Value Chain and the Integrated Development of Manufacturing and Modernized Services: A Case Study of Shandong Province, China

Abstract

1. Introduction

2. Literature Review

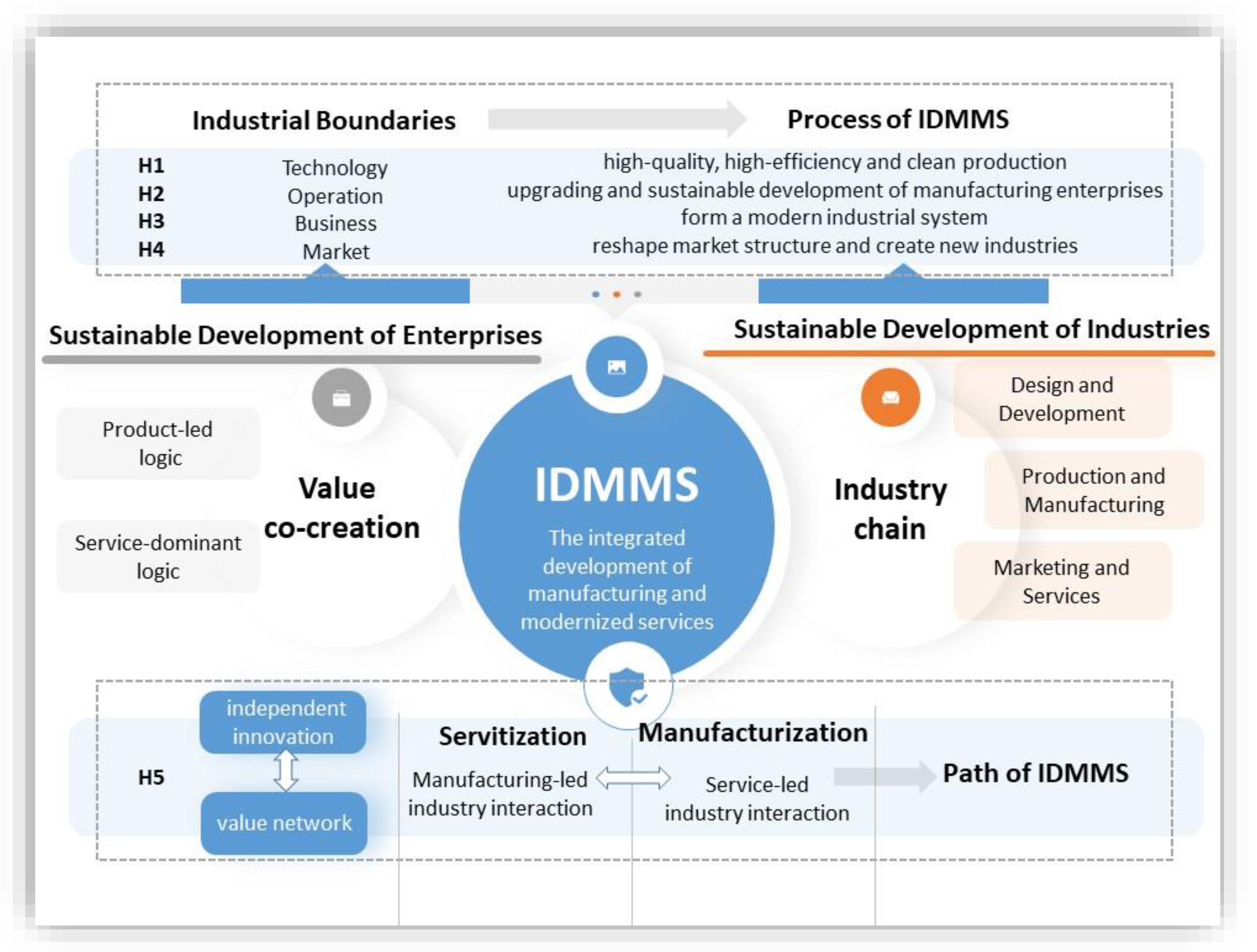

2.1. Industrial Boundaries and the Process of IDMMS

2.2. Degree of IDMMS

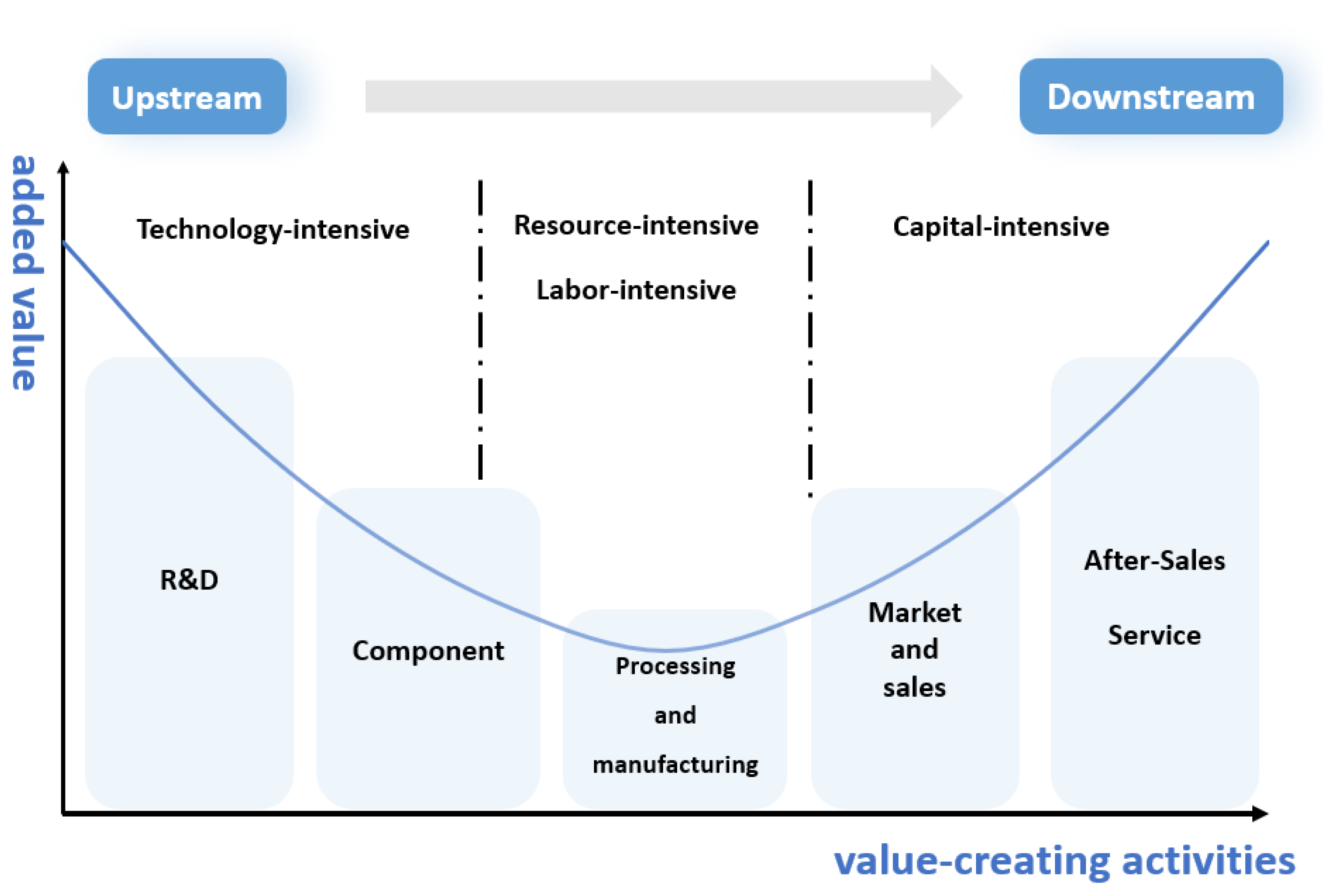

2.3. Industry Chain and the Path of IDMMS

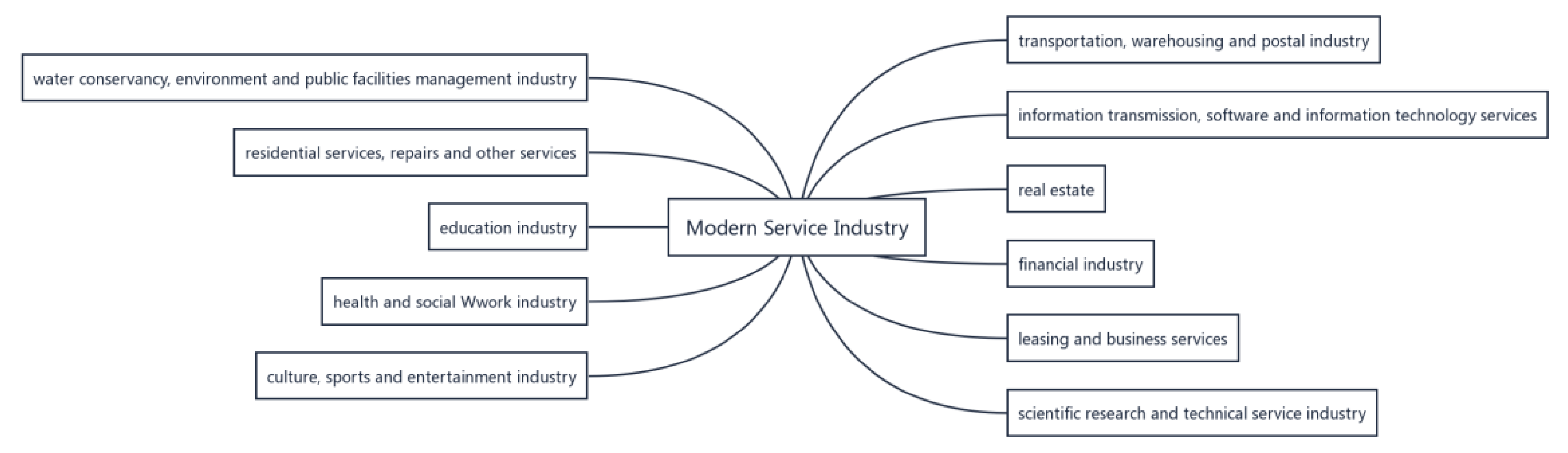

3. Materials and Methods

3.1. Study Area

3.2. Research Method

3.2.1. Input-Output Analysis Method

- ●

- The servitization of manufacturing-input, indicating the proportion of services as an intermediate product in manufacturing inputs, shows a trend of gradually increasing with the increased interaction between manufacturing and modern service industry.

- ●

- The servitization of manufacturing-output. The “output” here involves two main meanings: firstly, the benefits and value of the services provided in the tangible products produced by manufacturing gradually increases; secondly, the manufacturing companies directly regard the services as products to provide.

- ●

- The manufacturization of service, that is, service companies expand their value chain into different manufacturing or production segments.

