Extraction and Characterisation of Maltene from Virgin Asphalt as a Potential Rejuvenating Agent

Abstract

1. Introduction

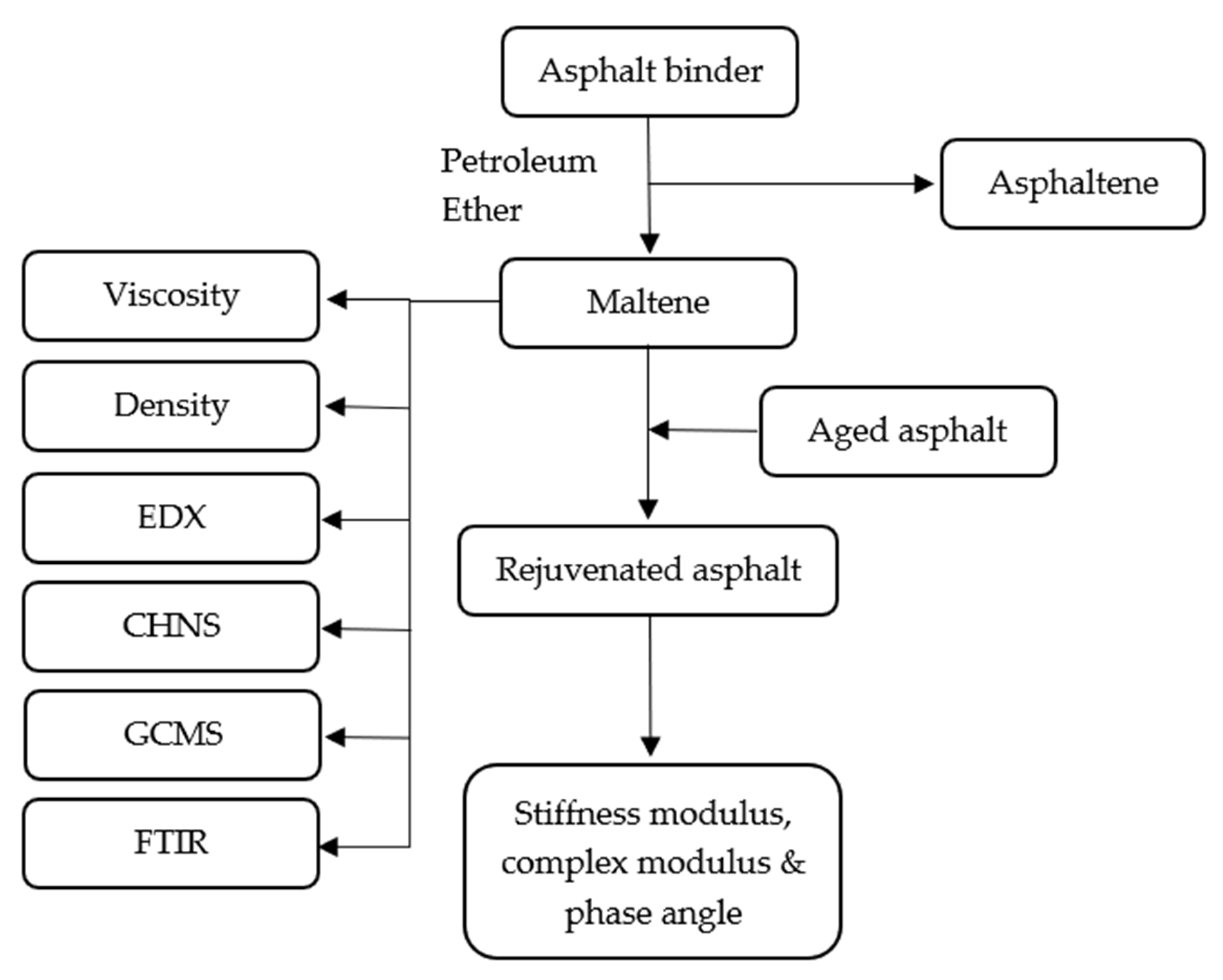

2. Methodology

2.1. Maltene Extraction Standard Methods

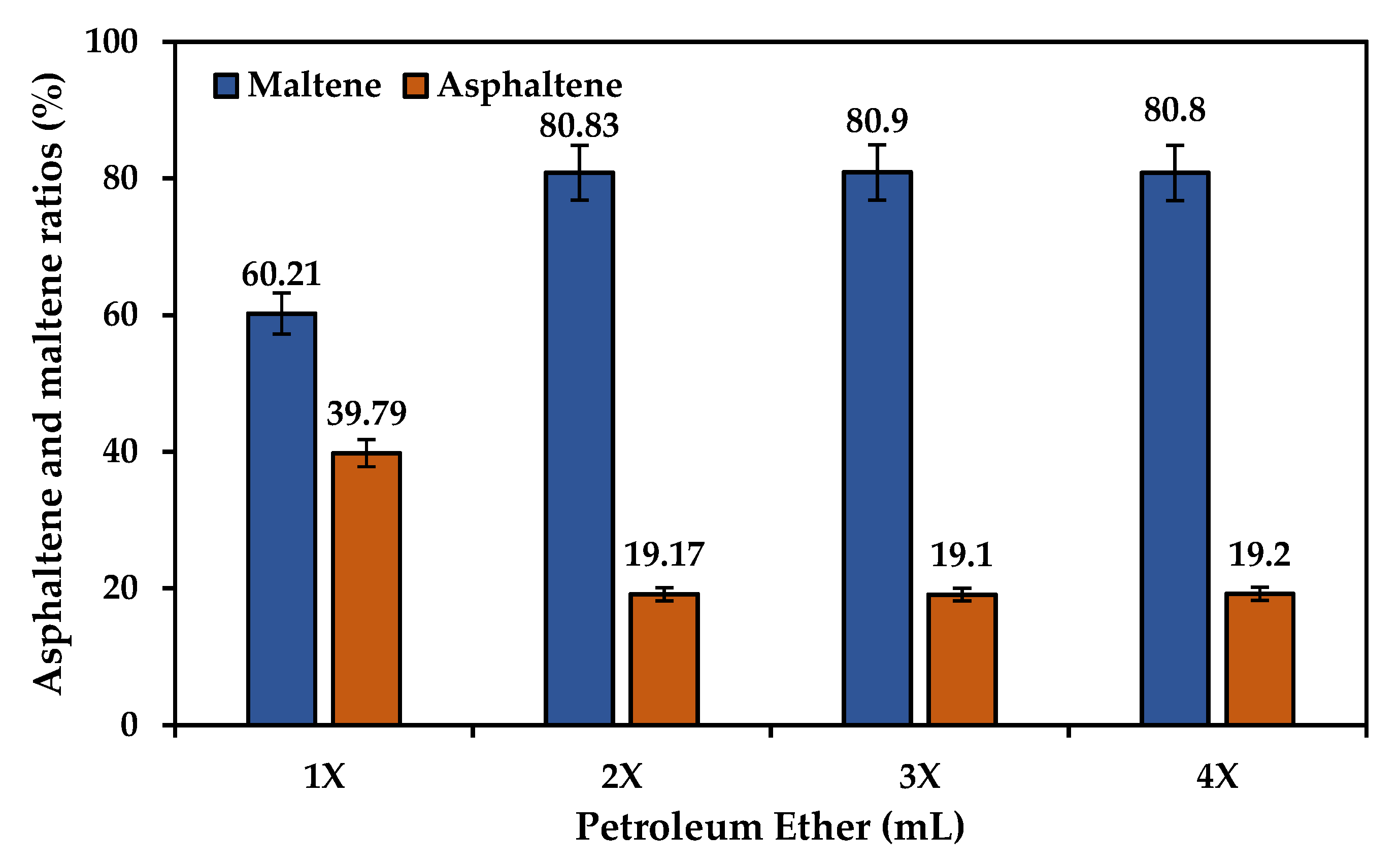

2.1.1. Determination of the Asphalt to Petroleum Ether Ratio

