Sustainable Technology Strategies for Transportation and Logistics Challenges: An Implementation Feasibility Study

Abstract

:1. Introduction

2. Literature Review

2.1. COVID-19 and Logistics Industry

2.2. Challenges and Driving Forces in the Logistics Industry

3. Methodology

Data Collection and Analysis

4. Findings and Discussion

4.1. Challenges Faced by Logistics Sector

4.1.1. Declining Revenues

“So, if we see this scenario, all type of dispatches of logistics including primary, secondary, inbound, outbound, all dispatches were declined because of production units and warehouses were closed which effected the businesses.”

4.1.2. Reduced Import and Export

“Second import, export orders reduced because of worldwide bans at all geographical locations … as initially the virus started from China … within Pakistan closure of Port Qasim as well as clearance issues related to customs impacted the (logistics) industry.”

4.1.3. Reduced Local Market Dispatch Orders across Pakistan

4.1.4. Limited Supplies—Food and Beverages Only

“During COVID-19, if we see that only the industries that were generating the logistic dispatch orders were affinity food and beverage industries, that was also globally running whereas import and export orders were reduced, local market orders were limited, raw material orders were reduced. Hygiene product orders were increased across Pakistan.”

| Type of Supplies | Logistic Operations during COVID-19 |

|---|---|

| Food and Beverage | Only supplies which were running globally |

| Import and Export | Reduced supplies |

| Local Market Orders | Limited orders |

| Raw material | Reduced and limited |

| Medicine and devices | Increased orders |

| Health and Care | Increased orders |

| E-Commerce | Increased orders |

4.1.5. Increased E-Commerce Business

4.1.6. Training Issues

“Most of them (employees) are illiterate, so it was a big challenge and a hurdle or a bottleneck to provide awareness to these people regarding COVID-19 and change in the work procedures.”

4.1.7. Lack of Relevant Standard Operating Procedures (SOPs)

4.1.8. Inefficient Operational Areas

4.1.9. Performance Management of Drivers

“It was also a big challenge during COVID how to monitor the drivers, how to monitor their performance and incentivize them. So, if you see that we found two types of culture in logistics, one is the corporate culture, the other one is “Seith” (illiterate boss of a company) culture.”

4.1.10. New Entrants in Market–Business Reshaping

“We have seen new entrants in the market as their actual businesses went unprofitable or shut down because of COVID-19 restrictions for example in logistic market a new company entered called momentum logistics. The owners of this company had a different business before which was apparel manufacturing. So, such new entrants reduced the market share and profits for the existing companies in this sector.”

