Life Cycle Assessment and Building Information Modeling Integrated Approach: Carbon Footprint of Masonry and Timber-Frame Constructions in Single-Family Houses

Abstract

:1. Introduction

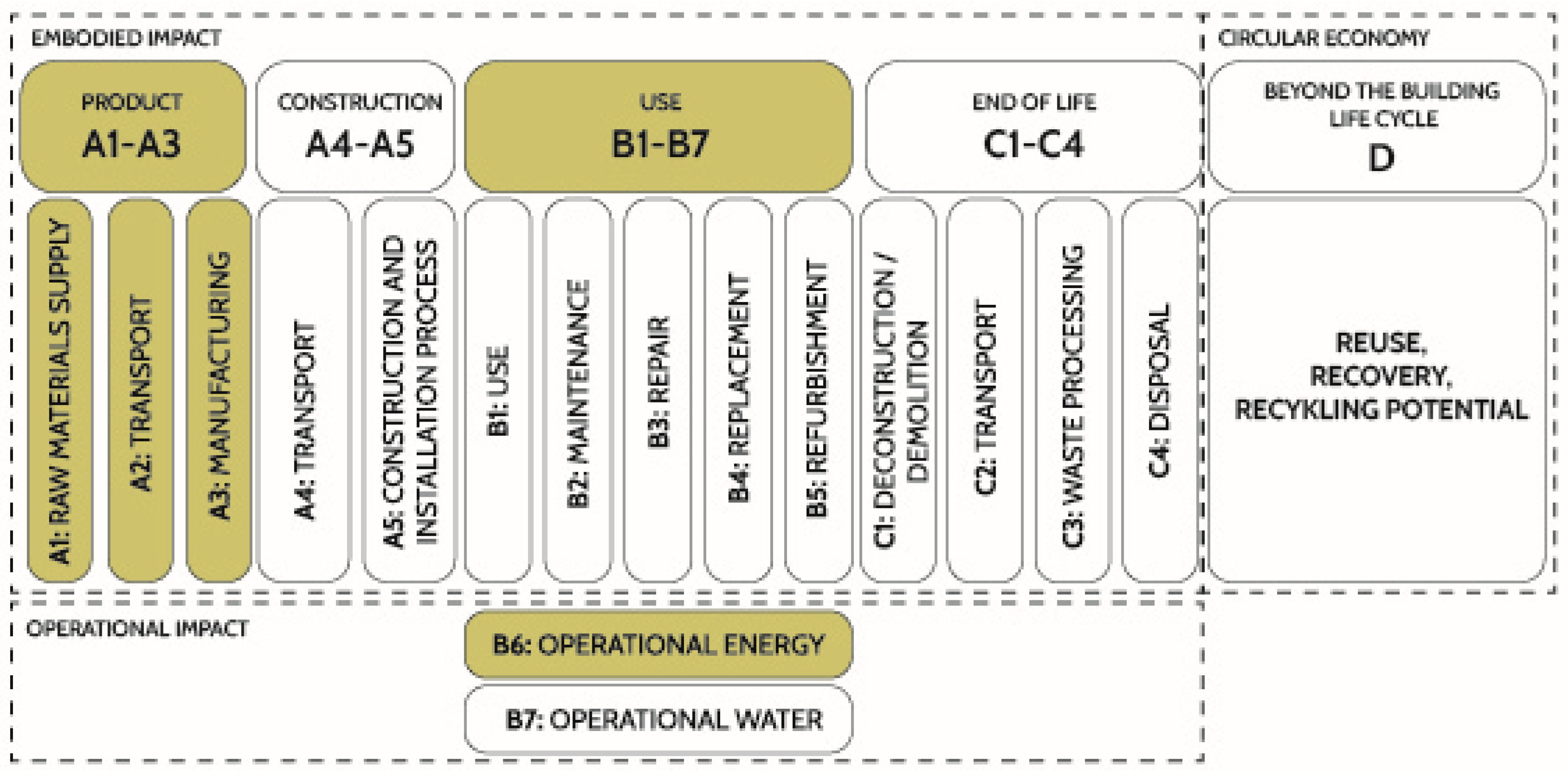

1.1. Building Carbon Footprint Assessment

1.2. BIM in Assessing the Carbon Footprint of Buildings

2. Materials and Methods

- Stage I. Designing a model for analysis, which is a single-family detached house in masonry construction, using BIM technology (in Archicad 26 software).

