Effect of Fertilisation Regime on Maise Yields

Abstract

:1. Introduction

- Natural—manure from livestock, in the form of manure, slurry, intended for agricultural use;

- Mineral (inorganic)—produced by physicochemical transformations or the processing of mineral raw materials;

- Organic—made from organic substances and mixtures of organic substances (e.g., composts);

- Organic-mineral—mixtures of mineral and organic fertilisers.

- High biological activity of beneficial microflora;

- Neutralised effect of pathogenic micro-organisms (e.g., Salmonella);

- The high content of readily available ammoniacal nitrogen;

- Reducing the germination capacity of weed seeds contained in the digestate;

- No risk to groundwater.

2. Materials and Methods

- The plot was fertilised with a digestate (at a rate of 40 t per hectare).

- The plot was fertilised with a digestate (at a rate of 40 t per hectare) and an NPK fertiliser (N—87 kg per hectare, P—60 kg per hectare, and K—90 kg per hectare).

- The plot was fertilised with a digestate (at a rate of 40 t per hectare), an NPK fertiliser (at a rate of N—87 kg per hectare, P—60 kg per hectare, and K—90 kg per hectare), and micronutrients (in the form of Plonvit NPK at a rate of 3.0 l per hectare).

- The plot was fertilised with an NPK fertiliser (at a rate of N—140 kg per hectare, P—42 kg per hectare, and K—119 kg per hectare).

- The plot was fertilised with an NPK fertiliser (at a dose of N—140 kg per hectare, P—42 kg per hectare, and K—119 kg per hectare) and micronutrients (in the form of Plonvit NPK at a dose of 3.0 l per hectare).

3. Results and Discussion

- rxy = 0—variables are not correlated;

- 0 < rxy < 0.1—weak correlation;

- 0.1 ≤ rxy < 0.3—weak correlation;

- 0.3 ≤ rxy < 0.5—average correlation;

- 0.5 ≤ rxy < 0.7—high correlation;

- 0.7 ≤ rxy < 0.9—very high correlation;

- 0.9 ≤ rxy < 1—correlation almost certain;

- rxy = 1—correlation certain.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Act of 10 July 2007 on fertilizers and fertilization (Dz.U. 2007 nr 147 poz. 1033 as subsequently amended).

- Niemiec, M.; Sikora, J.; Szelag-Sikora, A.; Kubon, M.; Olech, E.; Marczuk, A. Applicability of food industry organic waste for methane fermentation. Przem. Chem. 2017, 96, 685–688. [Google Scholar] [CrossRef]

- Barwicki, J.; Borusiewicz, A.; Holden, L.; Kulcsar, L.; Skibko, Z.; Żuchowski, I.; Romaniuk, W. Leaching of Elements from Soil in Grassland Field Crops Treated with Raw and Acidified Slurry. Agric. Eng. 2022, 26, 145–156. [Google Scholar] [CrossRef]

- Voitik, A.; Kravchenko, V.; Pushka, O.; Kutkovetska, T.; Shchur, T.; Kocira, S. Comparison of NDVI, NDRE, MSAVI and NDSI Indices for Early Diagnosis of Crop Problems. Agric. Eng. 2023, 27, 47–57. [Google Scholar] [CrossRef]

- Skibko, Z.; Romaniuk, W.; Borusiewicz, A.; Porwisiak, H. Use of pellets from agricultural biogas plants in fertilisation of oxytrees in Podlasie, Poland. J. Water Land Dev. 2021, 51, 124–128. [Google Scholar] [CrossRef]

- Crinnion, W. Organic foods contain higher levels of certain nutrients, lower levels of pesticides and may provide health benefits for the consumer. Environ. Med. 2010, 15, 4–12. [Google Scholar] [PubMed]

- Arvaniti, F.; Magkos, F.; Zampelas, A. Organic food: Buying more safety or just peace of mind? A critical review of the literature. Crit. Rev. Food Sci. Nutr. 2006, 46, 23–56. [Google Scholar] [CrossRef]

- Singh, A.; Pandey, J. Metal contamination and health risk from consumption of organically grown vegetables influenced by atmospheric deposition in a seasonally dry tropical region of India. Bull. Environ. Contam. Toxicol. 2012, 89, 384–389. [Google Scholar] [CrossRef]

- Łagocka, A.; Kamiński, M.; Cholewiński, M. Biogas fermentation by-products—The utilisation as a full-value fertiliser and its impact on the rural areas. II Int. Conf. Human Ecology. Wyd. Uczel. Zachodniopom. Uniw. Technol. Szczecinie 2016, 124–125. [Google Scholar]

- Kamiński, E.; Markiewicz, W. Fertilization Technique with Natural Fertilizers. ITP. Falenty, Kłudzienko. 2014. Available online: https://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&ved=2ahUKEwib6M3j6P-AAxXsIRAIHRySDjcQFnoECBMQAQ&url=https%3A%2F%2Fwww.itp.edu.pl%2Fold%2Fnauka%2Fproduktypw%2FPoradnik%2520PW%2520Technika%2520nawozenia.pdf&usg=AOvVaw2D3QdZleVLSORaqJ9hpLyf&opi=89978449 (accessed on 2 October 2023).

