A Review of Wireless Pavement System Based on the Inductive Power Transfer in Electric Vehicles

Abstract

:1. Introduction

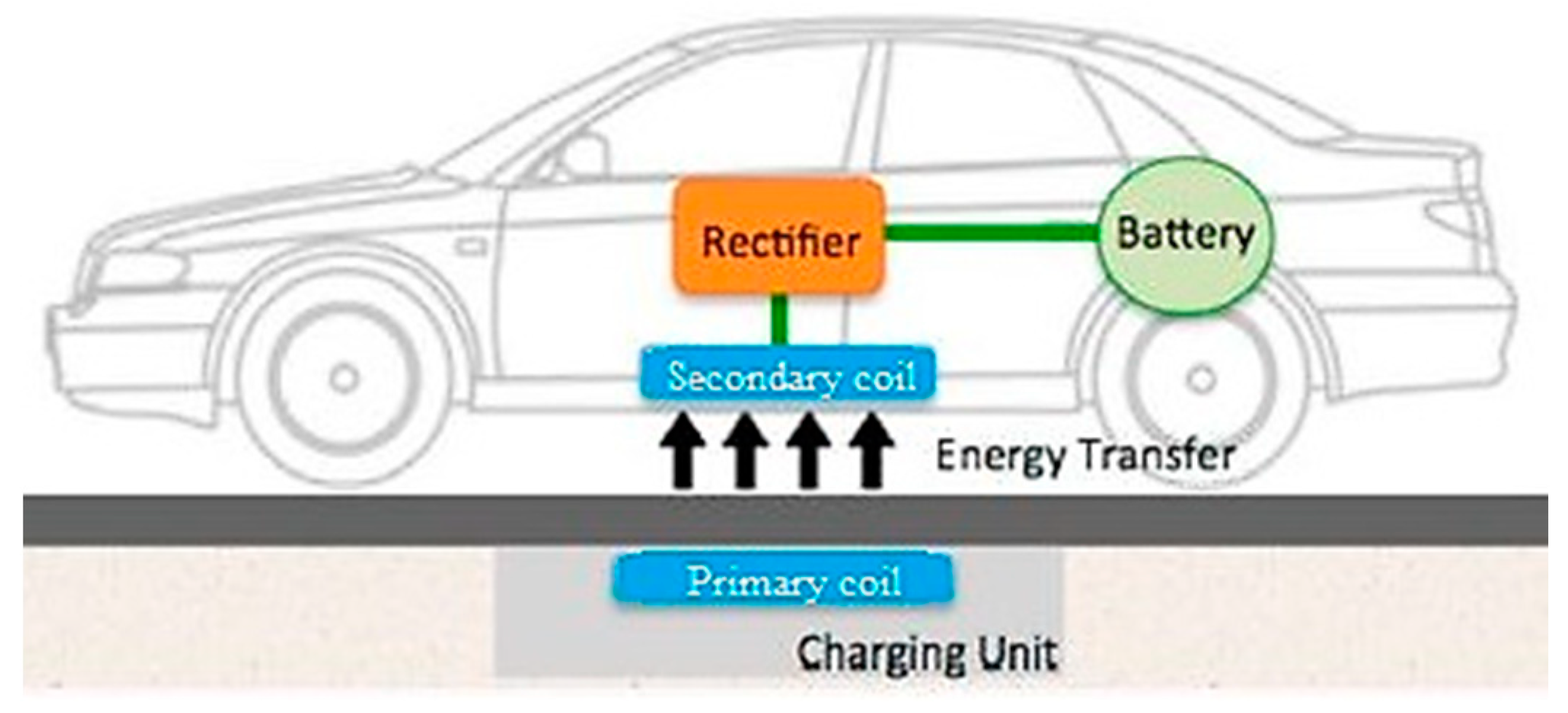

2. Wireless Charging System

3. Inductive Power Transfer

- –

- The power is directly derived through the power source, typically from the AC mains grid, to supply either a regulated DC supply to the inverter or a modulated AC frequency derived from the mains frequency.

- –

- The inverter transforms this DC or extremely low frequency (LF) AC input into a greater frequency voltage and current (commonly chosen to be in the LF range of 30–300 kHz) appropriate to drive the output compensation network and magnetics that enhance the power transfer ability of IPT systems. According to standard requirements, a nominal 85 kHz is selected for EV charging systems.

- –

- The primary and secondary pads optimize the coupled magnetic fields generated from both pads. The power is transferred through resonant IPT between the two pads. The primary pad is normally placed on or below the ground, and the secondary one is placed underneath and attached to EVs.

- –

- A secondary controller conditions and regulates the power to the load.

- –

- The load for an EV normally is a battery or an electric motor [30].

