Sustainability in Healthcare Sector: The Dental Aligners Case

Abstract

:1. Introduction

State of the Art

2. Materials and Methods

2.1. Goal and Scope Definition

2.2. Inventory Characterization

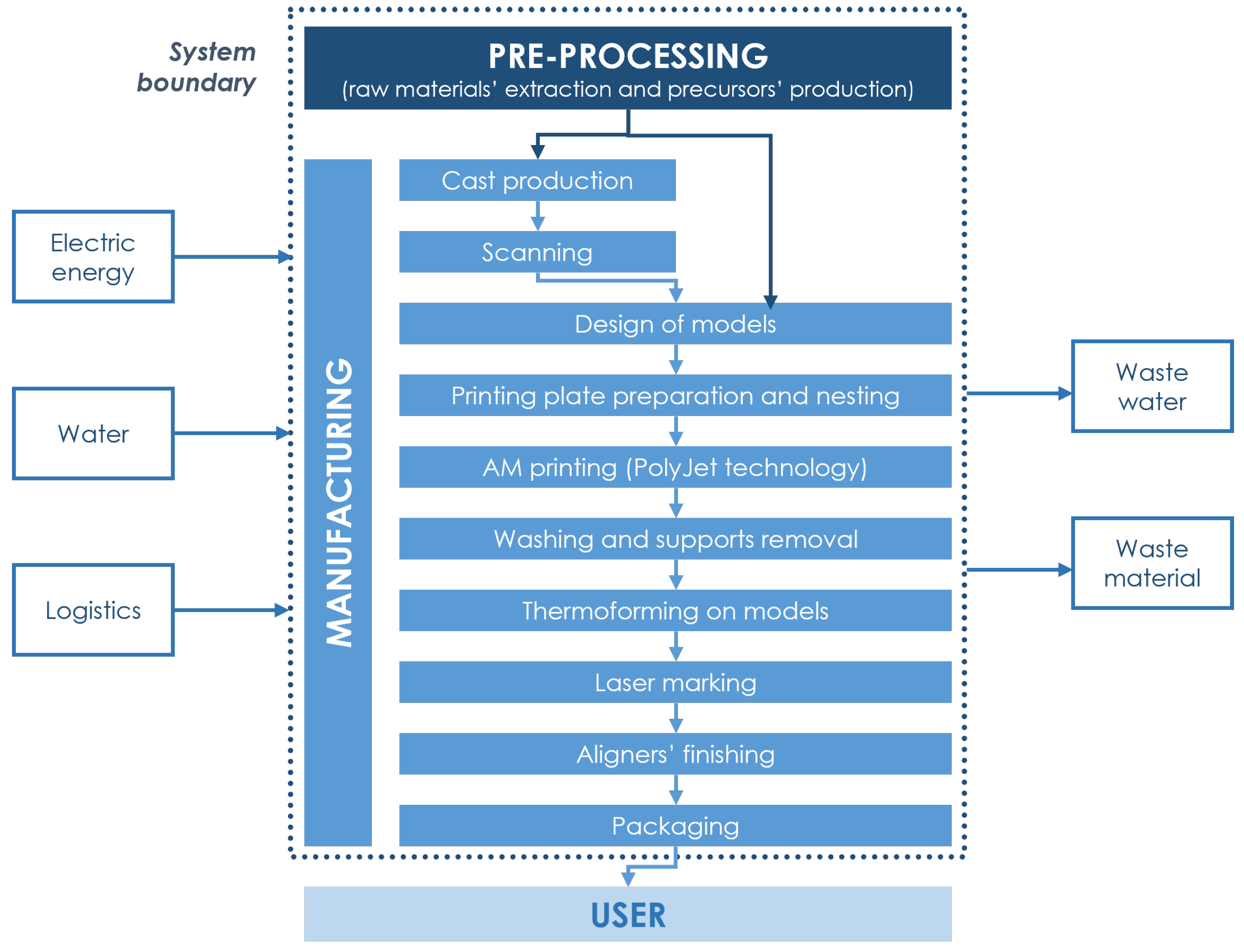

2.2.1. Thermoforming

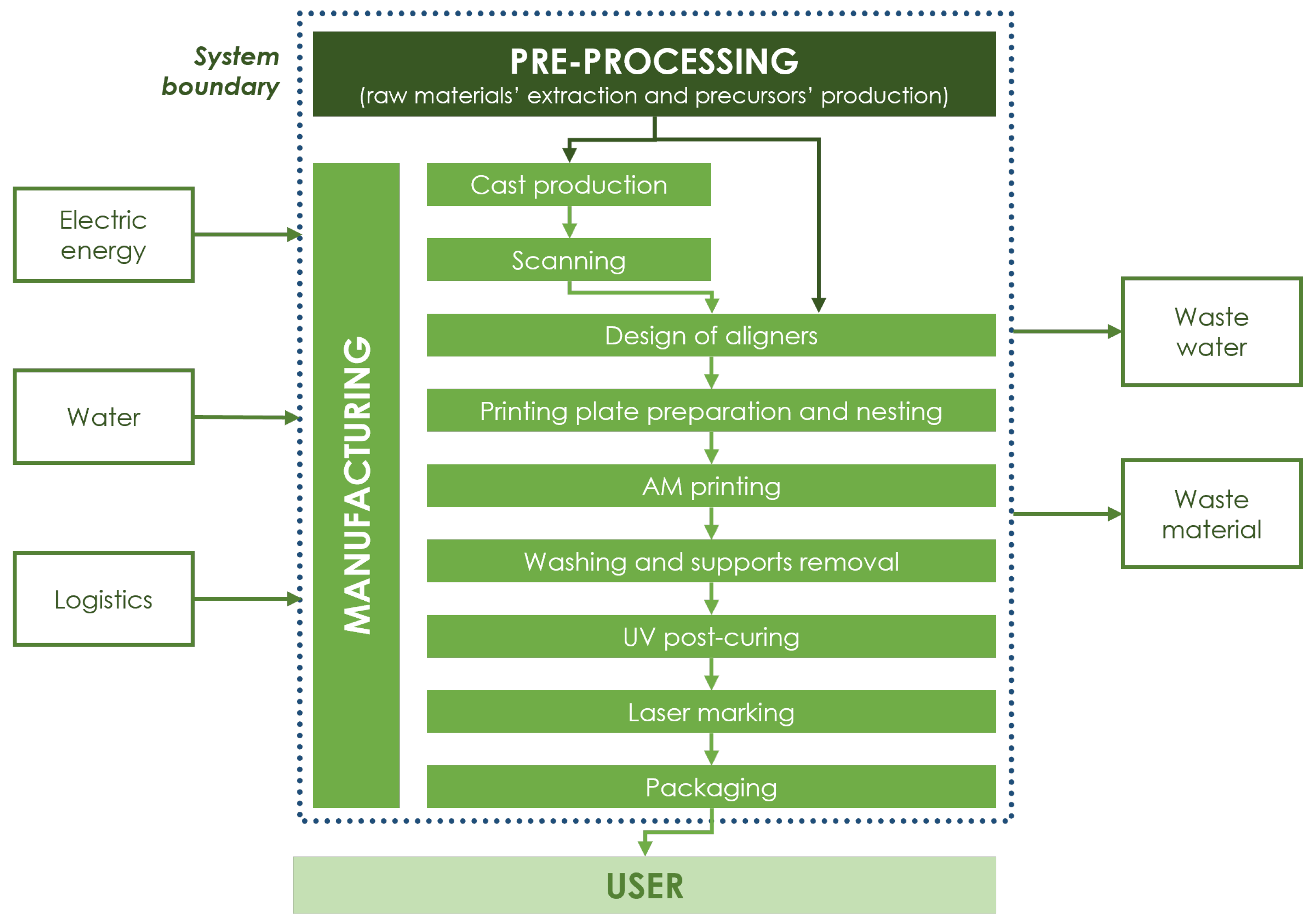

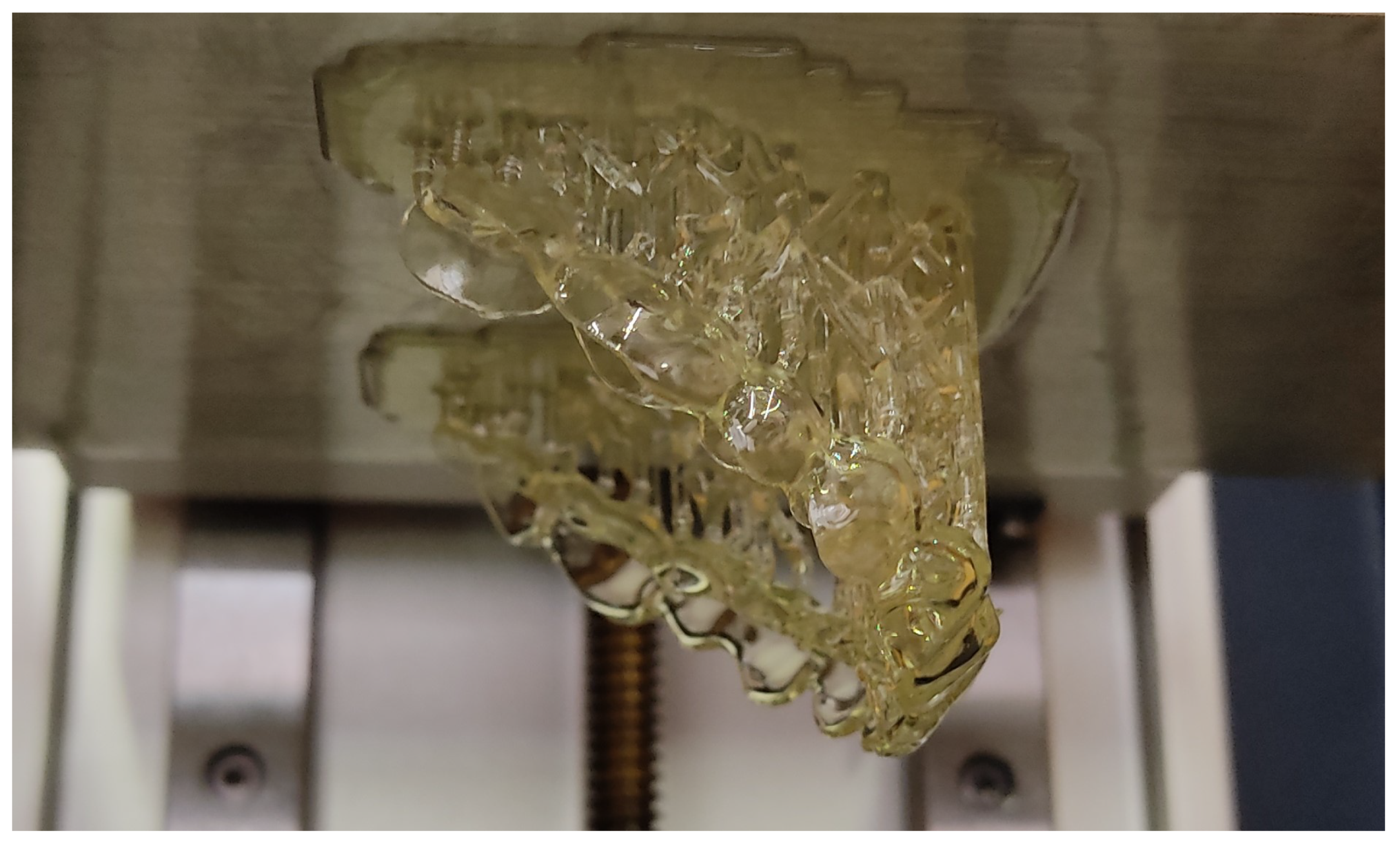