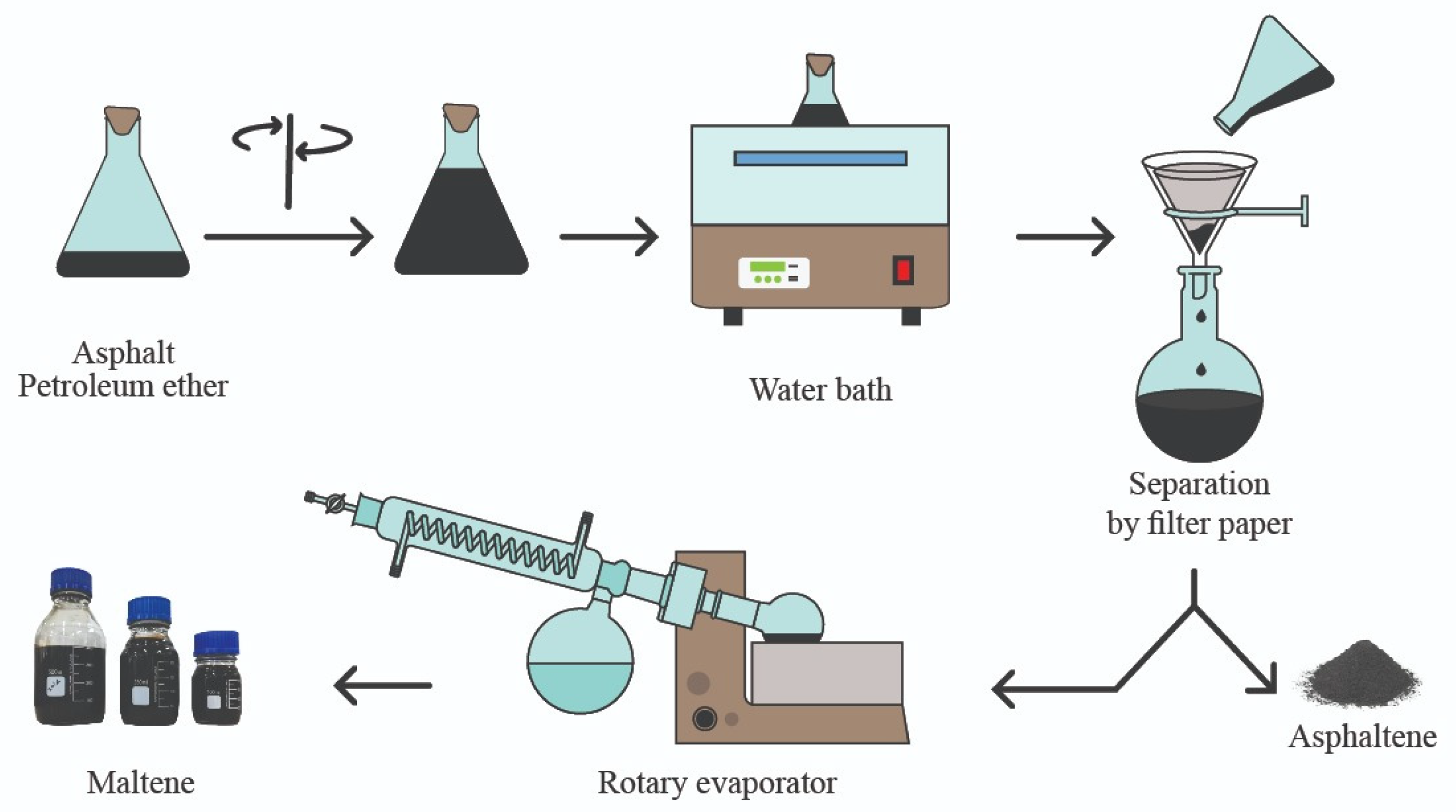

2.1.2. Extraction and Recovery of Maltene

2.2. Characterisation of Maltene

2.2.1. Viscosity

2.2.2. Density

2.2.3. Elemental Analysis Using Energy Dispersive X-ray (EDX)

2.2.4. Elemental Analysis Using Elemental Analyser

