Features and Sustainable Design of Firefighting Safety Footwear for Fire Extinguishing and Rescue Operations

Abstract

:1. Introduction

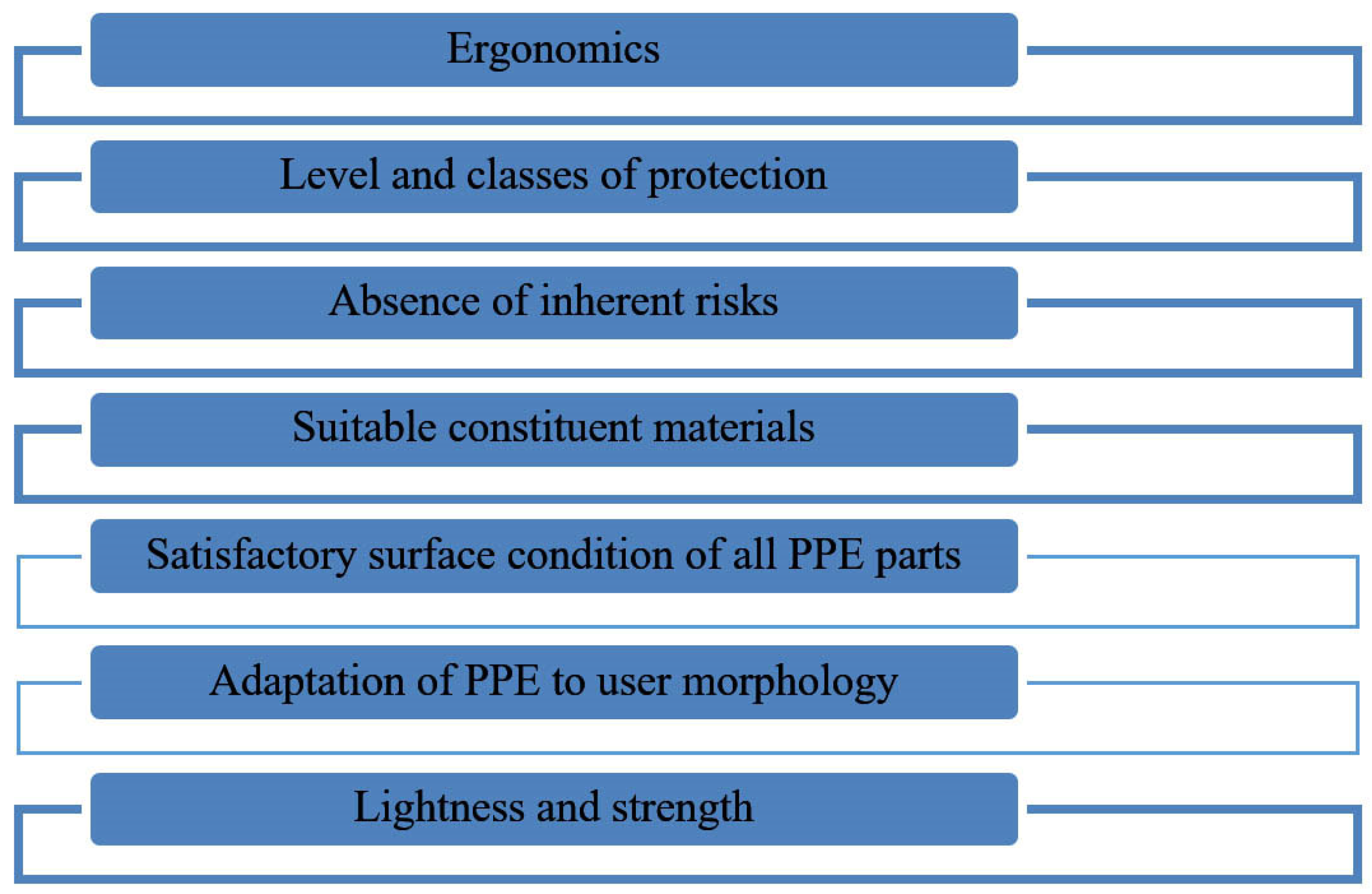

2. General Requirements Relating to All Kinds of PPE

3. Test Methods for Firefighting Footwear

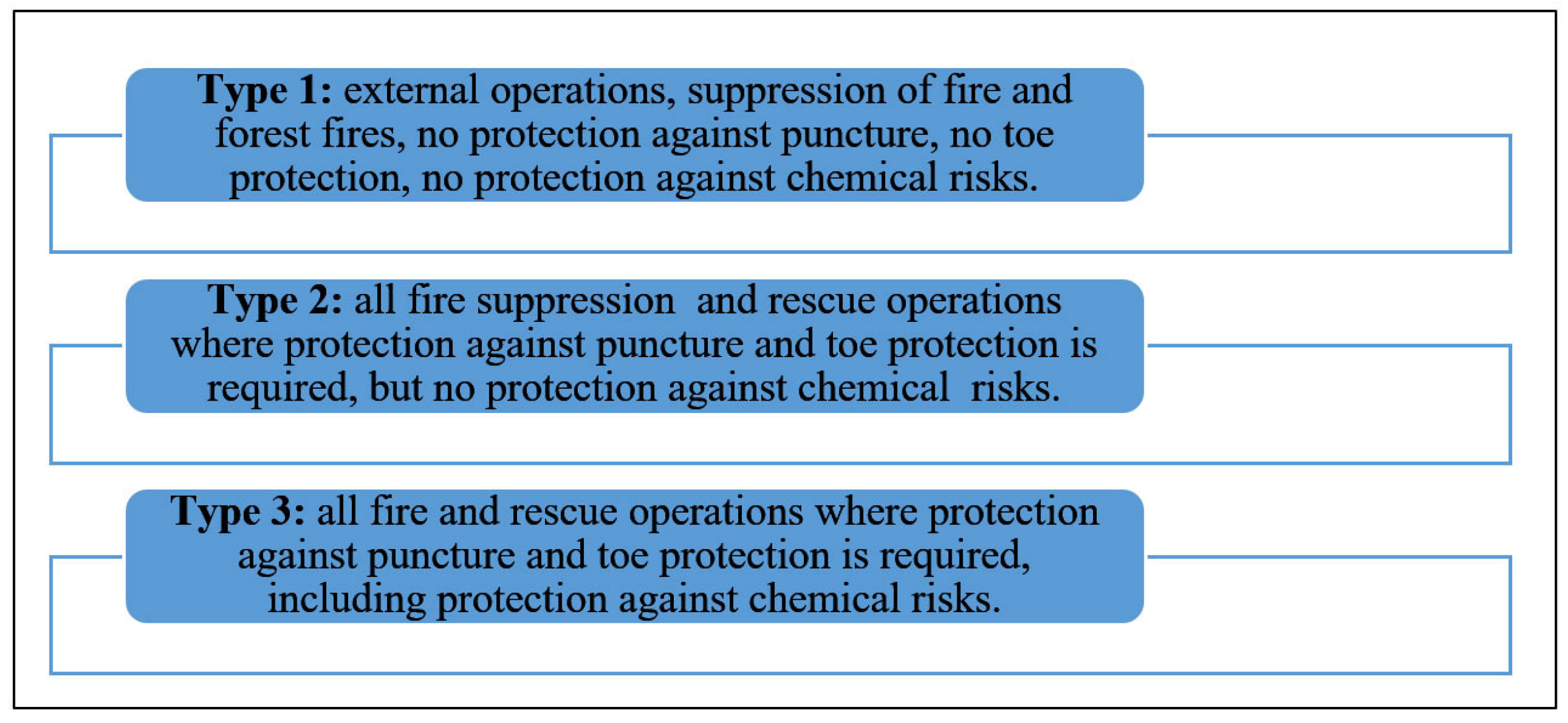

- Type 1—suitable for general rescue, firefighting involving forest fires, agricultural crops or agricultural land.

