Research on the Performance Parameters of a Compression-Ignition Engine Fueled by Blends of Diesel Fuel, Rapeseed Methyl Ester and Hydrotreated Vegetable Oil

Abstract

:1. Introduction

2. Materials and Methods

2.1. Equipment for the Measurement of Fuel Properties

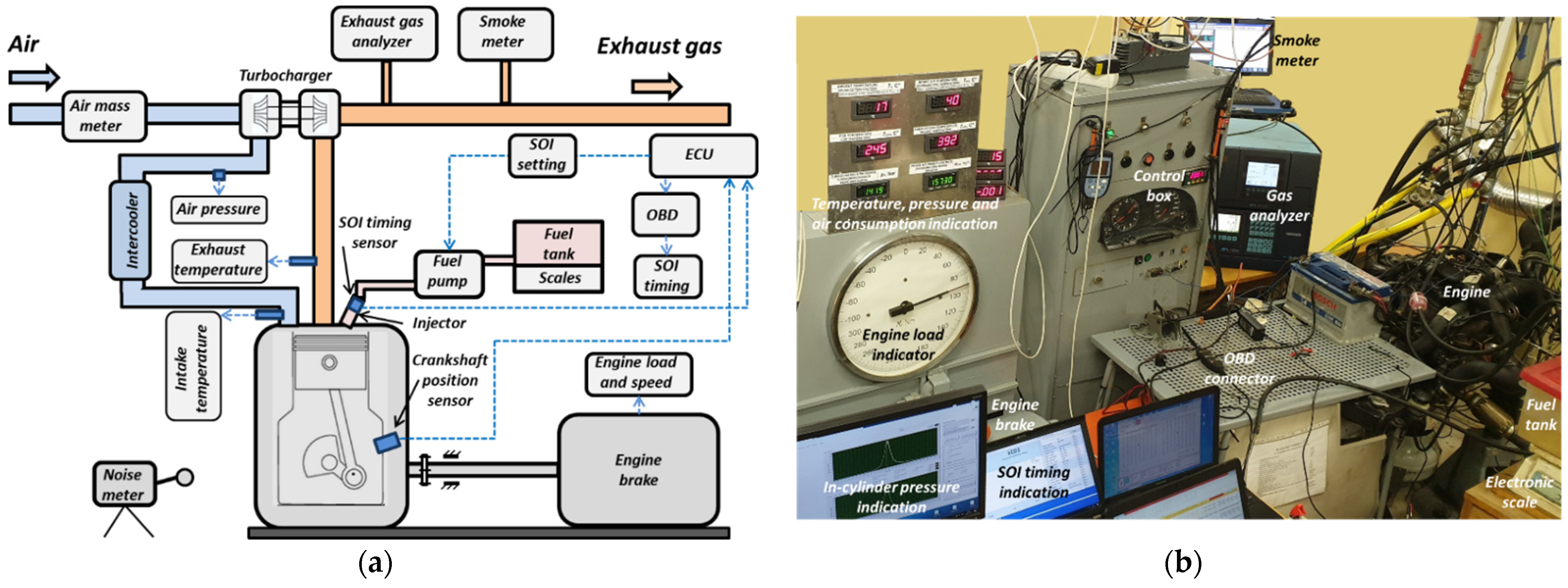

2.2. Engine Testing Equipment

2.3. Fuel Blends and Engine Test Conditions

3. Results and Discussion

4. Conclusions

- Mass BSFC was reduced by ~0.9–1.8% when two-component HVO blends were used. This effect was influenced by a higher heating value and better combustion features.

- Volumetric BSFC, which is more important for the fuel retailing market, remained very close to the D100 data. That means that adding renewable fuel with a lower density did not lead to higher fuel consumption.

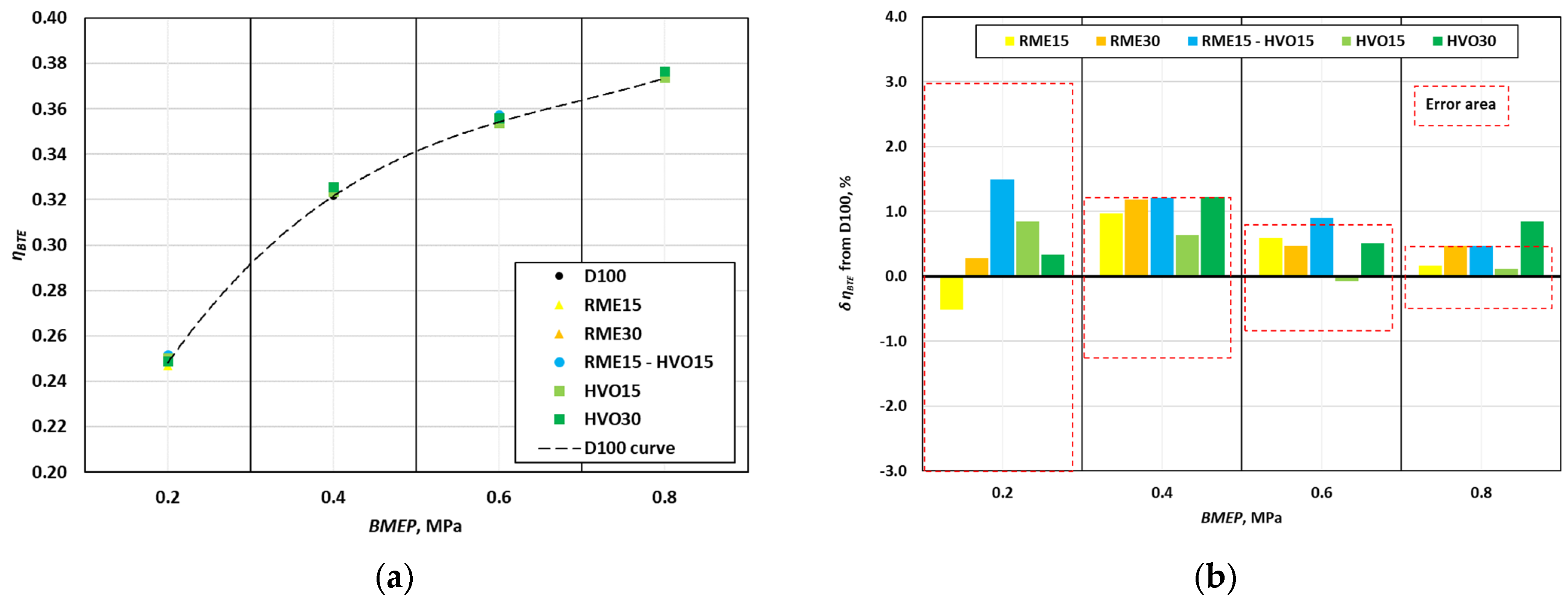

- The thermal efficiency ηBTE remained very close to D100 when HVO and RME fuel blends were tested. That means that an advanced renewable fuel with low density does not reduce the combustion efficiency or amount of energy released due to its higher heating value and chemical composition. This fact is very important when a new fuel is used instead of an existing fuel on the market.

