Factors Affecting Indoor Temperature in the Case of District Heating

Abstract

:1. Introduction

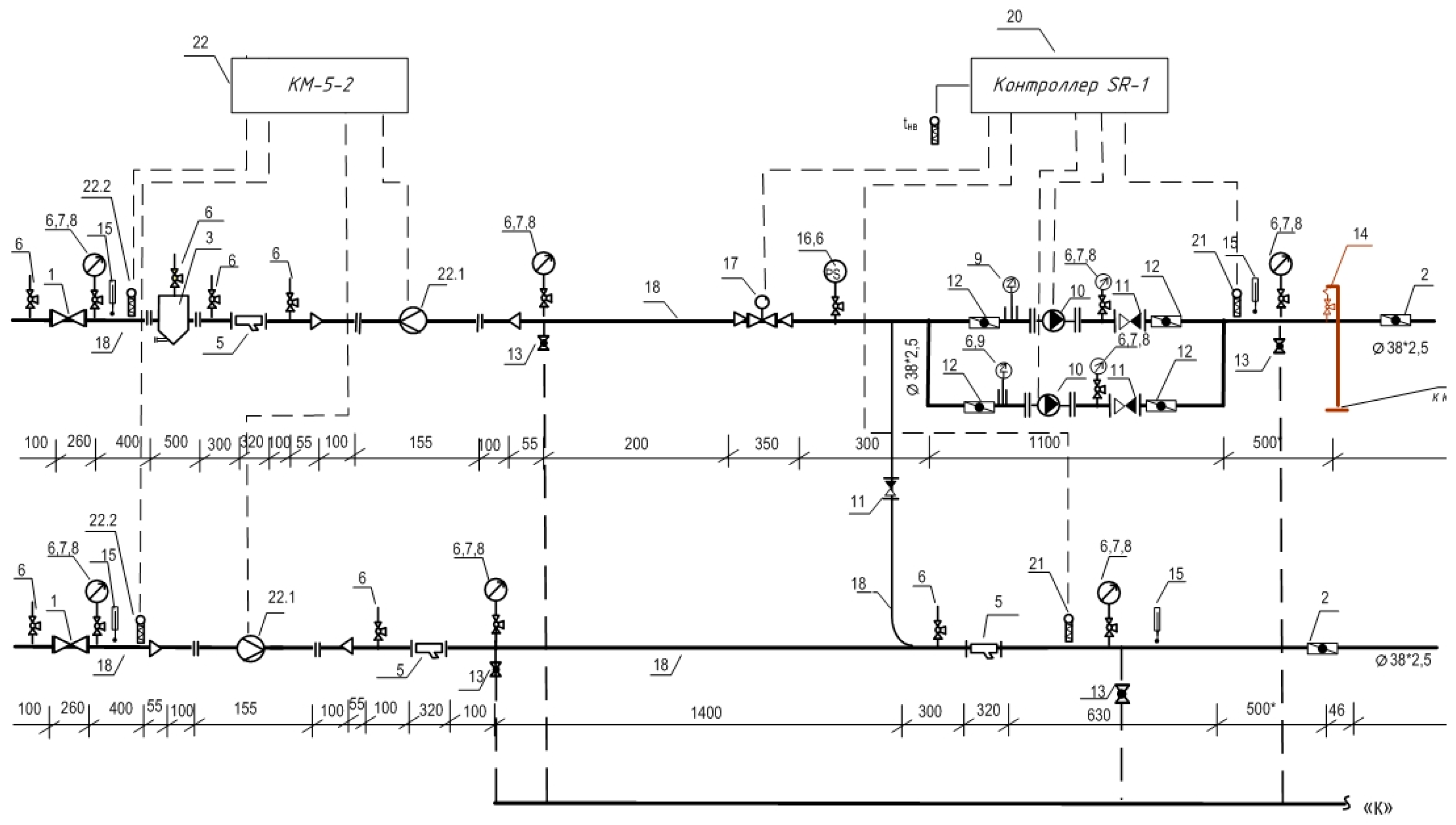

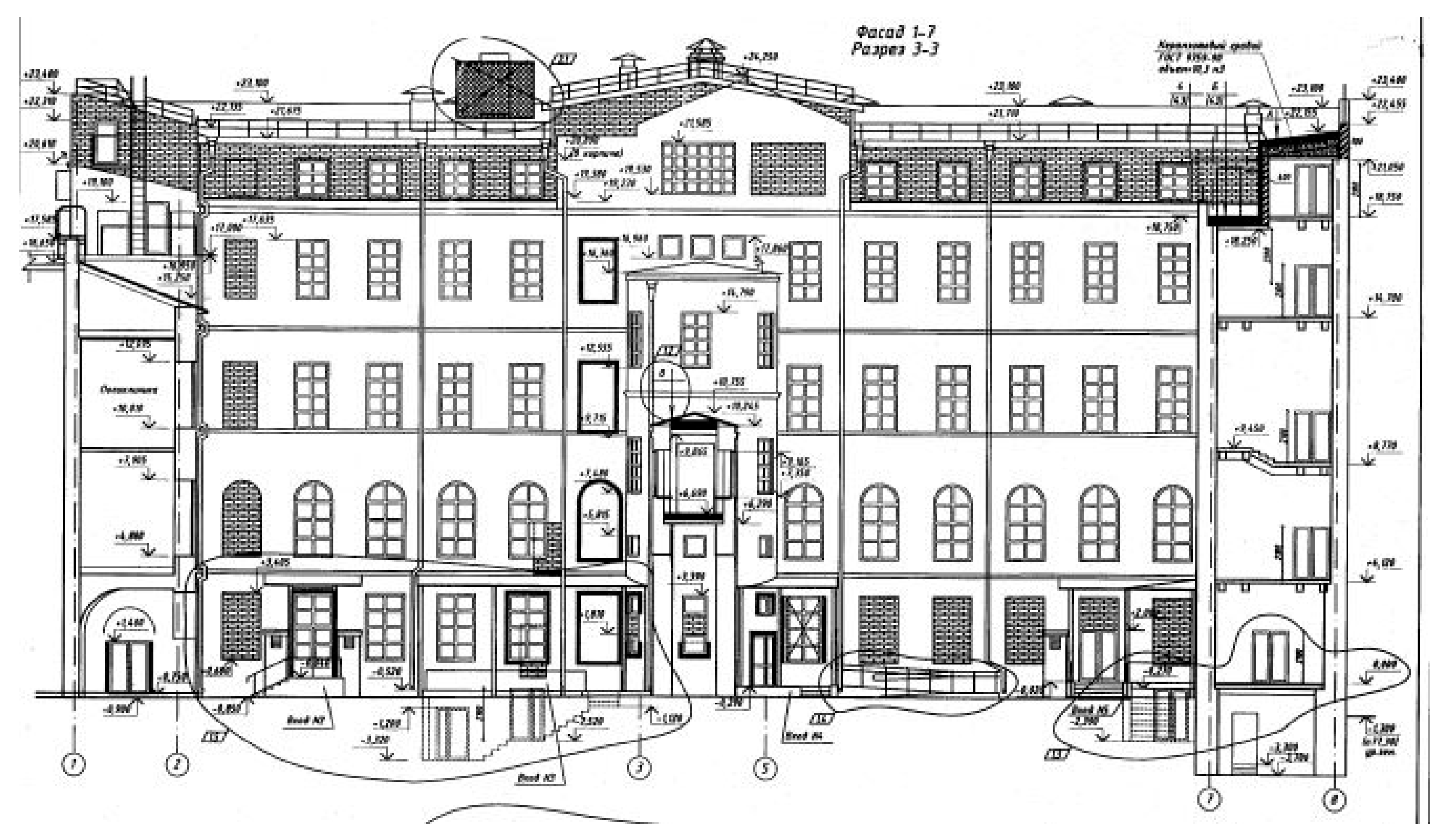

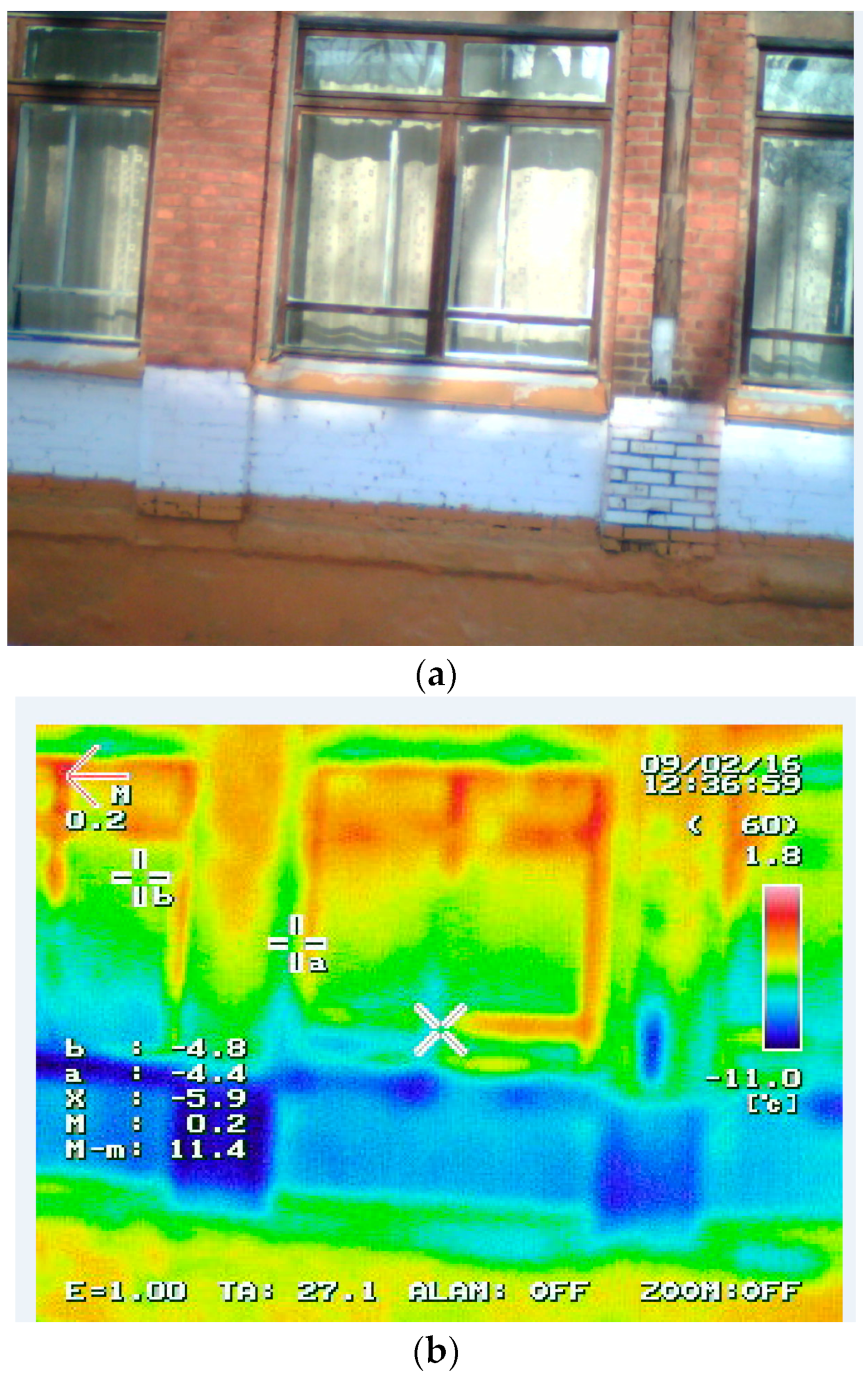

2. Materials and Methods

- β = 0.1 for indoor spaces oriented north (N), north-east (NE), north-west (NW), and east (E);

- β = −0.05 ditto, for south-east (SE) and west (W);

- β = −0.1 ditto, for south (S) and south-west (SW).

- β = 0.2∙H for triple doors and two airlocks between;

- β = 0.27∙H for double doors and one airlock between;

- β = 0.34∙H for double doors without an airlock;

- β = 0.42∙H for a single door;