- Żelezik, M. Why organic farming. Rocznik Świętokrzyski. Ser. B. Nauki Przyr. Kielce 2009, 30, 155–166. [Google Scholar]

- Kuboń, M.; Skibko, Z.; Tabor, S.; Malaga-Toboła, U.; Borusiewicz, A.; Romaniuk, W.; Zarajczyk, J.; Neuberger, P. Analysis of Voltage Distortions in the Power Grid Arising from Agricultural Biogas Plant Operation. Energies 2023, 16, 6189. [Google Scholar] [CrossRef]

- Borek, K.; Romaniuk, W.; Roman, K.; Roman, M.; Kuboń, M. The analysis of a prototype installation for biogas production from chosen agricultural substrates. Energies 2021, 14, 2132. [Google Scholar] [CrossRef]

- Sahlström, L. A review of survival of pathogenic bacteria in organic waste used in biogas plants. Bioresour. Technol. 2003, 87, 161–166. [Google Scholar] [CrossRef] [PubMed]

- Sassi, H.P.; Ikner, L.A.; Abd-Elmaksoud, S.; Gerba, C.P.; Pepper, I.L. Comparative survival of viruses during thermophilic and mesophilic anaerobic digestion. Sci. Total Environ. 2018, 615, 15–19. [Google Scholar] [CrossRef] [PubMed]

- Johansen, A.; Nielsen, H.B.; Hansen, C.M.; Andreasen, C.; Carlsgart, J.; Hauggard-Nielsen, H.; Roepstorff, A. Survival of weed seeds and animal parasites as affected by anaerobic digestion at meso- and thermophilic conditions. Waste Manag. 2013, 33, 807–812. [Google Scholar] [CrossRef] [PubMed]

- Zhou, L.; Hülsemann, B.; Merkle, W.; Guo, J.; Dong, R.; Piepho, H.-P.; Gerhards, R.; Müller, J.; Oechsner, H. Influence of Anaerobic Digestion Processes on the Germination of Weed Seeds. Gesunde Pflanz. 2020, 72, 181–194. [Google Scholar] [CrossRef]

- Tymińska, M.; Skibko, Z.; Borusiewicz, A. The Effect of Agricultural Biogas Plants on the Quality of Farm Energy Supply. Energies 2023, 16, 4600. [Google Scholar] [CrossRef]

- The Act of 27 April 2001 on waste. (Dz.U. 2001 nr 62 poz. 628 as subsequently amended).

- Regulation of the Minister of Maritime Affairs and Inland Navigation of 12 July 2019 on substances particularly harmful to the aquatic environment and conditions to be met when discharging wastewater into waters or into the ground, as well as when discharging rainwater or snowmelt into waters or into water facilities (Dz.U. 2019 poz. 1311).

- Lijó, L.; González-García, S.; Bacenetti, J.; Negri, M.; Fiala, M.; Feijoo, G.; Moreira, M.T. Environmental assessment of farm-scaled anaerobic co-digestion for bioenergy production. Waste Manag. 2015, 41, 50–59. [Google Scholar] [CrossRef]

- Teglia, C.; Tremier, A.; Martel, J.-L. Characterization of solid digestates: Part 1, review of existing indicators to assess solid digestates agricultural use. Waste Biomass Valorization 2011, 2, 43–58. [Google Scholar] [CrossRef]

- Regulation of the Minister of Agriculture and Rural Development of 16 April 2008 on the detailed manner of applying fertilisers and training in their use. Dz. U. Nr 80 poz. 479.

- Alburquerque, A.J.; Fuente, C.; Ferrer-Costa, A.; Carrasco, L.; Cegarra, A.b.a.d.M.; Bernal, P.M. Assessment of the fertiliser potential of digestates from farm and agroindustrial residues. Biomass Bioen. 2012, 40, 181–189. [Google Scholar] [CrossRef]

- Kratzeisen, M.; Starcevic, N.; Martinov, M.; Maurer, C.; Müller, J. Applicability of biogas digestate as solid fuel. Fuel 2010, 89, 2544–2548. [Google Scholar] [CrossRef]

- Baran, S.; Łabędowicz, J.; Krzywy, E. Naturalistic Use of Waste—Theoretical and Practical Basis; PWRiL: Warsow, Poland, 2011; pp. 1–321. ISBN 978-83-09-99031-4. [Google Scholar]

- Abubaker, J.; Risberg, K.; Pell, M. Biogas residues as fertilisers–Effects on wheat growth and soil microbial activities. Appl. Energy 2012, 99, 126–134. [Google Scholar] [CrossRef]

- Lukehurst, C.T.; Frost, P.; Al Seadi, T. Utilisation of digestate from biogas plants as biofertiliser. IEA Bioenergy 2010, 1–36. [Google Scholar]

- Möller, K.; Müller, T. Effects of anaerobic digestion on digestate nutrient availability and crop growth: A review. Eng. Life Sci. 2012, 12, 242–257. [Google Scholar] [CrossRef]

- Sikora, J.; Niemiec, M.; Szeląg-Sikora, A.; Gródek-Szostak, Z.; Kuboń, M.; Komorowska, M. The Effect of the Addition of a Fat Emulsifier on the Amount and Quality of the Obtained Biogas. Energies 2020, 13, 1825. [Google Scholar] [CrossRef]

- Dubský, M.; Chaloupková, Š.; Kaplan, L.; Vondráčková, S.; Tlustoš, P. Use of solid phase of digestate for production of growing horticultural substrates. Hortic. Sci. 2019, 46, 34–42. [Google Scholar] [CrossRef]

- Kolář, L.; Kužel, S.; Peterka, J.; Borová-Batt, J. Agrochemical value of the liquid phase of wastes from fermentem during biogas production. Plant Soil Environ. 2010, 56, 23–27. [Google Scholar] [CrossRef]

- Makádi, M.; Tomócsik, A.; Orosz, V. Digestate: A new nutrient source–review. Biogas 2012, 14, 295–312. [Google Scholar] [CrossRef]