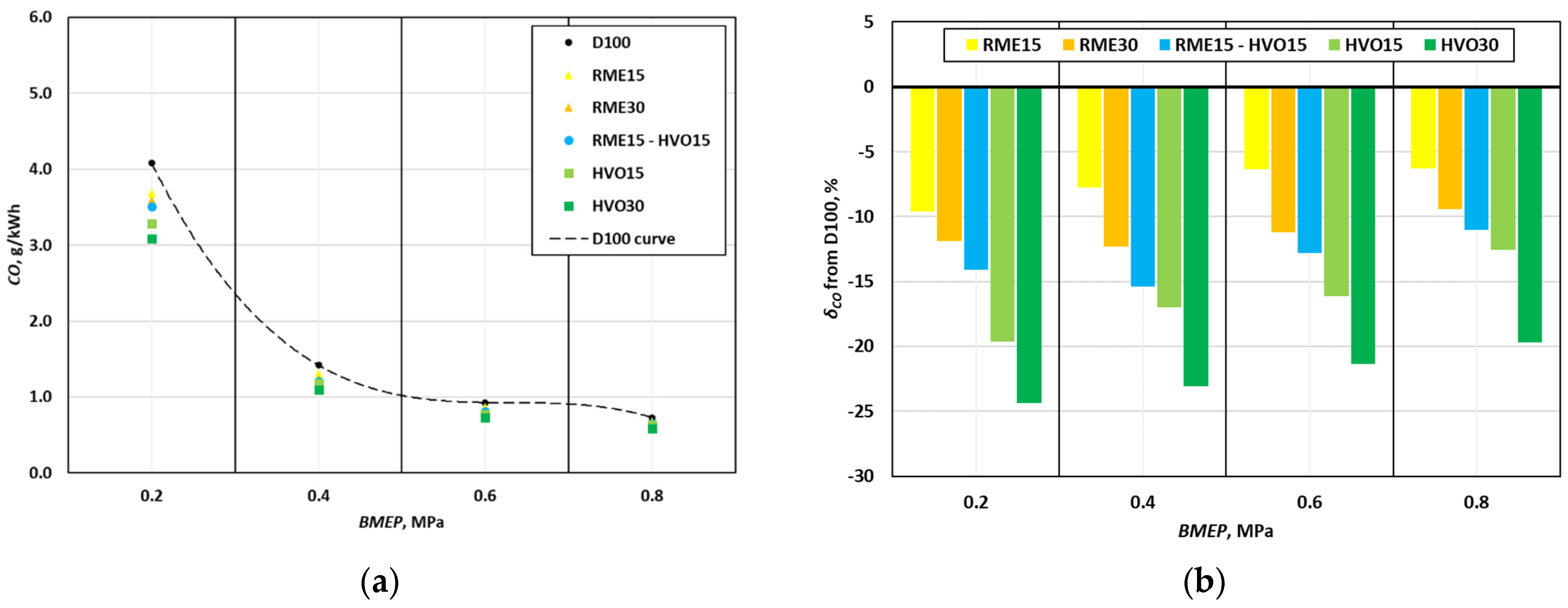

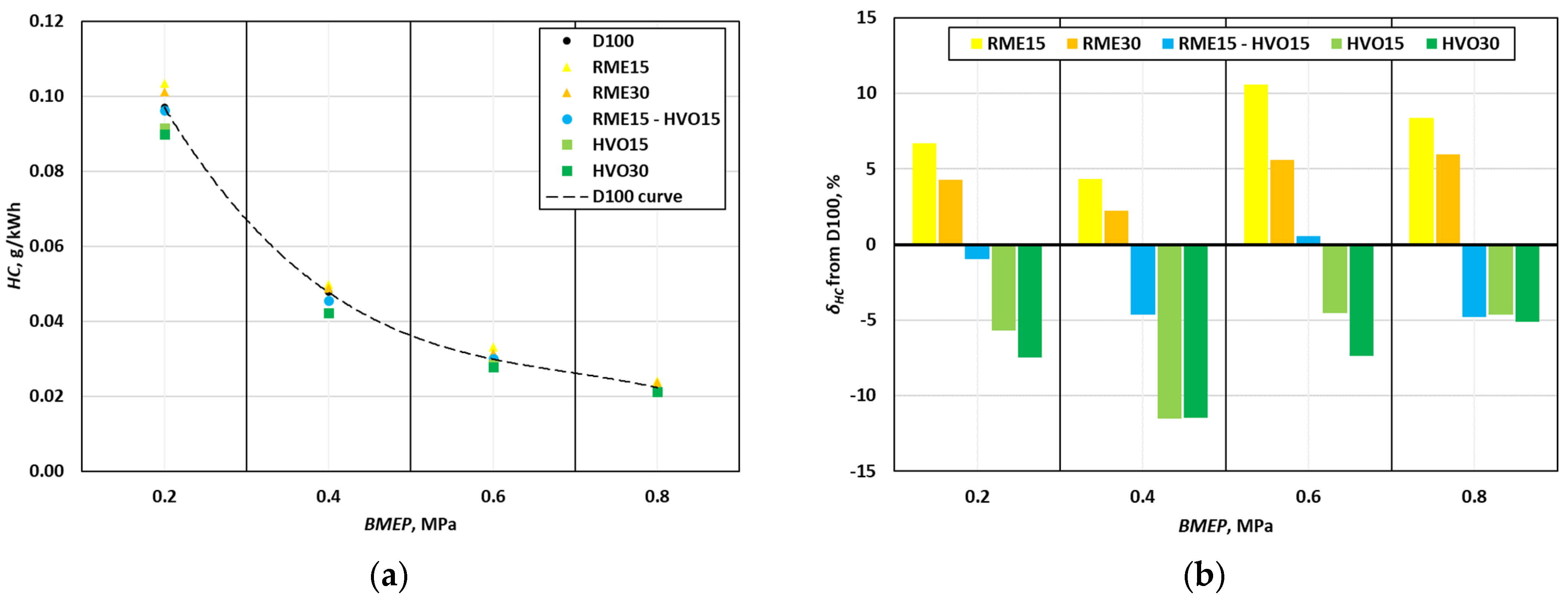

- Incomplete combustion compounds CO and HC, and smokiness, were reduced by HVO as well. The better combustion features of HVO resulted in ~12.5–25.0% lower emissions of CO in all tested engine load ranges. At the same time, the impact of RME on CO reduction was in the range ~6.0–12.0%. The reduction level of unburned HC reached ~5.0–12.0%, and opposite results were found when RME was used—an increase of 4.9–10.1%. Such contrasting results for both renewable fuels are due to differences in their molecular composition and structure. The smoke opacity measurement values were covered by an error area; however, a trend of reduced smoke emissions was