- β = 0.34∙H for a revolving door,

3. Case Study

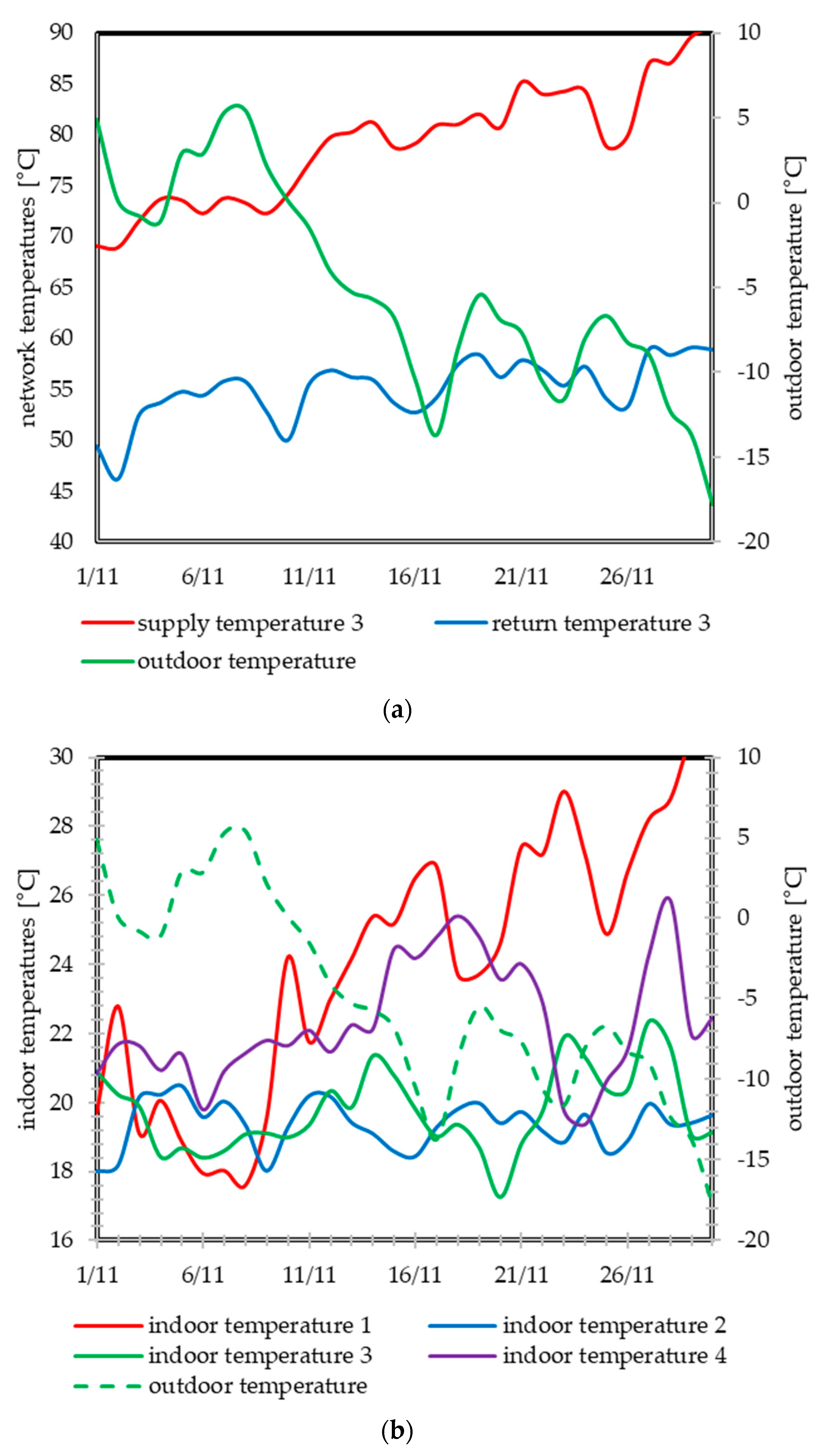

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| # | Office (Zone) | Target Indoor Temperature [°C] | Properties of Envelopes | |||

|---|---|---|---|---|---|---|

| Wall Title (According to the Blueprints) | Orientation | Dimensions [m] | Surface Area [m2] | |||

| Ground floor | ||||||

| 1 | Tool shop | 16 | Internal partition #1 | 113.4 | ||

| 16 | Internal partition #2 | 110.4 | ||||

| 16 | Internal partition #3 | 117.6 | ||||

| 16 | Internal partition #4 | 181.0 | ||||

| 16 | Window | NE | (0.6 × 1.2) × 6 | 4.32 | ||

| 16 | Door | SW | 2 × 1.2 | 2.4 | ||

| 2 | Storage room for household chemical goods, garage | 16 | Internal partition #1 | 135.0 | ||