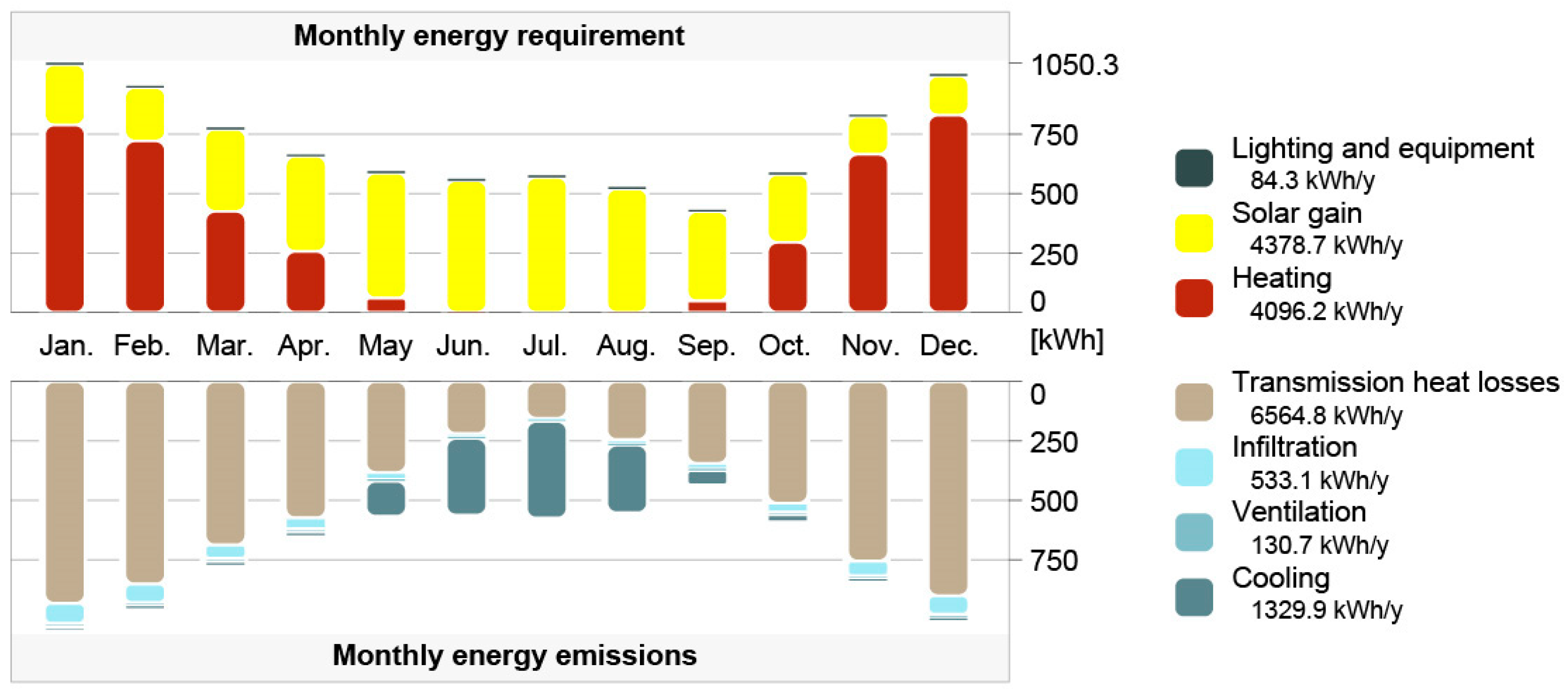

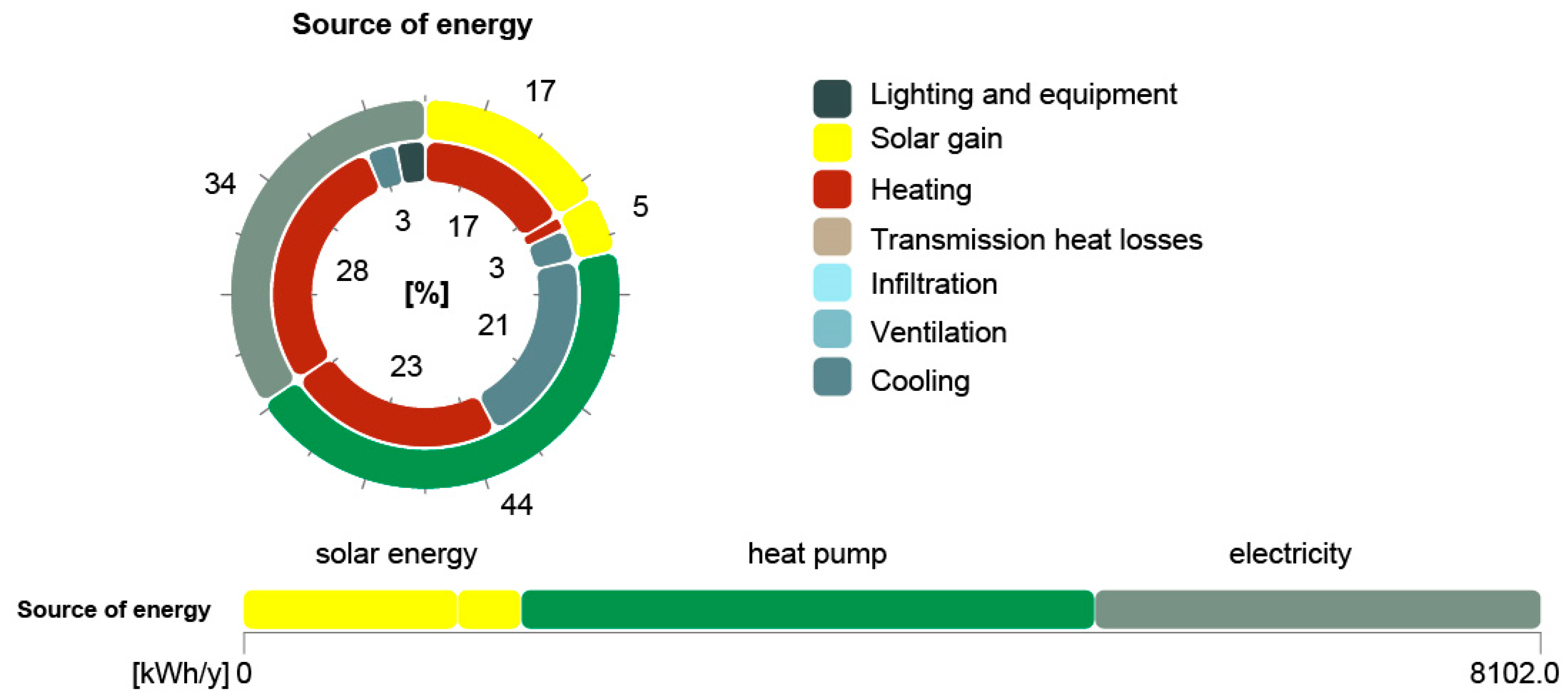

- Stage II. An energy performance simulation of the building was conducted in Archicad, using the EcoDesigner Star add-on. Through examination of the building’s geometry, materials, heating, lighting, and cooling systems, an energy simulation was performed to estimate the energy consumption over the life of the building. LCA analysis was based on a study period of 50 years, as recommended by EN1990 [57]. This period is important in determining the energy efficiency of a building for the B6 operational energy use point of the LCA analysis. Although buildings typically operate for much longer than 50 years, this period allows a comparison to be made between two buildings. This was confirmed by a study of an office building, where it was found that over a 50-year period, 80% of the life cycle energy was consumed in the case of the building analysed in Vancouver, while 90% was consumed for the same design but in Toronto [58].

- Stage IV. The second model constructed using a timber-frame structure was analysed. The previous stages (I–III) were repeated for this secondary model.

- Phase V. A comparative analysis of single-family building models in masonry and timber-frame construction was carried out.

