Assessing Hygrothermal Performance in Building Walls Engineered for Extreme Cold Climate Environments

Abstract

:1. Introduction

2. Literature Review

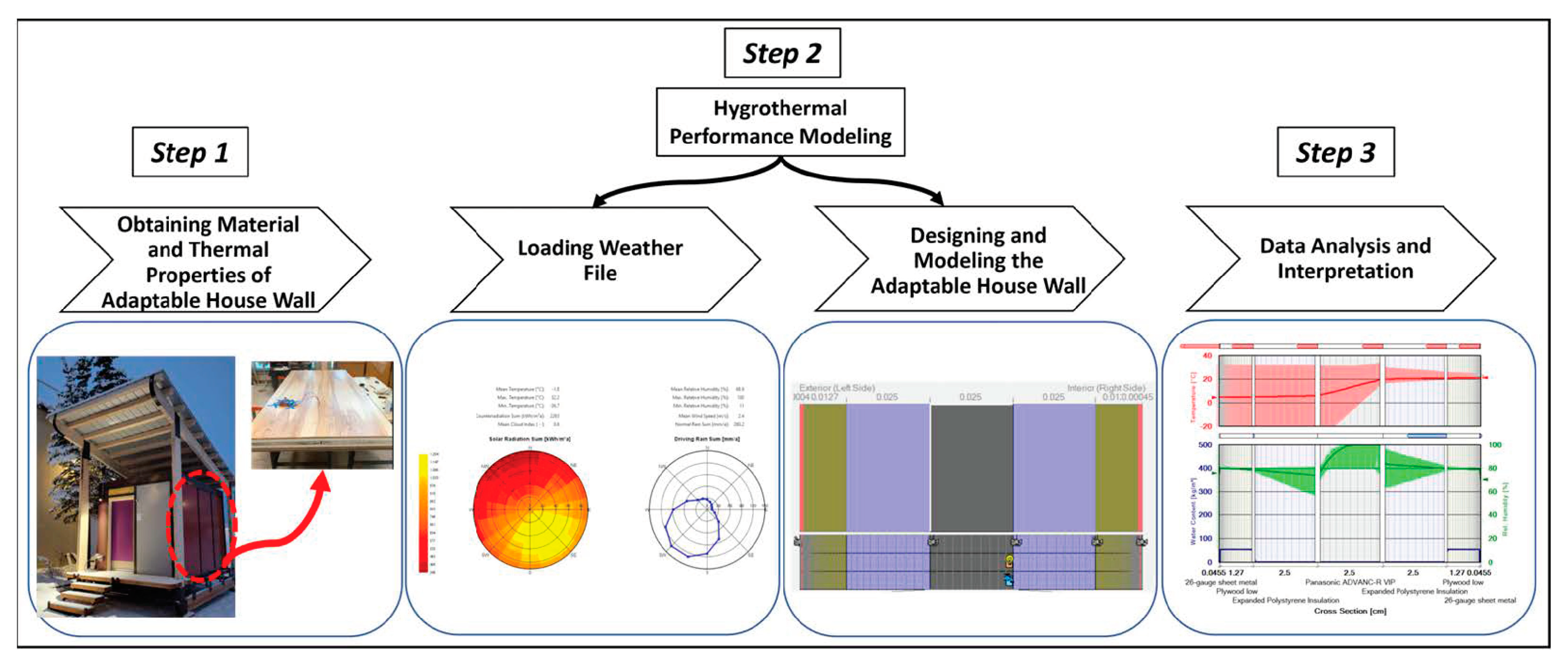

3. Methodology