2.2.2. Additive Manufacturing

2.2.3. Materials

2.2.4. Energy and Logistics

3. Results

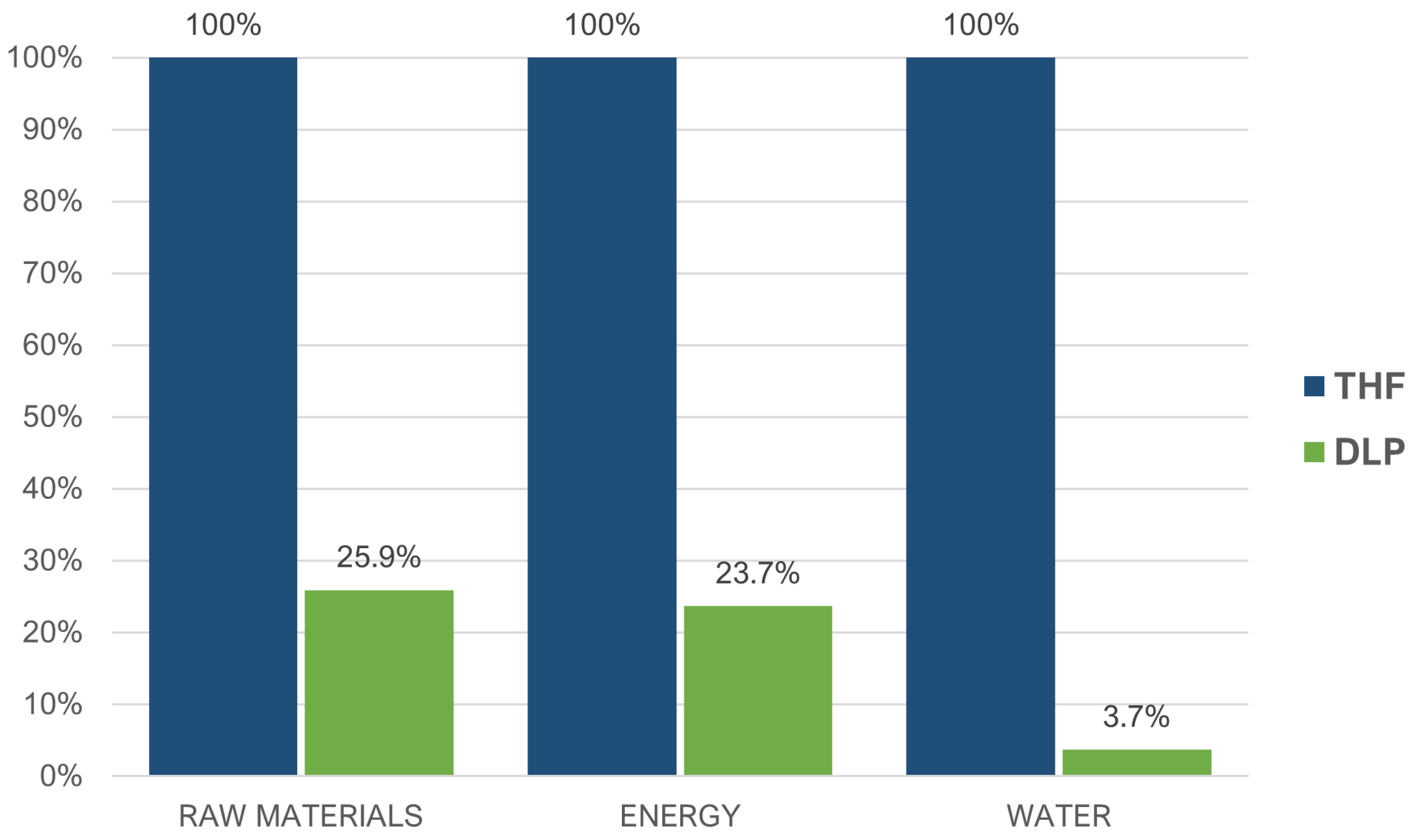

3.1. Comparative Analysis

3.2. Interpretation and Discussion

3.3. Limitations of the Study

4. Conclusions and Future Research

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Tech | Process Step | Item | Provider |

