Abstract

Red mud is a byproduct of the aluminum oxide refining process that is an industrial waste residue. The storage of red mud can seriously contaminate the soil, water system, and atmosphere while also taking up a lot of valuable land resources. However, the use of stabilized/amended red mud technology in road engineering is relatively limited. Consequently, this research investigates how additives (cement, lime, and phosphogypsum) affect the strength of amended red mud as road base material. Additionally, it examines the effects of dry–wet and freeze–thaw cycles on the UCS, pH, dry density, and evolution of micropore structure in amended red mud with different phosphogypsum content. The findings reveal that, after five dry–wet and freeze–thaw cycles, the samples with 2% phosphogypsum content have a strong assurance rate of more than 85%. The percentage of micropores (0.01–0.1 μm) is reduced, although the percentage of small pores (0.1–1 μm) and medium pores (1–10 μm) is increased by dry–wet and freeze–thaw cycles. The cumulative mercury intake rises as the percentage increases, and the dry–wet cycle has a greater impact on the strength of amended red mud than the freeze–thaw cycle.

1. Introduction

Red mud is a solid waste material with strong alkalinity that is produced during the manufacturing of aluminum oxide [1]. For each ton of alumina produced in industry, the red mud produced is about 0.8–1.5 tons [2]. Furthermore, red mud is mostly treated by stacking and covering soil, which not only occupies a large number of land resources but also has the risk of polluting soil, groundwater, and air with flying dust [3,4].

Based on its distinctive physical and chemical properties, as well as mineralized physical features, research on the comprehensive utilization of red mud has focused on the following three areas: first, extraction and recovery of valuable metals [5,6,7]; the second is to prepare building materials, such as bricks and red mud portland cement [8,9]; third, red mud adsorbent is employed to clean wastewater [10,11,12]. However, just a small portion of red mud could be consumed by the aforementioned studies. Red mud had many of the same physical characteristics and chemical makeup as soil. Additionally, red mud could be utilized as filler or foundation material for roads by adding additives, which creates a practical method for the comprehensive utilization of red mud.

Mukiza and Deelwal [13,14] investigated the viability of using red mud as road base and subbase materials. Moreover, red mud used as road base material had high UCS, frost resistance, and durability [15,16]. However, utilizing pure red mud as road base material alone carries some dangers. Therefore, red mud-amended additives should be utilized to increase strength and durability instead [17]. Liu et al. [18] investigated the use of pure lime-stabilized red mud in road construction. The findings demonstrated that, when lime content increased, the unconfined compressive strength (UCS) and California bearing ratio (CBR) also rose. Rao et al. [19] also investigated the properties of red mud consolidated with granulated blast furnace slag (GGBS) and its suitability as road base material. The findings demonstrated that the UCS and CBR of solidified red mud increased with the addition of GGBS when the content of GGBS was less than 25%. Furthermore, the effect of lime stabilizing the red mud was best after it had been solidified with lime, calcined lime powder, granulated blast furnace slag, and fly ash [20,21]. The strength of red mud was improved by using fly ash and desulfurized gypsum. The results exhibited that the UCS of red mud at 7 days of curing time reached the maximum and satisfied the strength requirements of the expressway [19]. According to the research on amended red mud, the addition of phosphogypsum, silica fume, and dealkali agents reduced the alkalinity of red mud and successfully addressed the issue of red mud contaminating the environment [22,23]. In order to strengthen the red mud, curing agents such as cement, lime, phosphogypsum, and high-polymer materials were used, which considerably improved the strength and was preferable to the addition of cement, lime, or phosphogypsum alone. The pH of red mud lowered after alteration, with no adverse effects on the ecosystem [24,25,26]. As the principal curing agents, cement, lime, and phosphogypsum were utilized to enhance red mud. The dosage of the modifier and the level of compaction were two crucial indicators for managing the enhanced red mud, and the blended stabilizer was a superior curing agent to the cement alone, according to laboratory and field experiments [27,28].

To strengthen red mud, many scholars have researched a variety of curing agents, primarily taking into account the UCS, CBR, liquid plastic limit, and other indicators. This demonstrated the viability of using amended red mud as road base material. However, there are few studies on the durability of the dry–wet and freeze–thaw cycles of red mud under different stabilizer proportions. Moreover, there is little discussion on the mechanism of strengthening red mud with curing agents at the microscale.

In conclusion, this work chooses cement and lime as alkali exciters, with phosphogypsum serving as a sulfur exciter to reduce alkalinity. To manufacture amended red mud samples, the three proportions were first tested, and three groups of proportions fulfilling the requirements of UCS were chosen. Furthermore, the study of bearing performance and durability during dry–wet and freeze–thaw cycles was performed. The evolution and development law of amended red mud pores in the microcosm was then revealed by testing the samples for mercury intrusion. Finally, the effect of pore sizes on UCS was examined. This research is anticipated to offer technical support and useful advice for the widespread use of red mud.

2. Materials and Methods

2.1. Materials

The testing materials used in this research were obtained from the Weiqiao Bayer red mud storage yard in Binzhou City, Shandong Province. The results of the red mud’s basic physical tests revealed that the material’s liquid limit is 42.89%, its plastic limit is 24.56%, and its water content is 37.4%. The basic physical characteristics of the red mud are shown in Table 1. Additionally, P.O. 42.5 silicate cement was used in this research. The lime was acquired from Jiuqi Building Material Company in Weifang City, Shandong Province, and the phosphogypsum used in the tests was obtained from Guizhou Lufa Industrial Co., Ltd. in Guiyang City, Guizhou Province. The chemical composition of the raw materials is shown in Table 2.

Table 1.

The Basic Physical Characteristics of Red Mud.

Table 2.

The Chemical Composition of Raw Materials (wt. %).