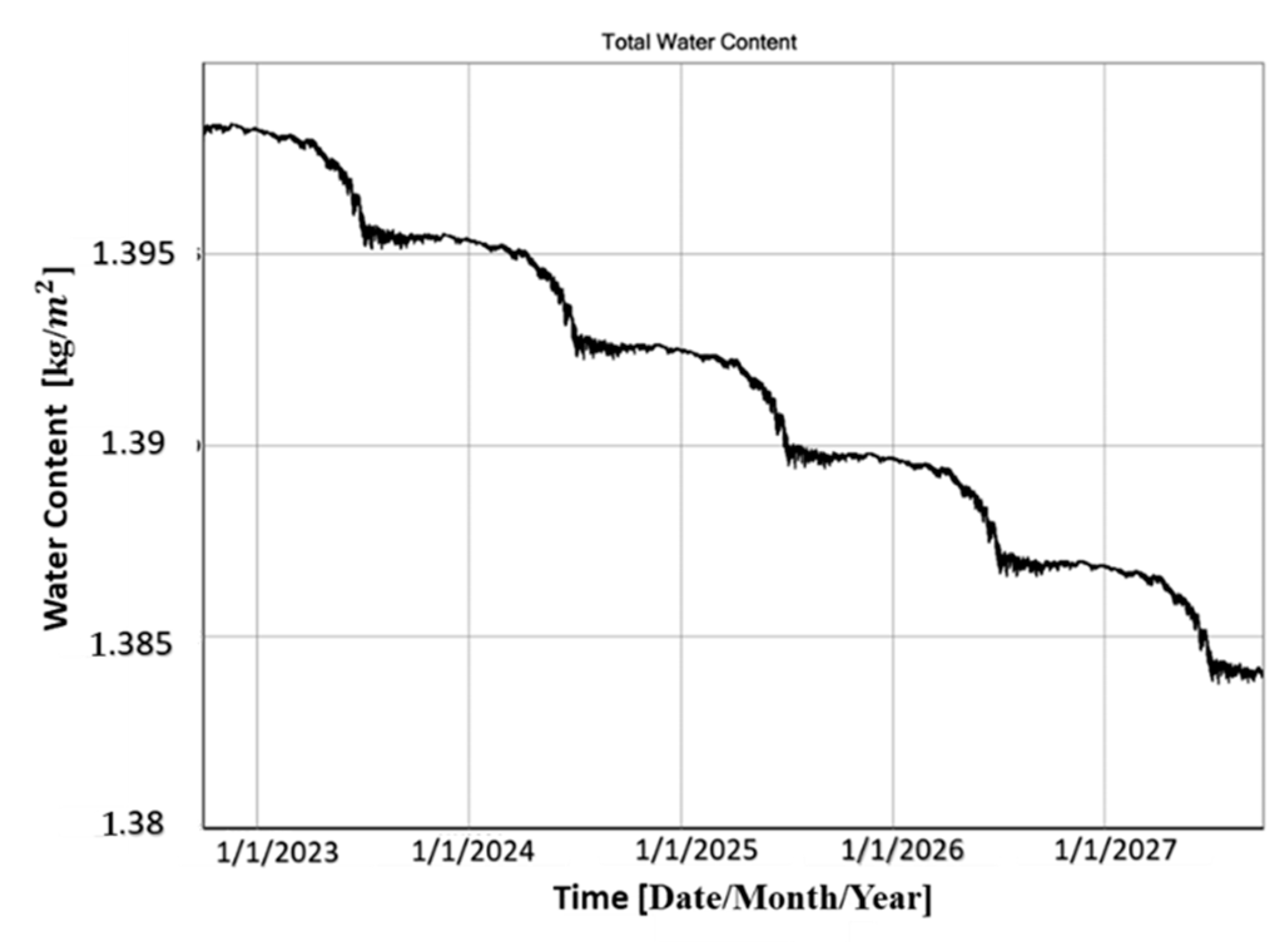

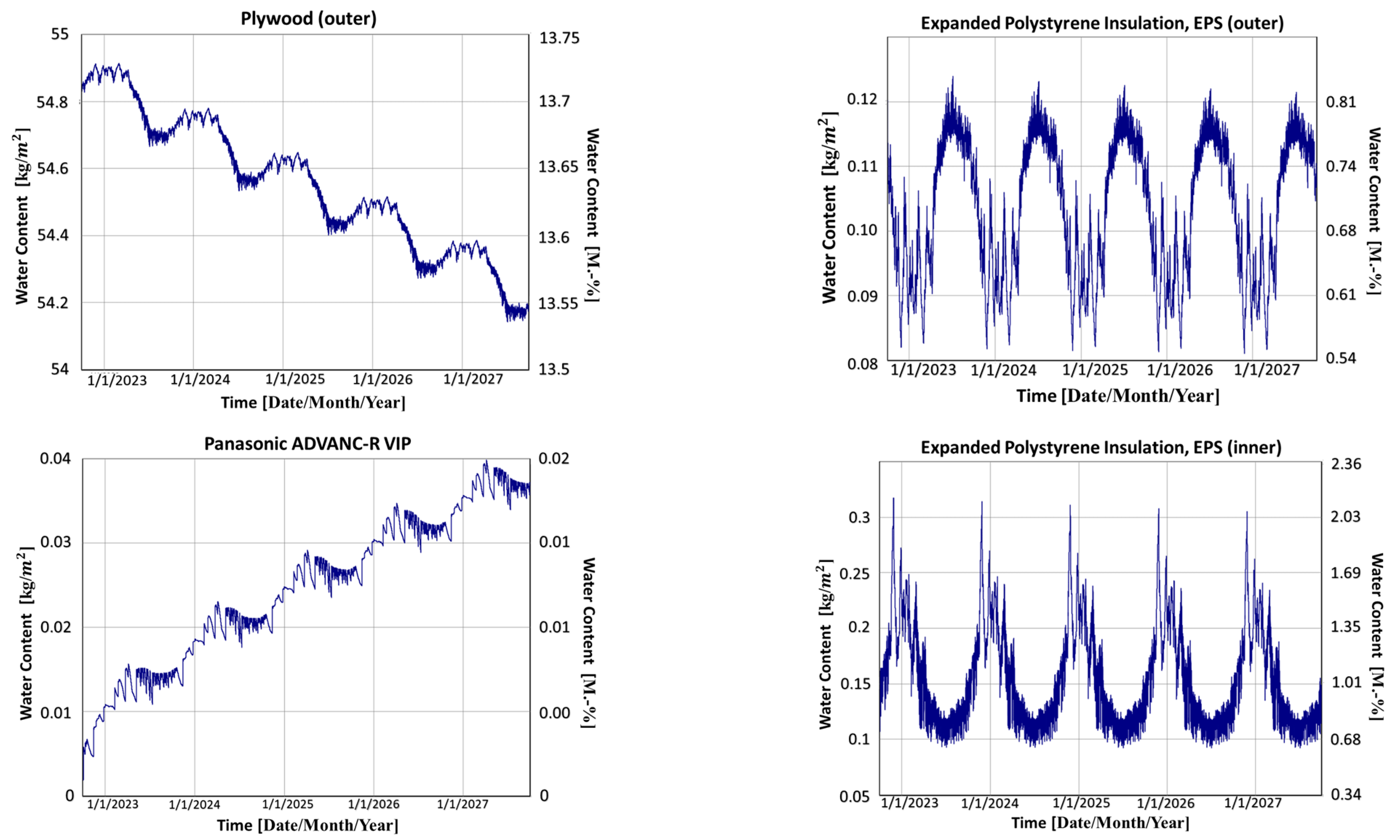

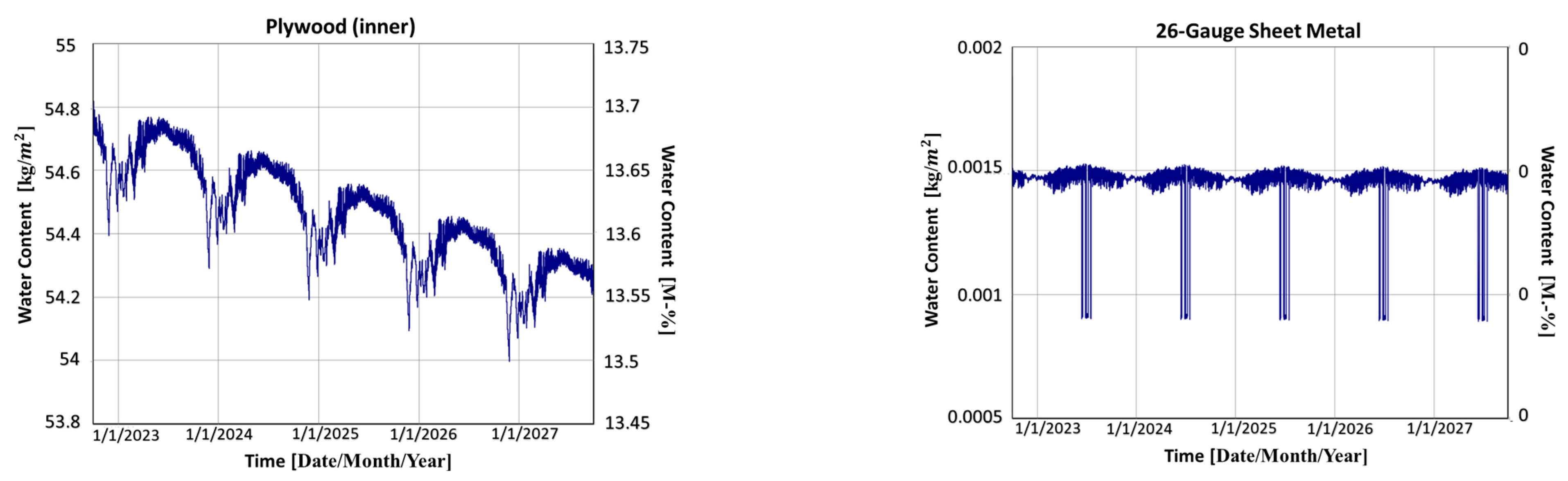

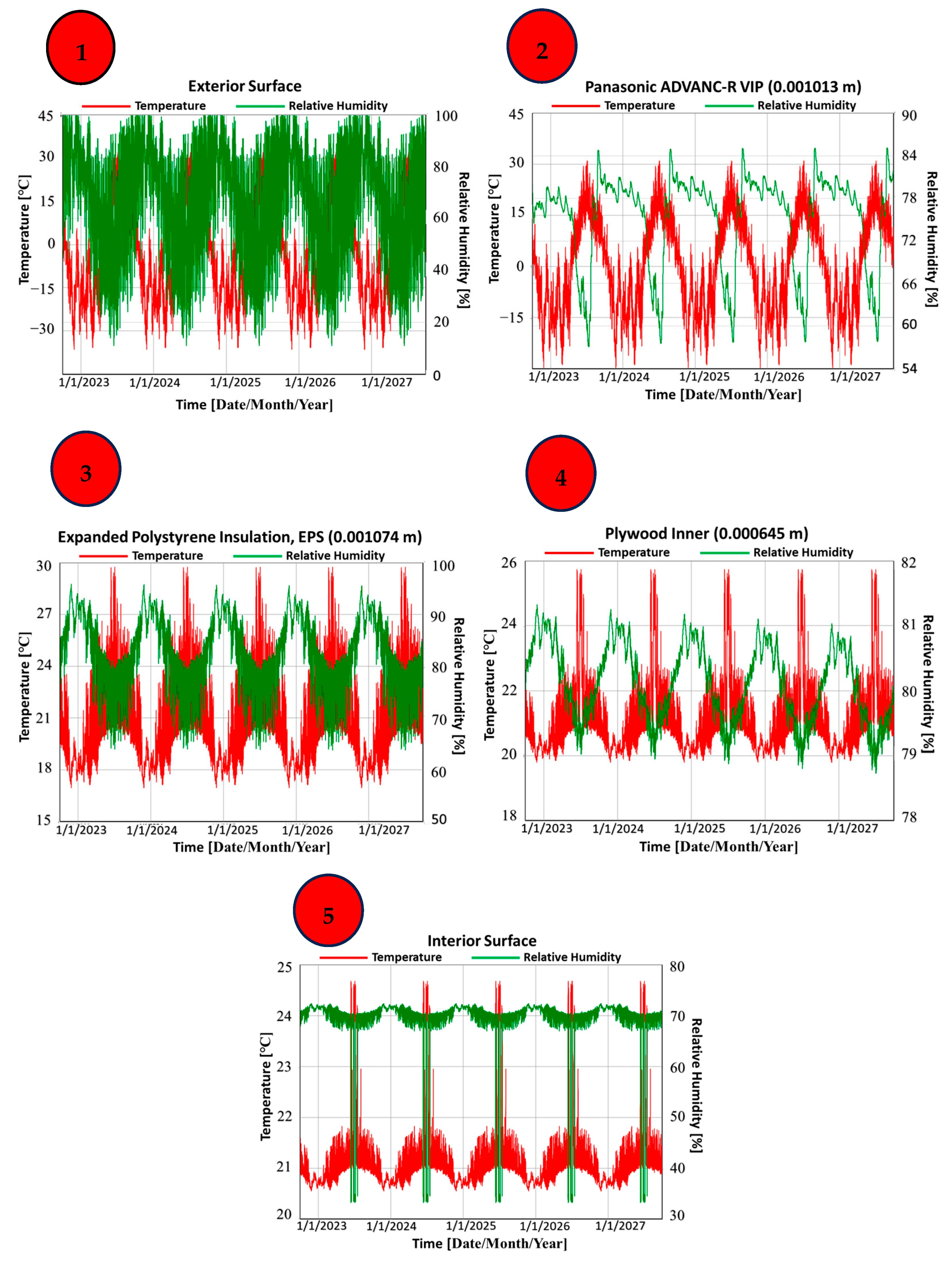

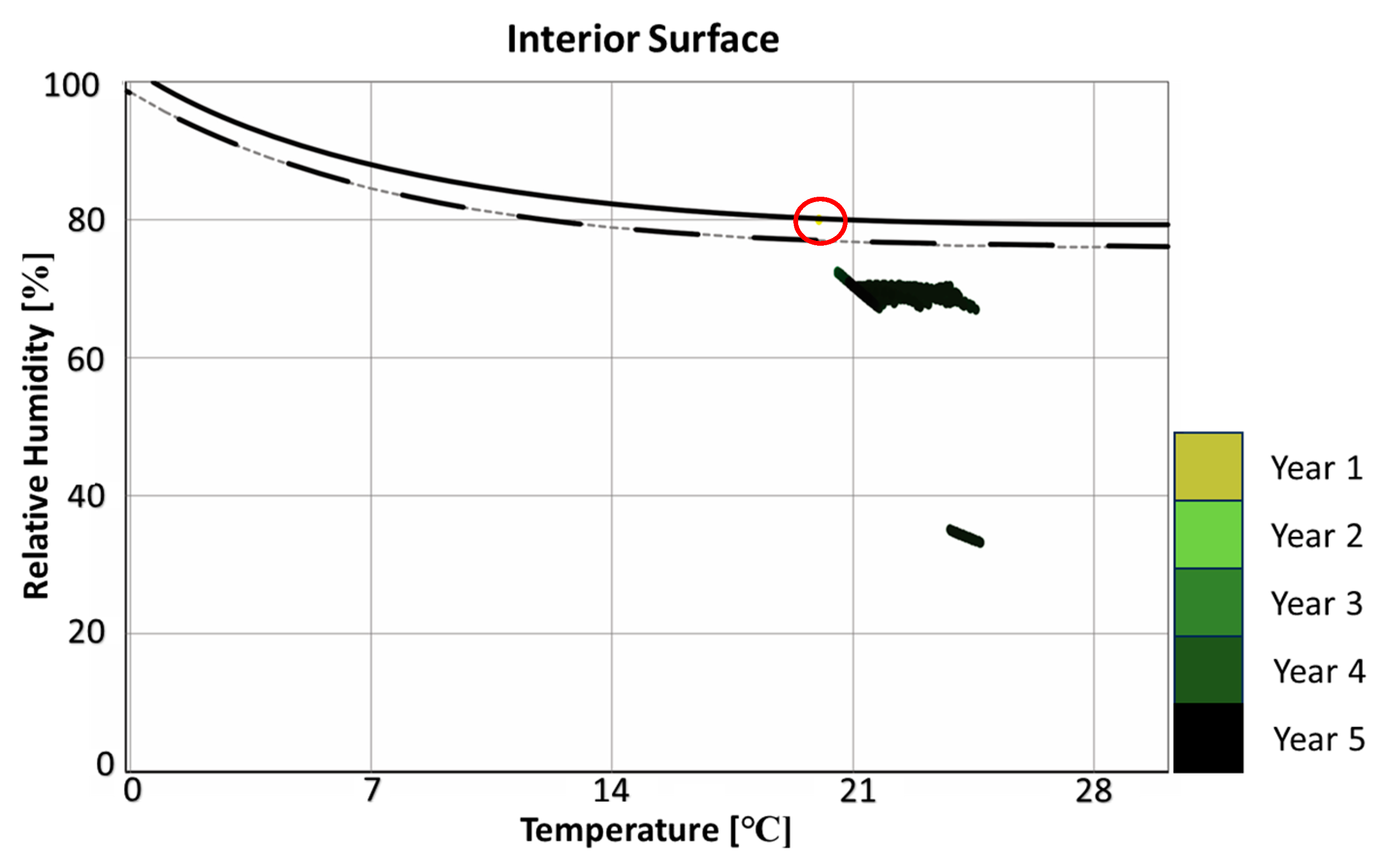

