Flexural Strength of High-Performance Soil-Cement: A New, Alternative, Sustainable Construction Material

Abstract

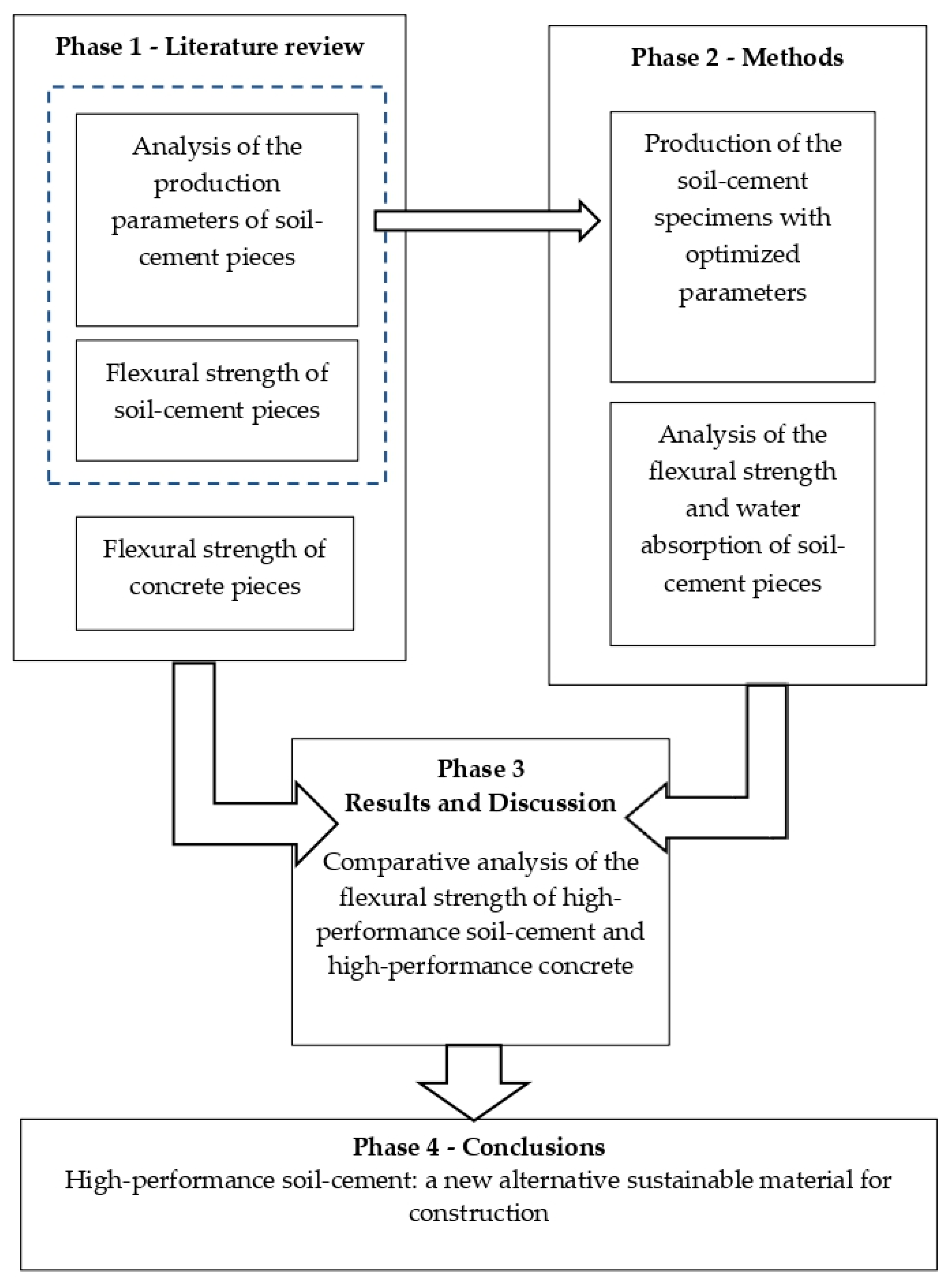

:1. Introduction

- To (a) review the literature on the relevant production parameters of soil-cement, their appropriate values, and the flexural strengths obtained when evaluated according to the test specified in ASTM C293 [28]; and (b) perform a limited literature review on the flexural strengths of HPC obtained as per ASTM C293 [28] and according to the cement content.

- To produce soil-cement specimens according to the appropriate parameters found in the literature (cement content, compaction pressure, moisture, and granulometry) and test them for flexural strength at different moments (7, 28, and 240 days), as per ASTM C293 [28], and evaluate the water absorption according to the NBR-13555 standard [29].

- To draw conclusions on the flexural strength of the HPSC produced and compare the results with those of HPC while considering cement consumption. If they are equivalent, HPSC could be a viable alternative to be considered for future new applications in construction.

2. Literature Review

2.1. Literature Review on the Production Parameters of Soil-Cement Pieces

- The compaction pressure—An increase in this parameter improves the strength of the soil-cement product [30]. According to the literature, the optimum values for compaction pressure are 4 to 10 MPa [31]. Studies of soil-cement produced with a compaction pressure over 10 Mpa were not found in the literature.

- 3.

- The amount of cement—Increasing the percentage of cement increases the strength [35], but it also increases its cost and environmental impact. To make a fair comparison between a soil-cement product and conventional concrete, it is necessary to know if both materials use a similar amount of cement to achieve the same strength. If similar amounts of cement are used on average, concrete would have a greater environmental impact. This is because, in addition to cement, other materials from mining (such as sand and gravel) that require transportation are used in concrete, and in many cases, chemical additives such as superplasticisers are also used [36]. Soil-cement consists of only two materials, soil, for the most part, and cement, and the soil can be extracted and reused from the construction site itself or nearby, thus reducing the need for transport and its consequent environmental impact. For this reason, it is essential to analyse whether the use of soil-cement for the production of construction pieces consumes similar amounts compared to producing concrete with a similar performance.

- 4.

- The granulometry of the soil—According to Venkatarama et al. [37], well-graded soils with percentages of clay lower than 15% should be used. According to Carvalho et al. [17], the ideal soil should allow the mass ratio of clay to cement in the soil-cement mixture to be 30%. Another possibility would be to use a grain size distribution adjusted to the theoretical particle size curve using the packing method [38].

2.2. Literature Review on the Flexural Strength of Soil-Cement Pieces

- Compaction pressure: The usual values in the literature, when found, ranged from 1 to 2.5 MPa. In several studies, it was difficult to find this data, and imprecise values were often reported. For example, in the studies by Jose et al. [40], it was mentioned that manual compaction was performed without specifying the compaction pressure. As explained earlier, this compaction pressure could reach up to 10 MPa to achieve the highest possible strengths [31].