4. Coil Design

5. Effect of IPT Pad on Power Transfer Performance

6. Effect of IPT Pad on Pavement Performance

7. Modification of Wireless Pavement Properties to Increase Performance and Conductivity

| Material | Optimal (%) | Test Device | Improvement (%) | Modification with | Reference |

|---|---|---|---|---|---|

| Steel wool fiber | 6 | ITS Electrical resistivity | 15.13 | Bitumen | [45] |

| Electric arc furnace | 8 | ITS, ITSM | 69 | Aggregate | [46] |

| Steel slag/steel fiber | 6 | Cantabro Semi-circle bending fracture Thermal constants | 57 | Aggregate Bitumen | [47] |

| Electric arc furnace | 3 | ITS | 50 | Aggregate | [48] |

| Steel wool fiber | N/A | Electromagnetic Induction heating | 66 | Bitumen | [49] |

| Metallic waste | 4 | Electrical resistivity X-ray Thermo physical | ✔ | Bitumen | [50] |

| Metallic fiber | 1.5 | ITS, ITSM | × | Bitumen | [44] |

| Waste steel shavings | 10 | Induction heating Electrical resistivity | ✔ | Aggregate | [51] |

| Ferrite powder | 0.5 | ITS Electrical resistivity | 17 | Limestone filler | [52] |

| Steel wool fiber | 4 | Crack-healing X-ray | ✔ | Bitumen | [53] |

| Steel fiber | 10 | Ice-melting | ✔ | N/A | [54] |

| Steel fibers and steel wool | 10 | ITS Electrical resistivity | 19 | Bitumen | [55] |

| Steel fibers | 6 | Induction heating Thermo physical | ✔ | Bitumen | [56] |

| Waste steel shavings | 8 | Heating power | ✔ | Bitumen | [57] |

| Steel wool fiber | 2 | Cantabro fatigue test | ✔ | Aggregate | [58] |

| Electric arc furnace Steel slag and copper | N/A | Rutting Creep ITS | 47 | Aggregate | [59] |

| Steel fiber | 6 | Semi-circular bending Induction heating | ✔ | Bitumen | [60] |

| Steel wool fiber | 1.5 | ITS | 25 | Bitumen | [61] |

| Micron-scale steel fiber with carbon fiber | 0.2 | ITS Dynamic modulus | 29 | Bitumen | [62] |

| Steel fiber | N/A | Wheel tracking ITS Pull out | ✔ | Bitumen | [63] |

| Steel slag | N/A | ITS ITSM Electrical resistivity | 34 | Aggregate | [64] |

8. Simulation and Comparative Analysis of IPT Pad Performance

9. Effect of Environmental Conditions on the Performance of IPT Pad

10. Discussion

11. Conclusions

- Scalability and Infrastructure: The scalability of the system to accommodate a growing number of EVs is crucial. A robust and scalable WPS infrastructure is necessary for simultaneous and efficient charging in urban and rural areas.

- Standardization and Interoperability: Establishing industry-wide guidelines and protocols is essential to ensure compatibility between different EVs and WPS implementations.

- Environmental Impact: A comprehensive life cycle assessment is needed to evaluate and minimize the ecological footprint of IPT technology.

- Integration with Smart Grids: Integrating IPT with smart grids can optimize energy management, contribute to grid stability, and support renewable energy integration.

- Cost-effectiveness: Research efforts should focus on developing cost-efficient materials, processes, and installation techniques to make the technology economically viable.

- Public Awareness: Collaborative efforts involving stakeholders and the public are essential to promote the adoption of IPT technology.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, S.; Zhou, Z.; Luo, R.; Zhao, R.; Xiao, Y.; Xu, Y. A low-carbon, fixed-tour scheduling problem with time windows in a time-dependent traffic environment. Int. J. Prod. Res. 2023, 61, 6177–6196. [Google Scholar] [CrossRef]

- Zhang, X.; Wen, S.; Yan, L.; Feng, J.; Xia, Y. A hybrid-convolution spatial–temporal recurrent network for traffic flow prediction. Comput. J. 2022, bxac171. [Google Scholar] [CrossRef]

- Min, H.; Fang, Y.; Wu, X.; Lei, X.; Chen, S.; Teixeira, R.; Zhu, B.; Zhao, X.; Xu, Z. A fault diagnosis framework for autonomous vehicles with sensor self-diagnosis. Expert Syst. Appl. 2023, 224, 120002. [Google Scholar] [CrossRef]

- Zhang, X.; Fang, S.; Shen, Y.; Yuan, X.; Lu, Z. Hierarchical Velocity Optimization for Connected Automated Vehicles With Cellular Vehicle-to-Everything Communication at Continuous Signalized Intersections. IEEE Trans. Intell. Transp. Syst. 2023; Early Access. [Google Scholar] [CrossRef]

