Numerical Simulation Study on Flow Characteristics of Multistage Centrifugal Pumps under Different Inlet Gas Void Fractions

Abstract

:1. Introduction

2. Geometric Model and Numerical Method

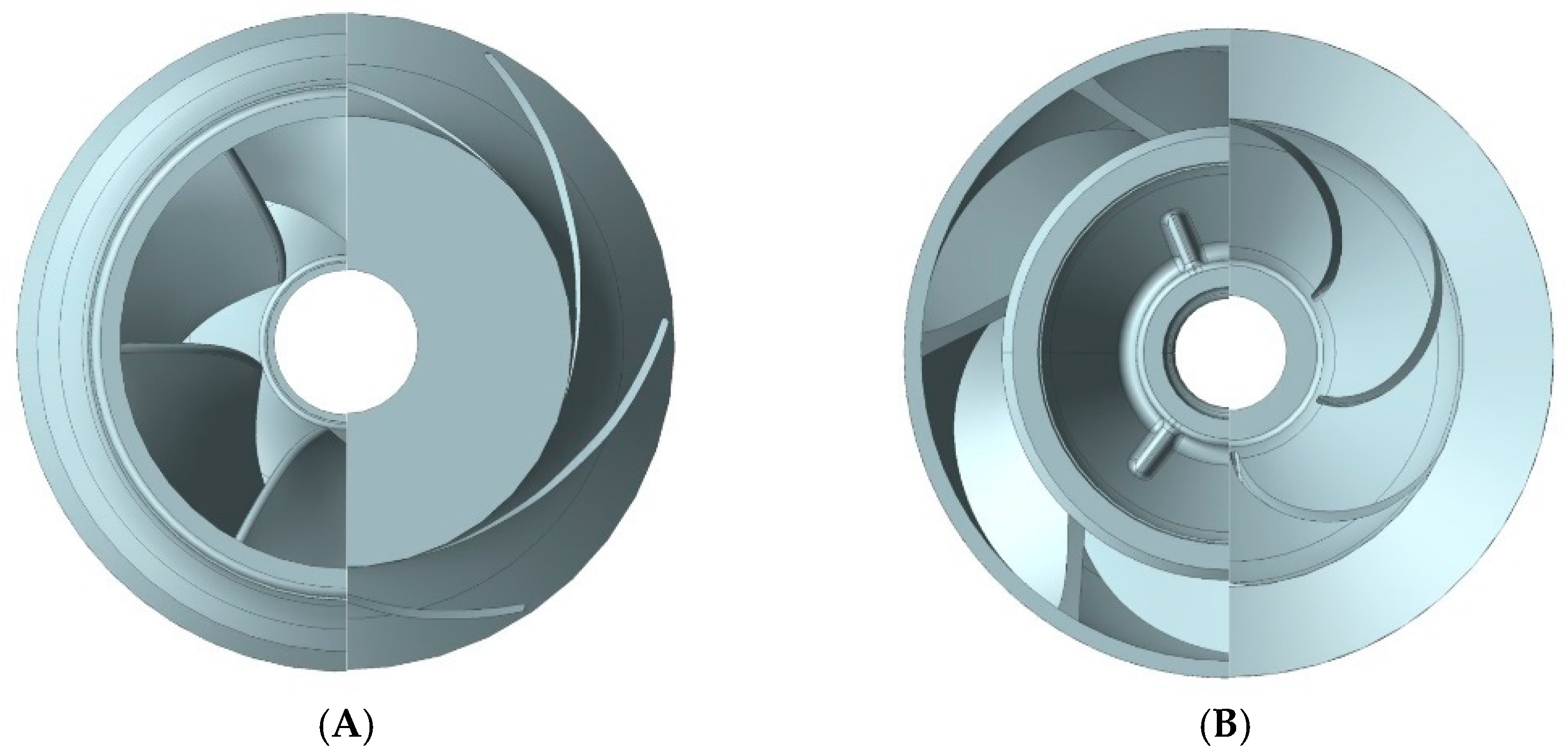

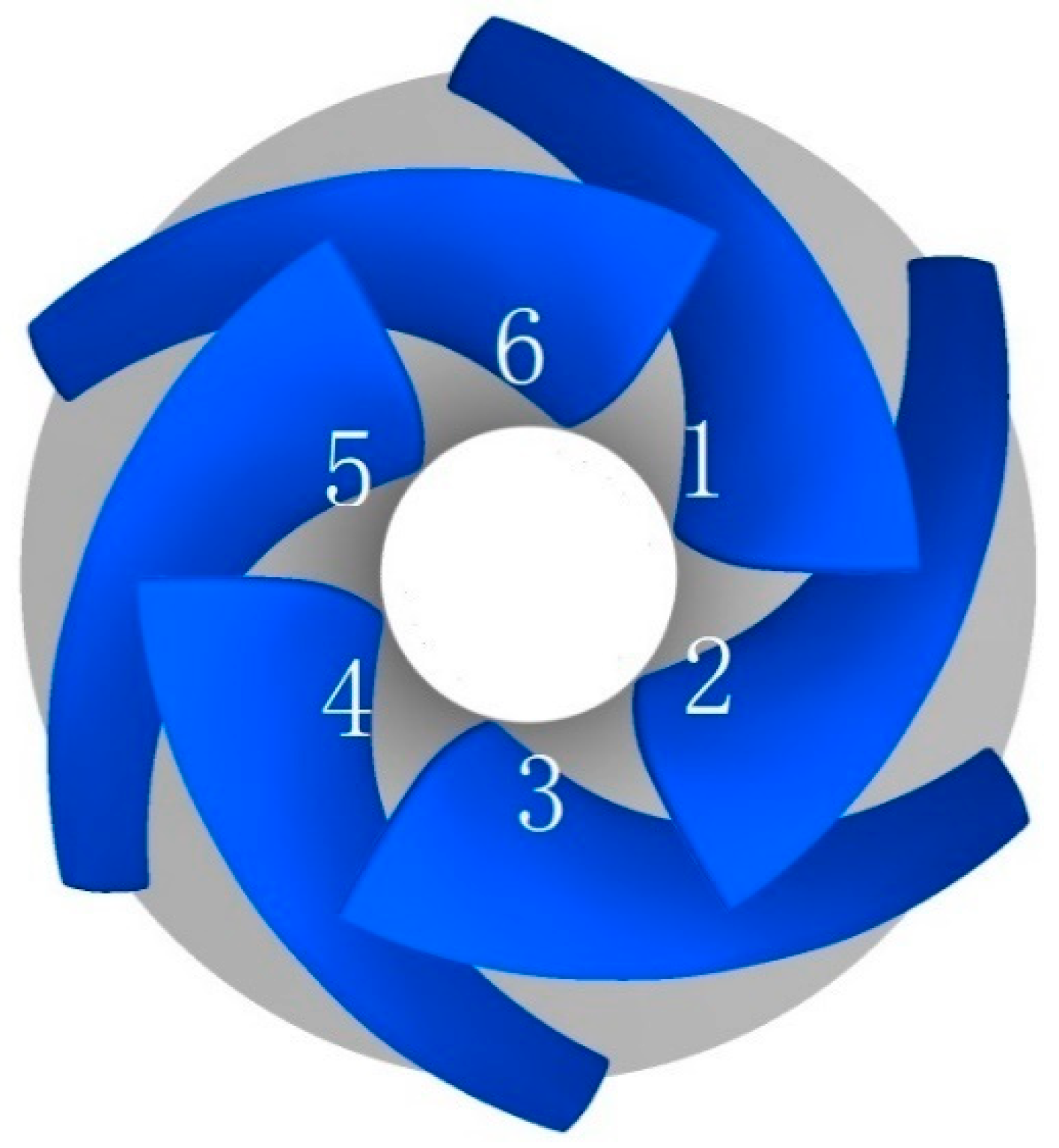

2.1. Model

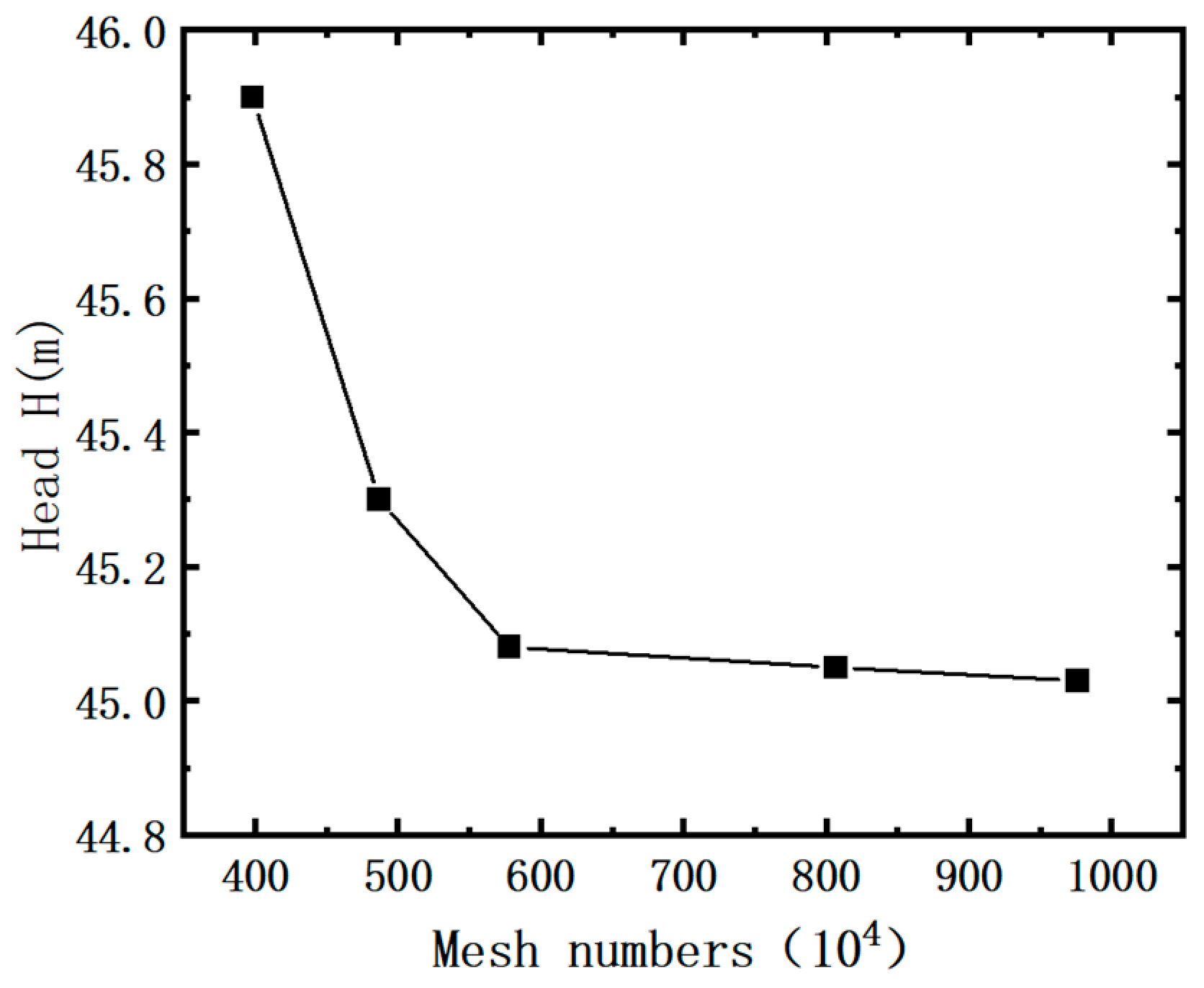

2.2. Mesh

2.3. Control Equation of Gas–Liquid Two-Phase Flow

2.4. Method of Calculation

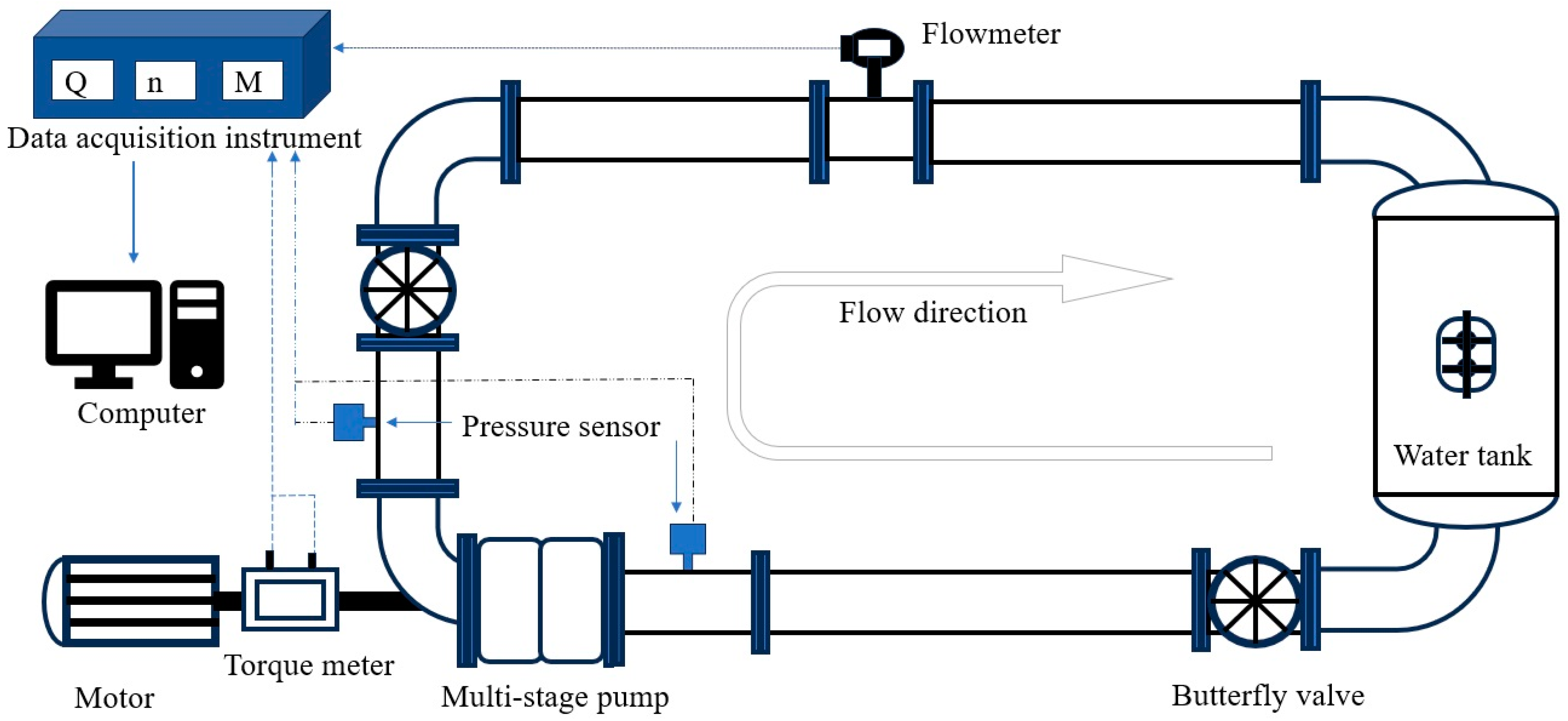

3. Experimental Setup and Verification

4. Results and Discussion

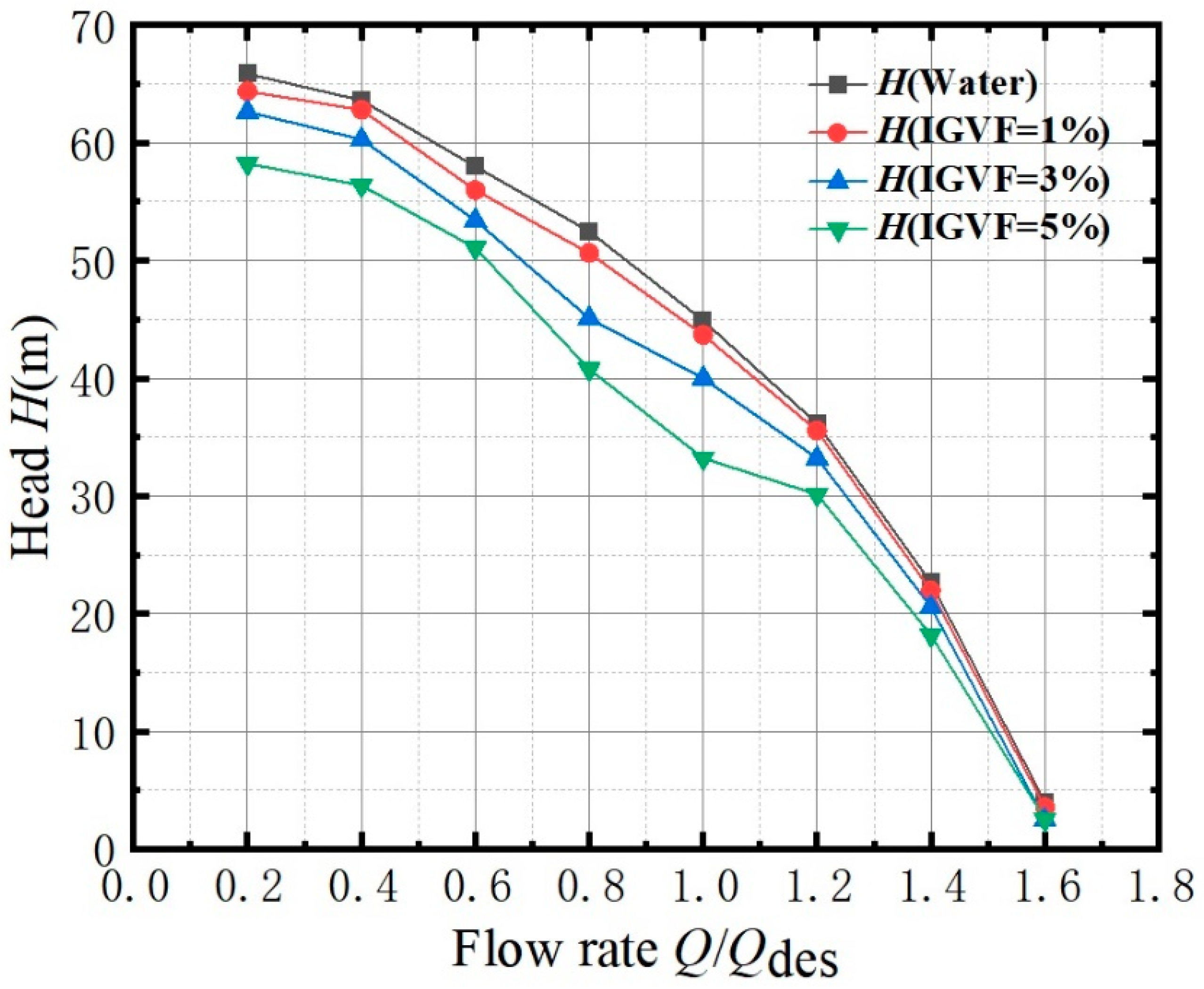

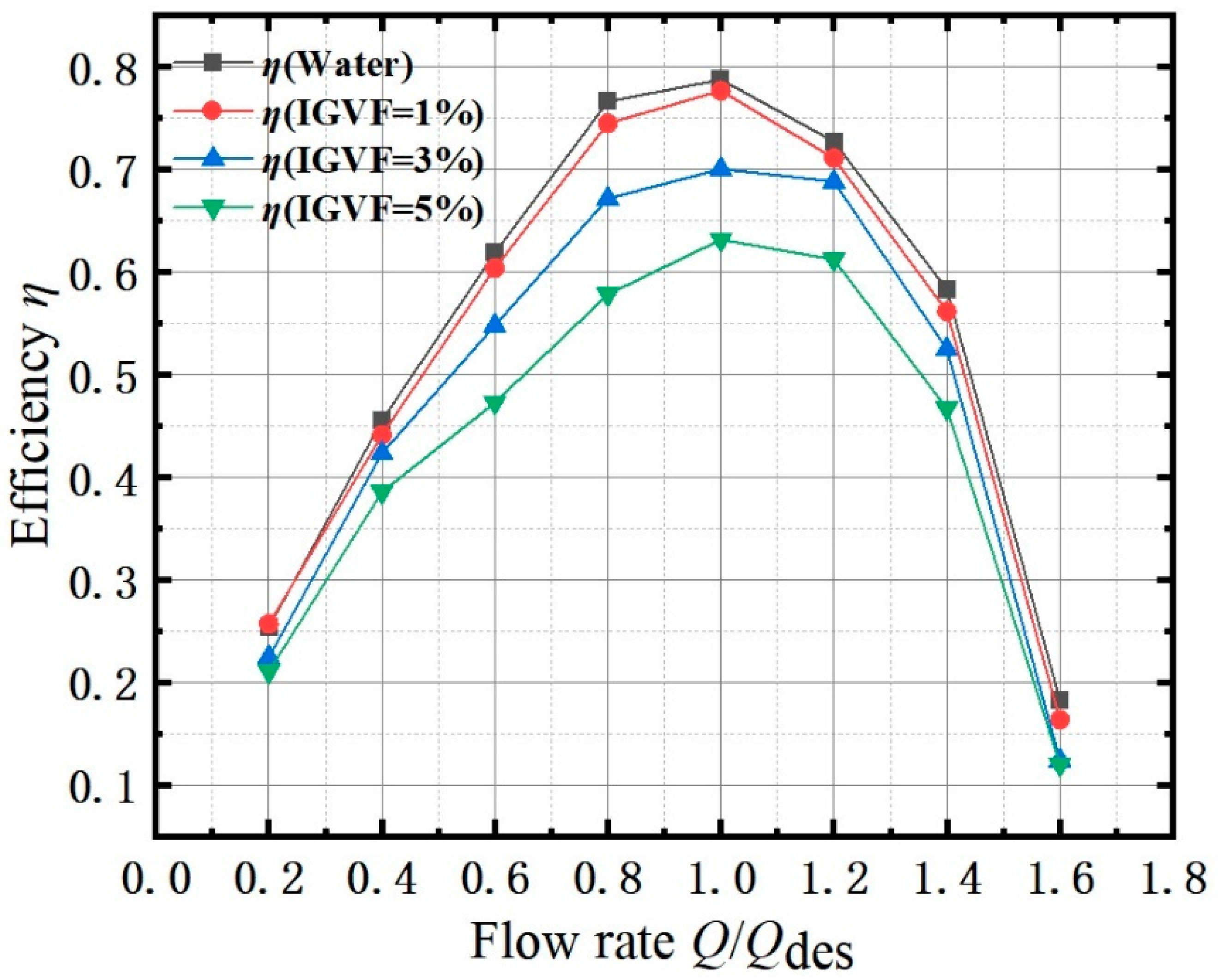

4.1. External Characteristics Comparison (2875 r/min, 140 m3/h, Three-Level)

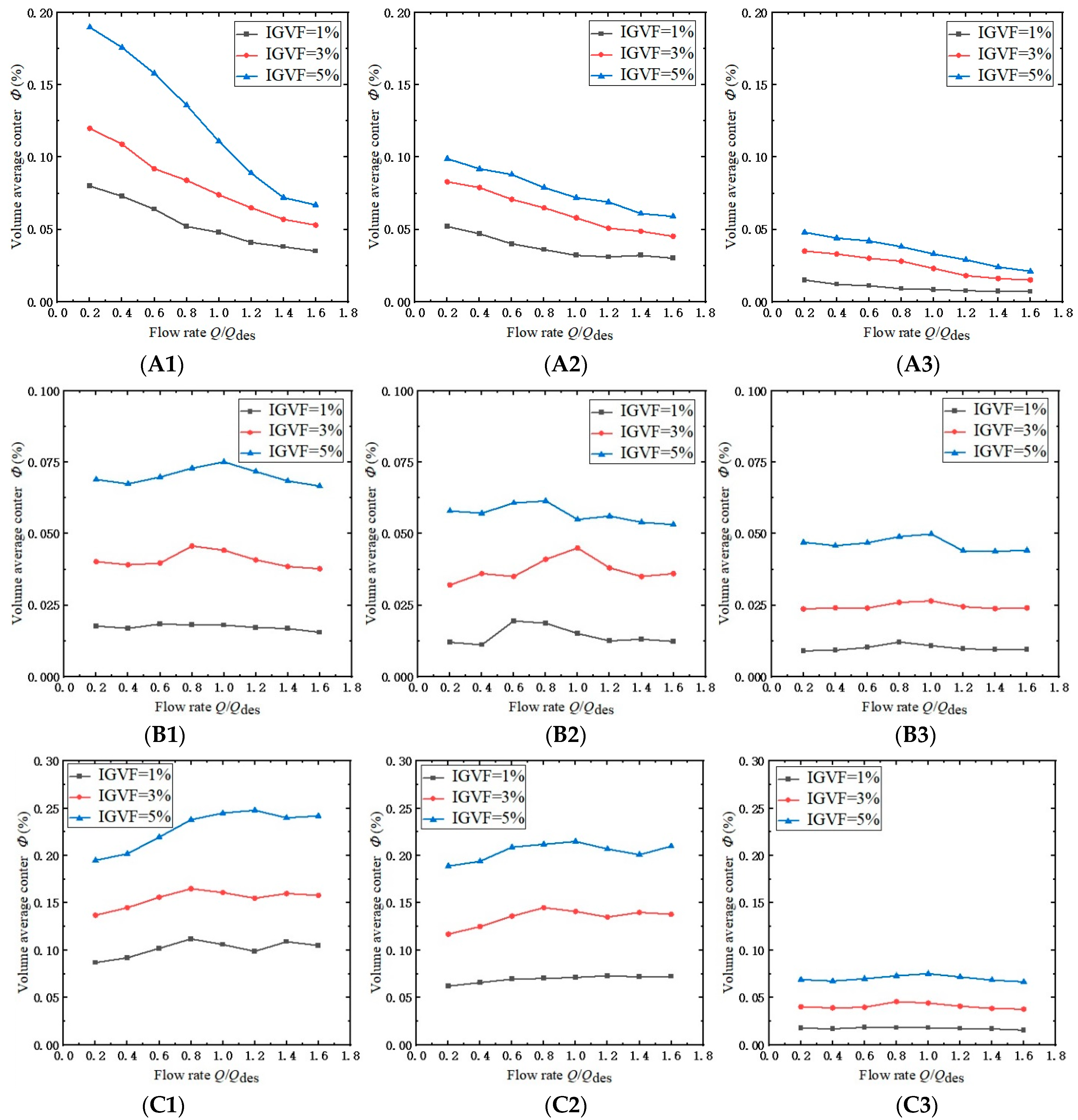

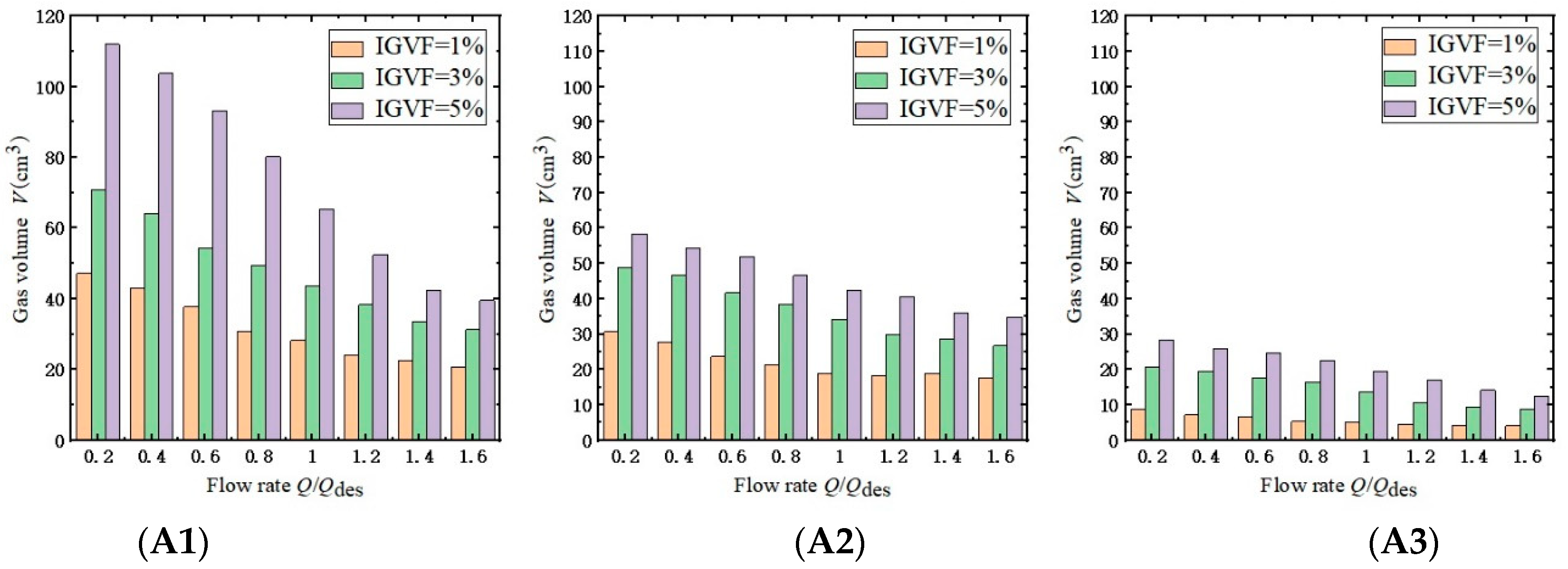

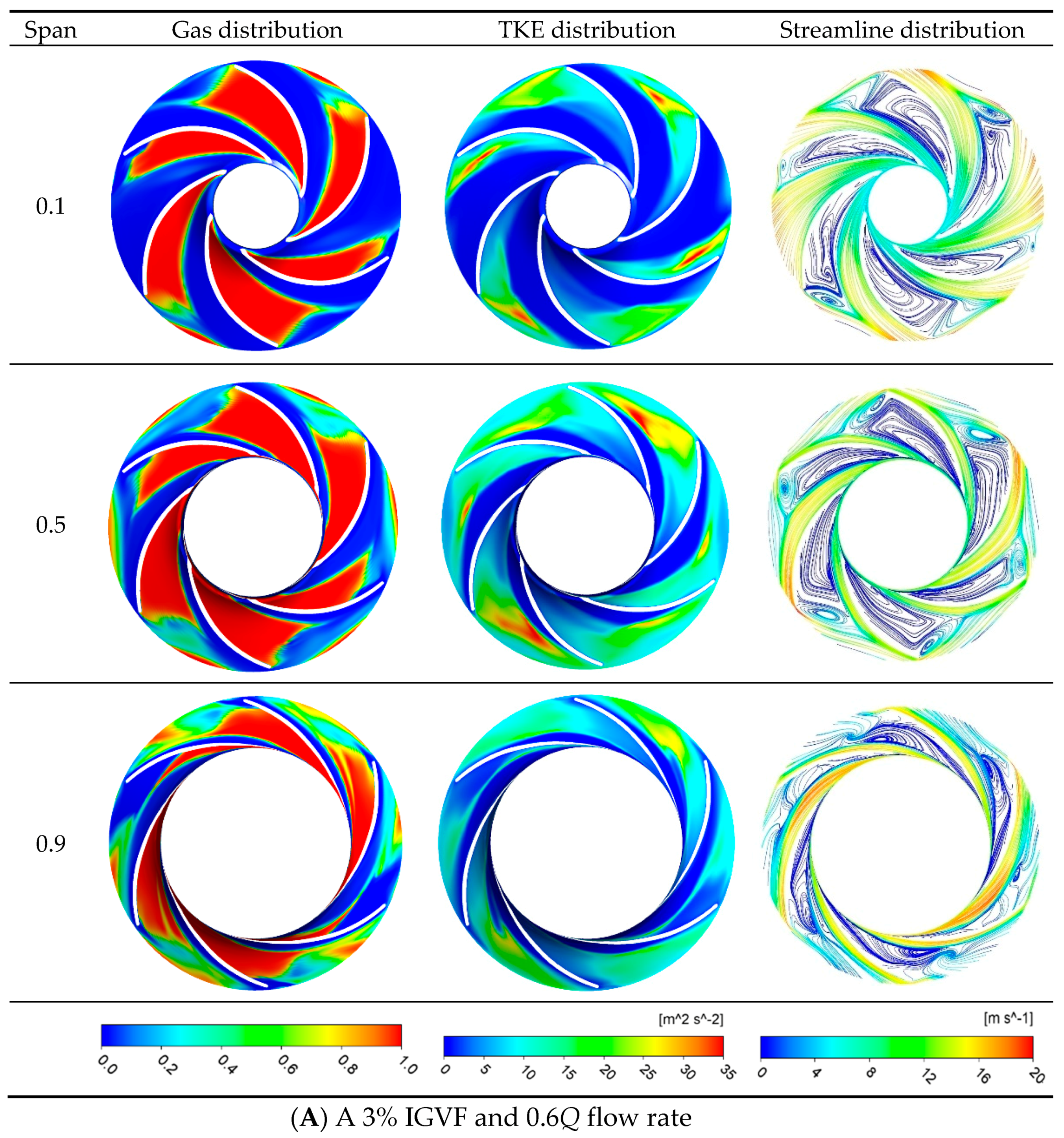

