoking time, and type of wood sawdust on polycyclic aromatic hydrocarbon accumulation levels in directly smoked pork sausages. J. Agric. Food Chem. 2020, 68, 9530–9536. [Google Scholar] [CrossRef] [PubMed]

- Arvanitoyannis, I.S.; Kotsanopoulos, K.V. Smoking of fish and seafood: History, methods and effects on physical, nutritional and microbiological properties. Food Bioprocess. Technol. 2012, 5, 831–853. [Google Scholar] [CrossRef]

- Onopiuk, A.; Kołodziejczak, K.; Szpicer, A.; Wojtasik-Kalinowska, I.; Wierzbicka, A.; Półtorak, A. Analysis of factors that influence the PAH profile and amount in meat products subjected to thermal processing. Trends Food Sci. Technol. 2021, 115, 366–379. [Google Scholar] [CrossRef]

- European Commission Regulation (EU) 2023/915 of 25 April 2023 on Maximum Levels for Certain Contaminants in Food. Available online: http://data.europa.eu/eli/reg/2023/915/oj (accessed on 15 November 2023).

- European Commission Regulation (EU) 1321/2013 of 10 December 2013 on Establishing the Union List of Authorized Smoke Flavoring Primary Products for Use as such in or on Foods and/or for the Production of Derived Smoke Flavorings. Available online: http://data.europa.eu/eli/reg_impl/2013/1321/oj (accessed on 15 November 2023).

- European Commission Regulation (EU) 835/2011 of 19 August 2011 Amending Regulation (EC) No 1881/2006 as Regards Maximum Levels for Polycyclic Aromatic Hydrocarbons in Foodstuffs. Available online: http://data.europa.eu/eli/reg/2011/835/oj (accessed on 15 November 2023).

- European Parliament Regulation and of the Council (EC) No 2065/2003 of 10 November 2003 on Smoke Flavorings Used or Intended for Use in or on Foods. Available online: http://data.europa.eu/eli/reg/2003/2065/2021-03-27 (accessed on 15 November 2023).

- Fardet, A.; Rock, E. Ultra-Processed Foods and Food System Sustainability: What Are the Links? Sustainability 2020, 12, 6280. [Google Scholar] [CrossRef]

- Krarup Hansen, K.; Sara, R.B.M.E.; Smuk, I.A.; Brattland, C. Sámi Traditional Knowledge of Reindeer Meat Smoking. Food Ethics 2022, 7, 13. [Google Scholar] [CrossRef]

- Plaza-Bolaños, P.; Frenich, A.G.; Vidal, J.L. Polycyclic aromatic hydrocarbons in food and beverages. Analytical methods and trends. J. Chromatogr. A 2010, 1217, 6303–6326. [Google Scholar] [CrossRef]

- Stockfelt, L.; Sallsten, G.; Olin, A.-C.; Almerud, P.; Samuelsson, L.; Johannesson, S.; Molnar, P.; Strandberg, B.; Almstrand, A.-C.; Bergemalm–Rynell, K.; et al. Effects on airways of short–term exposure to two kinds of wood smoke in a chamber study of healthy humans. Inhal. Toxicol. 2012, 24, 47–59. [Google Scholar] [CrossRef] [PubMed]

- Da Porto, C.; Moret, S.; Soldera, S. A study on the composition of distillates obtained from smoked marc. Anal. Chim. Acta 2006, 563, 396–400. [Google Scholar] [CrossRef]

- Kafouris, D.; Koukkidou, A.; Christou, E.; Hadjigeorgiou, M.; Yiannopoulos, S. Determination of polycyclic aromatic hydrocarbons in traditionally smoked meat products and charcoal grilled meat in Cyprus. Meat Sci. 2020, 164, 108088. [Google Scholar] [CrossRef] [PubMed]

- Šimko, P. Factors affecting elimination of polycyclic aromatic hydrocarbons from smoked meat foods and liquid smoke flavorings. Mol. Nutr. Food Res. 2005, 49, 637–647. [Google Scholar] [CrossRef] [PubMed]

- Mastanjević, K.; Kartalović, B.; Puljić, L.; Kovačević, D.; Habschied, K. Influence of Different Smoking Procedures on Polycyclic Aromatic Hydrocarbons Formation in Traditional Dry Sausage Hercegovačka kobasica. Processes 2020, 8, 918. [Google Scholar] [CrossRef]

- Iko Afé, O.H.; Douny, C.; Kpoclou, Y.E.; Igout, A.; Mahillon, J.; Anihouvi, V.; Hounhouigan, J.; Scippo, M.-L. Insight about methods used for polycyclic aromatic hydrocarbons reduction in smoked or grilled fishery and meat products for future re–engineering: A systematic review. Food Chem. Toxicol. 2020, 141, 111372. [Google Scholar] [CrossRef]

- Gómez-Estaca, J.; Gómez-Guillén, M.C.; Montero, P.; Sopelana, P.; Guillén, M.D. Oxidative stability, volatile components and polycyclic aromatic hydrocarbons of cold–smoked sardine (Sardina pilchardus) and dolphinfish (Coryphaena hippurus). LWT Food Sci. Technol. 2011, 44, 1517–1524. [Google Scholar] [CrossRef]

- Yang, K.-M.; Chiang, P.-Y. Effects of smoking process on the aroma characteristics and sensory qualities of dried longan. Food Chem. 2019, 287, 133–138. [Google Scholar] [CrossRef]

- Bienkiewicz, G.; Tokarczyk, G.; Czerniejewska–Surma, B.; Suryn, J. Changes in the EPA and DHA content and lipids quality parameters of rainbow trout (Oncorhynchus mykiss, Walbaum) and carp (Cyprinus carpio, L.) at individual stages of hot smoking. Heliyon 2019, 5, 02964. [Google Scholar] [CrossRef]

- Sokamté Tégang, A.; Mbougueng, P.D.; Mouafo Téné, H.; Douanla Nodem, N.F.; Sachindra, N.M.; Tatsadjieu Ngoune, L. Application of the spice Afrostyrax lepidophyllus Mildbr as a biopreservative and seasoning agent for hot smoked fillets of Pangasius hypophthalmus. J. Agric. Food Res. 2022, 10, 100449. [Google Scholar] [CrossRef]

- Raffray, G.; Sebastian, P.; Collignan, A. Simulation model for the optimization of a radiant plate hot–smoking process. J. Food Eng. 2015, 147, 56–67. [Google Scholar] [CrossRef]

- Baten, M.A.; Won, N.E.; Mohibbullah, M.; Yoon, S.-J.; Sohn, J.H.; Kim, J.-S.; Choi, J.-S. Effect of hot smoking treatment in improving sensory and physicochemical properties of processed Japanese Spanish Mackerel Scomberomorus niphonius. Food Sci. Nutr. 2020, 8, 3957–3968. [Google Scholar] [CrossRef] [PubMed]

