Geosynthetic Solutions for Sustainable Transportation Infrastructure Development

Abstract

:1. Introduction

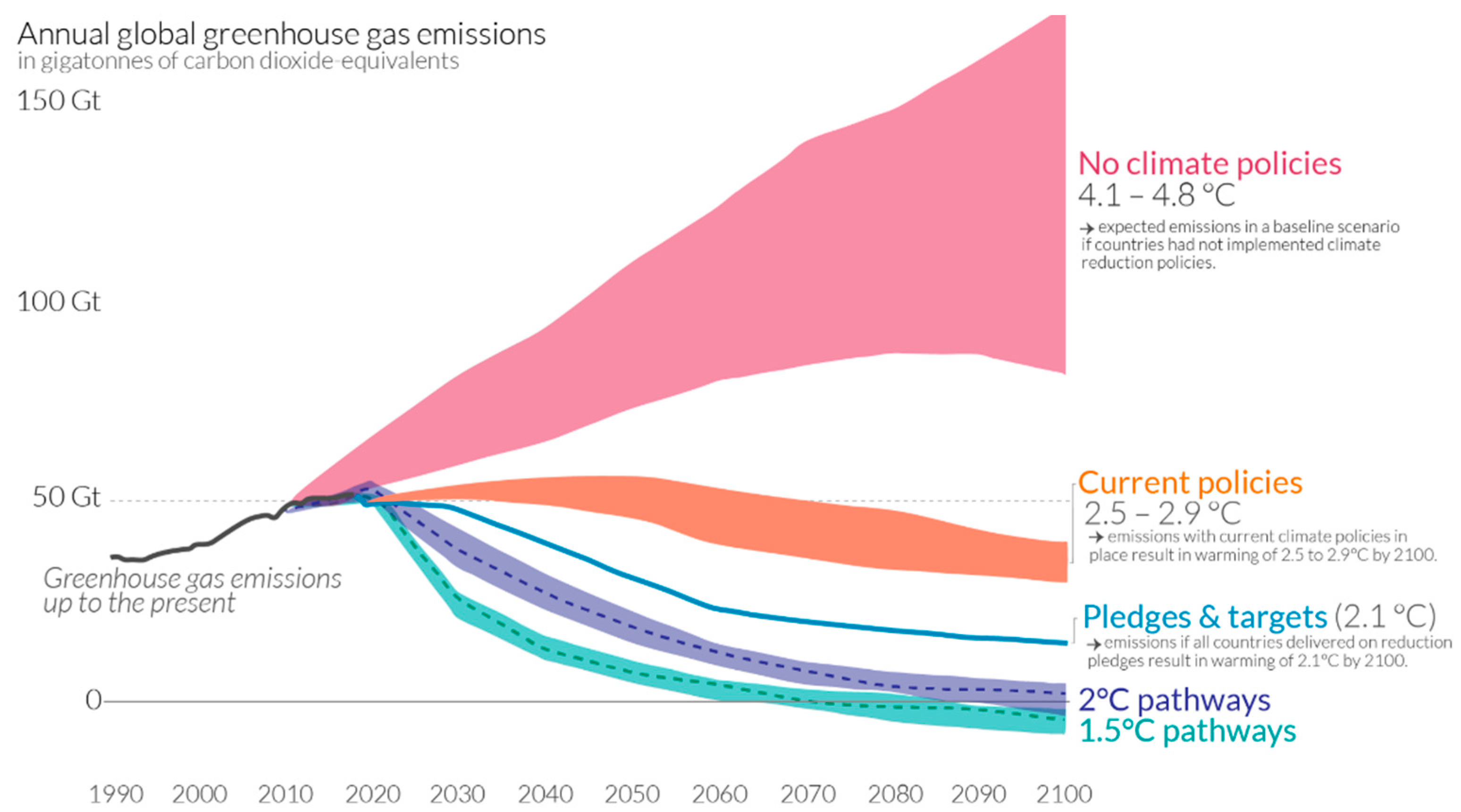

2. Climate Change: Implications for the Construction Industry

2.1. What We Know

2.2. The UN Sustainability Goals

2.3. Implications to the Construction Industry

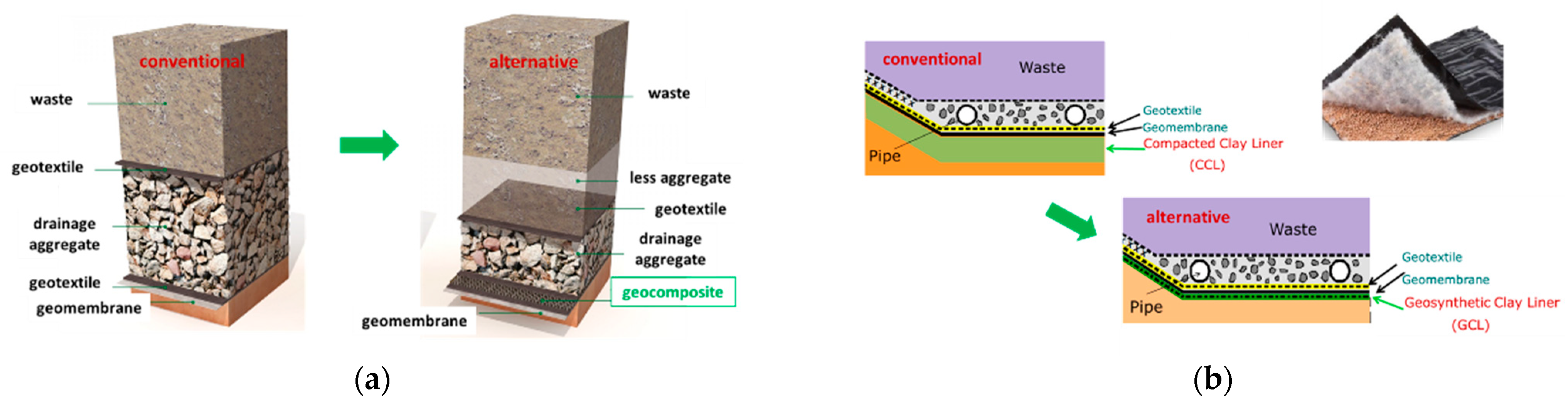

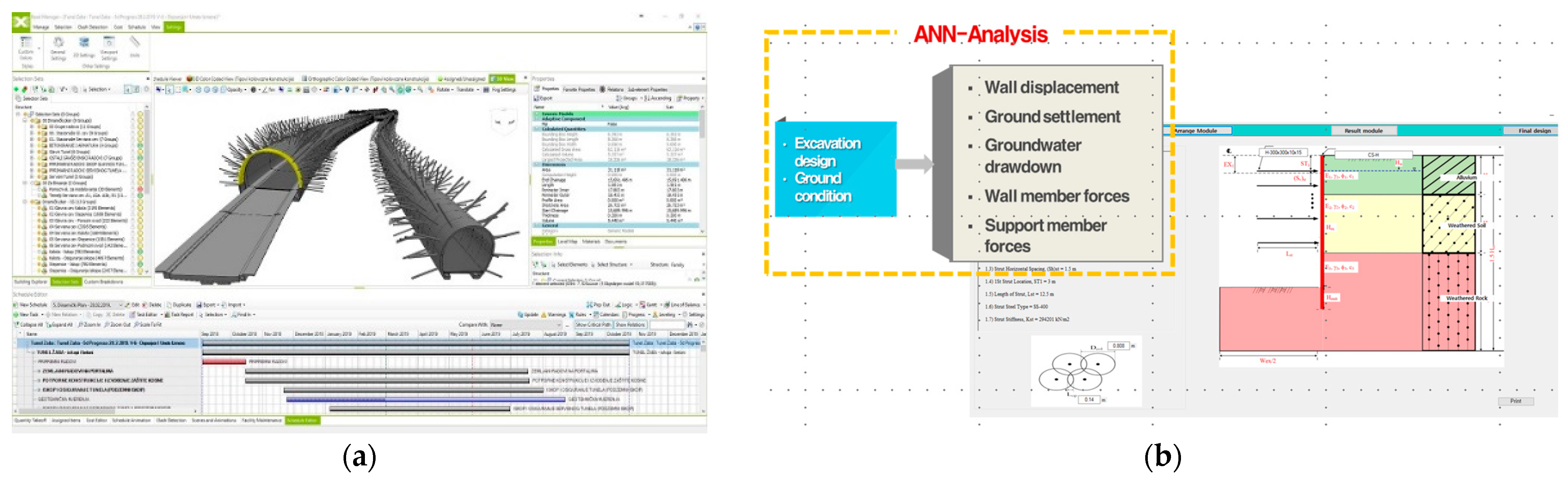

3. Geosynthetic Solutions in Transportation Infrastructure Development

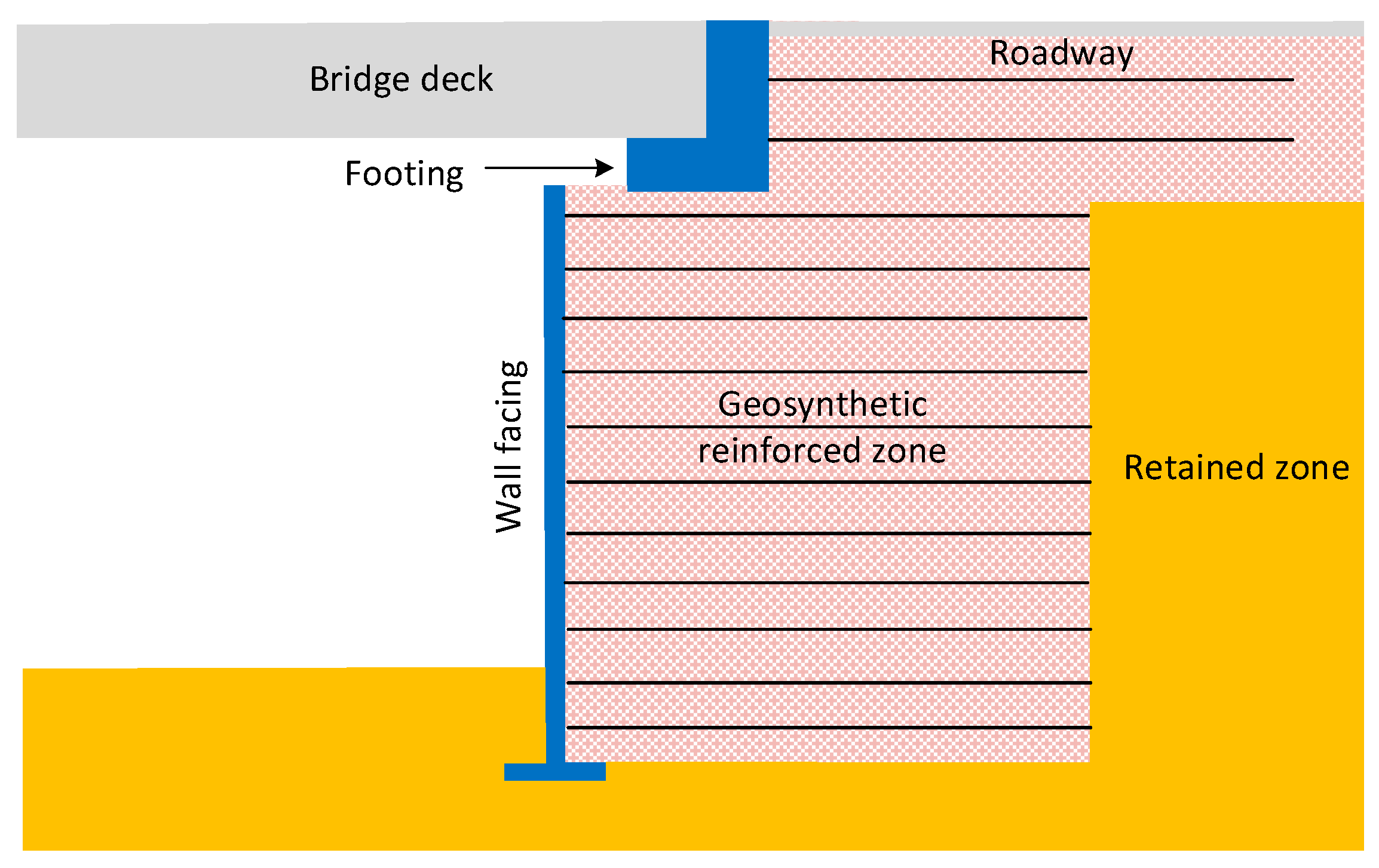

3.1. Geosynthetic Bridge Abutment

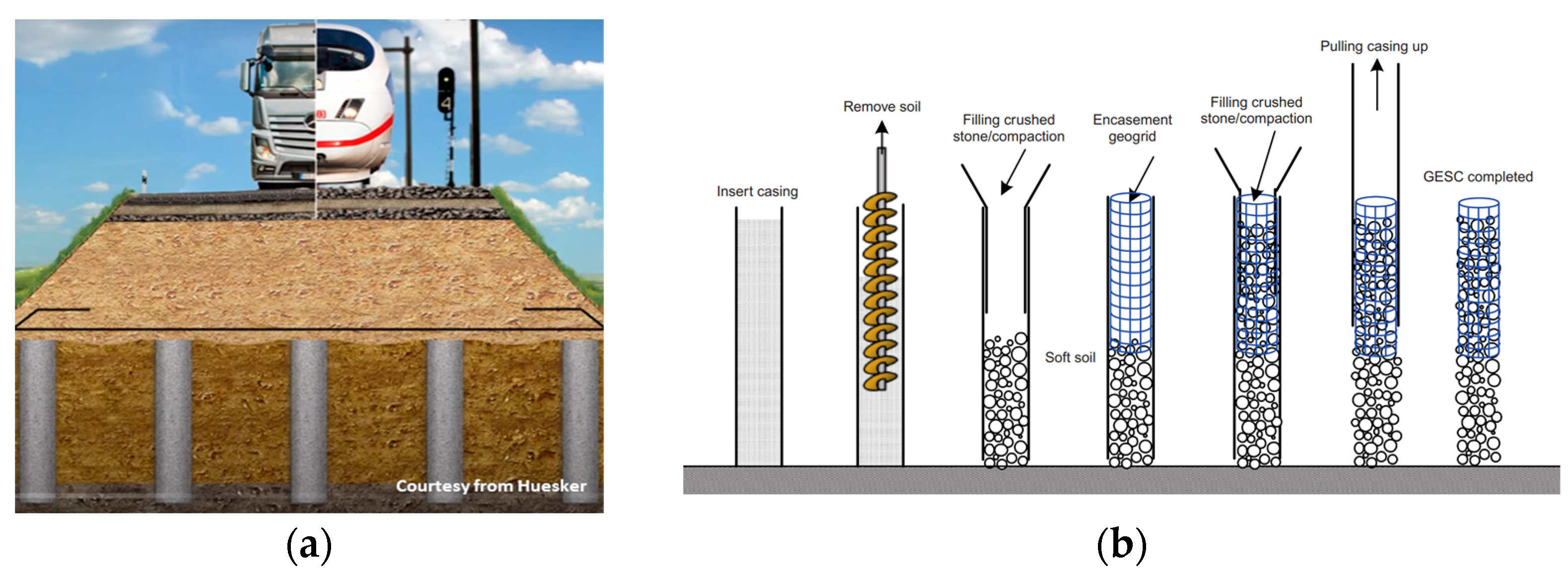

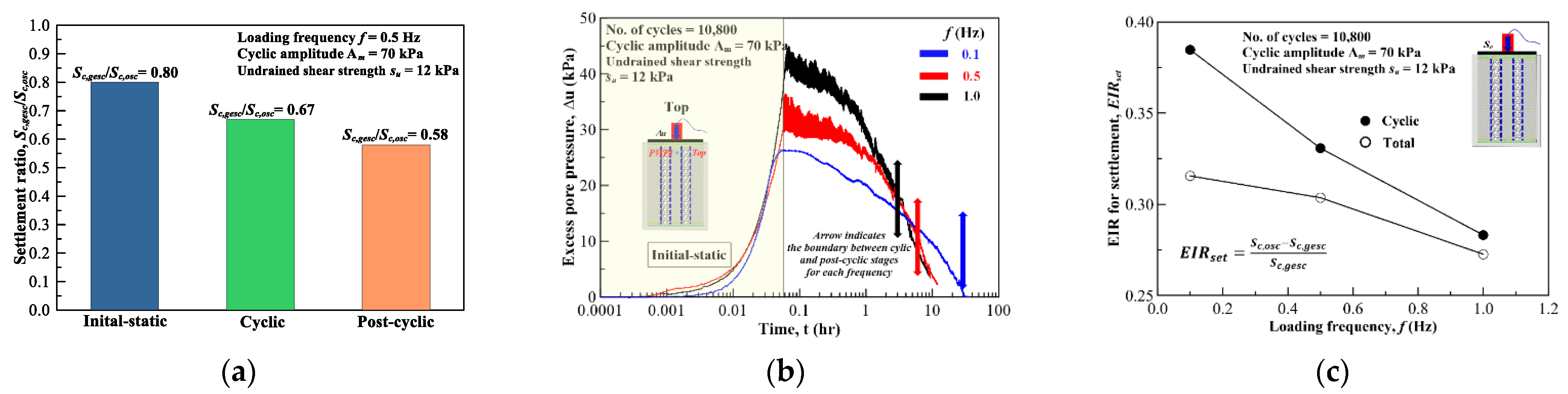

3.2. Geosynthetic-Encased Stone Column

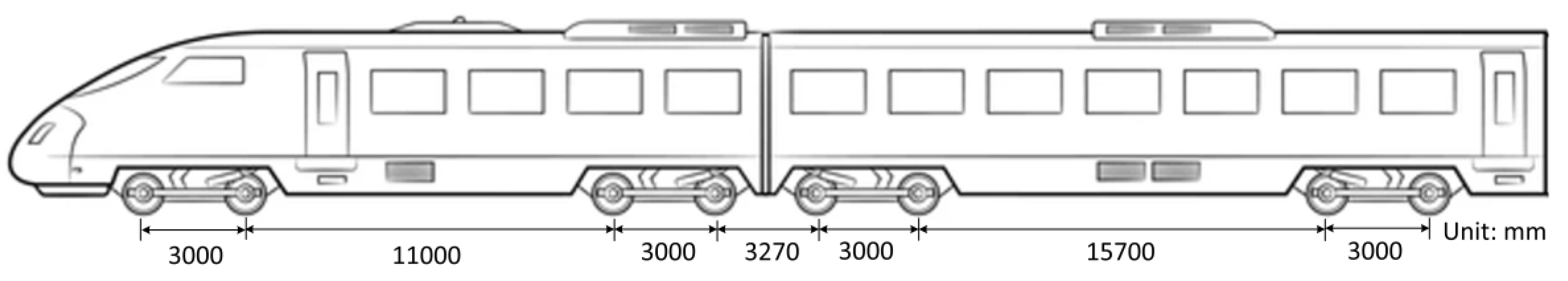

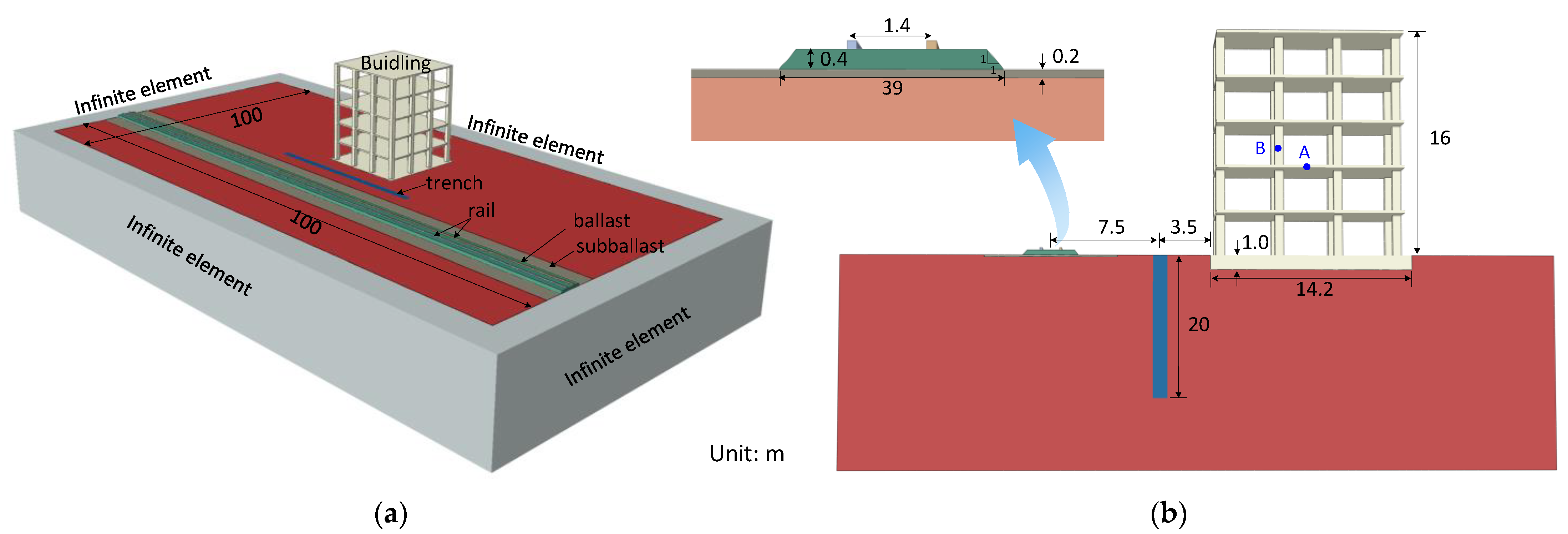

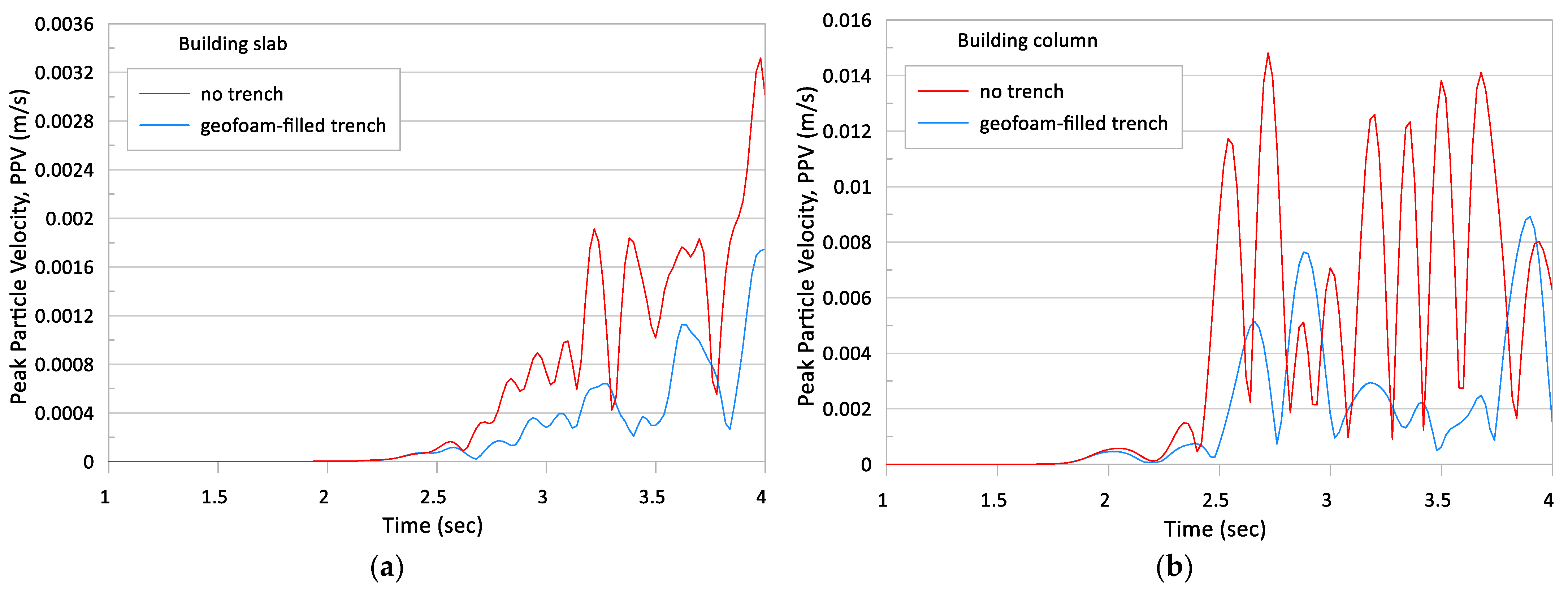

