Effect of High Biological Value Animal Protein Sources on the Techno-Functional Properties of Ice Cream

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of Ice Cream

2.2. Rheological Measurement of Liquid Ice Cream Mix

2.3. Texture Measurement of Frozen Ice Cream

2.4. Colour Measurement

2.5. Dry Matter Content Measurement

2.6. pH Measurement

2.7. Sensory Analysis

2.8. Statistical Analysis

3. Results and Discussion

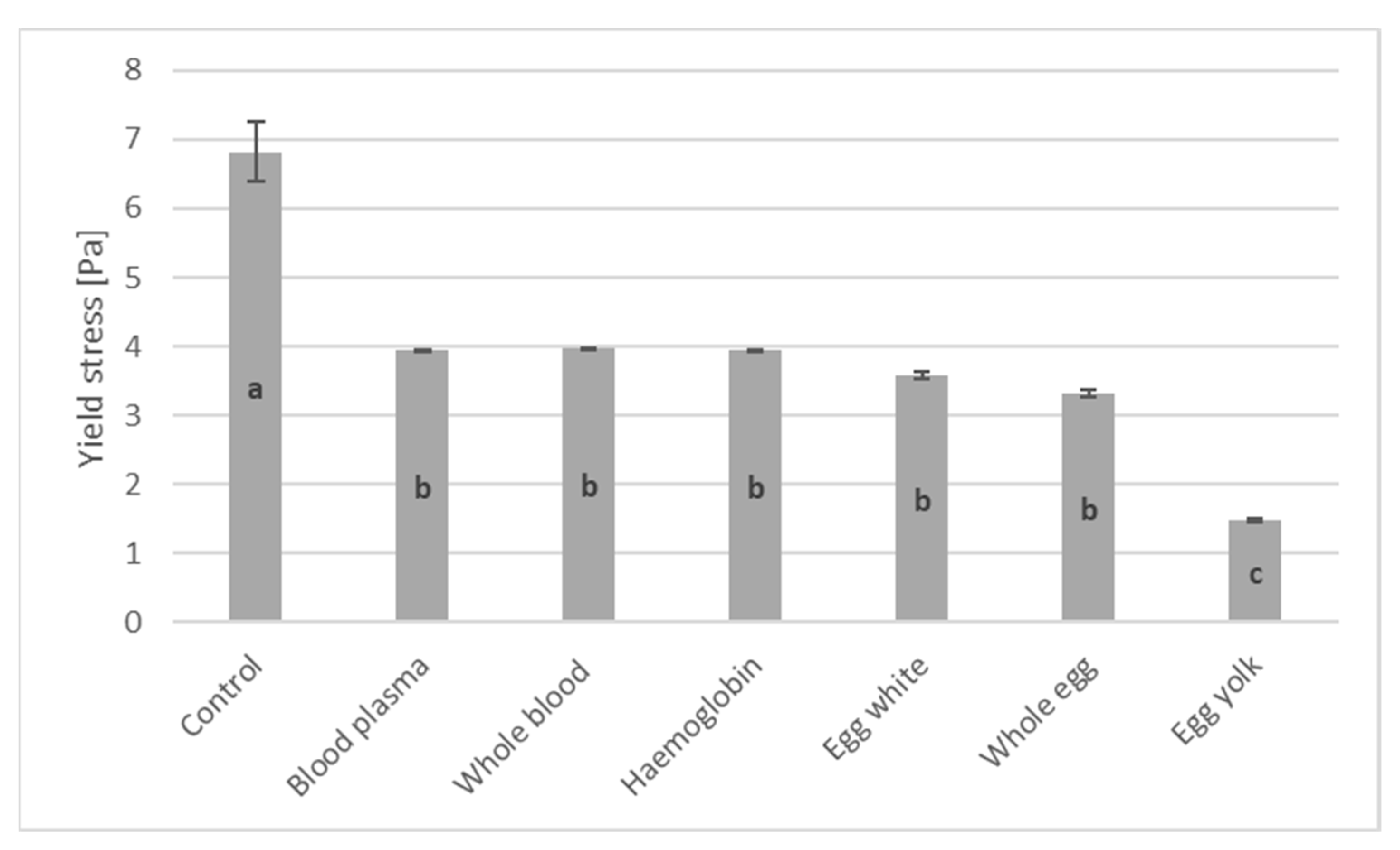

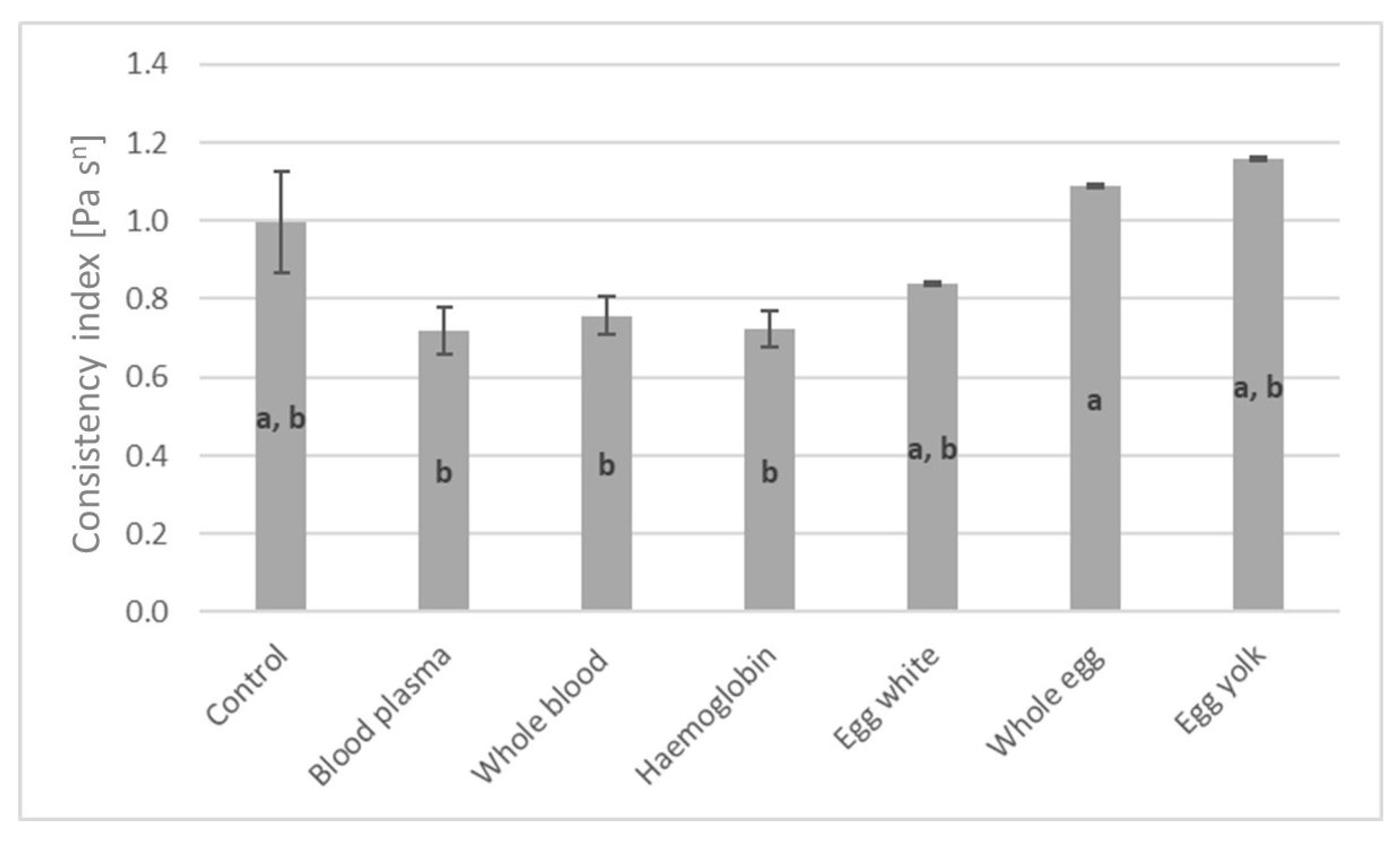

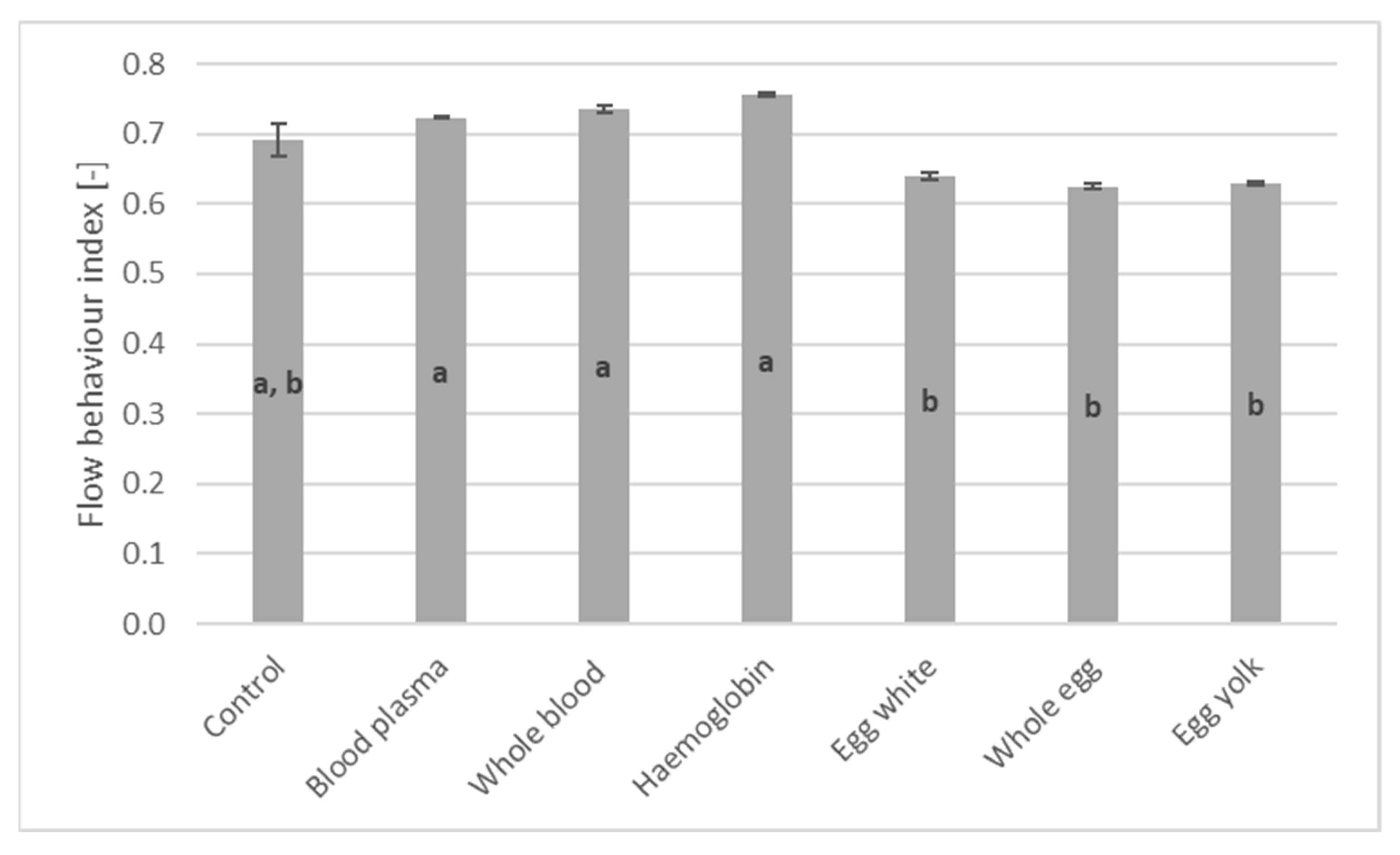

