Energy Evolution Characteristics of Water-Saturated and Dry Anisotropic Coal under True Triaxial Stresses

Abstract

1. Introduction

2. Experimental Setup and Procedures

2.1. Sample Materials

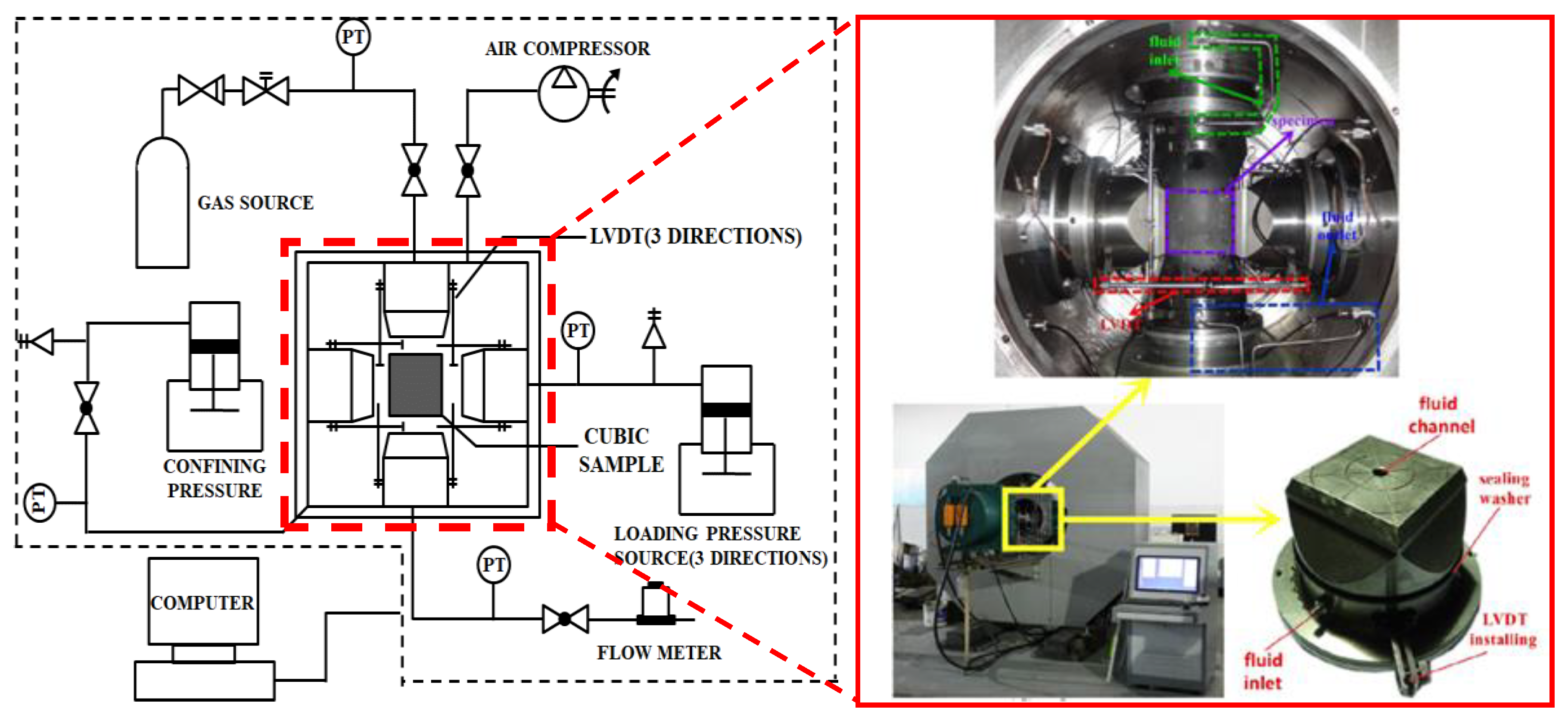

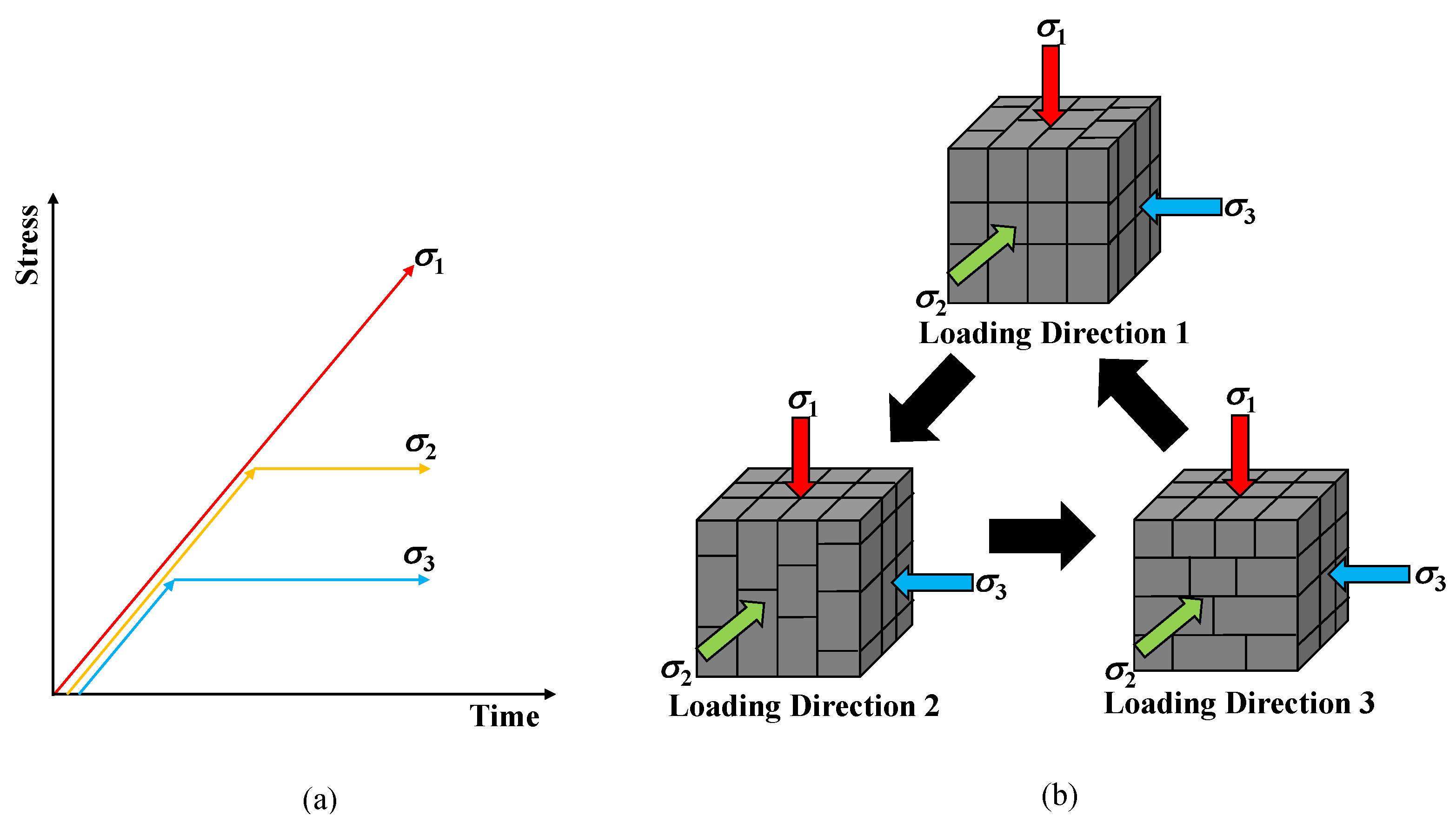

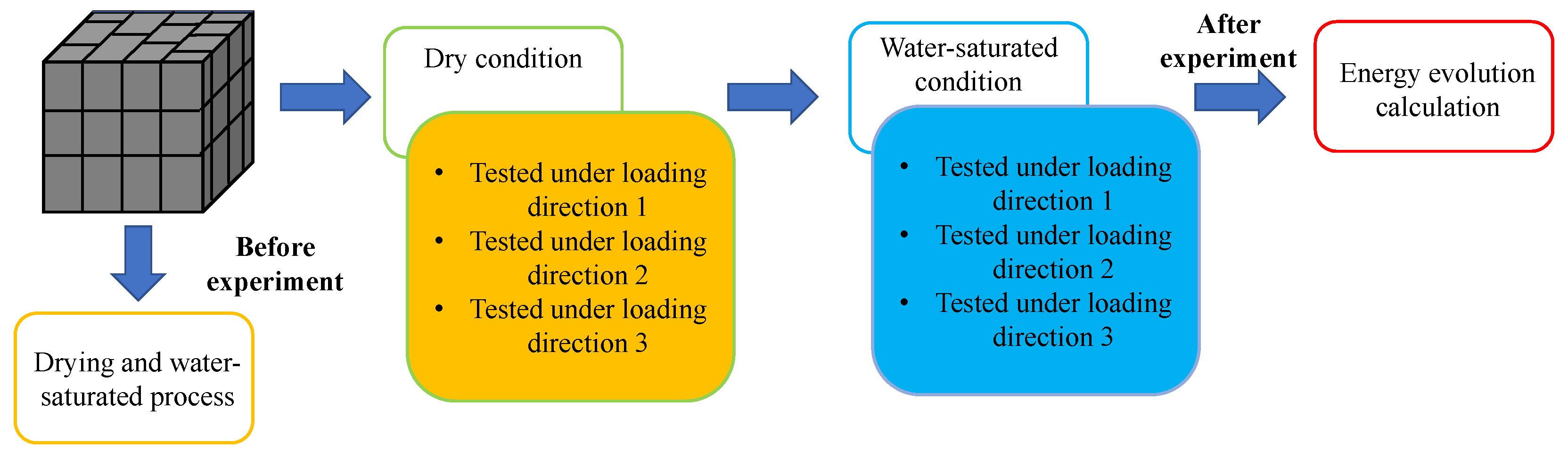