- Cao, B.; Zhang, W.; Wang, X.; Zhao, J.; Gu, Y.; Zhang, Y. A memetic algorithm based on two_Arch2 for multi-depot heterogeneous-vehicle capacitated arc routing problem. Swarm Evol. Comput. 2021, 63, 100864. [Google Scholar] [CrossRef]

- Wangsupphaphol, A.; Chaitusaney, S.; Salem, M. A Techno-Economic Assessment of a Second-Life Battery and Photovoltaics Hybrid Power Source for Sustainable Electric Vehicle Home Charging. Sustainability 2023, 15, 5866. [Google Scholar] [CrossRef]

- Alinejad, M.; Rezaei, O.; Habibifar, R.; Azimian, M. A Charge/Discharge Plan for Electric Vehicles in an Intelligent Parking Lot Considering Destructive Random Decisions, and V2G and V2V Energy Transfer Modes. Sustainability 2022, 14, 12816. [Google Scholar] [CrossRef]

- Guo, L.; Wang, H. A novel design of partially magnetized pavement for wireless power transfer to electric vehicles with improved efficiency and cost saving. Energy Convers. Manag. 2022, 252, 115080. [Google Scholar] [CrossRef]

- Abbasi, M.H.; Zhang, J.; Xu, B.; Krovi, V.N. Reinforcement Learning Based Fast Charging of Electric Vehicle Battery Packs; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2023; ISSN 0148-7191. [Google Scholar]

- Bi, Z.; Kan, T.; Mi, C.C.; Zhang, Y.; Zhao, Z.; Keoleian, G.A. A review of wireless power transfer for electric vehicles: Prospects to enhance sustainable mobility. Appl. Energy 2016, 179, 413–425. [Google Scholar] [CrossRef]

- Bi, Z.; Keoleian, G.A.; Lin, Z.; Moore, M.R.; Chen, K.; Song, L.; Zhao, Z. Life cycle assessment and tempo-spatial optimization of deploying dynamic wireless charging technology for electric cars. Transp. Res. Part C Emerg. Technol. 2019, 100, 53–67. [Google Scholar] [CrossRef]

- Marghani, A.; Wilson, D.; Larkin, T. Performance of Inductive Power Transfer-Based Pavements of Electrified Roads. In Proceedings of the 2019 IEEE PELS Workshop on Emerging Technologies: Wireless Power Transfer (WoW), London, UK, 18–21 June 2019. [Google Scholar]

- Balieu, R.; Chen, F.; Kringos, N. Life cycle sustainability assessment of electrified road systems. Road Mater. Pavement Des. 2019, 20 (Suppl. S1), S19–S33. [Google Scholar] [CrossRef]

- Liu, G. Data collection in mi-assisted wireless powered underground sensor networks: Directions, recent advances, and challenges. IEEE Commun. Mag. 2021, 59, 132–138. [Google Scholar] [CrossRef]

- Feng, H.; Tavakoli, R.; Onar, O.C.; Pantic, Z. Advances in high-power wireless charging systems: Overview and design considerations. IEEE Trans. Transp. Electrif. 2020, 6, 886–919. [Google Scholar] [CrossRef]

- Chen, Z.; Yin, Y.; Song, Z. A cost-competitiveness analysis of charging infrastructure for electric bus operations. Transp. Res. Part C Emerg. Technol. 2018, 93, 351–366. [Google Scholar] [CrossRef]

- Soares, L.; Wang, H. A study on renewed perspectives of electrified road for wireless power transfer of electric vehicles. Renew. Sustain. Energy Rev. 2022, 158, 112110. [Google Scholar] [CrossRef]

- Jeong, S.; Jang, Y.J.; Kum, D.; Lee, M.S. Charging automation for electric vehicles: Is a smaller battery good for the wireless charging electric vehicles? IEEE Trans. Autom. Sci. Eng. 2018, 16, 486–497. [Google Scholar] [CrossRef]

- Lin, Z.; Li, J.-M.; Dong, J. Dynamic Wireless Power Transfer: Potential Impact on Plug-In Electric Vehicle Adoption; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2014. [Google Scholar] [CrossRef]

- Pazouki, S.; Olamaei, J. The effect of heterogeneous electric vehicles with different battery capacities in parking lots on peak load of electric power distribution networks. Int. J. Ambient Energy 2019, 40, 734–738. [Google Scholar] [CrossRef]

- Haghifam, M.-R.; Pazouki, S.; Pazouki, S. Renewables and plug in electric vehicles modeling on electricity and gas infrastructures scheduling in presence of responsive demand. In Proceedings of the 2013 3rd International Conference on Electric Power and Energy Conversion Systems, Istanbul, Turkey, 2–4 October 2013. [Google Scholar]