| 16 | Internal partition #2 | 156.9 | ||||

| 16 | Internal partition #3 | 132.2 | ||||

| 16 | Internal partition #4 | 228.2 | ||||

| 16 | Window | NE | (0.6 × 1.2) × 7 | 5.04 | ||

| 16 | Door | NW | 2 × 1.2 | 2.4 | ||

| First floor | ||||||

| 13 | Office | 20 | Load-bearing wall | SW | 3.6 × 3.6 | 12.96 |

| 20 | Load-bearing wall | NW | 6.6 × 3.6 | 23.76 | ||

| 12 | Exhibition hall | 20 | Load-bearing wall | SW | 18 × 3.6 | 47.52 |

| 20 | Window | SW | 2.7 × 3.2 | 8.64 | ||

| 20 | Window | SW | 2.7 × 3.2 | 8.64 | ||

| 20 | Load-bearing wall | SE | 12.6 × 3.6 | 34.91 | ||

| 20 | Window | SE | 2.7 × 3.87 | 10.45 | ||

| 20 | Load-bearing wall | NW | 12 × 3.6 | 38.88 | ||

| 20 | Door | NE | 2.4 × 1.8 | 4.32 | ||

| 20 | Load-bearing wall | NE | 8 × 3.6 | 28.8 | ||

| 20 | Window | NE | 1.8 × 1.77 | 3.19 | ||

| 20 | Load-bearing wall | NE | 6 × 3.6 | 21.6 | ||

| 20 | Door | NW | 1.8 × 2.4 | 4.32 | ||

| 20 | Window | SW | 2.7 × 3.2 | 8.64 | ||

| Staircase/Vestibule | 16 | Load-bearing wall | SW | 3 × 3.6 | 10.8 | |

| 16 | Load-bearing wall | NW | 7 × 3.6 | 26.6 | ||

| 16 | Load-bearing wall | NE | 3 × 3.6 | 10.8 | ||

| 16 | Door | NE | 1 × 2.1 | 2.1 | ||

| 2 | Vestibule | 20 | Load-bearing wall | SW | 6 × 3.6 | 15.36 |

| 20 | Door | SW | 2.4 × 1.3 | 3.12 | ||

| 20 | Door | SW | 2.4 × 1.3 | 3.12 | ||

| 3 | Office | 20 | Window | NE | 5 × 3.6 | 18 |

| 20 | Window | SE | 5 × 3.6 | 18 | ||

| 20 | Internal partition #1 | 5 × 4 | 20 | |||

| 20 | Internal partition #2 | 2 × 3 + 2 × 0.4 | 6.8 | |||

| 20 | Internal partition #3 | 0.4 × 0.8 | 0.32 | |||

| Staircase | 16 | Load-bearing wall | NW | 7 × 3.6 | 23.1 | |

| 16 | Load-bearing wall | NE | 4.6 × 3.6 | 16.56 | ||

| 16 | Load-bearing wall | SW | 4.6 × 3.6 | 16.56 | ||

| 16 | Door | NW | 1 × 2.1 | 2.1 | ||

| 4 | Exhibition hall | 20 | Load-bearing wall | NW | 6 × 3.6 | 21.6 |

| 20 | Load-bearing wall | SW | 8 × 3.6 | 28.8 | ||

| 20 | Window | SW | 3.14 × 2.7 | 8.5 | ||

| 20 | Window | SE | 20 × 3.6 | 72 | ||

| 20 | Load-bearing wall | NE | 21 × 3.6 | 75.6 | ||

| 20 | Door | NE | 1.3 × 2.4 | 3.12 | ||

| 20 | Window | NE | 1.8 × 1.8 × 4 | 12.96 | ||

| 20 | Load-bearing wall | NW | 12 × 3.6 | 43.2 | ||

| 20 | Window | NW | 1.8 × 1.8 × 2 | 6.48 | ||

| 20 | Door | NW | 1.8 × 2.4 | 4.32 | ||

| 20 | Internal partition #1 | 20 × 2 + 5 × 2 | 50 | |||

| 20 | Internal partition #2 | 16 × 2 + 3 × 2 | 38 | |||

| 20 | Internal partition #3 | 18 × 1 | 18 | |||

| Second floor | ||||||

| 12 | Office | 20 | Window | SW | 21 × 3.75 | 78.75 |

| 20 | Window | NW | 10 × 3.75 | 37.5 | ||

| 20 | Window | SE | 10 × 3.75 | 37.5 | ||

| Staircase | 16 | Load-bearing wall | NE | 7 × 3.75 | 22.5 | |

| 16 | Window | NE | 3 × 1.25 | 3.75 | ||