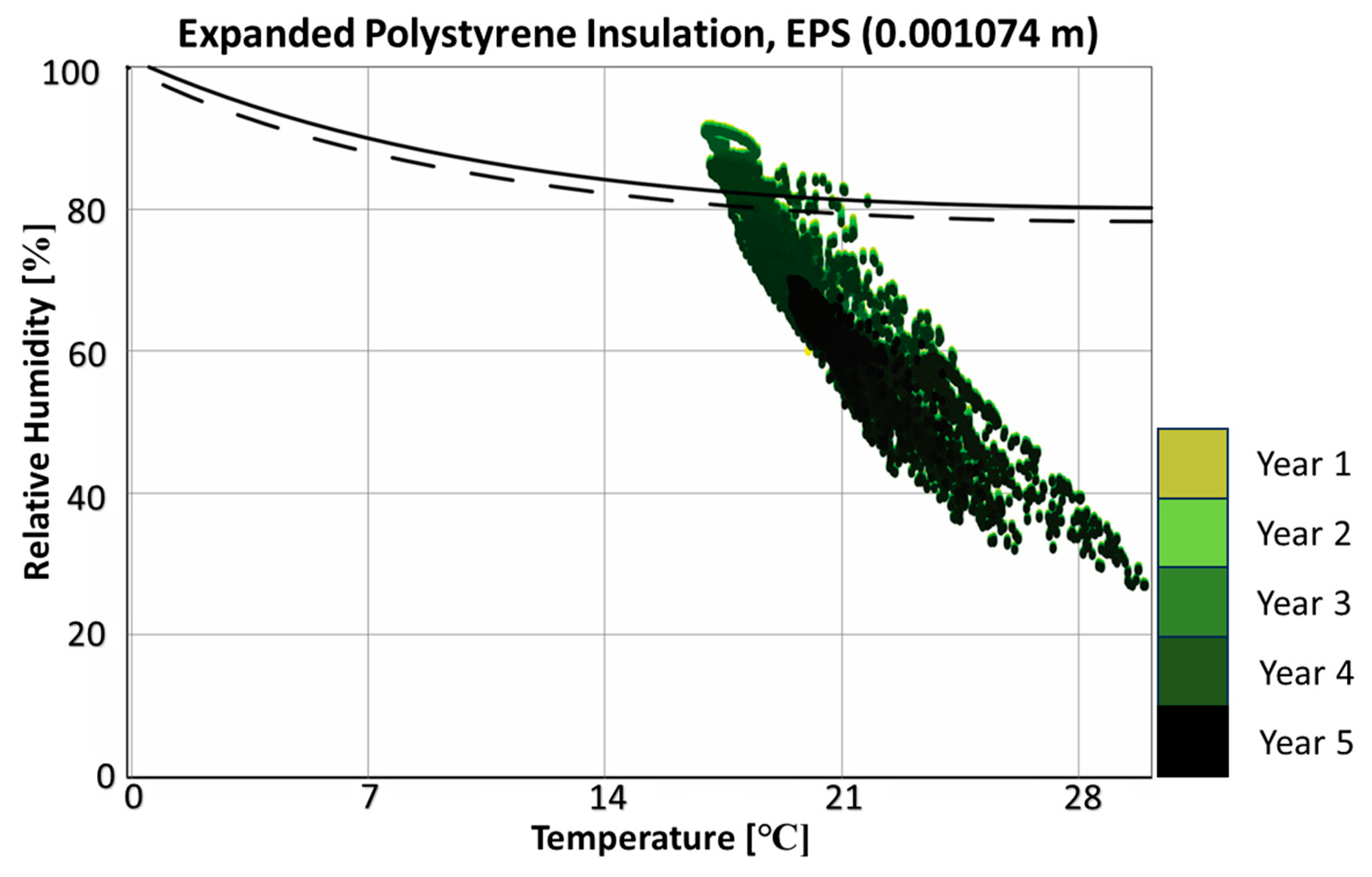

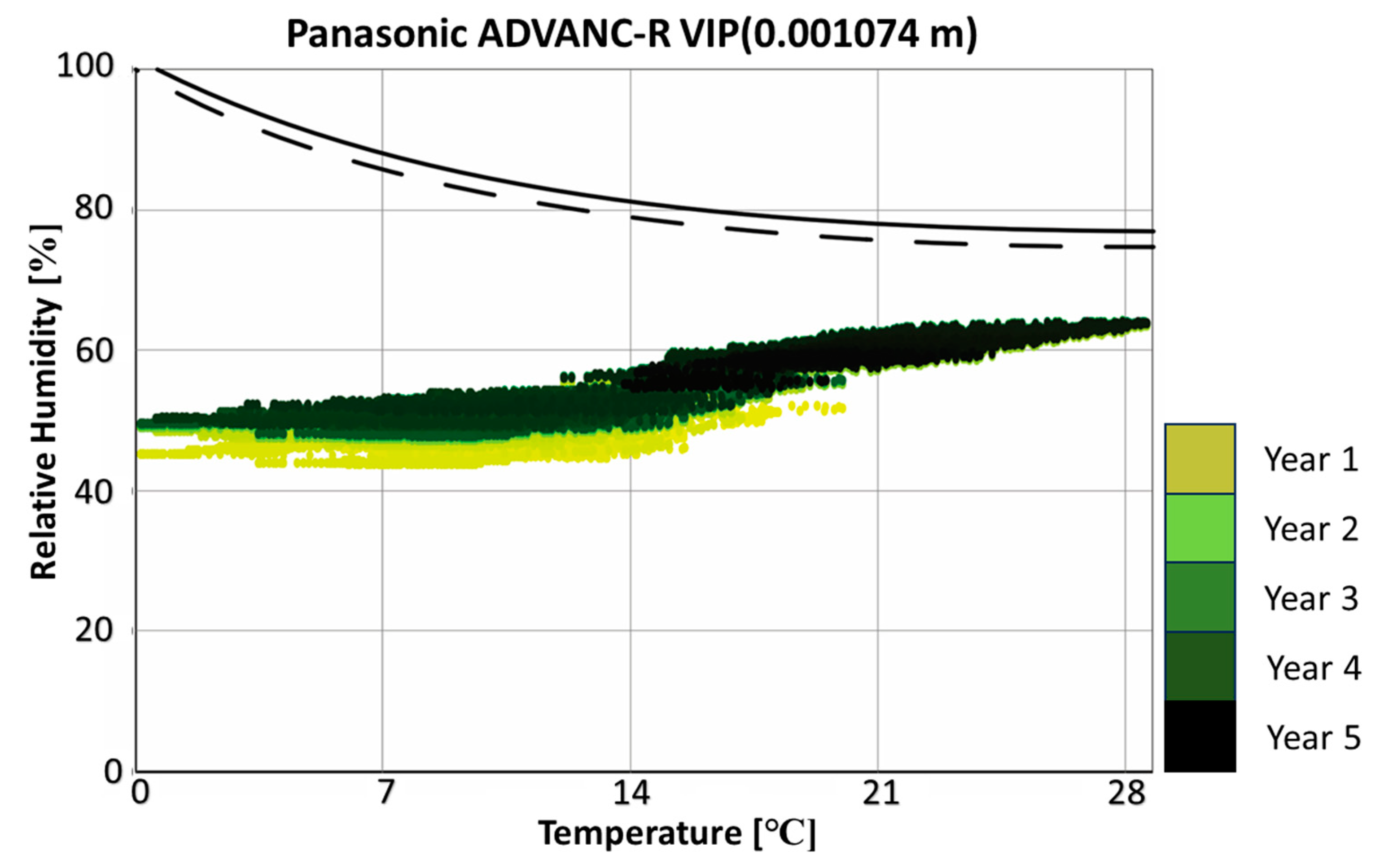

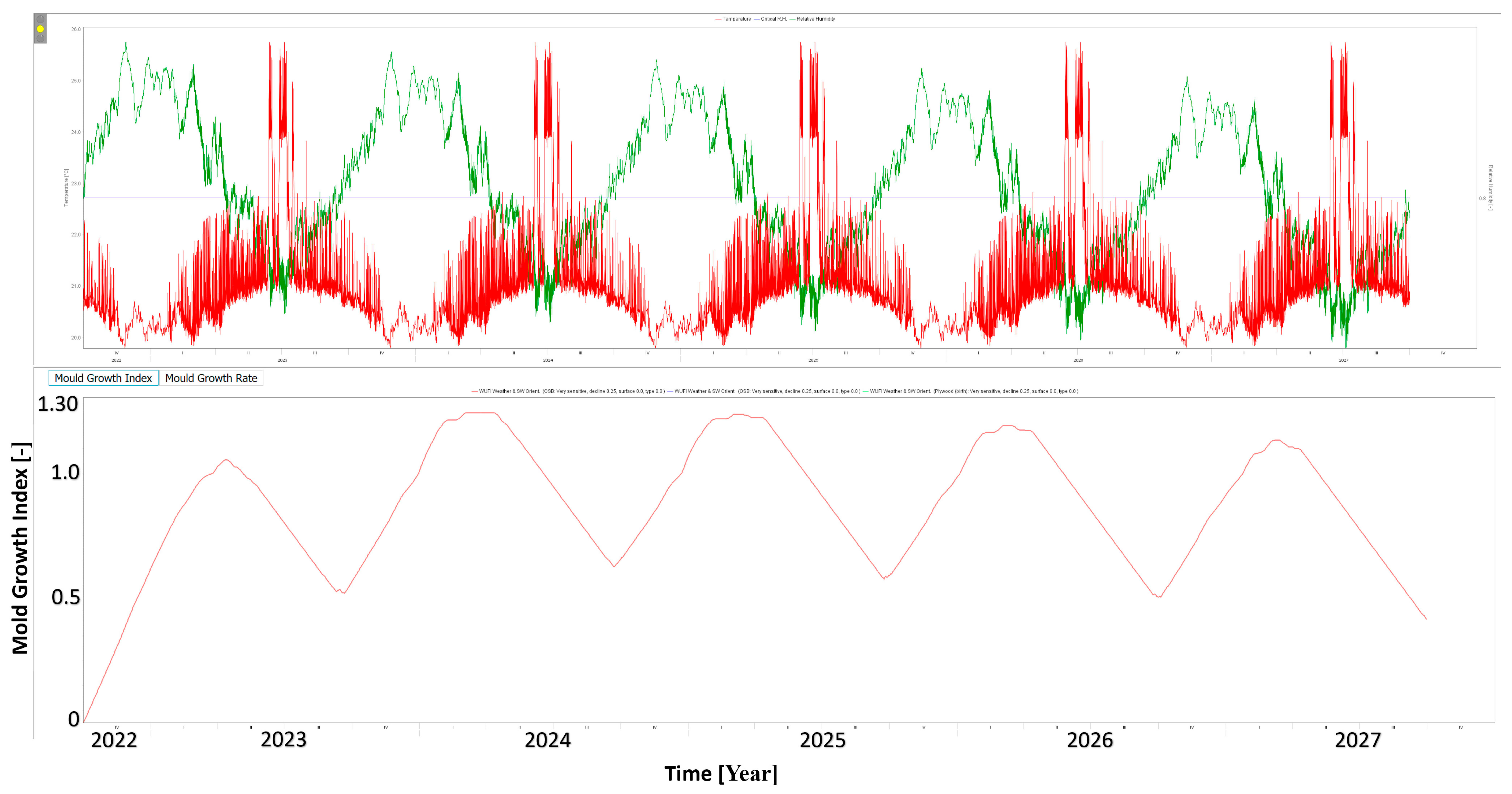

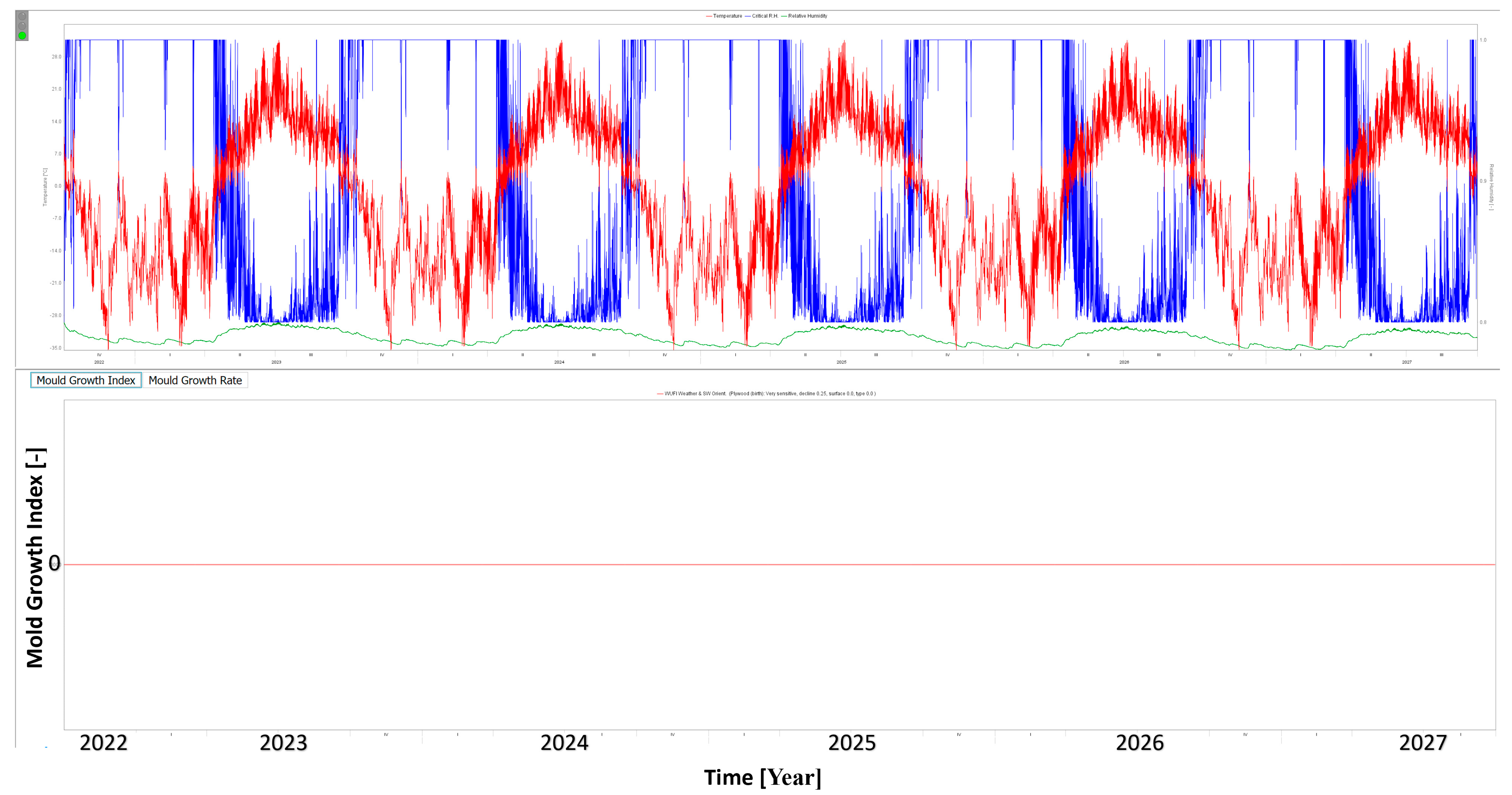

4. Hygrothermal Performance Analysis