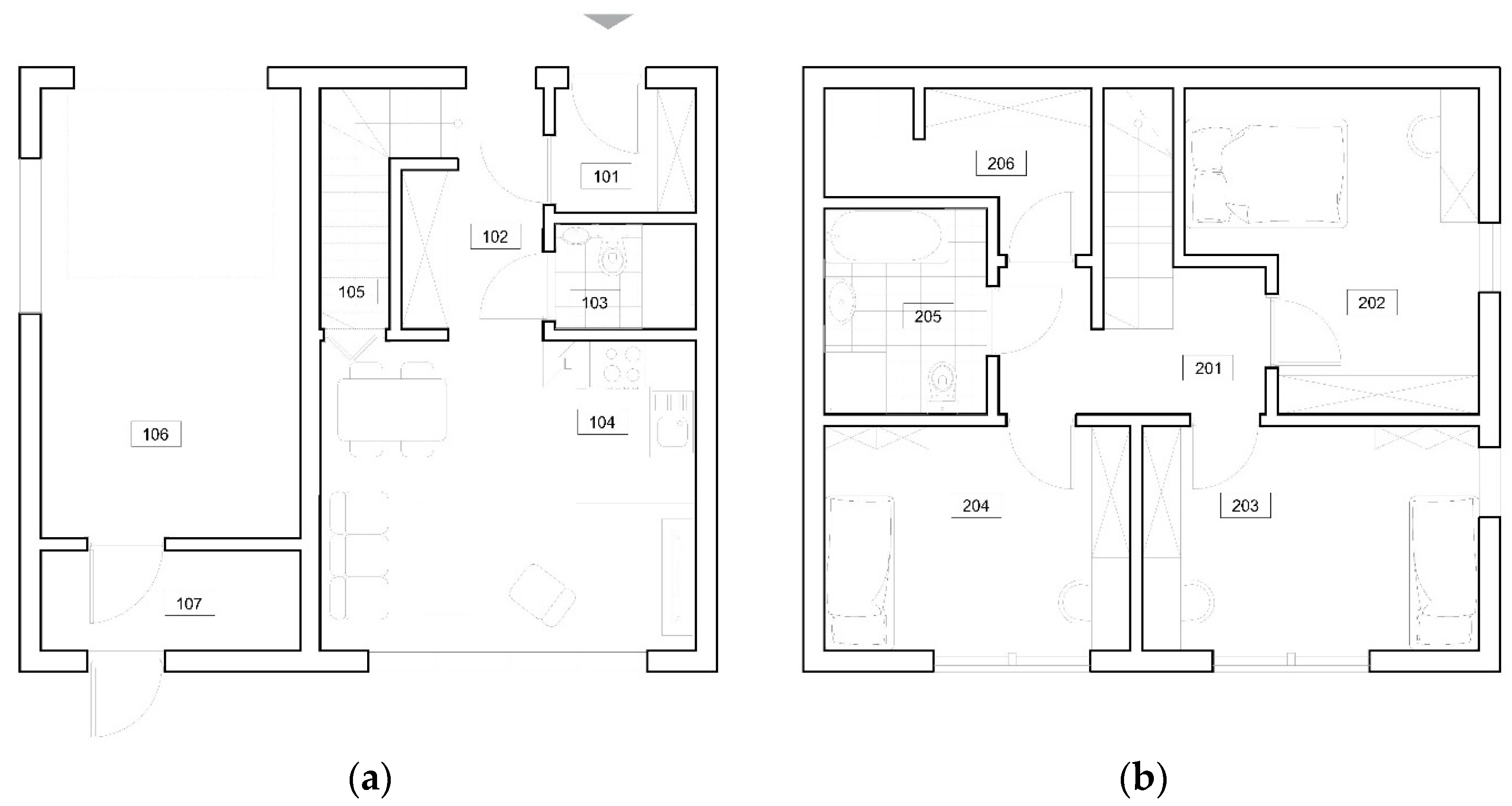

2.1. Design of a Single-Family House Model

2.1.1. Building A—Masonry Building

2.1.2. Building B—Timber Building

3. Results

LCA Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Name of the Material | Units | Building A Masonry Building | Building B Timber Building |

|---|---|---|---|

| Gypsum Fibreboard | m3 | 74.50 | 653.70 |

| Stone wool acoustic insulation | m3 | 0.37 | 10.99 |

| Gypsum plaster board | m2 | - | 38.47 |

| Clinker bricks | m3 | 1.53 | 1.37 |

| Stone wool heat insulation | m3 | 23.42 | 53.50 |

| SWISSKRONO OSB | m3 | 0.07 | 3.19 |

| Air barrier membrane | m2 | 58.28 | 131.41 |

| External silicone plaster | kg | 3236.64 | 983.19 |

| Extruded polystyrene (XPS) foam board | m3 | 48.15 | 20.61 |

| PE foil, dimpled | m2 | 10.01 | 10.01 |

| KVH construction timber | m3 | 6.53 | 27.08 |

| Aerated concrete P3 | m3 | 2.91 | - |

| Concrete C20/25 | m3 | 15.07 | 6.13 |

| Reinforcing steel | kg | 1544.78 | 1383.07 |

| Humidity variable air and vapour membrane | m2 | 60.22 | 62.44 |

| Sand | kg | 80,920.16 | 80,920.16 |

| Profiled aluminium sheets for roof | m2 | 83.57 | 75.54 |

| Underroof membrane-reinforced PE fabric | m2 | 83.57 | 75.54 |

| Stoneware tiles, glazed | m2 | 58.28 | 59.06 |

| Solid wood parquet | m2 | 60.22 | 62.44 |

| Internal gypsum plaster | m3 | 4.67 | - |

| Masonry bricks | m3 | 51.00 | - |

References

- Mazur, Ł.; Bać, A.; Vaverková, M.D.; Winkler, J.; Nowysz, A.; Koda, E. Evaluation of the Quality of the Housing Environment Using Multi-Criteria Analysis That Includes Energy Efficiency: A Review. Energies 2022, 15, 7750. [Google Scholar] [CrossRef]

- Shen, F.; Simayi, Z.; Yang, S.; Mamitimin, Y.; Zhang, X.; Zhang, Y. A Bibliometric Review of Household Carbon Footprint during 2000–2022. Sustainability 2023, 15, 6138. [Google Scholar] [CrossRef]

- Yan, X.; Cui, S.; Xu, L.; Lin, J.; Ali, G. Carbon Footprints of Urban Residential Buildings: A Household Survey-Based Approach. Sustainability 2018, 10, 1131. [Google Scholar] [CrossRef]

- Isaksson, R.; Rosvall, M.; Espuny, M.; Nunhes, T.V.; De Oliveira, O.J. How Is Building Sustainability Understood?—A Study of Research Papers and Sustainability Reports. Sustainability 2022, 14, 12430. [Google Scholar] [CrossRef]

- Architecture 2030 Why the Building Sector? 2022. Available online: https://architecture2030.org/ (accessed on 10 September 2023).