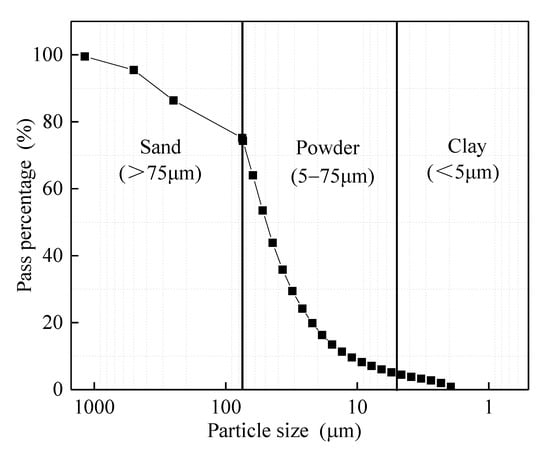

The particle gradation of the red mud was determined by the water-flushing classification method. The curve of the particle size distribution is shown in Figure 1. As can be seen in Figure 1, the majority of the red mud was composed of particles with a size of less than 0.075 mm comprising up to 75.17%; particles between 0.075 and 1.18 mm made up 24.78%; the smallest portion was composed of particles larger than 1.18 mm.

Figure 1.

The Particle Size Distribution of Red Mud.

2.2. Methods

2.2.1. Sample Preparation

According to the maximum dry density and optimal water content of the samples, a cylindrical sample of Φ50 mm × 50 mm was prepared by the static pressure method, with a compaction degree of 96%. Samples were put in a plastic bag after demoulding and weighing, then moved into the standard curing room (temperature of 20 ± 2 °C, relative humidity ≥ 95%). After the samples were cured for the desired age, samples were taken out and immersed in water for 24 h before being tested. The samples can be seen in Figure 2.

Figure 2.

The Picture of Samples.

2.2.2. The Tests of UCS, Dry Density, and pH

In this research, the unconfined compressive strength (UCS) and dry density were tested according to Test Methods of Soils for Highway Engineering (JTG3430-2020) [29]. The pH value of the samples was tested according to the ASTM D4972 [30]. After the UCS tests, the samples were collected in multiple grams and dried in an oven at 105 °C. For pH tests, 10 g of dry red mud was combined with 10 g of distilled water and the mixture remained for an hour.

2.2.3. The Dry–Wet and Freeze–Thaw Cycle Tests

In the dry–wet cycle tests, the test steps were as follows: ① After the samples were cured for 28 days, they were moved into an oven at 40 °C for 16 h, cooled to room temperature for 30 min, and then soaked in water for 8 h to complete a dry–wet cycle. ② After the dry–wet cycle, samples were taken out to test the quality and UCS. ③ Steps ① and ② were repeated until all 5 dry–wet cycles had been completed.

In the freeze–thaw cycle tests, the test steps were as follows: ① After the samples were cured for 28 days, they were moved into a refrigerator at −23 °C for 16 h, and then samples were taken out and moved into a water tank at 20 °C for 8 h to complete a freeze–thaw cycle. ② After the freeze–thaw cycle, samples were taken out to test the quality and UCS. ③ Steps ① and ② were repeated until all 5 freeze–thaw cycles had been completed.

2.2.4. Microstructure Analysis

In this research, the material composition and morphology of the samples were analyzed by scanning electron microscope (SEM) (Guangzhou Jiarui Scientific Instrument Co., Ltd., Guangzhou, China). Before observation, the samples were sprayed with gold. The experiment’s settings were determined as follows: the resolution was set to High-Vaccum mode 1.0 nm @ 20 kV WD = 2 mm, and the magnification was set to 20×~900,000×.

An automatic mercury porosimeter (Micromeritics Instrument Corporation, Norcross, GA, USA) was used to study the pore structural alterations of the samples. The freeze-dried samples were put into the mercury porosimeter and the low-pressure test and high-pressure test were performed sequentially. The low-pressure test was used to fill the mercury and measure the coarse pore size. Furthermore, the high-pressure test was used to pressurize the mercury into the sample pores in accordance with the predetermined maximum pressure. In this research, the mercury surface tension was 0.48 N/m, the contact angle was 140°, and the maximum pressure was 345 MPa.

3. Results and Discussion

3.1. Selection of Mixture Ratio

3.1.1. Influence of Cement Content

This set of experiments aimed to establish the appropriate cement content of road base materials that satisfy the strength requirements. In the tests, the cement contents were set at 0%, 3%, 5%, 7%, and 10%, respectively, and compaction tests were used to determine the maximum dry density and optimum water content under different cement contents. The mix proportion and sample preparation requirements for each set of tests are listed in Table 3.

Table 3.

The ingredient proportion of cement-stabilized red mud.

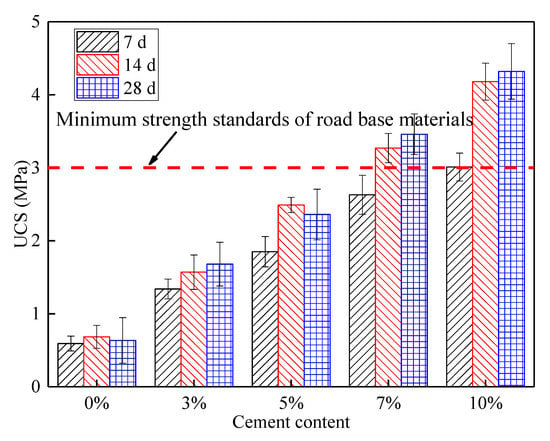

The strength of the stabilized red mud after 7, 14, and 28 days of curing is shown in Figure 3. The figure shows that, as cement content was increased, the UCS of cement-stabilized red mud increased, and at 7 days of curing, the strength of pure red mud was approximately 0.6 MPa. Moreover, when the cement content was higher than 7%, the increase in UCS after 7 days of curing tended to be slower, and the cement content must be around 10% in order to achieve the UCS of 3–5 MPa for minimum strength standards of road base materials [31]. Therefore, this research is based on the cement content of 10%.

