Evolution of Geocells as Sustainable Support to Transportation Infrastructure

Abstract

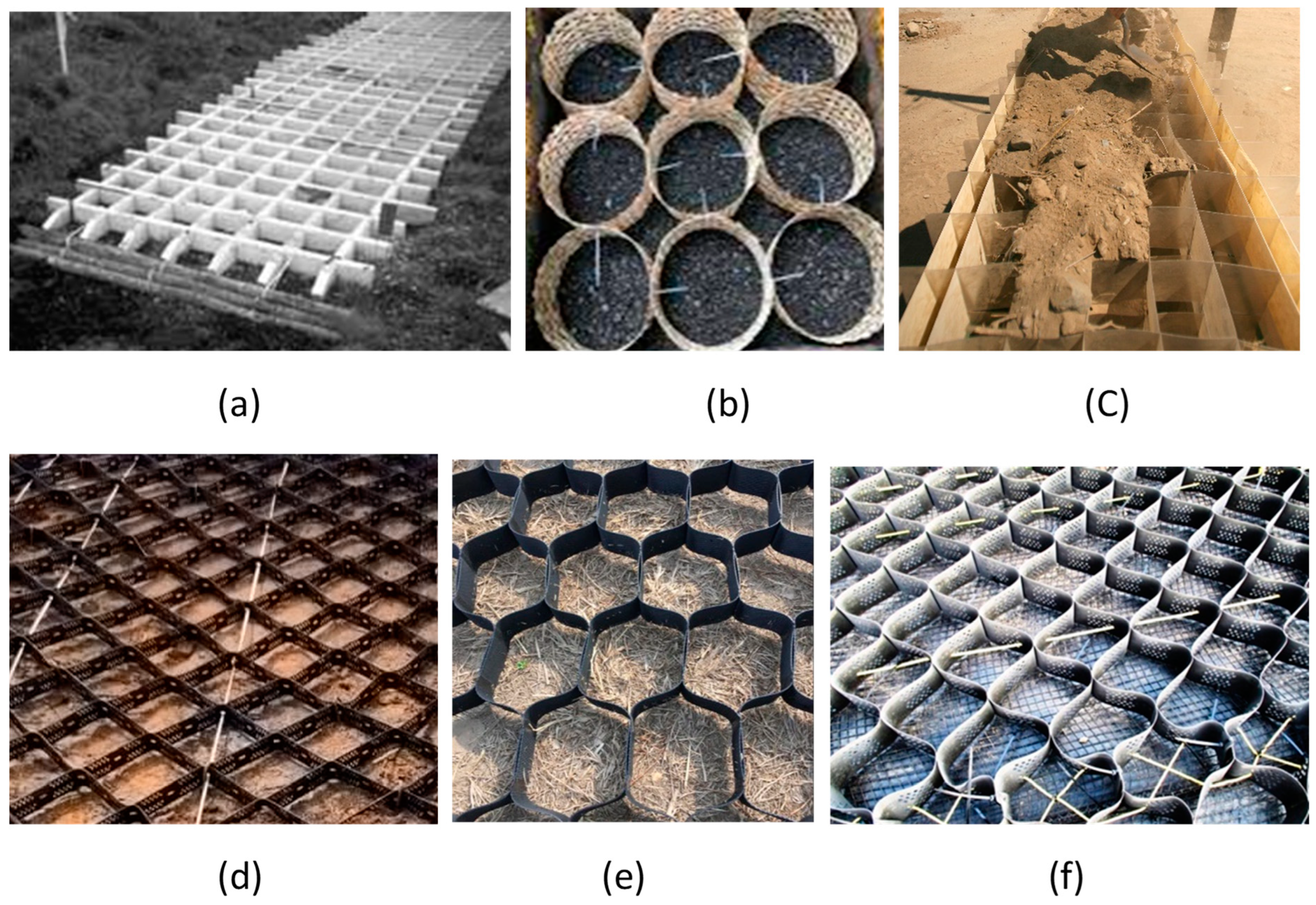

1. Introduction

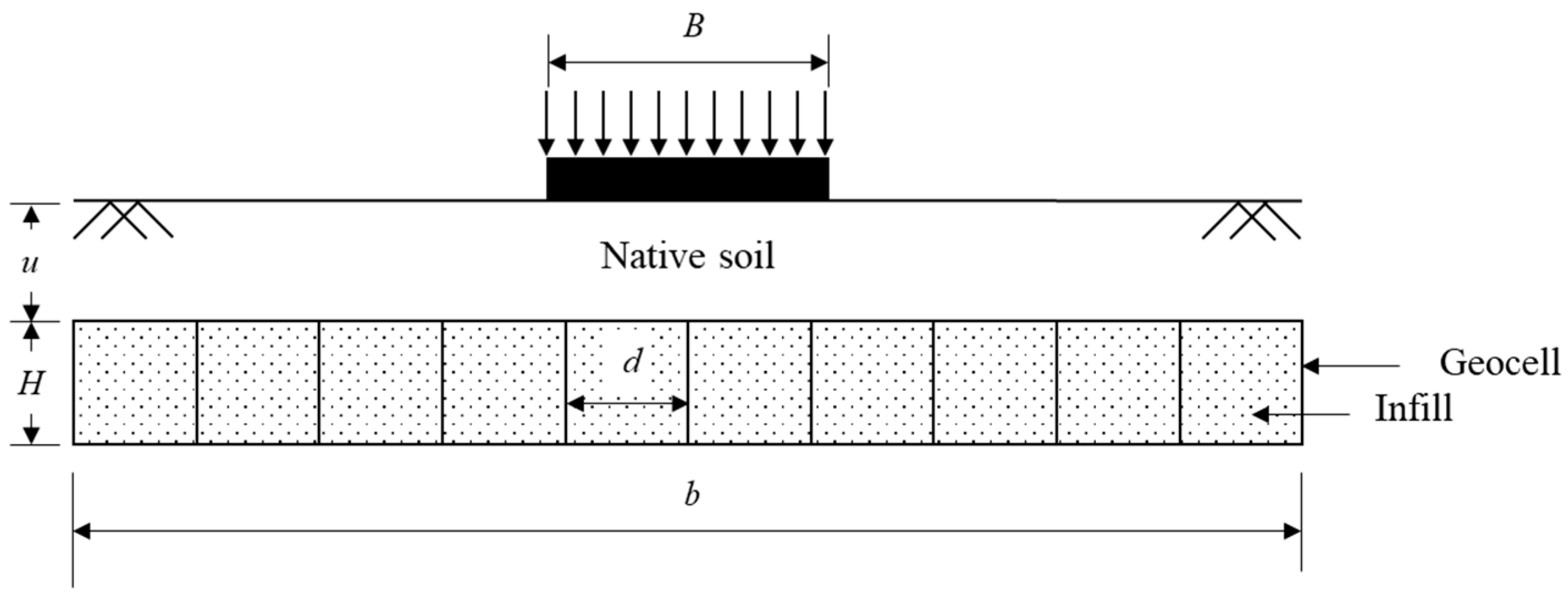

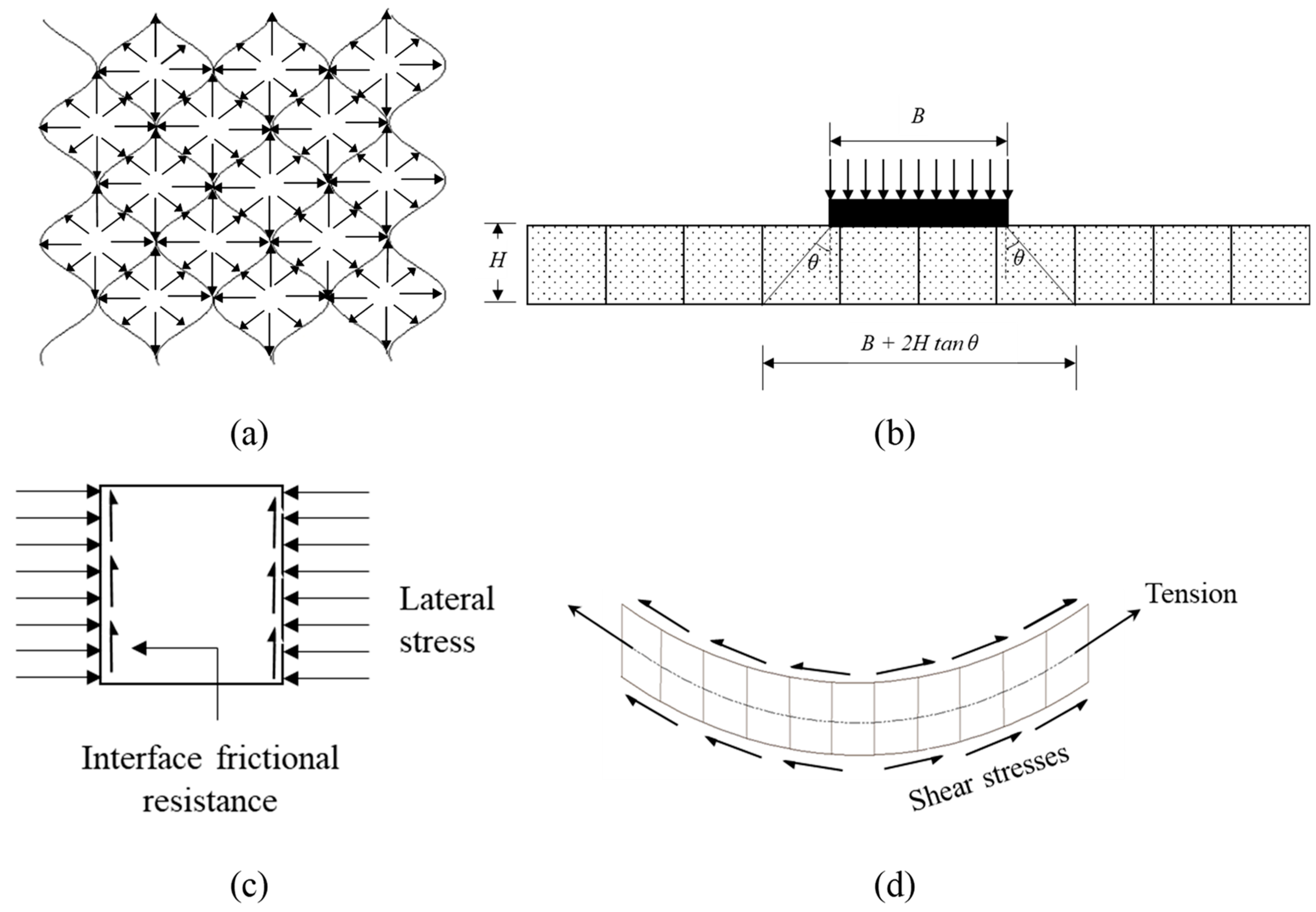

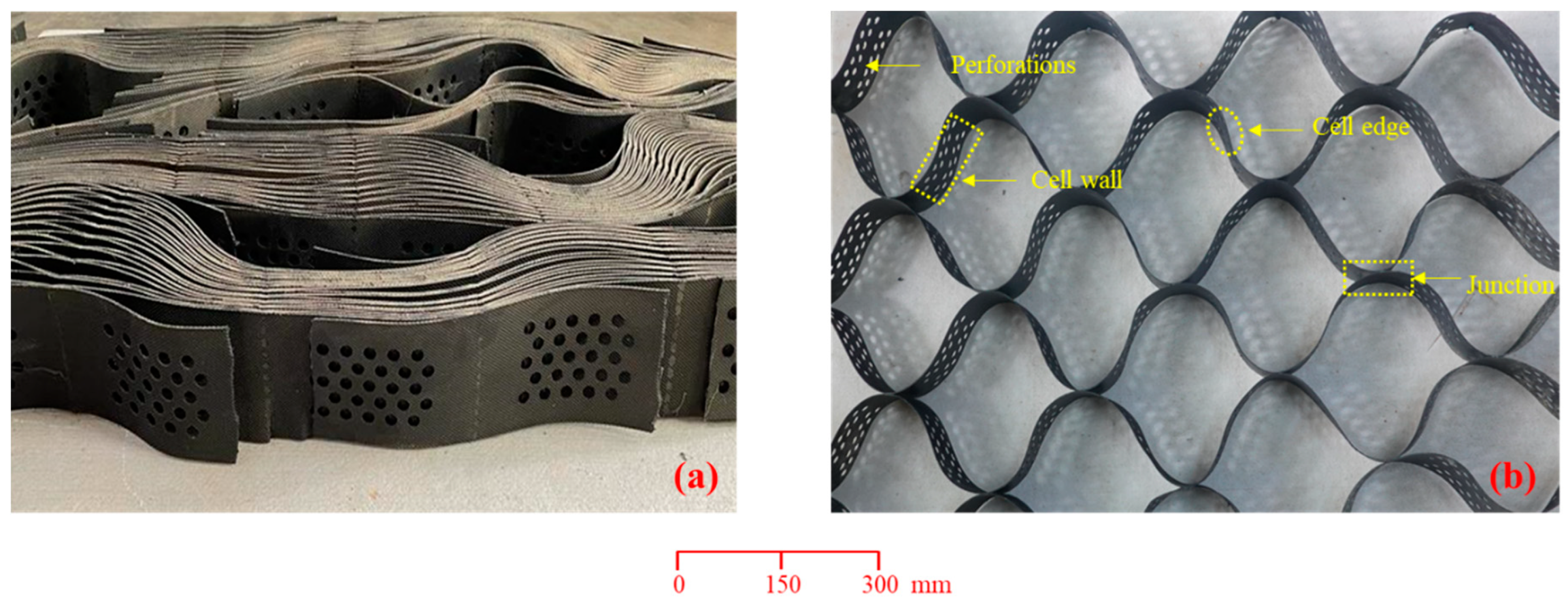

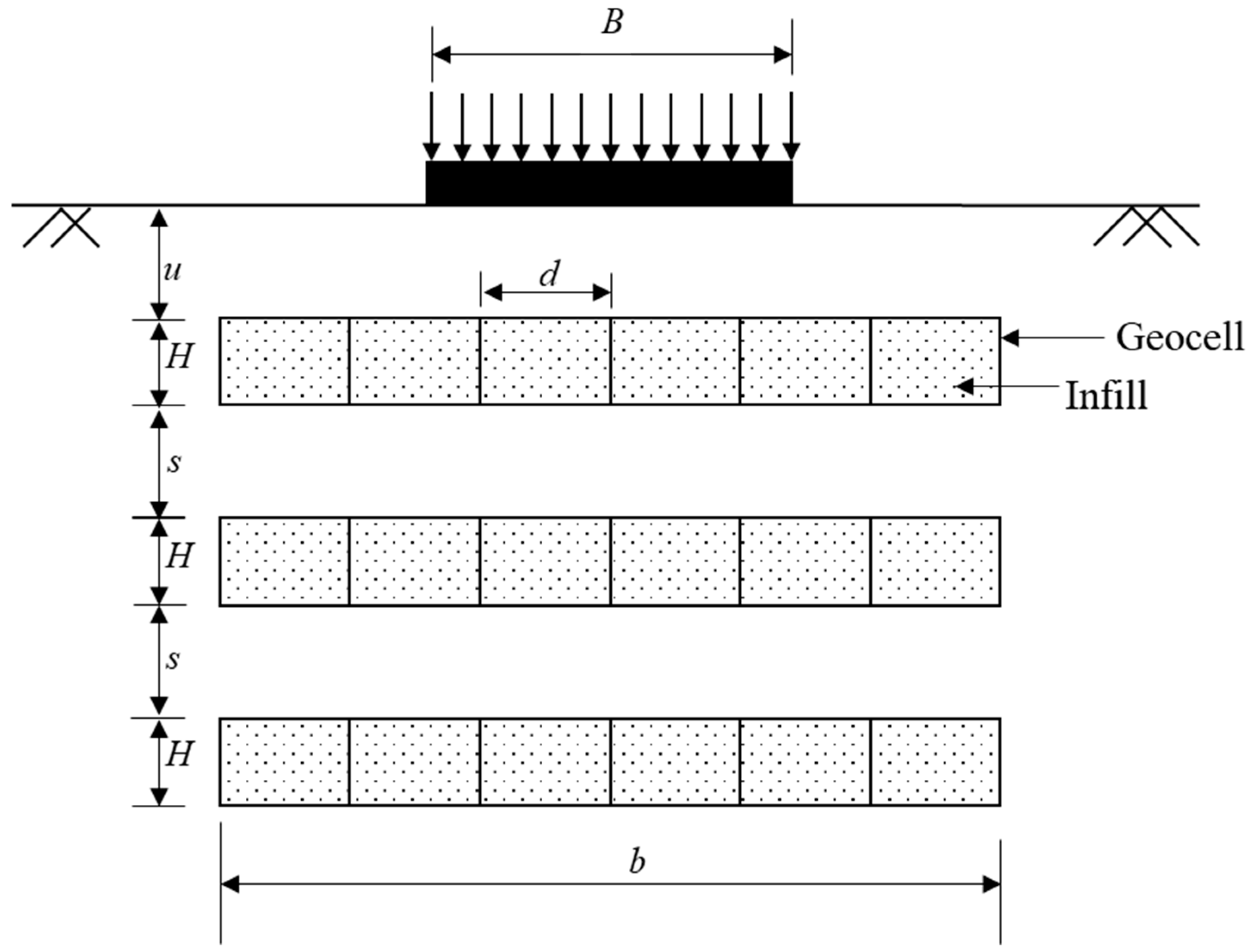

2. Geocell Configuration

2.1. Height of the Geocells (H)