- Czekała, W.; Nowak, M.; Bojarski, W. Anaerobic Digestion and Composting as Methods of Bio-Waste Management. Agric. Eng. 2023, 27, 173–186. [Google Scholar] [CrossRef]

- Coelho, J.J.; Prieto, M.L.; Dowling, S.; Hennessy, A.; Casey, I.; Woodcock, T.; Kennedy, N. Physical-chemical traits, phytotoxicity and pathogen detection in liquid anaerobic digestates. Waste Manag. 2018, 78, 8–15. [Google Scholar] [CrossRef]

- Boryga, M.; Kołodziej, P. Reverse Engineering in Modeling Agricultural Products. Agric. Eng. 2022, 26, 105–117. [Google Scholar] [CrossRef]

- Balanda, O.; Serafinowska, D.; Marchenko, O.; Svystunova, I. Innovative Technology of Accelerated Composting of Chicken Manure to Obtain an Organic Fertilizer with a High Content of Humic Acids. Agric. Eng. 2022, 26, 133–144. [Google Scholar] [CrossRef]

- Sogn, T.A.; Dragicevic, I.; Linjordet, R.; Krogstad, T.; Eijsink, V.G.; Eich-Greatorex, S. Recycling of biogas digestates in plant production: NPK fertiliser value and risk of leaching. Int. J. Recycl. Org. Waste Agric. 2018, 7, 49–58. [Google Scholar] [CrossRef]

- Tsachidou, B.; Scheuren, M.; Gennen, J.; Debbaut, V.; Toussaint, B.; Hissler, C.; George, I.; Delfosse, P. Biogas residues in substitution for chemical fertilisers: A comparative study on a grassland in the Walloon Region. Sci. Total Environ. 2019, 666, 212–225. [Google Scholar] [CrossRef] [PubMed]

- Koszel, M.; Lorencowicz, E. Agricultural use of biogas digestate as a replacement fertilisers. Agric. Agric. Sci. Procedia 2015, 7, 119–124. [Google Scholar] [CrossRef]

- Romaniuk, W.; Mazur, K.; Borek, K.; Borusiewicz, A.; Wardal, W.J.; Tabor, S.; Kuboń, M. Biomass energy technologies from innovative dairy farming systems. Processes 2021, 9, 335. [Google Scholar] [CrossRef]

- Chambers, B.J.; Smith, K.A.; Pain, B.F. Strategies to encourage better use of nitrogen in animal manures. Soil Use Manag. 2000, 16, 157–161. [Google Scholar] [CrossRef]

- Gołębiewska, M.; Wróbel, E. Effect of nitrogen fertilisation on maize yield. Bull. Inst. Plant Breed. Acclim. 2009, 251, 121–136. [Google Scholar]

- Bereś, P.K.; Gaj, R.; Grzebisz, W.; Kaniuczak, Z.; Mrówczyński, M.; Paradowski, A.; Pruszyński, G.; Pruszyński, S.; Siódmiak, J.; Sulewska, H.; et al. Methodology of Integrated Maize Production; Kaniuczak, Z., Pruszyński, S., Eds.; IOR–PIB: Warsaw, Poland, 2023; ISBN 978-83-64655-81-4. [Google Scholar]

- Brandt, K.; Molgaard, P. Organic agriculture: Does it enhance or reduce the nutritional value of plant foods? J. Sci. Food Agric. 2001, 81, 924–931. [Google Scholar] [CrossRef]

- Kazimierczak, R.; Hallmann, E.; Sokołowska, O.; Rembiałkowska, E. The content of bioactive compounds in herbal plants from organic and conventional cultivation. J. Res. Appl. Agric. Eng. 2011, 56, 200–205. [Google Scholar]

- Księżak, J.; Bojarszczuk, J.; Staniak, M. Productivity of corn and sorghum depending on the level of nitrogen fertilization. Pol. J. Agron. 2012, 8, 20–28. [Google Scholar]