3.3. Geosynthetic-Based Ground-Borne Vibration Mitigation

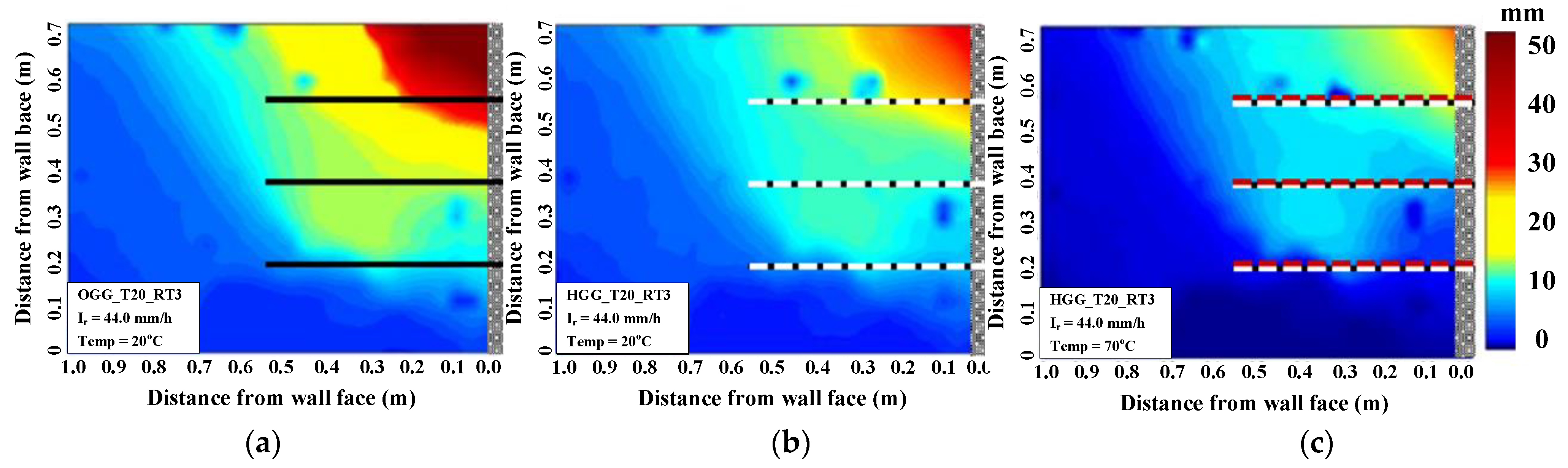

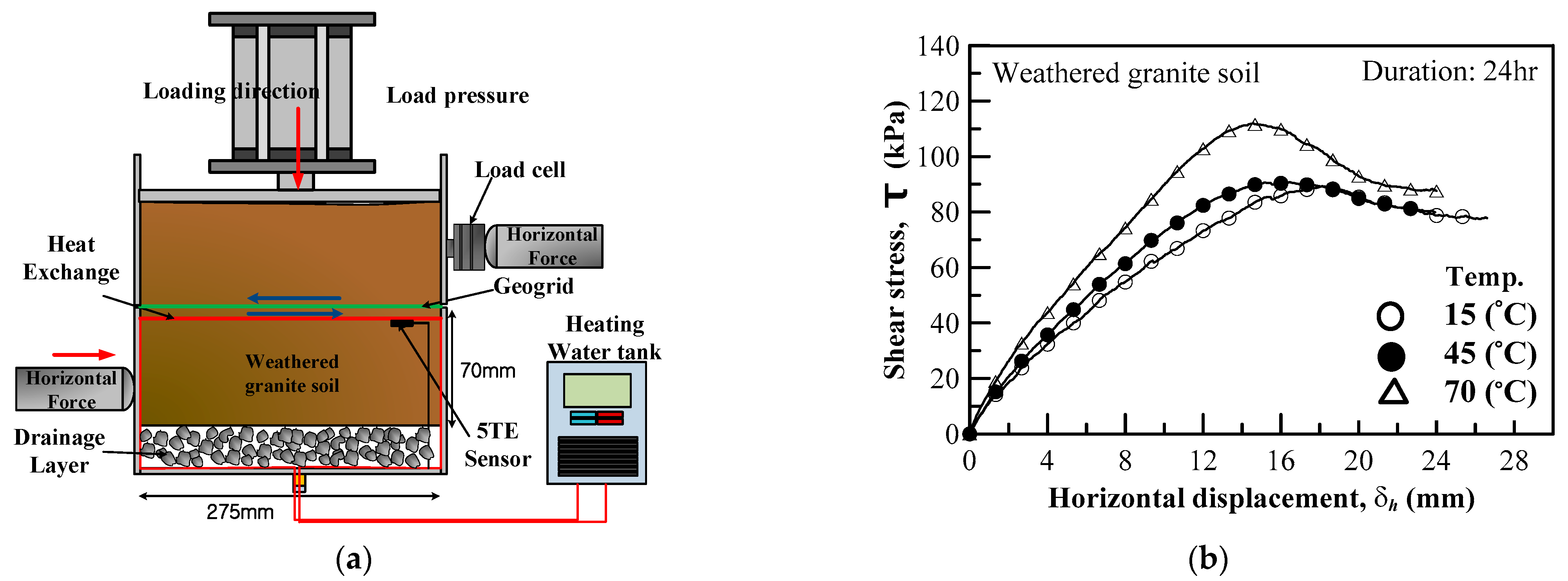

4. GRS Structure: Climate Change Adaption and Mitigation

5. Conclusions

- Climate change-induced global warming has raised global temperatures approximately 1.0 °C above pre-industrial levels, and if current rates are maintained, this will likely reach 1.5 °C between 2030 and 2052. The construction industry, as one of the larger producers of GHG emissions, has a huge responsibility to implement specific action plans to achieve sustainable construction targets.

- Geosynthetics can also be used as key elements in achieving some of the 17 UN sustainable development goals, particularly in the environmental and economic