4.1. Collection of Material and Thermal Properties of Adaptable House Walls

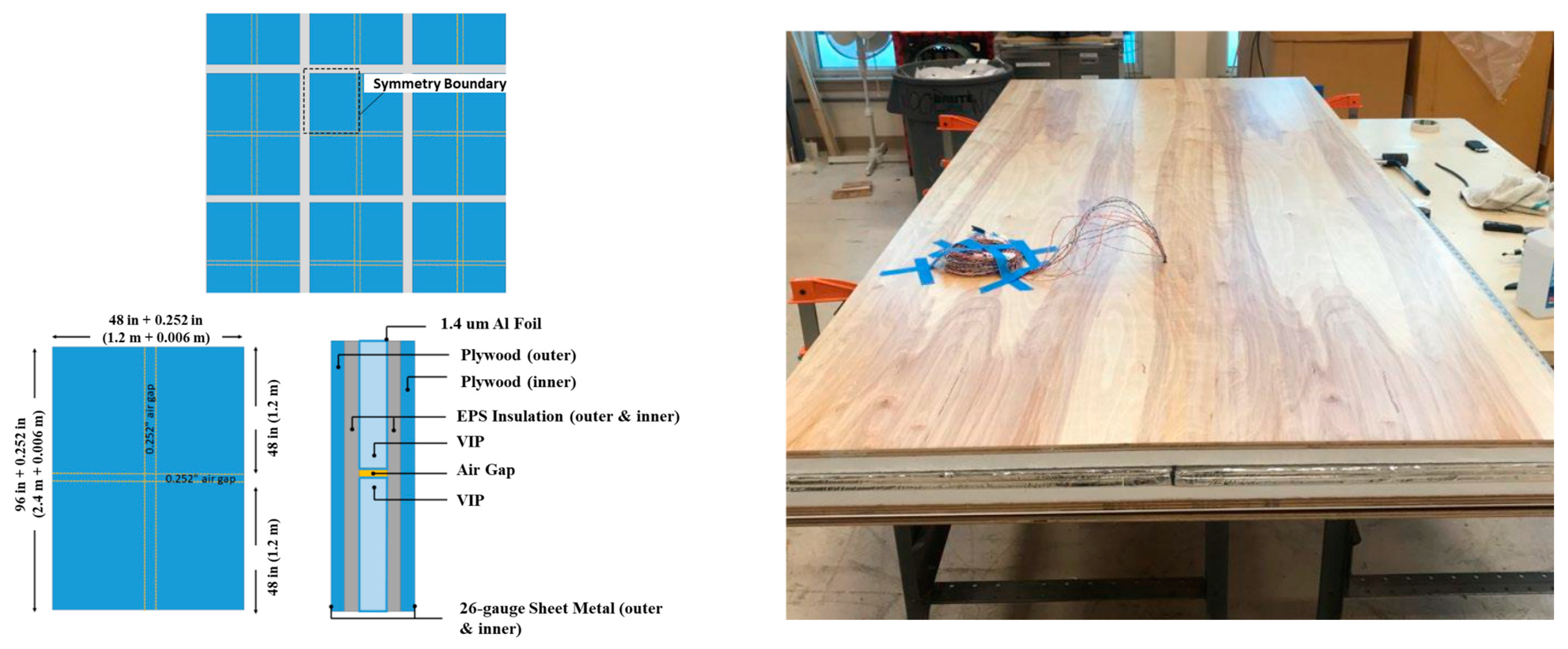

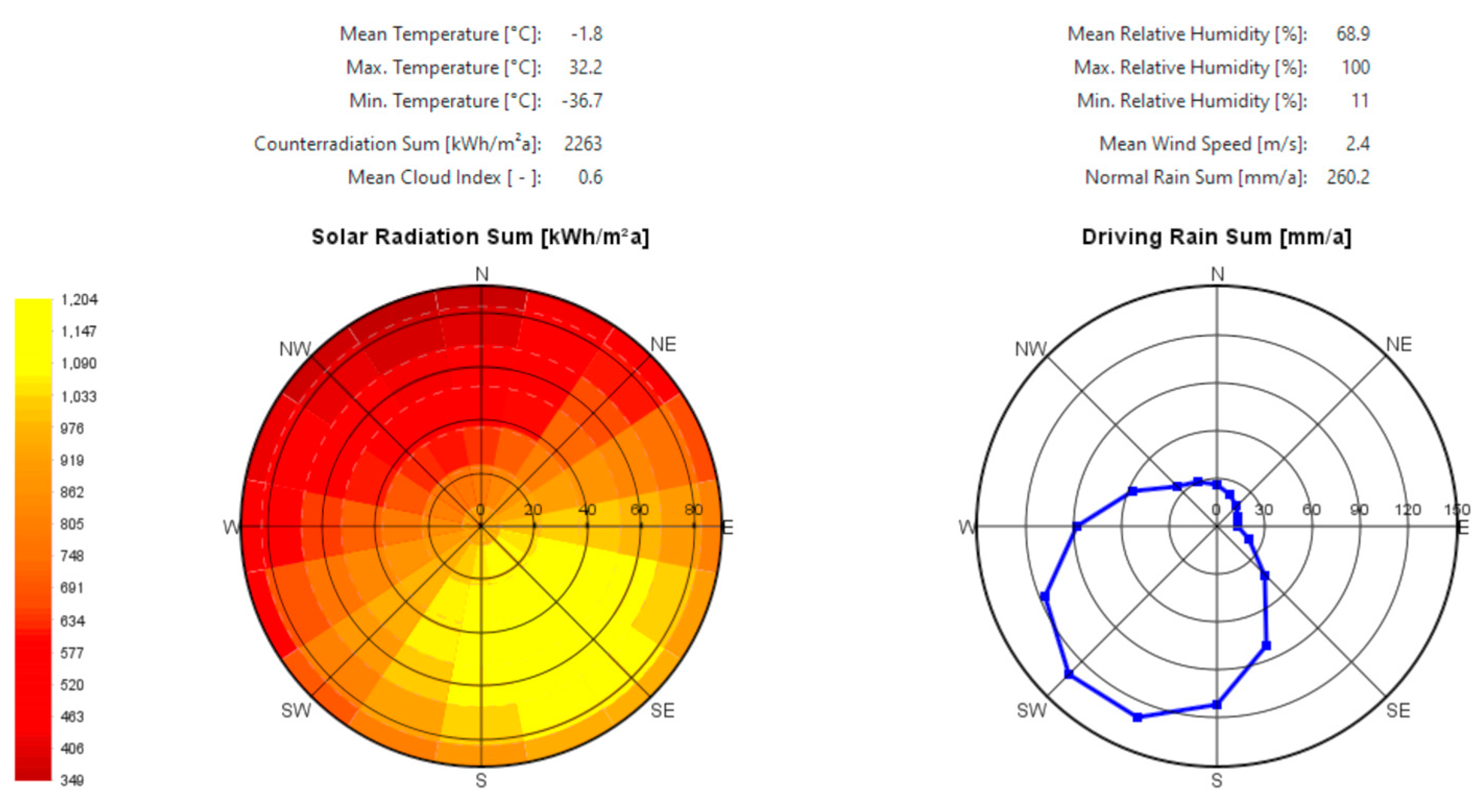

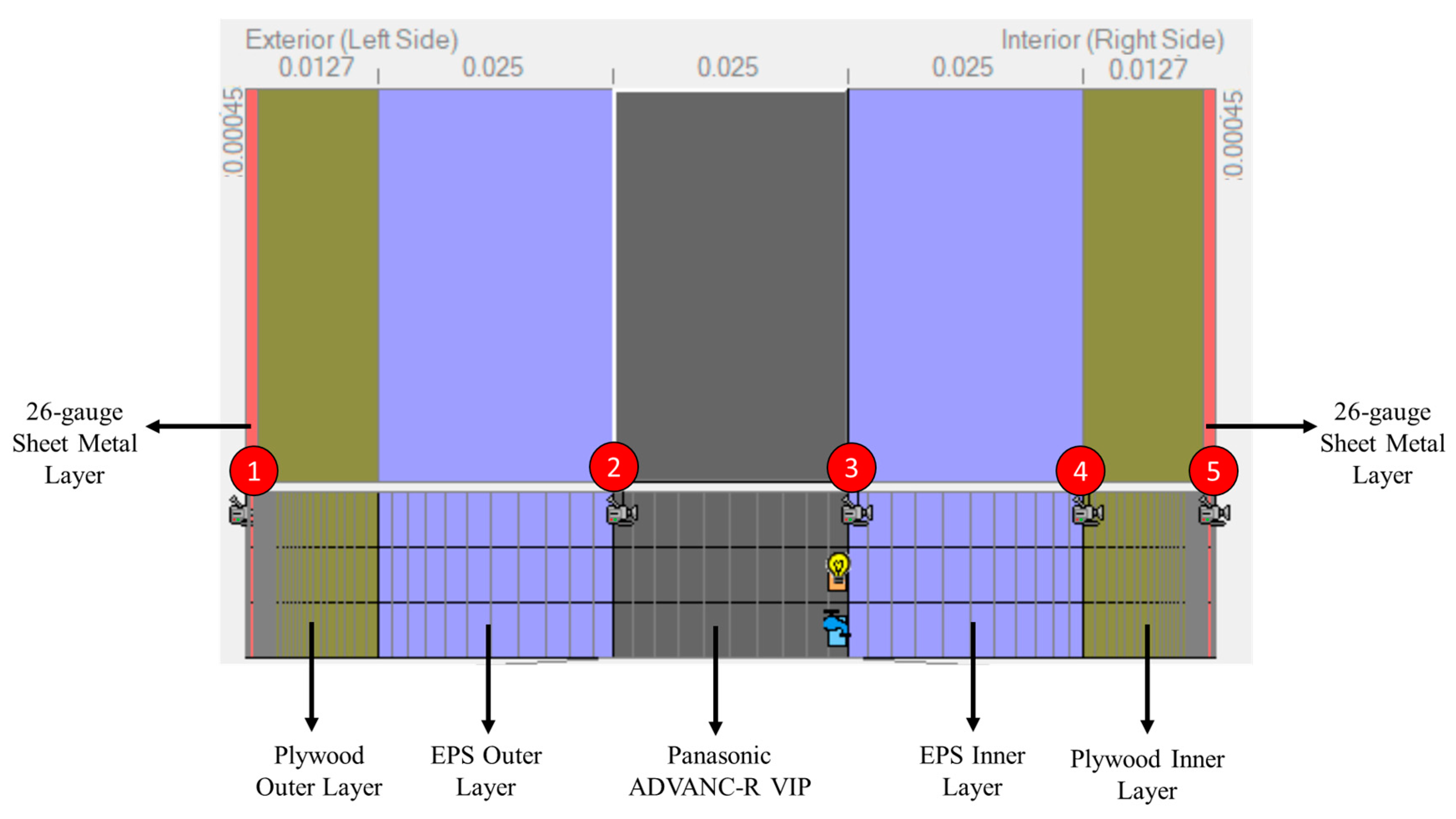

4.2. Hygrothermal Performance Modeling for Adaptable House Walls

- : Total thermal resistance (R-value) of the AHW with VIP, m2·K/W;

- : Total thermal resistance (R-value) of the AHW with air gap excluding VIP, m2·K/W;

- : Total area of the AHW covered with VIP, m2;

- : Total area of the AHW covered with air (highlighted in yellow lines in Figure 2), m2;

- : Total area of the whole modeled AHW, m2.