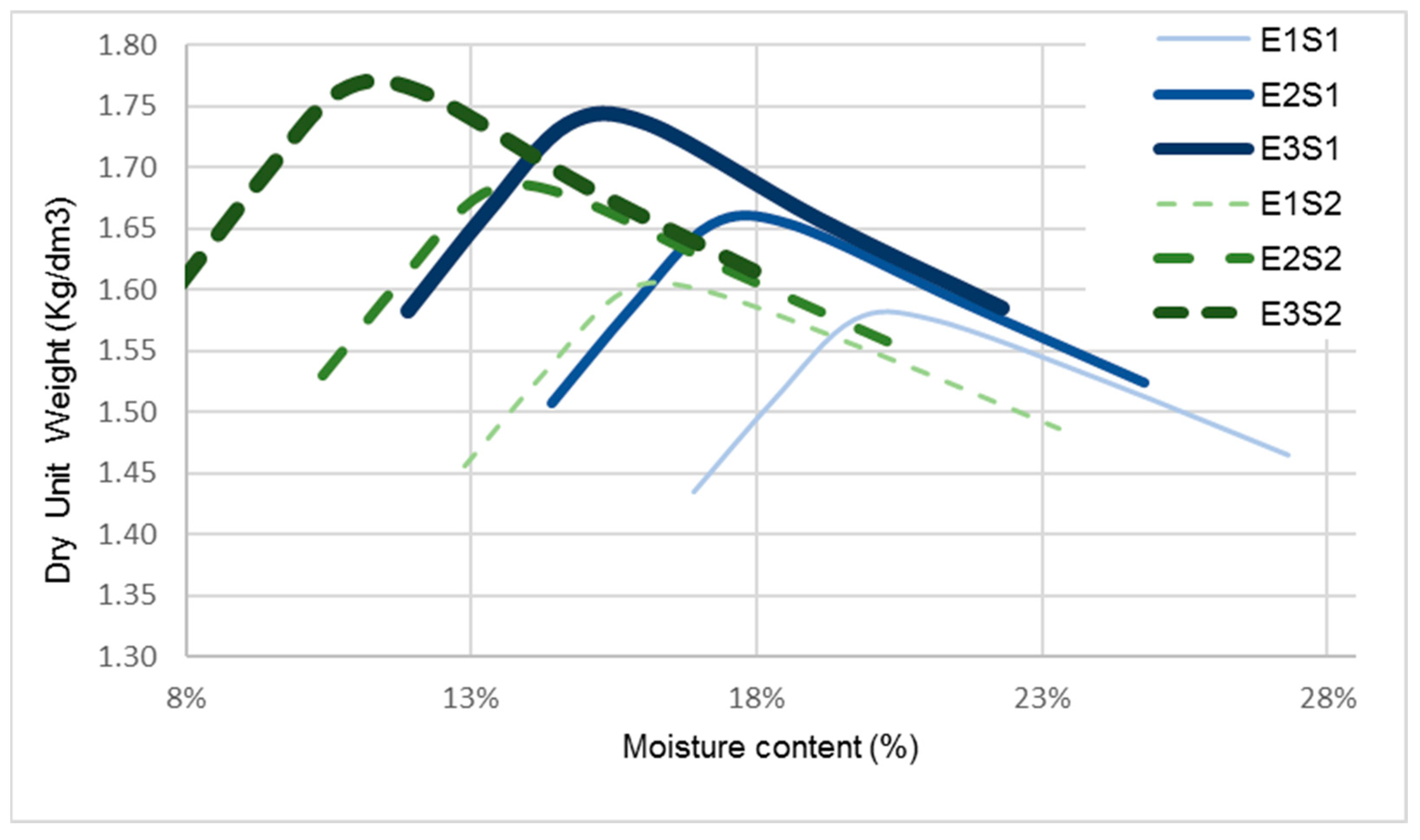

- Compaction moisture: It was described in two ways depending on the study, as the water-to-cement mass ratio (w/c) or as a percentage (%) of the weight of the dried piece. The w/c form is commonly used when producing concrete components. Lower w/c ratios are usually associated with higher strengths in concrete [21]. However, this is not always the case with soil-cement. As explained earlier, there is an optimum compaction moisture for a specific energy level and soil type (Figure 2). Typically, to facilitate the production process of soil-cement, the compaction moisture values used are below the optimum value. In this case, an increase in moisture (higher water content) would increase the compaction of the specimen and, consequently, its strength. Three studies directly described the values of compaction moisture as a percentage of the weight of the dried piece: Rocha et al. [23], with values of 13% moisture when using 30, 40, and 50% cement; Sitton et al. [41], with values of 11.4% moisture when using 10.9% cement; and Donkor et al. [42], with values of 9% moisture when using 8% cement. The specific optimum compaction moisture cannot be determined as it varies depending on the compaction energy used. However, when the compaction pressures are below 2.5 MPa, it is estimated that the moisture should be above 12% as in the study by Souza et al. [43].

- Cement percentage used: As previously explained, higher cement percentages result in higher strength. However, for environmental and cost reasons, this parameter should ideally be kept as low as possible. By examining some examples of concrete products [44,45], it was estimated that flexural strengths close to or greater than 6 MPa can be achieved with cement percentages ranging from 17 to 23%. In most of the soil-cement studies found, the cement percentage values are below 13%. Only in the studies by Rocha et al. [23], Namboonruang [46,47], and Ademati et al. [48] were higher cement percentages used.

| Reference | Dimensions of the Piece | Compaction Pressure (MPa) | Compaction Moisture | Cement Percentage (by Weight) | Flexural Strength (MPa) (at 28 Days of Age Unless Indicated Otherwise) |

|---|---|---|---|---|---|

| Jose, A. and Kasthurba, A. K. (2021a) [49] | 305 × 143 × 100 mm | 2.5 | w/c = 0.3 | 2.5 to 12.5% | <2 MPa |

| Namboonruang, W., Rawangkul, R., Yodsudjai, W., Suphadon, N., Boongurd, A., and Yong-Amnuai, P. (2013) [50] | 125 × 250 × 100 mm | - | w/c = 0.26 to 0.45 | 10% | <1.6 MPa |

| Rocha, H. J. A., Roa, J. P. B., de Carvalho, F. A., Junior, M. F. D. S. S., Gonçalves, H. H. A., Junior, A. C. L. A., and Prat, B. V. (2023) [23] | 140 × 60 × 40 mm | 1.2 MPa | Moisture 13% | 30% | 4.6 MPa at 120 days |

| 40% | 5.6 MPa at 120 days | ||||

| 50% | 5.8 MPa at 120 days | ||||

| Namboonruang, W., Rawangkul, R., Yodsudjai, W., and Suphadon, N. (2012a) [46] | 125 × 100 × 250 mm | - | w/c = 0.165 for 8% of cement w/c = 0.35 for 35% cement w/c = 0.45 for 50% cement | 8% | <1.5 at 28 days <2.0 at 360 days |

| 35% | 4.5 at 28 days 6.4 at 360 days | ||||

| 50% | <5.5 at 28 days <8.5 at 360 days | ||||

| Namboonruang, W., Rawangkul, R., and Yodsudjai, W. (2012b) [47] | 125 × 100 × 250 mm | - | w/c = 0.45 | 50% | <5.5 MPa at 28 days <7.5 MPa at 180 days |

| Curto, A., Lanzoni, L., Tarantino, A. M., and Viviani, M. (2020) [51] | 150 × 150 × 150 mm | - | - | 12.5% | < 2.28 MPa |

| Jose, A., and Kasthurba, A. K. (2021b) [40] | 305 × 143 × 100 mm | Manual Press | w/c = 0.3 | 2.5 to 12.5% | <3.5 MPa for 12.5% cement |

| Sitton, J. D., Zeinali, Y., Heidarian, W. H., and Story, B. A. (2018) [41] | 355 × 110 × 180 mm | - | 11.4% for 10.9% of cement | 3.6 to 10.9% | <2.01 MPa for 10.9% cement |

| Donkor, P., Obonyo, E., Matta, F., and Erdogmus, E. (2014) [42] | 413 × 102 × 102 mm | 1.6 MPa | 9% | 8% | < 1.03 MPa |

| Namboonruang, W., and Yongam-Nuai, P. (2016) [52] | 125 × 250 × 100 mm | - | w/c = 0.15 to 0.39 | 10% | <1.7 MPa at 200 days |

| Ademati, A. O., Akinwande, A. A., Balogun, O. A., and Romanovski, V. (2022) [48] | Clay Bricks | - | - | 24.82% | 1.98 MPa |