2.2.5. Gas Chromatography–Mass Spectrometry (GC–MS)

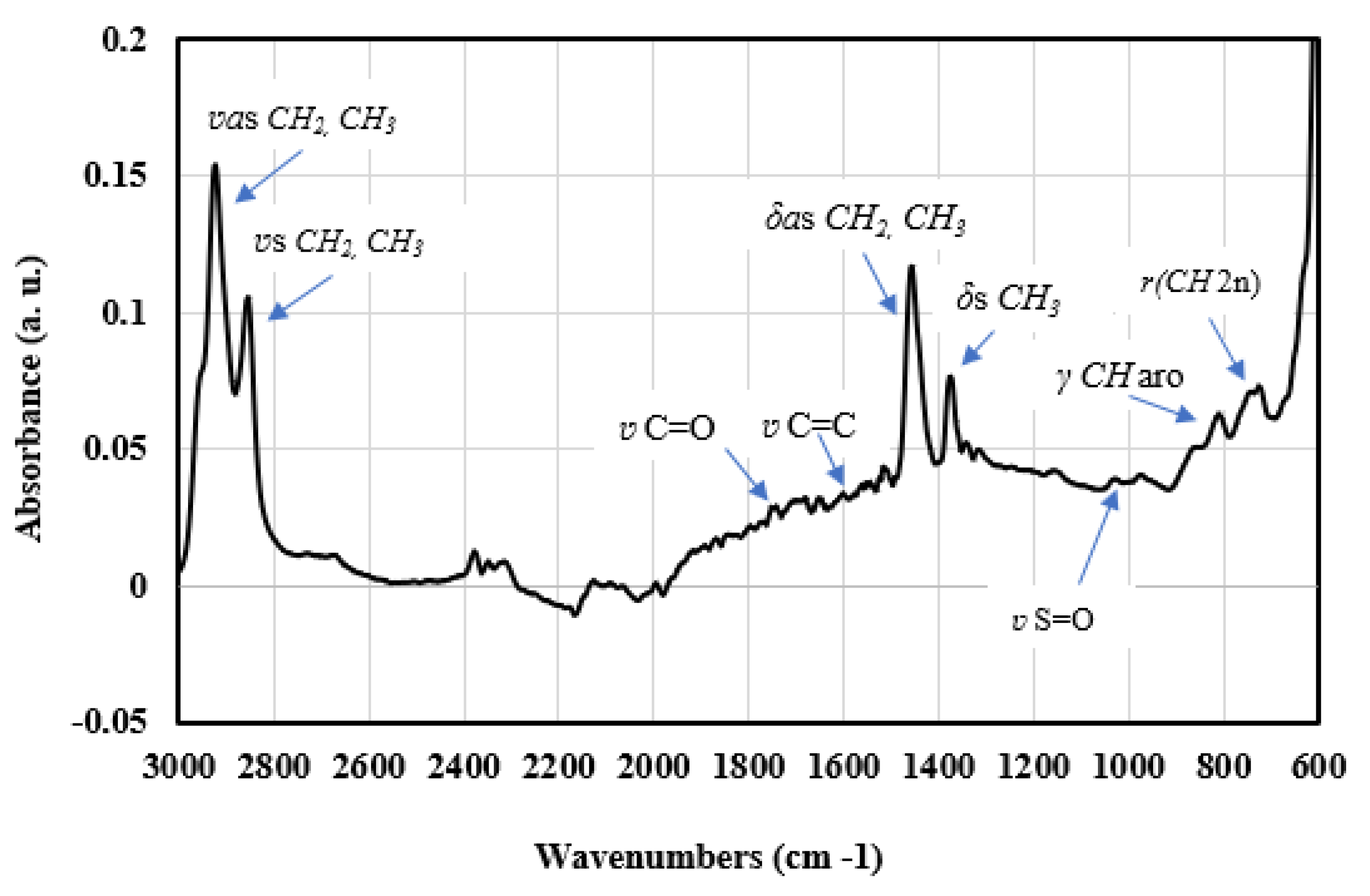

2.2.6. Fourier-Transform Infrared (FTIR)

2.2.7. Aged Binder’s Properties Restoration

3. Results and Discussion

3.1. Determining the Asphalt to Petroleum Ether Ratio

3.2. Viscosity and Density of Maltene

3.3. Chemical Compounds Analysis

