1. Introduction

In order to achieve global sustainable development, the Chinese government has proposed to all countries in the world to strive to achieve “carbon peak” before 2030 and “carbon neutrality” before 2060, that is, “double carbon” goal. According to the “China Building Energy Consumption Research Report (2020)” issued by the Energy Conservation Committee of China Building Energy Conservation Association, the total carbon emissions of the whole process of China’s construction in 2018 was 4.93 billion tons, accounting for 51.3% of the national carbon emissions. Therefore, whether the construction industry can achieve the ”double carbon” goal is crucial to China’s sustainable development.

In recent years, the prefabricated building industry are increasingly focused on “carbon peaking and carbon neutrality” in the construction field. Prefabricated building construction not only greatly saves water, energy, steel, wood and other resources, but also reduces construction waste and noise pollution. At the same time, prefabricated building construction can alleviate the shortage of labor force in the construction industry, and realize the transformation of the construction mode from the traditional extensive production and inefficient management to green, assembly, informatization and intelligentization. Therefore, it is particularly urgent to vigorously promote prefabricated buildings. At present, prefabricated buildings have achieved desired results in developed countries such as Europe, Japan, and Singapore, but promoting prefabricated buildings has been restricted to a certain extent in China [

1].

Since 2016, the China State Council has issued a series of documents such as “Guiding Opinions on Vigorously Developing Prefabricated Buildings”, which put forward the specific goal, which is to have prefabricated buildings account for 30% of new construction within a decade. The document requires that the application of prefabricated buildings should be enlarged with the three major urban agglomerations of Beijing-Tianjin-Hebei, Yangtze River Delta and Pearl River Delta as key areas. In 2017, the Ministry of Housing and Urban-Rural Development of China issued three major documents, namely, “The 13th Five-Year Plan for Prefabricated Buildings”, “Administrative Measures for Prefabricated Building Demonstration Cities”, and “Administrative Measures for Prefabricated Building Industry Bases”, indicating that the development of prefabricated buildings has risen to the national strategic level [

2]. In 2017, the Jiangsu Provincial Department of Housing and Urban-Rural Development issued the “Jiangsu Construction 2025 Action Outline”, which promotes the development of engineering construction methods to the integration direction of the “four modernizations” including refining construction, information technology, green construction and industrialization, and vigorously put a policy into practice in four new construction methods, namely lean construction, digital construction, green construction and prefabricated construction.

The document, namely “Implementation Opinions on Accelerating the Development of Prefabricated Buildings”, was released by the Yancheng government in 2017, and pointed out that the development path of government-guided, market-led, industry-driven and enterprise operation by the popularization and application of BIM technology to promote the development of prefabricated building design, production and construction. During the “Thirteenth Five-Year Plan” period, new prefabricated buildings of 3,795,900 square meters were built in Yancheng, and the ratio of prefabricated buildings area to new buildings area increased from 4% in 2018 to 30% in 2020. Six construction industry modernization demonstration bases have been settled in Yancheng, such as Funing Green Intelligent Building Industrial Base, and Jiangsu Shenggong Construction Co., Ltd. (240,000 cubic meters PC components). There are 32 manufacturers of prefabricated building components, such as Jiangsu Qianhe Prefabricated Building Technology Co., Ltd. and Jiangsu Jinmao Construction Group Co., Ltd., whose production covers concrete components, wood components and steel components. Yancheng Pioneer International Hotel project and Yancheng Hope Residential Community project were included in Jiangsu Province prefabricated building demonstration project in 2021. Yancheng government issued the document “Implementation Opinions on Vigorously Promoting the Development of Prefabricated Buildings”, which proposed the development goal of prefabricated buildings. Prefabricated buildings should account for more than 35% of initiated construction buildings, and assembled decoration buildings should take a proportion of more than 10% of new housing in 2021. By the end of 2025, prefabricated buildings will reach 50% of initiated construction buildings, and assembled decoration buildings will exceed 30% of delivered housing.