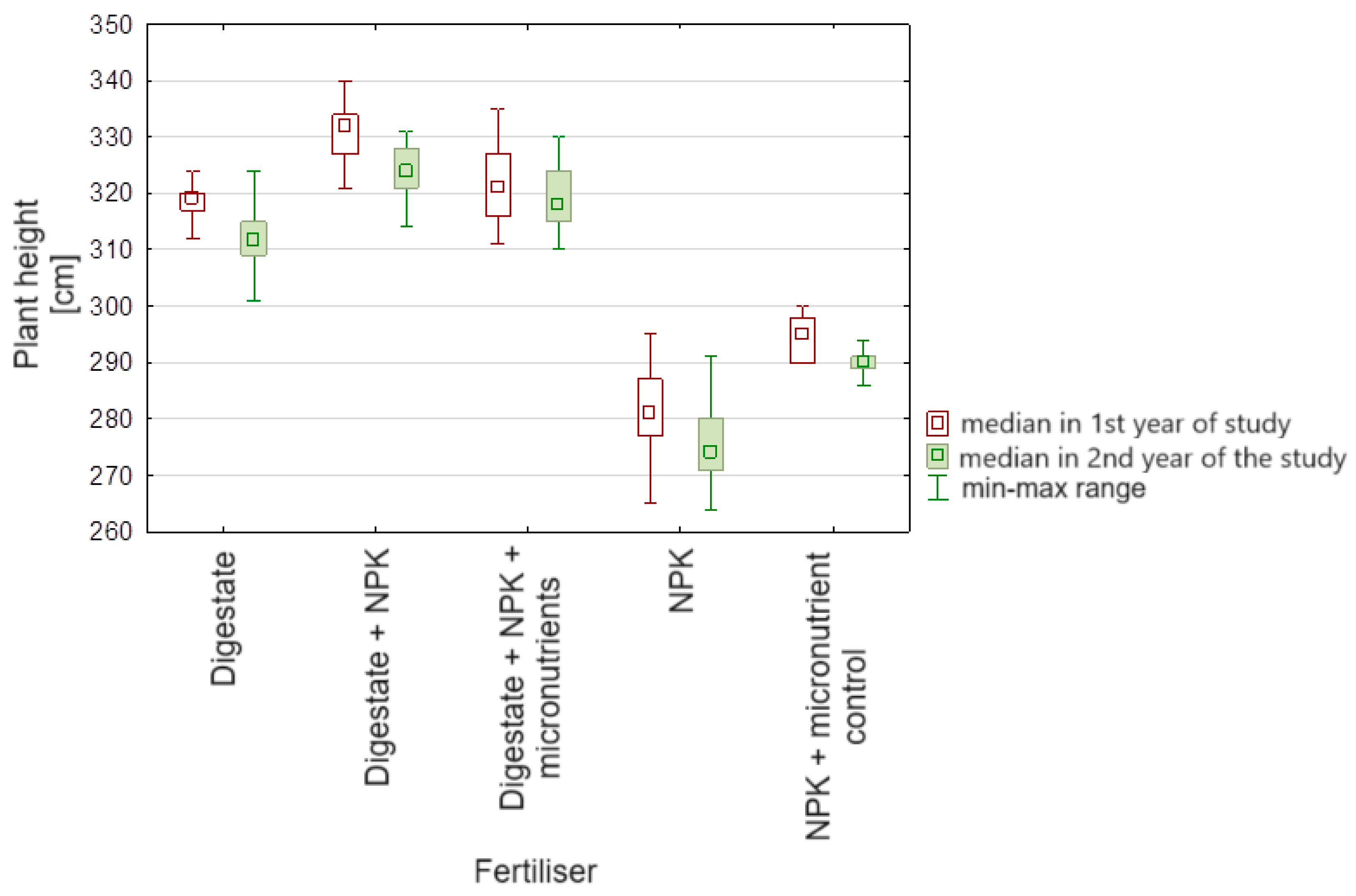

- Zieleniewicz, W.; Swędrzyńska, D.; Swędrzyński, A. Influence of the application of varying nitrogen rates on the morphological properties of corn grown for silage. Łąkarstwo W Polsce 2018, 21, 177–190. [Google Scholar]

- Stanisz, A. An Accessible Statistics Course Using STATISTICA PL with Examples from Medicine Volume 1 Basic Statistics; StatSoft Polska: Kraków, Poland, 2006; ISBN 10-83-88724-18-5. [Google Scholar]

- Creegan, E.F.; Flynn, R.; Brewer, C.E.; Heerema, R.J.; Darapuneni, M.; Velasco-Cruz, C. Pecan Biomass and Dairy Manure Utilization: Compost Treatment and Soil In-Situ Comparisons of Selected Pecan Crop and Soil Variables. Processes 2023, 11, 2046. [Google Scholar] [CrossRef]

- Chen, X.; Tao, T.; Zhou, J.; Yu, H.; Guo, H.; Chen, H. Simulation and Prediction of Greenhouse Gas Emissions from Beef Cattle. Sustainability 2023, 15, 11994. [Google Scholar] [CrossRef]

| Metal | Maximum Content |

|---|---|

| [mg·kg−1] | |

| Cadmium | 5 |

| Chrome | 100 |

| Nickel | 60 |

| Lead | 140 |

| Mercury | 2 |

| Manure Origin | Macronutrients [%] | Micronutrients [mg·kg−1] | ||||||||

| N | P2O5 | K2O | CaO | MgO | B | Cu | Mn | Mo | Zn | |

| Cattle | 0.47 | 0.29 | 0.67 | 0.45 | 0.16 | 4.46 | 4.46 | 64.65 | 0.29 | 34.60 |

| Pigs | 0.49 | 0.71 | 0.68 | 0.44 | 0.16 | 3.60 | 5.38 | 63.22 | 0.33 | 48.51 |

| Horses | 0.54 | 0.29 | 0.95 | 0.45 | 0.16 | 3.51 | 3.36 | 70.41 | 0.25 | 25.91 |

| Sheep | 0.76 | 0.40 | 1.25 | 0.61 | 0.21 | 5.81 | 5.14 | 84.22 | 0.34 | 32.37 |

| Poultry | 1.20 | 0.79 | 0.80 | 0.73 | 0.21 | 9.59 | 8.73 | 76.63 | 0.52 | 66.60 |

| Mixed manure | 0.49 | 0.31 | 0.68 | 0.44 | 0.16 | 4.65 | 5.05 | 73.31 | 0.34 | 40.50 |

| Digestate | Dry Matter | Total Nitrogen | Nitrogen NH4 | P | K |

|---|---|---|---|---|---|

| [%] | [kg·m−3] | [kg·m−3] | [kg·m−3] | [kg·m−3] | |

| bovine slurry—100% | 5.1 | 5 | 3.3 | 1.8 | 6.5 |

| maise silage—70% + cattle slurry—30% | 9 | 5.8 | 3.8 | 2.3 | 9.1 |

| maise silage—40% + pig slurry—60% | 6.3 | 5.5 | 3.6 | 2.6 | 5.2 |

| maise silage—85% + pig slurry—10% + wheat grain—5% | 10.5 | 7.5 | 4.9 | 3.6 | 10.1 |