| Banker-Hix, W. A. (2014) [53] | - | - | - | 8 to 12% | <1 MPa |

| Dormohamadi, M. And Rahimnia, R. (2020) [54] | - | - | - | 0% | <2 MPa |

2.3. Literature Review on the Flexural Strength of High-Performance Concrete

| Reference | Cement (%) | Silica or Metakaolin (%) | Use of Superplasticizer (%) | Age (Days) | Flexural Strength by ASTM C293 Method (MPa) |

|---|---|---|---|---|---|

| Fares et al., 2020 [56] | 21.4% | 0 | 0.24% | 7 | 4.25 |

| 21.4% | 0 | 0.24% | 28 | 6 | |

| 21.4% | 0 | 0.24% | 90 | 7.8 | |

| Manigandan et al., 2021 [57] | 21.4% | 0 | 0 | 7 | 4.7 |

| 21.4% | 0 | 0 | 28 | 6 | |

| 21.4% | 0 | 0 | 56 | 6.5 | |

| Hilles and Ziara, 2019 [58] | 28.57% | 0 | 2% | 7 | 4.84 |

| 28.57% | 0 | 2% | 28 | 6.35 | |

| Wang et al., 2022 [59] | 34% | 10% of silica fume | 3.1% | 14 | 17.46 |

| 34% | 10% of silica fume | 3.1% | 28 | 17.89 | |

| Aghayari et al., 2019 [60] | 42.8% | 6.4% of silica fume | 3% | 28 | 14.28 |

3. Materials and Methods

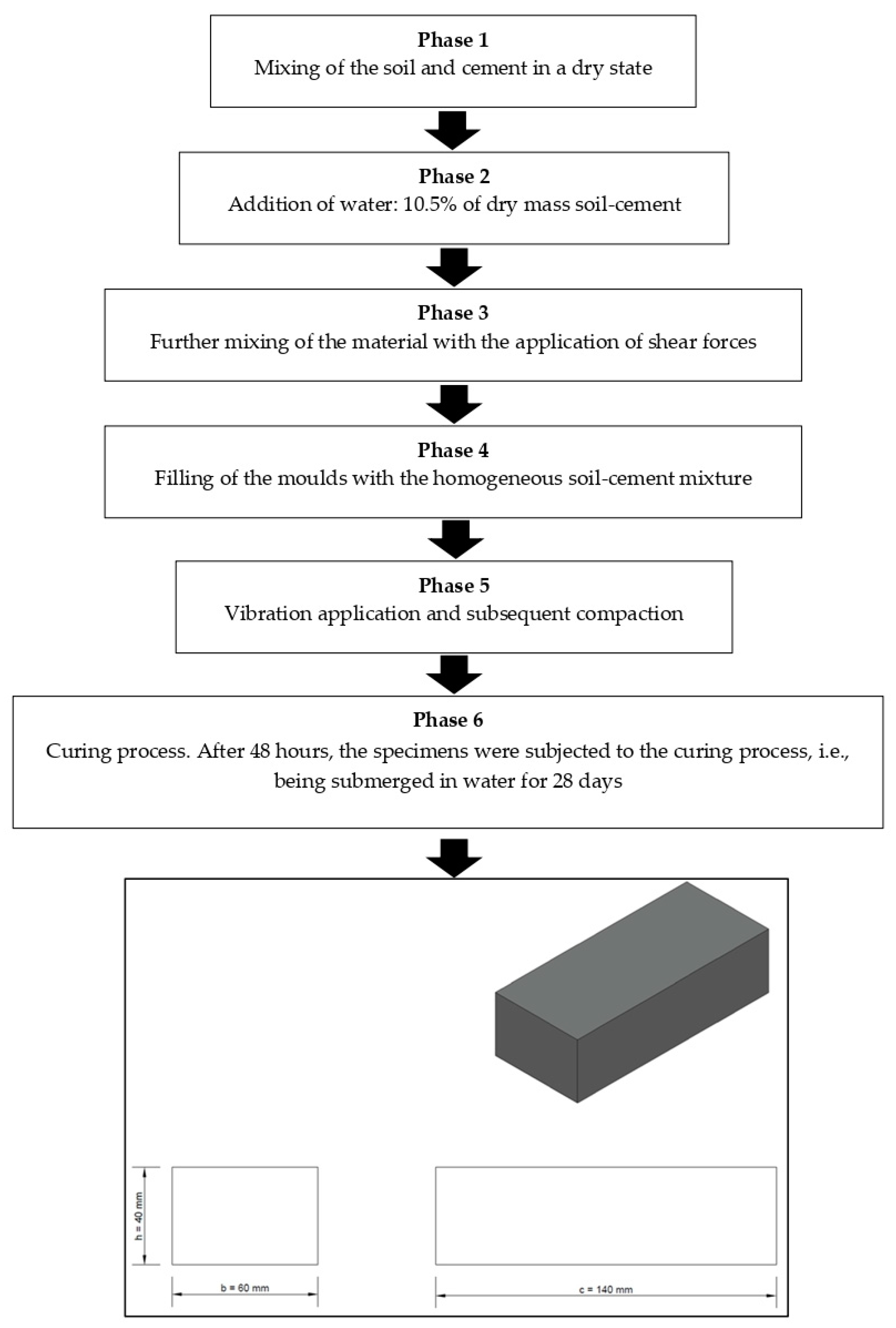

3.1. Phase 1–Production of the Specimens

- (1)

- The soil and cement were mixed in a dry state until a homogeneous mass was obtained.

- (2)

- Water was added to obtain the optimal compaction moisture content (10.5%).

- (3)

- The material was mixed further with the application of shear forces to ensure that the clay contained in the soil was homogeneously mixed. The clay fraction has a high specific surface area which increases soil cohesion due to the attraction between particles through electrostatic forces [64]. The application of shear forces during the mixing process promotes the rupture of soil aggregates and, consequently, the individualisation of clay particles, obtaining a more homogeneous soil-cement mixture.

- (4)

