A Review of Optimization for Corrugated Boards

Abstract

:1. Introduction

- RQ1.

- What is the current landscape of optimization methodologies in the corrugated board industry, and how do these methodologies contribute to the economic and environmental outcomes?

- RQ2.

- How have these methodologies evolved, and what are the key drivers behind these changes?

- RQ3.

- What current state-of-the-art limitations may lead to potential trends that can be anticipated in optimizing corrugated boards?

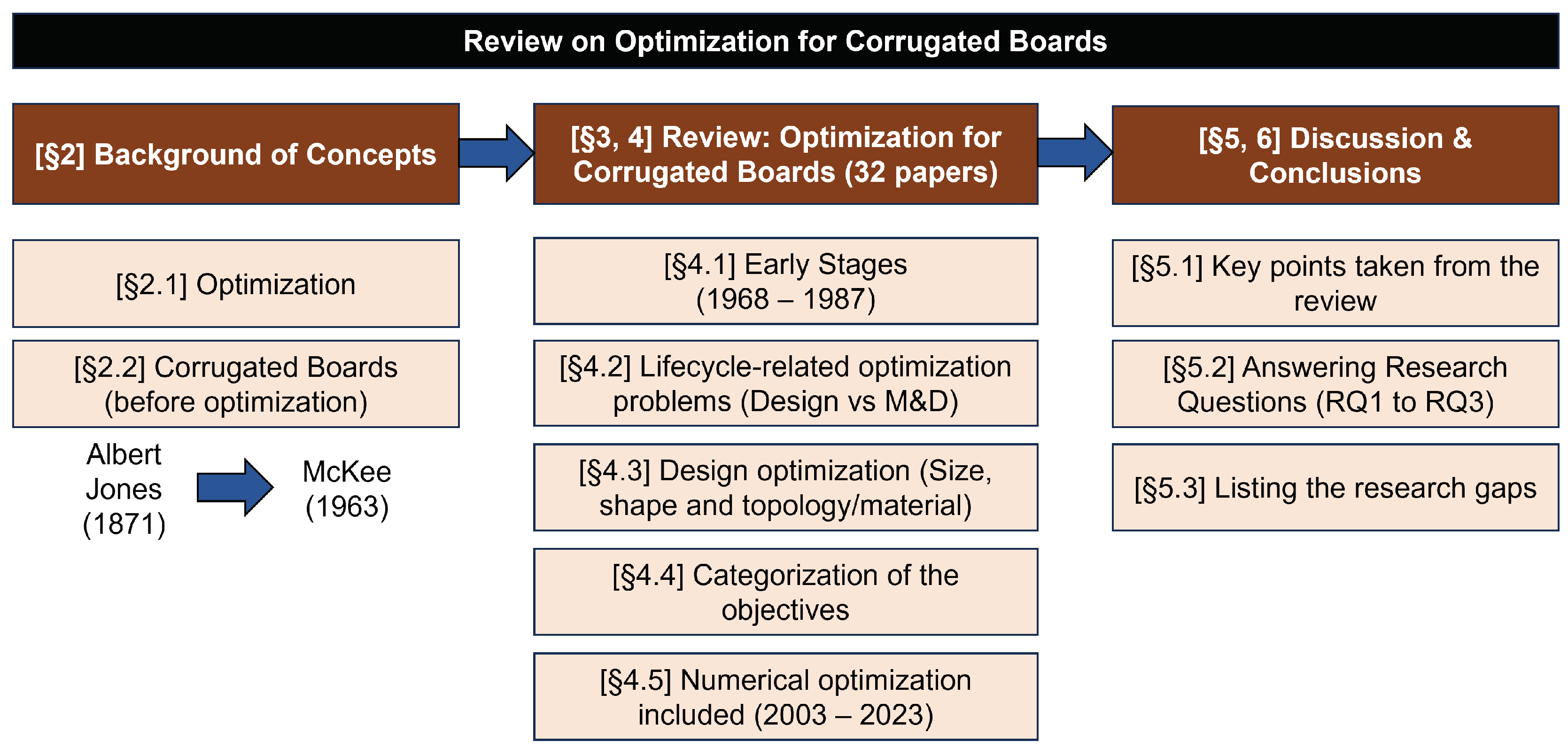

- The early stages of optimization of corrugated boards.

- Advances of optimization in the design and manufacturing of corrugated boards.

- Design optimization of the structure.

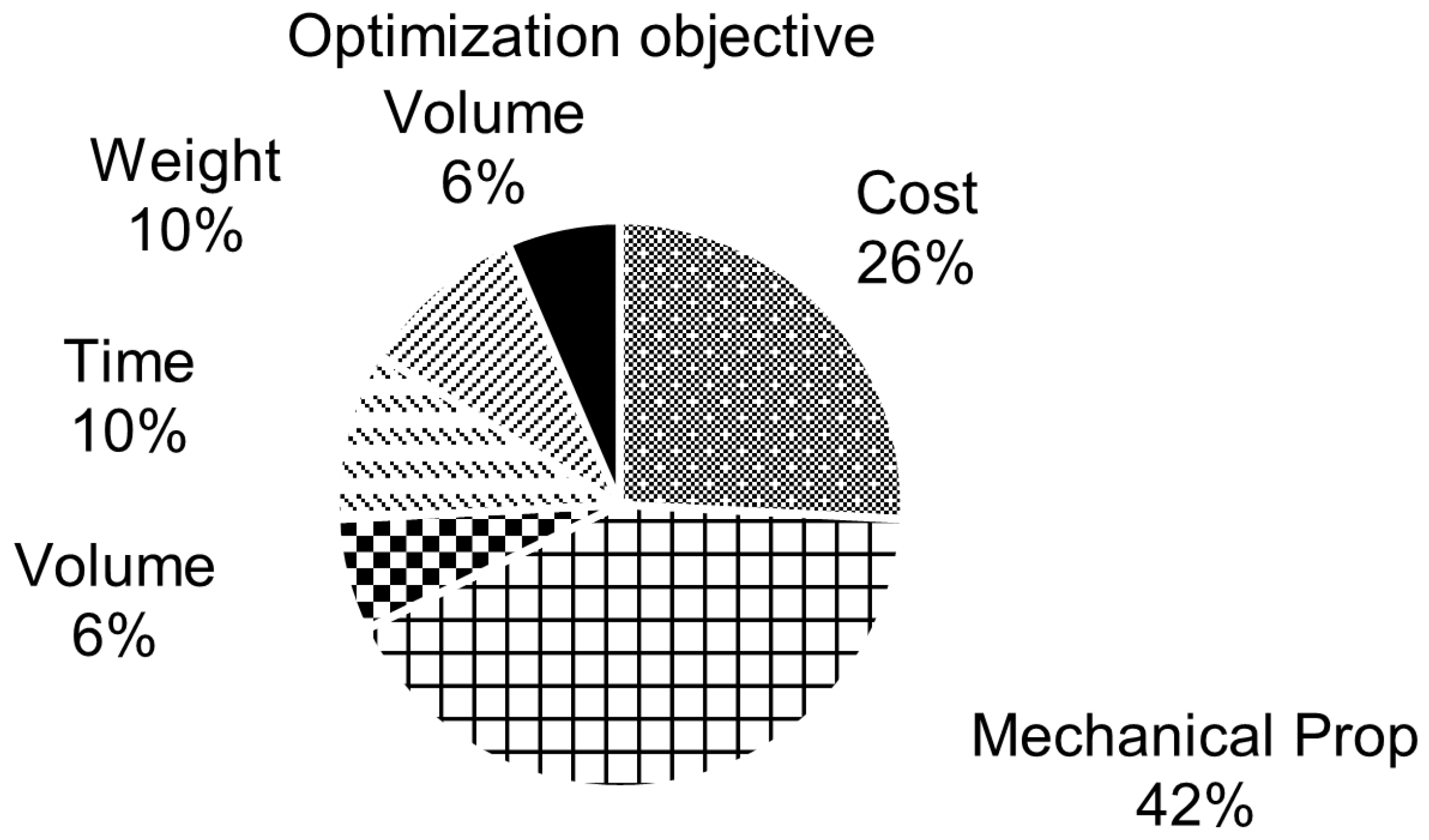

- Optimization objectives.