3.1. Rheological Behaviour of Liquid Ice Cream Mix

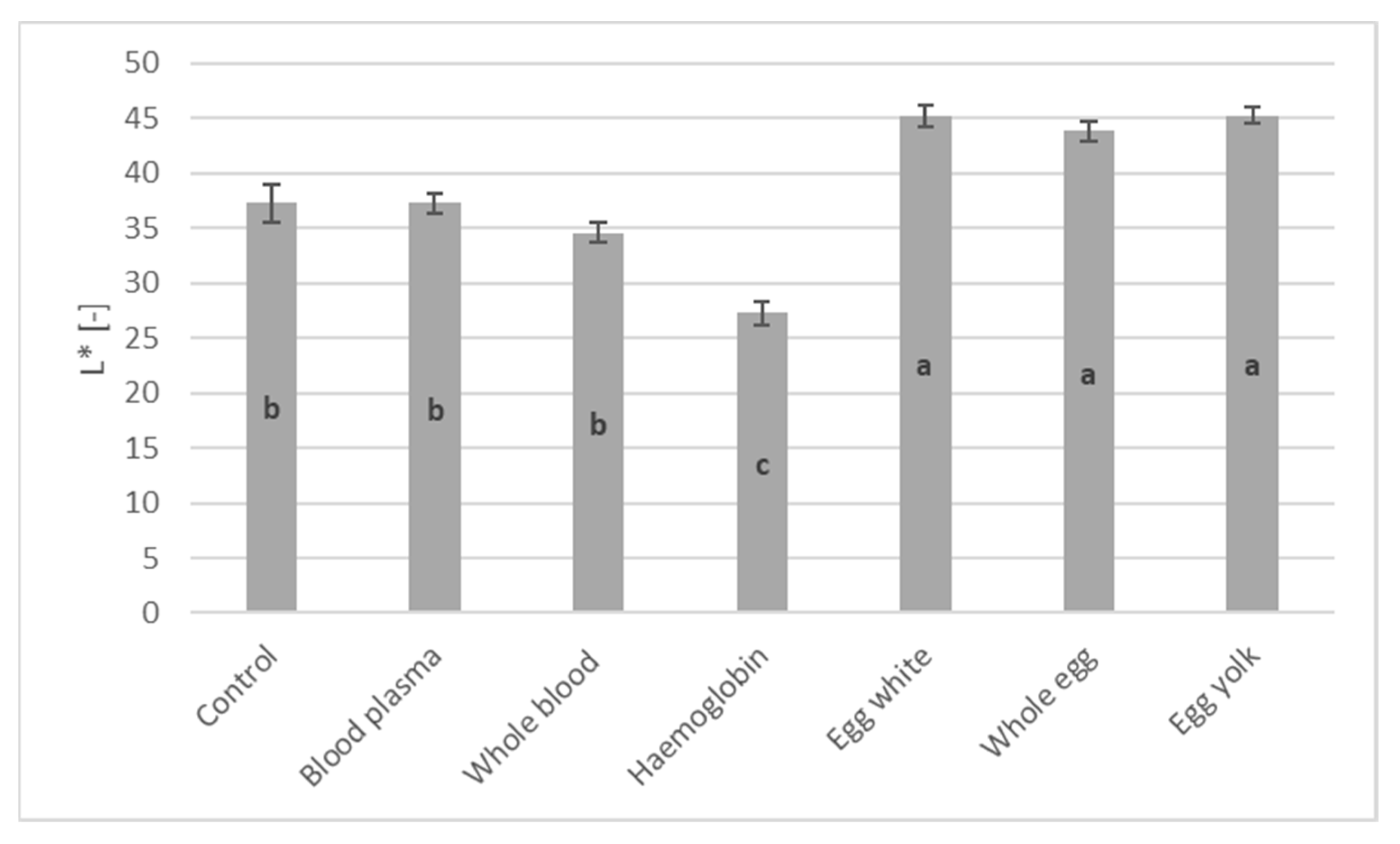

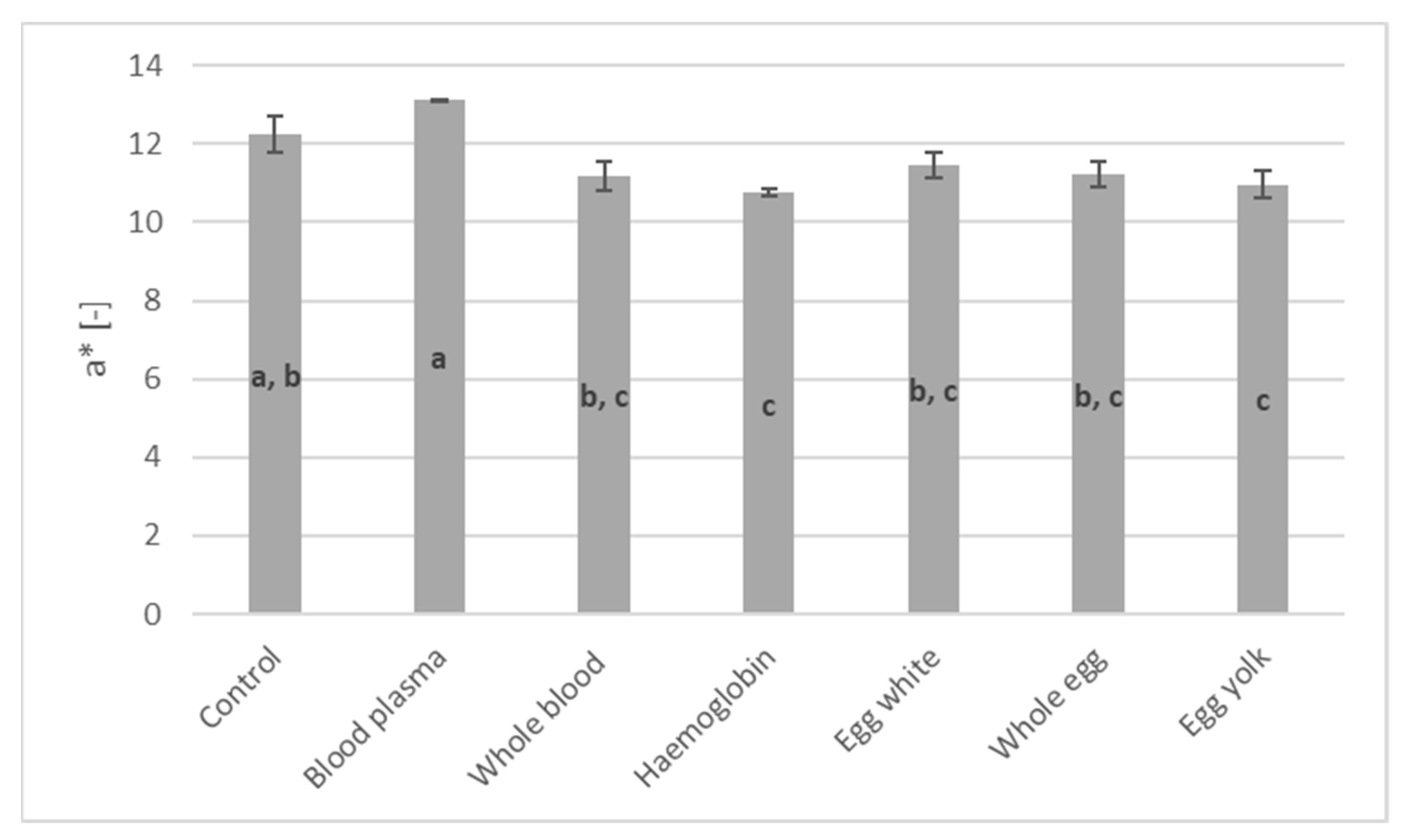

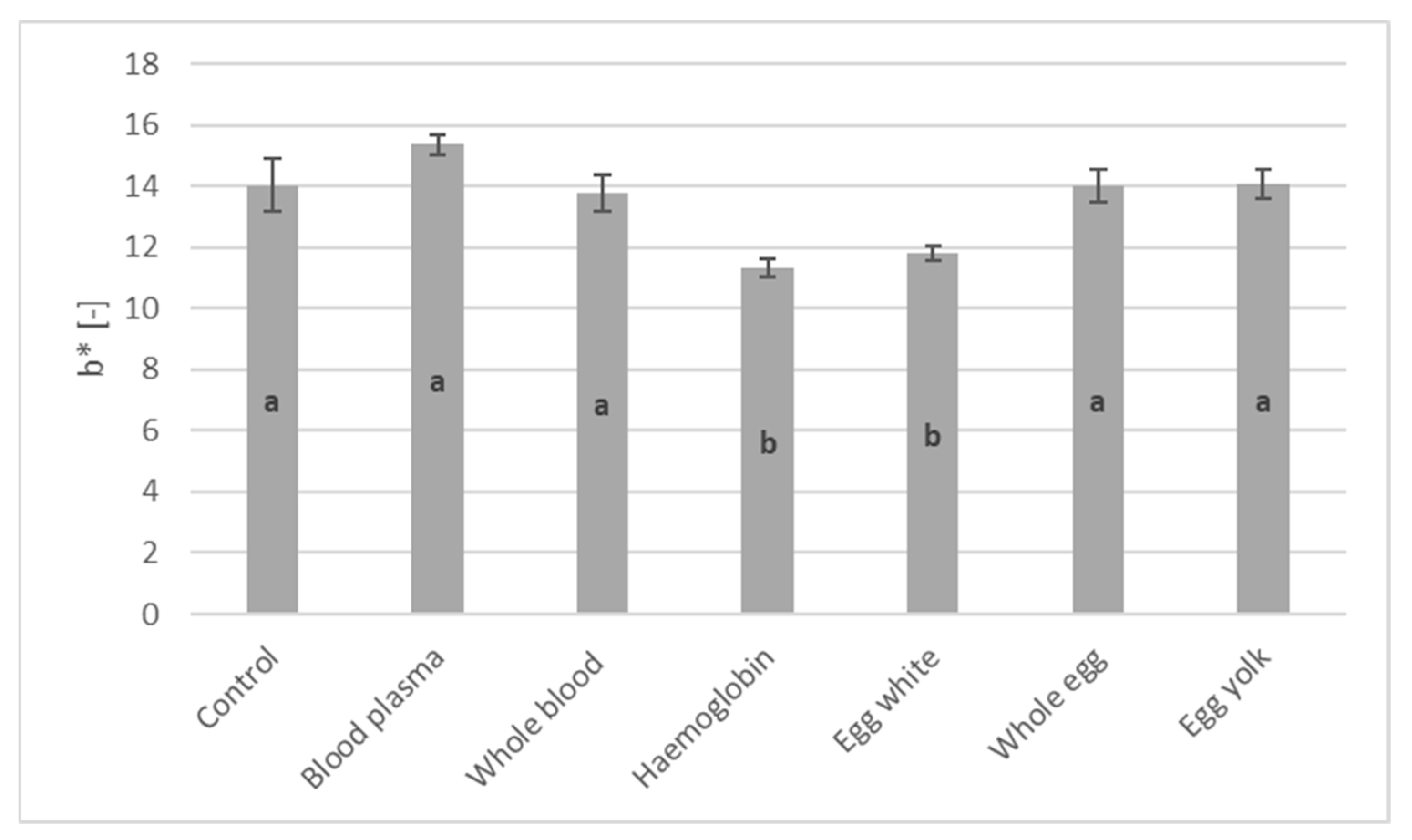

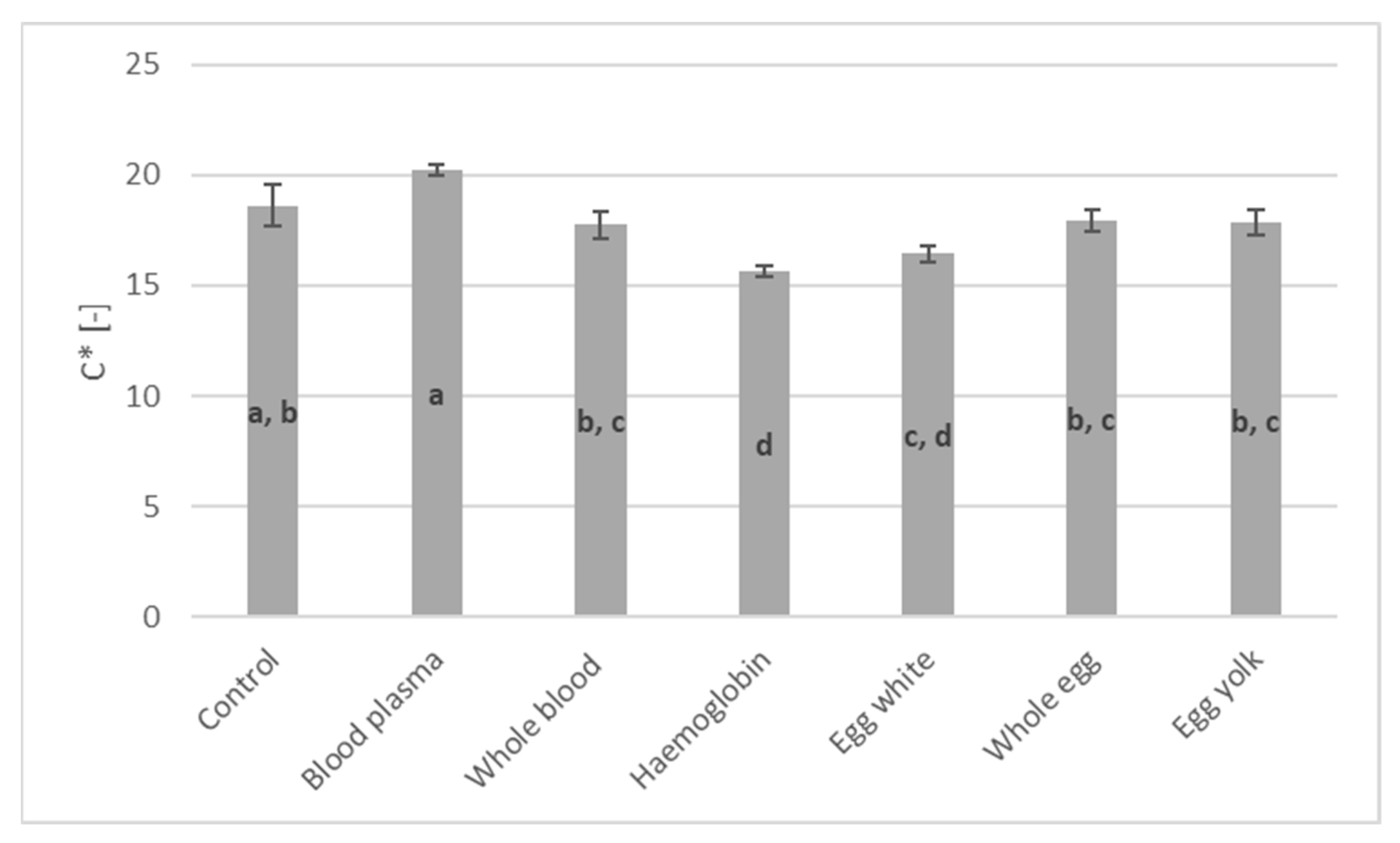

3.2. Colour Attributes

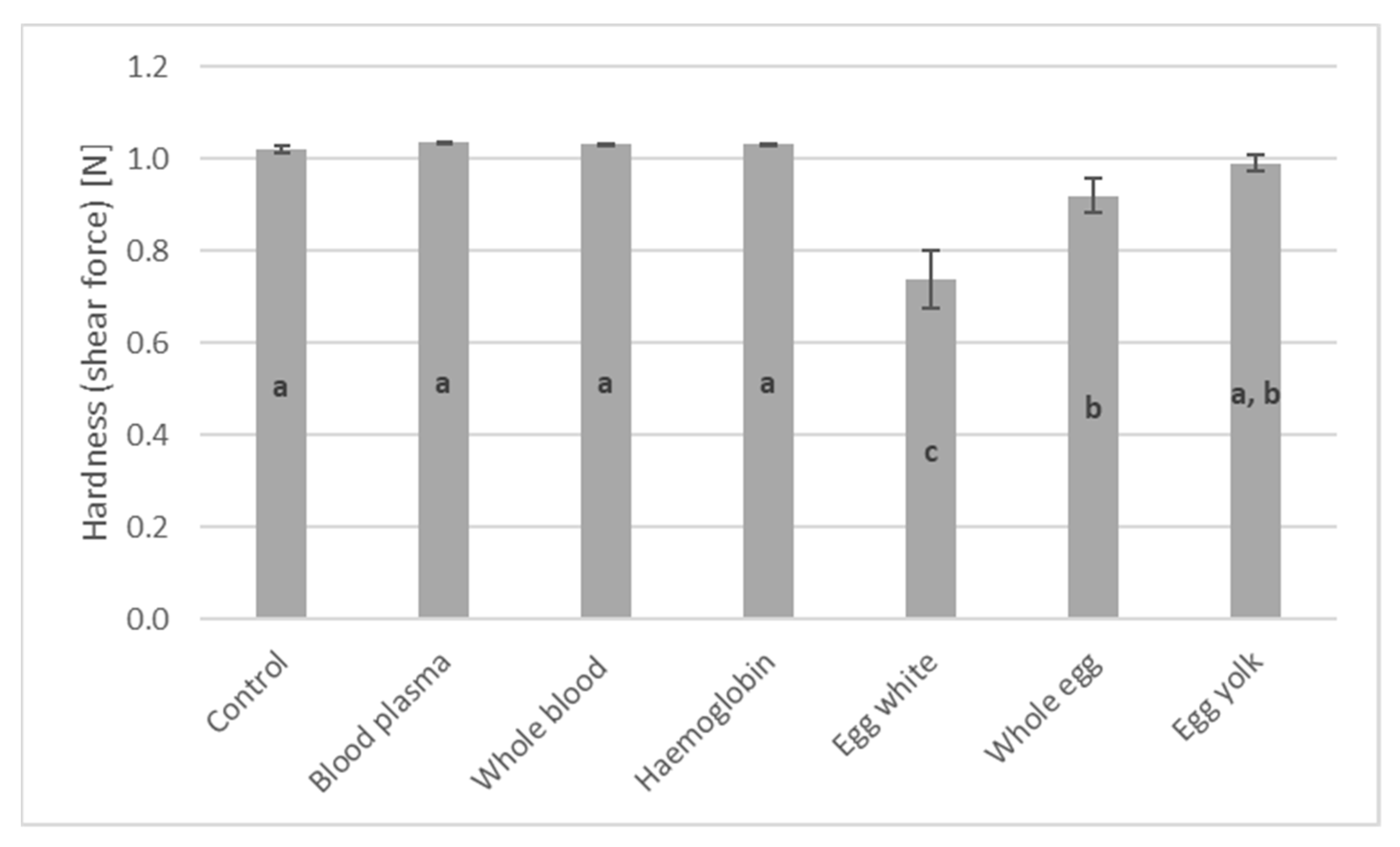

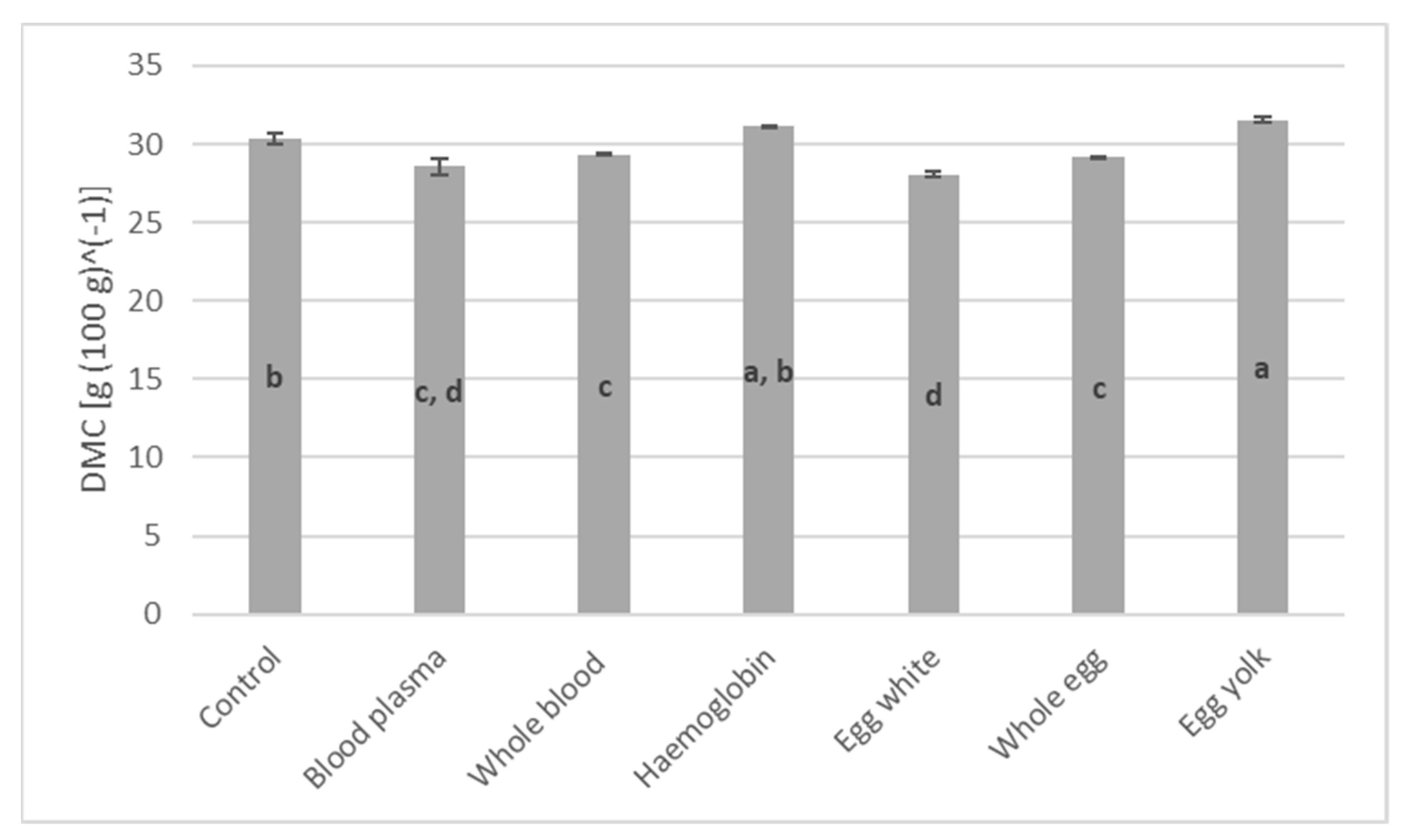

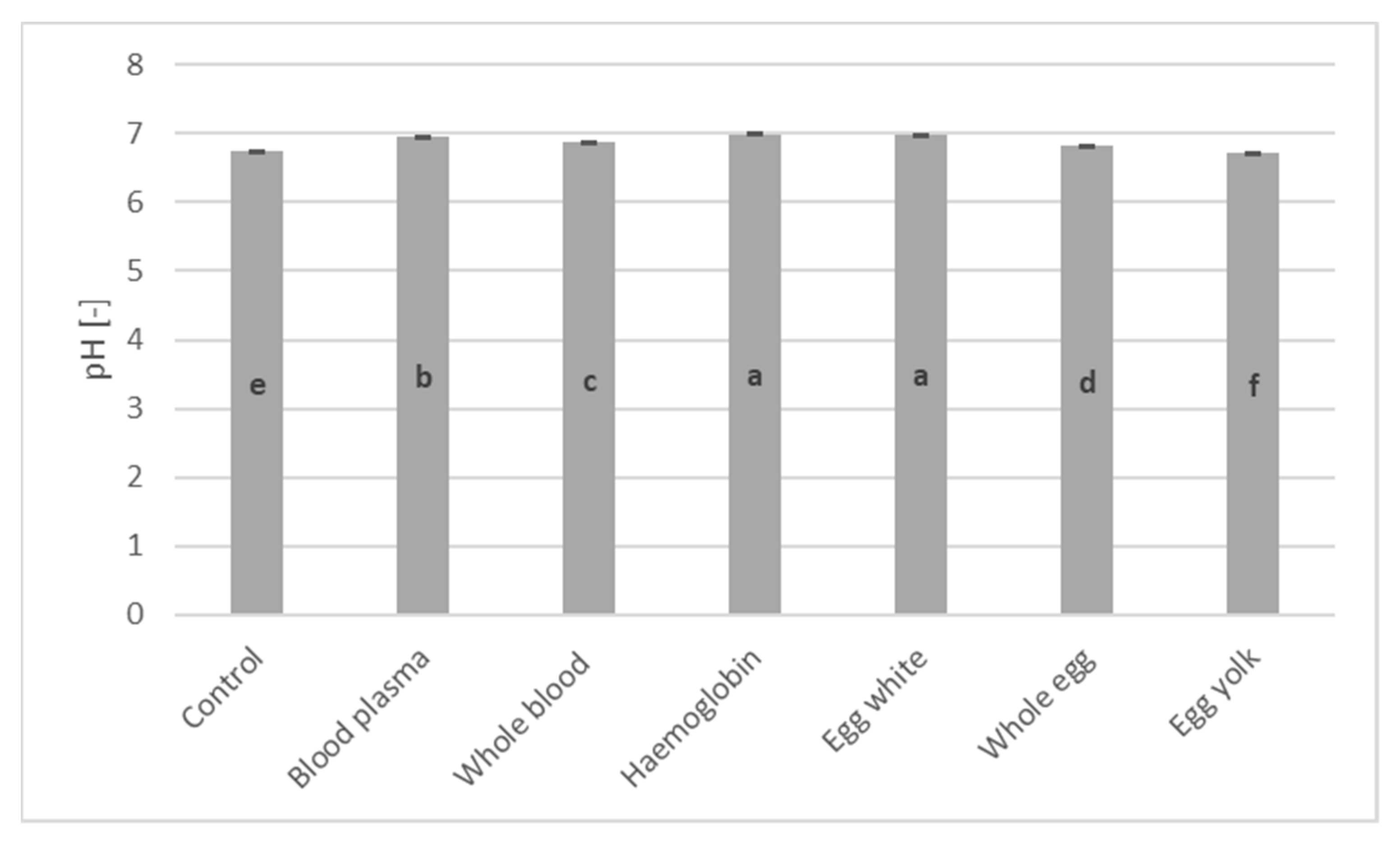

3.3. Hardness of Frozen Ice Cream, Dry Matter Content, pH

3.4. Sensory Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Csurka, T.; Pásztor-Huszár, K.; Tóth, A.; Friedrich, L.F.; Németh, C. Animal blood, as a safe and valuable resource. J. Hyg. Eng. Des. 2021, 35, 41–47. [Google Scholar]