3.2.2. Index System Construction

- ①

- Degree of Endogenous Fusion

- ➁

- Degree of Exogenous correlation

4. Results and Analysis

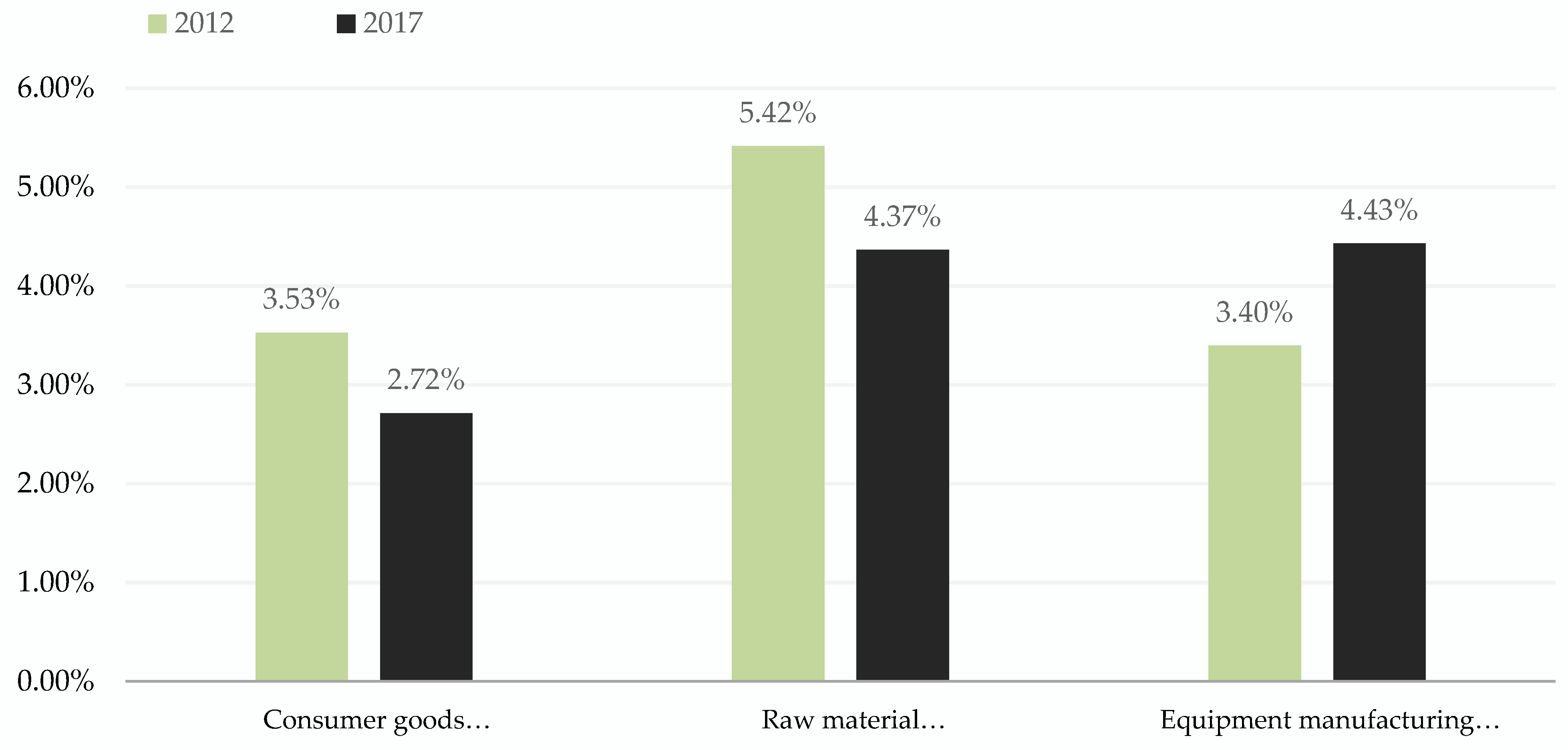

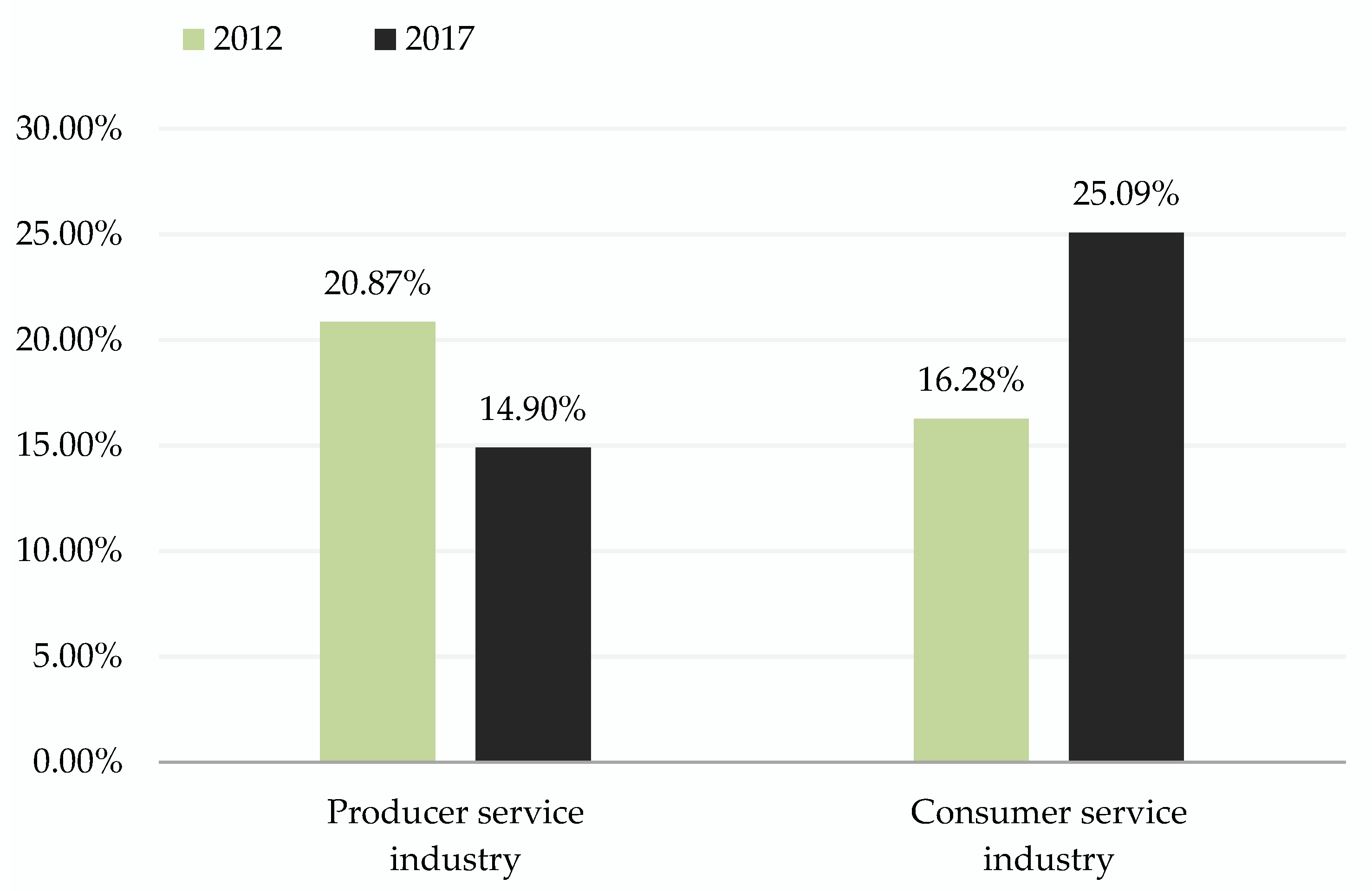

4.1. Results of Endogenous Fusion Degree

4.2. Results of Exogenous Correlation Degree

5. Discussion

5.1. Existing Problems of Shandong’s IDMMS