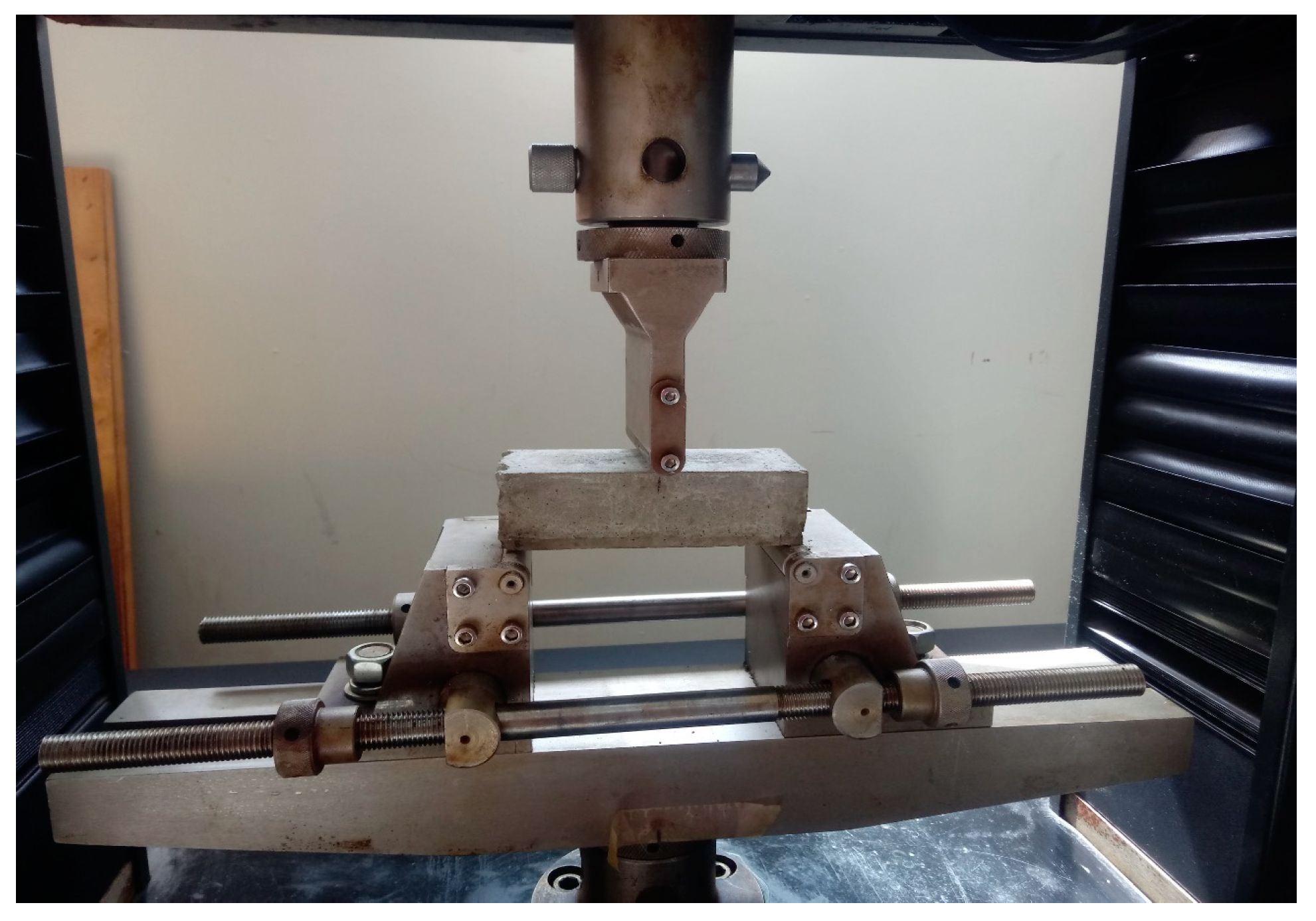

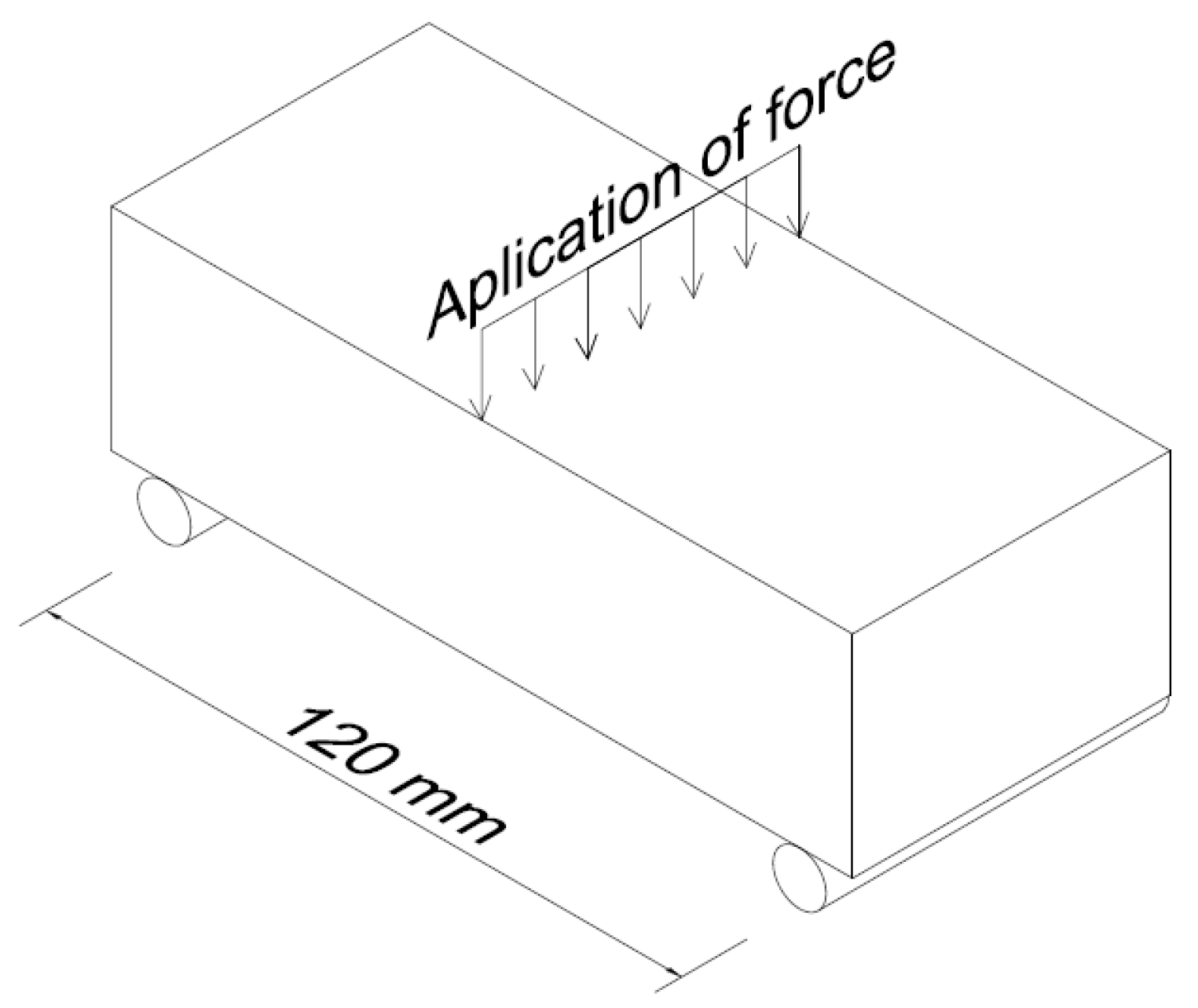

- The moulds were filled with the homogeneous soil-cement mixture. Figure 3 shows the dimensions of the specimens produced according to the ASTMC293 standard (60 mm × 40 mm × 140 mm).

- (5)

- Vibration application and subsequent compaction were performed using a hydraulic press. The applied pressure was 10 MPa, as recommended by Fay et al. [31], for a minimum time of 60 s.

- (6)

- The specimens were placed on a bench for 48 h in a room with a controlled environment with an average temperature of 20 °C and humidity above 50%. This is the observed necessary time for the specimen to not undergo changes when submerged. After the 48 h, the specimens were subjected to the curing process by being submerged in water for 28 days. A longer curing period was chosen instead of the usual 7 days to ensure the correct hydration of the cement.

- (7)

- Subsequently, the specimens were placed in the laboratory at room temperature before being tested for strength and water absorption. Only the specimens that were tested at 7 days of age were submerged in water for fewer days in order to test their breakage.