In Yancheng, prefabricated buildings have been gradually promoted, and relevant documents and policies had been launched to stimulate the prefabricated construction market. but there are still constraints on the vigorous development of prefabricated buildings, and problems that need to be deeply studied and solved urgently, for example, the secondary deepening design is not matched with some standards and specifications, and prefabricated buildings are assembled only on “three plates”(prefabricated interior and exterior wall plate, prefabricated stair plate, prefabricated floor plate), The lack of qualified construction professionals and unadvanced operation tools lead to low work efficiency, and it is even difficult to guarantee the installation quality of prefabricated structures. Therefore, the cost of prefabricated construction is not advantageous. At present, prefabricated building is limited to concrete structure, prefabricated steel-concrete composite structure is less, the information level of prefabricated building is not systematized to fail to achieve information management, and so on. The author participated in 30-31# group project construction of Yancheng Institute of Technology dormitory. The designed and produced inner wall plate (Autoclaved Lightweight Concrete (ALC)) does not integrate water and electricity pipelines, which led to slotting ALC to arrange the pipelines. Simple installation equipment, unprofessional construction workers, and inefficient construction make it difficult to guarantee the construction quality of dormitory buildings.

2. Literature Review

Factors influencing the promotion of prefabricated buildings are classified into driving factors and restrictive factors. In terms of driving factors, Li et al. analyzed three aspects: direct factors, indirect factors and fundamental factors [

3]. The results show that shortening the construction period, saving energy and reducing consumption, improving resource utilization and reducing on-site operations are the main driving factors. Wang et al. used a hybrid model to assess the environmental impact of prefabricated buildings and traditional cast-in-place buildings over the whole life cycle in Japanese construction cases [

4]. It was found that the total energy consumption and carbon emissions of 40% assembly buildings downed 7%, and compared to those of traditional cast-in-place buildings. Prefabricated buildings cost less than traditional cast-in-place buildings, reducing the price per square meter by more than 10%. As the assembly rate increases, carbon emissions and costs drop, reaching the bottom when the assembly rate is 60%. Through literature reviews and industry interviews, zhang et al. have identified and discussed the factors reflecting major changes in the current Australian prefabricated construction [

5]. These factors include prefabrication industry development, emerging benefits and challenges. The challenges identified from the interviews were grouped into eight fields, involving feasibility, design, manufacturing, transportation, site construction, standardization, skills and knowledge, funding and markets. With the increasing application of prefabricated structures in civil engineering, the seismic performance of prefabricated structures has attracted the wide attention of scholars all over the world. A novel seismic force-resisting system (SFRS) called Floor Isolated Re-entering Modular Construction System (FIRMOCS) has been proposed by Chen et al. for prefabricated modular mass timber (MT) construction [

6]. The preliminary results showed that FIRMOC systems significantly reduced the seismic demand on the prefabricated modular MT construction using nonlinear dynamic time-history analysis according to the National Building Code of Canada, thus leading to an improved seismic response. Moreover, modular integrated construction(MiC) is an important process to integrate and assemble prefabricated prefinished modules. Wuni et al. pointed out the critical success factors (CSFs) for implementing MiC projects during the period 1993–2019 [

7]. The study result showed that the US, UK, Malaysia, Australia, and Hong Kong are the largest contributors to the MiC CSFs. The further analysis generated 35 CSFs for implementing MiC projects. To improve the performance of the construction industry, design for manufacturing and assembly (DfMA) is introduced into the design of prefabricated buildings in the industrial building system (IBS) and prefabricated buildings, and combined with the parametric design of building information modeling (BIM). The main benefits, hindrances, and upsides of DfMA in the construction industry are discussed [

8,

9]. The implementation of the DfMA method in prefabricated construction projects is conducive to improving the level of green building activities. As can be seen from “World Green Building Trends 2021”, the highest levels of current green building activity are in Australia or New Zealand, Canada and the US. And the highest levels of growth in those doing a majority of green projects are expected in Brazil, Colombia, Canada and Mexico.