- Numerical optimization algorithms used in the context of corrugated boards.

2. Background of Concepts

2.1. Optimization—Definition and Strategies

2.2. Corrugated Boards—An Overview

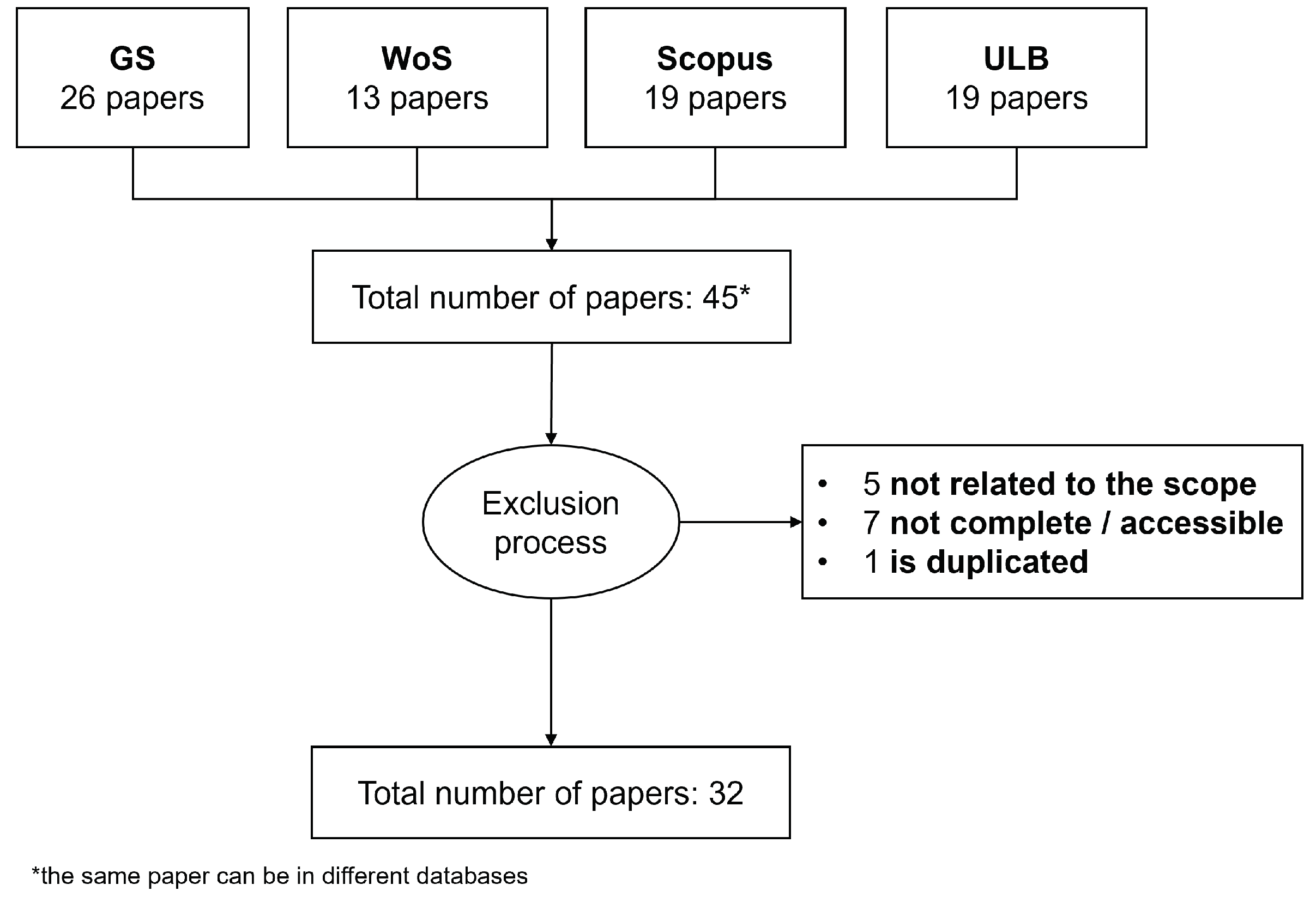

3. Methodology and General Overview

3.1. Databases and Keywords

3.2. Limitations

- It is possible that more English terms similar to those mentioned are being discarded.

- There might exist other libraries and databases that consider other papers that are not detected by Google Scholar, Scopus, Web of Science, and ULB.

- Despite the capability of the considered databases to detect papers written in languages other than English but using English keywords, this paper is limited by these databases’ own limitations of not finding other non-English written papers.

- It is also possible that “optimization”-related keywords are present in the body of the papers despite not being mentioned in the title. However, the authors are considering that optimization must be mentioned in the title so that it can be considered an optimization-related paper.

- Words such as “minimization” and “maximization” that are related to the optimization topic are not used, not only because there are multiple combinations of such words but also because they are not so widely used as “optimization”.