| 16 | Load-bearing wall | SW | 3 × 3.75 | 11.25 | ||

| 16 | Load-bearing wall | NW | 7 × 3.75 | 7.5 | ||

| 16 | Window | NW | 3 × 1.25 | 3.75 | ||

| 6 | Hallway | 20 | Load-bearing wall | NW | 7 × 3.75 | 23.52 |

| 20 | Door | NW | 2.1 × 1.3 | 2.73 | ||

| 20 | Load-bearing wall | NW | 1.8 × 3.75 | 6.75 | ||

| 20 | Load-bearing wall | NW | 1.8 × 3.75 | 6.75 | ||

| 20 | Load-bearing wall | NE | 4.8 × 3.75 | 15.3 | ||

| 20 | Window | NE | 0.9 × 1.5 × 2 | 2.7 | ||

| 20 | Load-bearing wall | SE | 2.6 × 3.75 | 7.95 | ||

| 20 | Window | NW | 1.2 × 1.5 | 1.8 | ||

| 11 | Office | 20 | Window | SW | 6 × 3.75 | 22.5 |

| 19 | Office | 20 | Load-bearing wall | NE | 4 × 3.75 | 15.0 |

| 20 | Window | NE | 1.2 × 1.5 | 1.8 | ||

| 20 | Load-bearing wall | NW | 6 × 3.75 | 22.5 | ||

| 20 | Window | NW | 1.2 × 1.5 | 1.8 | ||

| 1 | Office | 20 | Load-bearing wall | NW | 6 × 3.75 | 22.5 |

| 20 | Window | NW | 1.2 × 1.5 | 1.8 | ||

| 2.3 | Office | 20 | Load-bearing wall | NE | 12 × 3.75 | 45 |

| 20 | Window | NE | 1.2 × 1.5 × 4 | 7.2 | ||

| 4 | Office | 20 | Load-bearing wall | NE | 5 × 3.75 | 18.75 |

| 20 | Load-bearing wall | NE | 9 × 3.75 | 33.75 | ||

| 20 | Load-bearing wall | SE | 6 × 3.75 | 22.5 | ||

| 20 | Window | NE | 1.8 × 1.8 × 2 | 6.48 | ||

| 5 | Office | 20 | Window | SE | 6 × 3.75 | 22.5 |

| 10 | Office | 20 | Window | SE | 12 × 3.75 | 45 |

| 20 | Window | SW | 8 × 3.75 | 30 | ||

| 14 | Office | 20 | Load-bearing wall | NW | 6 × 3.75 | 22.5 |

| 20 | Window | NW | 1.2 × 1.5 | 1.8 | ||

| 20 | Office | 20 | Load-bearing wall | NW | 6 × 3.75 | 22.5 |

| 20 | Load-bearing wall | SW | 3 × 3.75 | 11.25 | ||

| 20 | Window | NW | 4 × 3.75 | 15 | ||

| 20 | Window | SW | 4 × 3.75 | 15 | ||

| Third floor | ||||||

| 14 | Office | 20 | Window | NW | ½(12 + 5.2) × 3.45 | 29.67 |

| 20 | Window | SW | ½(12 + 5.2) × 3.45 | 29.67 | ||

| 20 | Window | SE | ½(13.6 + 6) × 3.45 | 33.81 | ||

| 20 | Window | NE | ½(7 + 3) × 3.45 | 17.25 | ||

| 20 | Internal partition | 6 × 5.2 | 31.2 | |||

| 5 | Office | 20 | Window | NE | 6.6 × 3.45 | 22.77 |

| 20 | Window | NW | 8.8 × 3.45 | 30.36 | ||

| 20 | Door | NW | 0.7 × 2.1 | 1.47 | ||

| 1 | Security room | 20 | Window | NW | 2.4 × 3.45 | 8.28 |

| 13 | Hallway | 20 | Window | NW | 2.6 × 3.45 | 8.97 |

| 20 | Door | SE | 1 × 2.1 | 2.1 | ||

| 20 | Window | SW | 1.2 × 0.8 | 0.96 | ||

| 9 | Lounge | 20 | Window | SE | 9.2 × 3.45 | 31.74 |

| 20 | Window | SW | 4 × 3.45 | 13.8 | ||

| 6 | Exhibition hall | 20 | Window | NE | ½(14 + 10.4) × 3.45 | 42.09 |

| 20 | Window | SE | ½(7 + 4) × 3.45 | 18.98 | ||

| Vestibule | 20 | Window | SW | 6 × 3.45 | 20.7 | |

| 7 | Vestibule | 18 | Window | SE | 1.2 × 3.45 | 4.14 |