Figure 3.

The effect of cement contents on the strength of stabilized red mud.

3.1.2. Influence of Cement–Lime Content

This set of experiments aimed to establish the appropriate cement and lime contents of road base materials that satisfy the strength requirements. Lime was added to adequately reduce the cement content. In the tests, the lime contents were set at 0.5%, 1%, 1.5%, 2%, 2.5%, and 3%, respectively, and the overall cement and lime contents were kept constant at 10%. The mix proportion and sample preparation requirements for each set of tests are listed in Table 4.

Table 4.

The ingredient proportion of cement–lime-stabilized red mud.

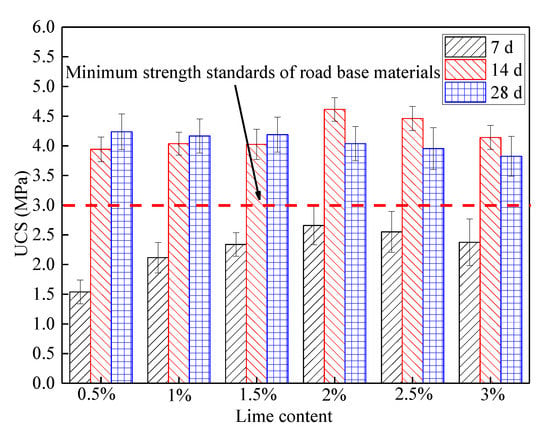

The strength of the stabilized red mud after 7, 14, and 28 days of curing is shown in Figure 4. As seen in Figure 4, with the lime content increased, the UCS increased at first and then decreased at 7 days of curing. Additionally, the strength began to decline as the lime content exceeded 2%. During 7 days of curing time, the strength of cement–lime-stabilized red mud was less than that of red mud without lime. When lime replaced cement, the cement hydration reaction reduced with a decrease in cement content, and the strength dropped substantially.

Figure 4.

The effect of cement and lime contents on the strength of stabilized red mud.

Moreover, when the content of lime exceeded 2%, the strength of the sample with a curing age of 28 days decreased. The reason for this is that lime has a high water-retention capacity. It will absorb water during the early hydration reaction, lowering the water–cement ratio and accelerating the hydration reaction. However, after 28 days of curing, excessive lime will lead to further expansion, weakening the strength of the samples. Therefore, in this research, the cement–lime content was chosen at 8:2.

3.1.3. Influence of Phosphogypsum Content

On the basis of the above results, the ratio of cement to lime was selected at 8:2. Additionally, analysis was conducted on the effect of various phosphogypsum contents on the mechanical properties of amended red mud as road base material, and designed four groups of different phosphogypsum contents of 2%, 5%, 8%, and 10%. In the research, the amount of phosphogypsum content was changed, while maintaining the total amount of other admixtures constant (cement and lime content was 10%). The corresponding mixture ratios for each group of tests are shown in Table 5.

Table 5.

The ingredient proportion of phosphogypsum-amended red mud.

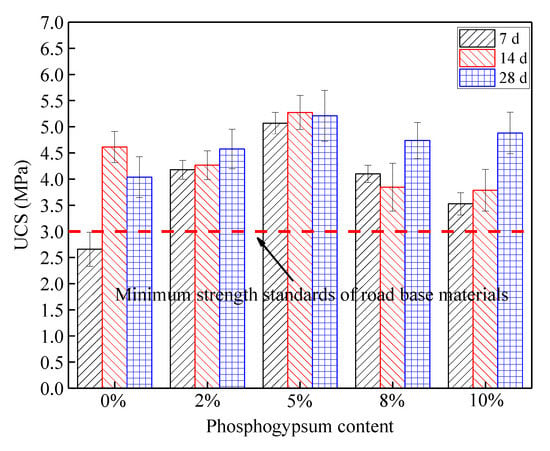

The effect of phosphogypsum content on the strength of amended red mud is shown in Figure 5.

Figure 5.

The effect of phosphogypsum content on the strength of amended red mud.

As can be seen in the figure, the UCS of the samples during 7 days of curing time was over 3 MPa, which satisfied the requirements for road base materials in terms of strength. Additionally, the strength was highest when the content of phosphogypsum was 5%. The reason was that the reaction was sped up and a lot of expanding ettringite crystals were created as a result of the Ca2+, SO42− in phosphogypsum. As ettringite crystals filled the sample pores and bound the particles through the interconnection of needle-like crystals, the structure became more compact and the strength was subsequently increased.

However, when the content of phosphogypsum was 8% and 10%, the strength decreased. The main reason for this phenomenon is that, when the content of phosphogypsum is too high, the sample will have excessive volume expansion, which will lead to expansion stress, damage the structure of samples, and reduce the strength.

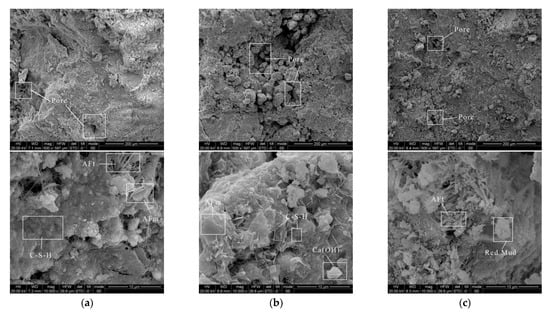

3.2. Scanning Electron Microscope (SEM)

Figure 6 shows the SEM of stabilized/amended red mud samples at 28 days of curing time. As shown in Figure 6a, there were a lot of fine particles connected by honeycomb structures, and there were numerous tiny pores between the honeycomb structures. Additionally, it was discovered that the samples included a minor quantity of hydrated calcium aluminosulfate (AFm) with monosulfide-type scattered. As shown in Figure 6b, the honeycomb structures of samples became smaller, and the stacked AFm crystals grew, gathered, and consolidated into plates. Additionally, the irregular petal-like AFm grew in the pores and filled the holes. Moreover, when lime was added, the sample’s round particles increased and pores rose, which decreased the sample’s strength. In Figure 6c, the samples show numerous blocky hydrated calcium aluminosilicate (AFt) structures, which under the connection of AFt eventually coalesced into a dense ensemble. As compared with Figure 6a,b, the samples have a much lower number of pores in Figure 6c. Since the hydrated calcium aluminate was created when the components of phosphogypsum reacted with cement, the structure of amended red mud became denser.