| maise silage—80% + rye silage—20% | 10.9 | 7 | 4.6 | 2.8 | 11.1 |

| cattle slurry—84.4% + oat and maise silage—11.6% | 3.1 | 4 | 2.4 | 0.8 | 3.1 |

| pig slurry—94.6% + maise residues—5.4% | 2.8 | 3.4 | 2.7 | 1.2 | 2.7 |

| pig slurry—91.4% + rapeseed residues—9.6% | 4.4 | 3.6 | 2.9 | 1.1 | 3.1 |

| pig slurry—95.5% + sunflower residue—4.5% | 3.8 | 3.5 | 2.6 | 1.1 | 3.1 |

| Fertiliser | Dry Matter | N | P2O2 | K2O |

|---|---|---|---|---|

| [%] | [g·kg−1 Fresh Weight] | |||

| Manure | 21–24 | 4.6–5.4 | 2.7–4.4 | 6.5–6.7 |

| Slurry | 5–9.5 | 0.6–8.2 | 0.2–9.6 | 0.1–5.1 |

| Digestate | 4–7 | 3.0–5.0 | 1.0–1.5 | 3.5–5.5 |

| Block No. | No. of Application of Fertiliser to the Plot | ||||

| First year of study | |||||

| 1 | 4 | 1 | 3 | 2 | 5 |

| 2 | 2 | 5 | 4 | 3 | 1 |

| 3 | 1 | 3 | 5 | 4 | 2 |

| Second year of study | |||||

| 1 | 4 | 3 | 2 | 1 | 5 |

| 2 | 1 | 2 | 5 | 4 | 3 |

| 3 | 3 | 4 | 1 | 5 | 2 |

| Parameter | Unit | First Year of Study | Second Year of Study | ||

|---|---|---|---|---|---|

| Before Sowing | After Harvesting | Before Sowing | After Harvesting | ||

| pH | - | 6.7 | 6.7 | 6.7 | 6.7 |

| P2O5 | mg per 100 g of soil | 13.2 | 14.4 | 13.8 | 14.0 |

| K2O | mg per 100 g of soil | 22.0 | 16.0 | 20.8 | 14.9 |

| Mg | mg per 100 g of soil | 5.7 | 4.9 | 5.4 | 4.9 |

| Specification | Year of Study | Months | |||||

|---|---|---|---|---|---|---|---|

| V | VI | VII | VIII | IX | V–IX | ||

| Average daily temperature [°C] | 1 | 12.2 | 19.4 | 21.8 | 17.0 | 12.4 | 16.6 |

| 2 | 12.2 | 18.3 | 18.4 | 21.0 | 10.9 | 16.2 | |

| Total precipitation [mm] | 1 | 77.9 | 61.2 | 122.8 | 114.2 | 54.8 | 430.9 |

| 2 | 64.9 | 46.4 | 115.3 | 31.4 | 93.8 | 333.8 | |

| Year of Study | - | 1 | 2 | Average | Deflection |

|---|---|---|---|---|---|

| Dry matter | % | 4.71 | 4.86 | 4.785 | 0.075 |

| Organic dry matter | % | 73.58 | 76.4 | 74.99 | 1.41 |

| Calcium (Ca) | g·kg−1 f.w. | 34.1 | 24.7 | 29.4 | 4.7 |

| Magnesium (Mg) | g·kg−1 f.w. | 10.4 | 11.17 | 10.785 | 0.385 |