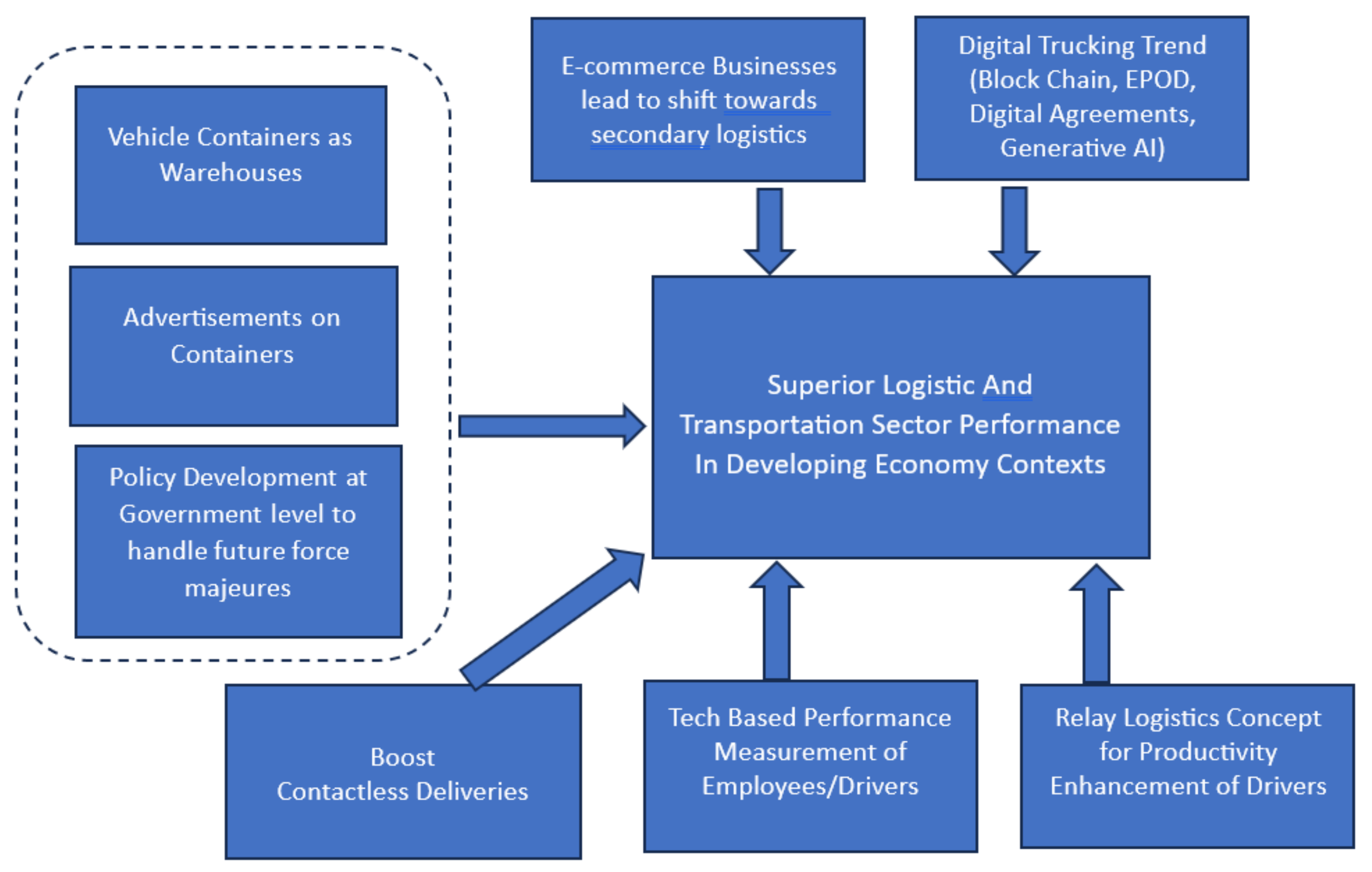

4.2. Sustainable Strategies

4.2.1. Focus on Increased Revenue Post-Pandemic

- Electronic ads or screens on vehicle containers may help to increase the revenue and revive business post-pandemic.

- Allowing local businesses and brands to paint their brand image and advertisements on containers may also help increase their revenue.

- Transporters can charge per day for using vehicle containers as warehouses in case no space is available in the warehouse.

- Door-to-door on-demand services (last-mile service) could be offered.

- Charging per kilometer, from freight to shipper, could increase revenues.

“So, here is a solution for that. If transporters can get leads for electronic ads or screens on vehicle container so they can add or increase revenues.”

“Another solution is vehicle containers as warehouse. Basically, it’s a new concept. Vehicle containers can be used where is no space in the warehouse by providing transporters per day halting expense. In this way containers are treated as warehouses.”

4.2.2. Contactless Deliveries

“Less human resources required in contactless deliveries. Smart parcel lockers and unmanned vehicles are fixed investment costs, but it greatly enhances visualization, traceability and also protects the health of crew.”

4.2.3. Expansion of E-Commerce Business Is Not a Threat to Transportation Business

“It is not a threat to logistic business. Actually, it is a transfer of business from primary logistics to secondary logistics.”