3.4. Elemental Analysis

3.5. Fourier-Transform Infrared (FTIR)

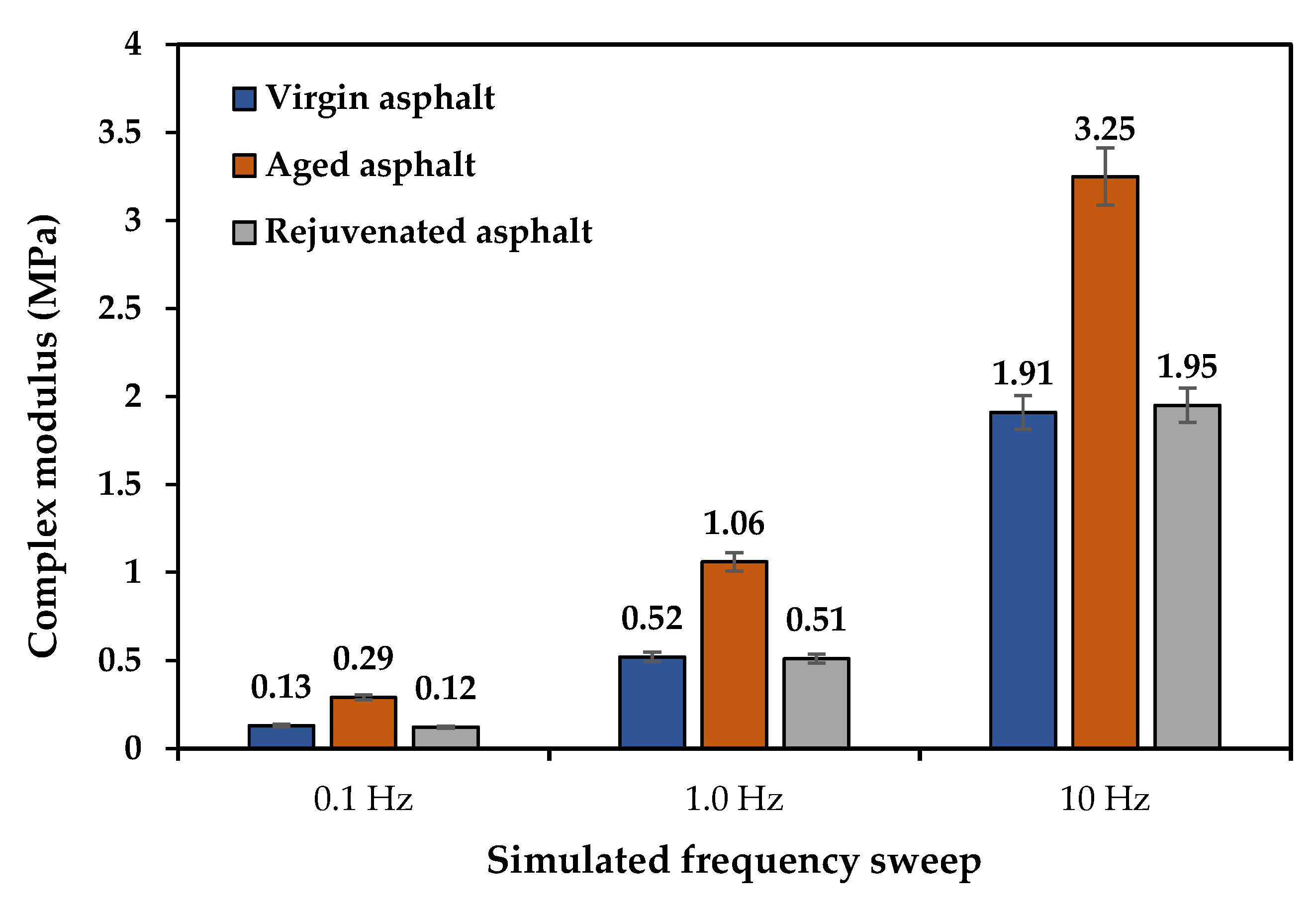

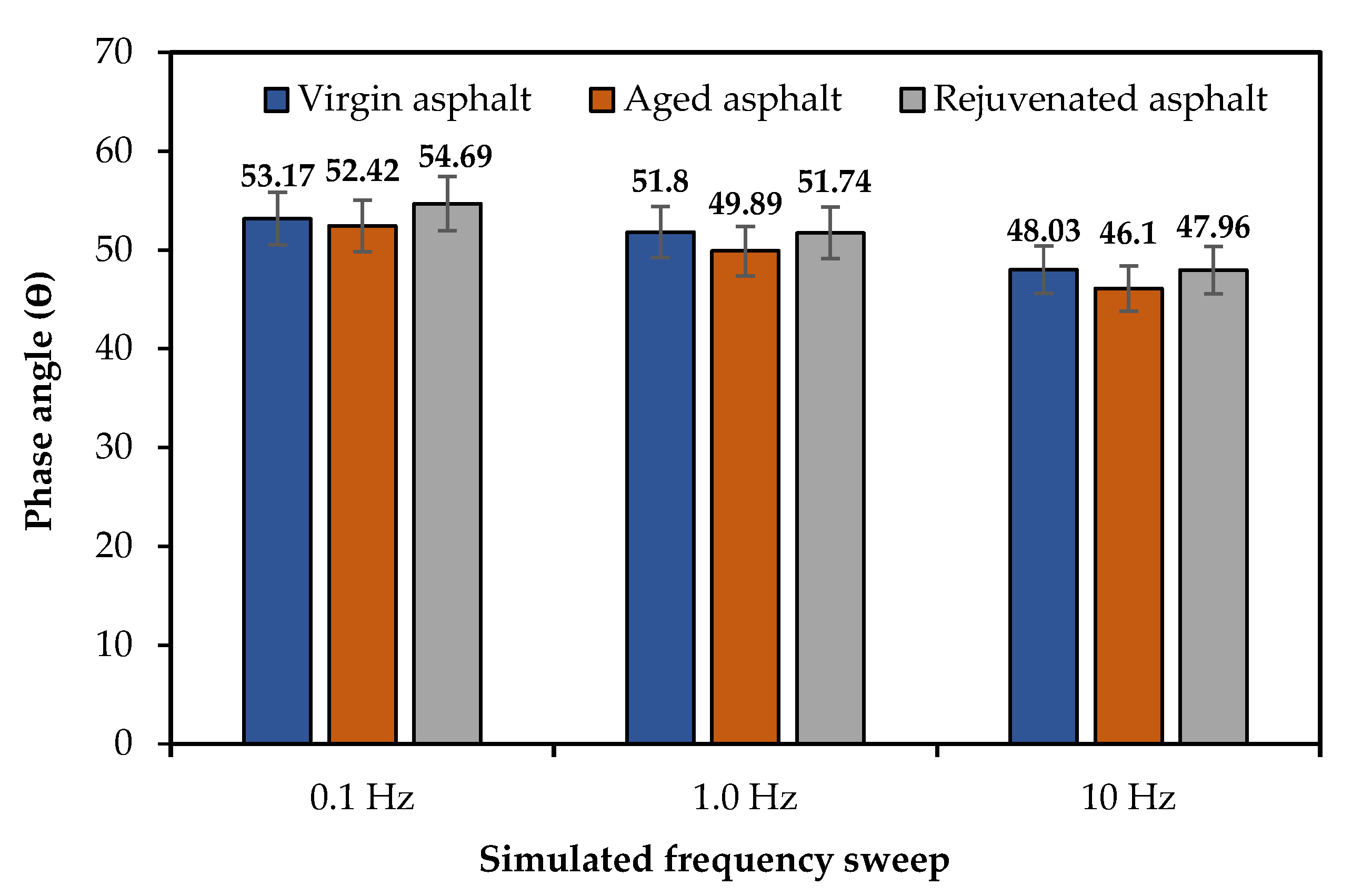

3.6. Stiffness at High and Low Temperatures

4. Conclusions

- Extraction and characterisation of maltene from more than one resource of asphalt is suggested.