- Stołyhwo, A.; Sikorski, Z.E. Polycyclic aromatic hydrocarbons in smoked fish—A critical review. Food Chem. 2005, 91, 303–311. [Google Scholar] [CrossRef]

- Theobald, A.; Arcella, D.; Carere, A.; Croera, C.; Engel, K.-H.; Gott, D.; Gürtler, R.; Meier, D.; Pratt, I.; Rietjens, I.M.; et al. Safety assessment of smoke flavouring primary products by the European Food Safety Authority. Food Sci. Technol. 2012, 27, 97–108. [Google Scholar] [CrossRef]

- Shao, W.; Campbell, Y.L.; Phillips, T.W.; Freeman, C.; Zhang, X.; Hendrix, J.D.; To, K.V.; Dinh, T.; Rogers, W.D.; Schilling, M.W. Using liquid smoke to control infestations of the ham mite, Tyrophagus putrescentiae, on dry-cured hams during aging. Meat Sci. 2023, 200, 109139. [Google Scholar] [CrossRef] [PubMed]

- Racioppo, A.; Speranza, B.; Pilone, V.; Stasi, A.; Mocerino, E.; Scognamiglio, G.; Sinigaglia, M.; Corbo, M.R. Optimizing liquid smoke conditions for the production and preservation innovative fish products. Food Biosci. 2023, 53, 102712. [Google Scholar] [CrossRef]

- Montazeri, N.; Himelbloom, B.H.; Oliveira, A.C.; Leigh, M.B.; Crapo, C.A. Refined liquid smoke: A potential antilisterial additive to cold–smoked sockeye salmon (Oncorhynchus nerka). J. Food Prot. 2013, 76, 812–819. [Google Scholar] [CrossRef]

- Xin, X.; Bissett, A.; Wang, J.; Gan, A.; Dell, K.; Baroutian, S. Production of liquid smoke using fluidised–bed fast pyrolysis and its application to green lipped mussel meat. Food Control 2021, 124, 107874. [Google Scholar] [CrossRef]

- Xin, X.; Dell, K.; Udugama, I.A.; Young, B.R.; Baroutian, S. Transforming biomass pyrolysis technologies to produce liquid smoke food flavouring. J. Clean. Prod. 2021, 294, 125368. [Google Scholar] [CrossRef]

- Martin, E.M.; O’Bryan, C.A.; Lary, R.Y.; Griffis, C.L.; Vaughn, K.L.; Marcy, J.A.; Ricke, S.C.; Crandall, P.G. Spray application of liquid smoke to reduce or eliminate Listeria monocytogenes surface inoculated on frankfurters. Meat Sci. 2010, 85, 640–644. [Google Scholar] [CrossRef]

- Tuesta-Chavez, T.; Monteza, J.; Silva Jaimes, M.I.; Ruiz-Pacco, G.A.; Changanaqui, K.; Espinoza-Suarez, J.B.; Alarcon, H.; Osorio-Anaya, A.M.; Valderrama-Negrón, A.C.; Sotomayor, M.D. Characterization and evaluation of antioxidant and antimicrobial capacity of prepared liquid smoke–loaded chitosan nanoparticles. J. Food Eng. 2022, 319, 110912. [Google Scholar] [CrossRef]

- Li, Z.; Wang, Y.; Pan, D.; Geng, F.; Zhou, C.; Cao, J. Insight into the relationship between microorganism communities and flavour quality of Chinese dry–cured boneless ham with different quality grades. Food Biosci. 2022, 50, 102174. [Google Scholar] [CrossRef]

- Huang, Y.; Li, H.; Huang, T.; Li, F.; Sun, J. Lipolysis and lipid oxidation during processing of Chinese traditional smoke–cured bacon. Food Chem. 2014, 149, 31–39. [Google Scholar] [CrossRef] [PubMed]

- Kjällstrand, J.; Petersson, G. Phenolic antioxidants in alder smoke during industrial meat curing. Food Chem. 2001, 74, 85–89. [Google Scholar] [CrossRef]

- Tian, X.; Li, Z.; Li, K.; Wu, Z.; Ren, R.; Wang, H.; Zeng, C. Flavor release from traditional dry–cured pork during oral processing. Food Sci. Hum. Wellness 2023, 12, 102–110. [Google Scholar] [CrossRef]

- Chen, F.; Shen, L.; Shi, X.; Deng, Y.; Qiao, Y.; Wu, W.; Xiong, G.; Wang, L.; Li, X.; Ding, A.; et al. Characterization of flavor perception and characteristic aroma of traditional dry–cured fish by flavor omics combined with multivariate statistics. LWT 2023, 173, 114240. [Google Scholar] [CrossRef]

- Bjørnevik, M.; Cardinal, M.; Vallet, J.-L.; Nicolaisen, O.; Arnarson, G.Ö. Effect of salting and cold–smoking procedures on Atlantic salmon originating from pre- or post rigor filleted raw material. Based on the measurement of physicochemical characteristics. LWT 2018, 91, 431–438. [Google Scholar] [CrossRef]

- Kang, J.; Tang, S.; Liu, R.H.; Wiedmann, M.; Boor, K.J.; Bergholz, T.M.; Wang, S. Effect of curing method and freeze–thawing on subsequent growth of Listeria monocytogenes on cold–smoked salmon. J. Food Prot. 2012, 75, 1619–1626. [Google Scholar] [CrossRef]

- Astruc, T.; Vénien, A.; Clerjon, S.; Favier, R.; Loison, O.; Mirade, P.-S.; Portanguen, S.; Rouel, J.; Lethiec, M.; Germond, A. Effect of dry salt versus brine injection plus dry salt on the physicochemical characteristics of smoked salmon after filleting. Heliyon 2022, 8, 11245. [Google Scholar] [CrossRef]

- Cardinal, M.; Cornet, J.; Sérot, T.; Baron, R. Effects of the smoking process on odour characteristics of smoked herring (Clupea harengus) and relationships with phenolic compound content. Food Chem. 2006, 96, 137–146. [Google Scholar] [CrossRef]

- Kalasee, W. Improvement soot particles separation equipments for rubber smoking chamber. Aerosol Air Qual. Res. 2009, 9, 333–341. [Google Scholar] [CrossRef]

- Sikorski, Z.; Sinkiewicz, I. Smoking: Traditional. In Encyclopedia of Meat Sciences, 2nd ed.; Dikeman, M., Devine, C., Eds.; Academic Press: Cambridge, MA, USA, 2014; pp. 321–327. [Google Scholar] [CrossRef]

- Tahir, M.; Salengke, S.; Mursalim; Metusalach; Caesarendra, W. Performance of smokehouse designed for smoking fish with the indirect method. Processes 2020, 8, 204. [Google Scholar] [CrossRef]

- Birkeland, S.; Røra, A.M.; Skåra, T.; Bjerkeng, B. Effects of cold smoking procedures and raw material characteristics on product yield and quality parameters of cold smoked Atlantic salmon (Salmo salar L.) fillets. Food Res. Int. 2004, 37, 273–286. [Google Scholar] [CrossRef]