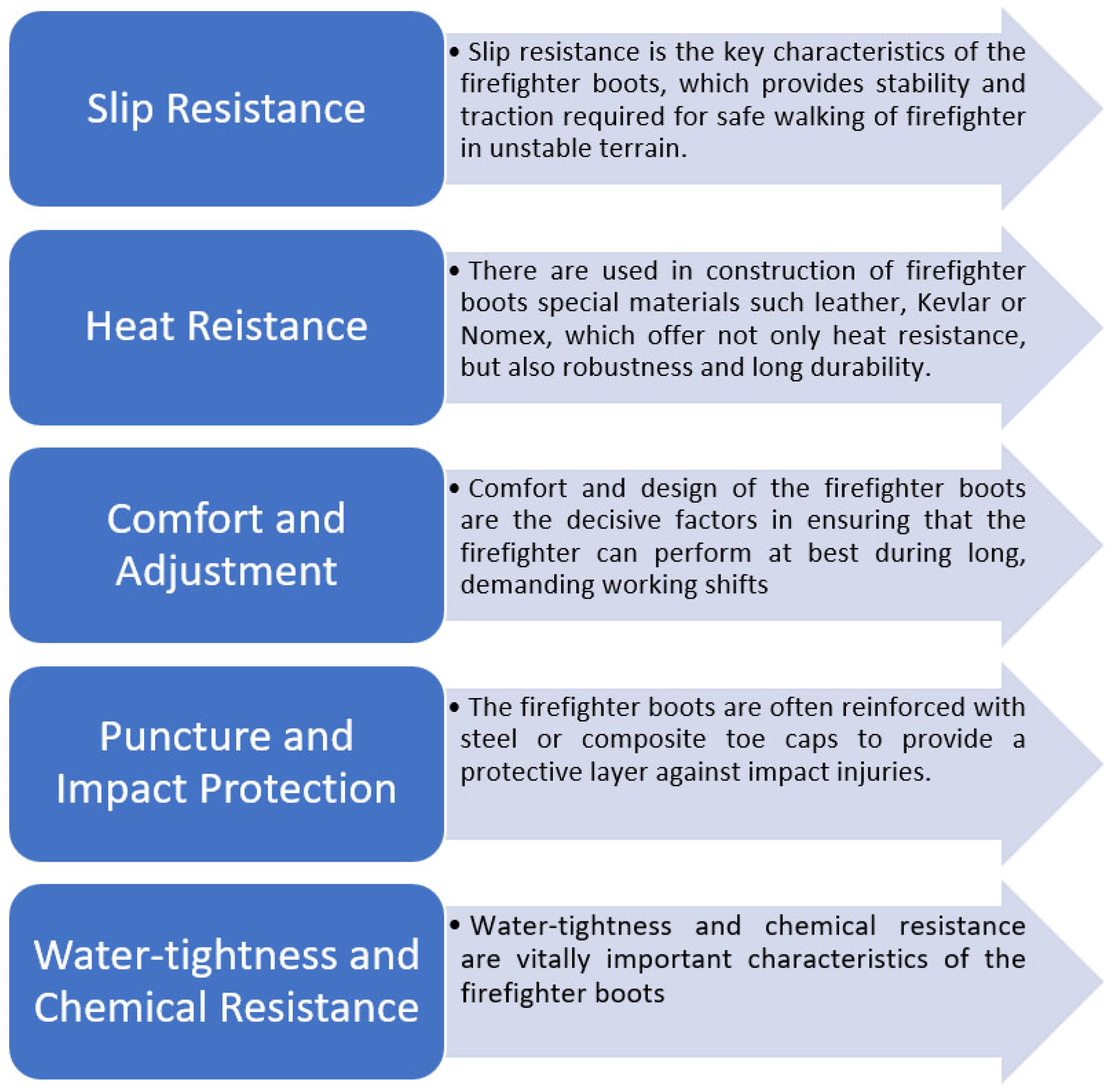

- Type 2—suitable for general rescue operations, fire extinguishing in buildings, in closed structures involved in fire. Type 2 includes all risks of Type 1.

- Type 3—suitable for hazardous material emergencies involving the release of dangerous chemicals, property conservation in aircraft, buildings, vehicles, etc.

- Insulation against heat;

- Radiant heat;

- Flame resistant test;

- Pressure resistance of toe cap;

- Test of zipper.