Many scholars have different reasons for restricting the development of prefabricated buildings in China. Bian et al. used principal component analysis to identify key factors, including market environment, industrial organization, policies and regulations, talent factors, technical systems, etc [

10]. Based on the willingness of developers, Lu et al. found that high construction costs and low customer perceived value are the main factors restricting the development of prefabricated buildings [

11]. Chen et al. pointed out from the perspective of the government that the problems in the implementation of prefabricated building policies included imperfect policy systems, insufficient environmental conditions for policy implementation, and low enthusiasm for policy executors [

12]. Chen et al. proposed to increase incentives, improve incentive mechanisms, strengthen standardization, upgrade technical systems, and enhance publicity and education efforts to promote assembly development by building an evolutionary model of “government-developer” and “government-consumer” [

13].

Zhai et al. concluded that low supply chain integration, the inability to freeze the design in the early stage, the high cost, and the lack of supportive policies and relevant standards are the main contradictions restricting the development of prefabricated buildings in China [

14]. Zhang et al. used fuzzy analytic hierarchy process to analyze the main factors, and the conclusion was that the lack of professional talents and completive industrial chain, and the imperfection of relevant norms and standards restricted the development of China’s prefabricated buildings [

15]. Based on actual cases, Hong et al. analyzed and found that the main reason for the higher cost of prefabricated buildings in China than traditional buildings is the additional transportation and assembly costs of components [

16]. Xue et al. found that little innovation is one major reason to obstruct the promotion of Chinese prefabricated buildings through social network analysis (SNA) and structural equation modeling [

17]. Wu et al. studied the development of Chinese prefabricated buildings from the perspective of technology promotion and constructed a model of influencing factors from five aspects, including industry, company, technology, government, and market. The results showed that technology has more influence on prefabricated buildings than cost [

18,

19,

20,

21,

22]. Lu et al. developed a lean-agile production system for prefabricated housing products based on market demand and production process to achieve a balance between market demand and production capacity [

23].

The prefabricated building construction method is similar to automobile production, relying on pre-designed components that are factory-made, specialized, and standardized. The main work on construction sites is to install components, which can cut down the construction period, on-site wet work and formwork, water and electricity consumption, construction waste, and help to protect the environment. Since China’s State Council promulgated “Guiding Opinions on Vigorously Developing Prefabricated Buildings” in 2016, and established 48 prefabricated building demonstration cities and 328 industrial demonstration bases [

24,

25]. the newly-started prefabricated building area in 2021 reached 740 million square meters, accounting for 24.5% of the new building area, and the newly-started prefabricated buildings in key construction areas accounted for 52.1% of the total in China [

26].

However, the popularization of prefabricated buildings increases construction costs and lacks supply-side resources and market awareness. Meanwhile, due to government requirements, market development, and environmental protection, most developers are still in passive acceptance and are forced to build prefabricated buildings. Prefabricated building construction is representative of advanced productive forces that can best reflect the advantages of technological progress and industrialization. In China, a package of policies and guidance has been formulated in the stage of exploration and development. Many challenges remain in technology, market, operation, and management that must be addressed for prefabricated building construction to become industrialized.

In recent years, the research on prefabricated buildings is on the rise, and most studies on constraints to the development of prefabricated buildings in China are comprehensive [

27,

28]. Due to the vast territory of China, the basic conditions and development status of prefabricated buildings in different provinces and cities are different, so specific and quantitative studies are needed. There are few reports on the development status and influencing factors of prefabricated buildings in a certain city in China. The present research is in the stage of theoretical research and qualitative analysis, lacking quantitative analysis and objective data support. Research on the interrelationship and hierarchical relationship of the restrictive factors that affect the promotion of prefabricated buildings is difficult to reflect the deep connection, and very unfavorable to formulate corresponding measures to develop prefabricated buildings.