2.2. Pocket Size or Aperture Opening Size (d)

2.3. Aspect Ratio of Geocells (H/d)

2.4. Width of Geocell Layer (b)

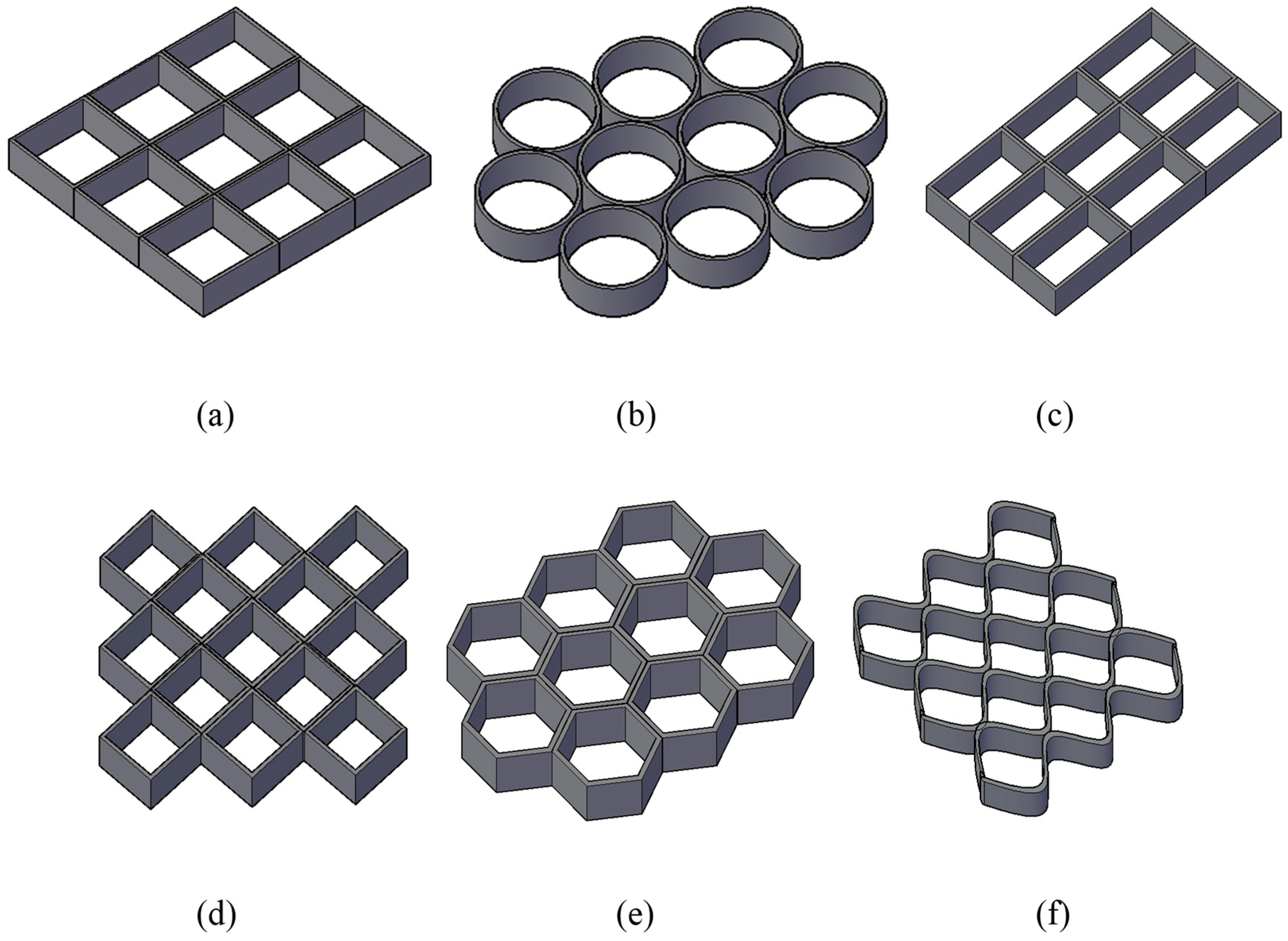

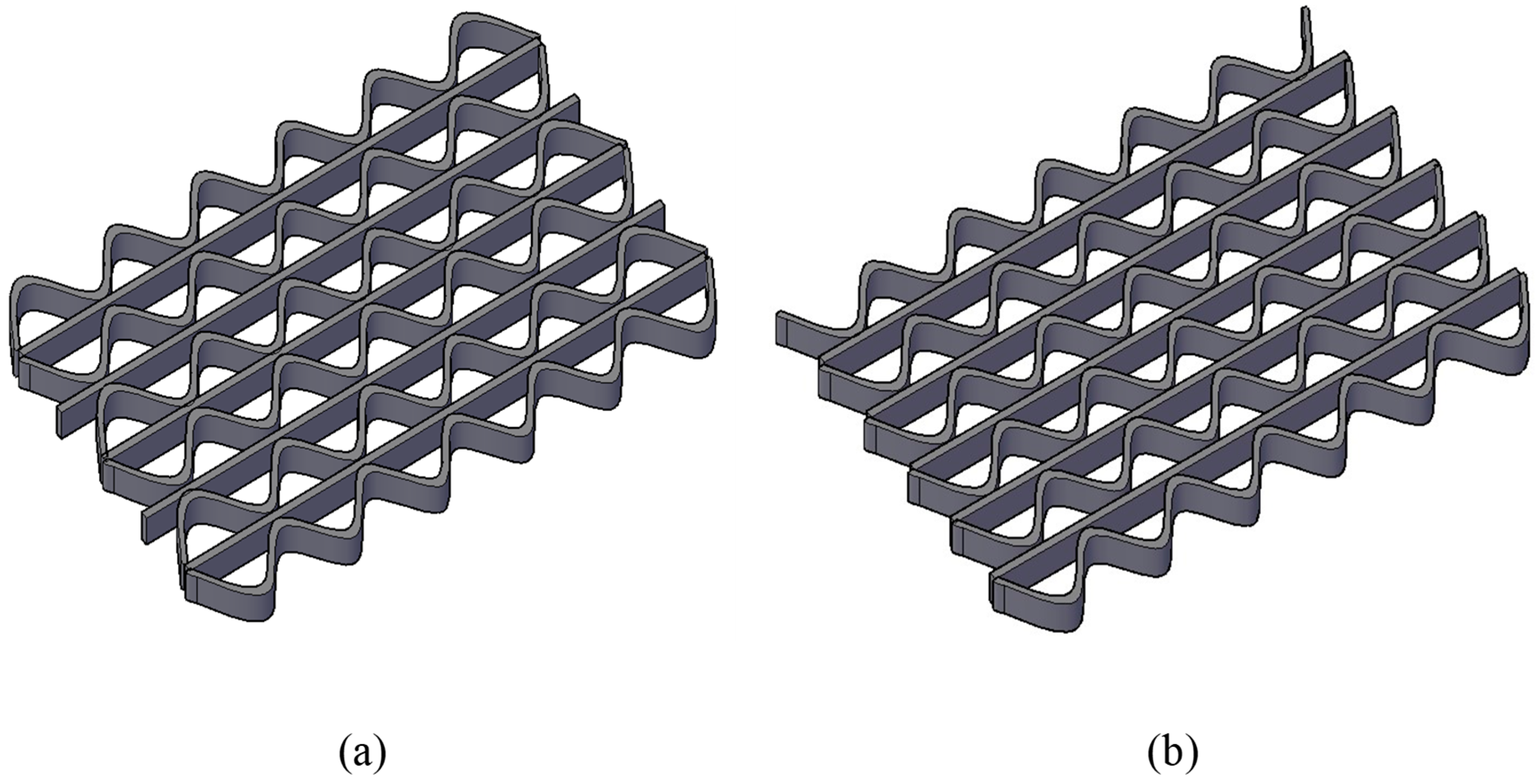

2.5. Pocket Shape of the Geocells

2.6. Pattern of Arrangement

2.7. Embedment Depth of Geocells (u)

2.8. Number of Geocell Layers (N)