- Cardinal, M.; Knockaert, C.; Torrissen, O.; Sigurgisladottir, S.; Mørkøre, T.; Thomassen, M.; Vallet, J.L. Relation of smoking parameters to the yield, colour and sensory quality of smoked Atlantic salmon (Salmo salar). Food Res. Int. 2001, 34, 537–550. [Google Scholar] [CrossRef]

- Sérot, T.; Baron, R.; Knockaert, C.; Vallet, J.L. Effect of smoking processes on the contents of 10 major phenolic compounds in smoked fillets of herring (Cuplea harengus). Food Chem. 2004, 85, 111–120. [Google Scholar] [CrossRef]

- Sebastian, P.; Bruneau, D.; Collignan, A.; Rivier, M. Drying and smoking of meat: Heat and mass transfer modeling and experimental analysis. J. Food Eng. 2005, 70, 227–243. [Google Scholar] [CrossRef]

- Stumpe-Vīksna, I.; Bartkevičs, V.; Kukāre, A.; Morozovs, A. Polycyclic aromatic hydrocarbons in meat smoked with different types of wood. Food Chem. 2008, 110, 794–797. [Google Scholar] [CrossRef]

- Hitzel, A.; Pöhlmann, M.; Schwägele, F.; Speer, K.; Jira, W. Polycyclic aromatic hydrocarbons (PAH) and phenolic substances in meat products smoked with different types of wood and smoking spices. Food Chem. 2013, 139, 955–962. [Google Scholar] [CrossRef]

- García–Falcón, M.S.; Simal-Gándara, J. Polycyclic aromatic hydrocarbons in smoke from different woods and their transfer during traditional smoking into chorizo sausages with collagen and tripe casings. Food Addit. Contam. 2005, 22, 1–8. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, Q.; Liu, Q.; Xia, X.; Wang, Y.; Kong, B. Effect of different types of smoking materials on the flavor, heterocyclic aromatic amines, and sensory property smoked chicken drumsticks. Food Chem. 2022, 367, 130680. [Google Scholar] [CrossRef]

- Karunanithy, C.; Muthukumarappan, K.; Gibbons, W.R. Extrusion pretreatment of pine wood chips. Appl. Biochem. Biotechnol. 2012, 167, 81–89. [Google Scholar] [CrossRef] [PubMed]

- Esteves, B.; Videira, R.; Pereira, H. Chemistry and ecotoxicity of heat–treated pine wood extractives. Wood Sci. Technol. 2010, 45, 661–676. [Google Scholar] [CrossRef]

- Kapu, N.S.; Trajano, H.L. Review of hemicellulose hydrolysis in softwoods and bamboo. Biofuels Bioprod. Biorefining 2014, 8, 857–870. [Google Scholar] [CrossRef]

- Ding, Y.; Ezekoye, O.A.; Lu, S.; Wang, C.; Zhou, R. Comparative pyrolysis behaviors and reaction mechanisms of hardwood and softwood. Energy Convers. Manag. 2017, 132, 102–109. [Google Scholar] [CrossRef]

- Silvy, N.; Shamim Reza, M.; Nazim Uddin, M.; Akther, M. Comparison between different components of some available hardwood and softwood in Bangladesh. J. Biotechnol. Biochem. 2018, 4, 1–5. [Google Scholar]

- Konnerth, J.; Kluge, M.; Schweizer, G.; Miljković, M.; Gindl-Altmutter, W. Survey of selected adhesive bonding properties of nine European softwood and hardwood species. Eur. J. Wood Wood Prod. 2016, 74, 809–819. [Google Scholar] [CrossRef]

- Borůvka, V.; Novák, D.; Šedivka, P. Comparison and analysis of radial and tangential bending of softwood and hardwood at static and dynamic loading. Forests 2020, 11, 896. [Google Scholar] [CrossRef]

- Lykidis, C.; Nikolakakos, M.; Sakellariou, E.; Birbilis, D. Assessment of a modification to the Brinell method for determining solid wood hardness. Mater. Struct. 2016, 49, 961–967. [Google Scholar] [CrossRef]

- de Assis, A.; Alexandre, R.; Ballarin, A. Dynamic hardness of wood—Measurements with an automated portable hardness tester. Holzforschung 2017, 5, 383–389. [Google Scholar] [CrossRef]

- Saldaña, E.; Saldarriaga, L.; Cabrera, J.; Behrens, J.H.; Selani, M.M.; Rios-Mera, J.; Contreras-Castillo, C.J. Descriptive and hedonic sensory perception of Brazilian consumers for smoked bacon. Meat Sci. 2019, 147, 60–69. [Google Scholar] [CrossRef]

- Del Toro-Gipson, R.S.; Rizzo, P.V.; Hanson, D.J.; Drake, M.A. Consumer perception of smoked Cheddar cheese. J. Dairy Sci. 2021, 104, 1560–1575. [Google Scholar] [CrossRef] [PubMed]

- Kostyra, E.; Baryłko-Pikielna, N. Volatiles composition and flavour profile identity of smoke flavourings. Food Qual. Prefer. 2006, 17, 85–89. [Google Scholar] [CrossRef]

- Guo, J.; Wang, Q.; Chen, C.; Yu, H.; Xu, B. Effects of different smoking methods on sensory properties, free amino acids and volatile compounds in bacon. J. Sci. Food Agric. 2021, 101, 2984–2993. [Google Scholar] [CrossRef] [PubMed]

- Du, H.; Liu, Q.; Chen, Q.; Xia, X.; Xu, M.; Kong, B. Effect of woodchip types on heterocyclic aromatic amine formation and quality characteristics of smoked bacon. Food Biosci. 2022, 47, 101709. [Google Scholar] [CrossRef]

- Cho, W.-H.; Choi, J.-S. Sensory quality evaluation of superheated steam-treated chicken leg and breast meats with a combination of marination and hot smoking. Foods 2021, 10, 1924. [Google Scholar] [CrossRef] [PubMed]

- Swaney-Stueve, M.; Talavera, M.; Jepsen, T.; Severns, B.; Wise, R.; Deubler, G. Sensory and consumer evaluation of smoked pulled pork prepared using different smokers and different types of wood. J. Food Sci. 2019, 84, 640–649. [Google Scholar] [CrossRef] [PubMed]

- Baten, A.M.; Won, N.E.; Sohn, J.H.; Kim, J.-S.; Mohibbullah, M.; Choi, J.-S. Improvement of sensorial, physicochemical, microbiological, nutritional and fatty acid attributes and shelf life extension of hot smoked half–dried Pacific saury (Cololabis saira). Foods 2020, 9, 1009. [Google Scholar] [CrossRef]

- Sharma, C.; Swaney-Stueve, M.; Severns, B.; Talavera, M. Using correspondence analysis to evaluate consumer terminology and understand the effects of smoking method and type of wood on the sensory perception of smoked meat. J. Sens. Stud. 2019, 34, 12535. [Google Scholar] [CrossRef]