|---|---|---|---|

| THF | Cast production | Cast material | market for gypsum, mineral|gypsum, mineral|Cutoff, U (RER) |

| THF | Cast production | Cast material | market for transport, freight, lorry, unspecified|transport, freight, lorry, unspecified|Cutoff, U (RER) |

| THF | Cast production | Water | market for tap water|tap water|Cutoff, U (Europe without Switzerland) |

| THF | Cast production | Cast | market for waste gypsum|waste gypsum|Cutoff, U (Europe without Switzerland) |

| THF | Scanning | Electric energy | electricity, low voltage, residual mix|electricity, low voltage|Cutoff, U (IT) |

| THF | Design of models | Electric energy | electricity, low voltage, residual mix|electricity, low voltage|Cutoff, U (IT) |

| THF | Printing plate preparation and nesting | Electric energy | electricity, low voltage, residual mix|electricity, low voltage|Cutoff, U (IT) |

| THF | AM printing | Electric energy | electricity, low voltage, residual mix|electricity, low voltage|Cutoff, U (IT) |

| THF | AM printing | Model material | Model material |

| THF | AM printing | Model material | market for transport, freight, lorry, unspecified|transport, freight, lorry, unspecified|Cutoff, U (RER) |

| THF | AM printing | Support material | Support material |

| THF | AM printing | Support material | market for transport, freight, lorry, unspecified|transport, freight, lorry, unspecified|Cutoff, U (RER) |

| THF | AM printing | Purges | market for hazardous waste, for incineration|hazardous waste, for incineration|Cutoff, U (Europe without Switzerland) |

| THF | Supports removal | Electric energy | electricity, low voltage, residual mix|electricity, low voltage|Cutoff, U (IT) |

| THF | Supports removal | Water | market for tap water|tap water|Cutoff, U (Europe without Switzerland) |

| THF | Supports removal | Wastewater | market for wastewater, average|wastewater, average|Cutoff, U (Europe without Switzerland) |

| THF | Thermoforming | Aligners material | PETG |

| THF | Thermoforming | Electric energy | electricity, low voltage, residual mix|electricity, low voltage|Cutoff, U (IT) |

| THF | Laser marking | Electric energy | electricity, low voltage, residual mix|electricity, low voltage|Cutoff, U (IT) |

| THF | Finishing | Electric energy | electricity, low voltage, residual mix|electricity, low voltage|Cutoff, U (IT) |

| THF | Finishing | Material waste | market for waste plastic, mixture|waste plastic, mixture|Cutoff, U (IT) |

| THF | Packaging | Plastic bags | LDPE bag |

| THF | Packaging | Cardboard box | folding boxboard carton production|folding boxboard carton|Cutoff, U (RER) |

| THF | Packaging | Info book | paper production, woodcontaining, supercalendered|paper, woodcontaining, supercalendered|Cutoff, U (RER) |

| THF | Packaging | Byte case | PP case |

| THF | Packaging | Plastic bags | market for transport, freight, lorry, unspecified|transport, freight, lorry, unspecified|Cutoff, U (RER) |

| THF | Packaging | Cardboard box | market for transport, freight, lorry, unspecified|transport, freight, lorry, unspecified|Cutoff, U (RER) |

| THF | Packaging | Info book | market for transport, freight, lorry, unspecified|transport, freight, lorry, unspecified|Cutoff, U (RER) |