- United Nations Environment Programme. 2022 Global Status Report for Buildings and Construction: Towards a Zero-Emission, Efficient and Resilient Buildings and Construction Sector; United Nations Environment Programme: Nairobi, Kenya, 2022. [Google Scholar]

- United Nations Environment Programme. Buildings and Climate Change: A Summary for Decision-Makers; UNEP DTIE, Sustainable Consumption and Production Branch: Paris, France, 2011; ISBN 978-92-807-3064-7. [Google Scholar]

- Atmaca, A.; Atmaca, N. Carbon Footprint Assessment of Residential Buildings, a Review and a Case Study in Turkey. J. Clean. Prod. 2022, 340, 130691. [Google Scholar] [CrossRef]

- Sizirici, B.; Fseha, Y.; Cho, C.-S.; Yildiz, I.; Byon, Y.-J. A Review of Carbon Footprint Reduction in Construction Industry, from Design to Operation. Materials 2021, 14, 6094. [Google Scholar] [CrossRef]

- Onat, N.C.; Kucukvar, M. Carbon Footprint of Construction Industry: A Global Review and Supply Chain Analysis. Renew. Sustain. Energy Rev. 2020, 124, 109783. [Google Scholar] [CrossRef]

- Ahmetoğlu, S.; Tanik, A. Management of Carbon Footprint and Determination of GHG Emission Sources in Construction Sector. Int. J. Environ. Geoinform. 2020, 7, 191–204. [Google Scholar] [CrossRef]

- Starzyk, A.; Donderewicz, M.; Rybak-Niedziółka, K.; Marchwiński, J.; Grochulska-Salak, M.; Łacek, P.; Mazur, Ł.; Voronkova, I.; Vietrova, P. The Evolution of Multi-Family Housing Development Standards in the Climate Crisis: A Comparative Analysis of Selected Issues. Buildings 2023, 13, 1985. [Google Scholar] [CrossRef]

- Kuda, D.; Petříčková, M. Modular Timber Gridshells. J. Sustain. Archit. Civ. Eng. 2021, 28, 72–79. [Google Scholar] [CrossRef]

- Mitterpach, J.; Štefko, J. An Environmental Impact of a Wooden and Brick House by the LCA Method. Key Eng. Mater. 2016, 688, 204–209. [Google Scholar] [CrossRef]

- Hrdlicka, T.; Cupal, M.; Komosna, M. Wood vs. Brick: Impact on Investment Costs of Houses. J. Build. Eng. 2022, 49, 104088. [Google Scholar] [CrossRef]

- Ansah, M.K.; Chen, X.; Yang, H.; Lu, L.; Lam, P.T.I. Developing an Automated BIM-Based Life Cycle Assessment Approach for Modularly Designed High-Rise Buildings. Environ. Impact Assess. Rev. 2021, 90, 106618. [Google Scholar] [CrossRef]

- Díaz, J.; Antön, L.Á. Sustainable Construction Approach through Integration of LCA and BIM Tools. In Proceedings of the Computing in Civil and Building Engineering 2014, American Society of Civil Engineers, Orlando, FL, USA, 17 June 2014; pp. 283–290. [Google Scholar]

- Cheng, B.; Li, J.; Tam, V.W.Y.; Yang, M.; Chen, D. A BIM-LCA Approach for Estimating the Greenhouse Gas Emissions of Large-Scale Public Buildings: A Case Study. Sustainability 2020, 12, 685. [Google Scholar] [CrossRef]

- Kylili, A.; Fokaides, P.A. Policy Trends for the Sustainability Assessment of Construction Materials: A Review. Sustain. Cities Soc. 2017, 35, 280–288. [Google Scholar] [CrossRef]

- Liu, Z.; Li, P.; Wang, F.; Osmani, M.; Demian, P. Building Information Modeling (BIM) Driven Carbon Emission Reduction Research: A 14-Year Bibliometric Analysis. Int. J. Environ. Res. Public Health 2022, 19, 12820. [Google Scholar] [CrossRef]

- Olawumi, T.O.; Chan, D.W.M. An Empirical Survey of the Perceived Benefits of Executing BIM and Sustainability Practices in the Built Environment. Constr. Innov. 2019, 19, 321–342. [Google Scholar] [CrossRef]

- Gan, V.J.L.; Deng, M.; Tse, K.T.; Chan, C.M.; Lo, I.M.C.; Cheng, J.C.P. Holistic BIM Framework for Sustainable Low Carbon Design of High-Rise Buildings. J. Clean. Prod. 2018, 195, 1091–1104. [Google Scholar] [CrossRef]

- Leszczyszyn, E.; Heräjärvi, H.; Verkasalo, E.; Garcia-Jaca, J.; Araya-Letelier, G.; Lanvin, J.-D.; Bidzińska, G.; Augustyniak-Wysocka, D.; Kies, U.; Calvillo, A.; et al. The Future of Wood Construction: Opportunities and Barriers Based on Surveys in Europe and Chile. Sustainability 2022, 14, 4358. [Google Scholar] [CrossRef]

- Freer-Smith, P.; Carnus, J.-M. The Sustainable Management and Protection of Forests: Analysis of the Current Position Globally. AMBIO A J. Hum. Environ. 2008, 37, 254–262. [Google Scholar] [CrossRef]

- Baker, S.C.; Spies, T.A.; Wardlaw, T.J.; Balmer, J.; Franklin, J.F.; Jordan, G.J. The Harvested Side of Edges: Effect of Retained Forests on the Re-Establishment of Biodiversity in Adjacent Harvested Areas. For. Ecol. Manag. 2013, 302, 107–121. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framewor. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- Pacheco-Torres, R.; Jadraque, E.; Roldán-Fontana, J.; Ordóñez, J. Analysis of CO2 Emissions in the Construction Phase of Single-Family Detached Houses. Sustain. Cities Soc. 2014, 12, 63–68. [Google Scholar] [CrossRef]