categories, including goals such as clean water and sanitation, clean energy, infrastructures, and sustainable cities. More specifically, in infrastructure development, geosynthetic solutions are considered sustainable solutions as they tend to use fewer natural resources, thus significantly reducing the carbon footprint compared to conventional systems.

- A wide array of geosynthetic solutions is available for infrastructure development such as geosynthetic bridge abutments, geosynthetic-encased stone columns, and geosynthetics-based ground-borne vibration mitigation. Further developments in geosynthetic technology in transportation applications will ensure safe, economical, and sustainable infrastructure development.

- Accelerated drainage of infiltrated rainwater from a geosynthetic reinforced structure can be achieved when implementing dual-function geosynthetic, i.e., internal drainage and reinforcement, together with elevated temperature, suggesting that geosynthetic technology can provide climate change adaptation and mitigation solutions for future infrastructure development.

Funding

Data Availability Statement

Conflicts of Interest

References

- Holtz, R.D. Geosynthetics for Soil Improvement, 9th ed.; Spencer, J., Ed.; Buchanan Lecture; Texas A&M University: College Station, TX, USA, 2001; pp. 1–19. [Google Scholar]

- Allen, M.R.O.P.; Dube, W.; Solecki, F.; Aragón-Durand, W.; Cramer, S.; Humphreys, M.; Kainuma, J.; Kala, N.; Mahowald, Y.; Mulugetta, R.; et al. Framing and Context. In Global Warming of 1.5 °C. An IPCC