- Research on the effect of short- and long-term ageing on the physical, rheological and microstructure characteristics of aged asphalt incorporating maltene is recommended.

- Future research should examine the surface-free energy (SFE), the binder bond strength (BBS) and compression pull-off test (CPOT) tests before and after ageing to understand the bonding and interactions between the aggregate and rejuvenated asphalt.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xu, M.; Zhang, Y. Study of rejuvenators dynamic diffusion behavior into aged asphalt and its effects. Constr. Build. Mater. 2020, 261, 120673. [Google Scholar] [CrossRef]

- Zhang, Y.; Bahia, H.U. Effects of recycling agents (RAs) on rutting resistance and moisture susceptibility of mixtures with high RAP/RAS content. Constr. Build. Mater. 2021, 270, 121369. [Google Scholar] [CrossRef]

- Al-Saffar, Z.H.; Yaacob, H.; Satar, M.K.I.M.; Kamarudin, S.N.N.; Mahmud, M.Z.H.; Ismail, C.R.; Hassan, S.A.; Mashros, N. A review on the usage of waste engine oil with aged asphalt as a rejuvenating agent. Mater. Today Proc. 2021, 42, 2374–2380. [Google Scholar] [CrossRef]

- Leng, Z.; Sreeram, A.; Padhan, R.K.; Tan, Z. Value-added application of waste PET based additives in bituminous mixtures containing high percentage of reclaimed asphalt pavement (RAP). J. Clean. Prod. 2018, 196, 615–625. [Google Scholar] [CrossRef]

- Hayat, U.; Rahim, A.; Khan, A.H.; Rehman, Z.U. Use of plastic wastes and reclaimed asphalt for sustainable development. Balt. J. Road Bridge Eng. 2020, 15, 182–196. [Google Scholar] [CrossRef]

- Ahmed, R.B.; Hossain, K. Waste cooking oil as an asphalt rejuvenator: A state-of-the-art review. Constr. Build. Mater. 2020, 230, 116985. [Google Scholar] [CrossRef]

- Bajaj, A.; Martin, A.E.; King, G.; Glover, C.; Kaseer, F.; Arámbula-Mercado, E. Evaluation and classification of recycling agents for asphalt binders. Constr. Build. Mater. 2020, 260, 119864. [Google Scholar] [CrossRef]

- Wang, F.; Xiao, Y.; Cui, P.; Lin, J.; Li, M.; Chen, Z. Correlation of asphalt performance indicators and aging Degrees: A review. Constr. Build. Mater. 2020, 250, 118824. [Google Scholar] [CrossRef]

- Zhang, Z.; Han, S.; Han, X.; Dong, S.; Yao, T. Performance changes of hot recycled asphalt mixture in different layers under coupling of multiple aging factors. Constr. Build. Mater. 2021, 269, 121343. [Google Scholar] [CrossRef]

- Al-Saffar, Z.H.; Yaacob, H.; Satar, M.K.I.M.; Jaya, R.P. Impacts of Maltene on the Wettability and Adhesion Properties of Rejuvenated Asphalt Binder. Arab. J. Sci. Eng. 2021, 46, 10557–10568. [Google Scholar] [CrossRef]

- Ding, H.; Hesp, S.A. Another look at the use of modulated differential scanning calorimetry to study thermoreversible aging phenomena in asphalt binders. Constr. Build. Mater. 2021, 267, 121787. [Google Scholar] [CrossRef]

- Fischer, H.R.; Cernescu, A. Relation of chemical composition to asphalt microstructure–Details and properties of micro-structures in bitumen as seen by thermal and friction force microscopy and by scanning near-filed optical microscopy. Fuel 2015, 153, 628–633. [Google Scholar] [CrossRef]

- Pasetto, M.; Baliello, A.; Giacomello, G.; Pasquini, E. Towards very high RAP content asphalt mixes: A comprehensive performance-based study of rejuvenated binders. J. Transp. Eng. Engl. Ed. 2021, 8, 1022–1035. [Google Scholar] [CrossRef]

- Speight, J.G. Asphalt Materials Science and Technology; Butterworth-Heinemann: Oxford, UK, 2015. [Google Scholar]

- Yang, C.; Xie, J.; Wu, S.; Amirkhanian, S.; Zhou, X.; Ye, Q.; Yang, D.; Hu, R. Investigation of physicochemical and rheological properties of SARA components separated from bitumen. Constr. Build. Mater. 2020, 235, 117437. [Google Scholar] [CrossRef]

- Zaumanis, M.; Boesiger, L.; Kunz, B.; Mazzoni, H.; Bruhin, P.; Mazor, S.; Poulikakos, L. Three indexes to characterise crushing and screening of reclaimed asphalt pavement. Int. J. Pavement Eng. 2021, 23, 4977–4990. [Google Scholar] [CrossRef]

- Cavalli, M.; Griffa, M.; Bressi, S.; Partl, M.; Tebaldi, G.; Poulikakos, L. Multiscale imaging and characterization of the effect of mixing temperature on asphalt concrete containing recycled components. J. Microsc. 2016, 264, 22–33. [Google Scholar] [CrossRef]

- Ali, A.W.; Mehta, Y.A.; Nolan, A.; Purdy, C.; Bennert, T. Investigation of the impacts of aging and RAP percentages on effectiveness of asphalt binder rejuvenators. Constr. Build. Mater. 2016, 110, 211–217. [Google Scholar] [CrossRef]