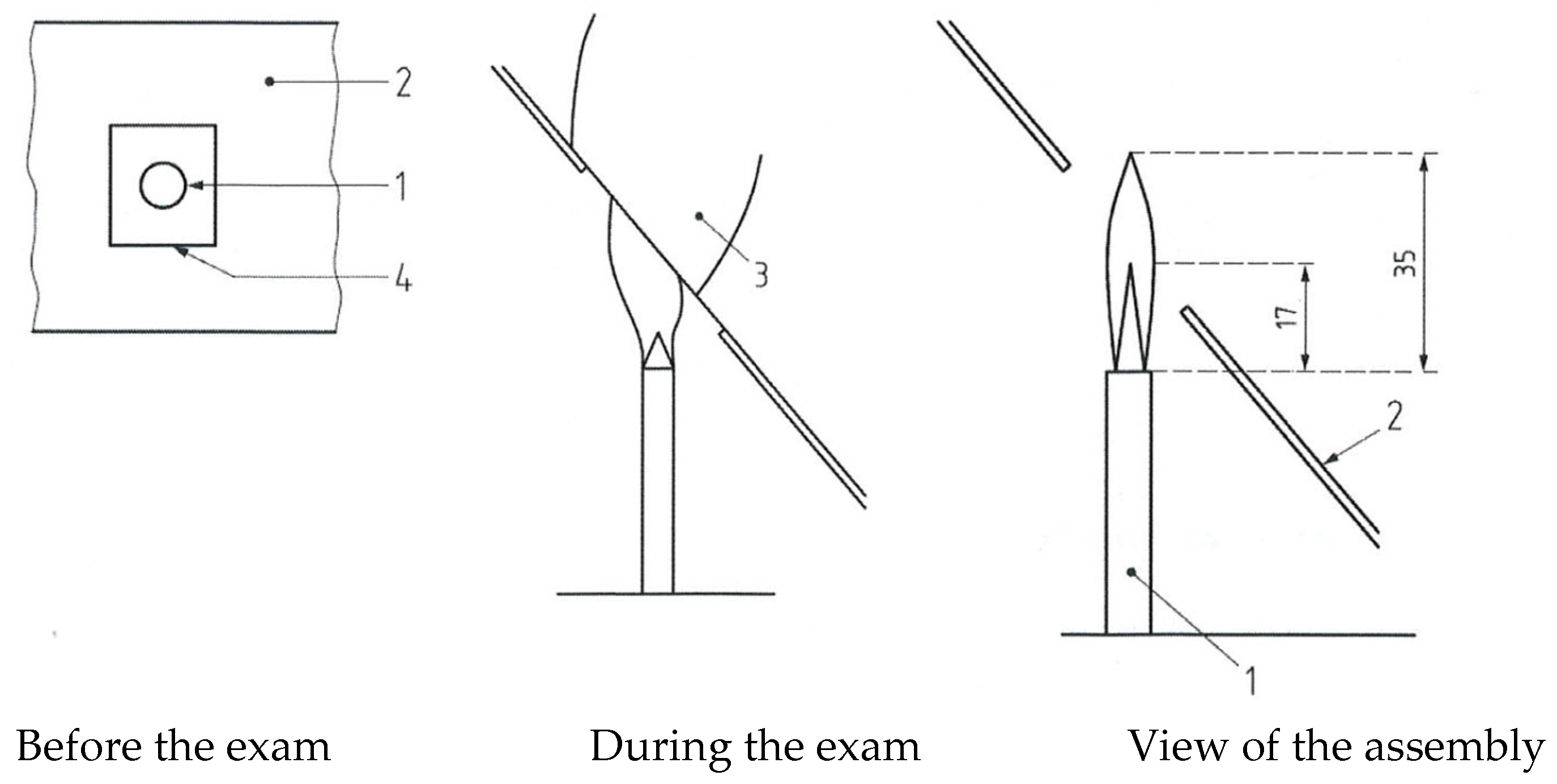

3.1. Testing of Footwear for Flame Resistance

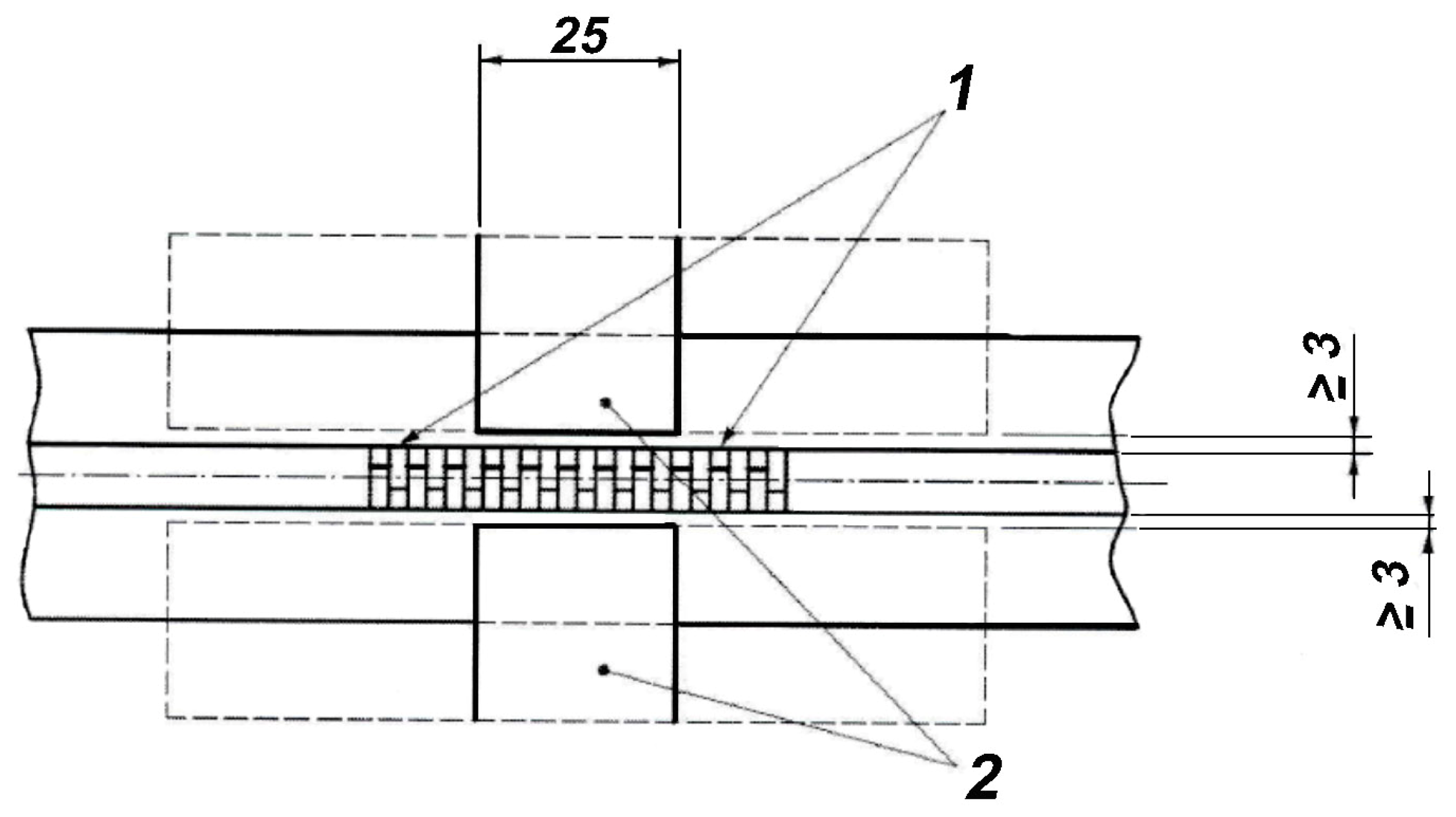

3.2. Test of Zipper

4. Marking of Firefighting Footwear

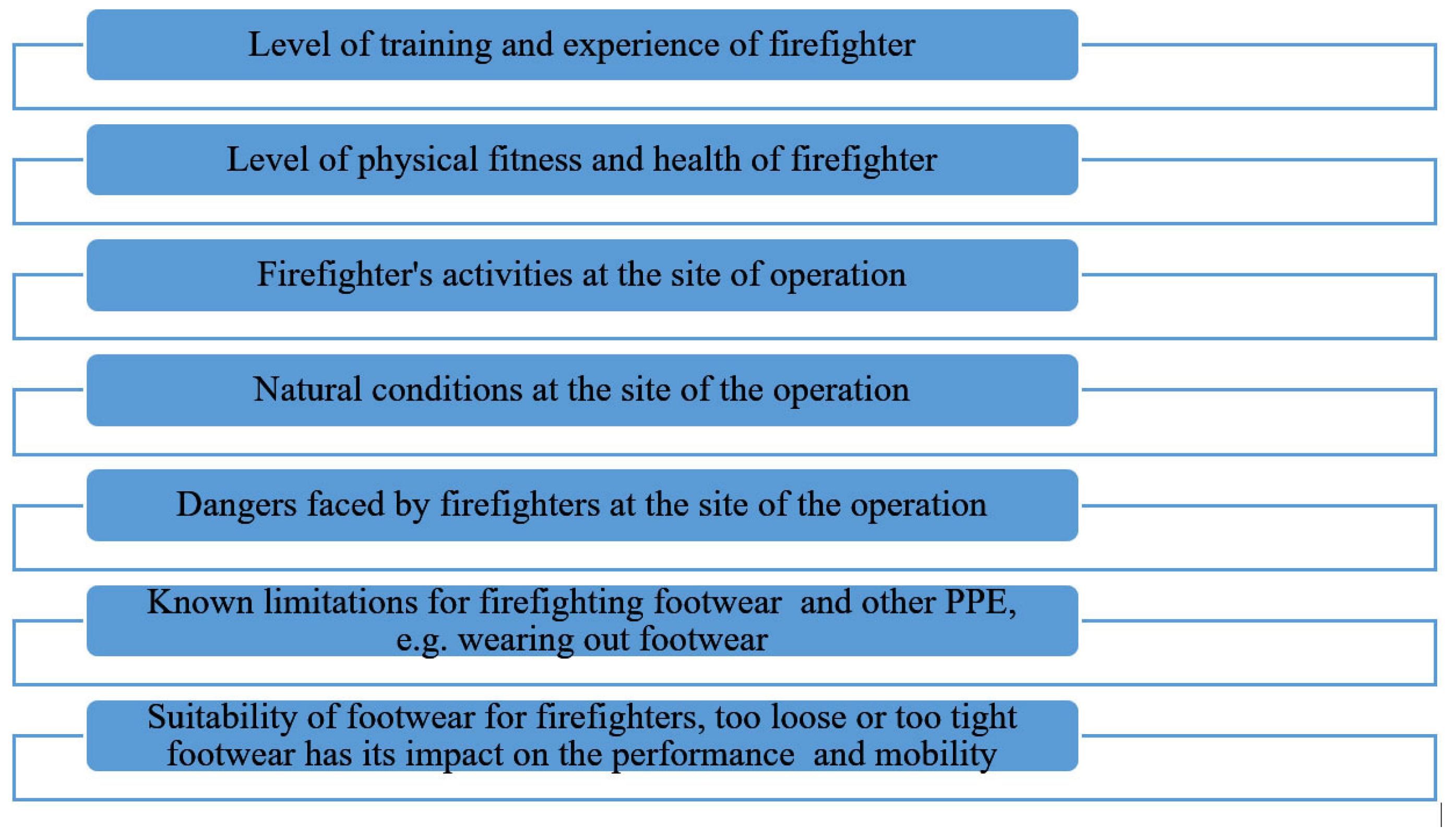

5. Assessment of Risks

- 1.

- Identification of risk

- 2.

- Assessment of risk

- 3.