- Das, H.S.; Nurunnabi, M.; Salem, M.; Li, S.; Rahman, M.M. Utilization of Electric Vehicle Grid Integration System for Power Grid Ancillary Services. Energies 2022, 15, 8623. [Google Scholar] [CrossRef]

- Habibifar, R.; Aris Lekvan, A.; Ehsan, M. A risk-constrained decision support tool for EV aggregators participating in energy and frequency regulation markets. Electr. Power Syst. Res. 2020, 185, 106367. [Google Scholar] [CrossRef]

- Huang, N.; He, Q.; Qi, J.; Hu, Q.; Wang, R.; Cai, G.; Yang, D. Multinodes interval electric vehicle day-ahead charging load forecasting based on joint adversarial generation. Int. J. Electr. Power Energy Syst. 2022, 143, 108404. [Google Scholar] [CrossRef]

- Abbasi, M.H.; Zhang, J.; Krovi, V. A Lyapunov Optimization Approach to the Quality of Service for Electric Vehicle Fast Charging Stations. In Proceedings of the 2022 IEEE Vehicle Power and Propulsion Conference (VPPC), Merced, CA, USA, 1–4 November 2022. [Google Scholar]

- Pazouki, S.; Haghifam, M.-R.; Pazouki, S. Short term economical scheduling in an energy hub by renewable and demand response. In Proceedings of the 2013 3rd International Conference on Electric Power and Energy Conversion Systems, Istanbul, Turkey, 2–4 October 2013. [Google Scholar]

- Farhadi, P.; Sedaghat, M.; Sharifi, S.; Taheri, B. Power point tracking in photovoltaic systems by sliding mode control. In Proceedings of the 2017 10th International Symposium on Advanced Topics in Electrical Engineering (ATEE), Bucharest, Romania, 23–25 March 2017. [Google Scholar]

- Taheri, B.; Jabari, F.; Foroud, A.A. A green cogeneration microgrid composed of water-source heat pumps, a gravity energy storage, and a bio-fueled gas turbine: Design and techno-economic optimization. Sustain. Cities Soc. 2023, 95, 104594. [Google Scholar] [CrossRef]

- Taheri, B.; Aghajani, G.; Sedaghat, M. Economic dispatch in a power system considering environmental pollution using a multi-objective particle swarm optimization algorithm based on the Pareto criterion and fuzzy logic. Int. J. Energy Environ. Eng. 2017, 8, 99–107. [Google Scholar] [CrossRef]

- Amirpour, M.; Kim, S.; Battley, M.P.; Kelly, P.; Bickerton, S.; Covic, G. Coupled electromagnetic-thermal analysis of roadway inductive power transfer pads within a model pavement. Appl. Therm. Eng. 2021, 189, 116710. [Google Scholar] [CrossRef]

- Covic, G.A.; Boys, J.T. Inductive power transfer. Proc. IEEE 2013, 101, 1276–1289. [Google Scholar] [CrossRef]

- Nagendra, G.R.; Covic, G.A.; Boys, J.T. Sizing of inductive power pads for dynamic charging of EVs on IPT highways. IEEE Trans. Transp. Electrif. 2017, 3, 405–417. [Google Scholar] [CrossRef]

- Chen, F.; Taylor, N.; Balieu, R.; Kringos, N. Dynamic application of the Inductive Power Transfer (IPT) systems in an electrified road: Dielectric power loss due to pavement materials. Constr. Build. Mater. 2017, 147, 9–16. [Google Scholar] [CrossRef]

- Varghese, B.J.; Kamineni, A.; Roberts, N.; Halling, M.; Thrimawithana, D.J.; Zane, R.A. Design considerations for 50 kW dynamic wireless charging with concrete-embedded coils. In Proceedings of the 2020 IEEE PELS Workshop on Emerging Technologies: Wireless Power Transfer (WoW), Seoul, Republic of Korea, 15–19 November 2020. [Google Scholar]

- Li, F.; Sun, X.; Zhou, S.; Chen, Y.; Hao, Z.; Yang, Z. Infrastructure material magnetization impact assessment of wireless power transfer pavement based on resonant inductive coupling. IEEE Trans. Intell. Transp. Syst. 2021, 23, 22400–22408. [Google Scholar] [CrossRef]

- Mohamed, N.; Aymen, F.; Issam, Z.; Bajaj, M.; Ghoneim, S.S.; Ahmed, M. The impact of coil position and number on wireless system performance for electric vehicle recharging. Sensors 2021, 21, 4343. [Google Scholar] [CrossRef]