4.3. Data Analysis

5. Conclusions

- Customize hygrothermal assessments to specific climate zones or micro-climates, offer more advanced and context-specific advice for decisionmakers, and potentially save significant construction costs during the design phase.

- Analyze the long-term performance of various wall designs or materials; and consider numerous factors like maintenance, durability, and energy efficiency, which play a crucial role in predicting the construction’s lifecycle. This insight can lead to substantial cost savings throughout the building’s operational lifespan.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AHW | Adaptable house wall |

| ASHRAE | American Society of Heating, Refrigerating and Air-Conditioning Engineers |

| CCHRC | Cold Climate Housing Research Center |

| EPS | Expanded polystyrene insulation |

| HVAC | Heating, ventilation, and air conditioning |

| IECC | International Energy Conservation Code |

| ISO | International Organization for Standardization |

| k | Thermal conductivity |

| K | Kelvin |

| m | Meter |

| MGI | Mold growth index |

| NREL | National Renewable Energy Laboratory |

| R | Thermal resistance |

| RH | Relative humidity |

| SW | Southwestern |

| VIP | Vacuum-insulated panels |

| W | Watts |

| WUFI® | Wärme-und Feuchtetransport instationär (transient heat and moisture transport) |

| XPS | Extruded polystyrene insulation |

References

- IEA Buildings. A Source of Enormous Untapped Efficiency Potential; International Energy Agency (IEA): Paris, France, 2021. [Google Scholar]

- Palani, H.; Acosta-Sequeda, J.; Derrible, S.; Karatas, A. Predicting energy use intensity of us hotel buildings using Cbecs microdata. Proc. Int. Struct. Eng. Constr. 2023, 10, 1–6. [Google Scholar] [CrossRef]

- Ozel, M. Thermal, Economical and Environmental Analysis of Insulated Building Walls in a Cold Climate. Energy Convers. Manag. 2013, 76, 674–684. [Google Scholar] [CrossRef]

- Aslani, A.; Bakhtiar, A.; Akbarzadeh, M.H. Energy-Efficiency Technologies in the Building Envelope: Life Cycle and Adaptation Assessment. J. Build. Eng. 2019, 21, 55–63. [Google Scholar] [CrossRef]

- Lucchi, E.; Roberti, F.; Alexandra, T. Definition of an Experimental Procedure with the Hot Box Method for the Thermal Performance Evaluation of Inhomogeneous Walls. Energy Build. 2018, 179, 99–111. [Google Scholar] [CrossRef]

- Palani, H.; Karatas, A. Investigating the Disparities between Experimental and Computational Analyses of Thermal Performance in Prefabricated Wall Panels. Appl. Therm. Eng. 2024, 236, 121568. [Google Scholar] [CrossRef]

- Chowdhury, D.; Neogi, S. Thermal Performance Evaluation of Traditional Walls and Roof Used in Tropical Climate Using Guarded Hot Box. Constr. Build. Mater. 2019, 218, 73–89. [Google Scholar] [CrossRef]

- Seitz, S.; Beaudry, K.; MacDougall, C. Thermal performance of panels with high density, randomly oriented straw bales. J. Green Build. 2018, 13, 31–55. [Google Scholar] [CrossRef]

- Palani, H.; Karatas, A. Innovative Environmental Chamber Construction for Accurate Thermal Performance Evaluation of Building Envelopes in Varied Climates. Buildings 2023, 13, 1259. [Google Scholar] [CrossRef]

- Hou, J.; Zhang, T.; Liu, Z.; Hou, C.; Fukuda, H. A study on influencing factors of optimum insulation thickness of exterior walls for rural traditional dwellings in northeast of Sichuan hills, China. Case Stud. Constr. Mater. 2022, 16, e01033. [Google Scholar] [CrossRef]

- Li, T.; Liu, Q.; Mao, Q.; Chen, M.; Ma, C.; Wang, D.; Liu, Y. Optimization design research of insulation thickness of exterior wall based on the orientation difference of solar radiation intensity. Appl. Therm. Eng. 2023, 223, 119977. [Google Scholar] [CrossRef]

- Bartko, M.; Jonkman, R.; Lacasse, M.; Moore, T.; Parekh, A.; Plescia, S. An Overview of Studies to Assess the Thermal and Hygrothermal Performance of Highly Insulated and Zero Energy Ready Wall Assemblies. In Proceedings of the 15th Canadian Conference on Building Science and Technology, Vancouver, BC, Canada, 6–8 November 2017. [Google Scholar]

- Boudreaux, P.; Pallin, S.; Accawi, G.; Desjarlais, A.; Jackson, R.; Senecal, D. A rule-based expert system applied to moisture durability of building envelopes. J. Build. Phys. 2018, 42, 416–437. [Google Scholar] [CrossRef]

- Pallin, S.; Boudreaux, P.; Jo, S.J.; Perez, M.; Albaugh, A. Simulations of Indoor Moisture Generation in U.S. Homes. In Advances in Hygrothermal Performance of Building Envelopes: Materials, Systems and Simulations; ASTM: West Conshohocken, PA, USA, 2017; pp. 261–290. [Google Scholar] [CrossRef]

- Kim, S.; Zirkelbach, D.; Künzel, H.M. Review of Methods to Create Meteorological Data Suitable for Moisture Control Design by Hygrothermal Building Envelope Simulation. Energies 2023, 16, 3271. [Google Scholar] [CrossRef]

- Recart, C.; Dossick, C.S. Hygrothermal behavior of post-retrofit housing: A review of the impacts of the energy efficiency upgrade strategies. Energy Build. 2022, 262, 112001. [Google Scholar] [CrossRef]

- Fedorik, F.; Heiskanen, R.; Laukkarinen, A.; Vinha, J. Impacts of multiple refurbishment strategies on hygrothermal behaviour of basement walls. J. Build. Eng. 2019, 26, 100902. [Google Scholar] [CrossRef]

- Mendell, M.J.; Mirer, A.G.; Cheung, K.; Tong, M.; Douwes, J. Respiratory and Allergic Health Effects of Dampness, Mold, and Dampness-Related Agents: A Review of the Epidemiologic Evidence. Environ. Health Perspect. 2011, 119, 748–756. [Google Scholar] [CrossRef] [PubMed]

- Quansah, R.; Jaakkola, M.S.; Hugg, T.T.; Heikkinen, S.A.M.; Jaakkola, J.J.K. Residential Dampness and Molds and the Risk of Developing Asthma: A Systematic Review and Meta-Analysis. PLoS ONE 2012, 7, e47526. [Google Scholar] [CrossRef] [PubMed]

- Kanchongkittiphon, W.; Mendell, M.J.; Gaffin, J.M.; Wang, G.; Phipatanakul, W. Indoor Environmental Exposures and Exacerbation of Asthma: An Update to the 2000 Review by the Institute of Medicine. Environ. Health Perspect. 2015, 123, 6–20. [Google Scholar] [CrossRef]

- Zhuge, Y.; Qian, H.; Zheng, X.; Huang, C.; Zhang, Y.; Zhang, M.; Li, B.; Zhao, Z.; Deng, Q.; Yang, X.; et al. Residential risk factors for childhood pneumonia: A cross-sectional study in eight cities of China. Environ. Int. 2018, 116, 83–91. [Google Scholar] [CrossRef]

- Morelli, M.; Møller, E.B. Energy savings and risk of mold growth in apartments renovated with internal insulation. Sci. Technol. Built Environ. 2019, 25, 1199–1211. [Google Scholar] [CrossRef]

- Du, C.; Wang, Y.; Li, B.; Xu, M.; Sadrizadeh, S. Grey image recognition-based mold growth assessment on the surface of typical building materials responding to dynamic thermal conditions. Build. Environ. 2023, 243, 110682. [Google Scholar] [CrossRef]

- ANSI/ASHRAE/IES Standard 90.1-2022; Energy Standard for Sites and Buildings Except Low Rise Residential Buildings. ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers): Atlanta, GA, USA, 2022.