4.2.4. Tech-Based Performance Management of Drivers

4.2.5. Digital Trucking

“If we see, during the pandemic, digital tracking concept emerged. So, in conventional concept it is proof of delivery (POD) which is a document signed and stamped manually by a factory manager. When shipment reaches the warehouse, it is again manually signed and stamped by the warehouse. When the stock is dispatched from there, the transporter signs and stamps on that proof of delivery and so on…., the pandemic brough in technology (electronic proof of delivery) and concept of contactless deliveries which is very new here in Pakistan and is good initiative even after pandemic.”

| Digital Trucking Features | Beneficiaries |

|---|---|

| Electronic proof of delivery (ePOD) | Gains for Shipper. |

| Improved cash flows for clients. | Gains for Transporter. |

| Digital Agreement | Mutual gains for shipper and Transporter. |

| Smart Contract | Mutual gains for shipper and Transporter. |

| Record of freight history | Mutual gains for shipper and Transporter |

| Open Enterprise Logistic Models (OEL Model) | Mutual gains for shipper and Transporter |

| Subcontracting 3PL contracts | Gains for Transporter |

| Block chain | Mutual gains for broker, shipper and Transporter. |

| Guarantee business availability | Gains for Transporter. |

| Fleet Management solutions | Gains for Transporter. |

| Affordable prices point | Gains for Shipper. |

| Simplified entire value chain | Mutual gains for broker, shipper and Transporter. |

| Transparent costing | Mutual gains for shipper and Transporter. |

| Dashboard for all your previous and upcoming bookings | Mutual gains for shipper and Transporter. |

| Secure and convenient payment methods | Mutual gains for shipper and Transporter. |

| Updates and notifications | Mutual gains for shipper and Transporter. |

| Cost saving | Gains for Shipper. |

| Flexibility and reliability | Gains for Shipper. |

| Live tracking and digital insights | Gains for Shipper. |

| Reduced carbon footprints | Gains for Shipper. |

| Revenue boost | Gains for Transporter. |

| Easy Payments | Gains for Transporter. |

| Reduced payment times | Gains for Transporter. |

| Value-added services | Gains for Transporter. |

5. Conclusions

5.1. Theoretical and Managerial Implications

5.2. Limitations and Future Research Directions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rehman, A.; Ma, H.; Ahmad, M.; Işık, C.; Ozturk, I. Estimating interlinks of carbon emissions from transportation, industrialization, and solid/liquid fuels with economic progress: Evidence from Pakistan. Int. J. Environ. Sci. Technol. 2023, 20, 1981–1996. [Google Scholar] [CrossRef]

- Cedillo-Campos, M.G.; Piña-Barcenas, J.; Pérez-González, C.M.; Mora-Vargas, J. How to measure and monitor the transportation infrastructure contribution to logistics value of supply chains? Transp. Policy 2022, 120, 120–129. [Google Scholar] [CrossRef]

- Geum, Y.; Jeon, H.; Lee, H. Developing new smart services using integrated morphological analysis: Integration of the market-pull and technology-push approach. Serv. Bus. 2016, 10, 531–555. [Google Scholar] [CrossRef]

- Fu, X.; Qiang, Y.; Liu, X.; Jiang, Y.; Cui, Z.; Zhang, D.; Wang, J. Will multi-industry supply chains’ resilience under the impact of COVID-19 pandemic be different? A perspective from China’s highway freight transport. Transp. Policy 2022, 118, 165–178. [Google Scholar] [CrossRef] [PubMed]

- Ansari, S.; Du, H.; Naghdy, F.; Sattar, A. Impact of Post-COVID-19 on driver behavior: A perspective towards pandemic-sustained transportation. J. Transp. Health 2023, 28, 101563. [Google Scholar] [CrossRef]

- van Hassel, E.; Vanelslander, T. Impacts of COVID-19 and other pandemics on the freight transport, logistics and supply chains, and policy responses. Transp. Policy 2022, 128, 240–242. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Bhatnagar, S. Impact of COVID-19 on ports, multimodal logistics and transport sector in India: Responses and policy imperatives. Transp. Policy 2023, 130, 15–25. [Google Scholar] [CrossRef]

- Mukherjee, A.A.; Raj, A.; Aggarwal, S. Identification of barriers and their mitigation strategies for industry 5.0 implementation in emerging economies. Int. J. Prod. Econ. 2023, 257, 108770. [Google Scholar] [CrossRef]