| 3 | Vestibule | 18 | Window | NW | 1.0 × 3.45 | 3.45 |

| 15 | Vestibule | 18 | Window | SW | 1.2 × 3.45 | 3.45 |

| Fourth floor | ||||||

| 2 | Principal’s office | 20 | Window | SW | ½(6 + 3) × 3.6 | 16.2 |

| 20 | Internal partition | 3 × 6 | 18.0 | |||

| 20 | Window | NW | ½(8 + 4.5) × 3.6 | 22.5 | ||

| 1 | Reception | 20 | Internal partition | 3 × 6 | 18.0 | |

| 20 | Window | NE | ½(6.4 + 3) × 3.6 | 16.92 | ||

| 20 | Window | SE | ½(7.6 + 4.2) × 3.6 | 21.24 | ||

| 4 | Bathroom | 20 | Window | NE | ½(1.6 + 0.8) × 3.6 | 4.32 |

| 3 | Lounge area | 20 | Window | NE | ½(5 + 2.5) × 3.6 | 13.5 |

| 20 | Window | NW | ½(3 + 1.5) × 3.6 | 8.1 | ||

References

- Buffa, S.; Cozzini, M.; D’Antoni, M.; Baratieri, M.; Fedrizzi, R. 5th generation district heating and cooling systems: A review of existing cases in Europe. Renew. Sustain. Energy Rev. 2019, 104, 504–522. [Google Scholar] [CrossRef]

- Wirtz, M.; Kivilip, L.; Remmen, P.; Müller, D. 5th Generation District Heating: A novel design approach based on mathematical optimization. Appl. Energy 2020, 260, 114158. [Google Scholar] [CrossRef]

- Vandermeulen, A.; van Oevelen, T.; van der Heijde, B.; Helsen, L. A simulation-based evaluation of substation models for network flexibility characterisation in district heating networks. Energy 2020, 201, 117650. [Google Scholar] [CrossRef]

- Guelpa, E. Impact of thermal masses on the peak load in district heating systems. Energy 2021, 214, 118849. [Google Scholar] [CrossRef]

- Ivanko, D.; Sørensen, Å.L.; Nord, N. Splitting measurements of the total heat demand in a hotel into domestic hot water and space heating heat use. Energy 2021, 219, 119685. [Google Scholar] [CrossRef]

- Braas, H.; Jordan, U.; Best, I.; Orozaliev, J.; Vajen, K. District heating load profiles for domestic hot water preparation with realistic simultaneity using DHWcalc and TRNSYS. Energy 2020, 117552. [Google Scholar] [CrossRef]

- Chicherin, S.; Starikov, A.; Zhuikov, A. Justifying network reconstruction when switching to low temperature district heating. Energy 2022, 248, 123618. [Google Scholar] [CrossRef]

- Luc, K.M.; Li, R.; Xu, L.; Nielsen, T.R.; Hensen, J.L.M. Energy flexibility potential of a small district connected to a district heating system. Energy Build. 2020, 225, 110074. [Google Scholar] [CrossRef]

- Johra, H.; Heiselberg, P.; Le Dréau, J. Influence of envelope, structural thermal mass and indoor content on the building heating energy flexibility. Energy Build. 2019, 183, 325–339. [Google Scholar] [CrossRef]

- Chicherin, S. A method for assessing heat losses in developing countries with a focus on operational data of a district heating (DH) system. Sustain. Energy Grids Netw. 2022, 30, 100616. [Google Scholar] [CrossRef]