3. Methodology

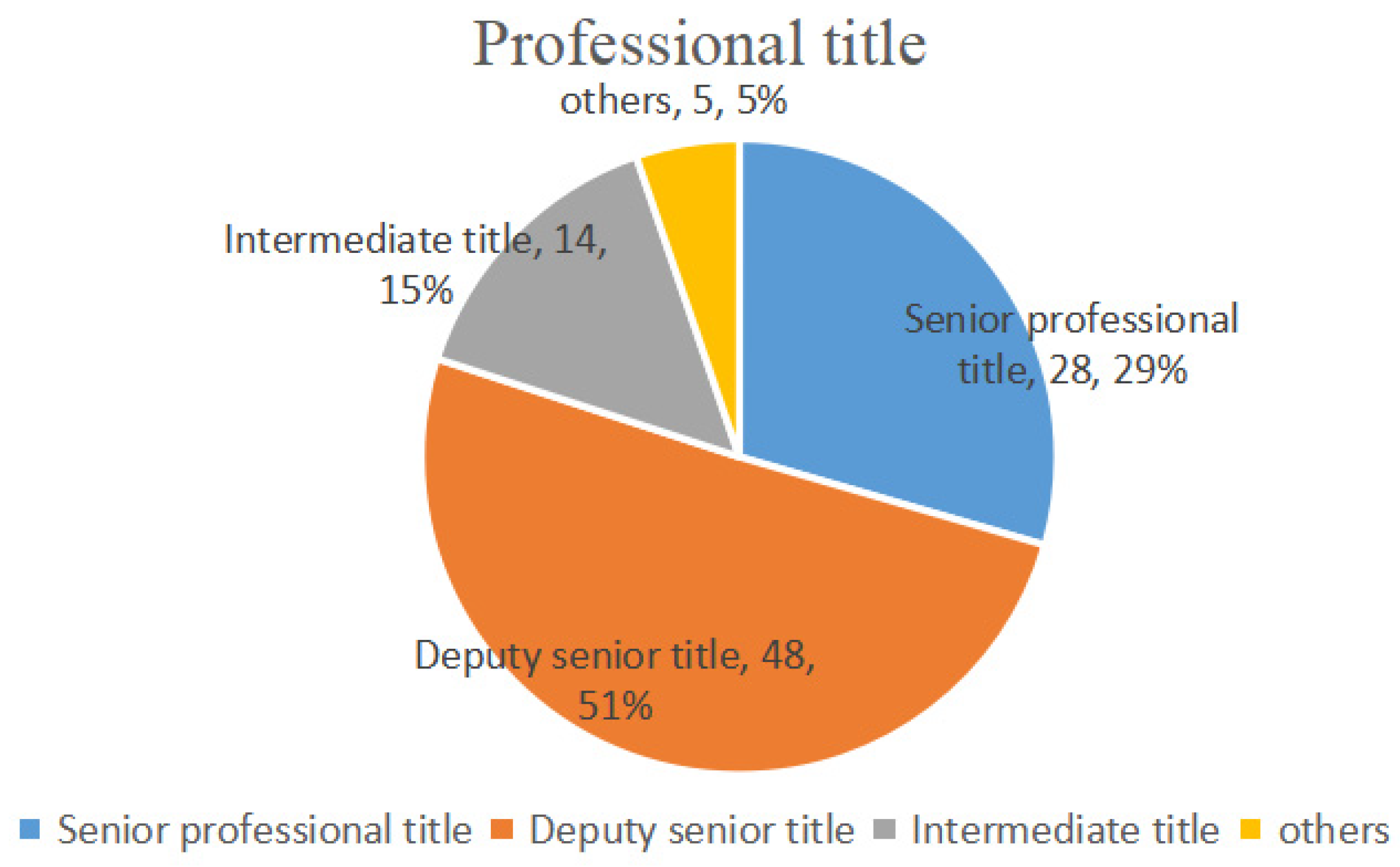

This paper takes the prefabricated building construction in Yancheng City, Jiangsu Province as an example. Taking into account the characteristics of geography, humanity, environment and economy, the constraints on the promotion and implementation of prefabricated buildings are sorted out and categorized, a constraint model is created. Factor analysis was carried out by IBM SPSS 22.0 software, and the reliability of the model was verified. The DEMATEL-ISM method was used to analyze the relationship between the influencing factors qualitatively and quantitatively. The main restricting factors were determined and the corresponding countermeasures were put forward.

3.1. Ideas for Extracting and Identifying Restrictive Factors

Using comparative and analytical research methods, many literatures in “CNKI” and “Web of Science” databases on the development and promotion of prefabricated buildings are reviewed, five types of constraints are identified by PEST theory: market, economy, technology, society, and policy.

Based on the analysis of the initial list of restricting factors, the framework table of the restricting factor index system is classified, the amendments based on expert opinions are drawn up, and the revised index system of restricting factors for the promotion and implementation of prefabricated buildings is established.