- Muñoz, M.; Haag, R.; Figi, R.; Schreiner, C.; Zaumanis, M.; Cavalli, M.; Poulikakos, L.; Heeb, N. Environmental impact of rejuvenators in asphalt mixtures containing high reclaimed asphalt content. Road Mater. Pavement Des. 2021, 23, 1400–1414. [Google Scholar] [CrossRef]

- Tang, W.; Yu, X.; Li, N.; Dong, F.; Wang, Z.; Zhang, Y. Effect of Rejuvenators on the Workability and Performances of Reclaimed Asphalt Mixtures. Materials 2021, 14, 6385. [Google Scholar] [CrossRef]

- Pan, P.; Kuang, Y.; Hu, X.; Zhang, X. A comprehensive evaluation of rejuvenator on mechanical properties, durability, and dynamic characteristics of artificially aged asphalt mixture. Materials 2018, 11, 1554. [Google Scholar] [CrossRef]

- Roberts, F.L.; Kandhal, P.S.; Brown, E.R.; Lee, D.-Y.; Kennedy, T.W. Hot Mix Asphalt Materials, Mixture Design and Construction; TRB: Lanham, MD, USA, 1996. [Google Scholar]

- Loise, V.; Caputo, P.; Porto, M.; Calandra, P.; Angelico, R.; Oliviero Rossi, C. A review on Bitumen Rejuvenation: Mechanisms, materials, methods and perspectives. Appl. Sci. 2019, 9, 4316. [Google Scholar] [CrossRef]

- Rathore, M.; Zaumanis, M. Impact of laboratory mixing procedure on the properties of reclaimed asphalt pavement mixtures. Constr. Build. Mater. 2020, 264, 120709. [Google Scholar] [CrossRef]

- Nsengiyumva, G.; Haghshenas, H.F.; Kim, Y.-R.; Kommidi, S.R. Mechanical-Chemical Characterization of the Effects of Type, Dosage, and Treatment Methods of Rejuvenators in Aged Bituminous Materials. Transp. Res. Rec. 2020, 2674, 126–138. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B.; Frank, R. Evaluation of rejuvenator’s effectiveness with conventional mix testing for 100% reclaimed Asphalt pavement mixtures. Transp. Res. Rec. 2013, 2370, 17–25. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B.; Poulikakos, L.; Frank, R. Influence of six rejuvenators on the performance properties of Reclaimed Asphalt Pavement (RAP) binder and 100% recycled asphalt mixtures. Constr. Build. Mater. 2014, 71, 538–550. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B.; Frank, R. 100% recycled hot mix asphalt: A review and analysis. Resour. Conserv. Recycl. 2014, 92, 230–245. [Google Scholar] [CrossRef]

- Moghaddam, T.B.; Baaj, H. The use of rejuvenating agents in production of recycled hot mix asphalt: A systematic review. Constr. Build. Mater. 2016, 114, 805–816. [Google Scholar] [CrossRef]

- Xiao, F.; Amirkhanian, S.N.; Shen, J.; Putman, B. Influences of crumb rubber size and type on reclaimed asphalt pavement (RAP) mixtures. Constr. Build. Mater. 2009, 23, 1028–1034. [Google Scholar] [CrossRef]

- Fernandes, S.; Peralta, J.; Oliveira, J.; Williams, R.; Silva, H. Improving asphalt mixture performance by partially replacing bitumen with waste motor oil and elastomer modifiers. Appl. Sci. 2017, 7, 794. [Google Scholar] [CrossRef]

- El-Shorbagy, A.M.; El-Badawy, S.M.; Gabr, A.R. Investigation of waste oils as rejuvenators of aged bitumen for sustainable pavement. Constr. Build. Mater. 2019, 220, 228–237. [Google Scholar] [CrossRef]

- DeDene, C.D.; You, Z.-P. The performance of aged asphalt materials rejuvenated with waste engine oil. Int. J. Pavement Res. Technol. 2014, 7, 145–152. [Google Scholar]

- Qurashi, I.A.; Swamy, A.K. Viscoelastic properties of recycled asphalt binder containing waste engine oil. J. Clean. Prod. 2018, 182, 992–1000. [Google Scholar] [CrossRef]

- Jia, X.; Huang, B.; Bowers, B.F.; Zhao, S. Infrared spectra and rheological properties of asphalt cement containing waste engine oil residues. Constr. Build. Mater. 2014, 50, 683–691. [Google Scholar] [CrossRef]

- Villanueva, A.; Ho, S.; Zanzotto, L. Asphalt modification with used lubricating oil. Can. J. Civ. Eng. 2008, 35, 148–157. [Google Scholar] [CrossRef]

- Borhan, M.N.; Suja, F.; Ismail, A.; Rahmat, R. The effects of used cylinder oil on asphalt mixes. Eur. J. Sci. Res. 2009, 28, 398–411. [Google Scholar]

- Al-Saffar, Z.H.; Yaacob, H.; Mohd Satar, M.K.I.; Saleem, M.K.; Jaya, R.P.; Lai, C.J.; Shaffie, E. Evaluating the Chemical and Rheological Attributes of Aged Asphalt: Synergistic Effects of Maltene and Waste Engine Oil Rejuvenators. Arab. J. Sci. Eng. 2020, 45, 8685–8697. [Google Scholar] [CrossRef]

- Elkashef, M.; Williams, R.C. Improving fatigue and low temperature performance of 100% RAP mixtures using a soybean-derived rejuvenator. Constr. Build. Mater. 2017, 151, 345–352. [Google Scholar] [CrossRef]

- Al-Saffar, Z.H.; Yaacob, H.; Satar, M.K.I.M.; Saleem, M.K.; Jaya, R.P.; Basar, N.; Radeef, H.R.; Hassan, N.A. Effects of maltene on the attributes of reclaimed asphalt pavement: Performance optimisation. Constr. Build. Mater. 2021, 302, 124210. [Google Scholar] [CrossRef]