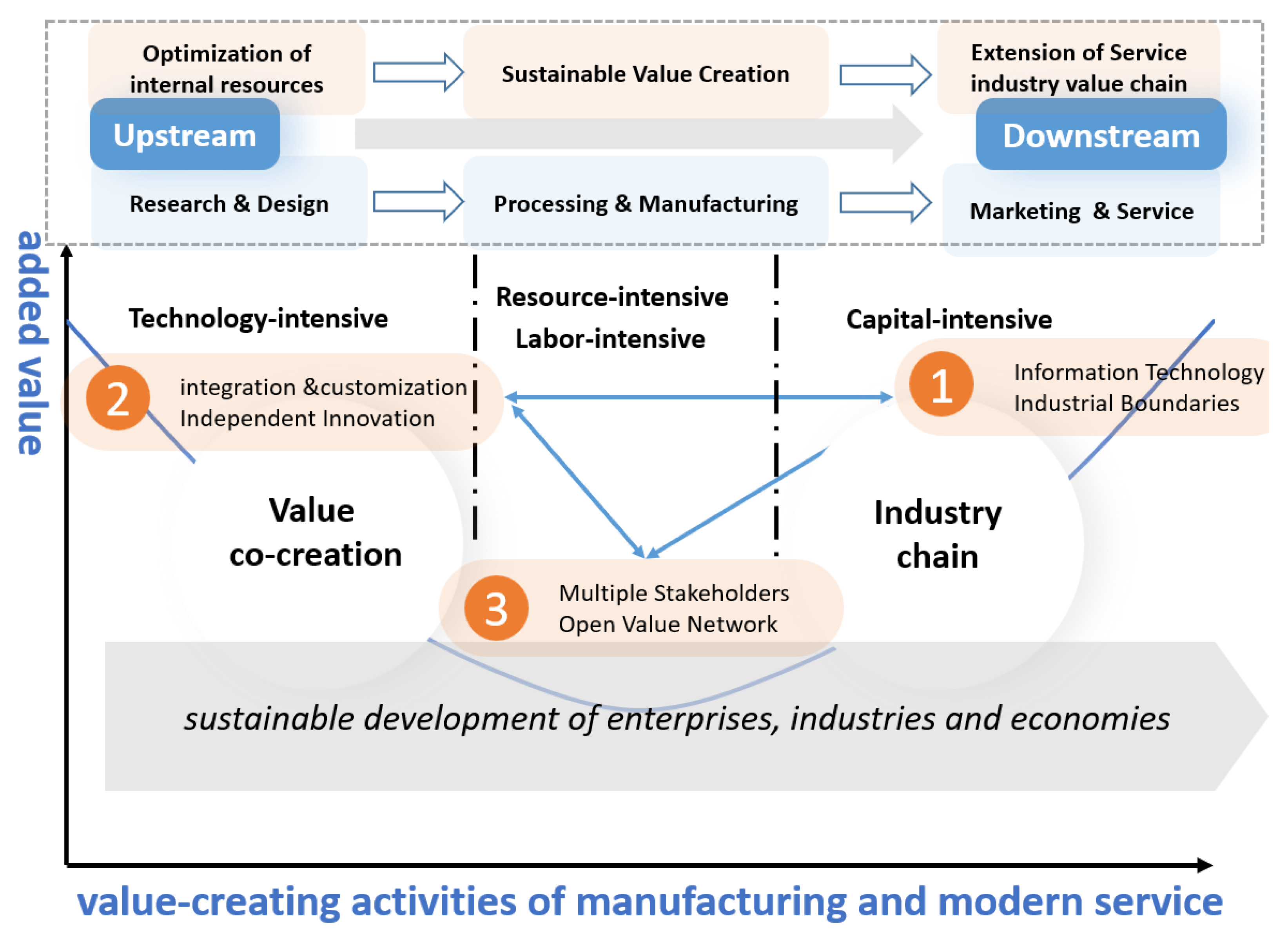

5.2. Value Co-Creation and the Mechanism of IDMMS

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jin, Y.; Xu, Y.; Li, R.; Zhao, C.; Yuan, Z. Comprehensive Evaluation of China’s Input–Output Sector Status Based on the Entropy Weight-Social Network Analysis Method. Sustainability 2022, 14, 14588. [Google Scholar] [CrossRef]