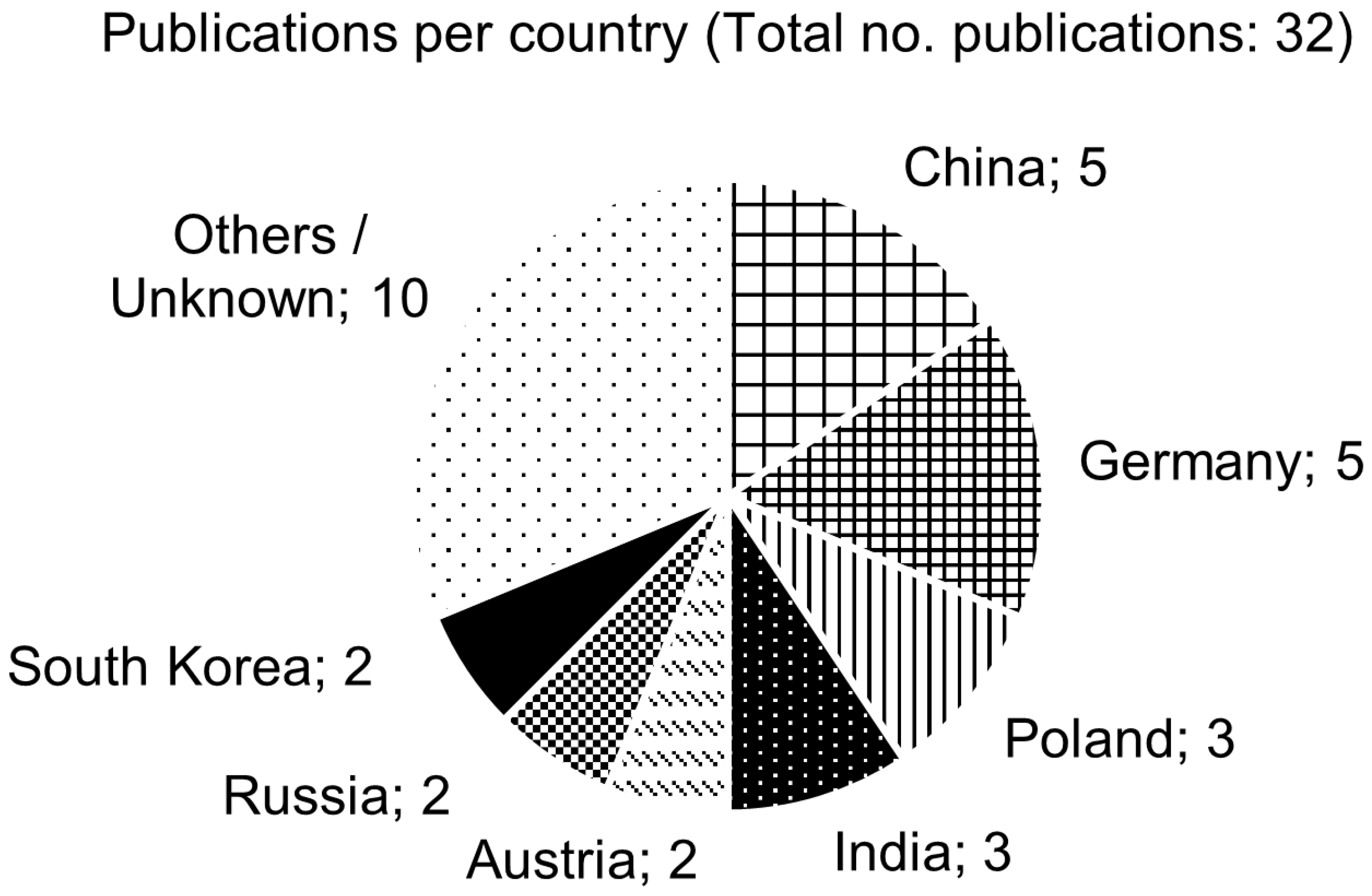

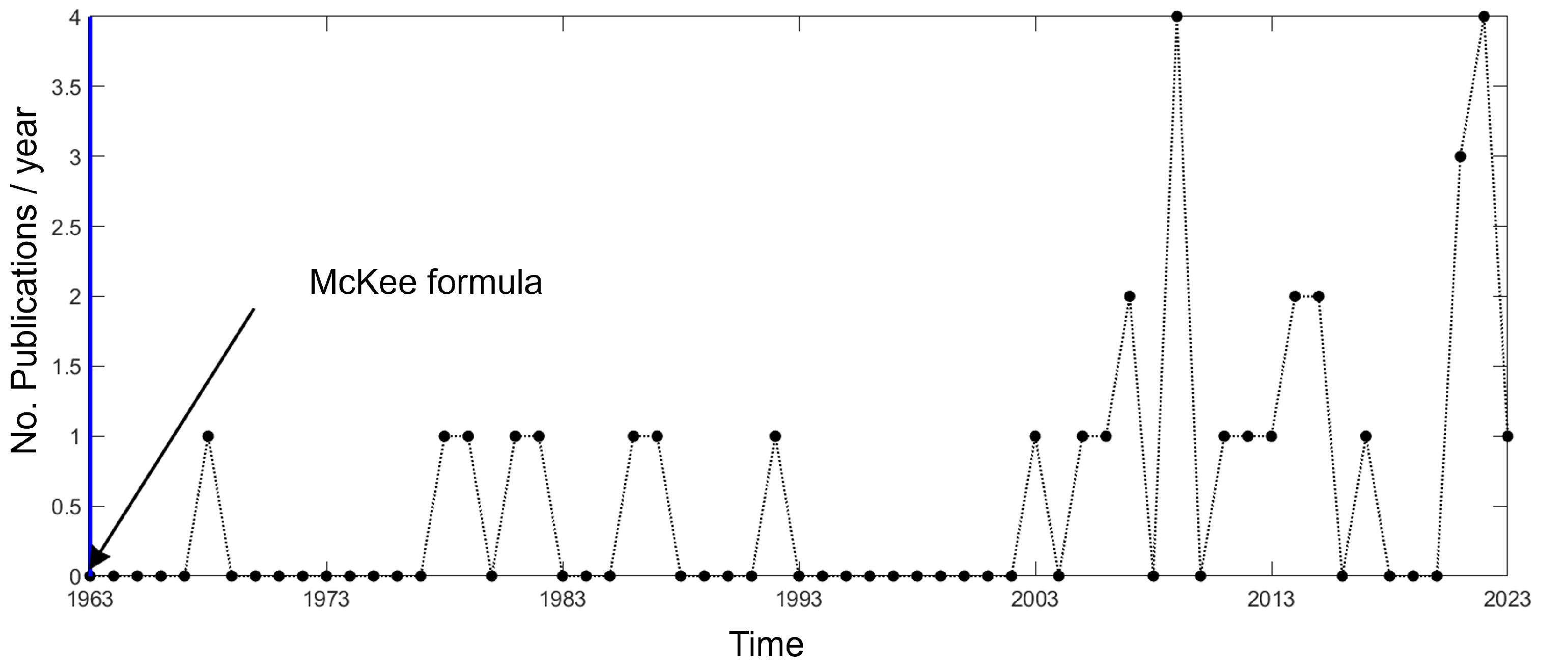

3.3. First Analysis of the Available Literature

- Five publications are excluded because they are not related to the scope of the current review, despite having the necessary keywords.

- Seven other publications are excluded because they are not complete or not accessible (due to policies that do not allow public consultation).

- One other publication is duplicated (i.e., with double reference) from another publication that is already considered in the final set of papers.