Figure 6.

Scanning electron micrograph of amended/stabilized red mud: (a) cement-stabilized red mud; (b) cement–lime-stabilized red mud; (c) Phosphogypsum-amended red mud.

3.3. The Effect of Dry–Wet and Freeze–Thaw Cycles on Phosphogypsum-Amended Red Mud

3.3.1. The Variation in UCS

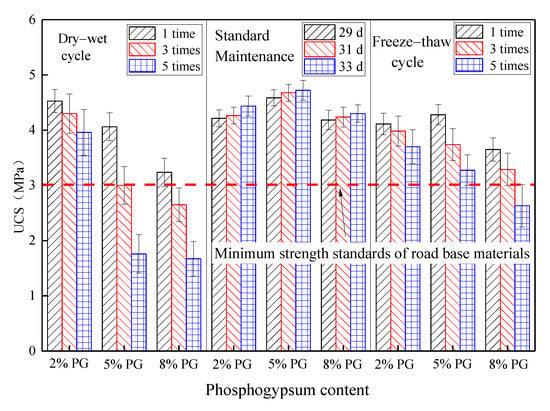

As can be seen in Figure 7, the UCS of samples decreased with an increasing numbers of dry–wet and freeze–thaw cycles. Under the effect of a one-time dry–wet cycle, the strength of all samples achieved the minimum strength requirements for road base materials, but the strength of samples mixed with 8% phosphogypsum reduced dramatically. However, only the strength of the samples with 2% phosphogypsum met the requirements of road base materials after five dry–wet cycles.

Figure 7.

The variation in UCS of amended red mud under dry–wet and freeze–thaw cycles.

For the freeze–thaw cycle, only the strength of the samples mixed with 8% phosphogypsum failed to meet the requirements for road base materials after five freeze–thaw cycles. Additionally, the strength of amended red mud mixed with 5% phosphogypsum still met the standards after five freeze–thaw cycles, but minor fractures appeared on the samples’ surfaces. Therefore, in the content of cement and lime at 10%, the phosphogypsum content should not exceed 5%.

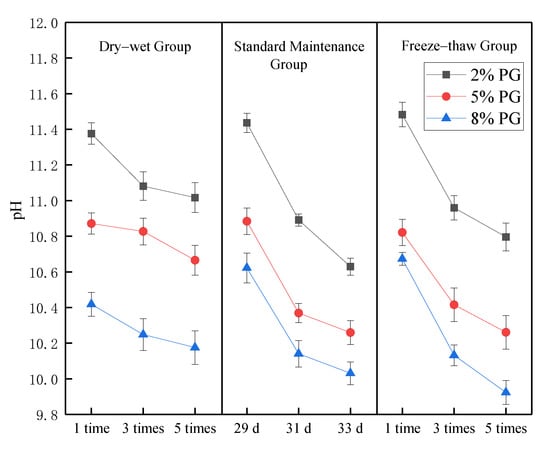

3.3.2. The Variation in pH and Dry density

The pH of amended red mud has some relationship with the degree of hydration. During the hydration process, Ca2+, Na+, and OH− in the samples were continuously consumed by the reaction, causing the samples to exhibit a fall in pH as the curing time was extended. As can be seen in Figure 8, the dry–wet cycles had little impact on the hydration of amended red mud, and the pH of amended red mud tended to decline as the number of dry–wet cycles rose. When the number of dry–wet cycles increased from 1 to 5, the pH of amended red mud with 2% phosphogypsum decreased from 11.48 to 10.8, and the pH of the samples with 5% and 8% phosphogypsum decreased from 10.83 and 10.67 to 10.25 and 9.91, respectively. For the freeze–thaw cycle, the pH of amended red mud decreased with an increased number of freeze–thaw cycles.

Figure 8.

The variation in pH under dry–wet and freeze–thaw cycles.

In conclusion, the pH decreased during the dry–wet cycle, freeze–thaw cycle, and conventional curing. Moreover, the pH marginally decreased under the influence of the dry–wet cycle, and the reaction process of samples was relatively slow. Additionally, the pH also dropped as the phosphogypsum content rose.

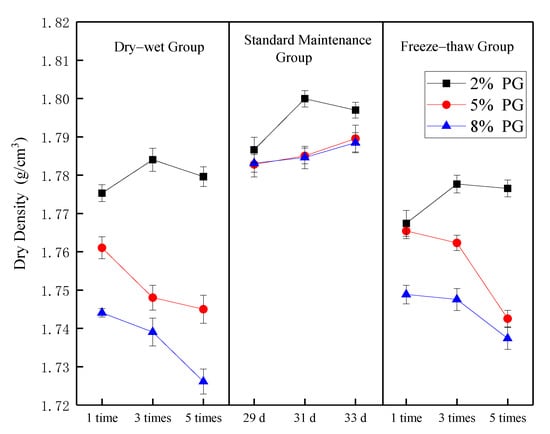

As can be seen from Figure 9, the dry density of samples with 2% phosphogypsum increased at first and then decreased as the number of dry–wet cycles or the curing time increased, and there was little variation in the dry density. In contrast, as the number of dry–wet cycles increased, the dry density of amended red mud with 5% and 8% phosphogypsum constantly fell. Additionally, it can be seen from Figure 9 that after one and three freeze–thaw cycles, amended red mud’s dry density changed slightly, whereas after five cycles, the dry density dramatically reduced. Furthermore, the porosity of the samples increased as the dry density fell.