- Throngnumchai, K.; Hanamura, A.; Naruse, Y.; Takeda, K. Design and evaluation of a wireless power transfer system with road embedded transmitter coils for dynamic charging of electric vehicles. World Electr. Veh. J. 2013, 6, 848–857. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, Q.; Jia, C.; Bai, J. Thermal evolution of chemical structure and mechanism of oil sands bitumen. Energy 2022, 244, 123190. [Google Scholar] [CrossRef]

- Liu, K.; Fu, C.; Dai, D.; Jin, C.; Li, W.; Li, S.; Xu, X. Induction heating performance of asphalt pavements incorporating electrically conductive and magnetically absorbing layers. Constr. Build. Mater. 2019, 229, 116805. [Google Scholar] [CrossRef]

- Chen, F.; Balieu, R.; Córdoba, E.; Kringos, N. Towards an understanding of the structural performance of future electrified roads: A finite element simulation study. Int. J. Pavement Eng. 2019, 20, 204–215. [Google Scholar] [CrossRef]

- Chen, F.; Kringos, N. Towards new infrastructure materials for on-the-road charging. In Proceedings of the 2014 IEEE International Electric Vehicle Conference (IEVC), Florence, Italy, 17–19 December 2014. [Google Scholar]

- Mahmud, M.H.; Elmahmoud, W.; Barzegaran, M.; Brake, N. Efficient wireless power charging of electric vehicle by modifying the magnetic characteristics of the transmitting medium. IEEE Trans. Magn. 2017, 53, 1–5. [Google Scholar] [CrossRef]

- Liu, K.; Dai, D.; Pan, S.; Wang, F.; Hou, C.; Xu, P. Numerical investigation and thermal predictions of asphalt pavement containing inductive materials under alternating magnetic field. Int. J. Therm. Sci. 2020, 153, 106353. [Google Scholar] [CrossRef]

- González, A.; Norambuena-Contreras, J.; Poulikakos, L.; Varela, M.J.; Valderrama, J.; Flisch, A.; Arraigada, M. Evaluation of asphalt mixtures containing metallic fibers from recycled tires to promote crack-healing. Materials 2020, 13, 5731. [Google Scholar] [CrossRef]

- Hosseinian, S.M.; Najafi Moghaddam Gilani, V.; Mehraban Joobani, P.; Arabani, M. Investigation of moisture sensitivity and conductivity properties of inductive asphalt mixtures containing steel wool fiber. Adv. Civ. Eng. 2020, 2020, 8890814. [Google Scholar] [CrossRef]

- Lizárraga, J.M.; Gallego, J. Self-healing analysis of half-warm asphalt mixes containing electric arc furnace (EAF) slag and reclaimed asphalt pavement (RAP) using a novel thermomechanical healing treatment. Materials 2020, 13, 2502. [Google Scholar] [CrossRef]

- Liu, Q.; Li, B.; Schlangen, E.; Sun, Y.; Wu, S. Research on the mechanical, thermal, induction heating and healing properties of steel slag/steel fibers composite asphalt mixture. Appl. Sci. 2017, 7, 1088. [Google Scholar] [CrossRef]

- Gulisano, F.; Crucho, J.; Gallego, J.; Picado-Santos, L. Microwave healing performance of asphalt mixture containing electric arc furnace (EAF) slag and graphene nanoplatelets (GNPs). Appl. Sci. 2020, 10, 1428. [Google Scholar] [CrossRef]

- Xu, C.; Wang, K.; Li, K.; Zong, Y. Deicing property of asphalt mixture containing steel wool fiber by electromagnetic induction heating. Coatings 2021, 11, 1276. [Google Scholar] [CrossRef]

- Norambuena-Contreras, J.; González, A.; Concha, J.; Gonzalez-Torre, I.; Schlangen, E. Effect of metallic waste addition on the electrical, thermophysical and microwave crack-healing properties of asphalt mixtures. Constr. Build. Mater. 2018, 187, 1039–1050. [Google Scholar] [CrossRef]

- Liu, K.; Dai, D.; Fu, C.; Li, W.; Li, S. Induction heating of asphalt mixtures with waste steel shavings. Constr. Build. Mater. 2020, 234, 117368. [Google Scholar] [CrossRef]

- Peinado, F.; Medel, E.; Silvestre, R.; Garcia, A. Open-grade wearing course of asphalt mixture containing ferrite for use as ferromagnetic pavement. Compos. Part B Eng. 2014, 57, 262–268. [Google Scholar] [CrossRef]

- González, A.; Norambuena-Contreras, J.; Storey, L.; Schlangen, E. Self-healing properties of recycled asphalt mixtures containing metal waste: An approach through microwave radiation heating. J. Environ. Manag. 2018, 214, 242–251. [Google Scholar] [CrossRef]