- ASHRAE Standard 160-2016; Criteria for Moisture Control Design Analysis in Buildings. American Society of Heating, Refrigerating and Air Conditioning Engineers: Atlanta, GA, USA, 2016.

- DOE (U.S. Department of Energy). Adaptable—Sustainable Housing Solutions for Every Climate. 2023. Available online: https://www.energy.gov/sites/default/files/2023-05/bto-peer-2023-adaptable.pdf (accessed on 13 October 2023).

- Cold Climate Housing Research Center, Inc. & National Renewable Energy Lab. 2023. Available online: https://acrobat.adobe.com/link/review?uri=urn:aaid:scds:US:68d4c2b4-82c6-33ef-878a-dc15948a6dde (accessed on 17 October 2023).

- Almeida, R.M.S.F.; Barreira, E. Monte Carlo Simulation to Evaluate Mould Growth in Walls: The Effect of Insulation, Orientation, and Finishing Coating. Adv. Civ. Eng. 2018, 2018, e8532167. [Google Scholar] [CrossRef]

- Bastien, D.; Winther-Gaasvig, M. Influence of driving rain and vapour diffusion on the hygrothermal performance of a hygroscopic and permeable building envelope. Energy 2018, 164, 288–297. [Google Scholar] [CrossRef]

- D’Orazio, M.; Cursio, G.; Graziani, L.; Aquilanti, L.; Osimani, A.; Clementi, F.; Yéprémian, C.; Lariccia, V.; Amoroso, S. Effects of water absorption and surface roughness on the bioreceptivity of ETICS compared to clay bricks. Build. Environ. 2014, 77, 20–28. [Google Scholar] [CrossRef]

- Gradeci, K.; Labonnote, N.; Time, B.; Köhler, J. Mould growth criteria and design avoidance approaches in wood-based materials—A systematic review. Constr. Build. Mater. 2017, 150, 77–88. [Google Scholar] [CrossRef]

- Klõšeiko, P.; Arumägi, E.; Kalamees, T. Hygrothermal performance of internally insulated brick wall in cold climate: A case study in a historical school building. J. Build. Phys. 2015, 38, 444–464. [Google Scholar] [CrossRef]

- Silveira, V.D.C.; Pinto, M.M.; Westphal, F.S. Influence of environmental factors favorable to the development and proliferation of mold in residential buildings in tropical climates. Build. Environ. 2019, 166, 106421. [Google Scholar] [CrossRef]

- WUFI. WUFI Pro. 2021. Available online: https://wufi.de/en/software/wufi-pro/ (accessed on 28 November 2023).

- DIN EN 15026:2007; Hygrothermal Performance of Building Components and Building Elements—Assessment of Moisture Transfer by Numerical Simulation. Deutsches Institut für Normung: Berlin, Germany, 2007.

- Kunzel, H.M. Simultaneous Heat and Moisture Transport in Building Components, One-And Two-Dimensional Calculation Using Simple Parameters; IRB-Verlag: Stuttgart, Germany, 1995; p. 65. [Google Scholar]

- Ozolins, A.; Jacovics, A.; Ratnieks, A. Moisture Risk in Multi-layered Walls—Comparison of COMSOL Multiphysics and WUFI Plus Models with Experimental Results. In Proceedings of the COMSOL 2013 Conference, Rotterdam, The Netherlands, 23–25 October 2013. [Google Scholar]

- Holzhueter, K.; Itonaga, K. An Evaluation of WUFI-Bio to Predict Mold Growth in Straw Bale Walls in Japan. J. Asian Arch. Build. Eng. 2017, 16, 357–362. [Google Scholar] [CrossRef]

- Yoo, J.; Chang, S.J.; Yang, S.; Wi, S.; Kim, Y.U.; Kim, S. Performance of the hygrothermal behavior of the CLT wall using different types of insulation; XPS, PF board and glass wool. Case Stud. Therm. Eng. 2021, 24, 100846. [Google Scholar] [CrossRef]

- Busser, T.; Berger, J.; Piot, A.; Pailha, M.; Woloszyn, M. Comparison of model numerical predictions of heat and moisture transfer in porous media with experimental observations at material and wall scales: An analysis of recent trends. Dry. Technol. 2019, 37, 1363–1395. [Google Scholar] [CrossRef]

- WUFI®. Creating Weather Files. 2023. Available online: https://wufi.de/en/service/downloads/creating-weather-files/ (accessed on 27 November 2023).

- ASHRAE 1365-RP; Thermal Performance of Building Envelope Details for Mid- and High-Rise Buildings. ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers): Atlanta, GA, USA, 2011.

- Kempton, L.; Kokogiannakis, G.; Green, A.; Cooper, P. Evaluation of thermal bridging mitigation techniques and impact of calculation methods for lightweight steel frame external wall systems. J. Build. Eng. 2021, 43, 102893. [Google Scholar] [CrossRef]

- Viitanen, H.; Krus, M.; Ojanen, T.; Eitner, V.; Zirkelbach, D. Mold Risk Classification Based on Comparative Evaluation of Two Established Growth Models. Energy Procedia 2015, 78, 1425–1430. [Google Scholar] [CrossRef]

| Layers (Outside to Inside) | Thickness (Meter, m) | Thermal Conductivity, k (Watt per Meter Kelvin, W/m·K) | Thermal Resistance, R (Square Meters Kelvin per Watt, m2·K/W) |

|---|---|---|---|

| 26-gauge sheet metal | (1/40)” = 4.55 × 10−4 | 60 | 7.6 × 10−7 |

| Plywood | 0.0125 | 0.065 | 0.192 |

| EPS foam | 0.025 | 0.036 | 0.694 |

| VIP | 0.025 | 0.0022 | 11.364 |

| EPS foam | 0.025 | 0.036 | 0.694 |

| Plywood | 0.0125 | 0.065 | 0.192 |

| 26-gauge sheet metal | 4.55 × 10−4 | 60 | 7.6 × 10−7 |

| Air gap | 0.025 | 0.094 | 0.265 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Palani, H.; Khaleghi, H.; Salehi, P.; Karatas, A. Assessing Hygrothermal Performance in Building Walls Engineered for Extreme Cold Climate Environments. Sustainability 2023, 15, 16597. https://doi.org/10.3390/su152416597

Palani H, Khaleghi H, Salehi P, Karatas A. Assessing Hygrothermal Performance in Building Walls Engineered for Extreme Cold Climate Environments. Sustainability. 2023; 15(24):16597. https://doi.org/10.3390/su152416597

Chicago/Turabian StylePalani, Hevar, Hamed Khaleghi, Parisa Salehi, and Aslihan Karatas. 2023. "Assessing Hygrothermal Performance in Building Walls Engineered for Extreme Cold Climate Environments" Sustainability 15, no. 24: 16597. https://doi.org/10.3390/su152416597

APA StylePalani, H., Khaleghi, H., Salehi, P., & Karatas, A. (2023). Assessing Hygrothermal Performance in Building Walls Engineered for Extreme Cold Climate Environments. Sustainability, 15(24), 16597. https://doi.org/10.3390/su152416597