- Rasheed, T. Supply Chain Sustainability Through Green Practices in Manufacturing: A Case Study from Pakistan. South Asian J. Oper. Logist. 2022, 1, 57–71. [Google Scholar] [CrossRef]

- Chan, D.W.; Sarvari, H.; Husein, A.A.J.A.; Awadh, K.M.; Golestanizadeh, M.; Cristofaro, M. Barriers to Attracting Private Sector Investment in Public Road Infrastructure Projects in the Developing Country of Iran. Sustainability 2023, 15, 1452. [Google Scholar] [CrossRef]

- Khaskheli, M.B.; Wang, S.; Yan, X.; He, Y. Innovation of the Social Security, Legal Risks, Sustainable Management Practices and Employee Environmental Awareness in The China–Pakistan Economic Corridor. Sustainability 2023, 15, 1021. [Google Scholar] [CrossRef]

- Shoukat, R.; Xiaoqiang, Z. Sustainable Logistics Network Optimization from Dry Ports to Seaport: A Case Study from Pakistan. Transp. Res. Rec. 2023, 2677, 302–318. [Google Scholar] [CrossRef]

- Abdullah, M.; Ali, N.; Hussain, S.A.; Aslam, A.B.; Javid, M.A. Measuring changes in travel behavior pattern due to COVID-19 in a developing country: A case study of Pakistan. Transp. Policy 2021, 108, 21–33. [Google Scholar] [CrossRef]

- Al-Mhdawi, M.; Brito, M.P.; Abdul Nabi, M.; El-Adaway, I.H.; Onggo, B.S. Capturing the impact of COVID-19 on construction projects in developing countries: A case study of Iraq. J. Manag. Eng. 2022, 38, 05021015. [Google Scholar] [CrossRef]

- Khan, A.; Shah, S.M.; Haasis, H.-D.; Freitag, M. Influence of Supply Chain Management & Logistics in the Wake of China Pakistan Economic Corridor (CPEC) on Domestic Industry in Pakistan. In Efficiency and Logistics; Springer: Cham, Switzerland, 2020; pp. 175–185. [Google Scholar] [CrossRef]

- Awan, M.A.; Ali, Y. Risk Assessment in Supply Chain Networks of China–Pakistan Economic Corridor (CPEC). Chin. Political Sci. Rev. 2022, 7, 550–573. [Google Scholar] [CrossRef]

- Ali, Y.; Saad, T.B.; ur Rehman, O. Integration of IoT technologies in construction supply chain networks; CPEC a case in point. Sustain. Oper. Comput. 2020, 1, 28–34. [Google Scholar] [CrossRef]

- Ali, Y.; Saad, T.B.; Sabir, M.; Muhammad, N.; Salman, A.; Zeb, K. Integration of green supply chain management practices in construction supply chain of CPEC. Manag. Environ. Qual. Int. J. 2020, 31, 185–200. [Google Scholar] [CrossRef]

- Shafiq, A.; Ahmed, M.U.; Mahmoodi, F. Impact of supply chain analytics and customer pressure for ethical conduct on socially responsible practices and performance: An exploratory study. Int. J. Prod. Econ. 2020, 225, 107571. [Google Scholar] [CrossRef]

- Tipu, S.A.A.; Fantazy, K.A. Supply chain strategy, flexibility, and performance. Int. J. Logist. Manag. 2014, 25, 399–416. [Google Scholar] [CrossRef]

- Remko, V.H. Research opportunities for a more resilient post-COVID-19 supply chain–closing the gap between research findings and industry practice. Int. J. Oper. Prod. Manag. 2020, 40, 341–355. [Google Scholar] [CrossRef]

- Sarkis, J. Supply chain sustainability: Learning from the COVID-19 pandemic. Int. J. Oper. Prod. Manag. 2020, 41, 63–73. [Google Scholar] [CrossRef]

- Sharma, R.; Shishodia, A.; Kamble, S.; Gunasekaran, A.; Belhadi, A. Agriculture supply chain risks and COVID-19: Mitigation strategies and implications for the practitioners. Int. J. Logist. Res. Appl. 2020, 1–27, in press. [Google Scholar] [CrossRef]