Figure 9.

The variation in dry density under dry–wet and freeze–thaw cycles.

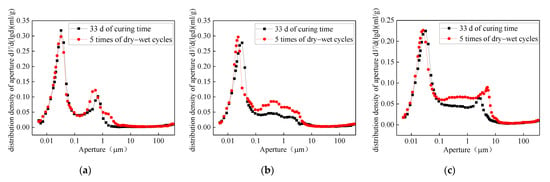

3.3.3. The Variation in Pore Distribution under Dry–Wet Cycles

As shown in Figure 10, the distribution of pore size of amended red mud with 2% phosphogypsum under dry–wet cycles and standard curing nearly overlapped, both displaying the typical double-peaked pattern. The pore size of the samples mainly ranged between 0.01 and 0.1 µm, and 0.1 to 1 µm, respectively. The first peak of the aperture density ranged from 0.3 to 0.35 µm, and the second peak ranged from 0.1 to 0.15 µm. It was evident that the pores in amended red mud with 2% phosphogypsum were primarily tiny pores (0.01–0.1 µm).

Figure 10.

The distribution density of amended red mud under dry–wet cycles: (a) 2% phosphogypsum content; (b) 5% phosphogypsum content; (c) 8% phosphogypsum content.

The pore size distribution of samples with 5% phosphogypsum under standard curing showed a three-peak distribution. The first peak occurred between 0.01 and 0.1 µm and the value was between 0.25 and 0.3; in contrast, the other two peaks after 0.1 µm were relatively flat. For the dry–wet cycle, the aperture between 0.1 and 1 µm exhibited a wider peak, and the value was around 0.1. Moreover, the aperture between 1 and 10 µm had a smaller edge, and the value was around 0.05, which is negligible.

The pore size distribution of samples with 8% phosphogypsum exhibited a bimodal distribution under both standard curing and dry–wet cycles. The second peak of the aperture density ranged from 1 to 10 µm. This indicates that the dry–wet cycle resulted in an increase in pore size in the range of 1–10 µm. Additionally, when the content of phosphogypsum was too high, the aperture of amended red mud rose.

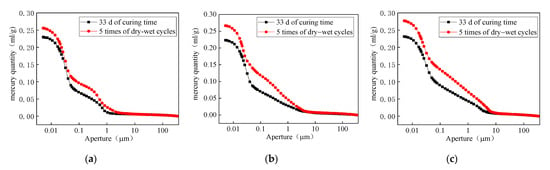

As shown in Figure 11, the cumulative mercury quantity input to the samples during the dry–wet cycle was higher than that under standard curing. After the dry–wet cycle, the unit mercury quantity of amended red mud with 2%, 5%, and 8% phosphogypsum was 0.257, 0.267, and 0.277 mL/g, respectively, which was 12.72%, 20.81%, and 19.4% higher than that of the standard curing (33 days). It was evident that the cumulative mercury quantity increased with phosphogypsum content. Ettringite content increased with phosphogypsum content, and the volume expansion resulted in an increase in microscopic pores with an aperture of 1–10 µm.

Figure 11.

The mercury quantity curve of amended red mud under dry–wet cycles: (a) 2% phosphogypsum content; (b) 5% phosphogypsum content; (c) 8% phosphogypsum content.

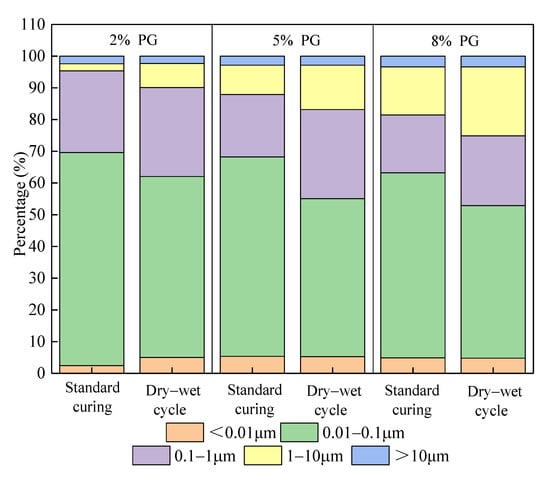

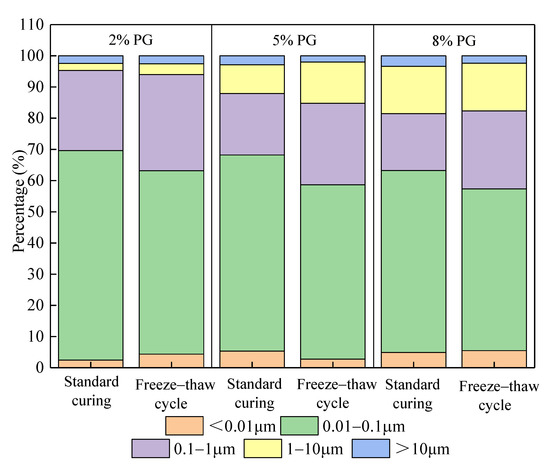

According to Figure 12, the percentage of micro-pores (0.01–0.1 μm) decreased from 67.15%, 62.85%, and 58.31% to 57.06%, 55.94%, and 48.11%, respectively, with 2%, 5%, and 8% phosphogypsum contents, while the percentage of small pores (0.1–1 μm) decreased from 25.74%, 19.70%, and 18.25% to 28.05%, 28.11%, and 21.79%, respectively. In the range of 1 to 10 μm, the aperture primarily grew.