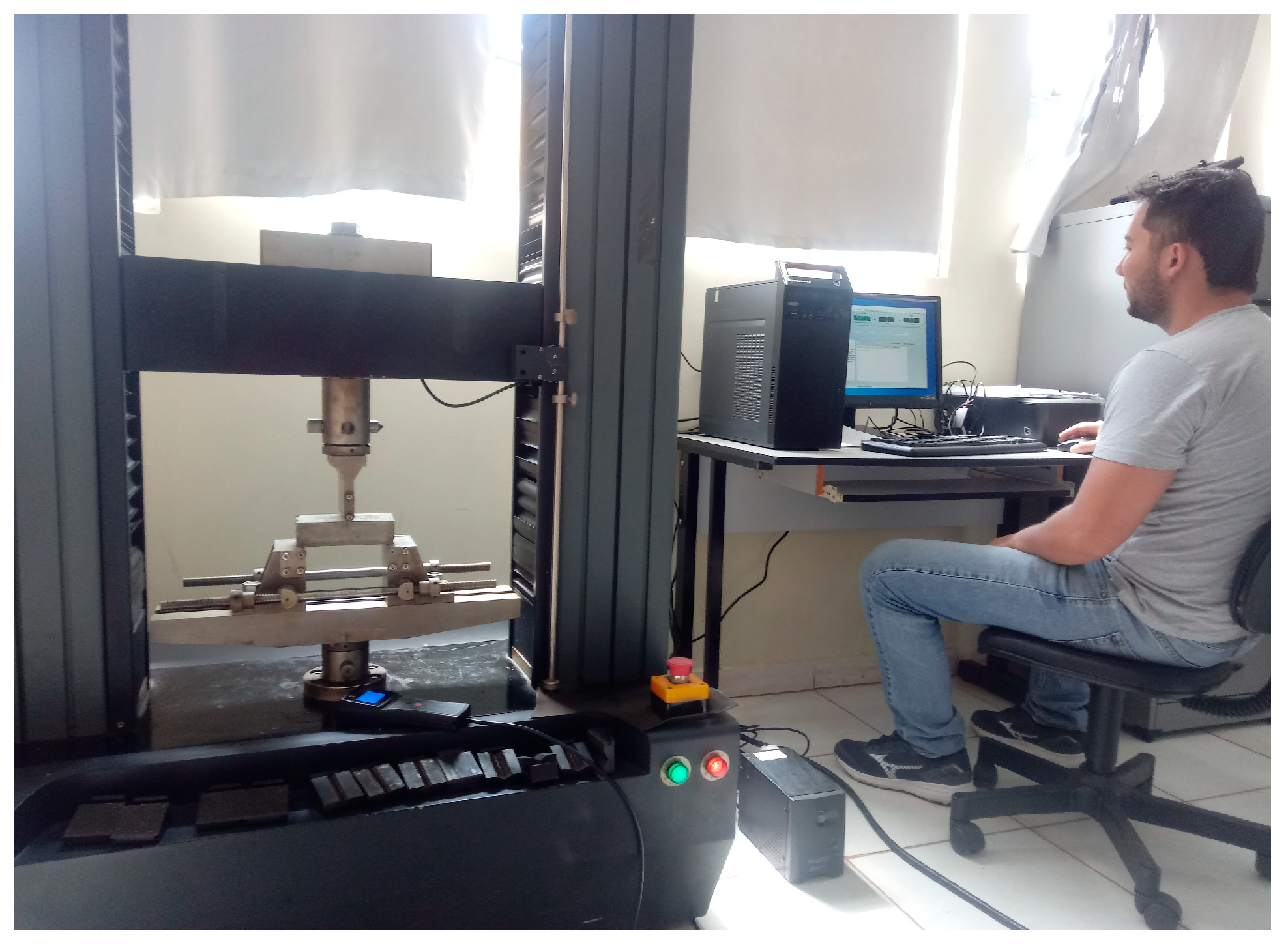

3.2. Phase 2–Analysis of Flexural Strength and Water Absorption

4. Results and Discussion

- (1)

- The flexural strengths at only 7 days of age already exceeded values of 2.5 MPa for the four specimens tested. As shown in the previous data from the literature review on the flexural strength of soil-cement (Table 1), the values at 28 days are typically below 2.5 MPa. These values can therefore be considered high-performance values for a soil-cement mixture [17].

- (2)

- On average, when the age of the specimens is 240 days, the flexural strength values increased by 83% compared to the results at 28 days of age. These values are similar to the compressive strength gains obtained in soil-cement blocks in other studies [43].

- (3)

- The water absorption values were below 8%, which enabled this soil-cement to be considered HPSC [17]. The deviation of the water absorption parameter was low when compared to its average, having a deviation of less than 5% of the mean value. This is due to the use of optimal compaction moisture (10.5%) and constant compaction pressure (10 MPa).

- (4)

- It has been observed in other studies [3] that a lower water absorption leads to a higher flexural strength. However, in this study, the variation in water absorption was minimal due to the consistent mixture type, compaction energy, and moisture content. Therefore, it can be considered that the variation in flexural strength may be attributed to other parameters such as dimensional error and/or imperfect sample homogeneity.

- (5)