- Shen, Z.M.; Sun, Y. Strengthening supply chain resilience during COVID-19: A case study of JD. com. J. Oper. Manag. 2023, 69, 359–383. [Google Scholar] [CrossRef]

- Jiang, Y.; Lai, P.L.; Yang, C.C.; Wang, X. Exploring the factors that drive consumers to use contactless delivery services in the context of the continued COVID-19 pandemic. J. Retail. Consum. Serv. 2023, 72, 103276. [Google Scholar] [CrossRef]

- Hobbs, J.E. Food supply chains during the COVID-19 pandemic. Can. J. Agric. Econ./Rev. Can. D’agroeconomie 2020, 68, 171–176. [Google Scholar] [CrossRef]

- CFLP. Liming He Gave a Video Lecture on ‘Current Development Trends and Countermeasures of the Logistics Industry’. 2020. Available online: http://www.chinawuliu.com.cn/lhhzq/202004/15/499109.shtml (accessed on 6 June 2020). (In Chinese).

- Kirch, M.; Poenicke, O.; Richter, K. RFID in Logistics and Production—Applications, Research and Visions for Smart Logistics Zones. Procedia Eng. 2017, 178, 526–533. [Google Scholar] [CrossRef]

- Pan, X.; Li, M.; Wang, M.; Zong, T.; Song, M. The Effects of a Smart Logistics Policy on Carbon Emissions in China: A Difference-in-Differences Analysis. Transp. Res. Part E Logist. Transp. Rev. 2020, 137, 101939. [Google Scholar] [CrossRef]

- Paul, S.K.; Chowdhury, P. A production recovery plan in manufacturing supply chains for a high-demand item during COVID-19. Int. J. Phys. Distrib. Logist. Manag. 2021, 51, 104–125. [Google Scholar] [CrossRef]

- Eryarsoy, E.; Kilic, H.S.; Zaim, S.; Doszhanova, M. Assessing IoT challenges in supply chain: A comparative study before and during-COVID-19 using interval valued neutrosophic analytical hierarchy process. J. Bus. Res. 2022, 147, 108–123. [Google Scholar] [CrossRef]

- Alam, S.T.; Ahmed, S.; Ali, S.M.; Sarker, S.; Kabir, G. Challenges to COVID-19 vaccine supply chain: Implications for sustainable development goals. Int. J. Prod. Econ. 2021, 239, 108193. [Google Scholar] [CrossRef]

- Pujawan, I.N.; Bah, A.U. Supply chains under COVID-19 disruptions: Literature review and research agenda. Supply Chain. Forum Int. J. 2022, 23, 81–95. [Google Scholar] [CrossRef]

- Raj, A.; Mukherjee, A.A.; de Sousa Jabbour, A.B.L.; Srivastava, S.K. Supply chain management during and post-COVID-19 pandemic: Mitigation strategies and practical lessons learned. J. Bus. Res. 2022, 142, 1125–1139. [Google Scholar] [CrossRef] [PubMed]

- Liu, A.; Li, D.; Jie, M.; Li, Z. Coordination through revenue sharing contract in an E-commerce supply chain with consumer preference. Manag. Decis. Econ. 2022, 43, 2467–2479. [Google Scholar] [CrossRef]

- Boyer, J.; Kokosy, A. Technology-push and market-pull strategies: The influence of the innovation ecosystem on companies’ involvement in the Industry 4.0 paradigm. J. Risk Financ. 2022. ahead-of-print. [Google Scholar] [CrossRef]

- Alsudani, M.Q.; Jaber, M.M.; Ali, M.H.; Abd, S.K.; Alkhayyat, A.; Kareem, Z.H.; Mohhan, A.R. Smart logistics with IoT-based enterprise management system using global manufacturing. J. Comb. Optim. 2023, 45, 57. [Google Scholar] [CrossRef]