- Al-Saffar, Z.H.; Yaacob, H.; Saleem, M.K.; Mohd Satar, M.K.I.; Putra Jaya, R.; Bilema, M.; Lai, C.J.; Mahmud, M.Z.H. A new approach to enhance the reclaimed asphalt pavement features: Role of maltene as a rejuvenator. Road Mater. Pavement Des. 2021, 23, 2507–2530. [Google Scholar] [CrossRef]

- Lesueur, D. The colloidal structure of bitumen: Consequences on the rheology and on the mechanisms of bitumen modification. Adv. Colloid Interface Sci. 2009, 145, 42–82. [Google Scholar] [CrossRef]

- Hussein, Z.; Yaacob, H.; Idham, M.; Hassan, N.; Choy, L.; Jaya, R. Restoration of Aged Bitumen Properties Using Maltenes. In Proceedings of the 2nd Global Congress on Construction, Material and Structural Engineering, Melaka, Malaysia, 26–27 August 2019; IOP Publishing: Bristol, UK, 2020; p. 012014. [Google Scholar] [CrossRef]

- Sharma, B.K.; Sharma, C.; Bhagat, S.; Erhan, S. Maltenes and asphaltenes of petroleum vacuum residues: Physico-chemical characterization. Pet. Sci. Technol. 2007, 25, 93–104. [Google Scholar] [CrossRef]

- Dehkissia, S.N.; Larachi, F.Ç.; Chornet, E. Catalytic (Mo) upgrading of Athabasca bitumen vacuum bottoms via two-step hydrocracking and enhancement of Mo–heavy oil interaction. Fuel 2004, 83, 1323–1331. [Google Scholar] [CrossRef]

- Speight, J.G. Handbook of Petroleum Product Analysis; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- ASTM-D4124; Standard Test Method for Separation of Asphalt into Four Fractions. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM-D7042; Standard Test Method for Dynamic Viscosity and Density of Liquids by Stabinger Viscometer (and the Calculation of Kinematic Viscosity). ASTM International: West Conshohocken, PA, USA, 2014.

- Feng, Z.-G.; Bian, H.-J.; Li, X.-J.; Yu, J.-Y. FTIR analysis of UV aging on bitumen and its fractions. Mater. Struct. 2016, 49, 1381–1389. [Google Scholar] [CrossRef]

- Hunter, R.N.; Self, A.; Read, J.; Hobson, E. The Shell Bitumen Handbook; Ice Publishing: London, UK, 2015; Volume 514. [Google Scholar]

- Zhang, R.; Wang, H.; You, Z.; Jiang, X.; Yang, X. Optimization of bio-asphalt using bio-oil and distilled water. J. Clean. Prod. 2017, 165, 281–289. [Google Scholar] [CrossRef]

- Fini, E.H.; Kalberer, E.W.; Shahbazi, A.; Basti, M.; You, Z.; Ozer, H.; Aurangzeb, Q. Chemical characterization of biobinder from swine manure: Sustainable modifier for asphalt binder. J. Mater. Civ. Eng. 2011, 23, 1506–1513. [Google Scholar] [CrossRef]

- Yang, X.; Mills-Beale, J.; You, Z. Chemical characterization and oxidative aging of bio-asphalt and its compatibility with petroleum asphalt. J. Clean. Prod. 2017, 142, 1837–1847. [Google Scholar] [CrossRef]

- Gong, M.; Yang, J.; Zhang, J.; Zhu, H.; Tong, T. Physical–chemical properties of aged asphalt rejuvenated by bio-oil derived from biodiesel residue. Constr. Build. Mater. 2016, 105, 35–45. [Google Scholar] [CrossRef]

- Yusoff, N.I.M.; Breem, A.A.S.; Alattug, H.N.; Hamim, A.; Ahmad, J. The effects of moisture susceptibility and ageing conditions on nano-silica/polymer-modified asphalt mixtures. Constr. Build. Mater. 2014, 72, 139–147. [Google Scholar] [CrossRef]

- PubChem Compound Database; National Center for Biotechnology Information: Bethesda, MD, USA, 2016. Available online: https://pubchem.ncbi.nlm.nih.gov/ (accessed on 25 November 2022).

- Royal Society of Chemistry, C. S. a. S. C. 2015. Available online: https://www.rsc.org/ (accessed on 25 November 2022).

- Sihombing, A.V.R.; Subagio, B.S.; Hariyadi, E.S.; Yamin, A. Chemical, morphological, and high temperature rheological behaviour of Bioasbuton® as an alternative binder for asphalt concrete in Indonesia. J. King Saud Univ. Eng. Sci. 2021, 33, 308–317. [Google Scholar] [CrossRef]

- Al-Saffar, Z.H.; Yaacob, H.; Mohd Satar, M.K.I.; Putra Jaya, R.; Ismael, C.R.; Mohamed, A.; Rogo, K.U. Physical, rheological and chemical features of recycled asphalt embraced with a hybrid rejuvenating agent. Int. J. Pavement Eng. 2021, 23, 3036–3054. [Google Scholar] [CrossRef]

- Zhang, R.; You, Z.; Wang, H.; Chen, X.; Si, C.; Peng, C. Using bio-based rejuvenator derived from waste wood to recycle old asphalt. Constr. Build. Mater. 2018, 189, 568–575. [Google Scholar] [CrossRef]

- Zhang, R.; You, Z.; Wang, H.; Ye, M.; Yap, Y.K.; Si, C. The impact of bio-oil as rejuvenator for aged asphalt binder. Constr. Build. Mater. 2019, 196, 134–143. [Google Scholar] [CrossRef]

- Zhu, H.; Xu, G.; Gong, M.; Yang, J. Recycling long-term-aged asphalts using bio-binder/plasticizer-based rejuvenator. Constr. Build. Mater. 2017, 147, 117–129. [Google Scholar] [CrossRef]