- Wang, Q.; Su, M. A Preliminary Assessment of the Impact of COVID-19 on Environment—A Case Study of China. Sci. Total Environ. 2020, 728, 138915. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, F. What Does the China’s Economic Recovery after COVID-19 Pandemic Mean for the Economic Growth and Energy Consumption of Other Countries? J. Clean. Prod. 2021, 295, 126265. [Google Scholar] [CrossRef]

- Chen, Y.; Wu, Z.; Yi, W.; Wang, B.; Yao, J.; Pei, Z.; Chen, J. Bibliometric Method for Manufacturing Servitization: A Review and Future Research Directions. Sustainability 2022, 14, 8743. [Google Scholar] [CrossRef]

- Zhou, R.; Tang, D.; Da, D.; Chen, W.; Kong, L.; Boamah, V. Research on China’s Manufacturing Industry Moving towards the Middle and High-End of the GVC Driven by Digital Economy. Sustainability 2022, 14, 7717. [Google Scholar] [CrossRef]

- Szirmai, A.; Verspagen, B. Manufacturing and Economic Growth in Developing Countries, 1950–2005. Struct. Chang. Econ. Dyn. 2015, 34, 46–59. [Google Scholar] [CrossRef]

- Zhang, J. Impact of Manufacturing Servitization on Factor Productivity of Industrial Sector Using Global Value Chain. Sustainability 2022, 14, 5354. [Google Scholar] [CrossRef]

- Peng, B.; Wang, Y.; Zahid, S.; Wei, G.; Elahi, E. Platform Ecological Circle for Cold Chain Logistics Enterprises: The Value Co-Creation Analysis. Ind. Manag. Data Syst. 2020, 120, 675–691. [Google Scholar] [CrossRef]

- Li, G.; Wu, J.; Li, N. Identifying the Value Co-Creation Model and Upgrading Path of Manufacturing Enterprises from the Value Network Perspective. Sustainability 2022, 14, 16008. [Google Scholar] [CrossRef]

- Vandermerwe, S.; Rada, J. Servitization of Business: Adding Value by Adding Services. Eur. Manag. J. 1988, 6, 314–324. [Google Scholar] [CrossRef]

- Francois, J.; Woerz, J. Producer Services, Manufacturing Linkages, and Trade. J. Ind. Compet. Trade 2008, 8, 199–229. [Google Scholar] [CrossRef]

- Greenstein, S.; Khanna, T. What Does Industry Mean? In Competing in the Age of Digital Convergence; The President and Fellows of Harvard Press: Boston, MA, USA, 1997; pp. 14–28. [Google Scholar]

- Yoffie, D.B. Service-Led Growth: The Role of the Service Sector in World Development. By Dorothy I. Riddle. New York: Praeger Publishers, 1986. Pp. xiv, 289. Index. $37.95. Am. J. Int. Law 1988, 82, 224–225. [Google Scholar] [CrossRef]

- Eichengreen, B.; Gupta, P. The Two Waves of Service-Sector Growth. Oxf. Econ. Pap. 2013, 65, 96–123. [Google Scholar] [CrossRef]

- Legewie, J. The Political Economy of Industrial Integration in ASEAN: The Role of Japanese Companies. J. Asia Pac. Econ. 2000, 5, 204–233. [Google Scholar] [CrossRef]

- Li, T.; Liu, X.; Li, X. Some Theoretical Analysis About the Service of Manufacturing Industry. Forum Sci. Technol. China 2018, 0, 75–82. [Google Scholar]

- Li, W.; Xia, J. Integration of Manufacturing and Service Industries Based on Independent Innovation: Mechanism and Path. J. Nanjing Univ. (Philos. Humanit. Soc. Sci.) 2012, 49, 60–67. [Google Scholar]

- Qi, L.; Cai, Y.; Wang, C. Study on the Influence Factors of the Convergence of China’s Equipment Manufacturing Industry. Sci. Technol. Prog. Policy 2017, 34, 92–97. [Google Scholar]

- Zhao, X.; Zhang, Y. Technological Progress and Industrial Performance: A Case Study of Solar Photovoltaic Industry. Renew. Sustain. Energy Rev. 2018, 81, 929–936. [Google Scholar] [CrossRef]

- Mattila, A.S.; Wirtz, J. Congruency of Scent and Music as a Driver of In-Store Evaluations and Behavior. J. Retail. 2001, 77, 273–289. [Google Scholar] [CrossRef]

- Hong, Q. Current Situation of the Convergence of Advanced Manufacturing and Modern Service in China and the Strategic Focus of the “14th Five-Year Plan”. Contemp. Econ. Manag. 2021, 43, 74–81. [Google Scholar]

- Zhou, Z. Industrial Convergence: New Power of Industrial Development and Economic Growth. China Ind. Econ. 2003, 4, 46–52. [Google Scholar]

- Bastas, A. Sustainable Manufacturing Technologies: A Systematic Review of Latest Trends and Themes. Sustainability 2021, 13, 4271. [Google Scholar] [CrossRef]

- United Nations Infrastructure and Industrialization–United Nations Sustainable Development. Available online: https://www.un.org/sustainabledevelopment/infrastructure-industrialization/ (accessed on 14 December 2022).