| Sodium (Na) | g·kg−1 f.w. | 10.3 | 8.52 | 9.41 | 0.89 |

| Phosphorus (P) | g·kg−1 f.w. | 11.2 | 9.24 | 10.22 | 0.98 |

| Potassium (K) | g·kg−1 f.w. | 51.5 | 49.9 | 50.7 | 0.8 |

| Molybdenum (Mo) | mg·kg−1 f.w. | 2.24 | 2.91 | 2.575 | 0.335 |

| Cobalt (Co) | mg·kg−1 f.w. | 1.94 | 1.83 | 1.885 | 0.055 |

| Manganese (Mn) | g·kg−1 f.w. | 0.333 | 0.362 | 0.3475 | 0.0145 |

| Zinc (Zn) | mg·kg−1 f.w. | 401 | 398 | 399.5 | 1.5 |

| Lead (Pb) | mg·kg−1 f.w. | 3.65 | 3.44 | 3.545 | 0.105 |

| Cadmium (Cd) | mg·kg−1 f.w. | 0.325 | 0.328 | 0.3265 | 0.0015 |

| Chromium (Cr) | mg·kg−1 f.w. | 2.78 | 2.98 | 2.88 | 0.1 |

| Copper (Cu) | mg·kg−1 f.w. | 167 | 167.7 | 167.35 | 0.35 |

| Nickel (Ni) | mg·kg−1 f.w. | 8.08 | 7.98 | 8.03 | 0.05 |

| Nitrogen (N) | g·kg−1 f.w. | 3.1 | 2.8 | 2.95 | 0.15 |

| Carbon (C) | g·kg−1 f.w. | 29.4 | 14.56 | 21.98 | 7.42 |

| Mercury (Hg) | mg·kg−1 f.w. | 0.019 | 0.016 | 0.0175 | 0.0015 |

| Ammonium nitrogen (NNH4) | mg·kg−1 f.w. | 931 | 834 | 882.5 | 48.5 |

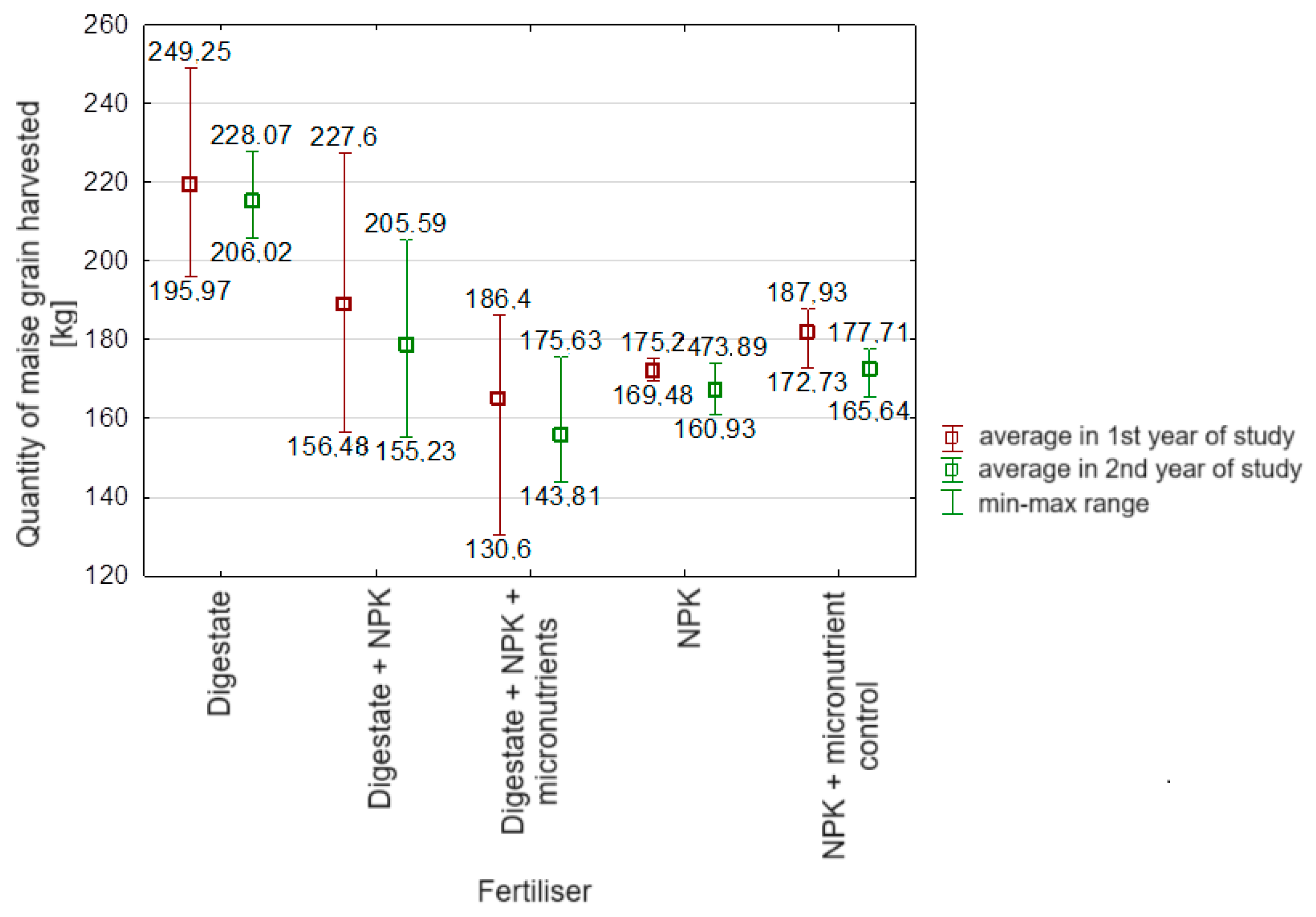

| Fertiliser | Plot No. | First Year of Study | Second Year of Study | Total of Two Years | |||||

|---|---|---|---|---|---|---|---|---|---|

| Grain Weight | Average | Deviation | Grain Weight | Average | Deviation | Deviation | Deviation | ||

| [Mg/ha] | [Mg/ha] | [Mg/ha] | [Mg/ha] | [Mg/ha] | [Mg/ha] | [Mg/ha] | [Mg/ha] | ||

| Digestate | 1 | 11.82 | 12.19 | 1.24 | 11.73 | 11.95 | 0.52 | 12.07 | 0.12 |

| 2 | 13.85 | 12.67 | |||||||

| 3 | 10.89 | 11.45 | |||||||

| Digestate + NPK | 1 | 10.15 | 10.50 | 1.63 | 11.42 | 9.93 | 1.15 | 10.21 | 0.28 |

| 2 | 12.64 | 9.75 | |||||||

| 3 | 8.69 | 8.62 | |||||||

| Digestate + NPK + micronutrients | 1 | 10.36 | 9.15 | 1.36 | 9.76 | 8.64 | 0.79 | 8.90 | 0.26 |

| 2 | 9.85 | 8.19 | |||||||

| 3 | 7.26 | 7.99 | |||||||

| NPK | 1 | 9.42 | 9.56 | 0.13 | 8.94 | 9.29 | 0.29 | 9.42 | 0.13 |

| 2 | 9.52 | 9.26 | |||||||

| 3 | 9.73 | 9.66 | |||||||

| Control NPK + microelements | 1 | 9.60 | 10.10 | 0.36 | 9.20 | 9.58 | 0.28 | 9.84 | 0.26 |