According to the above index system, questionnaires and statistical regression analysis, the authors identify effective constraints and verify the rationality of the constraint index system.

3.2. DEMATEL-ISM Combined Model Analysis Method

3.2.1. DEMATEL Analysis Steps

- (1)

Identifying influencing factors Sn.

- (2)

The numbers 0–4 represent the association between the factors, where the number 0–4 indicates the level of association between the factors from none, low, average, relatively high and high, respectively.

- (3)

Establishing the initial direct influence matrix.

The influence relationship between the factors can be shown from the matrix to create the initial direct influence matrix D. Dij represents the degree of influence of Si on Sj, Dij = 0,1,2,3,4.

- (4)

Normalizing the matrix.

The standardization matrix

B is obtained by normalizing the direct influence matrix

D, as shown in Equation (1).

- (5)

Calculating normalized direct influence matrix to obtain the combined influence matrix T, as shown in Equation (2).

where element matrix

I denotes the influence of the factor itself.

- (6)

Calculating influence degree fi, affected degree ei, centrality degree zi and cause degree yi for each factor.

Influence degree

fi and affected degree

ei are equal to the sum of each value in row

i and column

i of combined influence matrix

T, respectively. Centrality degree

zi which represents the degree of each factor’s importance is the sum of influence degree

fi and affected degree

ei, influence degree

fi minus affected degree

ei is equal tocause degree

yi, The Equations (3)–(6) are as follows.

- (7)

Centrality degree zi and cause degree yi of each factor are respectively taken as horizontal and vertical coordinates in the factor-cause-result diagram, and the position of each constraint is marked in the coordinate axis for intuitive analysis of the importance of each constraint.

3.2.2. DEMATEL-ISM Method

After completing step (7) of DEMATEL model analysis, Dematel-ISM model analysis is carried out in the following steps.

- (8)

Calculating the overall influence matrix

H. It is considered that the influence of each factor on itself is to be added, and the influence of the factors themselves can be reflected by the element matrix

I, the overall influence matrix

H can be obtained according to Equation (7).

- (9)

Calculating reachability matrix R according to specific threshold λ.

where λ is threshold value, in the process of selecting specific threshold, it is necessary to ensure the appropriate nodes and coordinate with the key nodes obtained by the DEMATEL method.

- (10)

Analysyzing hierarchical relation.

After solving reachable matrix R in step (9), reachable set P(Si) and antecedent set Q(Si) can be derived, P(Si) is the column set containing 1 in row i of R, and Q(Si) is rowset containing 1 in column i of R. When , 1st layer of factors can be obtained, and deleting this layer creates R1. In the same way, the ith layer of factors can be set up, and so on.

- (11)

Drawing the hierarchical diagram of constraints.

5. Discussion

5.1. DEMATEL Analysis Results

- (1)

Influence degree Analysis

The larger the influence degree value of a factor is, the more the factor influences other factors. Compared to the value of influence degree, the top five factors are S15, S13, S12, S14, and S9, as shown in

Table 15.

- (2)

Affected degree analysis

The higher the affected degree value of a factor is, the greater the factor is constrained by other factors. As can be seen from

Table 16, the top five most affected factors are S12 (insufficient market demand), S4 (insufficient enthusiasm for enterprise transformation), S11 (low public awareness and willingness to buy), and S1 (high construction cost and low-cost performance), S3 (low social acceptance).

- (3)

Centrality degree Analysis

It can be concluded from

Table 17, the larger the centrality degree is the closer the relationship between this factor and other factors in the system. In

Table 17, the top five factors with centrality values from large to small are S12, S1, S4, S3 and S9. S12 with the largest value of centrality degree is the most important factor, which closely relates to other constraints in the entire system.

- (4)

Cause degree Analysis

The larger the value of the degree of cause, the greater the influence this element has on other elements in the system. The reason degree sorting table is shown in

Table 18. It can be seen from the table that the top five causes are: S15, S14, S13, S5, and S9. Among them, S15 (Insufficient publicity by the government) has the highest degree of reason, indicating that the insufficient publicity of policies and regulations by the government in terms of prefabricated buildings has the greatest impact on other factors in the entire restrictive factor system.