- Chen, W.; Huang, X.; Liu, Y.; Song, Y. Does Industry Integration Improve the Competitiveness of China’s Electronic Information Industry?—Evidence from the Integration of the Electronic Information Industry and Financial Industry. Sustainability 2019, 11, 2695. [Google Scholar] [CrossRef]

- Uekusa, M. Some Policy and Regulatory Issues in the Japanese Electric Power Industry. In Electricity 21: Power Industry Technology and Management Strategies for the Twenty-First Century; OECD Publications and Information Centre: Washington, DC, USA, 1993; pp. 319–324. [Google Scholar]

- Xia, L. Spatial Effect of Industrial Integration on Total Factor Productivity: From the Perspective of the Integration of Advanced Manufacturing Industry and Modern Service Industry. J. Beijing Univ. Aeronaut. Astronaut. (Soc. Sci. Ed.) 2022. [Google Scholar] [CrossRef]

- Yoffie, B.D. Competing in the Age of Digital Convergence. Calif. Manag. Rev. 1996, 38, 31–53. [Google Scholar] [CrossRef]

- Liu, J.; Dai, M.; Yi, S. Integration of Advanced Manufacturing and Modern Service Industry: Mechanism and Path. Study Pract. 2014, 23–34. [Google Scholar] [CrossRef]

- Wang, W.; Lai, K.-H.; Shou, Y. The Impact of Servitization on Firm Performance: A Meta-Analysis. Int. J. Oper. Prod. Manag. 2018, 38, 1562–1588. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Y.; Li, Y. Facilitating Servitization in Manufacturing Firms: The Influence of Strategic Orientation. Sustainability 2021, 13, 13541. [Google Scholar] [CrossRef]

- Benedettini, O.; Neely, A.; Swink, M. Why Do Servitized Firms Fail? A Risk-Based Explanation. Int. J. Oper. Prod. Manag. 2015, 35, 946–979. [Google Scholar] [CrossRef]

- Neely, A. Exploring the Financial Consequences of the Servitization of Manufacturing. Oper. Manag. Res. 2008, 1, 103–118. [Google Scholar] [CrossRef]

- Baines, T.S.; Lightfoot, H.W.; Benedettini, O.; Kay, J.M. The Servitization of Manufacturing: A Review of Literature and Reflection on Future Challenges. J. Manuf. Technol. Manag. 2009, 20, 547–567. [Google Scholar] [CrossRef]

- Shah, S.A.A.; Jajja, M.S.S.; Chatha, K.A.; Farooq, S. Servitization and Supply Chain Integration: An Empirical Analysis. Int. J. Prod. Econ. 2020, 229, 107765. [Google Scholar] [CrossRef]

- Sousa, R.; da Silveira, G.J.C. Capability Antecedents and Performance Outcomes of Servitization. Int. J. Oper. Prod. Manag. 2017, 37, 444–467. [Google Scholar] [CrossRef]

- Mathieu, V. Product Services: From a Service Supporting the Product to a Service Supporting the Client. J. Bus. Ind. Mark. 2001, 16, 39–61. [Google Scholar] [CrossRef]

- Szász, L.; Demeter, K.; Boer, H.; Cheng, Y. Servitization of Manufacturing: The Effect of Economic Context. J. Manuf. Technol. Manag. 2017, 28, 1011–1034. [Google Scholar] [CrossRef]

- Gambardella, A.; Torrisi, S. Does Technological Convergence Imply Convergence in Markets? Evidence from The Electronics Industry. Res. Policy 1998, 27, 445–463. [Google Scholar] [CrossRef]

- Helleno, A.L.; Simon, A.T.; Papa, M.C.O.; Ceglio, W.E.; Rossa Neto, A.S.; Mourad, R.B.A. Integration University-Industry: Laboratory Model for Learning Lean Manufacturing Concepts in the Academic and Industrial Environments. Int. J. Eng. Educ. 2013, 29, 1387–1399. [Google Scholar]

- Curran, C.-S.; Bröring, S.; Leker, J. Anticipating Converging Industries Using Publicly Available Data. Technol. Forecast. Soc. Chang. 2010, 77, 385–395. [Google Scholar] [CrossRef]

- Fai, F.; von Tunzelmann, N. Industry-Specific Competencies and Converging Technological Systems: Evidence from Patents. Struct. Change Econ. Dyn. 2001, 12, 141–170. [Google Scholar] [CrossRef]

- Cheng, G.; Yang, C. China’s Provincial Industry Convergence Capability: Theoretical Deconstruction, Evaluation Methods and Spatiotemporal Differentiation. Sci. Technol. Prog. Policy 2019, 36, 61–67. [Google Scholar]

- Chu, M. Study on Convergence Degree between Producer Services and Equipment Manufacturing Industry in the Yang-Tze River Delta—Based on the Comparative Analysis of Input-Output Table. Shanghai J. Econ. 2015, 94–100. [Google Scholar] [CrossRef]

- Li, L.; Zhao, Y. Research on the Industrial Linkage-Development between Manufacturing and Information Service Industry of Hubei Province. Wuhan Univ. Technol. (Soc. Sci. Ed.) 2017, 30, 24–31. [Google Scholar]

- Zhang, Z. The Influence of Information Industry on Manufacturing Industry: An Empirical Analysis Based on Chongqing Data. Sci. Technol. Manag. Res. 2019, 39, 110–117. [Google Scholar]

- Zhang, J.; Yan, X. Latest Trend of the Integration of Beijing’s Producer Services and Manufacturing: From the Perspective of Ex-Panding Opening-Up. J. Cap. Univ. Econ. Bus. 2022, 24, 18–31. [Google Scholar]

- Yao, X.; Pu, Y.; Wu, G.; Wang, B.; Wang, L. China’s Level and Status of Industry Convergence in the Belt and Road Initiative: Industry Comparisons, Regional Gaps and Associated Factors. Econ. Res. J. 2019, 54, 172–186. [Google Scholar]

- Barry, P.B.; Jack, E.T. The Early 21st Century U.S. Productivity Expansion Is Still in Services. Int. Product. Monit. 2007, 14, 3–19. [Google Scholar]

- Cao, D.; Yu, C.; Xu, B. The Collaborative Mechanisms between High-End Services and Advanced Manufacturing and the Empirical Analysis—Research on the Yangtze River Delta. Res. Econ. Manag. 2014, 76–86. [Google Scholar] [CrossRef]