- Vilches, A.; Garcia-Martinez, A.; Sanchez-Montañes, B. Life Cycle Assessment (LCA) of Building Refurbishment: A Literature Review. Energy Build. 2017, 135, 286–301. [Google Scholar] [CrossRef]

- Banias, G.F.; Karkanias, C.; Batsioula, M.; Melas, L.D.; Malamakis, A.E.; Geroliolios, D.; Skoutida, S.; Spiliotis, X. Environmental Assessment of Alternative Strategies for the Management of Construction and Demolition Waste: A Life Cycle Approach. Sustainability 2022, 14, 9674. [Google Scholar] [CrossRef]

- Rodríguez, L.; Martínez, L.; Panameño, R.; París, O.; Muros, A.; Rodríguez, R.; Javier, R.; González, C. LCA of the NZEB El Salvador Building, a Model to Estimate the Carbon Footprint in a Tropical Country. J. Clean. Prod. 2023, 408, 137137. [Google Scholar] [CrossRef]

- Säynäjoki, A.; Heinonen, J.; Junnila, S. Carbon Footprint Assessment of a Residential Development Project. Int. J. Environ. Sci. Dev. 2011, 2, 116–123. [Google Scholar] [CrossRef]

- Tulevech, S.M.; Hage, D.J.; Jorgensen, S.K.; Guensler, C.L.; Himmler, R.; Gheewala, S.H. Life Cycle Assessment: A Multi-Scenario Case Study of a Low-Energy Industrial Building in Thailand. Energy Build. 2018, 168, 191–200. [Google Scholar] [CrossRef]

- Ciroth, A. ICT for Environment in Life Cycle Applications OpenLCA—A New Open Source Software for Life Cycle Assessment. Int. J. Life Cycle Assess 2007, 12, 209–210. [Google Scholar] [CrossRef]

- Silva, D.A.L.; Nunes, A.O.; da Silva Moris, V.A.; Piekarski, C.M. How Important Is the LCA Software Tool You Choose? Comparative Results from GaBi, OpenLCA, SimaPro and Umberto. In Proceedings of the Conference: VII Conferencia Internacional de Análisis de Ciclo de Vida en Latinoamérica, Medellin, Colombia, 10–15 June 2017. [Google Scholar]

- Hemmati, M.; Messadi, T.; Gu, H. Life Cycle Assessment of Cross-Laminated Timber Transportation from Three Origin Points. Sustainability 2021, 14, 336. [Google Scholar] [CrossRef]

- Luz, L.M.D.; Francisco, A.C.D.; Piekarski, C.M.; Salvador, R. Integrating Life Cycle Assessment in the Product Development Process: A Methodological Approach. J. Clean. Prod. 2018, 193, 28–42. [Google Scholar] [CrossRef]

- Olagunju, B.D.; Olanrewaju, O.A. Comparison of Life Cycle Assessment Tools in Cement Production. S. Afr. J. Ind. Eng. 2020, 31, 70–83. [Google Scholar] [CrossRef]

- Grossi, F.; Ge, H.; Zmeureanu, R.; Baba, F. Feasibility of Planting Trees around Buildings as a Nature-Based Solution of Carbon Sequestration—An LCA Approach Using Two Case Studies. Buildings 2022, 13, 41. [Google Scholar] [CrossRef]

- Pezeshki, Z.; Ivari, S.A.S. Applications of BIM: A Brief Review and Future Outline. Arch. Comput. Methods Eng. 2018, 25, 273–312. [Google Scholar] [CrossRef]

- Azhar, S. Building Information Modeling (BIM): Trends, Benefits, Risks, and Challenges for the AEC Industry. Leadersh. Manag. Eng. 2011, 11, 241–252. [Google Scholar] [CrossRef]

- Bahar, Y.; Pere, C.; Landrieu, J.; Nicolle, C. A Thermal Simulation Tool for Building and Its Interoperability through the Building Information Modeling (BIM) Platform. Buildings 2013, 3, 380–398. [Google Scholar] [CrossRef]

- Smith, P. BIM & the 5D Project Cost Manager. Procedia-Soc. Behav. Sci. 2014, 119, 475–484. [Google Scholar] [CrossRef]

- Antón, L.Á.; Díaz, J. Integration of Life Cycle Assessment in a BIM Environment. Procedia Eng. 2014, 85, 26–32. [Google Scholar] [CrossRef]

- Doan, D.T.; Ghaffarianhoseini, A.; Naismith, N.; Ghaffarianhoseini, A.; Zhang, T.; Tookey, J. Examining Green Star Certification Uptake and Its Relationship with Building Information Modelling (BIM) Adoption in New Zealand. J. Environ. Manag. 2019, 250, 109508. [Google Scholar] [CrossRef]

- Potrč Obrecht, T.; Röck, M.; Hoxha, E.; Passer, A. BIM and LCA Integration: A Systematic Literature Review. Sustainability 2020, 12, 5534. [Google Scholar] [CrossRef]

- Soust-Verdaguer, B.; Llatas, C.; García-Martínez, A. Critical Review of Bim-Based LCA Method to Buildings. Energy Build. 2017, 136, 110–120. [Google Scholar] [CrossRef]

- Röck, M.; Hollberg, A.; Habert, G.; Passer, A. LCA and BIM: Visualization of Environmental Potentials in Building Construction at Early Design Stages. Build. Environ. 2018, 140, 153–161. [Google Scholar] [CrossRef]

- Carvalho, J.P.; Alecrim, I.; Bragança, L.; Mateus, R. Integrating BIM-Based LCA and Building Sustainability Assessment. Sustainability 2020, 12, 7468. [Google Scholar] [CrossRef]

- Bueno, C.; Fabricio, M.M. Comparative Analysis between a Complete LCA Study and Results from a BIM-LCA Plug-In. Autom. Constr. 2018, 90, 188–200. [Google Scholar] [CrossRef]

- Antón, L.Á.; Díaz, J. Integration of Lca And Bim For Sustainable Construction. World Acad. Sci. Eng. Technol. 2014, 8, 1378–1382. [Google Scholar] [CrossRef]

- Santos, R.; Costa, A.A.; Silvestre, J.D.; Pyl, L. Integration of LCA and LCC Analysis within a BIM-Based Environment. Autom. Constr. 2019, 103, 127–149. [Google Scholar] [CrossRef]