- Cavalli, M.C.; Zaumanis, M.; Mazza, E.; Partl, M.N.; Poulikakos, L.D. Effect of ageing on the mechanical and chemical properties of binder from RAP treated with bio-based rejuvenators. Compos. B Eng. 2018, 141, 174–181. [Google Scholar] [CrossRef]

| Method | Precipitant | Volume Precipitant per Gram of Sample |

|---|---|---|

| ASTM D893 | n-Pentane | 10 mL |

| ASTM D2007 | n-Pentane | 10 mL |

| ASTM D3279 | n-Heptane | 100 mL |

| ASTM D4124 | n-Heptane | 100 mL |

| ASTM D6560 | n-Heptane | 30 mL |

| Number | Viscosity (mPa.s) | Torque (%) | Shear Stress (N/m2) |

|---|---|---|---|

| 1 | 59.39 | 25.8 | 0.59 |

| 2 | 61.00 | 31.8 | 0.73 |

| 3 | 52.62 | 32.0 | 0.74 |

| 4 | 47.48 | 33.0 | 0.76 |

| N | Compound | Area (%) | Formula | Molecular Weight (g/mol) [56] | Boiling Point (°C) [56,57] |

|---|---|---|---|---|---|

| 1 | 1,4-Bis(trimethylsilyl)benzene | 43.08 | C12H22Si2 | 222.48 | 194.0 |

| 2 | Methyltris(trimethylsiloxy)silane | 8.67 | C10H30O3Si4 | 310.68 | 212.3 |

| 3 | Silane, 1,4-phenylenebis [trimethyl- | 5.12 | C14H26Si2 | 222.47 | 195.0 |

| 4 | Acetamide, N-[4-(trimethylsilyl)phenyl- | 4.22 | C11H17NOSi | 207.34 | 221.0 |

| 5 | Benzene, 2-[(tert-butyldimethylsilyl) oxy-1-isopropyl-4-methyl- | 3.46 | C16H28OSi | 264.48 | 300.5 |

| 6 | Cyclotrisiloxane, hexamethyl- | 3.38 | C6H18O3Si3 | 222.46 | 184.0 |

| 7 | Arsenous acid, tris(trimethylsilyl) ester | 3.15 | C9H27AsO3Si3 | 342.49 | 244.2 |

| 8 | Silicic acid, diethyl bis(trimethylsilyl) ester | 3.07 | C10H28O4Si3 | 296.58 | 231.0 |

| 9 | 2,4,6-Cycloheptatrien-1-one, 3,5-bis-trimethylsilyl- | 1.80 | C13H22OSi2 | 250.48 | 214.8 |

| 10 | benzenamine, 4-[2-(4-methoxyphenyl) ethenc-N,N-dimethyl- | 1.56 | C17H19NO | 253.34 | N/A |

| 11 | 1,2-Bis(trimethylsilyl)benzene | 1.41 | C12H22Si2 | 222.47 | 249.9 |

| 12 | 4-(4-Hydroxyphenyl)-4-methyl-2-pentanone | 1.19 | C12H16O2 | 192.25 | 309.6 |

| 13 | 4,5-Dibromo-6-chloro-2-benzoxazolinone | 0.96 | C7H2Br2ClNO2 | 327.36 | N/A |

| Test | C (%) | H (%) | N (%) | S (%) | O (%) |

|---|---|---|---|---|---|

| EDX | 93.6 | - | - | 5.5 | 0.8 |

| CHNS | 82.80 | 11.61 | 0.48 | 5.10 | - |

| Type of Asphalt | Loading Time: 1 s | |

|---|---|---|

| Stiffness at High Temperature (MPa) | Stiffness at Low Temperature (MPa) | |

| Virgin asphalt | 0.0061 | 72.12 |

| Aged asphalt | 0.0193 | 74.68 |

| Rejuvenated asphalt | 0.0063 | 72.37 |

| Type of asphalt | Loading time: 0.1 s | |

| Stiffness at high temperature | Stiffness at low temperature | |

| Virgin asphalt | 0.0481 | 175.5 |

| Aged asphalt | 0.1339 | 169.3 |

| Rejuvenated asphalt | 0.0499 | 174.9 |

| Type of asphalt | Loading time: 0.55 s | |

| Stiffness at high temperature | Stiffness at low temperature | |

| Virgin asphalt | 0.0104 | 92.43 |

| Aged asphalt | 0.3207 | 93.01 |

| Rejuvenated asphalt | 0.0108 | 92.48 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Saffar, Z.H.; Yaacob, H.; Al Jawahery, M.S.; Yousif, S.T.; Satar, M.K.I.M.; Jaya, R.P.; Radeef, H.R.; Eltwati, A.S.; Shaffie, E. Extraction and Characterisation of Maltene from Virgin Asphalt as a Potential Rejuvenating Agent. Sustainability 2023, 15, 909. https://doi.org/10.3390/su15020909

Al-Saffar ZH, Yaacob H, Al Jawahery MS, Yousif ST, Satar MKIM, Jaya RP, Radeef HR, Eltwati AS, Shaffie E. Extraction and Characterisation of Maltene from Virgin Asphalt as a Potential Rejuvenating Agent. Sustainability. 2023; 15(2):909. https://doi.org/10.3390/su15020909

Chicago/Turabian StyleAl-Saffar, Zaid Hazim, Haryati Yaacob, Mohammed S. Al Jawahery, Salim T. Yousif, Mohd Khairul Idham Mohd Satar, Ramadhansyah Putra Jaya, Hassanain Radhi Radeef, Ahmed Salama Eltwati, and Ekarizan Shaffie. 2023. "Extraction and Characterisation of Maltene from Virgin Asphalt as a Potential Rejuvenating Agent" Sustainability 15, no. 2: 909. https://doi.org/10.3390/su15020909

APA StyleAl-Saffar, Z. H., Yaacob, H., Al Jawahery, M. S., Yousif, S. T., Satar, M. K. I. M., Jaya, R. P., Radeef, H. R., Eltwati, A. S., & Shaffie, E. (2023). Extraction and Characterisation of Maltene from Virgin Asphalt as a Potential Rejuvenating Agent. Sustainability, 15(2), 909. https://doi.org/10.3390/su15020909