- Tang, X.; Zhang, X.; Li, Y. Dynamic Coordination Development in China’s Manufacturing and Manufacturing-Related Service Industries. Econ. Res. J. 2018, 53, 79–93. [Google Scholar]

- Cao, X. Study on Integration of Informatization and Industrialization Characteristics and Its Interation Relationship with Industrial Design. Int. J. Technol. Manag. 2015, 5, 829–833. [Google Scholar]

- Li, X.; Chen, H.; Zhang, X. Research on the Industrial Performance of the Covergence of Information Industry with Manufacturing Industry Based on the Data of Zhejiang Province. China Soft Sci. 2017, 32, 22–30. [Google Scholar]

- Hiroshi, I. Introduction to Input-Output Analysis; China Statitics Press: Beijing, China, 1990; ISBN 7-5037-0401-2. [Google Scholar]

- Peng, Y.; Hou, Y.; Luo, J.; Li, Y. Research on Configuration of Integration of Equipment Manufacturing Industry and Modernized Services Based on TOE Framework. Chin. J. Manag. 2022, 19, 333–341. [Google Scholar]

- Jian, Z.; Wu, Z. A Research on the Paths Selection of Servitization in Manufacturing: Based on the Viewpoint of Smiling Curve. Sci. Sci. Manag. S. T. 2011, 32, 137–143. [Google Scholar]

- Deng, Z. Historical Logic, Practical Significance and Path Exploration of the Integration and Development of Manufac-Turing Industry and Service Industry. J. Beijing Univ. Technol. (Soc. Sci. Ed.) 2019, 19, 61–69. [Google Scholar]

- Peng, H.; Kuang, X. To What Extent Does China’s Manufacturing and Productive Services Integrate—Base on 2010–2014 International Input-Output Analysis and Comparison. J. Int. Trade 2019, 10, 100–116. [Google Scholar]

- Wang, Y.; Ge, Y. Analysis on Characteristic of Input-Output Relation of Chinese Industrial Structure. J. Manag. World 2007, 61–68. [Google Scholar] [CrossRef]

- Vargo, S.L.; Maglio, P.P.; Akaka, M.A. On Value and Value Co-Creation: A Service Systems and Service Logic Perspective. Eur. Manag. J. 2008, 26, 145–152. [Google Scholar] [CrossRef]

| Buying Sectors | Final Demand | Total Outputs | ||||||

|---|---|---|---|---|---|---|---|---|

| s1 | s2 | (x) | ||||||

| Selling sectors | s1 | z11 | z12 | c1 | i1 | g1 | e1 | x1 |

| s2 | z21 | z22 | c2 | i2 | g2 | e2 | x2 | |

| Primary inputs | Value-added | l1 | l2 | L | ||||

| n1 | n2 | N | ||||||

| imports | m1 | m2 | mc | mi | mg | me | M | |

| Total inputs (x’) | C | I | G | E | X | |||

| Buying Sectors | Final Demand | Import | Inflows from Other Provinces | Others | Total Outputs | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Manufacturing N1 | Manufacturing N2 | … | Manufacturing N18 | Modernized services M1 | Modernized services M2 | … | Modernized Services M11 | |||||||

| Selling sectors | Manufacturing N1 | XN1N1 | XN1N2 | … | XN1N18 | XN1M1 | XN1M2 | … | XN1M11 | FN1 | IN1 | PN1 | EN1 | XN1 |

| Manufacturing N2 | XN2N1 | XN2N2 | … | XN2N18 | XN2M1 | XN2M2 | … | XN2M11 | FN2 | IN2 | PN2 | EN2 | XN2 | |

| … | … | … | … | … | … | … | … | … | … | … | … | … | … | |

| Manufacturing N18 | XN18N1 | XN18N2 | … | XN18N18 | XN18M1 | XN18M2 | … | XN18M11 | FN18 | IN18 | PN18 | EN18 | XN18 | |

| Modernized services M1 | XM1N1 | XM1N2 | … | XM1N18 | XM1M1 | XM1M2 | … | XM1M11 | FM1 | IM1 | PM1 | EM1 | XM1 | |

| Modernized services M2 | XM2N1 | XM2N2 | … | XM2N18 | XM2M1 | XM2M2 | … | XM2M11 | FM2 | IM2 | PM2 | EM2 | XM2 | |

| … | … | … | … | … | … | … | … | … | … | … | … | … | … | |

| Modernized services M11 | XM11N1 | XM11N2 | … | XM11N18 | XM11M1 | XM11M2 | … | XM11M11 | FM11 | IM11 | PM11 | EM11 | XM11 | |

| Value-added | VN1 | VN2 | … | VN18 | VM1 | VM2 | … | VM11 | ||||||

| Total inputs | XN1 | XN2 | … | XN18 | XM1 | XM2 | … | XM11 | ||||||

| The Intermediate Input Rate of Modernized Service to Various Manufacturing Industries | 2012 | 2017 | 2017–2012 |

|---|---|---|---|

| Food and tobacco industry | 3.18% | 2.29% | −0.89% |

| Textile industry | 3.50% | 1.95% | −1.56% |

| Textiles, garments, shoes, hats, leather, down feather, and their products | 3.48% | 2.31% | −1.17% |

| Wood products and furniture industry | 3.81% | 6.55% | 2.73% |

| Paper printing and cultural, educational, and sporting goods | 4.60% | 2.85% | −1.74% |

| Petroleum, coking products, and nuclear fuel processed products | 2.92% | 1.30% | −1.62% |

| Chemical products industry | 4.40% | 5.20% | 0.80% |

| Non-metallic mineral products industry | 11.05% | 5.47% | −5.57% |

| The metal smelting and rolling of processed products | 5.41% | 4.13% | −1.27% |

| Metal smelting and rolling processed products industry | 4.27% | 5.29% | 1.02% |