Figure 12.

The distribution of aperture ratio under a dry–wet cycle.

Due to the difference in water content between the inside and outside of the samples, the action of the dry–wet cycle caused tensile stress to form on the surface. However, the cementation between the particles was insufficient to resist the tensile stress, which resulted in cracks. Moreover, the expansion of ettringite lessened the samples’ resistance during the dry–wet cycle, which was one reason why the samples were destroyed by external forces.

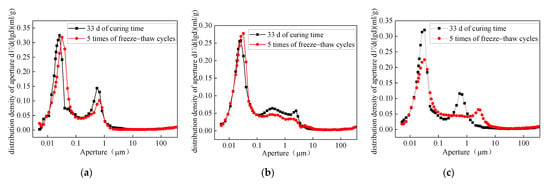

3.3.4. The Variation in Pore Distribution under Freeze–Thaw Cycles

As shown in Figure 13, the pore distribution curve of the samples with 2% and 8% phosphogypsum exhibited two obvious peaks both in the freeze–thaw cycle and the standard curing, while the samples with 5% phosphogypsum had three peaks. The two peaks of amended red mud with 2% phosphogypsum were, respectively, in the pore size range of 0.01–0.1 µm and 0.1–1 µm. Compared with the standard curing, the peak of the pore distribution curve of the freeze–thaw cycle was displaced to the right, which indicated that even if the range of the pore size was the same, the pore size of the freeze–thaw cycle was larger.

Figure 13.

The distribution density of amended red mud under freeze–thaw cycles: (a) 2% phosphogypsum; (b) 5% phosphogypsum; (c) 8% phosphogypsum.

The peak of amended red mud with 5% phosphogypsum was mostly in the range of 0.01–0.1 µm, and the other two peaks were not obvious, and were in the ranges of 0.1–1 µm and 1–10 µm. The peak of the freeze–thaw cycle, in the range of 0.1–10 µm, was less than that in the standard curing, and the peak shape was not obvious.

The two peaks of the samples with 8% phosphogypsum under standard curing were, respectively, in the range of 0.01–0.1 µm and 0.1–1 µm, but under freeze–thaw cycles the two peaks were, respectively, in the range of 0.01–0.1 µm and 1–10 µm. This indicates that the pores of the sample were enlarged by the freeze–thaw cycle.

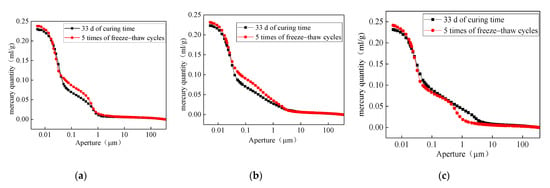

As shown in Figure 14, the unit mercury quantity was 0.238, 0.232, and 0.242 mL/g, respectively, under the freeze–thaw cycle of amended red mud with 2%, 5%, and 8% phosphogypsum, which was 4.04%, 4.39%, and 4.57% greater than that during the standard curing (33 days). Additionally, the unit mercury quantity did not significantly rise as compared to the dry–wet cycle. However, for the sample with 8% phosphogypsum, the unit mercury quantity was reduced to the aperture range of 0.1–10 µm.

Figure 14.

The mercury quantity curve of amended red mud under freeze–thaw cycles: (a) 2% phosphogypsum; (b) 5% phosphogypsum; (c) 8% phosphogypsum.

As shown in Figure 15, the percentage of micropores (0.01–0.1 μm) of amended red mud decreased and the percentage of small pores (0.1–1 μm) increased following the freeze–thaw cycle. The aforementioned results demonstrated that the freeze–thaw cycle had a more detrimental impact on the microstructure of amended red mud. The fraction of micropores declined while the proportion of tiny pores rose, resulting in a looser structure for the samples. It is suggested that the force of the water freezing between the soil particles is what causes the pore alteration in samples during the freeze–thaw cycle.

Figure 15.

The distribution of aperture ratio under freeze–thaw cycles.

Furthermore, the percentage of middle pores (1–10 μm) rose from 2.24%, 9.26%, and 15.16% to 3.43%, 13.21%, and 15.30%, respectively, in the samples during the freeze–thaw cycle. Thus, the red mud amended by phosphogypsum possessed the expansion of ettringite in addition to the squeezing force of freezing, which will decrease the resistance of the freeze–thaw cycle.

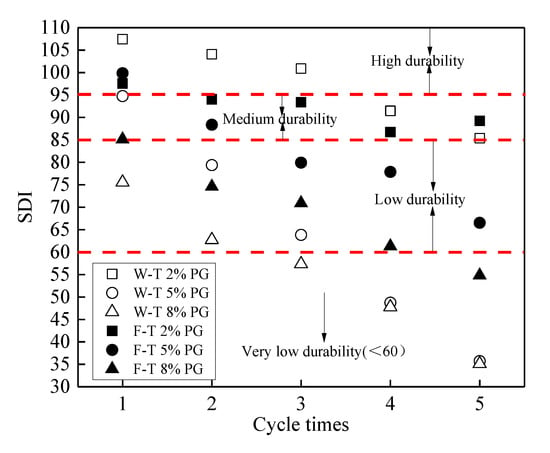

Additionally, the durability index (SDI) was used to evaluate the durability of amended red mud. The SDI can be calculated by Equation (1).

where R0 is the UCS during standard curing (MPa), and Rn is the UCS after n dry–wet or freeze–thaw cycles (MPa).