3. Properties of Geocell Material

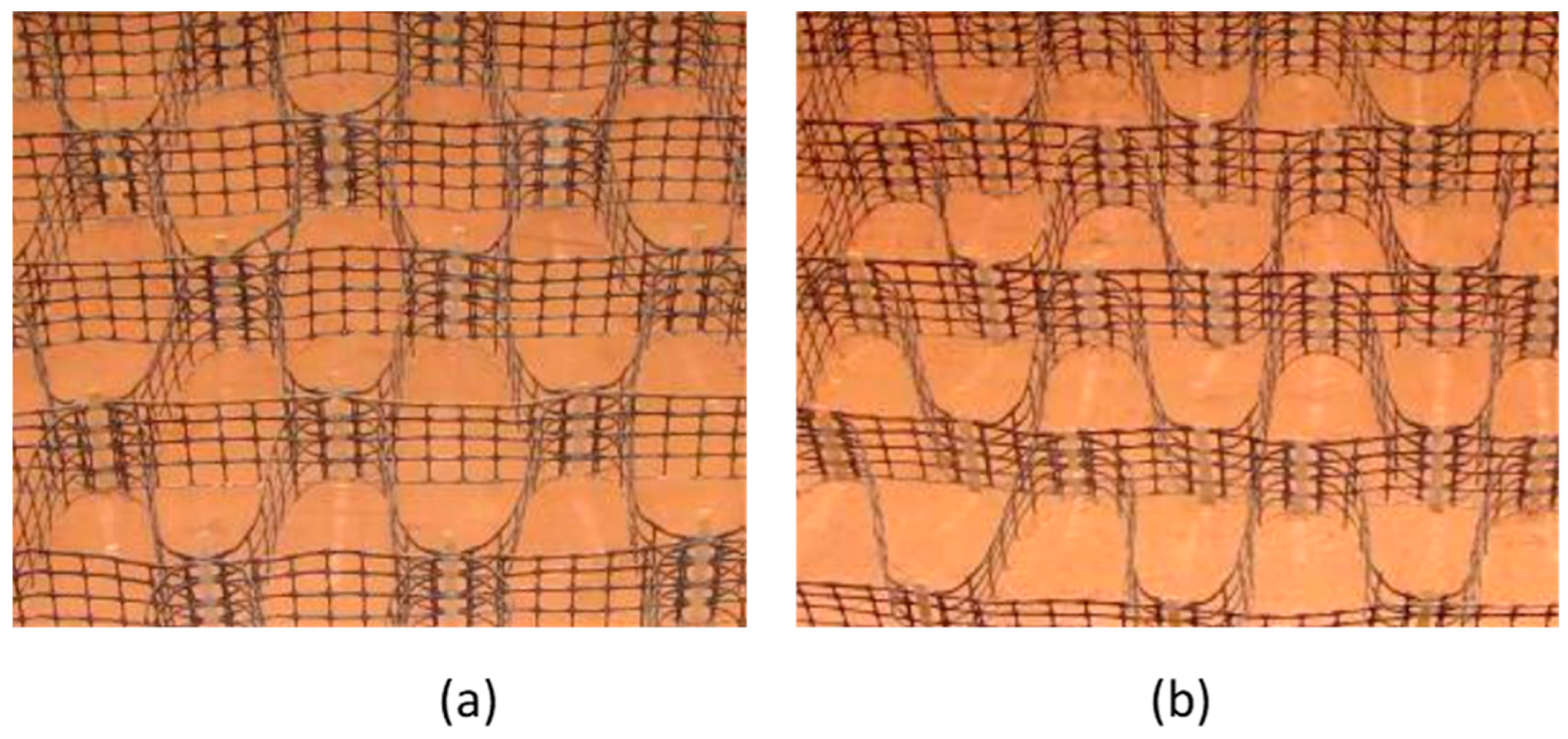

3.1. Surface Roughness of Geocells

3.2. Stiffness of Geocells

4. Soil Properties

4.1. Infill Soil Properties

4.2. Native Soil Properties

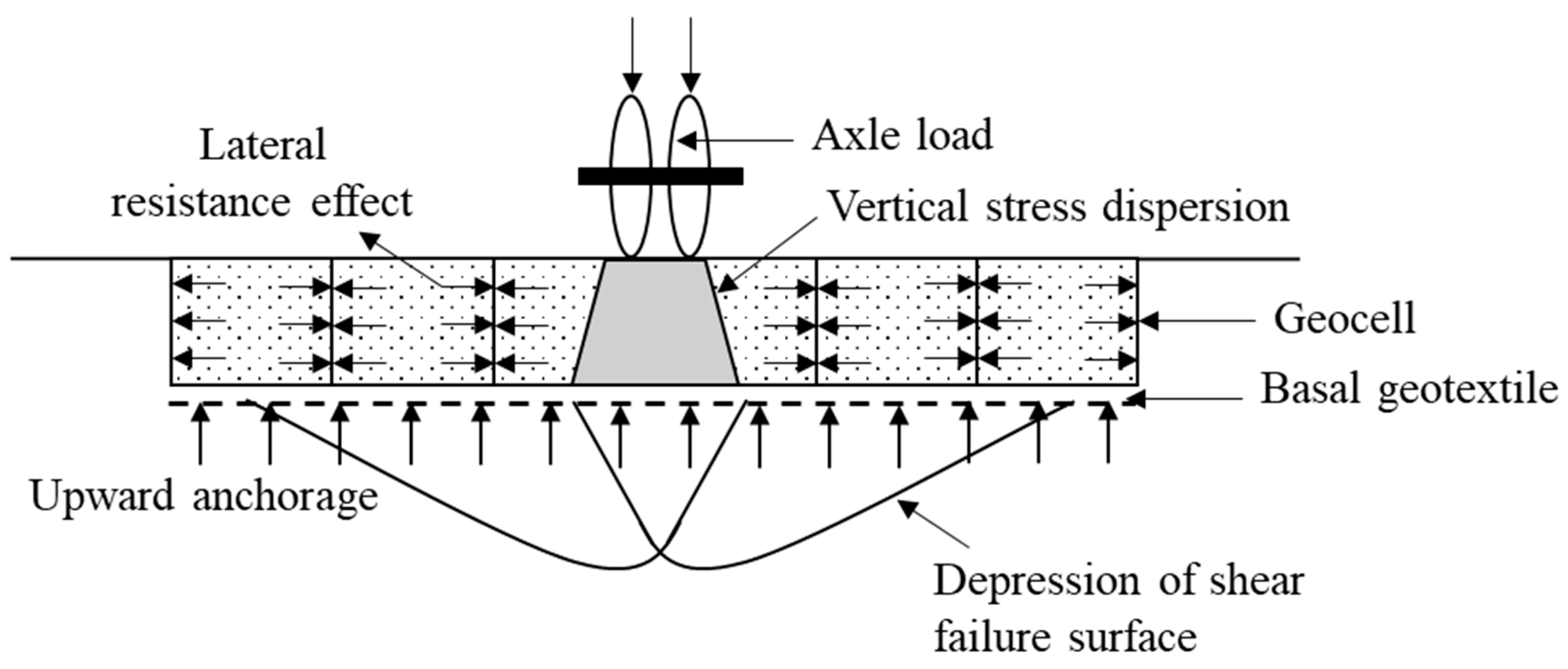

5. Geocells in Transportation Applications

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Webster, S.L.; Watkins, J.E. Investigation of Construction Techniques for Tactical Bridge Approach Roads across Soft Ground; US Waterways Experiment Station: Vicksburg, MS, USA, 1977; Volume 2. [Google Scholar]

- Rea, C.; Mitchell, J.K. Sand Reinforcement Using Paper Grid Cells; ASCE Spring Convention and Exhibit: Pittsburgh, PA, USA, 1978; pp. 24–28. [Google Scholar]

- Meyer, K.G. Managing Degraded off-Highway Vehicle Trails in Wet, Unstable, and Sensitive Environments; USDA Forest Service, Technology and Development Program, Missoula Technology and Development Center: Missoula, MT, USA, 2002; Available online: https://www.google.co.in/books/edition/Managing_Degraded_Off_highway_Vehicle_Tr/wc7sYHoj1j0C?hl=en (accessed on 18 July 2023).