4. Literature Review on the Optimization of Corrugated Boards

4.1. Early Stages

4.2. Design vs. Manufacturing and Distribution

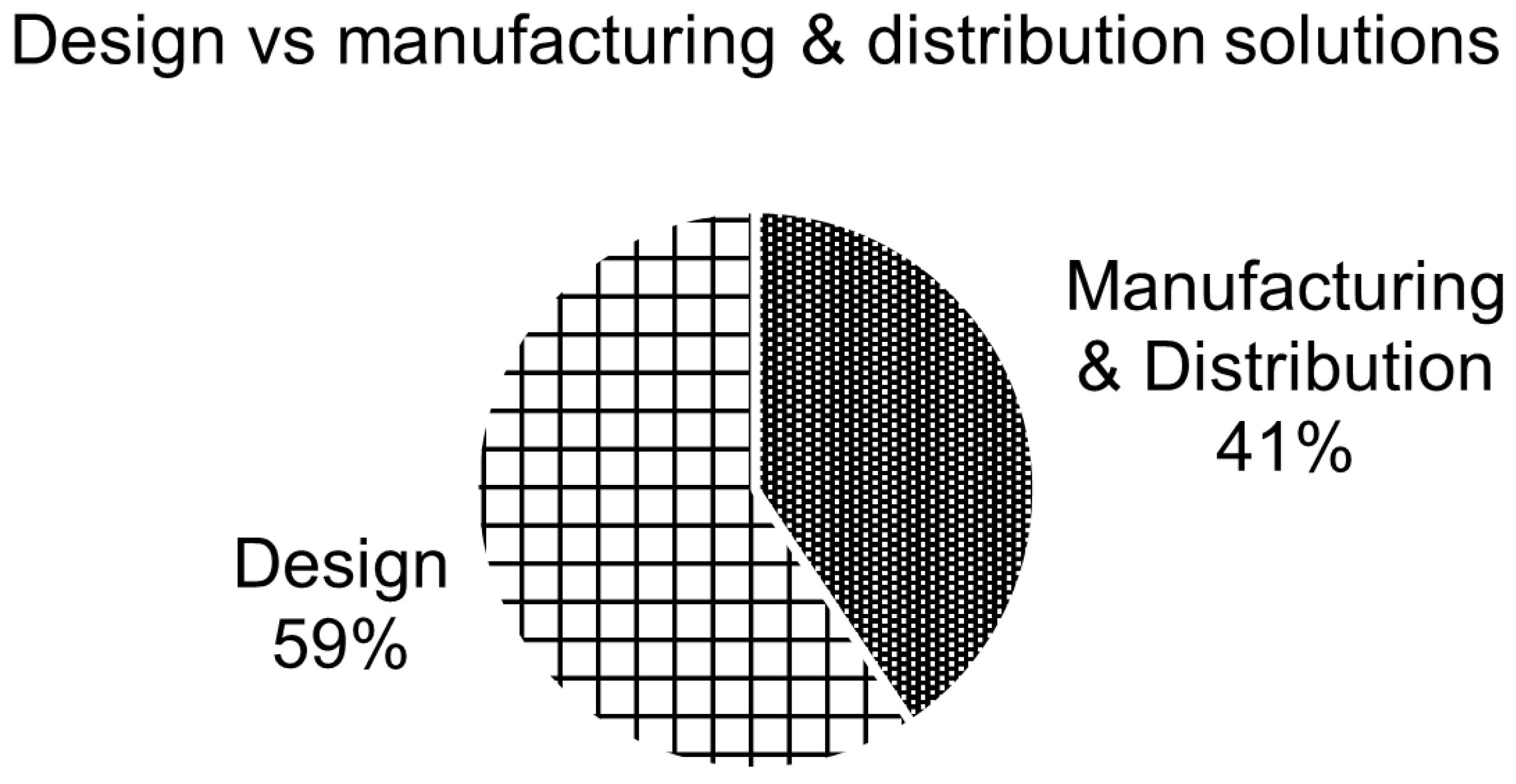

4.3. Design Optimization of the Corrugated Boards

4.4. Optimization Objectives

4.5. Numerical Optimization

5. Discussion of the Results Found

5.1. What Are the Main Common Findings throughout the Literature?

5.2. The Research Questions

5.3. The Gaps—And Research Directions

- It is clear that researchers have yet to fully explore the potential of corrugated boards in terms of weight reduction and safety enhancement. Despite a handful of studies on the subject, there appears to be a lack of consensus and focus on design optimization. Highlighting the benefits of corrugated boards could prove invaluable in establishing them as a reliable alternative to other materials in various structures and physical products. Therefore, it is imperative that more research is conducted in this area to realize the potential of corrugated boards fully. Future research directions: to establish new optimization strategies to reduce corrugated boards’ weight and enhance the design safety.

- There has been a significant amount of research conducted on weight minimization through different optimization approaches in applications such as composite structures [18]. These approaches include size, shape, and topology optimization. However, studies related to corrugated boards only focus on size and material optimization, and shape and topology optimization are not explored. Future research directions: to establish and tackle shape and topology optimization problems.

- The No Free Lunch Theorem [39] underscores the importance of a diversified optimization approach. Yet, the trend in corrugated board optimization research often showcases a heavy leaning toward expert-driven knowledge and a singular optimization strategy. This narrow approach potentially overlooks innovative solutions that a multifaceted, adaptive strategy could yield. Future research directions: to explore applying other optimization approaches by changing the algorithm or seeking surrogate models.

- While the FEM has proven invaluable in many engineering applications, its dominance in the realm of corrugated board weight minimization research is a double-edged sword. Sole reliance on FEM implies that the accuracy and reliability of optimization solutions are contingent upon the precision of the model. Exploring alternative or supplementary modeling techniques could enhance the robustness of the findings and their applicability in real-world scenarios. Future research directions: to explore the robustness of the simulation models and optimized solutions by exploring techniques in robust optimization.

- A discernible gap in the literature is the lack of emphasis on identifying future research directions. Such omissions might stifle the continuity and progression of knowledge in the field. Addressing limitations and articulating future research avenues not only fosters academic rigor but also galvanizes further exploration, ensuring the subject remains dynamic. Future research directions: to describe guidelines for future improvements.

- Given the complexity of real-world applications, it is often imperative to juggle multiple design objectives simultaneously. The noticeable absence of multi-objective design optimization in the literature suggests a missed opportunity. Incorporating such methodologies, especially in the context of customized solutions and robust optimization, could elevate the practical utility and adaptability of corrugated board designs. Future research directions: to more accurately apply and discuss such application of multi-objective optimization techniques.

- Factors such as environmental conditions, fire risks, and manufacturing defects profoundly influence the efficacy of any material in practical applications. The oversight of these critical variables in many studies indicates a somewhat myopic research perspective. Addressing these overlooked factors could not only bridge the prevailing research gap but also enrich the holistic understanding of corrugated board optimization in diverse conditions. Future research directions: to address new objectives that can also improve the sustainability related to the corrugated boards.

- One of the overarching gaps is the lack of a consolidated research framework. Such a framework would encompass standardized problems, methodologies, and assessment metrics, promoting consistency across studies. By working within a unified paradigm, researchers can build upon previous findings more effectively, propelling the field forward with cumulative knowledge. Future research directions: to enhance collaboration between the scientific community working in the field of the optimization of corrugated boards in order to work on standard problems instead of specific cases.

- Lastly, while theoretical advancements are crucial, there is an impending need to bridge the gap between theoretical research and its practical implications. Translational research, which focuses on turning academic findings into tangible, real-world applications, is vital. Such an approach would ensure that innovations in corrugated board optimization find their rightful place in industries and commercial products, maximizing their societal impact. Future research directions: to manage and monitor problems occurring from the application of the optimized solution or potential changes occurring in the objective function over time.