clearly seen in diagrams. The lower values were caused by the HVO composition (contains ~100% alkanes/paraffinic hydrocarbons) and the oxygen in the RME composition leading to more intensive oxidation during diffusion combustion.

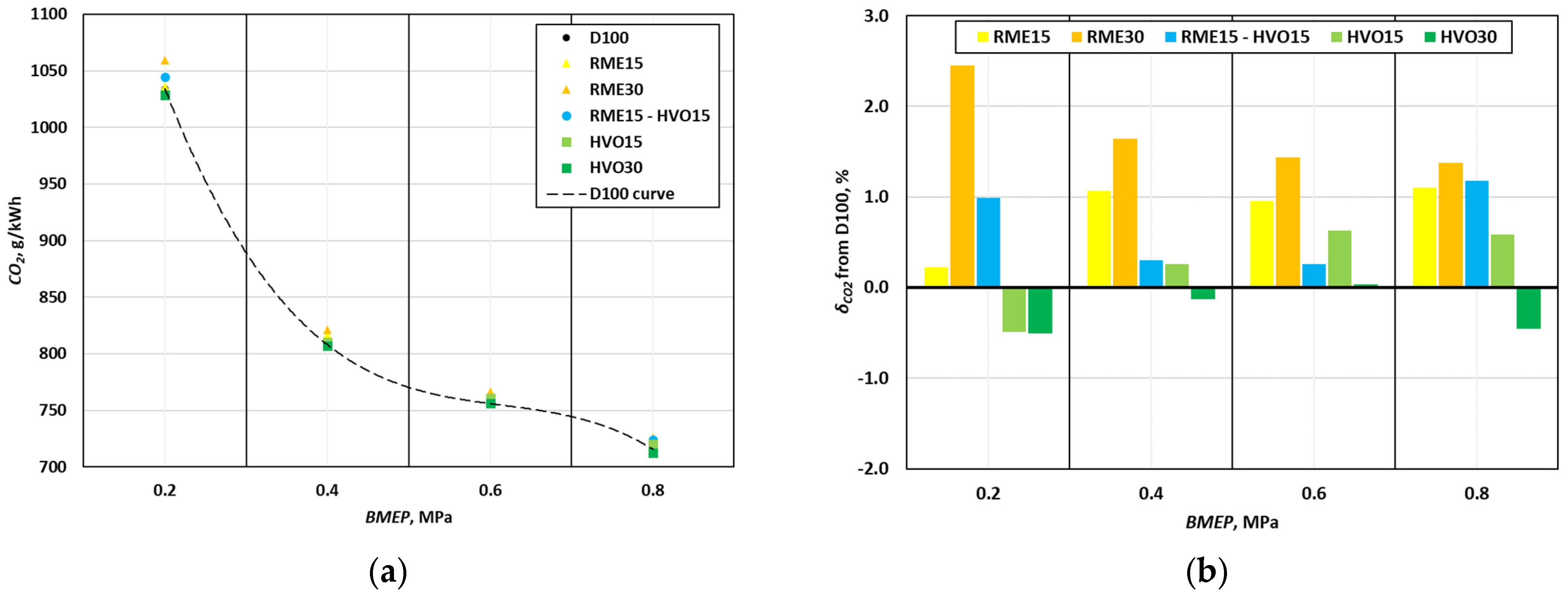

- The level of complete combustion of CO2 was covered by an error area in all cases except RME 30, which was ~1.5–2.5% higher than D100 due to the higher fuel consumption.

- Due to differences between the HVO and RME molecular composition and structure, there was an extended ignition delay, resulting in contrasting results of NOx formation in premixed combustion. NOx emissions were reduced by up to ~6.5% when HVO was used and increased by 1.5–6.0% when RME was used.