| General equipment industry | 3.92% | 4.47% | 0.55% |

| Special equipment industry | 2.49% | 4.19% | 1.70% |

| Transportation equipment industry | 1.97% | 3.98% | 2.01% |

| Electrical machinery and equipment industry | 4.90% | 4.01% | −0.89% |

| Communication equipment, computer, and other electronic equipment industry | 3.41% | 5.23% | 1.81% |

| Instrumentation industry | 1.84% | 2.39% | 0.56% |

| Other manufactured products and scrap industry | 2.58% | 3.45% | 0.87% |

| Metal products, machinery, and equipment repair services | 3.43% | 0.90% | −2.53% |

| All manufacturing | 4.27% | 3.92% | −0.35% |

| The Intermediate Input Rate of Manufacturing to Various Modernized Services | 2012 | 2017 | 2017–2012 |

|---|---|---|---|

| Transportation, warehousing, and postal industry | 19.74% | 12.04% | −7.71% |

| Information transmission, software and information technology services | 23.97% | 30.52% | 6.56% |

| Real estate | 19.50% | 12.47% | −7.03% |

| Financial industry | 2.85% | 4.65% | 1.80% |

| Leasing and business services | 22.87% | 13.17% | −9.70% |

| Scientific research and technical service industry | 26.96% | 25.84% | −1.12% |

| Water conservancy, environment, and public facilities management industry | 24.05% | 5.51% | −18.55% |

| Residential services, repairs and other services | 25.44% | 39.83% | 14.39% |

| Education industry | 11.39% | 5.54% | −5.85% |

| The health and social work industry | 36.20% | 62.39% | 26.19% |

| Culture, sports, and entertainment industry | 20.77% | 21.75% | 0.98% |

| All modernized services industry | 19.19% | 18.65% | −0.53% |

| Influence Coefficient of Manufacturing on Modernized Services | 2012 | 2017 | 2017–2012 |

|---|---|---|---|

| Food and tobacco industry | 0.540038 | 0.505003 | −0.035035 |

| Textile industry | 0.803648 | 0.793749 | −0.009899 |

| Textiles, garments, shoes, hats, leather, down feather, and their products | 0.956077 | 0.900975 | −0.055102 |

| Wood products and furniture industry | 0.879606 | 1.539759 | 0.660152 |

| Paper printing and cultural, educational, and sporting goods | 1.124759 | 1.085187 | −0.039572 |

| Petroleum, coking products, and nuclear fuel processed products | 0.451319 | 0.310106 | −0.141212 |

| Chemical products industry | 1.044877 | 1.166984 | 0.122107 |

| Non-metallic mineral products industry | 1.750349 | 1.170133 | −0.580215 |

| Metal smelting and rolling processed products | 1.156702 | 0.826973 | −0.329729 |

| Metal smelting and rolling processed products industry | 1.097578 | 1.213126 | 0.115547 |

| General equipment industry | 1.091613 | 1.054224 | −0.037389 |

| Special equipment industry | 0.933814 | 1.220954 | 0.287139 |

| Transportation equipment industry | 0.957194 | 1.28014 | 0.322945 |

| Electrical machinery and equipment industry | 1.318665 | 1.14101 | −0.177655 |

| Communication equipment, computer, and other electronic equipment industry | 1.320653 | 1.47184 | 0.151187 |

| Instrumentation industry | 0.86154 | 1.132928 | 0.271389 |

| Other manufactured products and scrap industry | 0.826207 | 0.498072 | −0.328135 |

| Metal products, machinery and equipment repair services | 0.885362 | 0.688838 | −0.196524 |

| Influence Coefficient of Modernized Services on Manufacturing | 2012 | 2017 | 2017–2012 |

|---|---|---|---|

| Transportation, warehousing and postal industry | 0.807691 | 0.891805 | 0.084114 |

| Information transmission, software and information technology services | 1.361739 | 1.507057 | 0.145318 |

| Real estate | 0.982343 | 0.655258 | −0.327086 |

| Financial industry | 0.24244 | 0.365747 | 0.123307 |

| Leasing and business services | 1.175388 | 0.714994 | −0.460394 |

| Scientific research and technical service industry | 1.324141 | 1.158146 | −0.165994 |

| Water conservancy, environment and public facilities management industry | 1.023389 | 0.326118 | −0.697271 |

| Residential services, repairs and other services | 1.14084 | 1.676315 | 0.535475 |

| Education industry | 0.522078 | 0.274846 | −0.247232 |

| The health and social work industry | 1.515445 | 2.31459 | 0.799145 |

| Culture, sports, and entertainment industry | 0.904506 | 1.115124 | 0.210618 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Shang, M.; Xu, J.; Zhang, L.; Hua, H. Value Chain and the Integrated Development of Manufacturing and Modernized Services: A Case Study of Shandong Province, China. Sustainability 2023, 15, 1439. https://doi.org/10.3390/su15021439

Liu Y, Shang M, Xu J, Zhang L, Hua H. Value Chain and the Integrated Development of Manufacturing and Modernized Services: A Case Study of Shandong Province, China. Sustainability. 2023; 15(2):1439. https://doi.org/10.3390/su15021439

Chicago/Turabian StyleLiu, Yuli, Mingyi Shang, Jianwei Xu, Lei Zhang, and Honglian Hua. 2023. "Value Chain and the Integrated Development of Manufacturing and Modernized Services: A Case Study of Shandong Province, China" Sustainability 15, no. 2: 1439. https://doi.org/10.3390/su15021439

APA StyleLiu, Y., Shang, M., Xu, J., Zhang, L., & Hua, H. (2023). Value Chain and the Integrated Development of Manufacturing and Modernized Services: A Case Study of Shandong Province, China. Sustainability, 15(2), 1439. https://doi.org/10.3390/su15021439