| 2 | 10.25 | 9.66 | |||||||

| 3 | 10.44 | 9.87 | |||||||

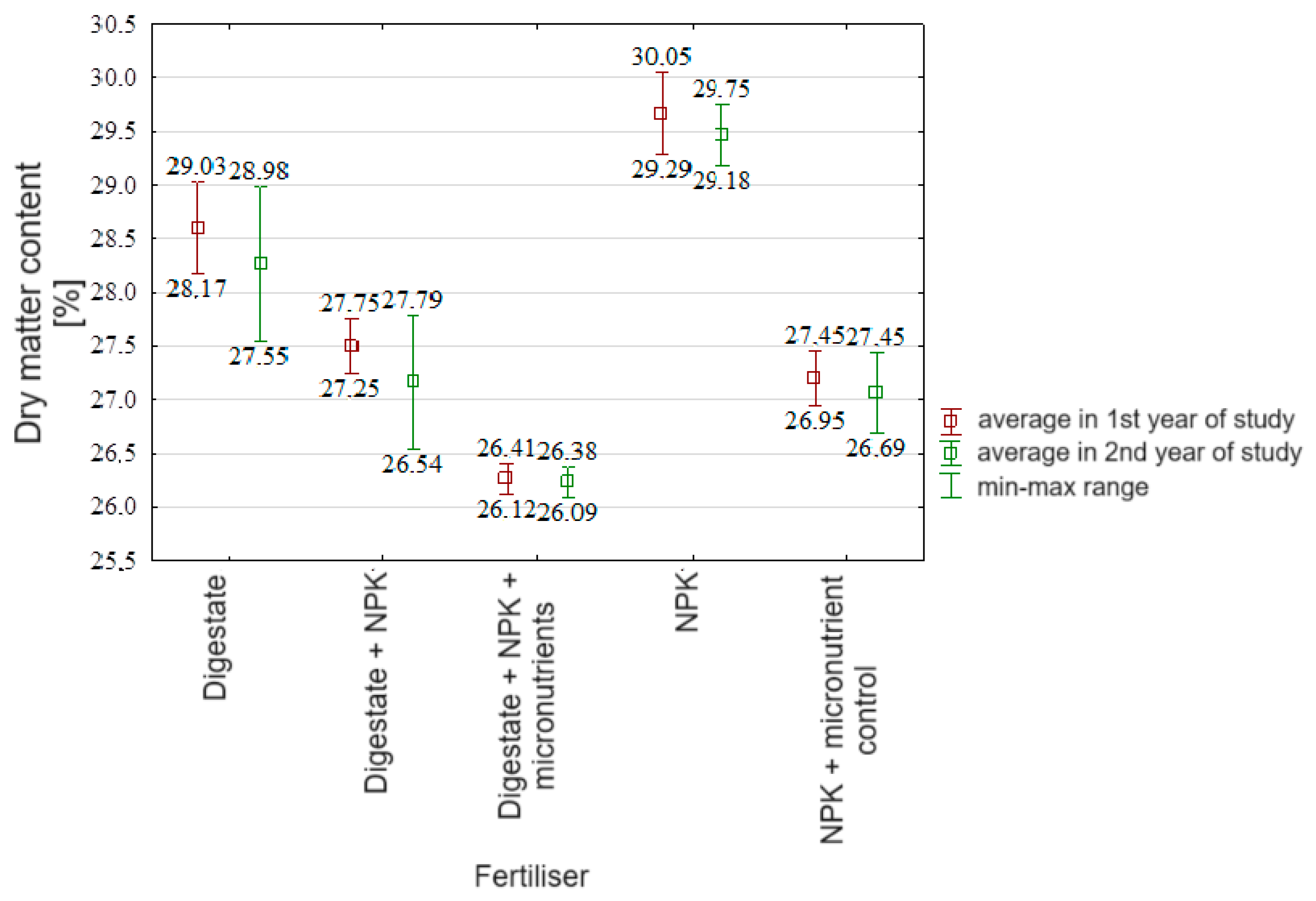

| Variable under Study | Significance Level p in First Year of Study | Significance Level p in Second Year of Study |

|---|---|---|

| Quantity of grain harvested | 0.139153 | 0.007452 |

| Plant height | 0.000003 | 0.000000 |

| Dry matter content | 0.000000 | 0.000000 |

| Quantity of Grain Harvested | ||||||

|---|---|---|---|---|---|---|

| First year of study | ||||||

| Fertiliser | 1 | 2 | 3 | 4 | 5 | |

| 1 | Digestate | 0.574081 | 0.119222 | 0.202293 | 0.386015 | |

| 2 | Digestate + NPK | 0.574081 | 0.748282 | 0.909924 | 0.995848 | |

| 3 | Digestate + NPK + micronutrients | 0.119222 | 0.748282 | 0.995811 | 0.909640 | |

| 4 | NPK | 0.202293 | 0.909924 | 0.995811 | 0.986975 | |

| 5 | NPK + micronutrient control | 0.386015 | 0.995848 | 0.909640 | 0.986975 | |

| Second year of study | ||||||

| Fertiliser | 1 | 2 | 3 | 4 | 5 | |

| 1 | Digestate | 0.088697 | 0.005314 | 0.021103 | 0.040396 | |

| 2 | Digestate + NPK | 0.088697 | 0.394353 | 0.878812 | 0.984503 | |

| 3 | Digestate + NPK + micronutrients | 0.005314 | 0.394353 | 0.878812 | 0.668698 | |

| 4 | NPK | 0.021103 | 0.878812 | 0.878812 | 0.992448 | |

| 5 | NPK + micronutrient control | 0.040396 | 0.984503 | 0.668698 | 0.992448 | |