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jestratijevic, I.; Vrabič-Brodnjak, U. Sustainable and Innovative Packaging Solutions in the Fashion Industry: Global Report. Sustainability 2022, 14, 13476. [Google Scholar] [CrossRef]

- Enlund, E.; Nilsson, J. Sustainable Decision-Making in the Fashion Industry: How to Influence the Fashion Industry to Adopt More Sustainable Packaging Solutions. Master’s Thesis, KTH, Industrial Economics and Management (Dept.), Stockholm, Sweden, 2021. [Google Scholar]

- Global Packaging Market—Growth, Trends, COVID-19 Impact, and Forecasts (2022–2027). 2022. Available online: https://go.gale.com/ps/i.do?p=HRCA&u=anon~47c0114e&id=GALE|A716172748&v=2.1&it=r&sid=sitemap&asid=6f2e9970 (accessed on 4 October 2023).

- Paper & Paperboard Packaging Market Global Forecast to 2026. 2021. Available online: https://www.marketsandmarkets.com/Market-Reports/paper-paperboard-packaging-market-23392290.html (accessed on 4 October 2023).

- Mrówczyński, D.; Knitter-Pia̧tkowska, A.; Garbowski, T. Optimal Design of Double-Walled Corrugated Board Packaging. Materials 2022, 15, 2149. [Google Scholar] [CrossRef] [PubMed]

- United States Patent Office. Improvement in Paper for Packing. U.S. Patent 122023A, 19 December 1871.

- Kouko, J.; Lehto, J.; Tuovinen, T.; Vahala-Partanen, P. On the founding of the corrugated board industry and the introduction of box compression testing: 1871–1914. In Proceedings of the Progress in Paper Physics Seminar, Jyväskylä, Finland, 1–3 September 2020. [Google Scholar]

- Schmitt, C. Investigation of the Influence of Fibre Sources on the Strength of Corrugated Boxes and Prediction of Final Strength Properties from Basic Furnish Properties. Ph.D. Thesis, Technische Universität Darmstadt, Darmstadt, Germany, 2019. [Google Scholar]

- Chen, L.; Xiao, S.; Li, Y.; You, S. Modeling and Simulation of Pre-compressed Multilayered Corrugated Board during Impact. In Proceedings of the 2009 International Conference on Computer Modeling and Simulation, Macau, China, 20–22 February 2009; pp. 143–146. [Google Scholar] [CrossRef]

- Nyman, U. Continuum Mechanics Modelling of Corrugated Board; Lund University: Lund, Sweden, 2004. [Google Scholar]

- Niskanen, K. (Ed.) Mechanics of Paper Products; De Gruyter: Berlin, Boston, 2012. [Google Scholar] [CrossRef]

- Adamopoulos, S. Fiber analysis techniques for sustainable manufacturing of corrugated board and packaging. Manag. Dev. Mt. Isl. Areas 2006, 1. [Google Scholar]

- Flatscher, T. Modellierung der Steifigkeit und der Stabilität von Wellpappe. PhD Thesis, Technische Universität Wien, Vienna, Austria, 2007. (In German). [Google Scholar]

- Ojstersek, R.; Brezocnik, M.; Buchmeister, B. Multi-objective optimization of production scheduling with evolutionary computation: A review. Int. J. Ind. Eng. Comput. 2020, 11, 359–376. [Google Scholar] [CrossRef]

- Ghosh, A.; Mal, P.; Majumdar, A. Advanced Optimization and Decision-Making Techniques in Textile Manufacturing; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar]

- Martins, J.R.R.A.; Lambe, A.B. Multidisciplinary Design Optimization: A Survey of Architectures. AIAA J. 2013, 51, 2049–2075. [Google Scholar] [CrossRef]

- Chinneck, J.W. Feasibility and Infeasibility in Optimization: Algorithms and Computational Methods; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2007; Volume 118. [Google Scholar]

- Fitas, R. Optimal Design of Composite Structures Using the Particle Swarm Method and Hybridizations. Ph.D. Thesis, University of Porto, Porto, Portugal, 2022. Available online: https://hdl.handle.net/10216/142456 (accessed on 25 July 2022).

- Gunantara, N. A review of multi-objective optimization: Methods and its applications. Cogent Eng. 2018, 5, 1502242. [Google Scholar] [CrossRef]

- Sun, Y.; Gao, Y.; Shi, X. Chaotic multi-objective particle swarm optimization algorithm incorporating clone immunity. Mathematics 2019, 7, 146. [Google Scholar] [CrossRef]

- Villarrubia, G.; De Paz, J.F.; Chamoso, P.; la Prieta, F.D. Artificial neural networks used in optimization problems. Neurocomputing 2018, 272, 10–16. [Google Scholar] [CrossRef]

- Roux, W.J.; Stander, N.; Haftka, R.T. Response surface approximations for structural optimization. Int. J. Numer. Methods Eng. 1998, 42, 517–534. [Google Scholar] [CrossRef]

- Kaymaz, I. Application of kriging method to structural reliability problems. Struct. Saf. 2005, 27, 133–151. [Google Scholar] [CrossRef]

- Fitas, R.; Hesseler, S.; Wist, S.; Greb, C. Kinematic Draping Simulation Optimization of a Composite B-Pillar Geometry using Particle Swarm Optimization. Heliyon 2022, 8, e11525. [Google Scholar] [CrossRef] [PubMed]

- Holland, J.H. Adaptation in Natural and Artificial Systems: An Introductory Analysis with Applications to Biology, Control, and Artificial Intelligence; MIT Press: Cambridge, MA, USA, 1992. [Google Scholar]

- Dorigo, M. Ant Colony Optimization—New Optimization Techniques in Engineering. Ant Colony Optim. 1991, 101–117. [Google Scholar]

- Kennedy, J.; Eberhart, R. Particle swarm optimization. In Proceedings of the ICNN’95—International Conference on Neural Networks, Perth, WA, Australia, 27 November–1 December 1995; Volume 4, pp. 1942–1948. [Google Scholar] [CrossRef]

- Sharma, S.; Kumar, V. A Comprehensive Review on Multi-objective Optimization Techniques: Past, Present and Future. Arch. Comput. Methods Eng. 2022, 29, 5605–5633. [Google Scholar] [CrossRef]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef]

- Coello, C.A.C. An Introduction to Multi-Objective Particle Swarm Optimizers. In Soft Computing in Industrial Applications; Gaspar-Cunha, A., Takahashi, R., Schaefer, G., Costa, L., Eds.; Springer: Berlin/Heidelberg, Germany, 2011; pp. 3–12. [Google Scholar]

- Fitas, R.; das Neves Carneiro, G.; António, C.C. Swarm intelligence hybridized with genetic search in multi-objective design optimization under constrained-Pareto dominance. Compos. Struct. 2023, 319, 117155. [Google Scholar] [CrossRef]

- Bottou, L. Large-scale machine learning with stochastic gradient descent. In Proceedings of the COMPSTAT’2010: 19th International Conference on Computational Statistics Keynote, Invited and Contributed Papers, Paris, France, 22–27 August 2010; Springer: Berlin/Heidelberg, Germany, 2010; pp. 177–186. [Google Scholar]

- Kingma, D.P.; Ba, J. Adam: A Method for Stochastic Optimization. arXiv 2017, arXiv:1412.6980. [Google Scholar]

- Ruder, S. An overview of gradient descent optimization algorithms. arXiv 2017, arXiv:1609.04747. [Google Scholar]

- Sutskever, I.; Martens, J.; Dahl, G.; Hinton, G. On the importance of initialization and momentum in deep learning. In Proceedings of the International Conference on Machine Learning, PMLR, Atlanta, GA, USA, 17–19 June 2013; pp. 1139–1147. [Google Scholar]