- Management of risk

Criteria for Risk Assessment

- Thermal resistance;

- Anti-corrosion resistance;

- Resistance to puncture, cut and abrasion;

- Resistance to conductive heat (limited inner sole temperature);

- Anti-slip resistance;

- Attachment strength (closure, cover cuffs and lacing);

- Anti-flame resistance;

- Thermal resistance of sewing thread.

6. Example of Footwear Suitability Assessment by Testing Thermal Properties in the Laboratory

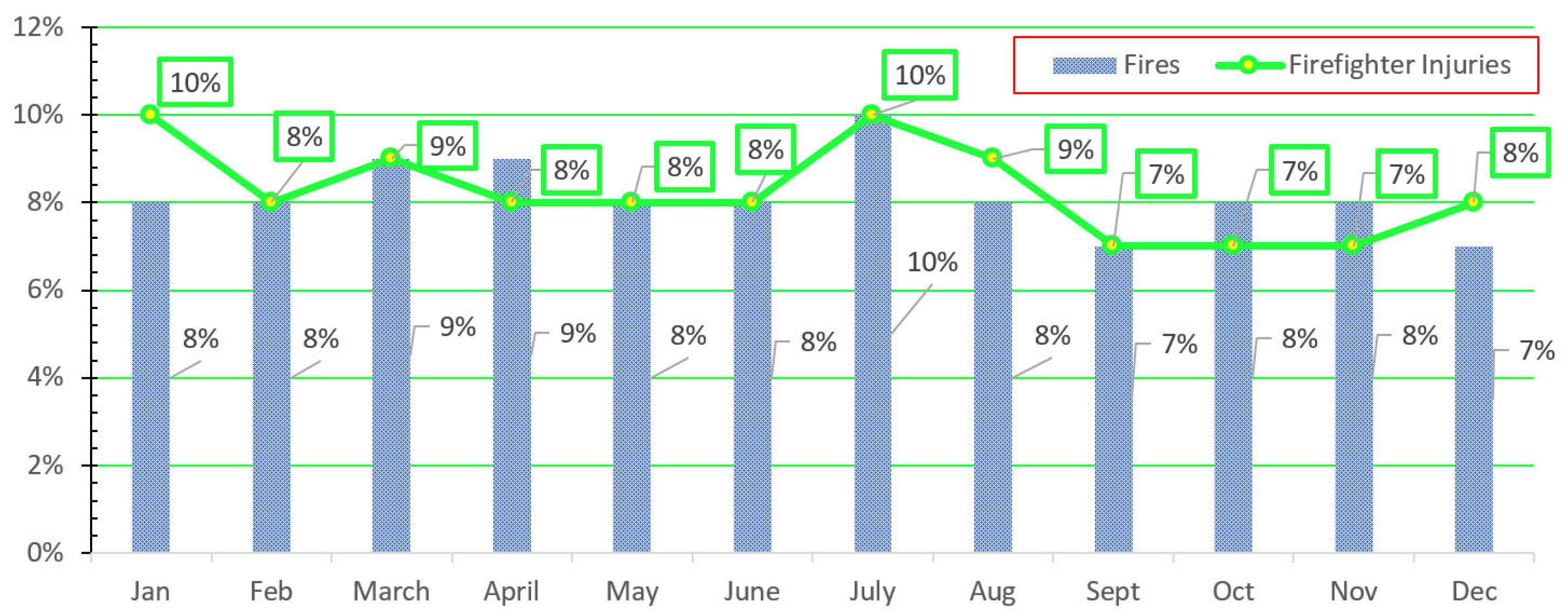

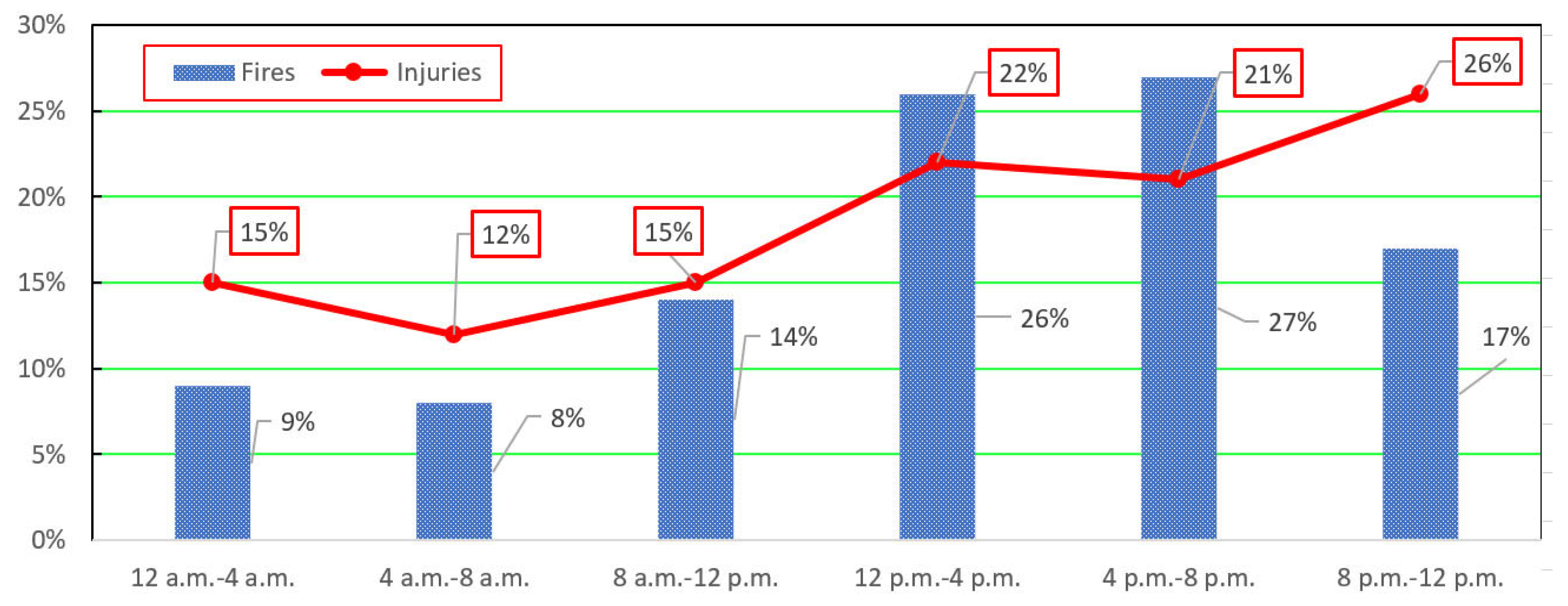

6.1. Importance of Protective Equipment during Firefighters’ Interventions

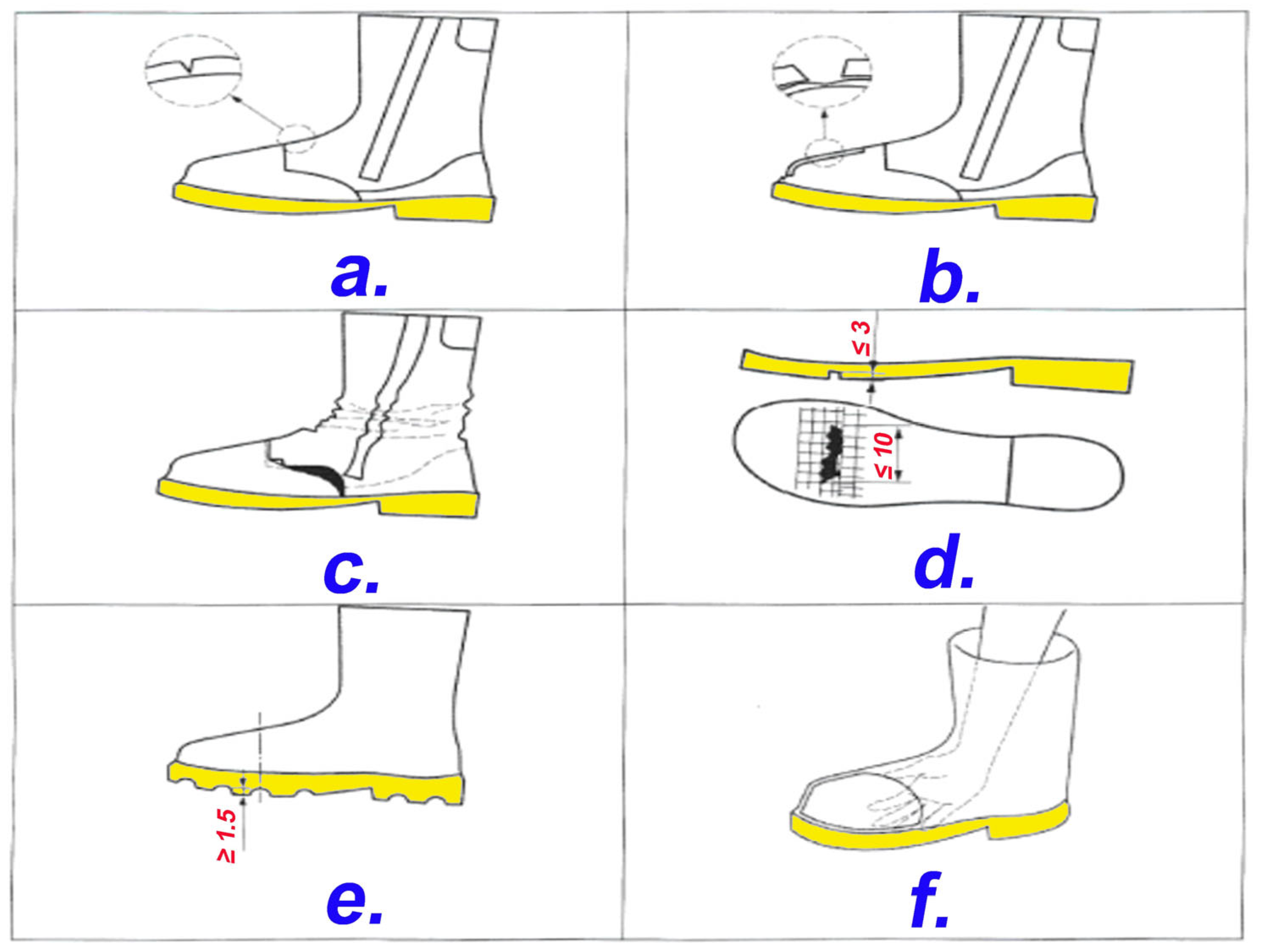

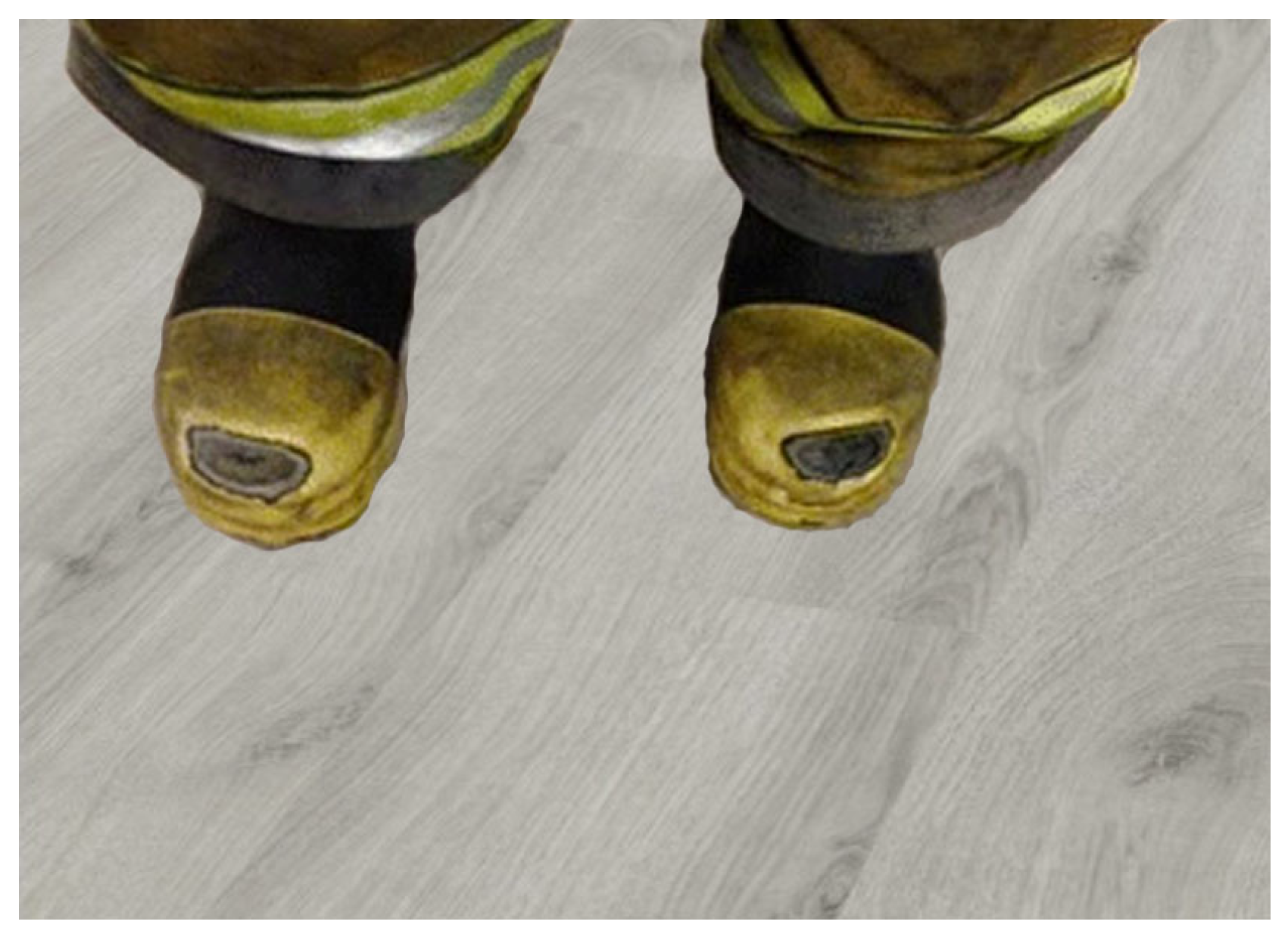

6.2. Firefighting Boots

- Hydrophobic waterproof leather;

- Lining laminate equipped with special foam interior is extra resistant to wear; the leather upper is covered by quality protective rubber;

- Rubber cap is placed in toe cap area.

7. Example of Footwear Determined for Firefighting Intervention

7.1. The Footwear for Firefighting Intervention in the Case of Forest Fires VFT XTREME BOOTS—EN 15090:2012 F1PA + HI3 + CI + SRC, Oeko-Tex

- it is a special piece of footwear determined for firefighting intervention in the case of field fires and forest fires;

- it stands out for its low weight, extreme comfort, top protection and high durability;

- it is designed for long-term firefighting interventions in difficult terrain;

- it contains innovative materials and structures;

- it is certified according to standards valid for firefighting footwear;

- it is fire resistant, glow resistant, waterproof and antistatic;

- the upper part of the shoe is made from a light fabric, which is resistant to mechanical wear and damage;