As shown in Figure 16, the dry–wet cycle had a greater impact on the strength of amended red mud than the freeze–thaw cycle. After five dry–wet cycles, the SDI of samples with 5% and 8% phosphogypsum was lower than 60. Furthermore, the SDI of samples with 5% phosphogypsum was higher than 60 after five freeze–thaw cycles. Moreover, the samples that included 2% phosphogypsum met the requirements for medium durability, and the SDI was greater than 85. It is evident that amended red mud exhibits poor resistance to the dry–wet cycle, and the strength was greatly reduced.

Figure 16.

The Influence of Number of Dry–Wet and Freeze–Thaw Cycles on SDI.

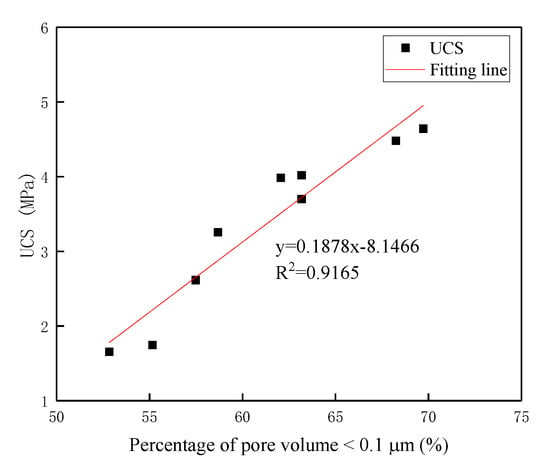

As shown in Figure 17, the association between the pore volume and UCS was positive. Under the conditions of the dry–wet or freeze–thaw cycle, the UCS of amended red mud dropped as the percentage of pore volume (<0.1 μm) decreased. The sample’s percentage of micropores was considerably decreased over the dry–wet and freeze–thaw cycles, particularly during the dry–wet cycle, as can be shown from the mercury intrusion tests. As a result, the dry–wet cycle caused a significant loss in the UCS of amended red mud.

Figure 17.

Relationship between UCS and percentage of pore volume (<0.1 μm).

4. Conclusions

In this study, a relatively suitable cement–lime ratio was established by the compressive strength test with different cement and lime contents, and phosphogypsum content was further altered to investigate the effect of phosphogypsum content on amended red mud. Furthermore, the influence of phosphogypsum content on the durability of amended red mud was studied mainly through UCS, pH, dry density, and pore size under dry–wet and freeze–thaw cycles, and the following conclusions were obtained:

- (1)

- Through the UCS of cement–lime-stabilized red mud, the optimal ratio was determined to be 8% cement and 2% lime. Additionally, the UCS of amended red mud was significantly increased by the addition of phosphogypsum, and after 7 days of curing time, the sample’s UCS reached the required strength for road base material (3–5 MPa). However, the UCS of the sample increased first and then declined with an increase in phosphogypsum content. The test findings indicated that phosphogypsum content should not be too high.

- (2)

- The UCS, dry density, and pH value of amended red mud were decreased by the dry–wet and freeze–thaw cycles. After five dry–wet cycles, only the samples with 2% phosphogypsum content met the requirements for road base material. Furthermore, after five freeze–thaw cycles, the strength of amended red mud with 8% phosphogypsum content did not meet the standard. Additionally, the impact of the dry–wet cycle was greater than the freeze–thaw cycle on UCS, pH, and dry density of amended red mud.

- (3)

- The percentage of micropores (0.01–0.1 μm) was reduced by dry–wet and freeze–thaw cycles, although the percentage of small pores (0.1–1 μm) and medium pores (1–10 μm) was increased. Additionally, the compactness and compressive strength also fell. The strength of amended red mud with 2% phosphogypsum content was less affected by the dry–wet and freeze–thaw cycles. After five dry–wet and freeze–thaw cycles, the strength assurance rate of the samples was greater than 85%.

Author Contributions

Methodology, H.W. and M.S.; Software, X.T.; Validation, X.D.; Formal analysis, H.W., X.T. and C.Y.; Resources, C.Y.; Data curation, H.W., C.Y. and X.D.; Writing—original draft, H.W.; Writing—review & editing, M.S.; Visualization, X.D.; Project administration, X.T.; Funding acquisition, M.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research is supported by the National Natural Science Foundation of China (Grant No. 41272312).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is unavailable due to privacy restrictions.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Lyu, F.; Hu, Y.; Wang, L.; Sun, W. Dealkalization processes of bauxite residue: A comprehensive review. J. Hazard. Mater. 2021, 403, 123671. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Jin, H.; Deng, Y.; Xiao, Y. Comprehensive utilization status of red mud in China: A critical review. J. Clean. Prod. 2020, 289, 125136. [Google Scholar] [CrossRef]

- Silveira Nathália, C.G.; Martins Maysa, L.F.; Bezerra Augusto, C.S.; Araújo Fernando, G.S. Red Mud from the Aluminium Industry: Production, Characteristics, and Alternative Applications in Construction Materials—A Review. Sustainability 2021, 13, 12741. [Google Scholar] [CrossRef]

- Li, W.Y.; Zhang, Z.Y.; Zhou, J.B. Preparation of building materials from Bayer red mud with magnesium cement. Constr. Build. Mater. 2022, 323, 126507. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, T.A.; Lyu, G.; Guo, F.; Zhang, W.; Zhang, Y. Recovery of alkali and alumina from bauxite residue (red mud) and complete reuse of the treated residue. J. Clean. Prod. 2018, 188, 456–465. [Google Scholar] [CrossRef]

- Vijayan, D.S.; Parthiban, D. Effect of Solid waste based stabilizing material for strengthening of Expansive soil—A review. Environ. Technol. Innov. 2020, 20, 101108. [Google Scholar] [CrossRef]

- Wang, K.; Yu, Y.; Wang, H.; Chen, J. Experimental study on extracting scandium from red mud by hydrochloric acid leaching. Rare Earth 2010, 31, 95–98. (In Chinese) [Google Scholar]