- Duchi, J.; Hazan, E.; Singer, Y. Adaptive subgradient methods for online learning and stochastic optimization. J. Mach. Learn. Res. 2011, 12, 2121–2159. [Google Scholar]

- Reddi, S.J.; Kale, S.; Kumar, S. On the convergence of Adam and beyond. In Proceedings of the 6th International Conference on Learning Representations, ICLR 2018—Conference Track Proceedings, Vancouver, BC, Canada, 30 April–3 May 2018. [Google Scholar]

- Yu, T.; Zhu, H. Hyper-Parameter Optimization: A Review of Algorithms and Applications. arXiv 2020, arXiv:2003.05689. [Google Scholar]

- Wolpert, D.H.; Macready, W.G. No free lunch theorems for optimization. IEEE Trans. Evol. Comput. 1997, 1, 67–82. [Google Scholar] [CrossRef]

- Mark, R.E.; Borch, J. Handbook of Physical Testing of Paper; CRC Press: Boca Raton, FL, USA, 2002; Volume 1. [Google Scholar]

- Cohen, A.J. Technological Change as Historical Process: The Case of the U.S. Pulp and Paper Industry, 1915–1940. J. Econ. Hist. 1984, 44, 775–799. [Google Scholar] [CrossRef]

- Soroka, W. Fundamentals of Packaging Technology; Institute of Packaging Professionals: St. Charles, IL, USA, 2002. [Google Scholar]

- Technical Association of the Pulp and Paper Industry. Bursting Strength of Corrugated Board; Technical Report T810 om-16; TAPPI: Peachtree Corners, GA, USA, 2016. [Google Scholar]

- Paper—Determination of Bursting Strength; Technical Report DIN EN ISO 2758; Deutsches Institut für Normung (DIN): Berlin, Germany, 2014.

- Technical Association of the Pulp and Paper Industry. Edgewise Compressive Strength of Corrugated Fiberboard; Technical Report T811 om-16; TAPPI: Peachtree Corners, GA, USA, 2016. [Google Scholar]

- Cardboard—Determination of Edgewise Crush Resistance; Technical Report DIN EN ISO 3037; Deutsches Institut für Normung (DIN): Berlin, Germany, 2022.

- Technical Association of the Pulp and Paper Industry. Flat Crush Test of Corrugated Board—Rigid Support Method; Technical Report T825 om-16; TAPPI: Peachtree Corners, GA, USA, 2016. [Google Scholar]

- Corrugating Medium—Determination of Flat Crush Resistance; Technical Report DIN EN ISO 7263; Deutsches Institut für Normung (DIN): Berlin, Germany, 2019.

- Technical Association of the Pulp and Paper Industry. Moisture in Pulp, Paper, and Paperboard; Technical Report T412 om-16; TAPPI: Peachtree Corners, GA, USA, 2016. [Google Scholar]

- Paper and Board—Determination of Moisture Content—Oven Drying Method; Technical Report DIN EN ISO 287; Deutsches Institut für Normung (DIN): Berlin, Germany, 2017.

- Standard Test Method for Moisture Content of Paper and Paperboard by Oven Drying; Technical Report ASTM D644-99; American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 1999.

- Technical Association of the Pulp and Paper Industry. Bending Resistance (Stiffness) of Paper (Taber-Type Tester in 0 to 10 Degrees Range); Technical Report T489 om-16; TAPPI: Peachtree Corners, GA, USA, 2016. [Google Scholar]

- Paper and Board—Determination of Bending Stiffness by Static Methods—Taber-Type Tester; Technical Report DIN 53121; Deutsches Institut für Normung (DIN): Berlin, Germany, 2014.

- Technical Association of the Pulp and Paper Industry. Compression Test of Fiberboard Shipping Containers; Technical Report T804 om-06; TAPPI: Peachtree Corners, GA, USA, 2006. [Google Scholar]

- Packaging—Complete, Filled Transport Packages—Compression and Stacking Tests Using a Compression Tester; Technical Report DIN EN ISO 12048; Deutsches Institut für Normung (DIN): Berlin, Germany, 1994.

- McKee, R.C.; Gander, J.W.; Wachuta, J.R. Compression strength formula for corrugated boxes. Paperboard Packag. 1963, 48, 149–159. [Google Scholar]

- Allerby, I.M.; Laing, G.N.; Cardwell, R.D. Compressive strength—From components to corrugated containers. Appita Conf. Notes 1985, 1, 11. [Google Scholar]

- Schrampfer, K.E.; Whitsitt, W.J.; Baum, G.A. Combined Board Edge Crush (ECT) Technology; Technical Report; Institute of Paper Chemistry: Appleton, WI, USA, 1987. [Google Scholar]

- Batelka, J.J.; Smith, C.N. Package Compression Model; Technical Report; Institute of Paper Science and Technology: Atlanta, GA, USA, 1993. [Google Scholar]

- Urbanik, T.J.; Frank, B. Box compression analysis of world-wide data spanning 46 years. Wood Fiber. Sci. 2006, 38, 399–416. [Google Scholar]

- Langaard, Ö. Optimization of the corrugated board construction considering the stacking crush resistance of the corrugated board box. In Proceedings of the 10th FEFCO conference, Monte Carlo, Monaco, 13 May 1968. [Google Scholar]

- Langaard, O. Optimisation de l’ondulé en vue de la résistance à la compression des caisses. Cote: FOL-JO-1322; N°/detail: L20. L’Auxiliaire Transform. 1969, 27–33. [Google Scholar]

- Seyffert, P. Model of an Optimization System for Planning of a Production Program for Corrugated Board Production. Wochenbl. Pap. 1982, 106, 849–853. (In German) [Google Scholar]

- Johnson, M.W.; Urbanik, T.J.; Denniston, W.E. Optimum Fiber Distribution in Singlewall Corrugated Fiberboard; Forest Products Laboratory: Madison, WI, USA, 1979; Volume 348. [Google Scholar]

- Optimierte Aufbereitung von Wellpappenleim/Optimal processing of corrugated-board glue. Coating 1981, 14, 35–38. (In German)

- Durinda, J.; Obetko, D. Optimierung von Klebstoff aus nativer Stärke für Wellpappe. Papír Celulósa 1982, 37, V7–V12. (In German) [Google Scholar]

- Kainulainen, M.; Toroi, M. Optimum Composition of Corrugated Board with Regard to the Compression Resistance of Boxes; Finnish Pulp and Paper Research Institute: Espoo, Finland, 1986; Volume 68, pp. 666–668. [Google Scholar]

- Vogelpohl, H.; Hohmann, H.J. Versuche zur Optimierung des Rillens von Wellpappen. Verpack. Rundsch. Techn.-Wiss. Beil. 1987, 38, 55–66. (In German) [Google Scholar]

- Cho, Y.M.; Um, G.J. Investigation on the Lab Scale Corrugator’s Optimum Operating Conditions for Making Microflute Corrugated Paperboards. J. Korea Tech. Assoc. Pulp Pap. Ind. 2007, 39, 54–59. [Google Scholar]