Special Report on the Impacts of Global Warming of 1.5 °C above Pre-Industrial Levels and Related Global Greenhouse Gas Emission Pathways, in the Context of Strengthening the Global Response to the Threat of Climate Change, Sustainable Development, and Efforts to Eradicate Poverty; Masson-Delmotte, V.P., Zhai, H.-O., Pörtner, D., Roberts, J., Skea, P.R., Shukla, A., Pirani, W., Moufouma-Okia, C., Péan, R., Pidcock, S., et al., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2018; pp. 49–92. [Google Scholar] [CrossRef]

- Yoo, C. Geosynthetics in Sustainable Transportation Infrastructure Construction. Keynote Lecture. In Proceedings of the 4th African Regional Conference on Geosynthetics, Cairo, Egypt, 20–23 February 2023. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change (IPCC). IPCC Special Report on Climate Change and Land (SRCCL). In Proceedings of the Bonn Climate Change Conference, Bonn, Germany, 17–19 June 2019. [Google Scholar]

- European Commission. Consequences of Climate Change. Available online: https://climate.ec.europa.eu/climate-change/consequences-climate-change_en (accessed on 19 January 2023).

- Ritchie, H.; Roser, M.; Rosado, P. CO2 and Greenhouse Gas Emissions. 2020. Published online at OurWorldInData.org. Available online: https://ourworldindata.org/co2-and-greenhouse-gas-emissions (accessed on 19 January 2023).

- United Nations. The UN Sustainable Development Goals; United Nations: New York, NY, USA, 2015; Available online: http://www.un.org/sustainabledevelopment/summit/ (accessed on 16 January 2023).