- Kim, J.B.; Jeong, W.; Clayton, M.J.; Haberl, J.S.; Yan, W. Developing a Physical BIM Library for Building Thermal Energy Simulation. Autom. Constr. 2015, 50, 16–28. [Google Scholar] [CrossRef]

- Kamel, E.; Memari, A.M. Review of BIM’s Application in Energy Simulation: Tools, Issues, and Solutions. Autom. Constr. 2019, 97, 164–180. [Google Scholar] [CrossRef]

- Wei, H.; Zheng, S.; Zhao, L.; Huang, R. BIM-Based Method Calculation of Auxiliary Materials Required in Housing Construction. Autom. Constr. 2017, 78, 62–82. [Google Scholar] [CrossRef]

- Kim, K.P. BIM-Enabled Sustainable Housing Refurbishment—LCA Case Study. In Sustainable Construction Technologies; Elsevier: Amsterdam, The Netherlands, 2019; pp. 349–394. ISBN 978-0-12-811749-1. [Google Scholar]

- EN 1990:2002+A1; Basis of Structural Design. European Committee For Standardization: Brussels, Belgium, 2002.

- Cole, R.J.; Kernan, P.C. Life-Cycle Energy Use in Office Buildings. Build. Environ. 1996, 31, 307–317. [Google Scholar] [CrossRef]

- Lendager Architects. Formfaktor Aps DesignLCA. Available online: https://www.designlca.com/ (accessed on 10 September 2023).

- Polish Green Building Council. Estimating the Carbon Footpront of Buildings. Whole Life Carbon Roadmap for Poland 2050; Polish Green Building Council: Gliwice, Poland, 2021. [Google Scholar]

- Bundesministerium für Wohnen, Stadtentwicklung und Bauwesen ÖKOBAUDAT. Available online: www.oekobaudat.de (accessed on 10 September 2023).

- EN 15804+A2; Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products. European Committee For Standardization: Brussels, Belgium, 2019.

- Čekon, M.; Struhala, K.; Slávik, R. Cardboard-Based Packaging Materials as Renewable Thermal Insulation of Buildings: Thermal and Life-Cycle Performance. J. Renew. Mater. 2017, 5, 84–93. [Google Scholar] [CrossRef]

- Slávik, R.; Čekon, M.; Štefaňák, J. A Nondestructive Indirect Approach to Long-Term Wood Moisture Monitoring Based on Electrical Methods. Materials 2019, 12, 2373. [Google Scholar] [CrossRef] [PubMed]

- EN 15978:2011; Sustainability of Construction Works. European Committee For Standardization: Brussels, Belgium, 2011.

- Winkler, J.; Jeznach, J.; Koda, E.; Sas, W.; Mazur, Ł.; Vaverková, M. Promoting Biodiversity: Vegetation in a Model Small Park Located in the Research and Educational Centre. J. Ecol. Eng. 2022, 23, 146–157. [Google Scholar] [CrossRef]

- Winkler, J.; Mazur, Ł.; Smékalová, M.; Podlasek, A.; Hurajová, E.; Koda, E.; Jiroušek, M.; Jakimiuk, A.; Vaverková, M.D. Influence of Land Use on Plant Community Composition in Vysocina Region Grasslands, Czech Republic. Environ. Protect. Eng. 2022, 48, 21–33. [Google Scholar] [CrossRef]

- Vijayan, D.S.; Devarajan, P.; Sivasuriyan, A.; Stefańska, A.; Koda, E.; Jakimiuk, A.; Vaverková, M.D.; Winkler, J.; Duarte, C.C.; Corticos, N.D. A State of Review on Instigating Resources and Technological Sustainable Approaches in Green Construction. Sustainability 2023, 15, 6751. [Google Scholar] [CrossRef]

- Magwood, C.; Bowden, E.; Javaria, A.; Deluca, M.; Treadaway, E.; Douglas, N. Establishing the Average Upfront Material Carbon Emissions in New Low-Rise Residential Home Construction in the City of Nelson & the City of Castlegar; Manager of Planning, Development & Sustainability, City of Castlegar: Castlegar, CB, Canada, 2022. [Google Scholar] [CrossRef]

- Magwood, C.; Huynh, T. The Hidden Climate Impact of Residential Construction; RMI: Basalt, CO, USA, 2023. [Google Scholar]

- Arceo, A.; Tham, M.; Guven, G.; MacLean, H.L.; Saxe, S. Capturing Variability in Material Intensity of Single-Family Dwellings: A Case Study of Toronto, Canada. Resour. Conserv. Recycl. 2021, 175, 105885. [Google Scholar] [CrossRef]

- Marchwiński, J.; Starzyk, A.; Kopyłow, O.; Kurtz-Orecka, K. Impact of Atrium Glazing with and without BIPV on Energy Performance of the Low-Rise Building: A Central European Case Study. Energies 2023, 16, 4683. [Google Scholar] [CrossRef]

- Struhala, K.; Čekon, M.; Slávik, R. Life Cycle Assessment of Solar Façade Concepts Based on Transparent Insulation Materials. Sustainability 2018, 10, 4212. [Google Scholar] [CrossRef]

- Bierwirth, A.; Thomas, S. Estimating the Sufficiency Potential in Buildings: The Space between under Dimensioned and Oversized. In Proceedings of the Eceee Summer Study Proceedings 2019, Giens Peninsula, France, 3–8 June 2019. [Google Scholar]

- Seo, S.; Hwang, Y. Estimation of CO2 Emissions in Life Cycle of Residential Buildings. J. Constr. Eng. Manag. 2001, 127, 414–418. [Google Scholar] [CrossRef]

- Moncaster, A.M.; Symons, K.E. A Method and Tool for ‘Cradle to Grave’ Embodied Carbon and Energy Impacts of UK Buildings in Compliance with the New TC350 Standards. Energy Build. 2013, 66, 514–523. [Google Scholar] [CrossRef]

- Rybak-Niedziółka, K.; Starzyk, A.; Łacek, P.; Mazur, Ł.; Myszka, I.; Stefańska, A.; Kurcjusz, M.; Nowysz, A.; Langie, K. Use of Waste Building Materials in Architecture and Urban Planning—A Review of Selected Examples. Sustainability 2023, 15, 5047. [Google Scholar] [CrossRef]