| Plant height | ||||||

| First year of study | ||||||

| Fertiliser | 1 | 2 | 3 | 4 | 5 | |

| 1 | Digestate | 0.148652 | 0.955973 | 0.000202 | 0.001920 | |

| 2 | Digestate + NPK | 0.148652 | 0.378238 | 0.000177 | 0.000226 | |

| 3 | Digestate + NPK + micronutrients | 0.955973 | 0.378238 | 0.000186 | 0.000848 | |

| 4 | NPK | 0.000202 | 0.000177 | 0.000186 | 0.074699 | |

| 5 | NPK + micronutrient control | 0.001920 | 0.000226 | 0.000848 | 0.074699 | |

| Second year of study | ||||||

| Fertiliser | 1 | 2 | 3 | 4 | 5 | |

| 1 | Digestate | 0.044766 | 0.395070 | 0.000178 | 0.000886 | |

| 2 | Digestate + NPK | 0.044766 | 0.582223 | 0.000176 | 0.000182 | |

| 3 | Digestate + NPK + micronutrients | 0.395070 | 0.582223 | 0.000176 | 0.000231 | |

| 4 | NPK | 0.000178 | 0.000176 | 0.000176 | 0.014398 | |

| 5 | NPK + micronutrient control | 0.000886 | 0.000182 | 0.000231 | 0.014398 | |

| Dry matter content | ||||||

| First year of study | ||||||

| Fertiliser | 1 | 2 | 3 | 4 | 5 | |

| 1 | Digestate | 0.000177 | 0.000176 | 0.000177 | 0.000176 | |

| 2 | Digestate + NPK | 0.000177 | 0.000176 | 0.000176 | 0.082564 | |

| 3 | Digestate + NPK + micronutrients | 0.000176 | 0.000176 | 0.000176 | 0.000186 | |

| 4 | NPK | 0.000177 | 0.000176 | 0.000176 | 0.000176 | |

| 5 | NPK + micronutrient control | 0.000176 | 0.082564 | 0.000186 | 0.000176 | |

| Second year of study | ||||||

| Fertiliser | 1 | 2 | 3 | 4 | 5 | |

| 1 | Digestate | 0.000413 | 0.000176 | 0.000276 | 0.000276 | |

| 2 | Digestate + NPK | 0.000413 | 0.001204 | 0.000176 | 0.965942 | |

| 3 | Digestate + NPK + micronutrients | 0.000176 | 0.001204 | 0.000176 | 0.002657 | |

| 4 | NPK | 0.000276 | 0.000176 | 0.000176 | 0.000176 | |

| 5 | NPK + micronutrient control | 0.000276 | 0.965942 | 0.002657 | 0.000176 | |

| Fertiliser | Quantity of Maise Grain Harvested—Dry Matter Content | Quantity of Maise Grain Harvested—Plant Height | Quantity of Maise Grain Harvested—Flask Seating Height | Dry Matter Content—Plant Height | Dry Matter Content—Flask Seating Height | Plant Height—Flask Seating Height |

|---|---|---|---|---|---|---|

| First year of study | ||||||

| Digestate | 0.951199 | −0.123258 | 0.197431 | 0.188982 | −0.114708 | −0.997176 |

| Digestate + NPK | 0.623842 | 0.623842 | −0.469310 | 1.000000 | 0.397360 | 0.397360 |

| Digestate + NPK + mikroelementy | 0.988519 | 0.846167 | 0.036710 | 0.755929 | −0.114708 | 0.563621 |

| NPK | 0.509771 | 0.997621 | −0.979778 | 0.449252 | −0.327327 | −0.991241 |

| NPK + micronutrient control | 0.952158 | 0.986050 | 0.919830 | 0.989743 | 0.755929 | 0.841698 |

| Second year of study | ||||||

| Digestate | −0.67843 | −0.980059 | −0.297024 | 0.810885 | −0.5 | 0.101361 |

| Digestate + NPK | 0.973936 | −0.956864 | −0.999968 | −0.866025 | −0.972088 | 0.959161 |

| Digestate + NPK + mikroelementy | −0.408848 | 0.971793 | 0.800001 | −0.182092 | −0.874639 | 0.635934 |

| NPK | 0.895558 | 0.984045 | 0.895508 | 0.960434 | 0.603957 | 0.802036 |

| NPK + micronutrient control | 0.895558 | 0.984045 | 0.895508 | 0.960434 | 0.603957 | 0.802036 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuboń, M.; Tymińska, M.; Skibko, Z.; Borusiewicz, A.; Filipkowski, J.; Tabor, S.; Derehajło, S. Effect of Fertilisation Regime on Maise Yields. Sustainability 2023, 15, 16133. https://doi.org/10.3390/su152216133

Kuboń M, Tymińska M, Skibko Z, Borusiewicz A, Filipkowski J, Tabor S, Derehajło S. Effect of Fertilisation Regime on Maise Yields. Sustainability. 2023; 15(22):16133. https://doi.org/10.3390/su152216133

Chicago/Turabian StyleKuboń, Maciej, Magdalena Tymińska, Zbigniew Skibko, Andrzej Borusiewicz, Jacek Filipkowski, Sylwester Tabor, and Stanisław Derehajło. 2023. "Effect of Fertilisation Regime on Maise Yields" Sustainability 15, no. 22: 16133. https://doi.org/10.3390/su152216133

APA StyleKuboń, M., Tymińska, M., Skibko, Z., Borusiewicz, A., Filipkowski, J., Tabor, S., & Derehajło, S. (2023). Effect of Fertilisation Regime on Maise Yields. Sustainability, 15(22), 16133. https://doi.org/10.3390/su152216133