- Ockerman, H.W.; Hansen, C.L. Animal Byproduct Processing and Utilization; CRC Press: Boca Raton, FL, USA, 2000; ISBN 9781566767774. [Google Scholar] [CrossRef]

- Sorapukdee, S.; Narunatsopanon, S. Comparative study on compositions and functional properties of porcine, chicken and duck blood. Korean J. Food Sci. Anim. Resour. 2017, 37, 228. [Google Scholar] [CrossRef] [PubMed]

- World Health Organization; United Nations University. Protein and Amino Acid Requirements in Human Nutrition; World Health Organization: Geneva, Switzerland, 2007; Volume 935, ISBN 9241209356. [Google Scholar]

- Gorbatov, V.M. Collection and Utilization of Blood and Blood Proteins for Edible Purposes in the USSR. In Advances in Meat Research; Elsevier Applied Science: London, UK; New York, NY, USA, 1988; ISSN 0885-2405. [Google Scholar]

- Satterlee, L.D. Improving utilization of animal by-products for human foods—A review. J. Anim. Sci. 1975, 41, 687–697. [Google Scholar] [CrossRef]

- Tybor, P.T.; Dill, C.W.; Landmann, W.A. Effect of decolorization and lactose incorporation on the emulsification capacity of spray-dried blood protein concentrates. J. Food Sci. 1973, 38, 4–6. [Google Scholar] [CrossRef]

- Bah CS, F.; Bekhit AE, D.A.; Carne, A.; McConell, A. Slaughterhouse blood: An emerging source of bioactive compounds. Compr. Rev. Food Sci. Food Saf. 2013, 12, 314–331. [Google Scholar] [CrossRef]

- Duarte, R.T.; Carvalho Simoes, M.C.; Sgarbieri, V.C. Bovine blood components: Fractionation, composition, and nutritive value. J. Agric. Food Chem. 1999, 47, 231–236. [Google Scholar] [CrossRef]

- Ofori, J.A.; Hsieh, Y.H.P. The Use of Blood and Derived Products as Food Additives; Food additive; IntechOpen: Rijeka, Croatia, 2012; ISBN 978-953-51-0067-6. [Google Scholar]

- Toldrá, F.; Aristoy, M.C.; Mora, L.; Reig, M. Innovations in value-addition of edible meat by-products. Meat Sci. 2012, 92, 290–296. [Google Scholar] [CrossRef] [PubMed]

- EUROSTAT. All Data/Agriculture, Forestry and Fisheries/Agriculture/Agricultural Production/Animal Production/Livestock and Meat/Meat Production. 2022. Available online: https://ec.europa.eu/eurostat/data/database (accessed on 15 September 2023).