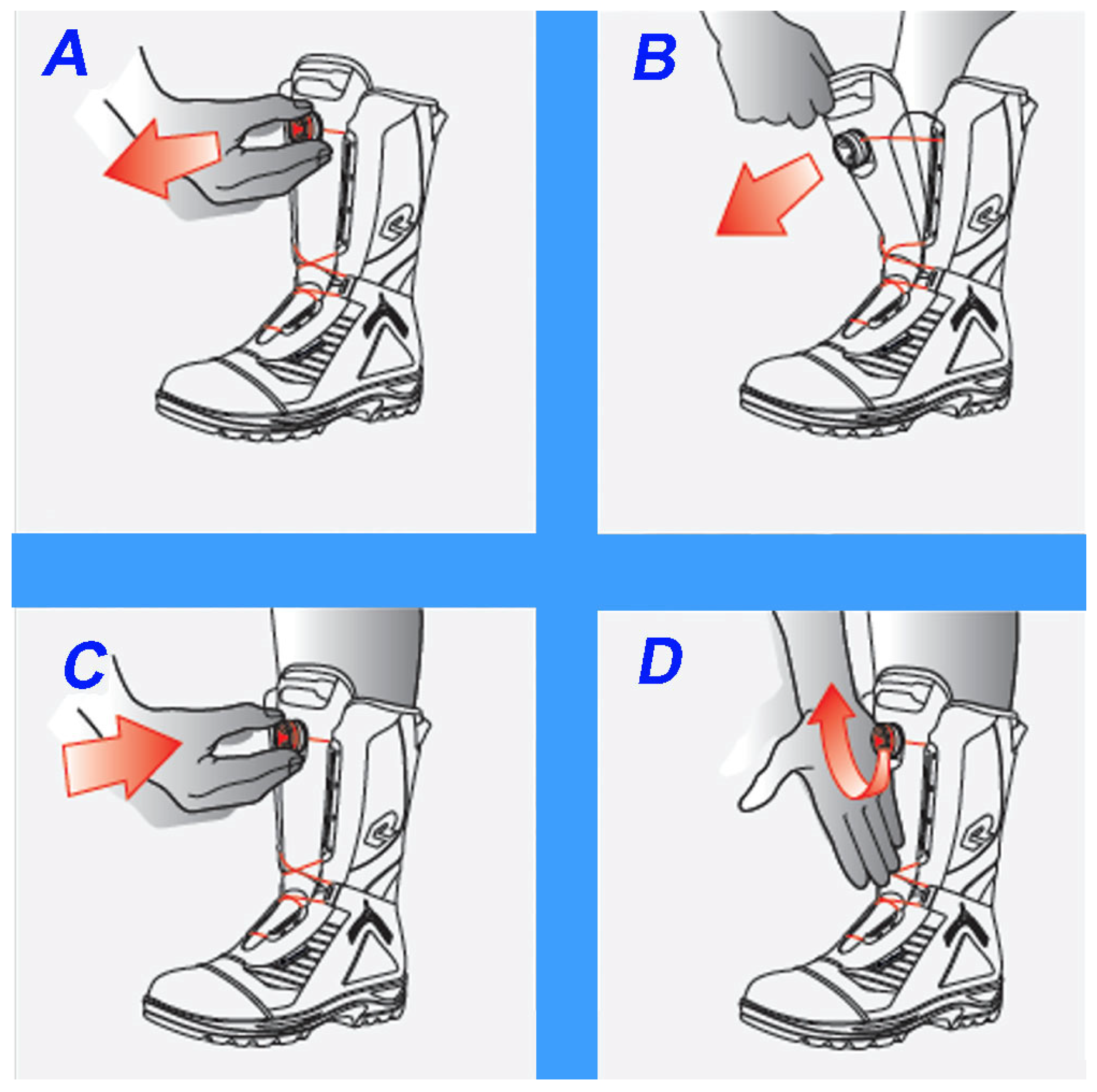

- the shoes are fastened by quick-release fasteners and non-flammable laces;

- it contains Kevlar protection against puncture;

- is equipped with a protection of the front part, which is made from durable microfibers, against impact of heavy objects and against digging;

- it has a nitrile-rubber sole;

- it is ecological, recyclable, antibacterial and antifungal.

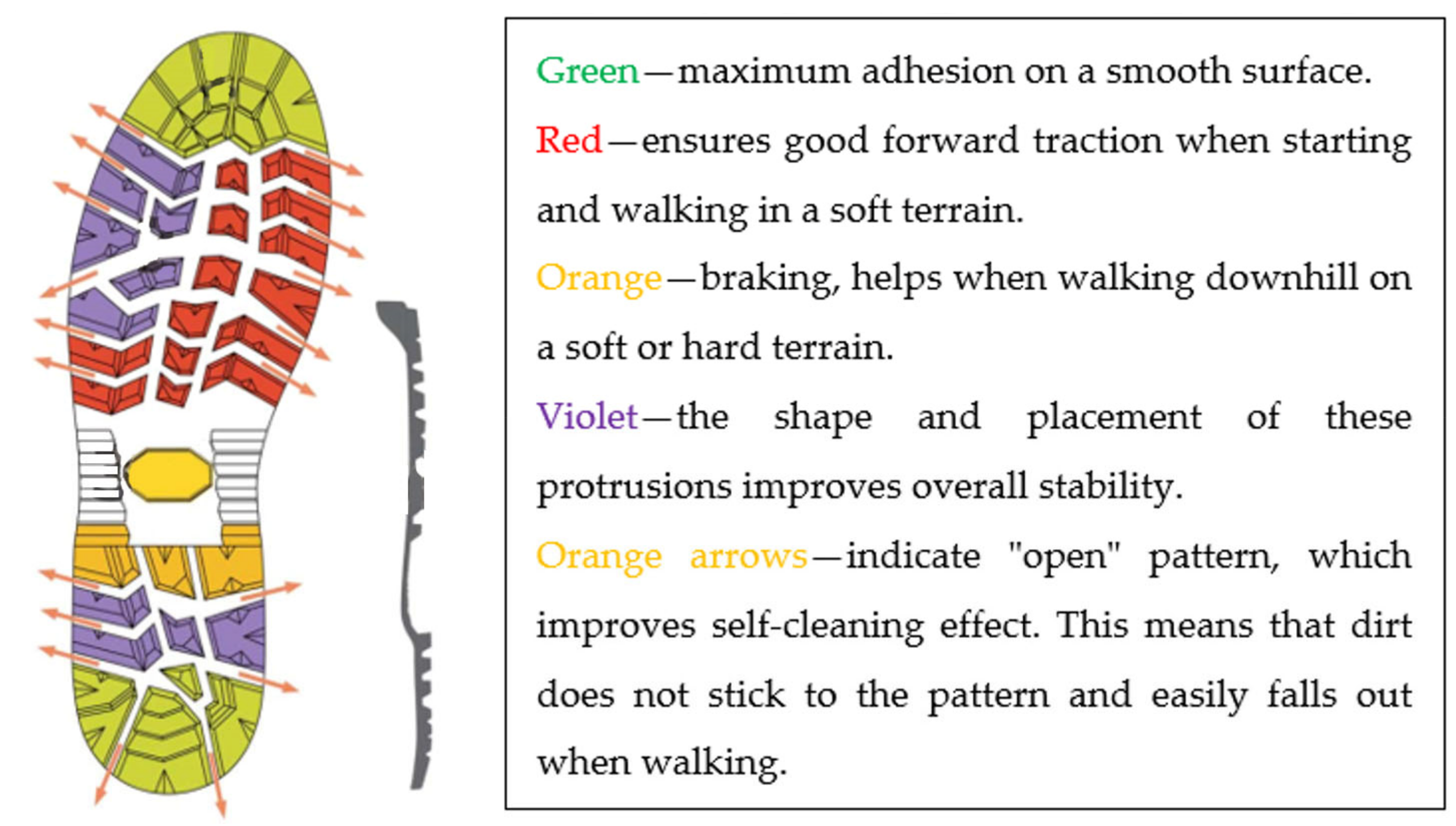

7.2. Special Functional Elements on Firefighter Shoes

- wide contact areas determined for grip on rocky surfaces;

- placement of areas in lines for natural bend and flexibility;

- slots in the ankle area help in uneven terrain;

- the overall pattern has a medium depth to be maximally functional on various surfaces.

7.3. The Footwear for Firefighting Intervention of Type TORNADO

8. Research Advances in Additive Manufacturing and in Sustainable Industrial Engineering

- Rubber Shin Guard—Ladder protection with cushioned backing for comfort and convenience;

- Heavyweight Kevlar—Premium thread to maximize seam length and durability.