- Cheng, Y.; Leible, M.; Weiss, J.; Gibis, M. The impact of temperature-controlled smoldering smoking on polycyclic aromatic hydrocarbons and heterocyclic amines contents in Frankfurter–type sausages. Food Chem. 2023, 423, 136258. [Google Scholar] [CrossRef]

- Varlet, V.; Prost, C.; Sérot, T. Volatile aldehydes in smoked fish: Analysis methods, occurrence and mechanisms of formation. Food Chem. 2007, 105, 1536–1556. [Google Scholar] [CrossRef]

- Ekonomou, S.I.; Parlapani, F.F.; Kyritsi, M.; Hadjichristodoulou, C.; Boziaris, I.S. Preservation status and microbial communities of vacuum–packed hot smoked rainbow trout fillets. Food Microbiol. 2022, 103, 103959. [Google Scholar] [CrossRef] [PubMed]

- Rigling, M.; Höckmeier, L.; Leible, M.; Herrmann, K.; Gibis, M.; Weiss, J.; Zhang, Y. Characterization of the aroma profile of food smoke at controllable pyrolysis temperatures. Separations 2023, 10, 176. [Google Scholar] [CrossRef]

- Seraj, M.; Chen, Q.; Jones, J.R. Food smoke generation by frictional heating. Wood Sci. Technol. 2022, 56, 241–257. [Google Scholar] [CrossRef]

- Luo, G.; Chandler, D.S.; Anjos, L.C.; Eng, R.J.; Jia, P.; Resende, F.L. Pyrolysis of whole wood chips and rods in a novel ablative reactor. Fuel 2017, 194, 229–238. [Google Scholar] [CrossRef]

- Li, Q.; Kang, J.; Wang, Y.; Feng, Y. Superheated steam similarity simulation on longitudinal distribution of maximum smoke temperature rise in tunnel fires. Therm. Sci. Eng. Prog. 2023, 37, 101550. [Google Scholar] [CrossRef]

- Heo, H.S.; Park, H.J.; Dong, J.-I.; Park, S.H.; Kim, S.; Suh, D.J.; Suh, Y.-W.; Kim, S.-S.; Park, Y.-K. Fast pyrolysis of rice husk under different reaction conditions. J. Ind. Eng. Chem. 2010, 16, 27–31. [Google Scholar] [CrossRef]

- Chua, K.J.; Chou, S.K. Low–cost drying methods for developing countries. Trends Food Sci. Technol. 2003, 14, 519–528. [Google Scholar] [CrossRef]

- Wang, W.; Dong, L.; Zhang, Y.; Yu, H.; Wang, S. Reduction of the Heterocyclic Amines in Grilled Beef Patties through the Combination of Thermal Food Processing Techniques without Destroying the Grilling Quality Characteristics. Foods 2021, 10, 1490. [Google Scholar] [CrossRef]

- Ledesma, E.; Rendueles, M.; Díaz, M. Contamination of meat products during smoking by polycyclic aromatic hydrocarbons: Processes and prevention. Food Control 2016, 60, 64–87. [Google Scholar] [CrossRef]

- Essumang, D.K.; Dodoo, D.K.; Adjei, J.K. Effect of smoke generation sources and smoke curing duration on the levels of polycyclic aromatic hydrocarbon (PAH) in different suites of fish. Food Chem. Toxicol. 2013, 58, 86–94. [Google Scholar] [CrossRef]

- Shokin, G.; Shokina, Y. Modern Methods and Devices for Obtaining Technological Smoke: Review. KnE Life Sci. 2020, 5, 836–844. [Google Scholar] [CrossRef]

- Assogba, M.F.; Iko Afé, O.H.; Ahouansou, R.H.; Anihouvi, D.G.; Kpoclou, Y.E.; Djago, D.; Douny, C.; Igout, A.; Mahillon, J.; Hounhouigan, D.J.; et al. Performances of the barrel kiln used in cottage industry for fish processing and effects on physicochemical characteristics and safety of smoked fish products. J. Sci. Food Agric. 2022, 102, 851–861. [Google Scholar] [CrossRef] [PubMed]

- Goulas, A.E.; Kontominas, M.G. Effect of salting and smoking–method on the keeping quality of chub mackerel (Scomber japonicus): Biochemical and sensory attributes. Food Chem. 2005, 93, 511–520. [Google Scholar] [CrossRef]

- Waldenstrøm, L.; Gaarder, M.Ø.; Lerfall, J. Sensory methodology in product optimization of cold smoked Atlantic salmon (Salmo salar L.) processed with atomized purified condensed smoke. J. Food Sci. 2021, 86, 4650–4667. [Google Scholar] [CrossRef] [PubMed]

- Gedela, S.; Gamble, R.K.; Macwana, S.; Escoubas, J.R.; Muriana, P.M. Effect of inhibitory extracts derived from liquid smoke combined with postprocess pasteurization for control of Listeria monocytogenes on ready–to–eat meats. J. Food Prot. 2007, 70, 2749–2756. [Google Scholar] [CrossRef]

- Kim, H.-W.; Choi, J.-H.; Choi, Y.-S.; Kim, H.-Y.; Lee, M.-A.; Hwang, K.-E.; Song, D.-H.; Lee, J.-W.; Kim, C.-J. Effects of kimchi and smoking on quality characteristics and shelf life of cooked sausages prepared with irradiated pork. Meat Sci. 2014, 96, 548–553. [Google Scholar] [CrossRef]

- Rozentāle, I.; Stumpe-Vīksna, I.; Začs, D.; Siksna, I.; Melngaile, A.; Bartkevičs, V. Assessment of dietary exposure to polycyclic aromatic hydrocarbons form smoked meat products produced in Lativa. Food Control 2015, 54, 16–22. [Google Scholar] [CrossRef]

- Esposito, M.; Citro, A.; Marigliano, L.; Urbani, V.; Seccia, G.; Marotta, M.P.; De Nicola, C. Influence of different smoking techniques on contamination by polycyclic aromatic hydrocarbons in traditional smoked Mozzarella di Bufala Campana. Int. J. Dairy Technol. 2015, 68, 94–104. [Google Scholar] [CrossRef]

- Naccari, C.; Galceran, M.T.; Moyano, E.; Cristani, M.; Siracusa, L.; Trombetta, D. Presence of heterocyclic aromatic amines (HAs) in smoked “Provola” cheese from Calabria (Italy). Food Chem. Toxicol. 2009, 47, 321–327. [Google Scholar] [CrossRef]

- Guillén, M.D.; Palencia, G.; Ibargoitia, M.L.; Fresno, M.; Sopelana, P. Contamination of cheese by polycyclic aromatic hydrocarbons in traditional smoking. Influence of the position in the smokehouse on the contamination level of smoked cheese. J. Dairy Sci. 2011, 94, 1679–1690. [Google Scholar] [CrossRef]