| THF | Packaging | Byte case | market for transport, freight, lorry, unspecified|transport, freight, lorry, unspecified|Cutoff, U (RER) |

| AM DLP | Cast production | Cast material | market for gypsum, mineral|gypsum, mineral|Cutoff, U (RER) |

| AM DLP | Cast production | Cast material | market for transport, freight, lorry, unspecified|transport, freight, lorry, unspecified|Cutoff, U (RER) |

| AM DLP | Cast production | Water | market for tap water|tap water|Cutoff, U (Europe without Switzerland) |

| AM DLP | Cast production | Cast waste | market for waste gypsum|waste gypsum|Cutoff, U (Europe without Switzerland) |

| AM DLP | Scanning | Electric energy | electricity, low voltage, residual mix|electricity, low voltage|Cutoff, U (IT) |

| AM DLP | Design of aligners | Electric energy | electricity, low voltage, residual mix|electricity, low voltage|Cutoff, U (IT) |

| AM DLP | Printing plate preparation and nesting | Electric energy | electricity, low voltage, residual mix|electricity, low voltage|Cutoff, U (IT) |

| AM DLP | AM printing | Electric energy | electricity, low voltage, residual mix|electricity, low voltage|Cutoff, U (IT) |

| AM DLP | AM printing | Aligner material | Aligner AM DLP |

| AM DLP | AM printing | Aligner material | market for transport, freight, lorry, unspecified|transport, freight, lorry, unspecified|Cutoff, U (RER) |

| AM DLP | AM printing | Material waste | market for waste plastic, mixture|waste plastic, mixture|Cutoff, U (IT) |

| AM DLP | AM printing | Electric energy | electricity, low voltage, residual mix|electricity, low voltage|Cutoff, U (IT) |

| AM DLP | Supports removal | Water | market for tap water|tap water|Cutoff, U (Europe without Switzerland) |

| AM DLP | Supports removal | Wastewater | market for wastewater, average|wastewater, average|Cutoff, U (Europe without Switzerland) |

| AM DLP | UV post-curing | Electric energy | electricity, low voltage, residual mix|electricity, low voltage|Cutoff, U (IT) |

| AM DLP | Laser marking | Electric energy | electricity, low voltage, residual mix|electricity, low voltage|Cutoff, U (IT) |

| AM DLP | Packaging | Plastic bags | LDPE bag |

| AM DLP | Packaging | Cardboard box | folding boxboard carton production|folding boxboard carton|Cutoff, U (RER) |

| AM DLP | Packaging | Info book | paper production, woodcontaining, supercalendered|paper, woodcontaining, supercalendered|Cutoff, U (RER) |

| AM DLP | Packaging | Byte case | PP case |

| AM DLP | Packaging | Plastic bags | market for transport, freight, lorry, unspecified|transport, freight, lorry, unspecified|Cutoff, U (RER) |

| AM DLP | Packaging | Cardboard box | market for transport, freight, lorry, unspecified|transport, freight, lorry, unspecified|Cutoff, U (RER) |

| AM DLP | Packaging | Info book | market for transport, freight, lorry, unspecified|transport, freight, lorry, unspecified|Cutoff, U (RER) |

| AM DLP | Packaging | Byte case | market for transport, freight, lorry, unspecified|transport, freight, lorry, unspecified|Cutoff, U (RER) |