- Sathre, R.; O’Connor, J. Meta-Analysis of Greenhouse Gas Displacement Factors of Wood Product Substitution. Environ. Sci. Policy 2010, 13, 104–114. [Google Scholar] [CrossRef]

- Polgár, A. Carbon Footprint and Sustainability Assessment of Wood Utilisation in Hungary. Environ. Dev. Sustain. 2023. [Google Scholar] [CrossRef]

- Gustavsson, L.; Pingoud, K.; Sathre, R. Carbon Dioxide Balance of Wood Substitution: Comparing Concrete- and Wood-Framed Buildings. Mitig. Adapt. Strat. Glob. Chang. 2006, 11, 667–691. [Google Scholar] [CrossRef]

- Werner, F.; Richter, K. Wooden Building Products in Comparative LCA: A Literature Review. Int. J. Life Cycle Assess 2007, 12, 470–479. [Google Scholar] [CrossRef]

- Shao, L.; Chen, G.Q.; Chen, Z.M.; Guo, S.; Han, M.Y.; Zhang, B.; Hayat, T.; Alsaedi, A.; Ahmad, B. Systems Accounting for Energy Consumption and Carbon Emission by Building. Commun. Nonlinear Sci. Numer. Simul. 2014, 19, 1859–1873. [Google Scholar] [CrossRef]

- Kasperski, J.; Bać, A.; Oladipo, O. A Simulation of a Sustainable Plus-Energy House in Poland Equipped with a Photovoltaic Powered Seasonal Thermal Storage System. Sustainability 2023, 15, 3810. [Google Scholar] [CrossRef]

- Ramesh, T.; Prakash, R.; Shukla, K.K. Life Cycle Energy Analysis of Buildings: An Overview. Energy Build. 2010, 42, 1592–1600. [Google Scholar] [CrossRef]

- Min, J.; Yan, G.; Abed, A.M.; Elattar, S.; Amine Khadimallah, M.; Jan, A.; Elhosiny Ali, H. The Effect of Carbon Dioxide Emissions on the Building Energy Efficiency. Fuel 2022, 326, 124842. [Google Scholar] [CrossRef]

- Feist, W. Active for More Comfort: Passive House; Nternational Passive House Association: Darmstadt, Germany, 2018. [Google Scholar]

- Peper, S.; Feist, W. Energy Efficiency of the Passive House Standard: Expectations Confirmed by Measurements in Practice; Passive House Institute: Darmstadt, Germany, 2015. [Google Scholar]

- James, M.; Bill, J. Passive House in Different Climates: The Path to Net Zero; Routledge, Taylor & Francis Group: New York, NY, USA, 2016; ISBN 978-1-138-90403-3. [Google Scholar]

- Wąs, K.; Radoń, J.; Sadłowska-Sałęga, A. Maintenance of Passive House Standard in the Light of Long-Term Study on Energy Use in a Prefabricated Lightweight Passive House in Central Europe. Energies 2020, 13, 2801. [Google Scholar] [CrossRef]

| Software | Description |

|---|---|

| OpenLCA 2.0.3 | OpenLCA is an advanced open source software for LCA and Environmental Impact Assessment (EIA) of products and services. It has the advantage of being accessible and versatile, making it widely used in research and industrial practice [34]. |

| SimaPro + Report Maker | SimaPro is a professional tool that provides a comprehensive assessment of the environmental footprint of products and processes. Report Maker is a tool that integrates with SimaPro and allows the creation of advanced reports and visualisations of LCA results [35]. |

| Tally (2023.09.13.01) | Tally is a specialised software used for analysis in the construction sector. It is used mainly in the United States [36]. |

| Umberto LCA+ | Umberto LCA+ can calculate carbon footprints, perform LCA analysis, create EPD declarations, and use the integrated ecoinvent database [37,38]. |

| One-Click LCA Product Carbon & EPD Generator | One-Click LCA is an expert package that can be split into an LCA and a Carbon Footprint + EPD module. However, the functionality of this software is limited the calculation of carbon footprint. It is integrated with an EPD generator based on the EN15804 standard [39]. |

| Software | Description |

|---|---|

| One-Click LCA | This is a common assessment tool used to measure the environmental sustainability of construction projects. One-Click LCA can be added to Autodesk Revit, ArchiCAD, and SketchUp as an additional feature. It enables users to perform sustainability assessments during the design process, considering factors such as building materials, energy usage, and emissions. |

| Tally (2023.09.13.01) | This is an add-on to Autodesk Revit that allows you to explore the environmental impact of buildings as you design them. It allows the assessment of various aspects of sustainability, including carbon footprint, energy consumption, water consumption, materials, and waste. |

| Cerclos | This is a cloud-based LCA tool that integrates with BIM programme such as Revit and ArchiCAD. It allows detailed LCA analyses to be carried out, taking into account various aspects of the building, such as building materials, energy consumption, waste management, and GHG emissions. |

| EC3 (Embodied Carbon in Construction Calculator) | This is an LCA tool developed by the Carbon Leadership Forum. It can be added on to BIM programme such as Revit, Rhino, and Grasshopper. It makes it easy to measure the carbon footprint of building materials, which can help designers choose sustainable materials and make informed decisions about construction. |

| Parameter | Building A Masonry Building | Building B Timber Building | Unit |

|---|---|---|---|

| Gross floor area | 153.80 | 139.80 | m2 |

| Usable floor area | 113.90 | 115.70 | m2 |

| Number of storeys | 2 | 2 | |

| Number of bedrooms | 3 | 3 | units |

| U-value heat transfer coefficient (thermal transmittance) (W/m2K) | |||

| External walls | 0.16 | 0.17 | W/m2K |

| Roof | 0.12 | 0.12 | W/m2K |

| Floor | 0.14 | 0.14 | W/m2K |

| Net heating energy | 57.21 | 41.32 | kWh/m2y |

| Net cooling energy | 5.02 | 12.13 | kWh/m2y |

| Total net energy | 62.23 | 53.45 | kWh/m2y |

| Energy consumption | 63.02 | 54.19 | kWh/m2y |

| Fuel consumption | 9.34 | 9.11 | kWh/m2y |

| CO2e emissions | 2.02 | 1.97 | kg/m2y |

| Internal temperature (annual average value) | |||

| Heated rooms | 20.66 | 21.51 | °C |

| Non-heated rooms | 14.83 | 15.32 | °C |

| Material | Unit | Density (kg/m3) | Embodied Energy (MJ/kg) PENRT * A1–A3 | Carbon Data (kg CO2/unit) | Water m3/m3 |