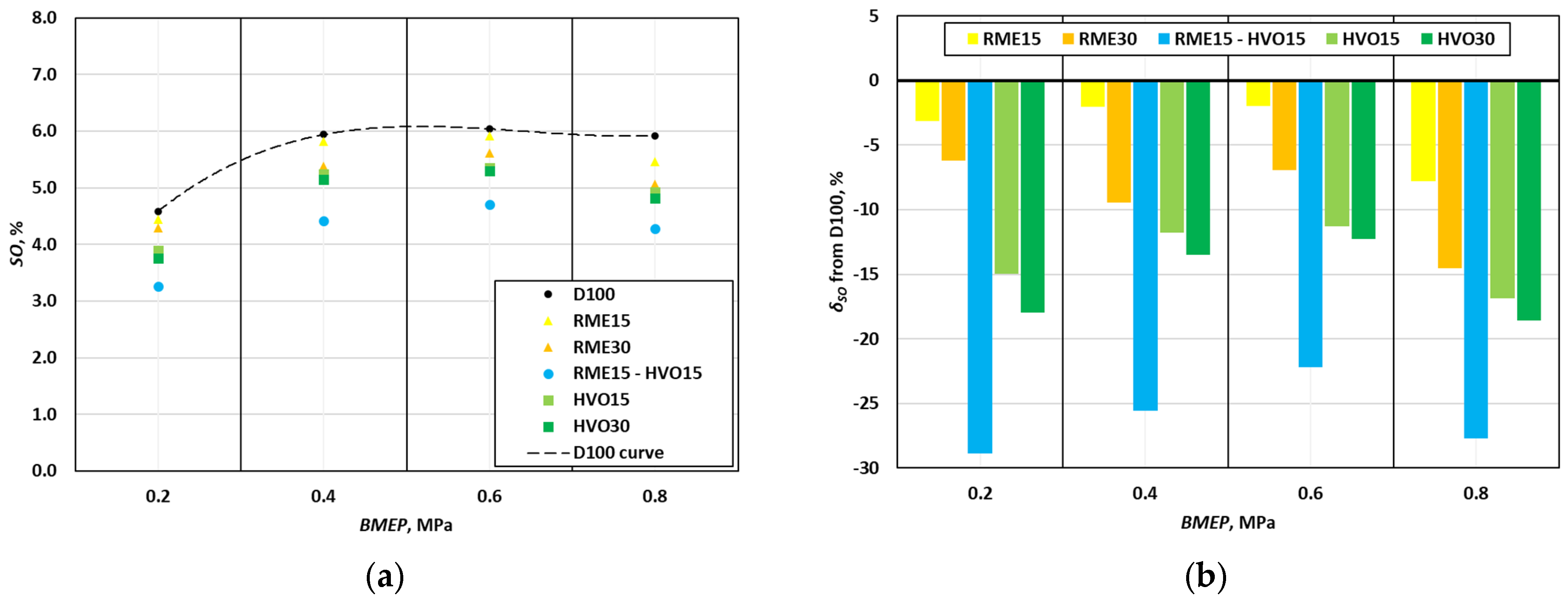

- A significant reduction in smokiness was observed when blends were used. The relative deviation was up to ~18% for two-component blends and an up to ~29% reduction was observed when a three-component blend was used. The two-component HVO blends (with a relative change of ~11–18%) showed better results compared with two-component RME blends (with a relative change of ~2–15%). Research data on the three-component RME15–HVO15 blend in most cases were distributed between the data of two-component RME and HVO blends; however, the lowest rates of smokiness were found for the three-component blend. This could be explained by the impact of oxygen from the RME composition and the combustion features of HVO.

- The range of noise data distribution was very narrow (~94.3–95.1 dB) and covered by an error area; however, HVO blends were characterized by a lower level of noise compared with D100 and RME blends due to lower peaks of energy release in premixed combustion. The relative deviation of two-component HVO blends data was lower, up to 0.4%, while RME blends showed a higher noise level, up to ~0.2%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Bf | Hourly fuel consumption |

| BMEP | Brake mean effective pressure |

| BSFC | Brake-specific fuel consumption |

| CAD bTDC | Crank angle degree before top dead center |

| CIE | Compression ignition engine |

| CO | Carbon monoxide |

| CO2 | Carbon dioxide |

| EGR | Exhaust gas recirculation |

| FAME | Fatty acid methyl esters |

| HC | Hydrocarbons |

| HVO | Hydrogenated vegetable oil |

| ICE | Internal combustion engine |

| MB | Brake torque |

| n | Engine speed |

| NOx | Nitrogen oxides |

| RME | Rapeseed methyl ester |

| SMSO | Smoke opacity |

| SOI | Start of injection |

| ηBTEBTE | Brake thermal efficiency |

References

- Díaz-Secades, L.A.; González, R.; Rivera, N. Waste Heat Recovery from Marine Main Medium Speed Engine Block. Energy, Exergy, Economic and Environmental (4E) Assessment—Case Study. Ocean Eng. 2022, 264, 112493. [Google Scholar] [CrossRef]

- Sun, L.; Zhang, T.; Liu, S.; Wang, K.; Rogers, T.; Yao, L.; Zhao, P. Reducing Energy Consumption and Pollution in the Urban Transportation Sector: A Review of Policies and Regulations in Beijing. J. Clean. Prod. 2021, 285, 125339. [Google Scholar] [CrossRef]

- Fayyazbakhsh, A.; Bell, M.L.; Zhu, X.; Mei, X.; Koutný, M.; Hajinajaf, N.; Zhang, Y. Engine Emissions with Air Pollutants and Greenhouse Gases and Their Control Technologies. J. Clean. Prod. 2022, 376, 134260. [Google Scholar] [CrossRef]

- Lion, S.; Vlaskos, I.; Taccani, R. A Review of Emissions Reduction Technologies for Low and Medium Speed Marine Diesel Engines and Their Potential for Waste Heat Recovery. Energy Convers. Manag. 2020, 207, 112553. [Google Scholar] [CrossRef]

- Galimova, T.; Ram, M.; Breyer, C. Mitigation of Air Pollution and Corresponding Impacts during a Global Energy Transition towards 100% Renewable Energy System by 2050. Energy Rep. 2022, 8, 14124–14143. [Google Scholar] [CrossRef]

- Zhang, Z.; Lv, J.; Li, W.; Long, J.; Wang, S.; Tan, D.; Yin, Z. Performance and Emission Evaluation of a Marine Diesel Engine Fueled with Natural Gas Ignited by Biodiesel-Diesel Blended Fuel. Energy 2022, 256, 124662. [Google Scholar] [CrossRef]

- Barreiro, J.; Zaragoza, S.; Diaz-Casas, V. Review of Ship Energy Efficiency. Ocean Eng. 2022, 257, 111594. [Google Scholar] [CrossRef]

- Chou, M.-T.; Hsu, Y.-P.; Hsu, C.-T.; Ding, J.-F. Reconstruction Mechanism and Strategy of Global Maritime Green Supply Chain against the Backdrop of Nuclear Pollution. Mar. Pollut. Bull. 2022, 185, 114235. [Google Scholar] [CrossRef]

- Kwon, Y. High-Resolution Spatial Distribution of Marine Vessel Emission and Its Significance in Sustainable Port Air Quality Management: A Case Study of Port of Incheon. Ocean Eng. 2022, 258, 111799. [Google Scholar] [CrossRef]