The factors with high centrality are more closely related to other factors in the system and have greater influence, which are used as the basis to screen these important factors. According to the value of cause degree to rank 15 factors in

Table 18, the top five factors are A15, S14, S13, S5 and S9, which should be paid attention to develop Yancheng prefabricated buildings.

The factor with a high affected degree is defined as the resulting factor, which is easily affected by other factors in the system during the development of prefabricated buildings. In the process of formulating measures, it is concluded from

Figure 4 that it is necessary to take targeted measures for these factors.

Yancheng is a relatively underdeveloped city in Jiangsu Province, the Yancheng government has limited financial resources for the development of prefabricated buildings every year. Although the policies and documents have been formulated and promulgated to vigorously promote prefabricated buildings, the publicity of the policies only remains within the construction industry. Due to the lack of effective research and innovation system, the public generally believes that the structure of prefabricated buildings is unsafe, which restricts the promotion of Yancheng. From the perspective of long-term development, increasing financial investment, improving research & innovation, and strengthening public awareness and acceptance, all of which are the basis for vigorously promoting Yancheng prefabricated buildings.

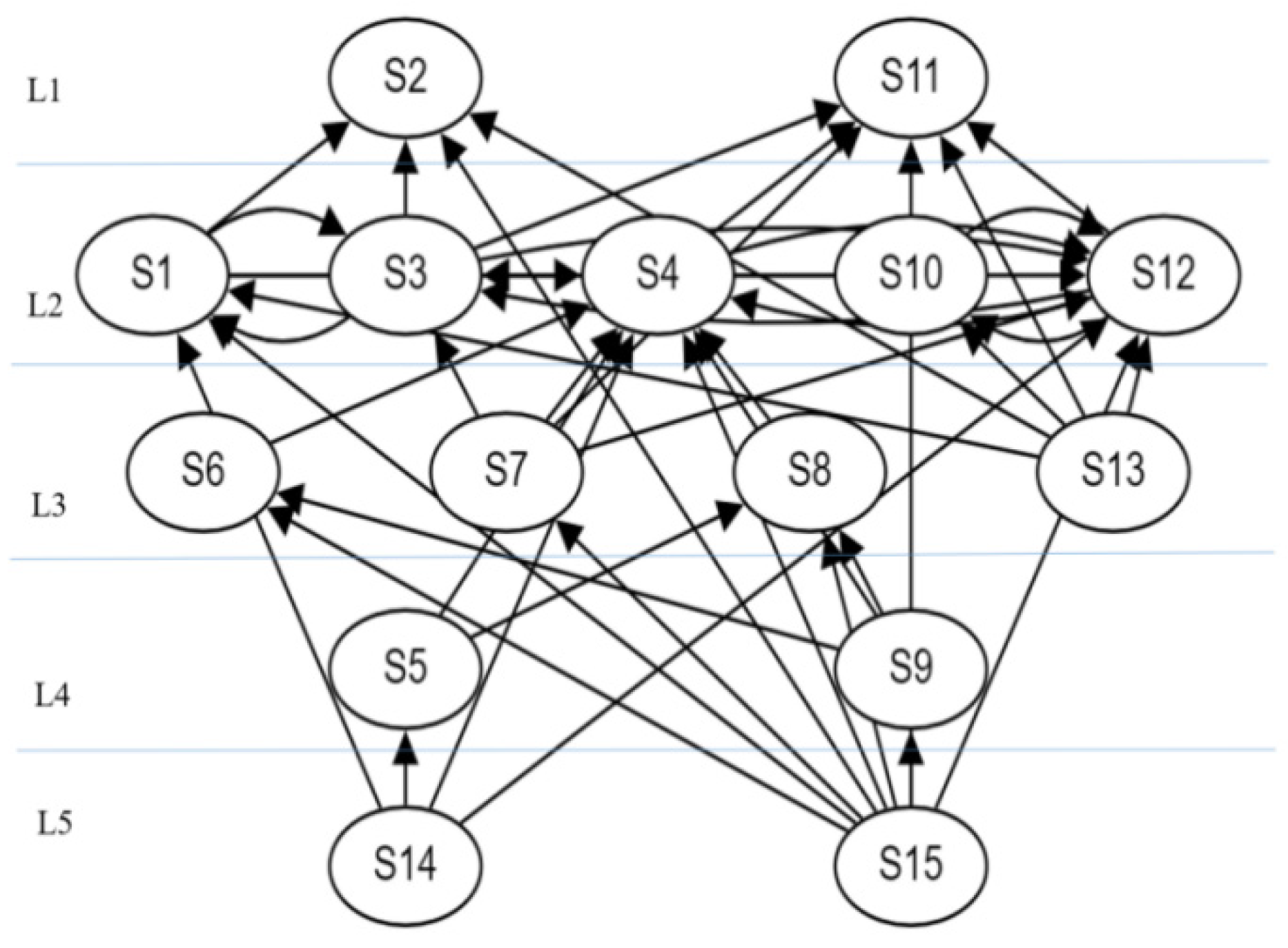

5.2. ISM Analysis Results

Figure 5 shows the multi-layer hierarchical relation obtained by the ISM method, then an important conclusion can be drawn that the constraint factor system of Yancheng prefabricated buildings is a five-layer hierarchical structure, and the hierarchy of the constraint factors is from simple to complex and from top to bottom.

The first layer of factors is the superficial restrictive factor, also known as the cause of proximity, including imperfect supporting industrial chain, low public awareness and low purchase willingness. In terms of the imperfection of the industrial chain, it is mainly reflected in the insufficient design capabilities, as well as the insufficient number and production capacity of component manufacturers. It is mainly reflected that the public with low awareness and willingness hardly initiate buying prefabricated houses and believing that the structure is safe. These factors are the direct reasons for the vigorous promotion of Yancheng prefabricated buildings.