|---|---|---|---|---|---|

| Reinforcing steel | kg | 7850.00 | 5545.00 | 0.47 | 1.4540 |

| Concrete C20/25 | kg/m3 | 2400.00 | 912.00 | 178.00 | 0.7600 |

| Masonry bricks | kg/m3 | 575.00 | 1180.00 | 113.00 | 0.1710 |

| KVH construction timber | kg/m3 | 492.92 | 1124.00 | −767.80 | 0.2247 |

| External silicone plaster | kg | 1700.00 | 13,79 | 0.69 | 0.0219 |

| Internal gypsum plaster | kg/m3 | 1000.00 | 87.27 | 119.40 | 0.2412 |

| Steel galvanised | kg | 7850.00 | 25.86 | 2.78 | 0.0031 |

| Gypsum fibreboard | kg/m3 | 1180.00 | 17.40 | 1.14 | 0.0070 |

| Gypsum plaster board | kg/m2 | 10.00 | 34.85 | 1.62 | 0.0079 |

| Swisskrono OSB | kg/m3 | 614.50 | 3950.00 | −890.00 | 0.7980 |

| Solid wood parquet | kg/m2 | 575.00 | 87.27 | −18.74 | 0.0230 |

| Aerated concrete P3 | kg/m3 | 380.00 | 1263 | 184.40 | 0.6385 |

| Sand | kg | 1.00 | 0.03 | 0.00 | 0.0000 |

| Profiled aluminium sheets for roof | kg/m2 | 2.900 | 360.30 | 27.03 | 0.3715 |

| Stoneware tiles, glazed | kg/m2 | 20.00 | 100.40 | 6.18 | 0.0135 |

| Stone wool acoustic insulation | kg/m3 | 155.00 | 1836.00 | 196.60 | 0.4590 |

| Stone wool heat insulation | kg/m3 | 155.00 | 1836.00 | 196.60 | 0.4590 |

| Extruded polystyrene (XPS) foam board | kg/m3 | 32.70 | 786.5 | 54.24 | 0.3555 |

| Air barrier membrane | kg/m2 | 0.17 | 15.81 | 1.18 | 0.0149 |

| PE foil, dimpled | kg/m2 | 1.20 | 114.7 | 4.12 | 0.0161 |

| Humidity variable air and vapour membrane | kg/m2 | 0.09 | 12.53 | 0.53 | 0.0035 |

| Underroof membrane-reinforced PE fabric | kg/m2 | 0.14 | 10.96 | 0.43 | 0.0037 |

| Construction Component | Building A Masonry Building | Building B Timber Building | ||

|---|---|---|---|---|

| (kg CO2e) | (%) | (kg CO2e) | (%) | |

| Foundations | 1045.61 | 4.10% | 1030.86 | 41.98% |

| External walls | 9829.70 | 38.56% | 159.75 | 6.51% |

| Internal walls | 1307.40 | 5.13% | −754.03 | −30.70% |

| Inter-storey floor | 4076.31 | 15.99% | −5191.64 | −211.41% |

| Roof | 1305.31 | 5.12% | 1376.55 | 56.05% |

| Internal installations | 2317.00 | 9.09% | 223.00 | 9.08% |

| Stairs | −573.88 | −2.25% | −573.88 | −23.37% |

| Windows | 5971.84 | 23.43% | 5971.84 | 243.18% |

| Doors | 213.30 | 0.84% | 213.30 | 8.69% |

| Global Warming Potential—total (GWP-total) | 25,492.59 | 100.00% | 2455.75 | 100.00% |

| Total emission | 26,066.47 | 8975.30 | ||

| Excess CO2 accumulation | −573.88 | −6519.55 | ||

| Life Cycle Phase | a. Cumulative Energy (MJ) | |

|---|---|---|

| Building A Masonry Building | Building B Timber Building | |

| A1–A3 production stage | 8,839,875.65 | 7,936,714.68 |

| b. Carbon footprint(kg CO2e) | ||

| A1–A3 production stage | 25,492.59 | 2455.75 |

| B6 energy consumption over a 50-year life cycle | 17,734.35 | 11,066.38 |

| Total | 43,226.94 | 13,522.13 |

| c. Water consumption(m3) | ||

| A1–A3 production stage | 2406.34 | 2121.80 |

| House Type | Net Emissions kg CO2e | Emission Intensity kg CO2e/m2 | Emission Intensity kg CO2e/m2/yr | Emission Intensity kg CO2e/Bedroom | Energy * kWh/yr |

|---|---|---|---|---|---|

| Building A—Masonry building | 43,226.94 | 281.06 | 5.62 | 14,408.98 | 94.87 |

| Building B—Timber building | 13,522.13 | 96.72 | 1.93 | 4507.38 | 47.72 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mazur, Ł.; Olenchuk, A. Life Cycle Assessment and Building Information Modeling Integrated Approach: Carbon Footprint of Masonry and Timber-Frame Constructions in Single-Family Houses. Sustainability 2023, 15, 15486. https://doi.org/10.3390/su152115486

Mazur Ł, Olenchuk A. Life Cycle Assessment and Building Information Modeling Integrated Approach: Carbon Footprint of Masonry and Timber-Frame Constructions in Single-Family Houses. Sustainability. 2023; 15(21):15486. https://doi.org/10.3390/su152115486

Chicago/Turabian StyleMazur, Łukasz, and Anatolii Olenchuk. 2023. "Life Cycle Assessment and Building Information Modeling Integrated Approach: Carbon Footprint of Masonry and Timber-Frame Constructions in Single-Family Houses" Sustainability 15, no. 21: 15486. https://doi.org/10.3390/su152115486

APA StyleMazur, Ł., & Olenchuk, A. (2023). Life Cycle Assessment and Building Information Modeling Integrated Approach: Carbon Footprint of Masonry and Timber-Frame Constructions in Single-Family Houses. Sustainability, 15(21), 15486. https://doi.org/10.3390/su152115486