- Lagorio, A.; Cimini, C.; Pinto, R.; Cavalieri, S. 5G in Logistics 4.0: Potential applications and challenges. Procedia Comput. Sci. 2023, 217, 650–659. [Google Scholar] [CrossRef]

- He, D.; Liu, W. Research on Modern Logistics Service System, 2nd ed.; China Fortune Press: Beijing, China, 2018. [Google Scholar]

- Liu, W.; Liang, Y.; Bao, X.; Qin, J.; Lim, M.K. China’s logistics development trends in the post COVID-19 era. Int. J. Logist. Res. Appl. 2022, 25, 965–976. [Google Scholar] [CrossRef]

- Gao, Y.; Gao, H.; Xiao, H.; Yao, F. Vaccine supply chain coordination using blockchain and artificial intelligence technologies. Comput. Ind. Eng. 2023, 175, 108885. [Google Scholar] [CrossRef]

- Shah, H.M.; Gardas, B.B.; Narwane, V.S.; Mehta, H.S. The contemporary state of big data analytics and artificial intelligence towards intelligent supply chain risk management: A comprehensive review. Kybernetes 2023, 52, 1643–1697. [Google Scholar] [CrossRef]

- Zhang, P.; Zheng, J.; Lin, H.; Liu, C.; Zhao, Z.; Li, C. Vehicle Trajectory Data Mining for Artificial Intelligence and Real-Time Traffic Information Extraction. IEEE Trans. Intell. Transp. Systems. 2023, 1–11. [Google Scholar] [CrossRef]

- Patton, M.Q. Qualitative Research and Evaluation Methods; Sage Publications: Thousand Oaks, CA, USA, 2002. [Google Scholar]

- Kvale, S.L. Interviews: An Introduction to Qualitative Research Interviewing; Sage: Thousand Oaks, CA, USA, 1994. [Google Scholar]

- Sumbal, M.S.; Ključnikov, A.; Durst, S.; Ferraris, A.; Saeed, L. Do you want to retain your relevant knowledge? The role of contextual factors in the banking sector. J. Knowl. Manag. 2023, 27, 2414–2433. [Google Scholar] [CrossRef]

- Creswell, J.W. Research Design: Qualitative, Quantitative, and Mixed Methods Approach; Sage Publications: Thousand Oaks, CA, USA, 2013. [Google Scholar]

- Tan, S.P.; Ng, L.C.; Lyndon, N.; Aman, Z.; Kannan, P.; Hashim, K.; Teo, H.M.; Ibrahim, M.S.C. A review on post-COVID-19 impacts and opportunities of agri-food supply chain in Malaysia. PeerJ 2023, 11, e15228. [Google Scholar] [CrossRef] [PubMed]

- Huang, H.L. Challenges for contactless online food delivery services during the COVID-19 pandemic in Taiwan: Moderating effects of perceived government response. Eval. Program Plan. 2023, 97, 102249. [Google Scholar] [CrossRef]

- Kunovjanek, M.; Wankmüller, C. Containing the COVID-19 pandemic with drones—Feasibility of a drone enabled back-up transport system. Transp. Policy 2021, 106, 141–152. [Google Scholar] [CrossRef]

- Arvis, J.F.; Ojala, L.; Wiederer, C.; Shepherd, B.; Raj, A.; Dairabayeva, K.; Kiiski, T. Logistics Performance Index. 2007. Available online: https://lpi.worldbank.org/sites/default/files/2023-02/LPI_2007_Report.pdf (accessed on 1 January 2020).

- Shabbir, M.S.; Kassim, N.M. Supply chain management drivers and sustainability of green initiatives in manufacturing enterprises: A case in Pakistan. Int. J. Entrep. 2018, 22, 1–19. [Google Scholar]