Appendix B

| Impact Category | THF | AM DLP |

|---|---|---|

| acidification | 4.077 × 10 | 1.119 × 10 |

| climate change (GWP100) | 1.251 × 10 | 3.120 × 10 |

| climate change: biogenic | 4.602 × 10 | 1.537 × 10 |

| climate change: fossil | 1.245 × 10 | 3.099 × 10 |

| climate change: land use and land use change | 9.599 × 10 | 5.742 × 10 |

| ecotoxicity: freshwater | 1.309 × 10 | 2.228 × 10 |

| ecotoxicity: freshwater, inorganics | 9.837 × 10 | 1.264 × 10 |

| ecotoxicity: freshwater, organics | 3.257 × 10 | 9.637 × 10 |

| energy resources: non-renewable | 1.889 × 10 | 5.215 × 10 |

| eutrophication: freshwater | 3.160 × 10 | 7.543 × 10 |

| eutrophication: marine | 1.257 × 10 | 2.500 × 10 |

| eutrophication: terrestrial | 8.218 × 10 | 2.023 × 10 |

| human toxicity: carcinogenic | 6.141 × 10 | 1.827 × 10 |

| human toxicity: carcinogenic, inorganics | 3.350 × 10 | 6.145 × 10 |

| human toxicity: carcinogenic, organics | 2.791 × 10 | 1.212 × 10 |

| human toxicity: non-carcinogenic | 1.462 × 10 | 3.158 × 10 |

| human toxicity: non-carcinogenic, inorganics | 1.359 × 10 | 2.975 × 10 |

| human toxicity: non-carcinogenic, organics | 1.030 × 10 | 1.830 × 10 |

| ionising radiation: human health | 9.190 × 10 | 3.155 × 10 |

| land use | 7.305 × 10 | 5.065 × 10 |

| abiotic depletion potential (ADP) | 8.306 × 10 | 1.889 × 10 |

| ozone depletion (ODP) | 3.798 × 10 | 9.062 × 10 |

| particulate matter formation | 4.518 × 10 | 1.662 × 10 |

| photochemical oxidant formation | 3.041 × 10 | 8.898 × 10 |

| water use | 4.322 × 10 | 1.041 × 10 |

References

- Alfaify, A.; Saleh, M.; Abdullah, F.M.; Al-Ahmari, A.M. Design for Additive Manufacturing: A Systematic Review. Sustainability 2020, 12, 7936. [Google Scholar] [CrossRef]

- Suárez, L.; Domínguez, M. Sustainability and environmental impact of fused deposition modelling (FDM) technologies. Int. J. Adv. Manuf. Technol. 2020, 106, 1267–1279. [Google Scholar] [CrossRef]

- Kellens, K.; Baumers, M.; Gutowski, T.G.; Flanagan, W.; Lifset, R.; Duflou, J.R. Environmental Dimensions of Additive Manufacturing: Mapping Application Domains and Their Environmental Implications. J. Ind. Ecol. 2017, 21, S49–S68. [Google Scholar] [CrossRef]

- Tamburrino, F.; D’Antò, V.; Bucci, R.; Alessandri-Bonetti, G.; Barone, S.; Razionale, A.V. Mechanical properties of thermoplastic polymers for aligner manufacturing: In vitro study. Dent. J. 2020, 8, 47. [Google Scholar] [CrossRef] [PubMed]

- Available online: https://www.dental-tribune.com/news/when-do-you-waste-unused-aligners-and-how-can-you-avoid-it/ (accessed on 20 June 2023).

- BS EN ISO 14040:2006; Environmental Management. Life Cycle Assessment. Principles and Framework. BSI: London, UK, 2006.

- BS EN ISO 14044:2006; Environmental Management. Life Cycle Assessment. Requirements and Guidelines. BSI: London, UK, 2006.

- Tartaglia, G.M.; Mapelli, A.; Maspero, C.; Santaniello, T.; Serafin, M.; Farronato, M.; Caprioglio, A. Direct 3D printing of clear orthodontic aligners: Current state and future possibilities. Materials 2021, 14, 1799. [Google Scholar] [CrossRef] [PubMed]

- Milovanović, A.; Sedmak, A.; Golubović, Z.; Mihajlović, K.Z.; Žurkić, A.; Trajković, I.; Milošević, M. The effect of time on mechanical properties of biocompatible photopolymer resins used for fabrication of clear dental aligners. J. Mech. Behav. Biomed. Mater. 2021, 119, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Koenig, N.; Choi, J.Y.; McCray, J.; Hayes, A.; Schneider, P.; Kim, K.B. Comparison of dimensional accuracy between direct-printed and thermoformed aligners. Korean J. Orthod. 2022, 52, 249–257. [Google Scholar] [CrossRef] [PubMed]