- Premium Full-Grain Cowhide Leather—Flame-resistant, water-resistant, leather upper, flexible joint transitions for world-class comfort;

- Power Toe Protection—Updated innovation for outstanding abrasion resistant durability;

- Oblique Steel Toe Cap—A roomy fit without unnecessary bulk;

- Leather-Reinforced Pull Straps—Easy grip and kind to pants and legs;

- Footwear Fabric Lining—Full-height protection and comfort from underfoot to the boot-top line. Waterproof and blood borne pathogen resistant;

- Leather Top Binding—Always a smooth, finished interface for pants and legs;

- Heel and Ankle Grip System—Moulded heel counter, contoured, lined, integrated cushion support for outstanding fit and comfort;

- Heel Kicker—High visibility doffing aid;

- Reflective Trim—Located below the pant line for maximum benefit. Cleanable and heat resistant;

- Rugged Reliable Protection—Steel triple-ladder shank and steel flex-sole plate. Puncture and penetration resistance.

9. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| PPE | Personal protective equipment |

| IPCC | Intergovernmental Panel on Climate Change |

| STN | Slovak technical standard |

| EN | European standard |

References

- IPCC. Climate change 2014: Synthesis report. In Contribution of Working Groups I, II and III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Core Writing Team, Pachauri, R.K., Meyer, L.A., Eds.; IPCC: Geneva, Switzerland, 2014; p. 151. [Google Scholar]

- Toledo, M.; Poorter, L.; Peña-Claros, M.; Alarcón, A.; Balcázar, J.; Leaño, C.; Licona, J.C.; Llanque, O.; Vroomans, V.; Zuidema, P.; et al. Climate is a stronger driver of tree and forest growth rates than soil and disturbance. J. Ecol. 2010, 99, 254–264. [Google Scholar] [CrossRef]

- Jones, M.W.; Abatzoglou, J.T.; Veraverbeke, S.; Andela, N.; Lasslop, G.; Forkel, M.; Smith, A.J.P.; Burton, C.; Betts, R.A.; van der Werf, G.R.; et al. Global and Regional Trends and Drivers of Fire Under Climate Change. Rev. Geophys. 2022, 60, 108–129. [Google Scholar] [CrossRef]

- Jazebi, S.; de Leon, F.; Nelson, A. Review of Wildfire Management Techniques—Part I: Causes, Prevention, Detection, Suppression, and Data Analytics. IEEE Trans. Power Deliv. 2020, 35, 430–439. [Google Scholar] [CrossRef]

- Miller, C.; Plucinski, M.; Sullivan, A.; Stephenson, A.; Huston, C.; Charman, K.; Prakash, M.; Dunstall, S. Electrically caused wildfires in Victoria, Australia Are over-Represented when Fire Danger is Elevated. Landsc. Urban Plan. 2017, 167, 267–274. [Google Scholar] [CrossRef]

- Xu, K.; Zhang, X.; Chen, Z.; Wu, W.; Li, T. Risk Assessment for Wildfire Occurrence in High-Voltage Power Line Corridors by Using Remote-Sensing Techniques: A Case Study in Hubei Province, China. Int. J. Remote Sens. 2016, 37, 4818–4837. [Google Scholar] [CrossRef]

- Collins, K.M.; Penman, T.D.; Price, O.F. Some Wildfire Ignition Causes Pose More Risk of Destroying Houses than Others. PLoS ONE 2016, 11, e0162083. [Google Scholar] [CrossRef]

- Deb, P.; Moradkhani, H.; Abbaszadeh, P.; Kiem, A.S.; Engström, J.; Keellings, D.; Sharma, A. Causes of the Widespread 2019–2020 Australian Bushfire Season. Earth’s Future 2020, 8, e2020EF001671. [Google Scholar] [CrossRef]

- Teague, B.; McLeod, R.; Pascoe, S. Final Report, 2009; Technical Report; Victorian Bushfires Royal Commision: Melbourne, Australia, 2010. [Google Scholar]

- ECO Canada. Available online: https://eco.ca/career-profiles/forest-firefighter/ (accessed on 14 July 2023).

- Brooks, M.L. Peak Fire Temperatures and Effects on Annual Plants in the Mojave Desert. Ecol. Appl. 2002, 12, 1088–1102. [Google Scholar] [CrossRef]

- Hartley, I.P.; Hill, T.C.; Chadburn, S.E.; Hugelius, G. Temperature effects on carbon storage are controlled by soil stabilisation capacities. Nat. Commun. 2021, 12, 6713. [Google Scholar] [CrossRef] [PubMed]

- Hou, X.; Orth, R. Observational evidence of wildfire-promoting soil moisture anomalies. Sci. Rep. 2020, 10, 11008. [Google Scholar]

- Tian, X.-R.; Shu, L.-F.; Zhao, F.-J.; Wang, M.-Y.; McRae, D.J. Future impacts of climate change on forest fire danger in northeastern China. J. For. Res. 2011, 22, 437–446. [Google Scholar] [CrossRef]

- Liu, Z.; Yang, J.; Chang, Y.; Weisberg, P.J.; He, H.S. Spatial patterns and drivers of fire occurrence and its future trend under climate change in a boreal forest of Northeast China. Glob. Chang. Biol. 2012, 18, 2041–2056. [Google Scholar] [CrossRef]

- Abatzoglou, J.T. Development of gridded surface meteorological data for ecological applications and modelling. Int. J. Climatol. 2013, 33, 121–131. [Google Scholar] [CrossRef]

- Lawson, B.D.; Armitage, O.B. Weather Guide for the Canadian Forest Fire Danger Rating System; National Resources Canada: Edmonton, AB, Canada, 2008. [Google Scholar]

- Sabater, J.M. ERA5-Land Hourly Data from 1981 to Present; Copernicus Climate Change Service (C3S); Climate Data Store (CDS): The Hague, The Netherlands, 2019. [Google Scholar]

- Flegner, P.; Kačur, J.; Durdán, M.; Leššo, I.; Laciak, M. Measurement and processing of vibro-acoustic signal from the process of rock disintegration by rotary drilling. Measurement 2014, 56, 178–193. [Google Scholar] [CrossRef]

- Phelps, N.; Woolford, D.G. Guidelines for effective evaluation and comparison of wildland fire occurrence prediction models. Int. J. Wildland Fire 2021, 30, 225–240. [Google Scholar] [CrossRef]

- Won, A.Y.; Yun, C. The effects of laundering on the protective performance of firefighter clothing. Fibers Polym. 2021, 22, 3232–3239. [Google Scholar] [CrossRef]

- Chang, T.-Y.; Lu, H.-P.; Luor, T.-Y.; Chang, P.-W. Weighting of Firefighting Turnout Gear Risk Factors According to Expert Opinion. Sustainability 2022, 14, 7040. [Google Scholar] [CrossRef]

- Fonseca, A.; Neves, S.; Campos, J. Thermal performance of a PCM firefighting suit considering transient periods of fire exposure, post-fire exposure and resting phases. Appl. Therm. Eng. 2021, 182, 115769. [Google Scholar] [CrossRef]

- Orr, R.; Maupin, D.; Palmer, R.; Canetti, E.F.D.; Simas, V.; Schram, B. The Impact of Footwear on Occupational Task Performance and Musculoskeletal Injury Risk: A Scoping Review to Inform Tactical Footwear. Int. J. Environ. Res. Public Health 2022, 19, 10703. [Google Scholar] [CrossRef]

- Vu, V.; Walker, A.; Ball, N.; Spratford, W. Ankle restrictive firefighting boots alter the lumbar biomechanics during landing tasks. Appl. Ergon. 2017, 65, 123–129. [Google Scholar] [CrossRef]

- STN EN 1509; Playing Field Equipment—Badminton Equipment—Functional and Safety Requirements, Test Methods. Slowakische Technische Norm: Bratislava, Slovakia, 2009.