The second to fourth layers belong to the middle-level constraints, also known as transition causes, including insufficient enthusiasm for enterprise transformation, insufficient market demand, high construction costs, low-cost performance, lack of talents, low social recognition, backward manufacturing management mode, unsound design standardization, modularization, and integrated systems, insufficient construction experience, imperfect industry policy and standard system, the relatively large initial investment, and the insufficient basic research and innovation. While these factors which belong to the middle part of the internal influence path of the system directly or indirectly affect surface factors, and are also affected by bottom constraint factors. In Yancheng, the cost and construction period of prefabricated buildings are higher than those of cast-in-place buildings, and the integrated design of various specialties has not been truly achieved. There is a lack of professional technicians and skilled installation workers. The on-site management mode still relies on traditional methods and lacks an intelligence management platform, etc. The factors that cause these problems are involved in market, economy, technology, society, and policy, with a wide distribution and a large number.

The fifth layer of factors belongs to the bottom constraints, also known as essential causes, including insufficient financial support and insufficient government publicity. The bottom-level constraints are the most complicated factors affecting the promotion of prefabricated buildings in Yancheng, and they have a relatively large impact on other factors. The scope of action is mainly the middle-level constraints, and the mechanism of action is direct or indirect. The two constraints included in the bottom-level constraints are factors at the policy level, so it is crucial to promote prefabricated buildings in Yancheng. Therefore, the Yancheng government needs to increase financial support, especially in terms of basic innovation and market cultivation, and strengthen publicity efforts. so that good policies can take root and improve public awareness and willingness to buy prefabricated houses. If the attention of the government, the inclination of policies and the investment of various resources, the underlying constraints will have been improved, it has a positive impact on the middle and surface constraints, and thus the healthy development of prefabricated buildings will be greatly gone on.

From the above, the following points are obtained:

- (1)

In the DEMATEL method, the reasons for the high centrality include insufficient basic research and innovation of prefabricated buildings, imperfect industry policies and standard systems, insufficient government publicity, lack of talents, and relatively low initial investment in scientific research. Large and insufficient financial support. These factors are likely to affect other factors in the system and play a greater role in the system. However, low social recognition, high construction cost and low-cost performance, low public awareness and purchase willingness are the primary result factors with high centrality, which are easily affected by other factors in the system.