- Rajagopal, K.; Krishnaswamy, N.R.; Latha, G.M. Behavior of sand confined with single and multiple geocells. Geotext. Geomembr. 1999, 17, 171–184. [Google Scholar] [CrossRef]

- Leshchinsky, B.; Ling, H. Effects of geocell confinement on strength and deformation behavior of gravel. J. Geotech. Geoenvironment. Eng. 2013, 120, 339–351. [Google Scholar] [CrossRef]

- Latha, G.M. Geocells for transportation geotechnical applications. Indian Geotech. J. 2021, 50, 602–613. [Google Scholar] [CrossRef]

- Latha, G.M.; Somwanshi, A. Effect of reinforcement form on the bearing capacity of square footings on sand. Geotext. Geomembr. 2009, 27, 399–412. [Google Scholar] [CrossRef]

- Gedela, R.; Karpurapu, R. Influence of pocket shape on numerical response of geocell reinforced foundation systems. Geosynth. Int. 2021, 28, 327–337. [Google Scholar] [CrossRef]

- Henkel, D.J.; Gilbert, G.D. The effect of the rubber membrane on the measured triaxial compression strength of clay specimens. Geotechnique 1951, 3, 20–29. [Google Scholar] [CrossRef]

- Bathurst, R.J.; Karpurapu, R. Large-Scale Triaxial Compression Testing of Geocell-Reinforced Granular Soils. Geotech. Test. J. 1993, 16, 296–303. [Google Scholar]

- Garcia, R.S.; Neto, J.A. Stress-dependent method for calculating the modulus improvement factor in geocell-reinforced soil layers. Geotext. Geomembr. 2021, 48, 145–157. [Google Scholar] [CrossRef]

- Zhang, L.; Zhao, M.; Zou, X.; Zhao, H. Deformation analysis of geocell reinforcement using Winkler model. Comput. Geotech. 2009, 36, 977–983. [Google Scholar] [CrossRef]

- Dash, S.K.; Rajagopal, K.; Krishnaswamy, N.R. Behavior of geocell-reinforced sand beds under strip loading. Can. Geotech. J. 2007, 43, 905–916. [Google Scholar] [CrossRef]

- Mandal, J.N.; Gupta, P. Stability of geocell-reinforced soil. Constr. Build. Mater. 1994, 8, 54–61. [Google Scholar] [CrossRef]

- Bush, D.I.; Jenner, C.G.; Bassett, R.H. The design and construction of geocell foundation mattresses supporting embankments over soft grounds. Geotext. Geomembr. 1990, 9, 83–98. [Google Scholar] [CrossRef]

- Pokharel, S.K. Experimental Study on Geocell-Reinforced Bases under Static and Dynamic Loading. Ph.D. Thesis, University of Kansas, Lawrence, KS, USA, 2010. [Google Scholar]

- Gedela, R.; Kalla, S.; Sudarsanan, N.; Karpurapu, R. Assessment of load distribution mechanism in geocell reinforced foundation beds using digital imaging correlation techniques. Transp. Geotech. 2021, 31, 100664. [Google Scholar] [CrossRef]

- Dash, S.K.; Rajagopal, K.; Krishnaswamy, N.R. Performance of different geosynthetic reinforcement materials in sand foundations. Geosynth. Int. 2004, 11, 35–41. [Google Scholar] [CrossRef]

- Tafreshi, S.M.; Sharifi, P.; Dawson, A.R. Performance of circular footings on sand by use of multiple-geocell or-planar geotextile reinforcing layers. Soils Found. 2016, 55, 984–997. [Google Scholar] [CrossRef]

- Liu, Y.; Deng, A.; Jaksa, M. Failure mechanisms of geocell walls and junctions. Geotext. Geomembr. 2019, 46, 104–120. [Google Scholar] [CrossRef]

- Dash, S.K.; Rajagopal, K.; Krishnaswamy, N.R. Strip footing on geocell reinforced sand beds with additional planar reinforcement. Geotext. Geomembr. 2001, 19, 519–5211. [Google Scholar] [CrossRef]

- Dash, S.K.; Krishnaswamy, N.R.; Rajagopal, K. Bearing capacity of strip footings supported on geocell-reinforced sand. Geotext. Geomembr. 2001, 19, 235–255. [Google Scholar] [CrossRef]

- Sitharam, T.G.; Sireesh, S.; Dash, S.K. Model studies of a circular footing supported on geocell-reinforced clay. Can. Geotech. J. 2005, 41, 693–703. [Google Scholar] [CrossRef]

- Thallak, S.G.; Saride, S.; Dash, S.K. Performance of surface footing on geocell-reinforced soft clay beds. Geotech. Geol. Eng. 2007, 25, 499–514. [Google Scholar] [CrossRef]

- Lal, D.; Sankar, N.; Chandrakaran, S. Behaviour of square footing on sand reinforced with coir geocell. Arab. J. Geosci. 2017, 10, 345. [Google Scholar] [CrossRef]

- Tafreshi, S.M.; Dawson, A.R. Comparison of bearing capacity of a strip footing on sand with geocell and with planar forms of geotextile reinforcement. Geotext. Geomembr. 2010, 28, 72–114. [Google Scholar] [CrossRef]

- Sherin, K.S.; Chandrakaran, S.; Sankar, N. Effect of geocell geometry and multi-layer system on the performance of geocell reinforced sand under a square footing. Int. J. Geosynth. Ground Eng. 2017, 3, 20. [Google Scholar] [CrossRef]

- Dash, S.K.; Reddy, P.D.T.; Raghukanth, S.T.G. Subgrade modulus of geocell-reinforced sand foundations. Proc. Inst. Civ. Eng. Ground Improv. 2008, 160, 79–117. [Google Scholar] [CrossRef]

- Muthukumar, S.; Sakthivelu, A.; Shanmugasundaram, K.; Mahendran, N.; Ravichandran, V. Performance assessment of square footing on jute geocell-reinforced sand. Int. J. Geosynth. Ground Eng. 2019, 5, 25. [Google Scholar] [CrossRef]

- Shin, E.C.; Kang, H.H.; Park, J.J. Reinforcement efficiency of bearing capacity with geocell shape and filling materials. KSCE J. Civ. Eng. 2017, 21, 1627–1655. [Google Scholar] [CrossRef]

- Tafreshi, S.M.; Shaghaghi, T.; Mehrjardi, G.T.; Dawson, A.R.; Ghadrdan, M. A simplified method for predicting the settlement of circular footings on multi-layered geocell-reinforced non-cohesive soils. Geotext. Geomembr. 2015, 42, 332–343. [Google Scholar] [CrossRef]

- Saride, S.; Gowrisetti, S.; Sitharam, T.G.; Puppala, A.J. Numerical simulation of geocell-reinforced sand and clay. Proc. Inst. Civ. Eng. Ground Improv. 2009, 161, 185–198. [Google Scholar] [CrossRef]