- Chicherin, S.; Zhuikov, A.; Kolosov, M.; Junussova, L.; Aliyarova, M.; Yelemanova, A. Optimizing building heat consumption: Weekday and weekend profiles. Energy Rep. 2021, 7, 166–170. [Google Scholar] [CrossRef]

- Jebamalai, J.M.; Marlein, K.; Laverge, J. Influence of centralized and distributed thermal energy storage on district heating network design. Energy 2020, 202, 117689. [Google Scholar] [CrossRef]

- Sleptsov, A.; Crisostomi, E.; Bischi, A. Control schemes for district heating substations considering user-defined building’s indoor temperature. Build Environ. 2021, 191, 107598. [Google Scholar] [CrossRef]

- Sommer, T.; Sulzer, M.; Wetter, M.; Sotnikov, A.; Mennel, S.; Stettler, C. The reservoir network: A new network topology for district heating and cooling. Energy 2020, 199, 117418. [Google Scholar] [CrossRef]

- Patureau, R.; Tran, C.T.; Gavan, V.; Stabat, P. The new generation of District heating & cooling networks and their potential development in France. Energy 2021, 236, 121477. [Google Scholar]

- Romanov, D.; Pelda, J.; Holler, S. Technical, economic and ecological effects of lowering temperatures in the Moscow district heating system. Energy 2020, 211, 118680. [Google Scholar] [CrossRef]

- Saletti, C.; Zimmerman, N.; Morini, M.; Kyprianidis, K.; Gambarotta, A. Enabling smart control by optimally managing the State of Charge of district heating networks. Appl. Energy 2020, 283, 116286. [Google Scholar] [CrossRef]

- Farouq, S.; Byttner, S.; Bouguelia, M.-R.; Nord, N.; Gadd, H. Large-scale monitoring of operationally diverse district heating substations: A reference-group based approach. Eng. Appl. Artif. Intell. 2020, 90, 103492. [Google Scholar] [CrossRef]

- Gadd, H.; Werner, S. Achieving low return temperatures from district heating substations. Appl. Energy 2014, 136, 59–67. [Google Scholar] [CrossRef]

- Ren, C.; Cao, S.J. Construction of linear temperature model using non-dimensional heat exchange ratio: Towards fast prediction of indoor temperature and heating, ventilation and air conditioning systems control. Energy Build. 2021, 251, 111351. [Google Scholar] [CrossRef]

- Harney, P.; Gartland, D.; Murphy, F. Determining the optimum low-temperature district heating network design for a secondary network supplying a low-energy-use apartment block in Ireland. Energy 2020, 192, 116595. [Google Scholar] [CrossRef]

- Fitó, J.; Hodencq, S.; Ramousse, J.; Wurtz, F.; Stutz, B.; Debray, F.; Vincent, B. Energy- and exergy-based optimal designs of a low-temperature industrial waste heat recovery system in district heating. Energy Convers. Manag. 2020, 211, 112753. [Google Scholar] [CrossRef]

- Quirosa, G.; Torres, M.; Soltero, V.M.; Chacartegui, R. Energetic and economic analysis of decoupled strategy for heating and cooling production with CO2 booster heat pumps for ultra-low temperature district network. J. Build. Eng. 2022, 45, 103538. [Google Scholar] [CrossRef]

- Sun, C.; Chen, J.; Cao, S.; Gao, X.; Xia, G.; Qi, C.; Wu, X. A dynamic control strategy of district heating substations based on online prediction and indoor temperature feedback. Energy 2021, 235, 121228. [Google Scholar] [CrossRef]

- Camci, M.; Karakoyun, Y.; Acikgoz, O.; Dalkilic, A.S. A comparative study on convective heat transfer in indoor applications. Energy Build. 2021, 242, 110985. [Google Scholar] [CrossRef]

- SP 50.13330.2012; Thermal Protection of Buildings. RussianGost|Official Regulatory Library: Moscow, Russia, 2018.

- Federal Law. ‘On Energy Saving and on Increasing Energy Efficiency and on Amendments to Certain Legislative Acts of the Russian Federation’ of 23.11.2009 N 261-FZ; Food and Agriculture Organization of the United Nations: Rome, Italy, 2009. [Google Scholar]

- Jangsten, M.; Lindholm, T.; Dalenbäck, J.O. Analysis of operational data from a district cooling system and its connected buildings. Energy 2020, 203, 117844. [Google Scholar] [CrossRef]

- Turski, M.; Sekret, R. Buildings and a district heating network as thermal energy storages in the district heating system. Energy Build. 2018, 179, 49–56. [Google Scholar] [CrossRef]

- He, R.; Li, M.; Gan, V.J.L.; Ma, J. BIM-enabled computerized design and digital fabrication of industrialized buildings: A case study. J. Clean. Prod. 2021, 278, 123505. [Google Scholar] [CrossRef]