- Molnár, S.; Szőllősi, L. Sustainability and quality aspects of different table egg production systems: A literature review. Sustainability 2020, 12, 7884. [Google Scholar] [CrossRef]

- Gunnarsson, S.; Arvidsson Segerkvist, K.; Göransson, L.; Hansson, H.; Sonesson, U. Systematic mapping of research on farm-level sustainability in egg and chicken meat production. Sustainability 2020, 12, 3033. [Google Scholar] [CrossRef]

- Gross, J.J.; Bruckmaier, R.M. Invited review: Metabolic challenges and adaptation during different functional stages of the mammary gland in dairy cows: Perspectives for sustainable milk production. J. Dairy Sci. 2019, 102, 2828–2843. [Google Scholar] [CrossRef]

- Hagemann, M.; Hemme, T.; Ndambi, A.; Alqaisi, O.; Sultana, M.N. Benchmarking of greenhouse gas emissions of bovine milk production systems for 38 countries. Anim. Feed. Sci. Technol. 2011, 166, 46–58. [Google Scholar] [CrossRef]

- Salter, A.M. Improving the sustainability of global meat and milk production. Proc. Nutr. Soc. 2017, 76, 22–27. [Google Scholar] [CrossRef] [PubMed]

- Arrieta, E.M.; Aguiar, S.; Fischer, C.G.; Cuchietti, A.; Cabrol, D.A.; González, A.D.; Jobbágy, E.G. Environmental footprints of meat, milk and egg production in Argentina. J. Clean. Prod. 2022, 347, 131325. [Google Scholar] [CrossRef]

- Ayar, A.; Siçramaz, H.; Öztürk, S.; Öztürk Yilmaz, S. Probiotic properties of ice creams produced with dietary fibres from by-products of the food industry. Int. J. Dairy Technol. 2018, 71, 174–182. [Google Scholar] [CrossRef]

- El-Nagar, G.; Clowes, G.; Tudoricǎ, C.M.; Kuri, V.; Brennan, C.S. Rheological quality and stability of yog-ice cream with added inulin. Int. J. Dairy Technol. 2002, 55, 89–93. [Google Scholar] [CrossRef]

- Gabbi, D.K.; Bajwa, U.; Goraya, R.K. Physicochemical, melting and sensory properties of ice cream incorporating processed ginger (Zingiber officinale). Int. J. Dairy Technol. 2018, 71, 190–197. [Google Scholar] [CrossRef]

- Kalicka, D.; Znamirowska, A.; Pawlos, M.; Buniowska, M.; Szajnar, K. Physical and sensory characteristics and probiotic survival in ice cream sweetened with various polyols. Int. J. Dairy Technol. 2019, 72, 456–465. [Google Scholar] [CrossRef]

- Tiwari, A.; Sharma, H.K.; Kumar, N.; Kaur, M. The effect of inulin as a fat replacer on the quality of low-fat ice cream. Int. J. Dairy Technol. 2015, 68, 374–380. [Google Scholar] [CrossRef]

- FrØst, M.B.; Heymann, H.; Bredie, W.L.; Dijksterhuis, G.B.; Martens, M. Sensory measurement of dynamic flavour intensity in ice cream with different fat levels and flavourings. Food Qual. Prefer. 2005, 16, 305–314. [Google Scholar] [CrossRef]

- Rossa, P.N.; Burin, V.M.; Bordignon-Luiz, M.T. Effect of microbial transglutaminase on functional and rheological properties of ice cream with different fat contents. LWT—Food Sci. Technol. 2012, 48, 224–230. [Google Scholar] [CrossRef]

- Hartel, R.W.; Muse, M.R.; Sofjan, R. Effects of structural attributes on hardness and meltingrate of ice cream. Ice cream II. In Proceedings of the Second IDF International Symposium on Ice Cream, International Dairy Federation, Thessaloniki, Greece, 14–16 May 2003; pp. 124–139, ISBN 9290980389. [Google Scholar]

- Javidi, F.; Razavi SM, A.; Behrouzian, F.; Alghooneh, A. The influence of basil seed gum, guar gum and their blend on the rheological, physical and sensory properties of low fat ice cream. Food Hydrocoll. 2016, 52, 625–633. [Google Scholar] [CrossRef]

- Putnam, F.W. The Plasma Proteins: Structure, Function, and Genetic Control; Academic Press: New York, NY, USA; San Francisco, CA, USA; London, UK, 1977; ISBN 0-12-568403-7. [Google Scholar]

- Liberal, Â.; Pinela, J.; Vívar-Quintana, A.M.; Ferreira, I.C.; Barros, L. Fighting iron-deficiency anemia: Innovations in food fortificants and biofortification strategies. Foods 2020, 9, 1871. [Google Scholar] [CrossRef]

- Weintraub, L.R.; Weinstein, M.B.; Huser, H.J.; Rafal, S. Absorption of hemoglobin iron: The role of a heme-splitting substance in the intestinal mucosa. J. Clin. Investig. 1968, 47, 531–539. [Google Scholar] [CrossRef]

- Pereira, A.D.; Gomide LA, M.; Cecon, P.R.; Fontes EA, F.; Fontes, P.R.; Ramos, E.M.; Vidigal, J.G. Evaluation of mortadella formulated with carbon monoxide-treated porcine blood. Meat Sci. 2014, 97, 164–173. [Google Scholar] [CrossRef]

- Oellingrath, I.M.; Slinde, E. Color, pigment and iron content of meat loaves with blood, blood emulsion, or mechanically deboned meat added. J. Food Sci. 1985, 50, 1551–1555. [Google Scholar] [CrossRef]

- Slinde, E.; Martens, M. Changes in sensory properties of sausages when small amounts of blood replace meat. J. Sci. Food Agric. 1982, 33, 760–762. [Google Scholar] [CrossRef]

- Ratnayake, W.S.; Geera, B.; Rybak, D.A. Effects of egg and egg replacers on yellow cake product quality. J. Food Process. Preserv. 2012, 36, 21–29. [Google Scholar] [CrossRef]

- Csurka, T.; Varga-Tóth, A.; Kühn, D.; Hitka, G.; Badak-Kerti, K.; Alpár, B.; Surányi, J.; Friedrich, L.F.; Pásztor-Huszár, K. Comparison of techno-functional and sensory properties of sponge cakes made with egg powder and different quality of powdered blood products for substituting egg allergen and developing functional food. Front. Nutr. 2022, 9, 979594. [Google Scholar] [CrossRef]

- Johnson, L.A.; Havel, E.F.; Hoseney, R.C. Bovine plasma as a replacement for egg in cakes. Cereal Chem. 1979, 56, 339–342. [Google Scholar]

- Lee, C.C.; Johnson, L.A.; Love, J.A.; Johnson, S. As an Egg White Substitute in Cakes’. Cereal Chem. 1991, 68, 100–104. [Google Scholar]

- Hidas, K.I.; Nyulas-Zeke, I.C.; Szepessy, A.; Romvári, V.; Gerhart, K.; Surányi, J.; Laczay, P.; Darnay, L. Physical properties of hemp drink-based ice cream with different plant proteins guar gum and microbial transglutaminase. LWT 2023, 182, 114865. [Google Scholar] [CrossRef]

- Varga-Tóth, A.; Németh Cs Dalmadi, I.; Csurka, T.; Csorba, R.; Elayan, M.; Enkhbold, M.; Hidas, K.; Friedrich, L.F. Investigation of the effects of bovine collagen peptides and mixed berries on rheological properties and biological activity of egg white-based beverage via central composite design. Front. Nutr. 2023, 9, 1011553. [Google Scholar] [CrossRef] [PubMed]

- Mezger, T.G. The Rheology Handbook: For Users of Rotational and Oscillatory Rheometers, 3rd ed.; Vincentz Network: Hannover, Germany, 2006; ISBN 978-3-86630-890-9. [Google Scholar]