- Tian, Y.; Yang, D.; Tian, F.; E, Y.; Hu, W.; Zhu, M. Method and System for Optimizing Cutting Area Efficiency of Corrugated Paper Board. CN112686478A, 20 April 2021. [Google Scholar]

- Kubera, H.; Tyczyński, P. Volume optimization of transport packages made of corrugated board on the basis of the shape of unit package; [Optymalizacja wykorzystania objȩtości opakowań transportowych z tektury falistej na podstawie kształtu opakowania jednostkowego. Czȩść II]. Prz. Pap. 2009, 65, 403–406. (In Polish) [Google Scholar]

- Mahakalkar, S.; Tatwawadi, V.; Giri, J.; Modak, J. Corrugated Box Production Process Optimization Using Dimensional Analysis and Response Surface Methodology. IJIEPR 2015, 26, 1–11. [Google Scholar] [CrossRef]

- Musielak, S. Electricity energy consumption in the corrugated board plant—Possibilities of optimization and forecast: Part 2; [Zużycie energii elektrycznej w tekturnicy - Możliwos̎ci optymalizacji oraz prognozowania: Czȩs̎ć 2]. Prz. Pap. 2014, 70, 623–628. (In Polish) [Google Scholar]

- Karabacakoğlu, B.; Tezakıl, F. Electrocoagulation of Corrugated Box Industrial Effluents and Optimization by Response Surface Methodology. Electrocatalysis 2023, 14, 159–169. [Google Scholar] [CrossRef]

- Wang, C.C.; Chen, C.H.; Jiang, B.C. Shock absorption characteristics and optimal design of corrugated fiberboard using drop testing. Appl. Sci. 2021, 11, 5815. [Google Scholar] [CrossRef]

- Mei, L.; Wang, Q. Structural Optimization in Civil Engineering: A Literature Review. Buildings 2021, 11, 66. [Google Scholar] [CrossRef]

- Xiao, A.; Wang, B.; Jin, Y. Evolutionary truss layout optimization using the vectorized structure approach. In Proceedings of the 2013 IEEE Congress on Evolutionary Computation, Cancun, Mexico, 20–23 June 2013; pp. 2879–2886. [Google Scholar] [CrossRef]

- Mikami, E.; Ibaraki, T.; Kodaka, I. Optimum Design of Flute Structure for Edgewise Compression of Corrugated Fiberboard. Jpn. Tappi J. 2005, 59, 94. [Google Scholar] [CrossRef]

- Litovski, Z.; Stoyanov, S.; Boeva, R.; Petkova, E. Optimization of paper production for corrugated board by using chemical-mechanical pulp. Cellul. Chem. Technol. 2003, 37, 423–429. [Google Scholar]

- Ihwah, A.; Dewi, I.A.; Sukardi, S.; Fitriani, Y. Proportion of raw material optimisation in handicraft paper making made of Pinang fibre (Areca catechu l.) and old corrugated cardboard (used cardboard). Int. J. Environ. Waste Manag. 2021, 28, 282–297. [Google Scholar] [CrossRef]

- Park, J.H.; Kim, H.J.; Lee, T.J.; Seo, Y.B. Studies on the development of corrugated board and investigation of optimum corrugating adhesive for archival quality container (Part 1). J. Korea Tech. Assoc. Pulp Pap. Ind. 2009, 41, 73–81. [Google Scholar]

- Song, F.; Liu, C.; Zhu, G. Optimization of the finite element model of Corrugated Cardboard based on an orthotropic material constitutive model. In Proceedings of the 2017 5th International Conference on Machinery, Materials and Computing Technology (ICMMCT 2017), Beijing, China, 25–26 March 2017; Atlantis Press: Amsterdam, The Netherlands, 2017; pp. 389–393. [Google Scholar] [CrossRef]

- Neidoni, N.; Bolos, V.; Buzdugan, M.I. Experimental optimization of perforations for corrugated board boxes. In Proceedings of the International Conference Interdisciplinarity in Engineering INTER-ENG, Târgu Mureș, Romania, 12–13 November 2009; Elsevier Limited: Amsterdam, The Netherlands, 2009; p. 287. [Google Scholar]

- Li, Z.S.; Jian, C.; Xiao, J.Y. Optimization Design for Production Logistics System of Corrugated Box. Adv. Mater. Res. 2012, 463–464, 962–966. [Google Scholar] [CrossRef]

- Yuan, W.; Sun, J.X.; Zhang, G.M.; Liao, D.Z.; Wang, Y.J. Corrugated Board UV Flute-Shaped Structure Size Optimization Design Based on the Finite Element. Appl. Mech. Mater. 2014, 469, 213–216. [Google Scholar] [CrossRef]

- Han, J.; Park, J.M. Finite element analysis of vent/hand hole designs for corrugated fibreboard boxes. Packag. Technol. Sci. Int. J. 2007, 20, 39–47. [Google Scholar] [CrossRef]

- Kalyankar, N.V.; Mahakalkar, S.G. A Review on Optimization and Design of Corrugated Sheet Box Size for an Industrial Part. Int. J. Recent Innov. Trends Comput. Commun. 2015, 3, 109–112. [Google Scholar]

- Mrówczyński, D.; Knitter-Pia̧tkowska, A.; Garbowski, T. Non-Local Sensitivity Analysis and Numerical Homogenization in Optimal Design of Single-Wall Corrugated Board Packaging. Materials 2022, 15, 720. [Google Scholar] [CrossRef]

- Rodríguez, A.; Vecchietti, A. Minlp and milp optimization models for solving the cutting stock problem in the corrugated board boxes industry. In Proceedings of the XXII Interamerican Congress of Chemical Engineering, CIIQ 2006 and V Argentinian Congress of Chemical Engineering, CAIQ 2006—Innovation and Management for Sustainable Development, Buenos Aires, Argentina, 1–4 October 2006. [Google Scholar]

- Daxner, T.; Flatscher, T.; Rammerstorfer, F.G. Optimum design of corrugated board under buckling constraints. In Proceedings of the 7th World Congress on Structural and Multidisciplinary Optimization, Seoul, Republic of Korea, 21–25 May 2007; pp. 21–25. [Google Scholar]

- Protalinskii, O.M.; Kokuev, A.G. Optimum control of process of manufacture of the corrugated cardboard. Vestn. Astrakhan State Tech. Univ. Ser. Manag. Comput. Sci. Inform. 2009, 105–110. [Google Scholar]

- Flatscher, T.; Daxner, T.; Pahr, D.H.; Rammerstorfer, F.G. Optimization of Corrugated Paperboard under Local and Global Buckling Constraints. In Multiscale Methods in Computational Mechanics: Progress and Accomplishments; Springer: Dordrecht, The Netherlands, 2011; pp. 329–346. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, L.; Peng, D.; Wang, T.; Xie, Y.; Li, J.; Wang, C.; Qiu, R.; Gao, Q. Crashworthiness optimization of a sandwich tube filled with CFRP sinusoidal corrugated board. Aerosp. Sci. Technol. 2023, 132, 108065. [Google Scholar] [CrossRef]

- Kalita, N.; Saxena, P.; Talha, M. Numerical Analysis and Optimization of Ventilated Corrugated Fibreboard Packages for Apple Industry. In Proceedings of the 20th Indian Society of Mechanical Engineers (ISME) Conference, Rupnagar, India, 19–21 May 2022. [Google Scholar]