- Fang, H.; Sun, Y.; Liu, Q.; Li, B.; Wu, S.; Tang, J. Ice melting properties of steel fiber modified asphalt mixtures with induction heating. IOP Conf. Ser. Mater. Sci. Eng. 2017, 182, 012042. [Google Scholar] [CrossRef]

- Liu, Q.; Schlangen, E.; García, Á.; van de Ven, M. Induction heating of electrically conductive porous asphalt concrete. Constr. Build. Mater. 2010, 24, 1207–1213. [Google Scholar] [CrossRef]

- Liu, Q.; Yu, W.; Wu, S.; Schlangen, E.; Pan, P. A comparative study of the induction healing behaviors of hot and warm mix asphalt. Constr. Build. Mater. 2017, 144, 663–670. [Google Scholar] [CrossRef]

- Liu, K.; Fu, C.; Xu, P.; Li, S.; Huang, M. An eco-friendliness inductive asphalt mixture comprising waste steel shavings and waste ferrites. J. Clean. Prod. 2021, 283, 124639. [Google Scholar] [CrossRef]

- Lastra-González, P.; Indacoechea-Vega, I.; Calzada-Pérez, M.A.; Vega-Zamanillo, Á.; Castro-Fresno, D. Assessment of induction heating in the performance of porous asphalt mixtures. Road Mater. Pavement Des. 2020, 21, 2302–2320. [Google Scholar] [CrossRef]

- Oluwasola, E.A.; Hainin, M.R.; Aziz, M.M.A. Comparative evaluation of dense-graded and gap-graded asphalt mix incorporating electric arc furnace steel slag and copper mine tailings. J. Clean. Prod. 2016, 122, 315–325. [Google Scholar] [CrossRef]

- Li, H.; Yu, J.; Wu, S.; Liu, Q.; Wu, Y.; Xu, H.; Li, Y. Effect of moisture conditioning on mechanical and healing properties of inductive asphalt concrete. Constr. Build. Mater. 2020, 241, 118139. [Google Scholar] [CrossRef]

- Karimi, M.M.; Darabi, M.K.; Jahanbakhsh, H.; Jahangiri, B.; Rushing, J.F. Effect of steel wool fibers on mechanical and induction heating response of conductive asphalt concrete. Int. J. Pavement Eng. 2020, 21, 1755–1768. [Google Scholar] [CrossRef]

- Huang, B.; Chen, X.; Shu, X. Effects of electrically conductive additives on laboratory-measured properties of asphalt mixtures. J. Mater. Civ. Eng. 2009, 21, 612–617. [Google Scholar] [CrossRef]

- Wang, H.; Yang, J.; Liao, H.; Chen, X. Electrical and mechanical properties of asphalt concrete containing conductive fibers and fillers. Constr. Build. Mater. 2016, 122, 184–190. [Google Scholar] [CrossRef]

- Ahmedzade, P.; Sengoz, B. Evaluation of steel slag coarse aggregate in hot mix asphalt concrete. J. Hazard. Mater. 2009, 165, 300–305. [Google Scholar] [CrossRef] [PubMed]

- Liu, K.; Fu, C.; Wang, H.; Wang, F.; Xu, P.; Kan, C. Exploring the energy-saving potential of electromagnetic induction pavement via magnetic concentrating technique. Energy 2020, 211, 118650. [Google Scholar] [CrossRef]

- Marinescu, A.; Tudorache, T.; Vintila, A.; Dumbrava, I. A comparative assessment of magnetic concrete versus ferrite for a high power inductive coupler. In Proceedings of the 2021 9th International Conference on Modern Power Systems (MPS), Cluj-Napoca, Romania, 16–17 June 2021. [Google Scholar]

- Edwards, K.A.; Al-Abed, S.H.; Hosseini, S.; Brake, N.A. Properties of a magnetic concrete core transformer for application in wireless power transfer systems. Constr. Build. Mater. 2019, 227, 117041. [Google Scholar] [CrossRef]

- Mohamed, N.; Aymen, F.; Alqarni, M.; Turky, R.A.; Alamri, B.; Ali, Z.M.; Aleem, S.H.A. A new wireless charging system for electric vehicles using two receiver coils. Ain Shams Eng. J. 2022, 13, 101569. [Google Scholar] [CrossRef]

- Chabot, A.; Deep, P. 2D Multilayer solution for an electrified road with a built-in charging box. Road Mater. Pavement Des. 2019, 20, S590–S603. [Google Scholar] [CrossRef]

- Chen, F. Inductive power transfer technology for road transport electrification. In Eco-Efficient Pavement Construction Materials; Elsevier: Amsterdam, The Netherlands, 2020; pp. 383–399. [Google Scholar]

- Chen, F.; Coronado, C.F.; Balieu, R.; Kringos, N. Structural performance of electrified roads: A computational analysis. J. Clean. Prod. 2018, 195, 1338–1349. [Google Scholar] [CrossRef]