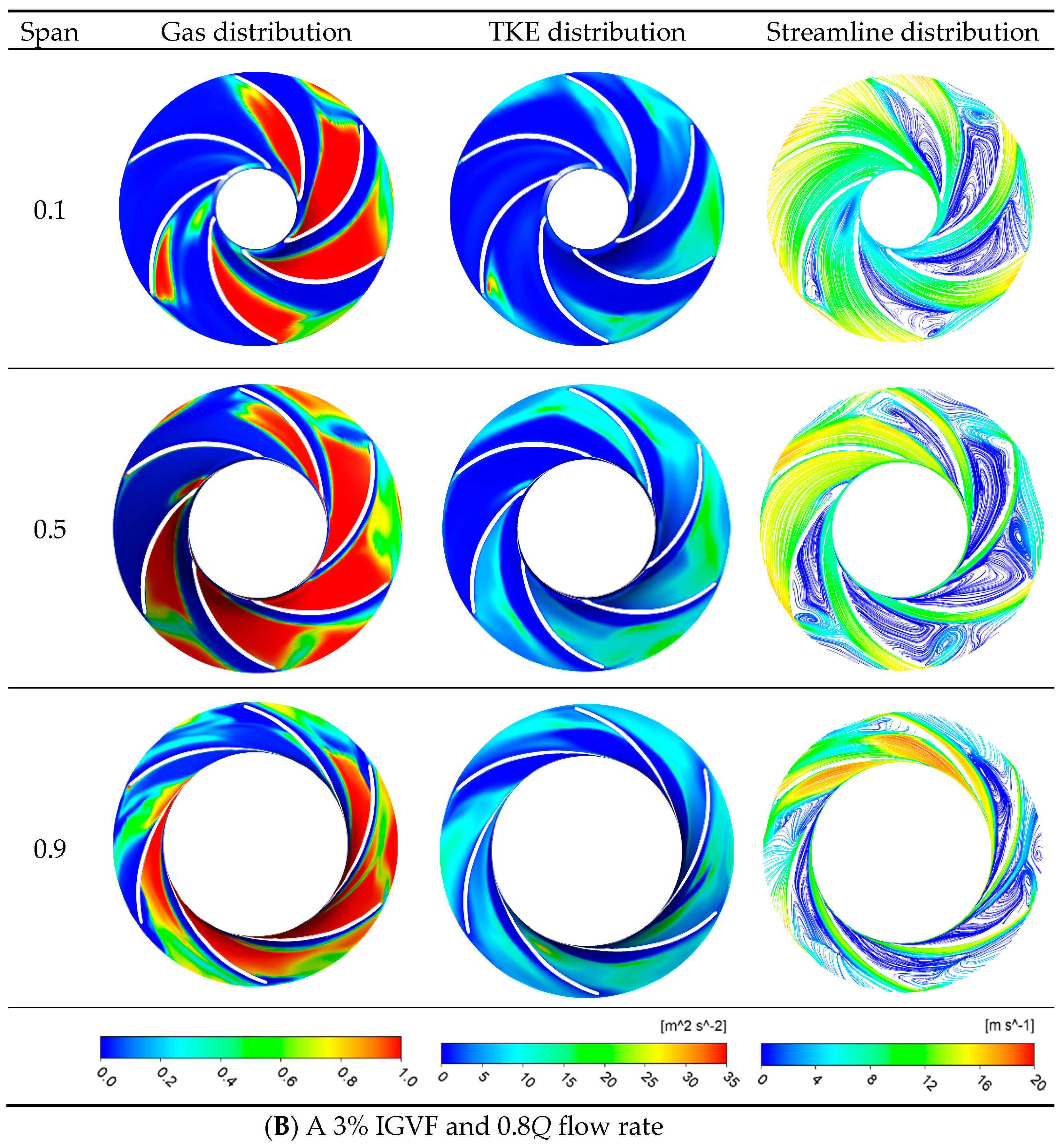

4.2. Gas Phase Distribution

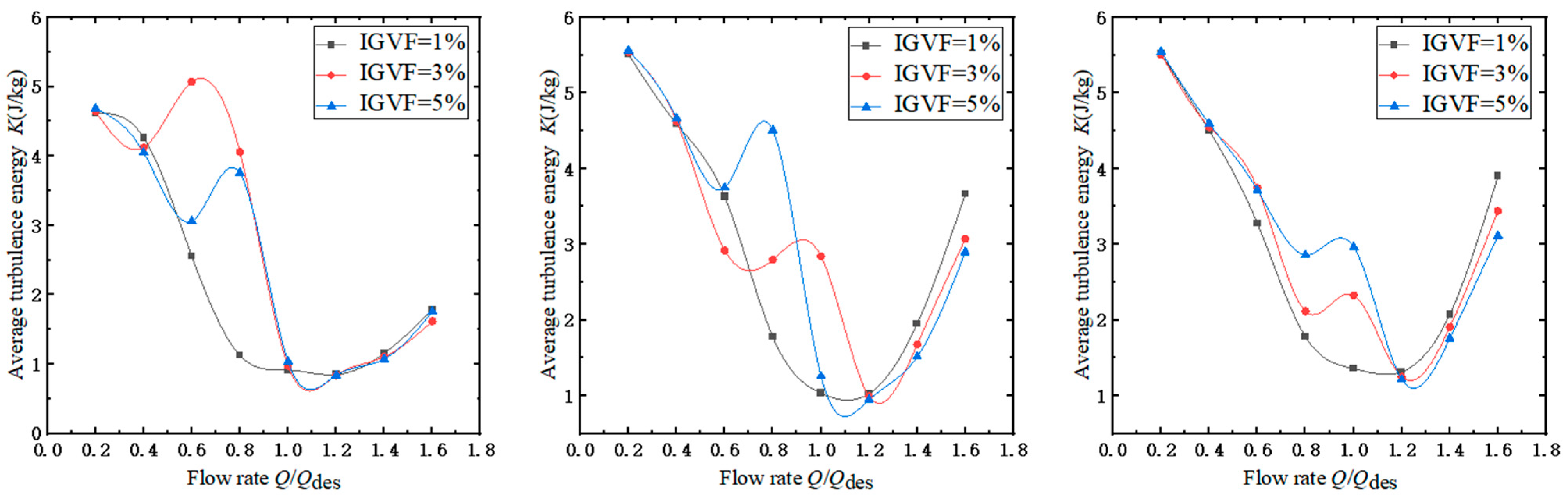

4.3. Turbulent Kinetic Energy Distribution

4.4. Distribution of Vortices in the First-Stage Impeller

5. Conclusions

- (1)

- By analyzing the performance curves under the different IGVF conditions of 1%, 3%, and 5%, it is observed that the performance of the multistage pump decreases as the IGVF increases. However, under IGVF conditions of 3% and 5%, the high-efficiency region of the multistage pump expands to a certain range. This suggests that under certain gas contents, increasing the flow rate can maintain the high-efficiency operation of the multistage pump.

- (2)