- Shakeel-Ur-Rehman; Farkye, N.Y.; Drake, M.A. The effect of application of cold natural smoke on the ripening of cheddar cheese. J. Dairy Sci. 2003, 86, 1910–1917. [Google Scholar] [CrossRef] [PubMed]

- Ledesma, E.; Laca, A.; Rendueles, M.; Díaz, M. Texture, colour and optical characteristics of a meat product depending on smoking time and casing type. LWT Food Sci. Technol. 2016, 65, 164–172. [Google Scholar] [CrossRef]

- Flores, M.; Mora, L.; Reig, M.; Toldrá, F. Risk assessment of chemical substances of safety concern generated in processed meats. Food Sci. Hum. Wellness 2019, 8, 244–251. [Google Scholar] [CrossRef]

- Chen, S.; Kao, T.H.; Chen, C.J.; Huang, C.H.; Chen, B.H. Reduction of carcinogenic polycyclic aromatic hydrocarbons in meat by sugar–smoking and dietary exposure assessment in Taiwan. J. Agric. Food Chem. 2013, 61, 7645–7653. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Peng, Z.; Wang, M.; Wang, R.; Rui, L. Optimization of extraction procedure for formaldehyde assay in smoked meat products. J. Food Compos. Anal. 2012, 28, 1–7. [Google Scholar] [CrossRef]

- Petričević, S.; Marušić Radovčić, N.; Lukić, K.; Listeš, E.; Medić, H. Differentiation of dry–cured hams from different processing methods by mean volatile compounds, physico–chemical and sensory analysis. Meat Sci. 2018, 137, 217–227. [Google Scholar] [CrossRef] [PubMed]

- Yin, X.; Chen, Q.; Liu, Q.; Wang, Y.; Kong, B. Influences of smoking in traditional and industrial conditions on flavour profile of Harbin red sausages by comprehensive two–dimensional gas chromatography mass spectrometry. Foods 2021, 10, 1180. [Google Scholar] [CrossRef]

- Shishov, A.; Gagarionova, S.; Bulatov, A. Deep eutectic mixture membrane–based microextraction: HPLC–FLD determination of phenols in smoked food samples. Food Chem. 2020, 314, 126097. [Google Scholar] [CrossRef]

- Albishi, T.; Banoub, J.H.; de Camargo, A.C.; Shahidi, F. Date palm wood as a new source of phenolic antioxidants in preparation of smoked salmon. J. Food Biochem. 2018, 43, 12760. [Google Scholar] [CrossRef]

- Ledesma, E.; Rendueles, M.; Díaz, M. Characterization of natural and synthetic casings and mechanism of BaP penetration in smoked meat products. Food Control 2015, 51, 195–205. [Google Scholar] [CrossRef]

- Erbay, Z.; Koca, N. Kinetics of total phenolic content and total color difference during liquid smoking of Kashar cheese. Int. J. Food Prop. 2013, 16, 852–866. [Google Scholar] [CrossRef]

- Ahmad, S.; Anzar, A.; Srivastava, A.K.; Srivastava, P.K. Effect of curing, antioxidant treatment, and smoking of Buffalo meat on pH, total plate count, sensory characteristics, and shelf life during refrigerated storage. Int. J. Food Prop. 2005, 8, 139–150. [Google Scholar] [CrossRef]

- Duma-Kocan, P.; Rudy, M.; Gil, M.; Stanisławczyk, R. The influence of temperature differences in smoking chamber and furnace and smoking time on the quality of medium–ground sausages. Molecules 2020, 25, 5515. [Google Scholar] [CrossRef] [PubMed]

- Somoza, V. Five years of research on health risks and benefits of Maillard reaction products: An update. Mol. Nutr. Food Res. 2005, 49, 663–672. [Google Scholar] [CrossRef]

- Wretling, S.; Eriksson, A.; Eskhult, G.A.; Larsson, B. Polycyclic aromatic hydrocarbons (PAHs) in Swedish smoked meat and fish. J. Food Compos. Anal. 2010, 23, 264–272. [Google Scholar] [CrossRef]

- Racovita, R.C.; Secuianu, C.; Israel-Roming, F. Quantification and risk assessment of carcinogenic polycyclic aromatic hydrocarbons in retail smoked fish and smoked cheeses. Food Control 2021, 121, 107586. [Google Scholar] [CrossRef]

- Visciano, P.; Perugini, M.; Amorena, M.; Ianieri, A. Polycyclic aromatic hydrocarbons in fresh and cold–smoked Atlantic salmon fillets. J. Food Prot. 2006, 69, 1134–1138. [Google Scholar] [CrossRef]

- Sonego, E.; Bhattarai, B.; Duedahl-Olesen, L. Detection of nitrated, oxygenated and hydrogenated polycyclic aromatic compounds in smoked fish and meat products. Foods 2022, 11, 2446. [Google Scholar] [CrossRef]

- Yurchenko, S.; Mölder, U. The determination of polycyclic aromatic hydrocarbons in smoked fish by gas chromatography mass spectrometry with positive–ion chemical ionization. J. Food Compos. Anal. 2005, 18, 857–869. [Google Scholar] [CrossRef]

- Cunha, S.C.; Siminel, D.; Guárdia, M.D.; de Alda, M.L.; López-Garcia, E.; Muñoz, I.; Ferreira, R.; Eljarrat, E.; Fernandes, J.O. Effect of processing smoked salmon on contaminant contents. Food Chem. Toxicol. 2021, 153, 112276. [Google Scholar] [CrossRef]

- Abou-Arab, N.M.; Abd-EL-Samea, M.S.; Malhat, F.M.; El-Taher, S.M. Detection of some potential carcinogenic polycyclic aromatic hydrocarbons in smoked fish. Glob. J. Agric. Food Saf. Sci. 2014, 1, 346–356. [Google Scholar]

- Iwegbue, C.M.; Bassey, F.I.; Agbozu, I.; Aganbi, E.; Obi, G. Concentrations and risks of polycyclic aromatic hydrocarbons in smoke-cured fish products in Nigeria. Int. J. Environ. Stud. 2016, 73, 827–843. [Google Scholar] [CrossRef]

- Asamoah, E.K.; Nunoo, F.K.; Addo, S.; Nyarko, J.O.; Hyldig, G. Polycyclic aromatic hydrocarbons (PAHs) in fish smoked using traditional and improved kilns: Levels and human health risk implications through dietary exposure in Ghana. Food Control 2021, 121, 107576. [Google Scholar] [CrossRef]

- Aksun Tümerkan, E.T. Investigations of the polycyclic aromatic hydrocarbon and elemental profile of smoked fish. Molecules 2022, 27, 7015. [Google Scholar] [CrossRef] [PubMed]