- Li, D.; Zhang, L.; Liu, X.; Du, Y.; Chen, Y. Research on high-content red mud sintered brick. New Build. Mater. 2009, 36, 26–29. (In Chinese) [Google Scholar]

- Kan, L.; Wang, F.; Zhang, Y.; Wei, Y.; Wu, M. An exploratory study on using red mud waste as a replacement for fly ash to prepare Engineered Cementitious Composites. Constr. Build. Mater. 2022, 342, 127900. [Google Scholar] [CrossRef]

- Sun, D.; Wang, F. Study on the removal of heavy metal ions from wastewater by red mud. Inorg. Salt Ind. 2008, 8, 47–49. (In Chinese) [Google Scholar]

- Wang, Y.; Huo, W. Study on the adsorption performance of granular red mud adsorbent for heavy metal ions. Ind. Water Wastewater 2008, 39, 82–85. (In Chinese) [Google Scholar]

- Zhou, G.; Chen, D.; Luo, J.; Song, Q. Application of high-efficiency flocculant for settling red mud. Min. Metall. 2003, 2, 41–44+48. (In Chinese) [Google Scholar]

- Mukiza, E.; Zhang, L.; Liu, X.; Zhang, N. Utilization of red mud in road base and subgrade materials: A review. Resour. Conserv. Recycl. 2019, 141, 187–199. [Google Scholar] [CrossRef]

- Deelwal, K.; Dharavath, K.; Kulshreshtha, M. Evaluation of characteristic properties of red mud for possible use as a geotechnical material in civil construction. Int. J. Adv. Eng. Technol. 2014, 7, 1053. [Google Scholar]

- Das, S.K.; Rout, S.; Alam, S. Characterization of Red Mud as a Subgrade Construction Material. In Proceedings of the 3rd Conference of Transport Research Group of India (CTRG), Kolkata, India, 17 December 2015. [Google Scholar]

- Zhang, Y.; Qu, Y.; Wu, S. Engineering geological properties and comprehensive utilization of the solid waste (red mud) in aluminium industry. Environ. Geol. 2001, 41, 249–256. [Google Scholar] [CrossRef]

- Sutar, H.; Mishra, S.C.; Sahoo, S.K.; Maharana, H.S. Progress of Red Mud Utilization: An Overview. Am. Chem. Sci. J. 2014, 4, 255–279. [Google Scholar] [CrossRef]

- Liu, S.; Li, Z.; Li, Y.; Cao, W. Strength properties of Bayer red mud stabilized by lime-fly ash using orthogonal experiments. Constr. Build. Mater. 2018, 166, 554–563. [Google Scholar] [CrossRef]

- Rao, C.H.; Naidu, G.; Satyanayarana, P.V.V.; Adiseshu, S. Application of GGBS stabilized Redmud in Road Construction. IOSR J. Eng. 2012, 2, 14–20. [Google Scholar]

- Zhang, J.; Li, C. Experimental Study on Lime and Fly Ash–Stabilized Sintered Red Mud in Road Base. J. Test. Eval. 2018, 46, 1539–1547. [Google Scholar] [CrossRef]

- Li, Y.; Liu, X.; Li, Z.; Ren, Y.; Wang, Y.; Zhang, W. Preparation, characterization and application of red mud, fly ash and desulfurized gypsum based eco-friendly road base materials. J. Clean. Prod. 2020, 284, 124777. [Google Scholar] [CrossRef]

- Tian, T.; Ke, W.S.; Zhu, F.; Wang, Q.L.; Ye, Y.Z.; Guo, Y.; Xue, S.G. Effect of substrate amendment on alkaline minerals and aggregate stability in bauxite residue. J. Cent. South Univ. 2019, 26, 393–403. [Google Scholar] [CrossRef]

- Wang, H.; Jiao, S.; Ge, Y.; Tang, H.; Zhang, J. Experimental study on red mud mixed with silica fume as road base material. Environ. Pollut. Prev. 2016, 38, 8–10+15. (In Chinese) [Google Scholar]

- Sun, Z. Research on Engineering Technology and Environmental Impact of Bayer Red Mud Filling Subgrade. Ph.D. Thesis, Shandong University, Jinan, China, 2017. (In Chinese). [Google Scholar]

- Li, Y.W.; Luo, X.H.; Li, C.X.; Millar, G.J.; Jiang, J.; Xue, S.G. Variation of alkaline characteristics in bauxite residue under phosphogypsum amendment. J. Cent. South Univ. 2019, 26, 361–372. [Google Scholar] [CrossRef]

- Occhicone, A.; Vukčević, M.; Bosković, I.; Ferone, C. Red Mud-Blast Furnace Slag-Based Alkali-Activated Materials. Sustainability 2021, 13, 11298. [Google Scholar] [CrossRef]

- Li, C. Research on the Basic Performance and Engineering Application of Bayer red Mud in Subgrade Filling. Ph.D. Thesis, Shandong University of Architecture, Jinan, China, 2018. (In Chinese). [Google Scholar]

- Qaidi, S.M.; Tayeh, B.A.; Ahmed, H.U.; Emad, W. A review of the sustainable utilisation of red mud and fly ash for the production of geopolymer composites. Constr. Build. Mater. 2022, 350, 128892. [Google Scholar] [CrossRef]

- JTG3430-2020; Test Methods of Soils for Highway Engineering. National Standards of the People’s Republic of China: Beijing, China, 2020. (In Chinese)

- ASTM D4972; Standard Test Methods for pH of Soils. American Society for Testing and Materials: West Conshohocken, PA, USA, 2013.

- JTJ034-2000; Ministry of Communications Technical Specification for Construction of Highway Pavement Base. National Standards of the People’s Republic of China: Beijing, China, 2019. (In Chinese)

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).