- With the increase in the IGVF, the gas aggregation degree of each component increases. However, the average gas volume in the fluid domain is inversely proportional to the flow rate, and the content of the gas decreases with the increase in the series. Furthermore, due to the centrifugal effect of the rotary unit, gases and liquids experience different centrifugal forces. Gases experience a relatively smaller centrifugal force, resulting in the occurrence of aggregation near the rotating axis within the pump chamber.

- (3)

- Under low flow conditions, the asymmetric distribution of the gas within the impeller occurs in the mid-to-rear sections of the suction side. Additionally, there is a strong correlation between turbulent energy and the location of gas aggregation, exhibiting significant fluctuations. This proves that the energy loss of multistage pump under gas-containing working conditions is indeed related to the IGVF. In subsequent high-flow conditions, the main factor affecting the variation of turbulence intensity shifts from gas distribution to the impact of turbulence. This leads to an increase in turbulence intensity and a decrease in the performance of multistage pumps.

- (4)

- In the first-stage impeller, the gas distribution significantly affects the variation of turbulent kinetic energy. The gas accumulates in regions where streamlines are relatively dense, indicating the presence of vortices at these locations. As the asymmetric gas distribution becomes more pronounced in the flow passage of the impeller, the regions of a dense streamline distribution increase, and in some cases, secondary vortices occur in particular flow passages, severely affecting the gas–liquid two-phase operation performance of the multistage pump.