- Visciano, P.; Perguini, M.; Conte, F.; Amorena, M. Polycyclic aromatic hydrocarbons in farmed rainbow trout (Oncorhynchus mykiss) processed by traditional flue gas smoking and by liquid smoke flavourings. Food Chem. Toxicol. 2008, 46, 1409–1413. [Google Scholar] [CrossRef] [PubMed]

- Mihalca, G.L.; Tiţa, O.; Tiţa, M.; Mihalca, A. Polycyclic aromatic hydrocarbons (PAHs) in smoked fish from three smoke-houses in Braşov county. J. Agroaliment. Process. Technol. 2011, 17, 392–397. [Google Scholar]

- Khalili, F.; Shariatifar, N.; Dehghani, M.H.; Yaghmaeian, K.; Nodehi, R.N.; Yaseri, M.; Moazzen, M. Polycyclic aromatic hydrocarbons (PAHs) in meat, poultry, fish and related product samples of Iran: A risk assessment study. J. Environ. Health Sci. Eng. 2023, 21, 215–224. [Google Scholar] [CrossRef]

- Djinovic, J.; Popovic, A.; Jira, W. Polycyclic aromatic hydrocarbons (PAHs) in different types of smoked meat products from Serbia. Meat Sci. 2008, 80, 449–456. [Google Scholar] [CrossRef]

- Mastanjević, K.; Puljić, L.; Kartalović, B.; Grbavac, J.; Grbavac, M.J.; Nadaždi, H.; Habschied, K. Analysis of polycyclic aromatic hydrocarbons in Heregovački pršut—traditionally smoked prosciutto. Int. J. Environ. Res. Public Health 2020, 17, 5097. [Google Scholar] [CrossRef]

- Pöhlmann, M.; Hitzel, A.; Schwägele, F.; Speer, K.; Jira, W. Content of polycyclic aromatic hydrocarbons (PAH) and phenolic substances in Frankfurter–type sausages depending on smoking conditions using glow smoke. Meat Sci. 2012, 90, 176–184. [Google Scholar] [CrossRef]

- Kartalovic, B.; Okanovic, D.; Babic, J.; Djordevic, V.; Jankovic, S.; Cirkovic, M. Polycyclic aromatic hydrocarbons in smoked ham. Procedia Food Sci. 2015, 5, 144–147. [Google Scholar] [CrossRef][Green Version]

- Chen, L.; Liu, R.; Wu, M.; Yu, H.; Ge, Q.; Zhang, W. Nitrosamines and polycyclic aromatic hydrocarbons in smoked–cured bacon (Larou) of artisanal and industrial origin. Foods 2021, 10, 2830. [Google Scholar] [CrossRef] [PubMed]

- Farqueza, M.J.; Laranjo, M.; Alves, S.; Fernandes, M.H.; Agulheiro-Santos, A.; Fernandes, M.J.; Potes, M.H.; Elias, M. Dry-cured meat products according to the smoking regime: Process optimization to control polycyclic aromatic hydrocarbons. Foods 2020, 9, 91. [Google Scholar] [CrossRef] [PubMed]

- Gomes, A.; Santos, C.; Almeida, J.; Elias, M.; Roseiro, L.C. Effect of fat content, casing type and smoking procedures on PAHs contents of Portuguese traditional dry fermented sausages. Food Chem. Toxicol. 2013, 58, 369–374. [Google Scholar] [CrossRef] [PubMed]

- Alsadat Mirbod, M.; Hadidi, M.; Huseyn, E.; Mousavi Khaneghah, A. Polycyclic aromatic hydrocarbon in smoked meat sausages: Effects of smoke generation source, smoking duration, and meat content. Food Sci. Technol. 2022, 42, 60921. [Google Scholar] [CrossRef]

- Coroian, C.O.; Coroian, A.; Becze, A.; Longodor, A.; Mastan, O.; Radu-Rusu, R.-M. Polycyclic aromatic hydrocarbons (PAHs) occurrence in traditionally smoked chicken, turkey and duck meat. Agriculture 2023, 13, 57. [Google Scholar] [CrossRef]

- Fasano, E.; Yerba-Pimentel, I.; Martínez-Carballo, E.; Simal-Gándara, J. Profiling, distribution and levels of carcinogenic polycyclic aromatic hydrocarbons in traditional smoked plant and animal foods. Food Control 2016, 59, 581–590. [Google Scholar] [CrossRef]

- Suchanová, M.; Hajšlová, J.; Tomaniová, M.; Kocourek, V.; Babička, L. Polycyclic aromatic hydrocarbons in smoked cheese. J. Sci. Food Agric. 2008, 88, 1307–1317. [Google Scholar] [CrossRef]

- Guillén, M.D.; Sopelana, P. Occurrence of polycyclic aromatic hydrocarbons in smoked cheese. J. Dairy Sci. 2004, 87, 556–564. [Google Scholar] [CrossRef]

- Węgrzyn, E.; Grześkiewicz, S.; Popławska, W.; Głód, B.K. Modified analytical method of polycyclic aromatic hydrocarbons, using SEC for sample preparation and RP-HPLC with fluorescence detection. Application to different food samples. Acta Chromatogr. 2006, 17, 233–264. [Google Scholar]

- Pluta-Kubica, A.; Filipczak-Fiutak, M.; Domagała, J.; Duda, I.; Migdał, W. Contamination of traditionally smoked cheeses with polycyclic aromatic hydrocarbons and biogenic amines. Food Control 2020, 112, 107115. [Google Scholar] [CrossRef]

- Pagulica, G.; Gazzotti, T.; Zironi, E.; Serrazanetti, G.P.; Mollica, D.; Rosmini, R. Determination of high molecular mass polycyclic aromatic hydrocarbons in a typical Italian smoked cheese by HPLC-FL. J. Agric. Food Chem. 2003, 51, 5111–5115. [Google Scholar] [CrossRef] [PubMed]

- Polak-Śliwińska, M.; Paszczyk, B.; Śliwiński, M. Evaluation of polycyclic aromatic hydrocarbons in smoked cheeses made in Poland by HPLC method. Molecules 2022, 27, 6909. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Dong, H.; Li, X.; Han, B.; Zhu, C.; Zhang, D. Quantitatively assessing the health risk of exposure to PAHs from intake of smoked meats. Ecotoxicol. Environ. Saf. 2016, 124, 91–95. [Google Scholar] [CrossRef]

| Soft Wood | Hard Wood | References | ||

|---|---|---|---|---|

| Main parameters [%] | Cellulose | 47.05 ± 10.69 | 49.98 ± 10.82 | [55,56,57,58,59,60] |

| Hemicellulose | 21.92 ± 12.75 | 21.16 ± 6.30 | ||

| Lignin | 24.90 ± 8.62 | 21.06 ± 8.04 | ||

| Water | ±12.15 | ±12.03 | [61,62,63,64] | |

| Density [kg/m3] | ±516 | ±660 | ||

| Hardness [MPa] | ±30 | ±71.5 | ||

| Type of Smoking Materials | Smoking Effect | References |

|---|---|---|

| Acacia | Yellow color, sweet flavor | [65] |

| Alder | Dark yellow to brown in color, mild flavor and aroma with no bitterness | [66] |