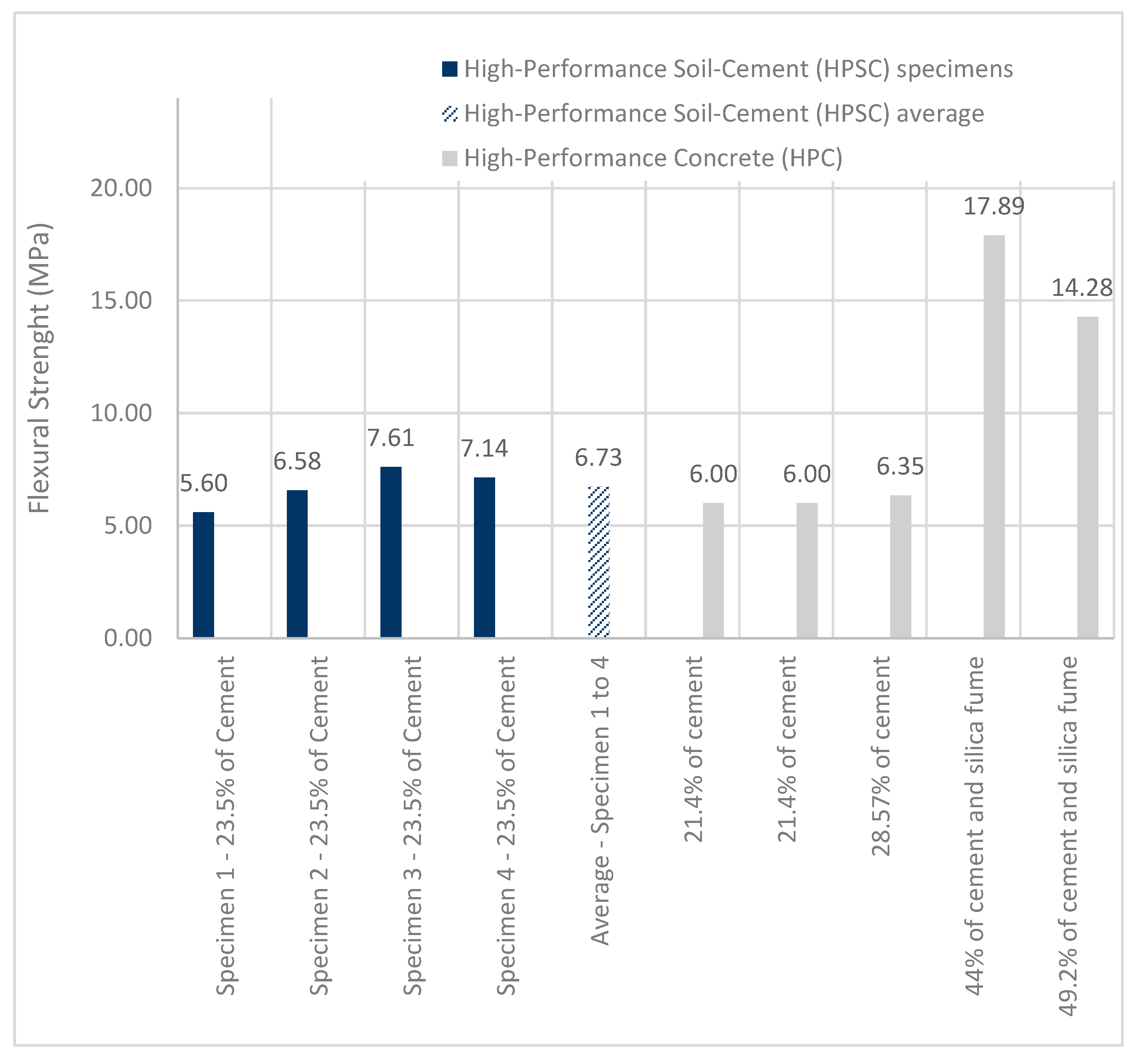

- The flexural strength values of these specimens were compared with those of the studies found in the literature review (Section 2 of the present study). Looking at the values from the literature review of soil-cement specimens with specific flexural tests according to the ASTM C293 standard [28], only three studies yielded similar strengths [23,46,47]. However, even in these cases, strengths above 6 MPa at 28 days were not achieved, and the amount of cement used in many cases was much higher (up to 50% cement). It is worth noting that in this study, a strength of 6.73 MPa was achieved at 28 days with a cement content of 23.5%. When comparing these findings with other soil-cement studies, the strengths in the present study were also significantly higher, as in Otoko’s study [65], a strength of 1.21 MPa was obtained with a 12% cement mixture; Gutiérrez et al. [66] achieved 0.67 MPa using 9% cement, and Venkatarama et al. [27] obtained 1.22 MPa with a 12% cement content. This seems to be due to the fact that, in the present study, the specimens were produced according to all the appropriate parameters found in the literature mentioned in Section 2.2.

Comparative Analysis of the Flexural Strength of the High-Performance Soil-Cement and the High-Performance Concrete

- (1)

- Compaction pressure of 10 MPa maintained for at least 60 s;

- (2)

- Use of 23.5% cement in a mixture with sandy soil and 10.5% clay;

- (3)

- Granulometry of the soil-cement mixture based on the packing method with a coefficient q = 0.325 [38];

- (4)

- Optimal compaction moisture content of 10.5%. This optimal moisture has been obtained for and is applicable to this type of mixture (sandy soil with 10.5% clay and for the compaction energy exerted under a pressure of 10 MPa maintained for a minimum time of 60 s).

5. Conclusions

6. Limitations and Recommendations for Future Research

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Giorgi, P.; Grigoletti, G.D.C.; Lima, R.C.A.D.; Lorenzi, L.S. Avaliação de sustentabilidade e habitabilidade de blocos de solo-cimento segundo a norma ABNT NBR 15575. Matéria 2018, 23, e12177. [Google Scholar] [CrossRef]

- Negreiros, R.L.; Nunes, K.G.; Bispo, C.; de Morais, A. Comparativo sustentável e econômico entre a utilização do tijolo solo-cimento e o tijolo cerâmico de vedação em habitação de interesse social na cidade de teófilo otoni-mg. Rev. Multidiscip. Nordeste Min.–Unipac ISSN 2018, 2178, 6925. [Google Scholar] [CrossRef]

- Vilela, A.P.; Eugênio, T.M.C.; de Oliveira, F.F.; Mendes, J.F.; Ribeiro, A.G.C.; Brandão, L.E.V.D.S.; Mendes, R.F. Technological properties of soil-cement bricks produced with iron ore mining waste. Constr. Build. Mater. 2020, 262, 120883. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; EIRES, R.; Jalali, S. Construção em Terra; Universidade do Minho. TecMinho: Braga, Portugal, 2009. [Google Scholar]

- San Fratello, V.; Rael, R. Innovating materials for large scale additive manufacturing: Salt, soil, cement and chardonnay. Cem. Concr. Res. 2020, 134, 106097. [Google Scholar] [CrossRef]

- Obonyo, E.; Exelbirt, J.; Baskaran, M. Durability of compressed earth bricks: Assessing erosion resistance using the modified spray testing. Sustainability 2010, 2, 3639–3649. [Google Scholar] [CrossRef]

- Augusto Euphrosino, C.; Jacintho, A.E.P.G.D.A.; Lorena Pimentel, L.; Camarini, G.; Fontanini, P.S.P. Tijolos de solo-cimento usados para Habitação de Interesse social (HIS) em mutirão: Estudo de caso em olaria comunitária. Matéria 2022, 27, e202147087. [Google Scholar] [CrossRef]

- Hammond, G.; Jones, C. A BSRIA guide. Embodied Carbon. In The Inventory of Carbon and Energy (ICE); University of Bath and BSRIA: Bath/Bracknell, UK, 2011. [Google Scholar]

- Nascimento, E.S.S.; de Souza, P.C.; de Oliveira, H.A.; Júnior, C.M.M.; de Oliveira Almeida, V.G.; de Melo, F.M.C. Soil-cement brick with granite cutting residue reuse. J. Clean. Prod. 2021, 321, 129002. [Google Scholar] [CrossRef]

- Rocha, J.H.A.; Galarza, F.P.; Chileno, N.G.C.; Rosas, M.H.; Peñaranda, S.P.; Diaz, L.L.; Abasto, R.P. Compressive strength assessment of soil–cement blocks incorporated with waste tire steel fiber. Materials 2022, 15, 1777. [Google Scholar] [CrossRef] [PubMed]

- Jeyasegaram, S.; Sathiparan, N. Influence of soil grading on the mechanical behavior of earth cement blocks. MRS Adv. 2020, 5, 2771–2782. [Google Scholar] [CrossRef]

- Sanbonsuge, K.; Vasconcelos, K.; Bernucci, L.; de Moura, E. Efeito da umidade inicial e do tempo de cura nas propriedades mecânicas de misturas solo-cimento. Transportes 2017, 25, 68–82. [Google Scholar] [CrossRef]

- Linares-Unamunzaga, A.; Pérez-Acebo, H.; Rojo, M.; Gonzalo-Orden, H. Flexural strength prediction models for soil–cement from unconfined compressive strength at seven days. Materials 2019, 12, 387. [Google Scholar] [CrossRef] [PubMed]

- Kim, B.I.; Wee, S.H.; Lee, S.H.; Kim, Y.U. Strength characteristics of soil-cement mixed with inorganic solidification liquid. KSCE J. Civ. Environ. Eng. Res. 2003, 23, 135–141. [Google Scholar]

- Farouk, A.; Shahien, M.M. Ground improvement using soil–cement columns: Experimental investigation. Alex. Eng. J. 2013, 52, 733–740. [Google Scholar] [CrossRef]

- Thoma, A.C.; Tassinari, D.; Prat, B.V.; Fernandes, J.S.C.; Silva, A.C. Erodibilidade de Neossolo Litólico pelo ensaio de Inderbitzen modificado e eficiência de blocos de solo-cimento para controle da erosão hídrica. Eng. Sanit. Ambient. 2022, 27, 511–522. [Google Scholar] [CrossRef]

- De Carvalho, F.A.; Silva, A.C.; Roa, J.P.B.; Prat, B.V. Caracterização Do Solo-Cimento De Alto Desempenho (Scad): Alternativa Construtiva Nos Vales De Jequitinhonha-Mg. Revista Vozes dos Vales: Publicações Acadêmicas. 2022. Available online: https://www.researchgate.net/publication/360876857_CARACTERIZACAO_DO_SOLO-CIMENTO_DE_ALTO_DESEMPENHO_SCAD_ALTERNATIVA_CONSTRUTIVA_NOS_VALES_DE_JEQUITINHONHA_-MG (accessed on 22 August 2023).