- Barone, S.; Neri, P.; Paoli, A.; Razionale, A.V.; Tamburrino, F. Development of a DLP 3D printer for orthodontic applications. Procedia Manuf. 2019, 38, 1017–1025. [Google Scholar] [CrossRef]

- Barazanchi, A.; Li, K.C.; Al-Amleh, B.; Lyons, K.; Waddell, J.N. Additive Technology: Update on Current Materials and Applications in Dentistry. J. Prosthodont. 2017, 26, 156–163. [Google Scholar] [CrossRef] [PubMed]

- Jindal, P.; Juneja, M.; Siena, F.L.; Bajaj, D.; Breedon, P. Mechanical and geometric properties of thermoformed and 3D printed clear dental aligners. Am. J. Orthod. Dentofac. Orthop. 2019, 156, 694–701. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Lambart, A.L.; Stawarczyk, B.; Reymus, M.; Spintzyk, S. Postpolymerization of a 3D-printed denture base polymer: Impact of post-curing methods on surface characteristics, flexural strength, and cytotoxicity. J. Dent. 2021, 115, 103856. [Google Scholar] [CrossRef] [PubMed]

- FayyazAhamed, S.; Kumar, S.M.; Vijayakumar, R.K.; AprosKanna, A.S.; Indrapriyadharshini, K. Cytotoxic evaluation of directly 3D printed aligners and Invisalign. Eur. J. Mol. Clin. Med. 2020, 7, 1129–1140. [Google Scholar]

- Maspero, C.; Tartaglia, G.M. 3D printing of clear orthodontic aligners: Where we are and where we are going. Materials 2020, 13, 5204. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.Y.; Kim, H.; Kim, H.J.; Chung, C.J.; Choi, Y.J.; Kim, S.J.; Cha, J.Y. Thermo-mechanical properties of 3D printed photocurable shape memory resin for clear aligners. Sci. Rep. 2022, 12, 6246. [Google Scholar] [CrossRef] [PubMed]

- Taddese, G.; Durieux, S.; Duc, E. Sustainability performance indicators for additive manufacturing: A literature review based on product life cycle studies. Int. J. Adv. Manuf. Technol. 2020, 107, 3109–3134. [Google Scholar] [CrossRef]

- Výtisk, J.; Kočí, V.; Honus, S.; Vrtek, M. Current options in the life cycle assessment of additive manufacturing products. Open Eng. 2019, 9, 674–682. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Caelli, C.; Tamburrino, F.; Brondi, C.; Razionale, A.V.; Ballarino, A.; Barone, S. Sustainability in Healthcare Sector: The Dental Aligners Case. Sustainability 2023, 15, 16757. https://doi.org/10.3390/su152416757

Caelli C, Tamburrino F, Brondi C, Razionale AV, Ballarino A, Barone S. Sustainability in Healthcare Sector: The Dental Aligners Case. Sustainability. 2023; 15(24):16757. https://doi.org/10.3390/su152416757

Chicago/Turabian StyleCaelli, Chiara, Francesco Tamburrino, Carlo Brondi, Armando Viviano Razionale, Andrea Ballarino, and Sandro Barone. 2023. "Sustainability in Healthcare Sector: The Dental Aligners Case" Sustainability 15, no. 24: 16757. https://doi.org/10.3390/su152416757

APA StyleCaelli, C., Tamburrino, F., Brondi, C., Razionale, A. V., Ballarino, A., & Barone, S. (2023). Sustainability in Healthcare Sector: The Dental Aligners Case. Sustainability, 15(24), 16757. https://doi.org/10.3390/su152416757