- Khan, S.A.R.; Qianli, D. Impact of green supply chain management practices on firms’ performance: An empirical study from the perspective of Pakistan. Environ. Sci. Pollut. Res. 2017, 24, 16829–16844. [Google Scholar] [CrossRef]

| Inbound Logistics | Logistics that carries raw material from market to production plant. |

| Out Bound Logistics | Logistics that carries finished goods from production plant to other factories and warehouses. |

| Primary Logistics | Logistics from factory to warehouse is known as primary logistics. |

| Secondary Logistics | Logistics from warehouse to supermarket is known as secondary logistics. |

| People Directly Related to Logistics Business. | Responsibilities |

|---|---|

| Driver | Two drivers on a truck are responsible for vehicle safe transit. |

| Helper | To help driver complete the journey within time. |

| Supervisor | Supervising a small group of trucks normally a fleet of 10 trucks. |

| Workshop Supervisor | Caretaker of truck repair and maintenance. |

| Assistant Manager | Responsible for all smooth operations of logistics including closing of trip. |

| Logistics Manager | Heading a region with a small fleet size providing 3PL service to customer. |

| Regional Manager | Heading and controlling several regions. |

| People Indirectly Related to Logistics Business. | Descriptions |

|---|---|

| Local Station “Addas” | They are brokers that arrange supply orders for transporters to lift and deliver stock to a customer’s premises. They personally don’t have any fleet of trucks. |

| Computerized Weight Balance | They provide facility to check and confirm weight of loaded and empty vehicle. |

| Labor | Group of people that load and unload trucks in warehouses or factory premises. |

| Fast Moving Consumer Goods | Includes all companies that produce products for end consumer. |

| Exercise & Taxation | Authority that holds power to permit or stop any truck due to lack of documentation of route permit, fitness certificate, insurance certificates and vehicle token tax. |

| Traffic Police | Responsible for penalizing any truck driver due to violation of traffic rules. |