- Latha, G.M.; Rajagopal, K.; Krishnaswamy, N.R. Experimental and theoretical investigations on geocell-supported embankments. Int. J. Geomech. 2006, 6, 30. [Google Scholar] [CrossRef]

- Madhavi Latha, G.; Dash, S.K.; Rajagopal, K. Equivalent continuum simulations of geocell reinforced sand beds supporting strip footings. Geotech. Geol. Eng. 2008, 26, 387–398. [Google Scholar] [CrossRef]

- Mhaiskar, S.Y.; Mandal, J.N. Investigations on soft clay subgrade strengthening using geocells. Constr. Build. Mater. 1996, 10, 281–286. [Google Scholar] [CrossRef]

- Cheung, Y.K.; Chan, H.C. Finite element analysis. In Reinforced Concrete Deep Baems; Kong, F.K., Ed.; Blackie Publication: Glasgow, UK, 1990; pp. 204–237. [Google Scholar]

- Saride, S.; Rayabharapu, V.K.; Vedpathak, S. Evaluation of rutting behavior of geocell reinforced sand subgrades under repeated loading. Indian Geotech. J. 2015, 44, 378–388. [Google Scholar] [CrossRef]

- Hegde, A.; Sitharam, T.G. 3-Dimensional numerical modelling of geocell reinforced sand beds. Geotext. Geomembr. 2015, 42, 171–181. [Google Scholar] [CrossRef]

- Kargar, M.; Mir Mohammad Hosseini, S.M. Effect of reinforcement geometry on the performance of a reduced-scale strip footing model supported on geocell-reinforced sand. Sci. Iran. 2017, 24, 96–109. [Google Scholar] [CrossRef]

- Krishnaswamy, N.R.; Rajagopal, K.; Latha, G.M. Model studies on geocell supported embankments constructed over a soft clay foundation. Geotech. Test. J. 2000, 23, 44–49. [Google Scholar]

- Shimizu, M.; Inui, T. Increase in the bearing capacity of ground with geotextile wall frame. In Proceedings of the Fourth International Conference on Geotextiles Geomembranes and Related Products, Hague, The Netherlands, 28 May–1 June 1990; pp. 1–29. [Google Scholar]

- Yang, X. Numerical Analyses of Geocell-Reinforced Granular Soils under Static and Repeated Loads. Ph.D. Thesis, University of Kansas, Lawrence, KS, USA, 2010. [Google Scholar]

- Saha, D.C.; Mandal, J.N. Performance of reclaimed asphalt pavement reinforced with bamboo geogrid and bamboo geocell. Int. J. Pavement Eng. 2020, 21, 571–582. [Google Scholar] [CrossRef]

- Bagli, S.P. A tryst with geosynthetics. Indian Geotech. J. 2022, 52, 1003–1053. [Google Scholar] [CrossRef]

- Leshchinsky, B.; Ling, H.I. Numerical modeling of behavior of railway ballasted structure with geocell confinement. Geotext. Geomembr. 2013, 36, 33–42. [Google Scholar] [CrossRef]

- Rai, M. Geocell-Sand Mattress Overlying Soft Clay Subgrade: Behaviour under Circular Loading. Ph.D. Thesis, IIT Guwahati, Guwahati, India, 2010. [Google Scholar]

- Khalaj, O.; Moghaddas Tafreshi, S.N.; Mask, B.; Dawson, A.R. Improvement of pavement foundation response with multi-layers of geocell reinforcement: Cyclic plate load test. Geomech. Eng. 2015, 9, 373–395. [Google Scholar] [CrossRef]

- Sitharam, T.G.; Sireesh, S. Effects of base geogrid on geocell-reinforced foundation beds. Geomech. Geoengin. Int. J. 2006, 1, 207–216. [Google Scholar] [CrossRef]

- Mehdipour, I.; Ghazavi, M.; Moayed, R.Z. Numerical study on stability analysis of geocell reinforced slopes by considering the bending effect. Geotext. Geomembr. 2013, 37, 23–34. [Google Scholar] [CrossRef]

- Davarifard, S.; Tafreshi, S.M. Plate load tests of multi-layered geocell reinforced bed considering embedment depth of footing. Procedia Earth Planet. Sci. 2015, 15, 105–110. [Google Scholar] [CrossRef]

- Arvin, M.R.; Zakeri, A.; Bahmani Shoorijeh, M. Using finite element strength reduction method for stability analysis of geocell-reinforced slopes. Geotech. Geol. Eng. 2019, 37, 1443–1456. [Google Scholar] [CrossRef]

- Tafreshi, S.M.; Dawson, A.R. A comparison of static and cyclic loading responses of foundations on geocell-reinforced sand. Geotext. Geomembr. 2012, 32, 54–68. [Google Scholar]

- Zhang, L.; Zhao, M.; Shi, C.; Zhao, H. Bearing capacity of geocell reinforcement in embankment engineering. Geotext. Geomembr. 2010, 28, 475–482. [Google Scholar] [CrossRef]

- Hegde, A.; Sitharam, T.G. Experiment and 3D-numerical studies on soft clay bed reinforced with different types of cellular confinement systems. Transp. Geotech. 2017, 10, 73–84. [Google Scholar] [CrossRef]

- Biabani, M.M.; Ngo, N.T.; Indraratna, B. Performance evaluation of railway subballast stabilised with geocell based on pull-out testing. Geotext. Geomembr. 2016, 43, 569–581. [Google Scholar] [CrossRef]

- Hegde, A.M.; Sitharam, T.G. Three-dimensional numerical analysis of geocell-reinforced soft clay beds by considering the actual geometry of geocell pockets. Can. Geotech. J. 2015, 51, 1206–1397. [Google Scholar] [CrossRef]

- Maheshwari, P.; Babu, G.S. Nonlinear deformation analysis of geocell reinforcement in pavements. Int. J. Geomech. 2017, 17, 03916043. [Google Scholar] [CrossRef]

- Latha, G.M. Design of geocell reinforcement for supporting embankments on soft ground. Geomech. Eng. 2011, 3, 87–130. [Google Scholar] [CrossRef]

- Wang, G.Y.; Zhang, J.P.; Zhao, J.W. Numerical analysis of geocell protective slope stability. Appl. Mech. Mater. 2013, 352, 505–610. [Google Scholar] [CrossRef]

- Sireesh, S.; Sitharam, T.G.; Dash, S.K. Bearing capacity of circular footing on geocell–sand mattress overlying clay bed with void. Geotext. Geomembr. 2009, 27, 89–98. [Google Scholar] [CrossRef]

- Biabani, M.M.; Indraratna, B.; Ngo, N.T. Modelling of geocell-reinforced subballast subjected to cyclic loading. Geotext. Geomembr. 2016, 43, 479–493. [Google Scholar] [CrossRef]

- Tang, X.; Yang, M. Investigation of flexural behavior of geocell reinforcement using three-layered beam model testing. Geotech. Geol. Eng. 2013, 31, 752–765. [Google Scholar] [CrossRef]