- Isaia, G.C.; Helene, P.; Tutikian, B.F. Concreto de alto e ultra-alto desempenho. Concreto Ciência E Tecnol. Cap 2011, 36, 1–44. [Google Scholar]

- Sohail, M.G.; Wang, B.; Jain, A.; Kahraman, R.; Ozerkan, N.G.; Gencturk, B.; Dawood, M.; Belarbi, A. Advancements in concrete mix designs: High-performance and ultrahigh-performance concretes from 1970 to 2016. J. Mater. Civ. Eng. 2018, 30, 04017310. [Google Scholar] [CrossRef]

- Kumar Mehta, P.; Aietcin, P.C. Principles underlying production of high-performance concrete. Cem. Concr. Aggreg. 1990, 12, 70–78. [Google Scholar] [CrossRef]

- Neville, A.M. Propriedades do Concreto, 5th ed.; Bookman Editora: Porto Alegre, Brazil, 2015. [Google Scholar]

- Duong, T.H.; Vo, H.N.; Tran, D.T. Studying the Strength of an Acidic Soil-Cement Mixing in Laboratory. In Modern Mechanics and Applications: Select Proceedings of ICOMMA 2020; Springer: Singapore, 2022; pp. 716–730. [Google Scholar]

- Rocha, H.J.A.; Roa, J.P.B.; de Carvalho, F.A.; Junior, M.F.D.S.S.; Gonçalves, H.H.A.; Junior, A.C.L.A.; Prat, B.V. Evaluation of flexural-tensile strength of high-performance soil-cement (HPSC) specimen bodies. Cuad. Educ. Y Desarro. 2023, 15, 1904–1924. [Google Scholar] [CrossRef]

- Venkatarama Reddy, B.V.; Lal, R.; Nanjunda Rao, K.S. Optimum soil grading for the soil-cement blocks. J. Mater. Civ. Eng. 2007, 19, 139–148. [Google Scholar] [CrossRef]

- Khedari, J.; Watsanasathaporn, P.; Hirunlabh, J. Development of fibre-based soil–cement block with low thermal conductivity. Cem. Concr. Compos. 2005, 27, 111–116. [Google Scholar] [CrossRef]

- Venkatarama Reddy, B.V.; Gupta, A. Tensile bond strength of soil-cement block masonry couplets using cement-soil mortars. J. Mater. Civ. Eng. 2006, 18, 36–45. [Google Scholar] [CrossRef]

- Venkatarama Reddy, B.V.; Gupta, A. Characteristics of soil-cement blocks using highly sandy soils. Mater. Struct. 2005, 38, 651–658. [Google Scholar] [CrossRef]

- ASTM C293/C293M-16; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Center-Point Loading). ASTM Int.: West Conshohocken, PA, USA, 2016.

- Associação Brasileira De Normas Técnicas. NBR 13555: Solo-Cimento: Determinação da Absorção de Água: Método de Ensaio; Associação Brasileira De Normas Técnicas: Rio de Janeiro, Brazil, 2012; p. 1. [Google Scholar]

- Mahdad, M.; Benidir, A. Hydro-mechanical properties and durability of earth blocks: Influence of different stabilisers and compaction levels. Int. J. Sustain. Build. Technol. Urban Dev. 2018, 9, 44–60. [Google Scholar]

- Fay, L.; Cooper, P.; de Morais, H.F. Innovative interlocked soil–cement block for the construction of masonry to eliminate the settling mortar. Constr. Build. Mater. 2014, 52, 391–395. [Google Scholar] [CrossRef]

- Baldovino, J.D.J.A.; Izzo, R.L.D.S.; Pereira, M.D.; Rocha, E.V.D.G.; Rose, J.L.; Bordignon, V.R. Equations controlling tensile and compressive strength ratio of sedimentary soil–cement mixtures under optimal compaction conditions. J. Mater. Civ. Eng. 2020, 32, 04019320. [Google Scholar] [CrossRef]

- Venkatarama Reddy, B.V.; Prasanna Kumar, P. Cement stabilised rammed earth. Part A: Compaction characteristics and physical properties of compacted cement stabilised soils. Mater. Struct. 2011, 44, 681–693. [Google Scholar] [CrossRef]

- de Sousa Pinto, C. Curso Básico de Mecânica dos Solos; Oficina de Textos: São Paulo, Brazil, 2016. [Google Scholar]

- Walker, P.; Stace, T. Properties of some cement stabilised compressed earth blocks and mortars. Mater. Struct. 1997, 30, 545–551. [Google Scholar] [CrossRef]

- Huang, H.; Yuan, Q.; Deng, D.; Peng, J.; Huang, Y. Effects of chemical and mineral admixtures on the foam indexes of cement-based materials. Case Stud. Constr. Mater. 2019, 11, e00232. [Google Scholar] [CrossRef]

- Venkatarama Reddy, B.V.; Latha, M.S. Influence of soil grading on the characteristics of cement stabilised soil compacts. Mater. Struct. 2014, 47, 1633–1645. [Google Scholar] [CrossRef]

- Lopes, H.M.T.; Peçanha, A.C.C.; Castro, A.L.D. Considerações sobre a eficiência de misturas de concreto de cimento Portland com base no conceito de empacotamento de partículas. Matéria 2020, 25, e12549. [Google Scholar] [CrossRef]

- França, B.R.; Azevedo, A.R.G.; Monteiro, S.N.; Garcia Filho, F.D.C.; Marvila, M.T.; Alexandre, J.; Zanelato, E.B. Durability of soil-cement blocks with the incorporation of limestone residues from the processing of marble. Mater. Res. 2018, 21, e20171118. [Google Scholar] [CrossRef]

- Jose, A.; Kasthurba, A.K. Stabilization of lateritic soil for masonry applications. Mag. Civ. Eng. 2021, 1, 10109. [Google Scholar]

- Sitton, J.D.; Zeinali, Y.; Heidarian, W.H.; Story, B.A. Effect of mix design on compressed earth block strength. Constr. Build. Mater. 2018, 158, 124–131. [Google Scholar] [CrossRef]

- Donkor, P.; Obonyo, E.; Matta, F.; Erdogmus, E. Effect of Polypropylene fiber length on the flexural and compressive strength of compressed stabilized earth blocks. In Proceedings of the Construction Research Congress 2014: Construction in a Global Network, Atlanta, GA, USA, 19–21 May 2014; pp. 661–670. [Google Scholar]

- Souza, M.I.; Segantini, A.A.; Pereira, J.A. Tijolos prensados de solo-cimento confeccionados com resíduos de concreto. Rev. Bras. Eng. Agrícola E Ambient. 2008, 12, 205–212. [Google Scholar] [CrossRef]

- Islam, A.; Shuvo, A.K.; Chowdhury, S.A.; Sharmin, S.; Hasan, M. A comparative study on the properties of natural, synthetic and steel fibre reinforced concrete. J. Civ. Eng. Constr. 2021, 10, 216–224. [Google Scholar] [CrossRef]

- Yaowarat, T.; Horpibulsuk, S.; Arulrajah, A.; Mirzababaei, M.; ARashid, A.S. Compressive and flexural strength of polyvinyl alcohol–modified pavement concrete using recycled concrete aggregates. J. Mater. Civ. Eng. 2018, 30, 04018046. [Google Scholar] [CrossRef]

- Namboonruang, W.; Rawangkul, R.; Yodsudjai, W.; Suphadon, N. 1 Year Long Term on Strength Properties of Pozzolanics Local Soil Bricks. Adv. Mater. Res. 2012, 399, 1381–1385. [Google Scholar] [CrossRef]

- Namboonruang, W.; Rawangkul, R.; Yodsudjai, W. Strength properties of low thermal conductivity fly ash bricks: Compressive and flexural strength aspects. Appl. Mech. Mater. 2012, 117, 1352–1357. [Google Scholar] [CrossRef]

- Ademati, A.O.; Akinwande, A.A.; Balogun, O.A.; Romanovski, V. Optimization of bamboo fiber–reinforced composite-clay bricks for development of low-cost farm settlements toward boosting rural agribusiness in Africa. J. Mater. Civ. Eng. 2022, 34, 04022335. [Google Scholar] [CrossRef]