- (2)

In the ISM method, Imperfect supporting industry chain, low public awareness and low willingness to purchase are superficial factors that directly affect the promotion and implementation of prefabricated buildings in Yancheng. Insufficient financial support and insufficient government publicity, as the underlying factors of the hierarchical structure, are the fundamental factors affecting the development of prefabricated buildings in Yancheng. They restrict the transitional factors and surface influencing factors within the system directly or indirectly. The problems must be solved with the promotion of prefabricated buildings in Yancheng.

6. Conclusions and Suggestions

Under the background of the “double carbon target” proposed by China, the development of the construction industry is towards green, low carbon, environmental protection and energy saving. The vigorous development of prefabricated buildings is in line with china’s sustainable development strategy. Yancheng in China, as an area for the promotion of prefabricated construction, has made some achievements in the development of the prefabricated construction industry, but there are still many unfavorable factors for its development. Through a series of studies in this paper, the index system of restricting factors affecting the development of the prefabricated construction industry is proposed and modified. the authors analyze the main restrictive factors of the prefabricated construction industry in Yancheng through the DEMATEL-ISM method and find out the key restrictive factors of vigorously promoting the prefabricated construction industry. It provides certain precision-oriented policies for promoting the development of prefabricated buildings in Yancheng. The main conclusions are as follows:

- (1)

Through literature review, it is concluded that prefabricated buildings are being gradually promoted around the world due to their low carbon, high efficiency, energy saving, green, and environmental protection. Among them, the United States, Canada, Australia and other countries have relatively high development levels by new methods of DfMA. The relatively rapid and high-quality development of the industrial chain in design, production and installation has been an important reference for the promotion of prefabricated buildings in China.

- (2)

Establishing the index system of restrictive factors of prefabricated buildings in Yancheng. Firstly, 25 restrictive factors of prefabricated buildings are preliminarily summarized and sorted out through literature analysis, and the general framework of the restrictive factor index system for the promotion and implementation of prefabricated buildings in Yancheng is initially formed. Then, through the form of asking for expert opinions and drawing on the experience of experts, the restrictive factors are revised to form an index system of restrictive factors for the promotion and implementation of prefabricated buildings in Yancheng. To ensure that the index system is reasonable and reliable, a large number of questionnaires are designed and issued to collect relevant data, and the reliability and validity analysis and factor analysis of the questionnaires are carried out to verify the scientificity of the index system of restrictive factors for the promotion and implementation of prefabricated buildings in Yancheng. Finally, the index system of restrictive factors for the promotion and implementation of prefabricated buildings in Yancheng is determined to be composed of 15 major restrictive factors in five aspects: market, economy, technology, society and policy.

- (3)

Analyzing the main constraints of prefabricated buildings in Yancheng. Based on the application of the DEMATEL method, we analyze the logical relationship and influence degree among the restrictive factors, and find out the cause factors and result factors in the constraint index system.; On the basis of the DEMATEL comprehensive matrix, ISM is used to establish an reachability matrix, and a hierarchical model including surface-level influencing factors, middle-level transition factors and bottom-level influencing factors is constructed, and the comprehensive level of each restrictive factor in the system is obtained. The key restrictive factors for the vigorous promotion of prefabricated buildings in Yancheng have been identified.

Based on the current situation of the development of prefabricated buildings in Yancheng, according to the research results: In terms of policies, regulations and standard systems, the government needs to continue to supplement and improve the system of policies and regulations related to prefabricated buildings, improve the implementability of various policies and standards, and strengthen the implementation of policies and standards.; In terms of government financial support, the Yancheng government needs to strengthen financial support and guarantee measures, and further refine and formulate specific incentive measures; In terms of government publicity, it is necessary to strengthen the exposure and promotion of major media, increase the enthusiasm of enterprise transformation and improve public awareness; In terms of technology and innovation, enterprises are encouraged to set up research and development institutions, focusing on the research and development of standardized design and construction technologies for prefabricated buildings.It is necessary to gradually promote the DfMA design method; In terms of personnel training, the government should encourage the cultivation of professional talents in colleges and universities in Yancheng, and strengthen the training of talents combining production, education and research; In terms of market cultivation, the government should focus on developing prefabricated construction industrial bases and parks, cultivate market production entities, and improve the industrial chain.