- Beeldensa, A.; Hauspiec, P.; Perikd, H. Inductive charging through concrete roads: A Belgian case study and application. In Proceedings of the 1st European Road Infrastructure Congress, Leeds, UK, 18–20 October 2016; 2016. [Google Scholar]

- Hanawa, K.; Imura, T.; Abe, N. Basic Evaluation of Electrical Characteristics of Ferrite-less and Capacitor-less Coils by Road Embedment Experiment for Dynamic Wireless Power Transfer. In Proceedings of the 2021 IEEE PELS Workshop on Emerging Technologies: Wireless Power Transfer (WoW), San Diego, CA, USA, 1–4 June 2021. [Google Scholar]

- Sun, G.; Yang, Y.; Zhang, J.; Cao, Y.; Tan, X.; Pei, J. Modeling and optimization of pavement scale-model for magnetically coupled resonant in wireless power transmission systems. Constr. Build. Mater. 2022, 319, 126066. [Google Scholar] [CrossRef]

- Aghcheghloo, P.D.; Larkin, T.; Wilson, D.; Holleran, G.; Amirpour, M.; Kim, S.; Bickerton, S.; Covic, G. The effect of an emulator inductive power transfer pad on the temperature of an asphalt pavement. Constr. Build. Mater. 2023, 392, 131783. [Google Scholar] [CrossRef]

- Li, F.; Li, Y.; Zhou, S.; Chen, Y.; Sun, X.; Deng, Y. Wireless power transfer tuning model of electric vehicles with pavement materials as transmission media for energy conservation. Appl. Energy 2022, 323, 119631. [Google Scholar] [CrossRef]

- Feng, Z.; Shimizu, O.; Sumiya, H.; Nagai, S.; Fujimoto, H.; Sato, M. Influence of Contamination Between Receiver Coil and Embedded Transmitter Coil for Dynamic Wireless Power Transfer System. In Proceedings of the 2021 IEEE PELS Workshop on Emerging Technologies: Wireless Power Transfer (WoW), San Diego, CA, USA, 1–4 June 2021. [Google Scholar]

- Gil, A.; Taiber, J. A literature review in dynamic wireless power transfer for electric vehicles: Technology and infrastructure integration challenges. In Sustainable Automotive Technologies 2013: Proceedings of the 5th International Conference ICSAT; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Yuan, C.; Liu, D.-D.; Zhu, Y.-J.; Zeng, T.; Jiang, B.-X.; Tang, C.-X.; Zhou, Y.; He, J.-L.; Li, Q. Effect of charge transport on electrical degradation in polypropylene/organic molecular semiconductor composites for HVDC cable insulation. Appl. Phys. Lett. 2023, 122, 112904. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, X.; Wang, M. Rapid texture depth detection method considering pavement deformation calibration. Measurement 2023, 217, 113024. [Google Scholar] [CrossRef]

- Luo, Z.; Wang, H.; Li, S. Prediction of international roughness index based on stacking fusion model. Sustainability 2022, 14, 6949. [Google Scholar] [CrossRef]

- Khordehbinan, M.; Kaymanesh, M.R. Chemical analysis and middle-low temperature functional of waste polybutadiene rubber polymer modified bitumen. Pet. Sci. Technol. 2020, 38, 8–17. [Google Scholar] [CrossRef]

- Rezaei, S.; Damadi, S.M.; Edrisi, A.; Fakhri, M.; Khordehbinan, M.W. Fatigue analysis of bitumen modified with composite of nano-SiO2 and styrene butadiene styrene polymer. Frat. Ed Integrità Strutt. 2020, 14, 202–209. [Google Scholar] [CrossRef]

- Shayesteh, A.; Ghasemisalehabadi, E.; Khordehbinan, M.W.; Rostami, T. Finite element method in statistical analysis of flexible pavement. J. Mar. Sci. Technol. 2017, 25, 15. [Google Scholar]

- Wang, H.; Zhang, X.; Jiang, S. A laboratory and field universal estimation method for tire–pavement interaction noise (TPIN) based on 3D image technology. Sustainability 2022, 14, 12066. [Google Scholar] [CrossRef]

- Lin, Z.; Wang, H.; Li, S. Pavement anomaly detection based on transformer and self-supervised learning. Autom. Constr. 2022, 143, 104544. [Google Scholar] [CrossRef]

- Zhu, H.; Xue, M.; Wang, Y.; Yuan, G.; Li, X. Fast visual tracking with siamese oriented region proposal network. IEEE Signal Process. Lett. 2022, 29, 1437–1441. [Google Scholar] [CrossRef]