- Dobson, J.A.; Riddiford-Harland, D.L.; Bell, A.F.; Wegener, C.; Steele, J.R. Effect of work boot shaft stiffness and sole flexibility on lower limb muscle activity and ankle alignment at initial foot-ground contact when walking on simulated coal mining surfaces: Implications for reducing slip risk. Appl. Ergon. 2019, 81, 102903. [Google Scholar] [CrossRef] [PubMed]

- Jo, J.; Sokolowski, S.; McQuerry, M.; Griffin, L.; Park, H. Firefighters’ feet: Differences by sex and weight-bearing. Appl. Ergon. 2022, 102, 103753. [Google Scholar] [CrossRef] [PubMed]

- Fire Product Search. Available online: https://www.fireproductsearch.com/what-makes-a-good-firefighting-boot/ (accessed on 14 July 2023).

- Chiou, S.S.; Turner, N.; Zwiener, J.; Weaver, D.L.; Haskell, W.E. Effect of boot weight and sole flexibility on gait and physiological responses of firefighters in stepping over obstacles. Hum. Factors J. Hum. Factors Ergon. Soc. 2012, 54, 373–386. [Google Scholar] [CrossRef] [PubMed]

- Wolf, P.; Stacoff, A.; Liu, A.; Nester, C.; Arndt, A.; Lundberg, A.; Stuessi, E. Functional units of the human foot. Gait Posture 2008, 28, 434–441. [Google Scholar] [CrossRef]

- Wang, J.; Saito, H.; Kimura, M.; Mochimaru, M.; Kanade, T. Human foot reconstruction from multiple camera images with foot shape database. IEICE Trans. Inf. Syst. 2006, E89-D, 1732–1742. [Google Scholar] [CrossRef]

- Park, H.; Park, J.; Lin, S.-H.; Boorady, L.M. Assessment of Firefighters’ needs for personal protective equipment. Fash. Text. 2014, 1, 8. [Google Scholar] [CrossRef]

- Turner, N.L.; Chiou, S.; Zwiener, J.; Weaver, D.; Spahr, J. Physiological effects of boot weight and design on men and women firefighters. J. Occup. Environ. Hyg. 2010, 7, 477–482. [Google Scholar] [CrossRef]

- Derby, H.; Chander, H.; Arachchige, S.N.K.K.; Turner, A.J.; Knight, A.C.; Burch, R.; Freeman, C.; Wade, C.; Garner, J.C. Occupational Footwear Design Influences Biomechanics and Physiology of Human Postural Control and Fall Risk. Appl. Sci. 2023, 13, 116. [Google Scholar] [CrossRef]

- Cikajlo, I.; Matjačić, Z. The influence of boot stiffness on gait kinematics and kinetics during stance phase. Ergonomics 2007, 50, 2171–2182. [Google Scholar] [CrossRef]

- Grega, R.; Homišin, J.; Puškár, M.; Kul’ka, J.; Petróci, J.; Konečný, B.; Kršák, B. The chances for reduction of vibrations in mechanical system with low-emission ships combustion engines. Int. J. Marit. Eng. 2015, 157, 235–240. [Google Scholar] [CrossRef]

- Homišin, J.; Grega, R.; Kaššay, P.; Fedorko, G.; Molnár, V. Removal of systematic failure of belt conveyor drive by reducing vibrations. Eng. Fail. Anal. 2019, 99, 192–202. [Google Scholar] [CrossRef]

- Žul’ová, L.; Grega, R.; Krajňák, J.; Fedorko, G.; Molnár, V. Optimization of noisiness of mechanical system by using a pneumatic tuner during a failure of piston machine. Eng. Fail. Anal. 2017, 2017, 845–851. [Google Scholar] [CrossRef]

- EN ISO 15025:2002; Protective Clothing—Protection against Heat and Flame—Method of Test For limited Flame Spread. EU: Brussels, Belgium, 2002.

- ISO 20344:2011; Specifies Methods for Testing Footwear Designed as Personal Protective Equipment. EU: Brussels, Belgium, 2011.

- ISO 6942:2002; Protective Clothing—Protection Against Heat and Fire—Method of Test: Evaluation of Materials and Material Assemblies When Exposed to a Source of Radiant Heat. EU: Brussels, Belgium, 2002.

- Rosenbauer Standorte. Available online: https://www.rosenbauer.com (accessed on 14 July 2023).

- Vft Vallfirest. Available online: https://www.vallfirest.com/en (accessed on 4 October 2023).

- BOSP. Available online: https://bosp.sk/gore-tex-products (accessed on 4 October 2023).

- EN 381; Personal Protective Equipment (PPE) for Users of Handheld Chainsaws. EU: Brussels, Belgium, 1995.

- EN 20345; Personal protective equipment—Safety Footwear. EU: Brussels, Belgium, 2021.

- Hameed, A.Z.; Kandasamy, J.; Raj, S.A.; Baghdadi, M.A.; Shahzad, M.A. Sustainable Product Development Using FMEA ECQFD TRIZ and Fuzzy TOPSIS. Sustainability 2022, 14, 14345. [Google Scholar] [CrossRef]

- Jovane, F.; Westkämper, E.; Williams, D. The ManuFuture Road: Towards Competitive and Sustainable High-Adding-Value Manufacturing; Springer: Berlin/Heidelberg, Germany, 2009; p. 261. ISBN 978-3-540-77011-1. [Google Scholar]

- The Firefighting Depot. Available online: https://www.thefirefightingdepot.com/products/honeywell-pro-series-nighthawk-5555-firefighting-boots (accessed on 4 October 2023).

- CNC Solutions—Robotic Production Solutions. Available online: https://en.huazhongcnc.com/cnc-controllers/ (accessed on 4 October 2023).

- HuazhongCNC. Available online: https://sk.hcncglobal.com/news/shoe-manufacturing-intelligent-molding-solutio-63405670.html (accessed on 4 October 2023).

| Classification | Description |

|---|---|

| Class I | Footwear produced from leather or from other kind of material, except all-polymer or all-rubber footwear |

| Class II | All-polymer footwear (entirely moulded) or all-rubber footwear (entirely vulcanised) |

| Type of Footwear | Symbol | Designated Properties |

|---|---|---|

| Type 1 | F1A | All the normative requirements are defined in the STN EN 15090 standard and requirements for antistatic properties |

| F1PA | Requirements for puncture resistance and antistatic properties | |

| F1I | Requirements for electrical insulation properties | |

| F1PI | Requirements for puncture resistance and to electrical insulation properties | |

| Type 2 | F2A | All the normative requirements are defined in the STN EN 15090 standard and requirements for antistatic properties |

| F2I | Requirements for electrical insulation properties | |

| Type 3 | F3A | All the normative requirements are defined in the STN EN 15090 standard and requirements for antistatic properties |

| F3I | Requirements for electrical insulation properties |

| Hazards | Causes and Types of Hazards | Criteria and Security Measures, Making Personal Protective Equipment |

|---|---|---|

| Mechanical |

|

|

| Electrical |

|

|

| Thermal |

|

|

| Chemical |

|

|

| Excessive load |

|

|

| PPE shortcomings | Causes and types of shortcomings | Criteria and security measures, making personal protective equipment |

| Discomfort, limitation, interference with work |

|

|

| General |

|

|

| Alteration of protective functions due to aging |

|

|

| Static electricity |

|

|

| Insufficient protective effect |

|

|

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tomaskova, M.; Krajňák, J. Features and Sustainable Design of Firefighting Safety Footwear for Fire Extinguishing and Rescue Operations. Sustainability 2023, 15, 15108. https://doi.org/10.3390/su152015108

Tomaskova M, Krajňák J. Features and Sustainable Design of Firefighting Safety Footwear for Fire Extinguishing and Rescue Operations. Sustainability. 2023; 15(20):15108. https://doi.org/10.3390/su152015108

Chicago/Turabian StyleTomaskova, Marianna, and Jozef Krajňák. 2023. "Features and Sustainable Design of Firefighting Safety Footwear for Fire Extinguishing and Rescue Operations" Sustainability 15, no. 20: 15108. https://doi.org/10.3390/su152015108

APA StyleTomaskova, M., & Krajňák, J. (2023). Features and Sustainable Design of Firefighting Safety Footwear for Fire Extinguishing and Rescue Operations. Sustainability, 15(20), 15108. https://doi.org/10.3390/su152015108