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhou, D.; Sachdeva, R. Simple model of electric submersible pump in gassy well. J. Pet. Sci. Eng. 2010, 70, 204–213. [Google Scholar] [CrossRef]

- Castellanos, M.B.; Serpa, A.L.; Biazussi, J.L.; Verde, W.M.; Sassim, N.D.S.D.A. Fault identification using a chain of decision trees in an electrical submersible pump operating in a liquid-gas flow. J. Pet. Sci. Eng. 2020, 184, 106490. [Google Scholar] [CrossRef]

- Zhang, W.; Zhu, B.; Yu, Z. Characteristics of bubble motion and distribution in a multiphase rotodynamic pump. J. Pet. Sci. Eng. 2020, 193, 107435. [Google Scholar] [CrossRef]

- Nimwegen, A.; Portela, L.; Henkes, R. The effect of surfactants on air–water annular and churn flow in vertical pipes. Part 1: Morphology of the air–water interface. Int. J. Multiph. Flow 2015, 71, 133–145. [Google Scholar] [CrossRef]

- Xiaoping, J.; Li, W.; Ling, Z.; Wei, L.; Chuan, W. Transient response analysis of cantilever multistage centrifugal pump based on multi-source excitation. J. Low Freq. Noise Vib. Act. Control 2019, 39, 146134841987231. [Google Scholar] [CrossRef]

- Zhang, M.; Jiang, Z.; Feng, K. Research on variational mode decomposition in rolling bearings fault diagnosis of the multistage centrifugal pump. Mech. Syst. Signal Process. 2017, 93, 460–493. [Google Scholar] [CrossRef]

- Sedlar, M.; Kratky, T.; Zima, P. Numerical Analysis of Unsteady Cavitating Flow around Balancing Drum of Multistage Pump. Int. J. Fluid Mach. Syst. 2016, 9, 119–128. [Google Scholar] [CrossRef]

- Verde, W.M.; Biazussi, J.; Porcel, C.E.; Estevam, V.; Tavares, A.; Neto, S.J.A.; Rocha, P.S.d.M.; Bannwart, A.C. Experimental investigation of pressure drop in failed Electrical Submersible Pump (ESP) under liquid single-phase and gas-liquid two-phase flow. J. Pet. Sci. Eng. 2020, 198, 108127. [Google Scholar] [CrossRef]

- Pirouzpanah, S.; Gudigopuram, S.R.; Morrison, G.L. Two-phase flow characterization in a split vane impeller Electrical Submersible Pump. J. Pet. Sci. Eng. 2017, 148, 82–93. [Google Scholar] [CrossRef]

- Matsushita, N.; Watanabe, S.; Okuma, K.; Hasui, T.; Furukawa, A. Similarity Law of Air-Water Two-Phase Flow Performance of Centrifugal Pump. In Proceedings of the ASME/JSME 2007 5th Joint Fluids Engineering Conference, San Diego, CA, USA, 30 July–2 August 2007. [Google Scholar] [CrossRef]