- Raja, J.; Doxon, N.; Fowmes, G.; Frost, M.; Assinder, P. Obtaining reliable embodied carbon values for geosynthetics. Geosynth. Int. 2015, 22, 393–401. [Google Scholar] [CrossRef]

- Touze, N. Healing the world: A geosynthetics solution. Geosynth. Int. 2021, 28, 1–31. [Google Scholar] [CrossRef]

- Ramsey, B. Geosynthetics and Sustainability: How Is Our Industry Doing? Available online: https://geosyntheticsmagazine.com/2022/04/01/geosynthetics-and-sustainability/ (accessed on 19 January 2023).

- United Nations. 2021 Global Status Report for Buildings and Construction; United Nations: New York, NY, USA, 2021; Available online: https://www.unep.org/resources/report/2021-global-status-report-buildings-and-construction (accessed on 23 January 2023).

- Gourbran, S. On the Role of Construction in Achieving the SDGs. J. Sustain. Res. 2019, 1, e190020. [Google Scholar] [CrossRef]

- International Geosynthetics Society. Geosynthetic Barries: Applications and Benefits. 2021. Available online: https://library.geosyntheticssociety.org/wp-content/uploads/resources/educational-documents/Leaflet/IGS%20Geosynthetics%20Barriers.pdf (accessed on 30 May 2023).

- Raja, M.N.A.; Shukla, S.K. Predicting the settlement of geosynthetic-reinforced soil foundations using evolutionary artificial intelligence technique. Geotext. Geomembr. 2021, 49, 1280–1293. [Google Scholar] [CrossRef]

- Chao, Z.; Shi, D.; Fowmes, G.; Xu, X.; Yue, W.; Cui, P.; Hu, T.; Yang, C. Artificial intelligence algorithms for predicting peak shear strength of clayey soil-geomembrane interfaces and experimental validation. Geotext. Geomembr. 2023, 51, 179–198. [Google Scholar]

- Adams, M.; Nicks, J.; Stabile, T.; Wu, J.; Schlatter, W.; Hartmann, J. Geosynthetic Reinforced Soil Integrated Bridge System Synthesis Report; Report No. FHWA-HRT-11-027; Federal Highway Administration: Washington, DC, USA, 2011. [Google Scholar]

- Ahmadi, H.; Bezuijen, A. Full-scale mechanically stabilized earth (MSE) walls under strip footing load. Geotext. Geomembranes 2018, 46, 297–311. [Google Scholar] [CrossRef]

- Shen, P.; Han, J.; Zornberg, J.; Tanyu, B.; Christopher, B.; Leschinsky, D. Responses of geosynthetic-reinforced soil (GRS) abutments under bridge slab loading: Numerical investigation. Comp. Geotech. 2020, 123, 103566. [Google Scholar] [CrossRef]

- Xu, P.; Li, T.; Hatami, K. Limit analysis of bearing capacity and failure geometry of GRS bridge abutments. Comp. Geotech. 2020, 127, 103758. [Google Scholar] [CrossRef]

- Hatami, K.; Doger, R. Load-bearing performance of model GRS bridge abutments with different facing and reinforcement spacing configurations. Geotext. Geomembranes 2021, 49, 1139–1148. [Google Scholar] [CrossRef]

- Askari, M.; Razeghi, H.R.; Mamaghanian, J. Numerical study of geosynthetic reinforced soil bridge abutment performance under static and seismic loading considering effects of bridge deck. Geotext. Geomembr. 2021, 49, 1339–1354. [Google Scholar] [CrossRef]

- Deng, J.; Zhang, J.; Qi, Z.; Zheng, Y.; Zheng, J.J. Experimental study on the load bearing behavior of geosynthetic reinforced soil bridge abutments on yielding foundation. Geotext. Geomembr. 2023, 51, 165–178. [Google Scholar] [CrossRef]

- Verma, A.; Mittal, S. Comparative assessment of stability of GRS abutments through 1 g physical model tests for field implementationeck. Trans. Geotech. 2023, 42, 101056. [Google Scholar] [CrossRef]

- Yoo, C.; Kim, S.B. Performance of a two-tier geosynthetic reinforced segmental retaining wall under a surcharge load: Full-scale load test and 3D finite element analysis. Geotext. Geomembr. 2008, 26, 460–472. [Google Scholar] [CrossRef]

- Yoo, C.; Lee, D. Performance of geogrid-encased stone columns in soft ground: Full-scale load test. Geosynth. Int. 2012, 19, 480–490. [Google Scholar] [CrossRef]

- Yoo, C. Performance of geosynthetic-encased stone columns in embankment construction: Numerical investigation. J. Geotech. Geoenviron. 2010, 136, 1148–1160. [Google Scholar] [CrossRef]

- Yoo, C.; Abbas, Q. Laboratory investigation of the behavior of a geosynthetic encased stone column in sand under cyclic loading. Geotext. Geomembr. 2020, 48, 431–442. [Google Scholar] [CrossRef]

- Almeida, M.S.S.; Hosseinpour, I.; Riccio, M. Performance of a geosynthetic-encased column (GEC) in soft ground: Numerical and analytical studies. Geosynth. Int. 2013, 20, 252–262. [Google Scholar] [CrossRef]

- Almeida, M.S.S.; Hosseinpour, I.; Riccio, M.; Alexiew, D. Behavior of geotextile–encased granular columns supporting test embankment on soft deposit. J. Geotech. Geoenviron. 2014, 141, 1–9. [Google Scholar] [CrossRef]

- Ali, K.; Shahu, J.T.; Sharma, K.G. Model tests on single and groups of stone columns with different geosynthetic reinforcement arrangement. Geosynth. Int. 2014, 21, 103–118. [Google Scholar]