- Wang, Y.; Cao, Q.; Liu, L.; Wu, Y.; Liu, H.; Gu, Z.; Zhu, C. A Review of Low and Zero Carbon Fuel Technologies: Achieving Ship Carbon Reduction Targets. Sustain. Energy Technol. Assess. 2022, 54, 102762. [Google Scholar] [CrossRef]

- Carvalho, F.; Portugal-Pereira, J.; Junginger, M.; Szklo, A. Biofuels for Maritime Transportation: A Spatial, Techno-Economic, and Logistic Analysis in Brazil, Europe, South Africa, and the USA. Energies 2021, 14, 4980. [Google Scholar] [CrossRef]

- Gülüm, M. Effects of Compression Ratio, Blending Ratio and Engine Speed on Fuel Cost, Performance and Exhaust Emissions of a Diesel Engine Fueled with Bio-Derived Alternative Fuels. Sustain. Energy Technol. Assess. 2022, 53, 102464. [Google Scholar] [CrossRef]

- Chuahy, D.F.F.; Finney, C.E.A.; Kaul, B.C.; Kass, M.D. Computational Exploration of Bio-Oil Blend Effects on Large Two-Stroke Marine Engines. Fuel 2022, 322, 123977. [Google Scholar] [CrossRef]

- Sathish, T.; Mohanavel, V.; Arunkumar, M.; Rajan, K.; Soudagar, M.E.M.; Mujtaba, M.A.; Salmen, S.H.; Al Obaid, S.; Fayaz, H.; Sivakumar, S. Utilization of Azadirachta Indica Biodiesel, Ethanol and Diesel Blends for Diesel Engine Applications with Engine Emission Profile. Fuel 2022, 319, 123798. [Google Scholar] [CrossRef]

- European Commission. White Paper 2011; European Commission: Brussels, Belgium, 2011. [Google Scholar]

- European Union. Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources (Recast) (Text with EEA Relevance); European Union: Brussels, Belgium, 2018; Volume 328. [Google Scholar]

- Adrian, V.N.; Catalin, N.D.; Radu, C. On Some Possible Effects of Using Renewable Oxygenated Fuels in a Large Marine Diesel Engine. Energy Rep. 2022, 8, 966–977. [Google Scholar] [CrossRef]

- Fei, C.; Qian, Z.; Yang, Z.; Ren, J.; Zhu, S.; Yan, Y.; Shu, Z. Combustion and Emission Performance of Isopropanol-Butanol-Ethanol (IBE) Mixed with Diesel Fuel on Marine Diesel Engine with Nano YSZ Thermal Barrier Coating. Energy 2022, 256, 124683. [Google Scholar] [CrossRef]

- Imran, S.; Emberson, D.R.; Wen, D.S.; Diez, A.; Crookes, R.J.; Korakianitis, T. Performance and Specific Emissions Contours of a Diesel and RME Fueled Compression-Ignition Engine throughout Its Operating Speed and Power Range. Appl. Energy 2013, 111, 771–777. [Google Scholar] [CrossRef]

- Sayin Kul, B.; Ciniviz, M. Assessment of Waste Bread Bioethanol-Gasoline Blends in Respect to Combustion Analysis, Engine Performance and Exhaust Emissions of a SI Engine. Fuel 2020, 277, 118237. [Google Scholar] [CrossRef]

- Hong, B.; Lius, A.; Mahendar, S.K.; Mihaescu, M.; Cronhjort, A. Energy and Exergy Characteristics of an Ethanol-Fueled Heavy-Duty SI Engine at High-Load Operation Using Lean-Burn Combustion. Appl. Therm. Eng. 2023, 224, 120063. [Google Scholar] [CrossRef]

- Abdellatief, T.M.M.; Ershov, M.A.; Kapustin, V.M.; Ali Abdelkareem, M.; Kamil, M.; Olabi, A.G. Recent Trends for Introducing Promising Fuel Components to Enhance the Anti-Knock Quality of Gasoline: A Systematic Review. Fuel 2021, 291, 120112. [Google Scholar] [CrossRef]

- Duchowny, A.; Engeländer, K.; Blümich, B.; Adams, A. Aging Analysis of Alternative Fuels and Biofuels in a Novel Test Rig. J. Energy Inst. 2023, 107, 101196. [Google Scholar] [CrossRef]

- Alves-Fortunato, M.; Ayoub, E.; Bacha, K.; Mouret, A.; Dalmazzone, C. Fatty Acids Methyl Esters (FAME) Autoxidation: New Insights on Insoluble Deposit Formation Process in Biofuels. Fuel 2020, 268, 117074. [Google Scholar] [CrossRef]

- Das, A.K.; Sahu, S.K.; Panda, A.K. Current Status and Prospects of Alternate Liquid Transportation Fuels in Compression Ignition Engines: A Critical Review. Renew. Sustain. Energy Rev. 2022, 161, 112358. [Google Scholar] [CrossRef]

- Emission Standards: Europe: Heavy-Duty Truck and Bus Engines. Available online: https://dieselnet.com/standards/eu/hd.php (accessed on 17 July 2023).

- Fajri, H.; Rieß, S.; Clemente Mallada, R.; Ruoff, I.; Wensing, M. Optical Measurements of Two Cylindrical and Conical Heavy-Duty Diesel Injector Nozzels—A Comparison of Reference Diesel, HVO, and RME Fuels. Energy Convers. Manag. 2023, 285, 117018. [Google Scholar] [CrossRef]

- Ovaska, T.; Niemi, S.; Sirviö, K.; Nilsson, O.; Portin, K.; Asplund, T. Effects of Alternative Marine Diesel Fuels on the Exhaust Particle Size Distributions of an Off-Road Diesel Engine. Appl. Therm. Eng. 2019, 150, 1168–1176. [Google Scholar] [CrossRef]

- Preuß, J.; Munch, K.; Denbratt, I. Performance and Emissions of Renewable Blends with OME3-5 and HVO in Heavy Duty and Light Duty Compression Ignition Engines. Fuel 2021, 303, 121275. [Google Scholar] [CrossRef]