- Jose, A.; Kasthurba, A.K. Laterite soil-cement blocks modified using natural rubber latex: Assessment of its properties and performance. Constr. Build. Mater. 2021, 273, 121991. [Google Scholar] [CrossRef]

- Namboonruang, W.; Rawangkul, R.; Yodsudjai, W.; Suphadon, N.; Boongurd, A.; Yong-Amnuai, P. Properties of Crumb Rubber Mixed in Local Thailand Soil Cement Brick Composites. Adv. Mater. Res. 2013, 821, 1271–1276. [Google Scholar] [CrossRef]

- Curto, A.; Lanzoni, L.; Tarantino, A.M.; Viviani, M. Shot-earth for sustainable constructions. Constr. Build. Mater. 2020, 239, 117775. [Google Scholar] [CrossRef]

- Namboonruang, W.; Yongam-Nuai, P. Thermal, strength and leachability characteristics of cellulose fibre reinforced lime-soil brick. Key Eng. Mater. 2016, 703, 386–395. [Google Scholar] [CrossRef]

- Banker-Hix, W.A. The Effect of Clay, Cement and Fibers on the Strength and Durability of Compressed Earth Blocks. Master’s Thesis, California Polytechnic State University, San Luis Obispo, CA, USA, 2014. [Google Scholar]

- Dormohamadi, M.; Rahimnia, R. Combined effect of compaction and clay content on the mechanical properties of adobe brick. Case Stud. Constr. Mater. 2020, 13, e00402. [Google Scholar] [CrossRef]

- Mashrei, M.A.; Sultan, A.A.; Mahdi, A.M. Effects of polypropylene fibers on compressive and flexural strength of concrete material. Int. J. Civ. Eng. Technol. 2018, 9, 2208–2217. [Google Scholar]

- Fares, G.; Albaroud, M.H.; Khan, M.I. Fine limestone dust from ornamental stone factories: A potential filler in the production of High-Performance Hybrid Fiber-Reinforced Concrete. Constr. Build. Mater. 2020, 262, 120009. [Google Scholar] [CrossRef]

- Manigandan, S.; Praveenkumar, T.R.; Al-Mohaimeed, A.M.; Brindhadevi, K.; Pugazhendhi, A. Characterization of polyurethane coating on high performance concrete reinforced with chemically treated Ananas erectifolius fiber. Prog. Org. Coat. 2021, 150, 105977. [Google Scholar]

- Hilles, M.M.; Ziara, M.M. Mechanical behavior of high strength concrete reinforced with glass fiber. Eng. Sci. Technol. Int. J. 2011, 22, 920–928. [Google Scholar] [CrossRef]

- Wang, W.C.; Huang, Y.; Lee, M.G.; Wang, Y.C.; Kan, Y.C.; Hsiao, Y.C.; Chang, H.W. Case study for ditch cover with ultra-high-performance concrete. Case Stud. Constr. Mater. 2022, 17, e01647. [Google Scholar] [CrossRef]

- Aghayari, R.; AL-Mwanes, A.O. An Experimental Investigation of Mechanical Properties of The Ultra-High Performance Fiber Reinforced Concrete (UHPFRC). Civ. Environ. Res. 2019, 11, 1–10. [Google Scholar]

- Prat, B.V.; Roa, J.P.B.; Silva, A.C.; Carvalho, F.A.; Freitas, N.S. Categoria: Produto e Processo. Instituição onde foi depositada: INPI—Instituto Nacional da Propriedade Industrial. País: Brasil BR1020230060722, 31 March 2023. [Google Scholar]

- Embrapa. Sistema Brasileiro de Classificação de Solos, 3rd ed.; dos Santos, H.G., Ed.; Embrapa: Brasília, DF, Brazil, 2013; 353p. [Google Scholar]

- Funk, J.E.; Dinger, D. Predictive Process Control of Crowded Particulate Suspensions: Applied to Ceramic Manufacturing; Springer Science & Business Media: New York, NY, USA, 1994. [Google Scholar]

- Silva, A.J.N.D.; Carvalho, F.G.D. Coesão e resistência ao cisalhamento relacionadas a atributos físicos e químicos de um Latossolo Amarelo de tabuleiro costeiro. Rev. Bras. Ciência Solo 2007, 31, 853–862. [Google Scholar] [CrossRef]

- Otoko, G.R. The use of laterites for production of soil-cement blocks. Int. J. Eng. Technol. Res. 2014, 2, 1–11. [Google Scholar]

- Gutiérrez-Orrego, D.A.; Garcia-Aristizabal, E.F.; Gomez-Botero, M.A. Mechanical and physical properties of soil-cement blocks reinforced with mineral wool and sisal fiber. J. Mater. Civ. Eng. 2017, 29, 04016225. [Google Scholar] [CrossRef]

| % Material | % of Cumulative Retained Material | Sieve Opening (mm) | % of Actual Passing Material | % of Theoretical Passing Material * | |

|---|---|---|---|---|---|

| Clay (grain size < 0.002 mm) | 6.9 | 100 | 0.00005 | 0 | 0 |

| Cement (grain size 0.002 to 0.06 mm) with uniform distribution | 23.5 | 93.1 | 0.002 | 6.9 | 7.2 |

| Fine sand (grain size 0.075 to 0.3 mm) with uniform distribution | 32.5 | 69.6 | 0.075 | 30.4 | 30.4 |

| Coarse sand (grain size 0.6 to 2.38 mm) with uniform distribution | 37.1 | 37.1 | 0.6 | 62.9 | 62.8 |

| Flexural Strength (MPa) | Water Absorption (%) | |||

|---|---|---|---|---|

| 7 days | 28 days | 240 days | 240 days | |

| 4.042 | 5.601 | 10.74 | 3.13 | |

| 4.281 | 6.577 | 12.23 | 3.33 | |

| 4.960 | 7.610 | 13.87 | 3.29 | |

| 4.750 | 7.141 | 12.52 | 3.22 | |

| 4.51 | 6.73 | 12.34 | 3.30 | |

| 0.421 | 0.864 | 1.284 | 0.09 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vinolas, B.; Casanovas-Rubio, M.d.M.; Silva, A.C.; Bretas Roa, J.P.; Andrade, A.C.L.; Carvalho, F.A.d.; Gonçalves, H.H.A.; Rocha, H.J.A. Flexural Strength of High-Performance Soil-Cement: A New, Alternative, Sustainable Construction Material. Sustainability 2023, 15, 15369. https://doi.org/10.3390/su152115369

Vinolas B, Casanovas-Rubio MdM, Silva AC, Bretas Roa JP, Andrade ACL, Carvalho FAd, Gonçalves HHA, Rocha HJA. Flexural Strength of High-Performance Soil-Cement: A New, Alternative, Sustainable Construction Material. Sustainability. 2023; 15(21):15369. https://doi.org/10.3390/su152115369

Chicago/Turabian StyleVinolas, Bernat, Maria del Mar Casanovas-Rubio, Alexandre Christofaro Silva, Juan Pedro Bretas Roa, Alan Cardek Lopes Andrade, Frank A. de Carvalho, Hugo Henrique A. Gonçalves, and Helton John A. Rocha. 2023. "Flexural Strength of High-Performance Soil-Cement: A New, Alternative, Sustainable Construction Material" Sustainability 15, no. 21: 15369. https://doi.org/10.3390/su152115369

APA StyleVinolas, B., Casanovas-Rubio, M. d. M., Silva, A. C., Bretas Roa, J. P., Andrade, A. C. L., Carvalho, F. A. d., Gonçalves, H. H. A., & Rocha, H. J. A. (2023). Flexural Strength of High-Performance Soil-Cement: A New, Alternative, Sustainable Construction Material. Sustainability, 15(21), 15369. https://doi.org/10.3390/su152115369