- Cengiz, C.; Güler, E. Seismic behavior of geosynthetic encased columns and ordinary stone columns. Geotext. Geomembr. 2018, 46, 40–51. [Google Scholar] [CrossRef]

- Alkhorshid, N.R.; Araujo, L.S.; Palmeira, E.M.; Zornberg, J.G. Large-scale load capacity tests on a geosynthetic encased column. Geotext. Geomembr. 2019, 47, 631–642. [Google Scholar] [CrossRef]

- Xu, Z.; Zhang, L.; Peng, B.; Zhou, S. DEM-FDM numerical investigation on load transfer mechanism of GESC-supported embankment. Comp. Geotech. 2021, 138, 104321. [Google Scholar] [CrossRef]

- Zhou, Y.; Kong, G.; Zheng, J.; Wen, L.; Yang, Q. Analytical solutions for geosynthetic-encased stone column-supported embankments with emphasis on nonlinear behaviours of columns. Geotext. Geomembr. 2021, 49, 1107–1116. [Google Scholar] [CrossRef]

- Amick, H.; Gendreau, M. Construction vibrations and their impact on vibration-sensitive facilities. In Proceedings of the 6th Construction Congress, ASCE, Orlando, FL, USA, 20–22 February 2000; pp. 758–767. [Google Scholar] [CrossRef]

- Rainer, J.H. Effect of vibrations on historic buildings: An overview. Bull. Assoc. Preserv. Technol. 1982, 14, 2–10. [Google Scholar]

- Khan, M.R.; Dasaka, S.M. High-Speed Train Vibrations in the Sub-soils Supporting Ballasted Rail Corridors. Transp. Infrastruct. Geotech. 2022, 10, 259–282. [Google Scholar] [CrossRef]

- Majumder, M.; Bhattacharyya, S. ANN-Based Model to Predict the Screening Efficiency of EPS Geofoam Filled Trench in Reducing High-Speed Train-Induced Vibration. In Seismic Hazards and Risk; Springer: Singapore, 2021. [Google Scholar] [CrossRef]

- Liu, W.; Yan, S.; Wu, L.; Zhou, J. Metamaterial approach to mitigate ground-borne vibrations induced by moving trains. Appl. Res. 2022, 2, e202200021. [Google Scholar] [CrossRef]

- Dassault Systems; ABAQUS, Hibbit, Karlsson Sorensen Inc.: Providence, RI, USA, 2022.

- Kaewunruen, S.; Qin, Z. Sustainability of Vibration Mitigation Methods Using Meta-Materials/Structures along Railway Corridors Exposed to Adverse Weather Conditions. Sustainability 2020, 12, 10236. [Google Scholar] [CrossRef]

- Koerner, R.M.; Soong, T.Y. Geosynthetic reinforced segmental retaining walls. Geotext. Geomembr. 2001, 19, 359–386. [Google Scholar] [CrossRef]

- Yoo, C.; Jung, H.Y. Case history of geosynthetics reinforced segmental retaining wall failure. J. Geotech. Geoenviron. 2006, 132, 1538–1548. [Google Scholar] [CrossRef]

- Yoo, C.; Tabish, A.; Yang, J.W.; Abbas, Q.; Song, J.S. Effect of internal drainage on deformation behavior of GRS wall during rainfall. Geosynth. Int. 2022, 29, 137–150. [Google Scholar] [CrossRef]

- Portelinha, F.H.; Zornberg, J.G. Effect of infiltration on the performance of an unsaturated geotextile reinforced soil wall. Geotext. Geomembr. 2017, 45, 211–226. [Google Scholar] [CrossRef]

- McCartney, J.S.; LaHaise, D.; LaHaise, T.; Rosenberg, J. Application of Geoexchange Experience to Geothermal Foundations. In Proceedings of the Art of Foundation Engineering Practice Congress 2010, West Palm Beach, FL, USA, 20 February 2010. [Google Scholar] [CrossRef]

| Series | Frequency, | Amplitude, | No. of Cycles, N | Encasement Length, | |

|---|---|---|---|---|---|

| A | 12 | 0.1, 0.5, 1.0 | 70 | 10,800 | 1.0 |

| B | 0.5 | 40, 70, 100 | 1.0 | ||

| C | 0.5 | 70 | 0.0, 0.3, 0.5, 1.0 |

| Material | Unit Weight | Young’s Modulus | Poisson’s Ratio, | Cohesion, | Int. Friction Angle, | Dilation Angle, |

|---|---|---|---|---|---|---|

| ballast | 16 | 15 | 0.35 | - | - | - |

| sub-ballast | 19 | 2000 | 0.35 | - | - | - |

| subgrade | 20 | 41 | 0.4 | 10 | 40 | 15 |

| concrete | 25 | 21,000 | 0.2 | - | - | - |

| rail | 78.5 | 200,000 | 0.35 | - | - | - |

| geofoam | 20 | 1500 | 0.49 | - | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yoo, C. Geosynthetic Solutions for Sustainable Transportation Infrastructure Development. Sustainability 2023, 15, 15772. https://doi.org/10.3390/su152215772

Yoo C. Geosynthetic Solutions for Sustainable Transportation Infrastructure Development. Sustainability. 2023; 15(22):15772. https://doi.org/10.3390/su152215772

Chicago/Turabian StyleYoo, Chungsik. 2023. "Geosynthetic Solutions for Sustainable Transportation Infrastructure Development" Sustainability 15, no. 22: 15772. https://doi.org/10.3390/su152215772

APA StyleYoo, C. (2023). Geosynthetic Solutions for Sustainable Transportation Infrastructure Development. Sustainability, 15(22), 15772. https://doi.org/10.3390/su152215772