| Ash | Golden color, ripe aroma, and preferability flavor, burns quickly, and roasts product | [67] |

| Beech | Golden color, mild flavor, sweet aroma | [49,68,69] |

| Maple | Mild and slightly sweet taste, golden color | [66] |

| Oak | Honey flavor with a slight bitterness, brown color | [26,69,70,71,72,73] |

| Walnut | Dark yellow color, specific aroma | [70,72] |

| Apple tree | Mild smoke with subtle fruit flavor, dark brown color | [55,69,70,71,72,73] |

| Cherry tree | Subtle fruit flavor with little bitterness, dark brown color | [70,72] |

| Method | Method Description | References |

|---|---|---|

| Flame methods | ||

| Smoldering | The crushed wood smoke-generating raw material pyrolysis at 400–80 0°C. The greater the degree of fragmentation, the lower the pyrolysis temperature. The smoke is not thick; smoky substances dominate it. A byproduct is the formation of tar. | [74,75] |

| Combustion | It takes place in an open fireplace with an entire supply of oxygen. The smoke produced is thick and dry. A flame is visible during combustion. The combustion temperature is very high (even >1000 °C). The smoke mainly contains CO2 and water steam. The share of smoking substances is negligible. The distance of the fireplace from the smoking chamber depends on the desired process temperature. | [76,77] |

| Flameless methods | ||

| Frictional heating | The friction force generated by moving a wooden element along a metal surface converts kinetic energy into thermal energy. The temperature achieved in this way does not exceed 500 °C. The resulting smoke is not thick but has many smoky substances. | [78,79] |

| Steaming | Exposing wood chips to superheated steam heated to a temperature of 400 °C with a pressure of 0.13 MPa, which, together with the smoke, condenses on the product’s surface. Thanks to this, the product absorbs moisture and heat simultaneously, thus remaining juicier. | [20,80] |

| Fluidized smoke generator | Simultaneous occurrence of the thermal decomposition of wood chips and the oxidation of particles in the fluidized state. Air is introduced into the smoking chamber and heated to 300 °C. This method has much greater efficiency in creating dry and thick smoke with a high content of smokable substances. | [81,82] |

| Two-step | Smoke develops due to pyrolysis in the presence of CO2 or N2 and then mixed with oxygen, which causes the smoke to burn out, making it denser and richer in smokeable substances. | [83,84] |

| Smelting | Pyrolysis of sawdust compressed into blocks. The advantage of this method is the constant parameters of the smoke generated and the possibility of using waste from the wood industry. | [85,86] |

| Smoked Food | Polycyclic Aromatic Hydrocarbons [µg/kg] | ||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| BaA | BbF | BkF | BjF | BgP | BaP | BcL | DlP | DiP | DeP | DhP | DhA | IcP | |||||||||||||||||||

| Fish | Salmon | 47.66 ± 47.36 | 4.13 ± 3.94 | 2.13 ± 2.08 | 2.25 ± 1.95 | 5.51 ± 5.26 | 4.85 ± 4.55 | nd | nd | 0.25 ± 0.25 | 0.35 ± 0.35 | 0.25 ± 0.25 | 0.53 ± 0.28 | 4.33 ± 4.08 | |||||||||||||||||

| Herring | 25.58 ± 12.41 | 4.30 ± 4.26 | 5.45 ± 5.25 | 2.80 ± 2.50 | 13.70 ± 13.40 | 14.70 ± 7.05 | nd | 0.25 ± 0.25 | 1.50 ± 1.00 | 0.85 ± 0.35 | 0.75 ± 0.25 | 1.05 ± 0.75 | 6.80 ± 6.50 | ||||||||||||||||||

| Mackerel | 19.68 ± 19.48 | 19.22 ± 19.03 | 13.74 ± 13.64 | 4.10 ± 3.80 | 6.09 ± 5.89 | 7.81 ± 7.71 | nd | 0.25 ± 0.25 | 0.25 ± 0.25 | 0.55 ± 0.25 | nd | 5.91 ± 5.71 | 6.01 ± 5.81 | ||||||||||||||||||

| Rainbow trout | 6.60 ± 6.30 | 5.11 ± 5.08 | 3.49 ± 3.19 | 2.25 ± 1.95 | 9.63 ± 9.56 | 4.21 ± 4.15 | nd | nd | 0.25 ± 0.25 | 0.35 ± 0.35 | 0.25 ± 0.25 | 0.55 ± 0.25 | 2.71 ± 2.69 | ||||||||||||||||||

| Meat | Ham | 38.28 ± 38.23 | 11.97 ± 11.94 | 9.36 ± 9.34 | 9.36 ± 9.34 | 9.52 ± 9.49 | 18.51 ± 18.49 | 4.50 ± 4.40 | 0.25 ± 0.25 | 0.40 ± 0.40 | 0.85 ± 0.85 | 0.30 ± 0.30 | 1.55 ± 1.55 | 10.31 ± 10.28 | |||||||||||||||||

| Bacon | 14.48 ± 14.33 | 5.12 ± 5.06 | 6.26 ± 6.01 | 3.51 ± 3.49 | 4.52 ± 4.28 | 7.97 ± 7.90 | 5.40 ± 5.20 | 0.25 ± 0.25 | 0.41 ± 0.40 | 0.51 ± 0.50 | 0.25 ± 0.25 | 1.37 ± 1.31 | 5.16 ± 5.12 | ||||||||||||||||||

| Sausage | 4.07 ± 3.76 | 0.34 ± 0.28 | 0.15 ± 0.15 | 0.19 ± 0.11 | 1.43 ± 1.26 | 0.54 ± 0.36 | 2.65 ± 2.15 | 0.01 ± 0.01 | 0.03 ± 0.02 | 0.02 ± 0.01 | 0.01 ± 0.01 | 1.69 ± 1.56 | 0.89 ± 0.78 | ||||||||||||||||||

| Poultry | 1.21 ± 0.91 | 0.15 ± 0.15 | 1.23 ± 0.85 | nd | 0.15 ± 0.15 | 0.45 ± 0.15 | nd | nd | nd | nd | nd | nd | nd | ||||||||||||||||||

| Cheese | Mozzarella | 20.58 ± 20.36 | 27.82 ± 25.79 | 4.47 ± 3.25 | nd | 1.01 ± 0.96 | 12.91 ± 10.32 | nd | nd | nd | nd | nd | 2.33 ± 2.25 | 0.23 ± 0.20 | |||||||||||||||||

| Curd | 4.87 ± 4.63 | 2.30 ± 2.19 | 1.18 ± 1.02 | nd | 0.97 ± 0.93 | 2.29 ± 1.21 | nd | nd | nd | nd | nd | 0.41 ± 0.39 | 1.17 ± 1.12 | ||||||||||||||||||