- Jang, R.; Collinge, W. Improving BIM asset and facilities management processes: A Mechanical and Electrical (M&E) contractor perspective. J. Build. Eng. 2020, 32, 101540. [Google Scholar]

| Normalized Influence | Covered by the Present Research | ||

|---|---|---|---|

| Residential Building | Office Building | ||

| Primary (network) supply temperature | 0.14 | 0.14 | Yes |

| Secondary (space heating) supply temperature | 0.23 | 0.23 | No |

| Return temperature | 0.08 | 0.08 | Yes |

| State of the space heating system (incl. radiators) | 0.17 | 0.15 | No |

| Envelope state (incl. infiltration) | 0.18 | 0.20 | Yes |

| Thermal inertia | 0.05 | 0.05 | No |

| Internal heat gains | 0.10 | 0.05 | Yes |

| Solar insolation (incl. glazing share and building orientation) | 0.05 | 0.10 | Yes |

| Total | 1.00 | 1.00 | n/a |

| # | Office (Zone) | Design Heat Demand [W] | Due to Infiltration [W] | Heat Gains [W] | Actual Heat Demand [W] |

|---|---|---|---|---|---|

| Column | 1 | 2 | 3 | 4 | 5 |

| Remark | Refer to Equation (2) | Refer to Equation (4) | Refer to [26] | Column #2 + Column #3 − Column #4 | |

| Ground floor | |||||

| 1 | Tool shop | 6325 | 12,689 | n/a | 19,014 |

| 2 | Storage room for household chemical goods, garage | 7899 | 17,168 | n/a | 25,067 |

| ∑44,081 | |||||

| First floor | |||||

| 13 | Office | 708 | 1124 | 411 | 1421 |

| 4 | Exhibition hall | 17,294 | 24,132 | 9028 | 32,398 |

| 2 | Vestibule | 936 | 1300 | n/a | 2236 |

| 3 | Office | 4720 | 965 | 467 | 5218 |

| 12 | Exhibition hall | 8569 | 19,191 | 7014 | 20,746 |

| Staircase | 1102 | 560 | n/a | 1662 | |

| Staircase | 1334 | 590 | n/a | 1924 | |

| ∑65,605 | |||||

| Second floor | |||||

| 12 | Office | 16,822 | 11,664 | 2209 | 26,277 |

| 6 | Hallway | 2001 | 5395 | n/a | 7396 |

| 11 | Office | 2375 | 1322 | 485 | 3212 |

| 19 | Office | 1164 | 858 | 538 | 1484 |

| 1 | Office | 657 | 2356 | 358 | 2655 |

| 2 | Office | 1731 | 3275 | 1223 | 3783 |

| 3 | Office | 1731 | 3275 | 1223 | 3783 |

| 4 | Office | 2224 | 6781 | 2291 | 6714 |

| 5 | Office | 2494 | 1634 | 765 | 3363 |

| 10 | Office | 8155 | 5258 | 1836 | 11,577 |

| 14 | Office | 6476 | 5365 | 3498 | 8343 |

| 20 | Office | 3976 | 2630 | 1649 | 4957 |

| ∑83,544 | |||||

| Third floor | |||||

| 14 | Office | 12,754 | 8973 | 2328 | 19,399 |

| 5 | Office | 6341 | 3110 | 1703 | 7748 |

| 1 | Security room | 961 | 1440 | n/a | 2058 |

| 13 | Hallway | 1376 | 2997 | n/a | 4373 |

| 9 | Lounge | 4975 | 2039 | 745 | 6269 |

| 6 | Exhibition hall | 6990 | 4805 | n/a | 11,795 |

| 7 | Vestibule | 422 | 108 | n/a | 530 |

| 3 | Vestibule | 386 | 85 | n/a | 471 |

| 15 | Vestibule | 351 | 108 | n/a | 459 |

| ∑53,101 | |||||

| Fourth floor | |||||

| 1 | Reception | 4565 | 2730 | 998 | 6297 |

| 2 | Principal’s office | 4569 | 2924 | 1069 | 6424 |

| 3 | Lounge area | 2509 | 1026 | 396 | 3139 |

| 4 | Bathroom | 502 | 233 | n/a | 735 |

| ∑16,595 | |||||

| Total | 262,926 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chicherin, S.; Zhuikov, A.; Junussova, L. Factors Affecting Indoor Temperature in the Case of District Heating. Sustainability 2023, 15, 15603. https://doi.org/10.3390/su152115603

Chicherin S, Zhuikov A, Junussova L. Factors Affecting Indoor Temperature in the Case of District Heating. Sustainability. 2023; 15(21):15603. https://doi.org/10.3390/su152115603

Chicago/Turabian StyleChicherin, Stanislav, Andrey Zhuikov, and Lyazzat Junussova. 2023. "Factors Affecting Indoor Temperature in the Case of District Heating" Sustainability 15, no. 21: 15603. https://doi.org/10.3390/su152115603

APA StyleChicherin, S., Zhuikov, A., & Junussova, L. (2023). Factors Affecting Indoor Temperature in the Case of District Heating. Sustainability, 15(21), 15603. https://doi.org/10.3390/su152115603