- Zou, W.; Sun, Y.; Zhou, Y.; Lu, Q.; Nie, Y.; Sun, T.; Peng, L. Limited sensing and deep data mining: A new exploration of developing city-wide parking guidance systems. IEEE Intell. Transp. Syst. Mag. 2020, 14, 198–215. [Google Scholar] [CrossRef]

- Liu, H.; Yue, Y.; Liu, C.; Spencer Jr, B.; Cui, J. Automatic recognition and localization of underground pipelines in GPR B-scans using a deep learning model. Tunn. Undergr. Space Technol. 2023, 134, 104861. [Google Scholar] [CrossRef]

- Xiao, Z.; Shu, J.; Jiang, H.; Min, G.; Chen, H.; Han, Z. Perception task offloading with collaborative computation for autonomous driving. IEEE J. Sel. Areas Commun. 2022, 41, 457–473. [Google Scholar] [CrossRef]

- Yao, Z.; Yoon, H.-S. Hybrid electric vehicle powertrain control based on reinforcement learning. SAE Int. J. Electrified Veh. 2021, 11, 165–176. [Google Scholar] [CrossRef]

- Liu, M.; Gu, Q.; Yang, B.; Yin, Z.; Liu, S.; Yin, L.; Zheng, W. Kinematics model optimization algorithm for six degrees of freedom parallel platform. Appl. Sci. 2023, 13, 3082. [Google Scholar] [CrossRef]

- Luo, P.; Wang, B.; Wang, H.; Ma, F.; Ma, H.; Wang, L. An ultrasmall bolt defect detection method for transmission line inspection. IEEE Trans. Instrum. Meas. 2023, 72, 1–12. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, W.; Yang, J. Analysis of stochastic process to model safety risk in construction industry. J. Civ. Eng. Manag. 2021, 27, 87–99. [Google Scholar] [CrossRef]

- Qu, Z.; Liu, X.; Zheng, M. Temporal-spatial quantum graph convolutional neural network based on Schrödinger approach for traffic congestion prediction. IEEE Trans. Intell. Transp. Syst. 2023, 24, 8677–8686. [Google Scholar] [CrossRef]

- Lv, Z.; Wu, J.; Li, Y.; Song, H. Cross-layer optimization for industrial Internet of Things in real scene digital twins. IEEE Internet Things J. 2022, 9, 15618–15629. [Google Scholar] [CrossRef]

- Lv, Z.; Qiao, L.; Nowak, R. Energy-efficient resource allocation of wireless energy transfer for the internet of everything in digital twins. IEEE Commun. Mag. 2022, 60, 68–73. [Google Scholar] [CrossRef]

- Min, C.; Pan, Y.; Dai, W.; Kawsar, I.; Li, Z.; Wang, G. Trajectory optimization of an electric vehicle with minimum energy consumption using inverse dynamics model and servo constraints. Mech. Mach. Theory 2023, 181, 105185. [Google Scholar] [CrossRef]

| Materials | rƐ |

|---|---|

| Air | 1 |

| Water | 81 |

| Snow | 6–12 |

| Ice | 4 |

| Sand | 2–6, 10–30 (wet) |

| Clay | 2–6 (dry), 5–40 (wet) |

| Limestone | 7 (dry), 8 (wet) |

| Granite | 5 (dry), 7 (wet) |

| Asphalt | 2–4 (day), 6–12 (wet) |

| Concrete | 4–10 (day), 10–20 (wet) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bozhi; Mohamed, M.; Gilani, V.N.M.; Amjad, A.; Majid, M.S.; Yahya, K.; Salem, M. A Review of Wireless Pavement System Based on the Inductive Power Transfer in Electric Vehicles. Sustainability 2023, 15, 14893. https://doi.org/10.3390/su152014893

Bozhi, Mohamed M, Gilani VNM, Amjad A, Majid MS, Yahya K, Salem M. A Review of Wireless Pavement System Based on the Inductive Power Transfer in Electric Vehicles. Sustainability. 2023; 15(20):14893. https://doi.org/10.3390/su152014893

Chicago/Turabian StyleBozhi, Mahmoud Mohamed, Vahid Najafi Moghaddam Gilani, Ayesha Amjad, Mohammed Sh. Majid, Khalid Yahya, and Mohamed Salem. 2023. "A Review of Wireless Pavement System Based on the Inductive Power Transfer in Electric Vehicles" Sustainability 15, no. 20: 14893. https://doi.org/10.3390/su152014893

APA StyleBozhi, Mohamed, M., Gilani, V. N. M., Amjad, A., Majid, M. S., Yahya, K., & Salem, M. (2023). A Review of Wireless Pavement System Based on the Inductive Power Transfer in Electric Vehicles. Sustainability, 15(20), 14893. https://doi.org/10.3390/su152014893