- De Huidobro, F.R.; Miguel, E.; Blázquez, B.; Onega, E. A comparison between two methods (Warner–Bratzler and texture profile analysis) for testing either raw meat or cooked meat. Meat Sci. 2005, 69, 527–536. [Google Scholar] [CrossRef] [PubMed]

- Cofrades, S.; Guerra, M.A.; Carballo, J.; Fernández-Martyn, F.; Colmenero, F.J. Plasma protein and soy fiber content effect on bologna sausage properties as influenced by fat level. J. Food Sci. 2000, 65, 281–287. [Google Scholar] [CrossRef]

- Pietrasik, Z.; Jarmoluk, A.; Shand, P.J. Effect of non-meat proteins on hydration and textural properties of pork meat gels enhanced with microbial transglutaminase. LWT 2007, 40, 915–920. [Google Scholar] [CrossRef]

- Nassu, R.T.; Uttaro, B.; Aalhus, J.L.; Zawadski, S.; Juárez, M.; Dugan, M.E. Type of packaging affects the colour stability of vitamin E enriched beef. Food Chem. 2012, 135, 1868–1872. [Google Scholar] [CrossRef]

- Nagy, D.; Zsom-Muha, V.; Németh Cs Felföldi, J. Sonication effect on foam properties of egg white. Prog. Agric. Eng. Sci. 2021, 17, 1–8. [Google Scholar] [CrossRef]

- Froning, G.W. Egg Products Industry and Future Perspectives. In Egg Bioscience and Biotechnology; Mine, Y., Ed.; John Wiley & Sons: Hoboken, NJ, USA, 2008; pp. 307–326. [Google Scholar] [CrossRef]

- Herald, T.J.; Osorio, F.A.; Smith, D.M. Rheological Properties of Pasteurized Liquid Whole Egg During Frozen Storage. J. Food Sci. 1989, 54, 35–38. [Google Scholar] [CrossRef]

- Kilcast, D.; Den Ridder, C. Sensory issues in reducing salt in food products. In Reducing Salt in Foods, Practical Strategies; Woodhead Publishing Series in Food Science, Technology and Nutrition; Woodhead Publishing: Sawston, UK, 2007; pp. 201–220. [Google Scholar] [CrossRef]

- Salger, M.; Stark, T.D.; Hofmann, T. Taste modulating peptides from overfermented cocoa beans. J. Agric. Food Chem. 2019, 67, 4311–4320. [Google Scholar] [CrossRef]

| Enrichment Material | Sensory Attribute | Average | Standard Deviation | Number of Samples |

|---|---|---|---|---|

| Control | Colour preference | 9.38 | 0.83 | 32 |

| Flavour preference | 8.59 | 1.29 | 32 | |

| Chocolate flavour intensity | 8.25 | 1.37 | 32 | |

| Chocolate aroma intensity | 8.31 | 1.18 | 32 | |

| Sweet flavour intensity | 7.5 | 1.52 | 32 | |

| Salty flavour intensity | 1.69 | 1.33 | 32 | |

| Blood plasma | Colour preference | 9.5 | 0.89 | 32 |

| Flavour preference | 8.88 | 1.63 | 16 | |

| Chocolate flavour intensity | 8.5 | 1.71 | 16 | |

| Chocolate aroma intensity | 8.75 | 1.44 | 16 | |

| Sweet flavour intensity | 6.75 | 1.91 | 16 | |

| Salty flavour intensity | 1.5 | 0.73 | 16 | |

| Whole blood | Colour preference | 9.75 | 0.58 | 16 |

| Flavour preference | 7.56 | 2.53 | 16 | |

| Chocolate flavour intensity | 7.38 | 2 | 16 | |

| Chocolate aroma intensity | 7.13 | 2.03 | 16 | |

| Sweet flavour intensity | 5.75 | 1.53 | 16 | |

| Salty flavour intensity | 1.5 | 0.73 | 16 | |

| Haemoglobin | Colour preference | 9.5 | 0.63 | 16 |

| Flavour preference | 8.13 | 1.78 | 16 | |

| Chocolate flavour intensity | 7.25 | 1.61 | 16 | |

| Chocolate aroma intensity | 7.5 | 1.37 | 16 | |

| Sweet flavour intensity | 6.25 | 1.61 | 16 | |

| Salty flavour intensity | 1.5 | 0.73 | 16 | |

| Egg white | Colour preference | 9.25 | 0.77 | 16 |

| Flavour preference | 7.75 | 1.77 | 16 | |

| Chocolate flavour intensity | 6.88 | 1.09 | 16 | |

| Chocolate aroma intensity | 6.88 | 1.09 | 16 | |

| Sweet flavour intensity | 6.19 | 1.68 | 16 | |

| Salty flavour intensity | 1.38 | 0.72 | 16 | |

| Whole egg | Colour preference | 9.19 | 0.83 | 16 |

| Flavour preference | 8.19 | 1.28 | 16 | |

| Chocolate flavour intensity | 7.06 | 1.29 | 16 | |

| Chocolate aroma intensity | 7.06 | 1.29 | 16 | |

| Sweet flavour intensity | 6.63 | 2.09 | 16 | |

| Salty flavour intensity | 1.44 | 0.81 | 16 | |

| Egg yolk | Colour preference | 9.19 | 1.11 | 16 |

| Flavour preference | 7.69 | 1.3 | 16 | |

| Chocolate flavour intensity | 7.13 | 0.96 | 16 | |

| Chocolate aroma intensity | 7.13 | 0.96 | 16 | |

| Sweet flavour intensity | 7.19 | 1.05 | 16 | |

| Salty flavour intensity | 1.25 | 0.58 | 16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Csurka, T.; Hidas, K.I.; Varga-Tóth, A.; Dalmadi, I.; Pásztor-Huszár, K.; Friedrich, L.F. Effect of High Biological Value Animal Protein Sources on the Techno-Functional Properties of Ice Cream. Sustainability 2023, 15, 16794. https://doi.org/10.3390/su152416794

Csurka T, Hidas KI, Varga-Tóth A, Dalmadi I, Pásztor-Huszár K, Friedrich LF. Effect of High Biological Value Animal Protein Sources on the Techno-Functional Properties of Ice Cream. Sustainability. 2023; 15(24):16794. https://doi.org/10.3390/su152416794

Chicago/Turabian StyleCsurka, Tamás, Karina Ilona Hidas, Adrienn Varga-Tóth, István Dalmadi, Klára Pásztor-Huszár, and László Ferenc Friedrich. 2023. "Effect of High Biological Value Animal Protein Sources on the Techno-Functional Properties of Ice Cream" Sustainability 15, no. 24: 16794. https://doi.org/10.3390/su152416794

APA StyleCsurka, T., Hidas, K. I., Varga-Tóth, A., Dalmadi, I., Pásztor-Huszár, K., & Friedrich, L. F. (2023). Effect of High Biological Value Animal Protein Sources on the Techno-Functional Properties of Ice Cream. Sustainability, 15(24), 16794. https://doi.org/10.3390/su152416794