- Han, J.; Thakur, J.K.; Parsons, R.L.; Pokharel, S.K.; Leshchinsky, D.; Yang, X. A summary of research on geocell-reinforced base courses. In Proceedings of the Design and Practice of Geosynthetic-Reinforced Soil Structures; Ling, H., Gottardi, G., Cazzuffi, D., Han, J., Tatsuoka, F., Eds.; DEStech Publications, Inc.: Lancaster, PA, USA, 2013; pp. 350–357. [Google Scholar]

- Song, F.; Liu, H.; Ma, L.; Hu, H. Numerical analysis of geocell-reinforced retaining wall failure modes. Geotext. Geomembr. 2018, 45, 284–296. [Google Scholar] [CrossRef]

- Mehdipour, I.; Ghazavi, M.; Ziaie Moayed, R. Stability analysis of geocell-reinforced slopes using the limit equilibrium horizontal slice method. Int. J. Geomech. 2017, 17, 05917007. [Google Scholar] [CrossRef]

- Dash, S.K. Influence of relative density of soil on performance of geocell-reinforced sand foundations. J. Mater. Civ. Eng. 2010, 22, 523–528. [Google Scholar] [CrossRef]

- Hegde, A.; Sitharam, T.G. Experimental and numerical studies on footings supported on geocell reinforced sand and clay beds. Int. J. Geotech. Eng. 2013, 7, 345–353. [Google Scholar] [CrossRef]

- Suku, L.; Prabhu, S.S.; Ramesh, P.; Babu, G.S. Behavior of geocell-reinforced granular base under repeated loading. Transp. Geotech. 2016, 9, 17–30. [Google Scholar] [CrossRef]

- Li, W.; Han, S.; Han, X.; Yao, Y. Experimental and numerical analysis of mechanical properties of geocell reinforced reclaimed construction waste composite base layer. Constr. Build. Mater. 2021, 304, 124587. [Google Scholar] [CrossRef]

- Zhou, H.; Wen, X. Model studies on geogrid-or geocell-reinforced sand cushion on soft soil. Geotext. Geomembr. 2008, 26, 231–238. [Google Scholar] [CrossRef]

- Kumar, V.V.; Saride, S. Rutting behavior of geocell reinforced base layer overlying weak sand subgrades. Procedia Eng. 2016, 143, 1409–1416. [Google Scholar] [CrossRef]

- Yang, X.; Han, J.; Pokharel, S.K.; Manandhar, C.; Parsons, R.L.; Leshchinsky, D.; Halahmi, I. Accelerated pavement testing of unpaved roads with geocell-reinforced sand bases. Geotext. Geomembr. 2012, 32, 95–103. [Google Scholar] [CrossRef]

- Al-Qadi, I.L.; Hughes, J.J. Field evaluation of geocell use in flexible pavements. Transp. Res. Rec. 2000, 1709, 26–35. [Google Scholar] [CrossRef]

- Emersleben, A.; Meyer, N. Bearing capacity improvement of gravel base layers in road constructions using geocells. In Proceedings of the 12th International Conference of International Association for Computer Methods and Advances in Geomechanics (IACMAG’08), Goa, India, 1–6 October 2008; pp. 3538–3545. [Google Scholar]

- Latha, G.; Nair, A.; Hemalatha, M. Performance of geosynthetics in unpaved roads. Int. J. Geotech. Eng. 2010, 4, 337–349. [Google Scholar] [CrossRef]

- Rajagopal, K.; Chandramouli, S.; Parayil, A.; Iniyan, K. Studies on geosynthetic-reinforced road pavement structures. Int. J. Geotech. Eng. 2014, 8, 287–298. [Google Scholar] [CrossRef]

- Rajagopal, K.; Veeragavan, A.; Chandramouli, S. Studies on geocell reinforced road pavement structures. In Proceedings of the Geosynthetics Asia, Bangkok, Thailand, 13–15 December 2012; pp. 497–502. [Google Scholar]

- Tafreshi, S.M.; Khalaj, O.; Dawson, A. R Repeated loading of soil containing granulated rubber and multiple geocell layers. Geotext. Geomembr. 2014, 42, 25–38. [Google Scholar] [CrossRef]

- Thakur, J.K.; Han, J.; Parsons, R.L. Creep behavior of geocell-reinforced recycled asphalt pavement bases. J. Mater. Civ. Eng. 2013, 25, 1533–1542. [Google Scholar] [CrossRef]

- Sheikh, I.R.; Mandhaniya, P.; Shah, M.Y. A parametric study on pavement with geocell reinforced rock quarry waste base on dredged soil subgrade. Int. J. Geosynth. Ground Eng. 2021, 7, 32. [Google Scholar] [CrossRef]

- Edil, T.B.; Benson, C.H.; Bin-Shafique, M.; Tanyu, B.F.; Kim, W.H.; Senol, A. Field evaluation of construction alternatives for roadways over soft subgrade. Transp. Res. Rec. 2002, 1786, 36–48. [Google Scholar] [CrossRef]

- Palese, J.W.; Hartsough, C.H.; Zarembski, A.M.; Thompson, H.; Ling, H.L. Life cycle benefits of subgrade reinforcement using geocell on a highspeed railway—A case study. In Proceedings of the AREMA Conference, Indianapolis, IN, USA, 17–20 September 2017; pp. 1–14. [Google Scholar]

| Property | Value |

|---|---|

| Density | 0.932–0.95 g/cm3 |

| Strip width | 50–300 mm |

| Strip thickness | 1.53 mm (±10%) |

| Percentage of perforations to cell wall area | 6–22% |

| Ultimate tensile strength | 16–25 kN/m |

| Junction peel strength | 7–10 kN/m |

| Elongation at maximum load | 20% (±15%) |

| Dynamic modulus at service temperature (−60 °C to 60 °C) | 650–800 MPa |

| Resistance to UV degradation | 250–400 min |

| Cumulative permanent deformation (creep resistance) | 2.7–3.5% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krishna, A.; Latha, G.M. Evolution of Geocells as Sustainable Support to Transportation Infrastructure. Sustainability 2023, 15, 11773. https://doi.org/10.3390/su151511773

Krishna A, Latha GM. Evolution of Geocells as Sustainable Support to Transportation Infrastructure. Sustainability. 2023; 15(15):11773. https://doi.org/10.3390/su151511773

Chicago/Turabian StyleKrishna, Aarya, and Gali Madhavi Latha. 2023. "Evolution of Geocells as Sustainable Support to Transportation Infrastructure" Sustainability 15, no. 15: 11773. https://doi.org/10.3390/su151511773

APA StyleKrishna, A., & Latha, G. M. (2023). Evolution of Geocells as Sustainable Support to Transportation Infrastructure. Sustainability, 15(15), 11773. https://doi.org/10.3390/su151511773