- Schmit, L.A.; Thornton, W.A. Synthesis of an Airfoil at Supersonic Mach Number; National Aeronautics and Space Administration: Washington, DC, USA, 1965.

| Ref. | Authors (Year) | Novelty | Objectives (Category) | Design Variables | Lifecycle |

|---|---|---|---|---|---|

| [61,62] | Langaard (1968) | Optimization of corrugated boards based on the McKee equation (first approach) | Mechanical Properties | Type and quality of the corrugated board | Design |

| [63] | P. Seyffert (1978) | Introduction of VERWEL | Time | Product order-related data | M&D |

| [64] | M. W. Johnson et al. (1979) | Formulation of a theory for short-column strength of the local buckling, Empirical stress–strain analysis | Mechanical Properties | Strain of the material | Design |

| [65] | Goldschmidt AG (1981) | Increase glue quality to achieve minimum defects | Mechanical Properties | Chemical concentrations; shear forces applied during mixing; temperature during the gelatinization process | M&D |

| [66] | Durinda and Obetko (1982) | Design of experiments for adhesives, with the purpose of saving manufacturing costs, while increasing efficiency in production and quality of the products | Cost | Gelatination temperature, apparent viscosity | Design |

| [67] | Kainulainen (1986) | Maximization of the compression resistance | Mechanical Properties | Basis weight, properties of fluting | Design |

| [68] | Vogelpohl and Hohmann (1987) | Maximization of the grooveability, bending resistance, and uniformity of moisture content in storage and minimization of cover damage during grooving, variability in grooving outcomes, and moisture loss during storage | Mechanical Properties | Gap width in relation to board thickness, type of corrugated board, groove profile used, storage conditions, especially humidity levels, creasing tool profile and the gap width | M&D |

| Ref. | Authors (Year) | Novelty | Objectives (Category) | Design Variables | Lifecycle |

|---|---|---|---|---|---|

| [69] | Cho and Um (2007) | Changing operation conditions in manufacture to improve physical properties of the product | Mechanical Properties | Operational conditions | M&D |

| [70] | Tian et al. (2021) | Cutting methodology to reduce cutting waste | Cost | Raw material | M&D |

| [71] | Kubera and Tyczyński (2009) | Fitting packages in a corrugated box | Volume | Production process and storage | M&D |

| [72] | Mahakalkar et al. (2015) | Use of Buckling Pis for an application in the production process | N/A | Buckling Pis | M&D |

| [73] | Musielak (2014) | Usage of ANN for minimization of electricity consumption for a corrugator | Cost | Corrugated board plant modules, corrugator speed and flute type | M&D |

| [74] | Karabacakoğlu and Tezakıl (2023) | Added energy consumption as an objective beyond Chemical Oxygen Demand (COD) related to corrugated board production | Cost | Current density, time, stirring speed | M&D |

| [75] | Wang et al. (2021) | Improvement of the procedure for selecting a corrugated board by measuring shock absorption characteristics | Mechanical Properties | Prediction model (hyperparameters)—input: drop height; static stress; cushion thickness; output—impact strength | Design |

| Ref. | Authors (Year) | Novelty | Objectives (Category) | Design Variables | Design Opt. (Category) |

|---|---|---|---|---|---|

| [78] | Mikami et al. (2005) | Maximum strength by considering several design parameters | Mechanical Properties | Geometric values (radius of curvature, glue width, flute weight, take-up factor, angle between liner and medium theta) | Size |

| [79] | Litovski et al. (2003) | Consideration of D-optimal experimental design for optimization | Mechanical Properties | Amount of chemical-mechanical pulp, freeness level of the fiber material | Topology (Material) |

| [80] | Ihwah et al. (2021) | Usage of the response surface methodology for material selection by optimizing the proportion of raw material | Mechanical Properties | Proportion of raw material | Topology (Material) |

| [81] | Park et al. (2009) | Development of a suitable design for corrugated board for archival quality containers | N/A | Types of corrugating adhesives used and the conditions of storage and curing temperatures | Topology (Material) |

| [82] | Song et al. (2017) | FEM element optimization for modelling corrugated boards | N/A | N/A | N/A |

| Ref. | Authors (Year) | Novelty | Objectives (Category) | Design Variables | Lifecycle |

|---|---|---|---|---|---|

| [83] | Neidoni et al. (2009) | Experimental approach to optimize perforations | Mechanical Properties | Type, dimensions, position of the perforations on the corrugated board boxes | Design |

| [84] | Li et al. (2012) | Minimize the mass transfer of honeycomb panels and the frequent handling of semi manufacturers | Time | Workshop layout by using parameters | M&D |

| [85] | Yuan et al. (2014) | Use of numerical simulation and mathematical modeling to optimize the structure size of UV-type corrugated board | Weight | Dimensions, structural parameters of the corrugated board | Design |

| [87] | Kalyankar et al. (2015) | Minimization of box size and clearance by using FEM | Volume | Box design parameters | Design |

| [5,88] | Mrówczyński et al. (2022) | Sensitivity analysis for the optimal selection of the components of a five-layer corrugated board was studied | Cost | Edge crush resistance, critical load of the packaging walls, and packaging load capacity | Design |

| Ref. | Authors (Year) | Numerical Algorithm Used | Objectives (Category) | Design Variables | Lifecycle |

|---|---|---|---|---|---|

| [89] | Rodríguez and Vecchietti (2006) | MINLP and MILP | Cost | Cutting patterns | M&D |

| [90] | Daxner et al. (2007) | COBYLA and Brent’s method | Weight | Width of the board, the height of the unit cell, and the thickness of the liners and fluting. | Design |

| [91] | Protalinskii and Kokuev (2009) | Local descent; a penalty is proposed to handle violated constraints | Cost | Dimensions, structural parameters of the corrugated board | M&D |

| [92] | Daxner et al. (2011) | COBYLA and Brent’s method | Weight | Width of the board, the height of the unit cell, and the thickness of the liners and fluting | Design |

| [93] | Zhang et al. (2022) | Finite Differences | Mechanical Properties | Sine wave parameters amplitude and the period, thicknesses of the inner, outer and sine layers | Design |

| [94] | Kalita et al. (2022) | Genetic Algorithm (and RSM as a surrogate model) | Mechanical Properties | Length, width, height, size of length stiffener, size of width stiffener | Design |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fitas, R.; Schaffrath, H.J.; Schabel, S. A Review of Optimization for Corrugated Boards. Sustainability 2023, 15, 15588. https://doi.org/10.3390/su152115588

Fitas R, Schaffrath HJ, Schabel S. A Review of Optimization for Corrugated Boards. Sustainability. 2023; 15(21):15588. https://doi.org/10.3390/su152115588

Chicago/Turabian StyleFitas, Ricardo, Heinz Joachim Schaffrath, and Samuel Schabel. 2023. "A Review of Optimization for Corrugated Boards" Sustainability 15, no. 21: 15588. https://doi.org/10.3390/su152115588

APA StyleFitas, R., Schaffrath, H. J., & Schabel, S. (2023). A Review of Optimization for Corrugated Boards. Sustainability, 15(21), 15588. https://doi.org/10.3390/su152115588