| Italian | 1.37 ± 1.32 | 0.24 ± 0.20 | 0.17 ± 0.13 | nd | 0.18 ± 0.17 | 0.52 ± 0.48 | nd | nd | nd | nd | nd | 0.21 ± 0.21 | 0.26 ± 0.23 | ||||||||||||||||||

| Hard cheese | 1.14 ± 0.96 | 0.02 ± 0.02 | 0.02 ± 0.01 | nd | 0.04 ± 0.02 | 0.46 ± 0.41 | nd | nd | nd | nd | nd | 0.01 ± 0.01 | nd | ||||||||||||||||||

| Smoked food | Polycyclic aromatic hydrocarbons [µg/kg] | References | |||||||||||||||||||||||||||||

| Cpp | 5MC | Chr | Pyr | Fle | Phe | Ant | Nap | Fla | Acl | Ace | |||||||||||||||||||||

| Fish | Salmon | 9.65 ± 9.35 | nd | 7.79 ± 7.74 | 1.70 ± 0.50 | 45.17 ± 44.77 | 20.48 ± 18.48 | 5.45 ± 3.55 | 30.20 ± 27.60 | 28.66 ± 26.66 | 10.97 ± 10.87 | 10.97 ± 10.87 | [99,110,111,112,113,114,115] | ||||||||||||||||||

| Herring | 34.70 ± 34.40 | 0.85 ± 0.55 | 12.46 ± 12.25 | 1.90 ± 0.50 | 2.58 ± 2.22 | 14.15 ± 4.35 | 4.25 ± 0.85 | 5.35 ± 0.75 | 2.94 ± 0.84 | 7.93 ± 7.38 | 0.90 ± 0.40 | [110,111,113,114,116] | |||||||||||||||||||

| Mackerel | 29.45 ± 29.15 | nd | 20.30 ± 20.00 | 36.95 ± 36.85 | 18.74 ± 16.03 | 27.23 ± 26.01 | 66.09 ± 65.00 | 47.95 ± 47.85 | 37.93 ± 35.83 | 11.69 ± 11.59 | 15.99 ± 15.82 | [110,111,113,114,117,118] | |||||||||||||||||||

| Rainbow trout | 9.65 ± 9.35 | nd | 7.82 ± 7.78 | 31.14 ± 24.74 | 17.75 ± 17.75 | 1.75 ± 1.75 | 15.62 ± 15.60 | 52.92 ± 52.89 | 8.52 ± 8.51 | 5.31 ± 5.29 | 15.35 ± 15.35 | [110,118,119,120,121,122] | |||||||||||||||||||

| Meat | Ham | 49.31 ± 49.20 | 0.16 ± 0.14 | 35.74 ± 35.66 | 3.71 ± 3.11 | 22.48 ± 21.78 | 13.66 ± 13.44 | 114.07 ± 113.90 | 10.33 ± 9.60 | 13.50 ± 12.70 | 19.78 ± 19.31 | 10.16 ± 9.65 | [17,99,110,123,124] | ||||||||||||||||||

| Bacon | 17.02 ± 16.89 | 0.16 ± 0.15 | 16.75 ± 16.55 | 1.75 ± 0.75 | 79.11 ± 78.41 | 253.19 ± 249.89 | 59.70 ± 59.30 | 88.19 ± 69.57 | 25.59 ± 24.78 | 170.64 ± 154.36 | 2.40 ± 2.40 | [17,110,113,125,126,127] | |||||||||||||||||||

| Sausage | 0.50 ± 0.38 | 0.47 ± 0.44 | 2.41 ± 2.05 | 7.81 ± 5.99 | 51.47 ± 47.79 | 20.23 ± 11.83 | 3.11 ± 2.58 | 134.14 ± 111.97 | 7.17 ± 5.38 | 172.49 ± 149.72 | 59.45 ± 38.33 | [17,123,128,129,130] | |||||||||||||||||||

| Poultry | 0.15 ± 0.15 | nd | 1.97 ± 1.57 | 1.81 ± 1.53 | 18.81 ± 18.21 | 47.10 ± 45.90 | 2.23 ± 1.83 | 10.25 ± 9.21 | 5.02 ± 4.71 | 6.88 ± 5.38 | 2.35 ± 1.45 | [99,110,131] | |||||||||||||||||||

| Cheese | Mozzarella | nd | nd | 5.48 ± 5.35 | 0.70 ± 0.10 | 5.35 ± 0.35 | 9.85 ± 2.15 | 1.30 ± 0.10 | 7.85 ± 5.15 | 1.35 ± 0.15 | nd | 1.25 ± 0.15 | [93,132,133] | ||||||||||||||||||

| Curd | nd | nd | 3.71 ± 3.59 | 33.73 ± 32.27 | 200.38 ± 198.32 | 395.97 ± 390.04 | 95.06 ± 94.25 | 604.66 ± 592.34 | 47.22 ± 45.87 | 600.18 ± 536.25 | 24.14 ± 22.89 | [95,134,135,136] | |||||||||||||||||||

| Italian | nd | nd | 0.89 ± 0.75 | 0.84 ± 0.58 | 1.66 ± 0.82 | 4.02 ± 1.93 | 1.22 ± 0.89 | 2.47 ± 1.68 | 1.34 ± 0.92 | 0.56 ± 0.43 | 0.33 ± 0.15 | [111,137] | |||||||||||||||||||

| Hard cheese | nd | nd | 0.50 ± 0.40 | 2.00 ± 1.40 | 10.05 ± 8.95 | 14.30 ± 10.20 | 4.75 ± 3.65 | 29.75 ± 25.32 | 3.50 ± 2.10 | nd | 4.90 ± 3.20 | [133,138] | |||||||||||||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nizio, E.; Czwartkowski, K.; Niedbała, G. Impact of Smoking Technology on the Quality of Food Products: Absorption of Polycyclic Aromatic Hydrocarbons (PAHs) by Food Products during Smoking. Sustainability 2023, 15, 16890. https://doi.org/10.3390/su152416890

Nizio E, Czwartkowski K, Niedbała G. Impact of Smoking Technology on the Quality of Food Products: Absorption of Polycyclic Aromatic Hydrocarbons (PAHs) by Food Products during Smoking. Sustainability. 2023; 15(24):16890. https://doi.org/10.3390/su152416890

Chicago/Turabian StyleNizio, Edyta, Kamil Czwartkowski, and Gniewko Niedbała. 2023. "Impact of Smoking Technology on the Quality of Food Products: Absorption of Polycyclic Aromatic Hydrocarbons (PAHs) by Food Products during Smoking" Sustainability 15, no. 24: 16890. https://doi.org/10.3390/su152416890

APA StyleNizio, E., Czwartkowski, K., & Niedbała, G. (2023). Impact of Smoking Technology on the Quality of Food Products: Absorption of Polycyclic Aromatic Hydrocarbons (PAHs) by Food Products during Smoking. Sustainability, 15(24), 16890. https://doi.org/10.3390/su152416890