- Roque, L.F.A.; da Costa, R.B.R.; de Souza, T.A.Z.; Coronado, C.J.R.; Pinto, G.M.; Cintra, A.J.A.; Raats, O.O.; Oliveira, B.M.; Frez, G.V.; Alves, L.F.R. Experimental Analysis and Life Cycle Assessment of Green Diesel (HVO) in Dual-Fuel Operation with Bioethanol. J. Clean. Prod. 2023, 389, 135989. [Google Scholar] [CrossRef]

- Rimkus, A.; Žaglinskis, J.; Rapalis, P.; Skačkauskas, P. Research on the Combustion, Energy and Emission Parameters of Diesel Fuel and a Biomass-to-Liquid (BTL) Fuel Blend in a Compression-Ignition Engine. Energy Convers. Manag. 2015, 106, 1109–1117. [Google Scholar] [CrossRef]

- Dimitriou, I.; Goldingay, H.; Bridgwater, A.V. Techno-Economic and Uncertainty Analysis of Biomass to Liquid (BTL) Systems for Transport Fuel Production. Renew. Sustain. Energy Rev. 2018, 88, 160–175. [Google Scholar] [CrossRef]

- Wilczynski, M.; Schanz, H. The Role of Market Perceptions in Bridging the Innovation Gap of Bio-Based Markets: The Example of Biomass-to-Liquid in Germany. J. Clean. Prod. 2021, 291, 125926. [Google Scholar] [CrossRef]

- McCaffery, C.; Zhu, H.; Sabbir Ahmed, C.M.; Canchola, A.; Chen, J.Y.; Li, C.; Johnson, K.C.; Durbin, T.D.; Lin, Y.-H.; Karavalakis, G. Effects of Hydrogenated Vegetable Oil (HVO) and HVO/Biodiesel Blends on the Physicochemical and Toxicological Properties of Emissions from an off-Road Heavy-Duty Diesel Engine. Fuel 2022, 323, 124283. [Google Scholar] [CrossRef]

- Suarez-Bertoa, R.; Kousoulidou, M.; Clairotte, M.; Giechaskiel, B.; Nuottimäki, J.; Sarjovaara, T.; Lonza, L. Impact of HVO Blends on Modern Diesel Passenger Cars Emissions during Real World Operation. Fuel 2019, 235, 1427–1435. [Google Scholar] [CrossRef]

- Ruggiero, A.; D’Amato, R.; Merola, M.; Valašek, P.; Müller, M. Tribological Characterization of Vegetal Lubricants: Comparative Experimental Investigation on Jatropha Curcas L. Oil, Rapeseed Methyl Ester Oil, Hydrotreated Rapeseed Oil. Tribol. Int. 2017, 109, 529–540. [Google Scholar] [CrossRef]

- Türck, J.; Singer, A.; Lichtinger, A.; Almaddad, M.; Türck, R.; Jakob, M.; Garbe, T.; Ruck, W.; Krahl, J. Solketal as a Renewable Fuel Component in Ternary Blends with Biodiesel and Diesel Fuel or HVO and the Impact on Physical and Chemical Properties. Fuel 2022, 310, 122463. [Google Scholar] [CrossRef]

- Hunicz, J.; Mikulski, M.; Shukla, P.C.; Gęca, M.S. Partially Premixed Combustion of Hydrotreated Vegetable Oil in a Diesel Engine: Sensitivity to Boost and Exhaust Gas Recirculation. Fuel 2022, 307, 121910. [Google Scholar] [CrossRef]

- Rimkus, A.; Žaglinskis, J.; Stravinskas, S.; Rapalis, P.; Matijošius, J.; Bereczky, Á. Research on the Combustion, Energy and Emission Parameters of Various Concentration Blends of Hydrotreated Vegetable Oil Biofuel and Diesel Fuel in a Compression-Ignition Engine. Energies 2019, 12, 2978. [Google Scholar] [CrossRef]

- d’Ambrosio, S.; Mancarella, A.; Manelli, A. Utilization of Hydrotreated Vegetable Oil (HVO) in a Euro 6 Dual-Loop EGR Diesel Engine: Behavior as a Drop-In Fuel and Potentialities along Calibration Parameter Sweeps. Energies 2022, 15, 7202. [Google Scholar] [CrossRef]

- Di Blasio, G.; Ianniello, R.; Beatrice, C. Hydrotreated Vegetable Oil as Enabler for High-Efficient and Ultra-Low Emission Vehicles in the View of 2030 Targets. Fuel 2022, 310, 122206. [Google Scholar] [CrossRef]

- Szeto, W.; Leung, D.Y.C. Is Hydrotreated Vegetable Oil a Superior Substitute for Fossil Diesel? A Comprehensive Review on Physicochemical Properties, Engine Performance and Emissions. Fuel 2022, 327, 125065. [Google Scholar] [CrossRef]

- Dimitriadis, A.; Seljak, T.; Vihar, R.; Žvar Baškovič, U.; Dimaratos, A.; Bezergianni, S.; Samaras, Z.; Katrašnik, T. Improving PM-NOx Trade-off with Paraffinic Fuels: A Study towards Diesel Engine Optimization with HVO. Fuel 2020, 265, 116921. [Google Scholar] [CrossRef]

- Omari, A.; Pischinger, S.; Bhardwaj, O.P.; Holderbaum, B.; Nuottimäki, J.; Honkanen, M. Improving Engine Efficiency and Emission Reduction Potential of HVO by Fuel-Specific Engine Calibration in Modern Passenger Car Diesel Applications. SAE Int. J. Fuels Lubr. 2017, 10, 756–767. [Google Scholar] [CrossRef]

- Wu, Y.; Ferns, J.; Li, H.; Andrews, G. Investigation of Combustion and Emission Performance of Hydrogenated Vegetable Oil (HVO) Diesel. SAE Int. J. Fuels Lubr. 2017, 10, 895–903. [Google Scholar] [CrossRef]

- Mancarella, A.; Marello, O. Effect of Coolant Temperature on Performance and Emissions of a Compression Ignition Engine Running on Conventional Diesel and Hydrotreated Vegetable Oil (HVO). Energies 2023, 16, 144. [Google Scholar] [CrossRef]