- Barrios, L.; Prado, M.G. Modeling Two Phase Flow Inside an Electrical Submersible Pump Stage. In Proceedings of the ASME 2009 28th International Conference on Ocean, Offshore and Arctic Engineering, Honolulu, HI, USA, 31 May–5 June 2009. [Google Scholar] [CrossRef]

- Zhang, W.; Yu, Z.; Li, Y.; Yang, J.; Ye, Q. Numerical analysis of pressure fluctuation in a multiphase rotodynamic pump with air–water two-phase flow. Oil Gas Sci. Technol.–Rev. IFP Energies Nouv. 2019, 74, 18. [Google Scholar] [CrossRef]

- Shi, G.; Wang, S.; Xiao, Y.; Liu, Z.; Li, H.; Liu, X. Effect of cavitation on energy conversion characteristics of a multiphase pump. Renew. Energy 2021, 177, 1308–1320. [Google Scholar] [CrossRef]

- Si, Q.; Cui, Q.; Zhang, K.; Yuan, J.; Bois, G. Investigation on centrifugal pump performance degradation under air-water inlet two-phase flow conditions. La Houille Blanche 2018, 104, 41–48. [Google Scholar] [CrossRef]

- Zhu, J.; Zhu, H.; Zhang, J.; Zhang, H.-Q. A numerical study on flow patterns inside an electrical submersible pump (ESP) and comparison with visualization experiments. J. Pet. Sci. Eng. 2019, 173, 339–350. [Google Scholar] [CrossRef]

- Poullikkas, A. Two phase flow performance of nuclear reactor cooling pumps. Prog. Nucl. Energy 2000, 36, 123–130. [Google Scholar] [CrossRef]

- Shi, Y.; Zhu, H. Proposal of a stage-by-stage design method and its application on a multi-stage multiphase pump based on numerical simulations. Adv. Mech. Eng. 2021, 13, 538–546. [Google Scholar] [CrossRef]

- Zhang, W.; Xie, X.; Zhu, B.; Ma, Z. Analysis of phase interaction and gas holdup in a multistage multiphase rotodynamic pump based on a modified Euler two-fluid model. Renew. Energy 2021, 164, 1496–1507. [Google Scholar] [CrossRef]

- Wang, B.; Zhang, H.; Deng, F.; Wang, C.; Si, Q. Effect of Short Blade Circumferential Position Arrangement on Gas-Liquid Two-Phase Flow Performance of Centrifugal Pump. Processes 2020, 8, 1317. [Google Scholar] [CrossRef]

- Zhang, H.; Yuan, S.; Deng, F.; Liao, M.; Chen, M.; Si, Q. Characteristics of gas-liquid two-phase flow in centrifugal pump based on dimensionless method. J. Drain. Irrig. Mach. Eng. 2021, 39, 451e6. [Google Scholar]

- El-Emam, M.A.; Zhou, L.; Yasser, E.; Bai, L.; Shi, W. Computational Methods of Erosion Wear in Centrifugal Pump: A State-of-the-Art Review. Arch. Comput. Methods Eng. 2022, 29, 3789–3814. [Google Scholar] [CrossRef]

- Zhang, J.; Cai, S.; Zhu, H.; Yang, K. Numerical investigation of compessible flow in a three-stage helico-axial multiphase pump. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2014, 45, 89–95. [Google Scholar] [CrossRef]

- Huang, S.; Su, X.; Guo, J.; Yue, L. Unsteady numerical simulation for gas–liquid two-phase flow in self-priming process of centrifugal pump. Energy Convers. Manag. 2014, 85, 694–700. [Google Scholar] [CrossRef]

- Sina, Y.; Xingqi, L.; Jianjun, F.; Guojun, Z.; Lefu, Z.; Senlin, C. Numerical Simulation of a Gas-Liquid Centrifugal Pump under Different Inlet Gas Volume Fraction Conditions. Int. J. Fluid Mach. Syst. 2019, 12, 56–63. [Google Scholar] [CrossRef]

- Launder, B.E.; Spalding, D.B. Lectures in Mathematical Model of Turbulence; Academic Press: Cambridge, MA, USA, 1972. [Google Scholar]

| Part | Hub Diameter at Inlet (mm) | Hub Diameter at Outlet (mm) | Shroud Diameter at Inlet (mm) | Shroud Diameter at Outlet (mm) |

|---|---|---|---|---|

| Impeller | 38 | 130 | 123 | 145.4 |

| Diffuser | 123 | 50 | 180 | 100 |

| (kg/s) | 0.2Q | 0.4Q | 0.6Q | 0.8Q | 1.0Q | 1.2Q | 1.4Q | 1.6Q |

|---|---|---|---|---|---|---|---|---|

| 0% | 7.78 | 15.56 | 23.33 | 31.11 | 38.89 | 46.67 | 54.44 | 62.22 |

| 1% | 7.7 | 15.4 | 23.1 | 30.8 | 38.5 | 46.2 | 53.9 | 31.9 |

| 3% | 7.54 | 15.09 | 22.63 | 30.18 | 37.72 | 45.28 | 52.81 | 60.36 |

| 5% | 7.39 | 14.78 | 22.17 | 29.56 | 16.94 | 44.33 | 51.72 | 59.11 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, X.; Yang, Y.; Shi, W.; Wu, S.; Jin, Y. Numerical Simulation Study on Flow Characteristics of Multistage Centrifugal Pumps under Different Inlet Gas Void Fractions. Sustainability 2023, 15, 15485. https://doi.org/10.3390/su152115485

Wu X, Yang Y, Shi W, Wu S, Jin Y. Numerical Simulation Study on Flow Characteristics of Multistage Centrifugal Pumps under Different Inlet Gas Void Fractions. Sustainability. 2023; 15(21):15485. https://doi.org/10.3390/su152115485

Chicago/Turabian StyleWu, Xianglong, Yongfei Yang, Weidong Shi, Sihao Wu, and Yongxin Jin. 2023. "Numerical Simulation Study on Flow Characteristics of Multistage Centrifugal Pumps under Different Inlet Gas Void Fractions" Sustainability 15, no. 21: 15485. https://doi.org/10.3390/su152115485

APA StyleWu, X., Yang, Y., Shi, W., Wu, S., & Jin, Y. (2023). Numerical Simulation Study on Flow Characteristics of Multistage Centrifugal Pumps under Different Inlet Gas Void Fractions. Sustainability, 15(21), 15485. https://doi.org/10.3390/su152115485