| Interviewee | City | Organization | Designation | Experience |

|---|---|---|---|---|

| F1 | Faisalabad | B | Head Logistics | 15 |

| H1 | Hattar | O | Operations Manager | 10 |

| I1 | Islamabad | A | Manager Logistics | 12 |

| I2 | Islamabad | C | Area Sales Manager | 10 |

| I3 | Islamabad | G | Branch Manager | 11 |

| I4 | Islamabad | K | Operations Manager | 18 |

| I5 | Islamabad | L | Supply Chain Manager | 19 |

| I6 | Islamabad | M | Head of Logistics | 13 |

| K1 | Karachi | T | Logistics Manager | 12 |

| L1 | Lahore | E | Supply Chain Manager | 15 |

| L2 | Lahore | F | Supervisor | 7 |

| L3 | Lahore | R | Manager Operations | 9 |

| R1 | Rahim Yar Khan | D | Logistics Manager | 16 |

| R2 | Rawalpindi | S | Supervisor | 15 |

| S1 | Sheikhupura | J | Manager Operations | 9 |

| S2 | Sheikhupura | H | Area Sales Manager | 15 |

| S3 | Sheikhupura | N | Operations Manager | 13 |

| S4 | Sheikhupura | P | Physical Logistics Manager | 17 |

| S5 | Sialkot | Q | Supervisor | 12 |

| T1 | Tarnol | I | Operations Manager | 10 |

| Sr. No | E-Commerce Companies | Websites |

|---|---|---|

| 1 | Daraz | Daraz.pk |

| 2 | Dastgyr | dastgyr.com |

| 3 | Tajir | tajir.app |

| 4 | Airlift | airlifttech.com |

| 5 | Bazaar | bazaar-tech.com |

| 6 | Food Panda | foodpanda.com |

| 7 | Cheetay | cheetay.pk |

| 8 | Jovi | jovi-app.com |

| 9 | Jugnu | jugnu.pk |

| 10 | Goto | Goto.com.pk |

| 11 | Ali Express | Aliexpress.com |

| 12 | Telemart | Telemart.pk |

| 13 | Shopon | Shopon.pk |

| 14 | Homeshopping | Homeshopping.pk |

| 15 | Ishopping | ishopping.pk |

| 16 | Yayvo | Yayvo.com |

| 17 | Symbios | Symbios.pk |

| 18 | Vmart | Vmart.pk |

| 19 | iBucket | iBucket.pk |

| 20 | Krave Mart | Kravemart.com |

| 21 | Amazon | amazon.com |

| 22 | Dawaai | Dawaai.pk |

| 23 | Grocer App | GrocerApp.pk |

| 24 | Price oye | Priceoye.pk |

| 25 | Baby Plannet | BabyPlannet.pk |

| 26 | 24seven | 24seven.pk |

| 27 | Shopistan | Shopistan.pk |

| 28 | Kamyu | kamyu.pk |

| 29 | Medical Store | MedicalStore.pk |

| 30 | Lootlo | lootlo.pk |

| Issues | Description |

|---|---|

| Out of control overhead costs | Every company has overhead costs such as rent, transport, insurance, taxes etc. but it depends on the operations and size of the company. Excessive overhead costs can have a negative impact on a company’s profitability. |

| Too much Waste | It is one of the most pressing operational issues in business. When the various resources are used ineffectively or being wasted, it impacts the performance of the organizations. |

| Lack of Performance monitoring | Monitoring the performance of various ongoing operations is very crucial for staff as it helps to resolve any issues and understand the root cause of the problems for possible solutions. |

| Lack of planning | Inadequate planning is a common operational issue particularly during periods of uncertainty. Organizations which fail to pay attention to downward trends, economic conditions and force majeures can land themselves in precarious positions. |

| Unstable Cash flow | Having enough financial resources is critical to manage the supply chain operations. Lack of funds can cause problems such as payment of staff salaries, or buying materials etc. |

| New Entrants in Freight Logistics | Type |

|---|---|

| Momentum Logistics | Finished goods Containers |

| Pyramid Logistics | Finished goods Containers |

| Faisal Mover Logistics | Open body and Finished goods Containers |

| Keep Trucking Inn | Digital Trucking |

| Truck Sher | Digital Trucking |

| Wahyd Logistics | Digital Trucking |

| 1. Kilometer travelled on daily and monthly basis. |

| 2. Harsh braking during driving hour. |

| 3. No of times over speeding during a month. |

| 4. Traffic police and excise and taxation Challans. |

| 5. Idling time during journey or a complete round trip. |

| 6. Achieving transit time of a complete trip. |

| 7. No of trips during a month verses target. |

| 8. Revenue generated by each driver during a month. |

| 9. Halting time throughout month. |

| 10. Workshop expenses throughout month. |

| 11. Diesel consumption and analysis. |

| 12. No of trips in hilly areas throughout the month. |

| (Karachi to Islamabad) | |

|---|---|

| No of Kms Travel | Driver Changed as per defined Kms |

| 0---------------400 Kms | Driver 1 |

| 401------------800 Kms | Driver 2 |

| 801------------1200 Kms | Driver 3 |

| 1201----------1600 Kms | Driver 4 |

| No of Kms Travel | Driver Changed as per defined Kms |

| 0---------------400 Kms | Driver 4 |

| 401------------800 Kms | Driver 3 |

| 801------------1200 Kms | Driver 2 |

| 1201----------1600 Kms | Driver 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sumbal, M.S.; Ahmed, W.; Shahzeb, H.; Chan, F. Sustainable Technology Strategies for Transportation and Logistics Challenges: An Implementation Feasibility Study. Sustainability 2023, 15, 15224. https://doi.org/10.3390/su152115224

Sumbal MS, Ahmed W, Shahzeb H, Chan F. Sustainable Technology Strategies for Transportation and Logistics Challenges: An Implementation Feasibility Study. Sustainability. 2023; 15(21):15224. https://doi.org/10.3390/su152115224

Chicago/Turabian StyleSumbal, Muhammad Saleem, Waqas Ahmed, Huzeifa Shahzeb, and Felix Chan. 2023. "Sustainable Technology Strategies for Transportation and Logistics Challenges: An Implementation Feasibility Study" Sustainability 15, no. 21: 15224. https://doi.org/10.3390/su152115224

APA StyleSumbal, M. S., Ahmed, W., Shahzeb, H., & Chan, F. (2023). Sustainable Technology Strategies for Transportation and Logistics Challenges: An Implementation Feasibility Study. Sustainability, 15(21), 15224. https://doi.org/10.3390/su152115224