- Hernández, J.J.; Rodríguez-Fernández, J.; Calle-Asensio, A. Performance and Regulated Gaseous Emissions of a Euro 6 Diesel Vehicle with Lean NOx Trap at Different Ambient Conditions: Sensitivity to the Type of Fuel. Energy Convers. Manag. 2020, 219, 113023. [Google Scholar] [CrossRef]

- Brynolf, S.; Grahn, M.; Hansson, J.; Korberg, A.D.; Malmgren, E. Chapter 9—Sustainable fuels for shipping. In Sustainable Energy Systems on Ships; Baldi, F., Coraddu, A., Mondejar, M.E., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 403–428. ISBN 978-0-12-824471-5. [Google Scholar]

- Mikkonen, S.; Kiiski, U.; Saikkonen, P.; Sorvari, J. Diesel Vehicle Cold Operability: Design of Fuel System Essential Besides Fuel Properties. SAE Int. J. Fuels Lubr. 2012, 5, 977–989. [Google Scholar] [CrossRef]

- Hor, C.J.; Tan, Y.H.; Mubarak, N.M.; Tan, I.S.; Ibrahim, M.L.; Yek, P.N.Y.; Karri, R.R.; Khalid, M. Techno-Economic Assessment of Hydrotreated Vegetable Oil as a Renewable Fuel from Waste Sludge Palm Oil. Environ. Res. 2023, 220, 115169. [Google Scholar] [CrossRef]

- Lorenzi, G.; Mignini, L.; Venezia, B.; Silva, C.; Santarelli, M. Integration of High-Temperature Electrolysis in an HVO Production Process Using Waste Vegetable Oil. Energy Procedia 2019, 158, 2005–2011. [Google Scholar] [CrossRef]

- de Souza, T.A.Z.; Pinto, G.M.; Julio, A.A.V.; Coronado, C.J.R.; Perez-Herrera, R.; Siqueira, B.O.P.S.; da Costa, R.B.R.; Roberts, J.J.; Palacio, J.C.E. Biodiesel in South American Countries: A Review on Policies, Stages of Development and Imminent Competition with Hydrotreated Vegetable Oil. Renew. Sustain. Energy Rev. 2022, 153, 111755. [Google Scholar] [CrossRef]

- Feng, S.; Xu, S.; Yuan, P.; Xing, Y.; Shen, B.; Li, Z.; Zhang, C.; Wang, X.; Wang, Z.; Ma, J.; et al. The Impact of Alternative Fuels on Ship Engine Emissions and Aftertreatment Systems: A Review. Catalysts 2022, 12, 138. [Google Scholar] [CrossRef]

- Ershov, M.A.; Savelenko, V.D.; Makhova, U.A.; Makhmudova, A.E.; Zuikov, A.V.; Kapustin, V.M.; Abdellatief, T.M.M.; Burov, N.O.; Geng, T.; Abdelkareem, M.A.; et al. Current Challenge and Innovative Progress for Producing HVO and FAME Biodiesel Fuels and Their Applications. Waste Biomass Valor. 2023, 14, 505–521. [Google Scholar] [CrossRef]

- No, S.-Y. Application of Hydrotreated Vegetable Oil from Triglyceride Based Biomass to CI Engines—A Review. Fuel 2014, 115, 88–96. [Google Scholar] [CrossRef]

- Zeman, P.; Hönig, V.; Kotek, M.; Táborský, J.; Obergruber, M.; Mařík, J.; Hartová, V.; Pechout, M. Hydrotreated Vegetable Oil as a Fuel from Waste Materials. Catalysts 2019, 9, 337. [Google Scholar] [CrossRef]

- Labeckas, G.; Slavinskas, S.; Kanapkienė, I. The Individual Effects of Cetane Number, Oxygen Content or Fuel Properties on the Ignition Delay, Combustion Characteristics, and Cyclic Variation of a Turbocharged CRDI Diesel Engine—Part 1. Energy Convers. Manag. 2017, 148, 1003–1027. [Google Scholar] [CrossRef]

- Bortel, I.; Vávra, J.; Takáts, M. Effect of HVO Fuel Mixtures on Emissions and Performance of a Passenger Car Size Diesel Engine. Renew. Energy 2019, 140, 680–691. [Google Scholar] [CrossRef]

- Neste MY Renewable DieselTM. Available online: https://www.neste.com/products/all-products/renewable-road-transport/neste-my-renewable-diesel (accessed on 10 August 2023).

- Guide to Fuel Specifications. Available online: https://www.crownoil.co.uk/guides/fuel-specifications-guide/ (accessed on 23 September 2023).

- Kim, D.; Kim, S.; Oh, S.; No, S.-Y. Engine Performance and Emission Characteristics of Hydrotreated Vegetable Oil in Light Duty Diesel Engines. Fuel 2014, 125, 36–43. [Google Scholar] [CrossRef]

- Valeika, G.; Matijošius, J.; Rimkus, A. Research of the Impact of EGR Rate on Energy and Environmental Parameters of Compression Ignition Internal Combustion Engine Fuelled by Hydrogenated Vegetable Oil (HVO) and Biobutanol—Castor Oil Fuel Mixtures. Energy Convers. Manag. 2022, 270, 116198. [Google Scholar] [CrossRef]

- Heywood, J.B. Internal Combustion Engine Fundamentals, 2nd ed.; McGraw-Hill Education: New York, NY, USA, 2018; ISBN 978-1-260-11610-6. [Google Scholar]

- Rakopoulos, C.D.; Giakoumis, E.G. Diesel Engine Transient Operation: Principles of Operation and Simulation Analysis; Springer: London, UK, 2009; ISBN 978-1-84882-374-7. [Google Scholar]

- Pinto, G.M.; de Souza, T.A.Z.; da Costa, R.B.R.; Roque, L.F.A.; Frez, G.V.; Coronado, C.J.R. Combustion, Performance and Emission Analyses of a CI Engine Operating with Renewable Diesel Fuels (HVO/FARNESANE) under Dual-Fuel Mode through Hydrogen Port Injection. Int. J. Hydrog. Energy 2023, 48, 19713–19732. [Google Scholar] [CrossRef]

- Çelebi, K.; Uludamar, E.; Tosun, E.; Yıldızhan, Ş.; Aydın, K.; Özcanlı, M. Experimental and Artificial Neural Network Approach of Noise and Vibration Characteristic of an Unmodified Diesel Engine Fuelled with Conventional Diesel, and Biodiesel Blends with Natural Gas Addition. Fuel 2017, 197, 159–173. [Google Scholar] [CrossRef]

- Giakoumis, E.G.; Rakopoulos, D.C.; Rakopoulos, C.D. Combustion Noise Radiation during Dynamic Diesel Engine Operation Including Effects of Various Biofuel Blends: A Review. Renew. Sustain. Energy Rev. 2016, 54, 1099–1113. [Google Scholar] [CrossRef]

- Biodiesel Prices (SME & FAME). Available online: https://www.neste.com/investors/market-data/biodiesel-prices-sme-fame (accessed on 21 September 2023).

| Parameter | Device | Method | Accuracy |

|---|---|---|---|

| Gross heating value, J/g | IKA C 5000 calorimeter | DIN 51900-2 | 130 J/g |

| Lower heating value LHV, J/g | |||

| Lubricity, µm | HFRR | ISO 12156 | 0.1% |

| Flash point, °C | FP93 5G2 Pensky–Martens analyzer | ISO 2719 | 0.03 °C |

| Dynamic viscosity, mPa∙s | Anton Paar SVM 3000/G2 Stabinger Viscometer | ASTM D7042 | 0.1% |

| Kinematic viscosity, mm2/s | 0.1% | ||

| Density, g/cm3 | 0.0002 g/cm3 | ||

| Oxidative stability, min. | PetroOXY analyzer | EN 16091 | 0.1% |

| CFPP, °C | FPP 5Gs analyzer | EN 116 | 1 °C |

| Pour point, °C | CPP 5Gs analyzer | ISO 3016 | 3 °C |

| Water content, % mass | Aquamax KF Coulometric analyzer | ISO 12937 | 0.0003% |

| Cetane number | PetroSpec analyzer | ASTM D613 | 0.05% |

| Cetane index | ASTM D4737 | 0.05% | |

| Sulfur, % mass | IKA C 5000 calorimeter, muffle furnace, scales | GOST 3877 | 0.04% |

| Parameter | Value |

|---|---|

| Displacement (cm3) | 1896 |

| Number of cylinders | 4/OHC |

| Compression ratio | 19.5 |

| Power (kW) | 66 (4000 rpm) |

| Torque (Nm) | 180 (2000–2500 rpm) |

| Bore (mm) | 79.5 |

| Stroke (mm) | 95.5 |

| Fuel injection | Direct injection (single) |

| Fuel injection-pump design | Axial-piston distributor injection pump |

| Nozzle type | Hole-type |

| Nozzle and holder assembly | Two-spring |

| Nozzle opening pressure (bar) | 190–200 |

| Properties | D100 | RME100 | HVO100 | Limits | ||

|---|---|---|---|---|---|---|

| EN 590 | EN 14214 | EN 15940 | ||||

| Gross heating value, MJ/kg | 45.89 | 40.13 | 47.19 | – | – | – |

| Lower heating value, MJ/kg | 42.83 | 37.47 | 43.63 | – | – | – |

| CFPP, °C | −22 | −14 | −44 | ≤+5 ≤−44 * | ≤0 ≤−20 * | ≤+5 ≤−44 * |

| Pour point, °C | −39 | −33 | <−50 | – | – | – |

| Dynamic viscosity 40 °C, mPa×s | 2.412 | 3.830 | 2.198 | – | – | – |

| Kinematic viscosity at 40 °C, cSt | 2.9401 | 4.421 | 2.876 | 2.0–4.5 | 3.5–5.0 | 2.0–4.5 |

| Density at 15 °C, g/mL | 0.838 | 0.884 | 0.782 | 0.800–0.845 | 0.860–0.900 | 0.765–0.800 |

| Dynamic viscosity at 15 °C, mPa×s | 4.441 | 7.317 | 4.014 | – | – | – |

| Kinematic viscosity at 15 °C, cSt | 5.302 | 8.274 | 5.136 | – | – | – |

| Density at 40 °C, g/mL | 0.820 | 0.866 | 0.764 | – | – | – |

| Oxidative stability, min | 98.0 | 27.0 | 76.1 | – | – | – |

| Water content, % V/V | 0.0028 | 0.0288 | 0.0021 | ≤0.02 | ≤0.05 | ≤0.02 |

| Lubricity, µm | 406 | 166 | 344 | ≤460 | ≤460 | ≤460 |

| Cetane number | ~53 | 51.7 | 74.3 | ≥51.0 | ≥51.0 | ≥70 |

| Flash point, °C | 74.8 | 110 | 65.0 | >55.0 | >120.0 | >55.0 |

| Elemental composition, H % | 13.31 | 11.82 | 15.62 | - | - | - |

| Elemental composition, C % | 86.69 | 77.52 | 84.38 | - | - | - |

| Elemental composition, S ppm | Below detection limit | ≤10 | ≤10 | ≤5 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Žaglinskis, J.; Rimkus, A. Research on the Performance Parameters of a Compression-Ignition Engine Fueled by Blends of Diesel Fuel, Rapeseed Methyl Ester and Hydrotreated Vegetable Oil. Sustainability 2023, 15, 14690. https://doi.org/10.3390/su152014690

Žaglinskis J, Rimkus A. Research on the Performance Parameters of a Compression-Ignition Engine Fueled by Blends of Diesel Fuel, Rapeseed Methyl Ester and Hydrotreated Vegetable Oil. Sustainability. 2023; 15(20):14690. https://doi.org/10.3390/su152014690

Chicago/Turabian StyleŽaglinskis, Justas, and Alfredas Rimkus. 2023. "Research on the Performance Parameters of a Compression-Ignition Engine Fueled by Blends of Diesel Fuel, Rapeseed Methyl Ester and Hydrotreated Vegetable Oil" Sustainability 15, no. 20: 14690. https://doi.org/10.3390/su152014690

APA StyleŽaglinskis, J., & Rimkus, A. (2023). Research on the Performance Parameters of a Compression-Ignition Engine Fueled by Blends of Diesel Fuel, Rapeseed Methyl Ester and Hydrotreated Vegetable Oil. Sustainability, 15(20), 14690. https://doi.org/10.3390/su152014690