2.2. Apparatus and Procedures

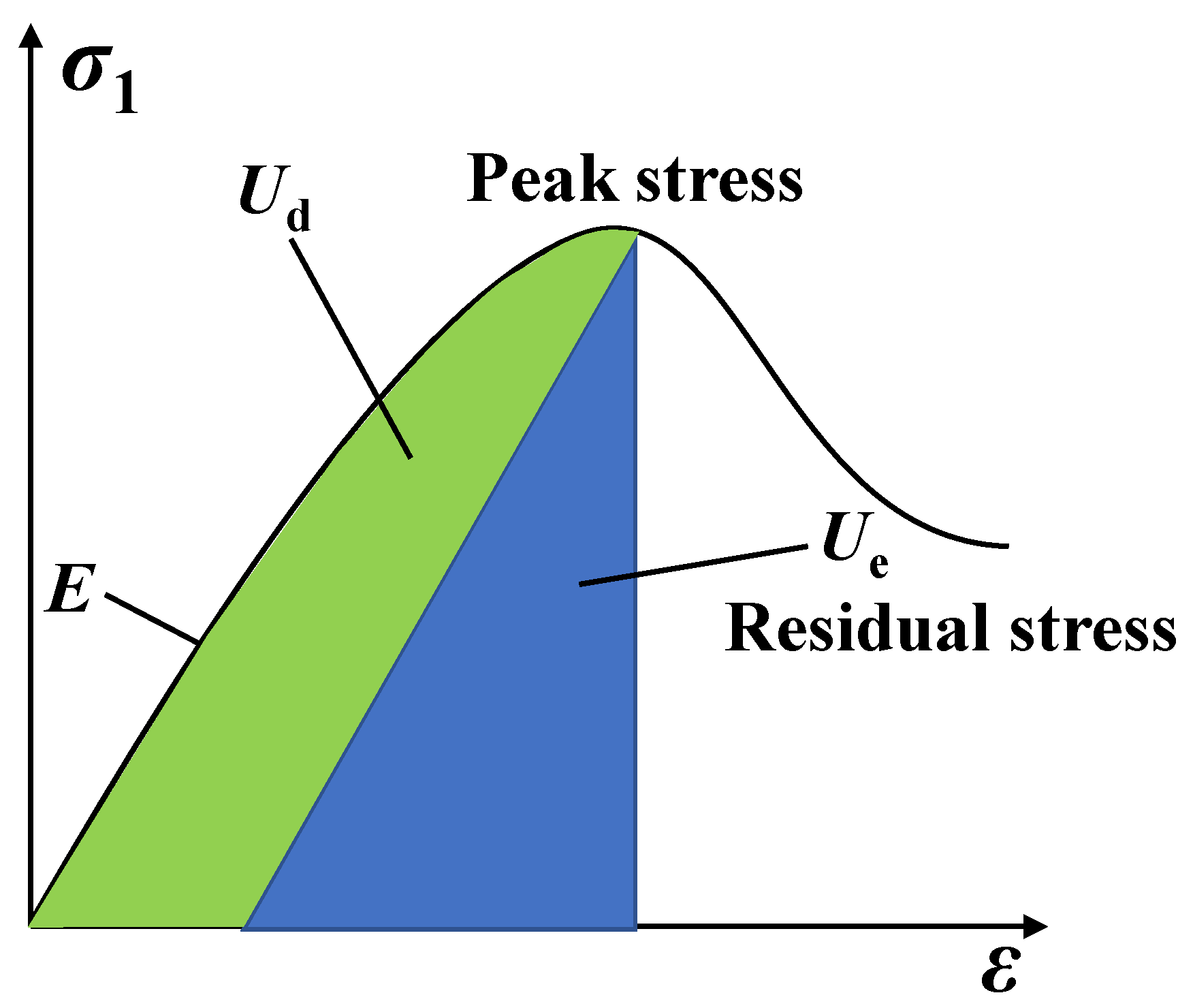

2.3. Energy Evolution Calculation

3. Results and Analysis

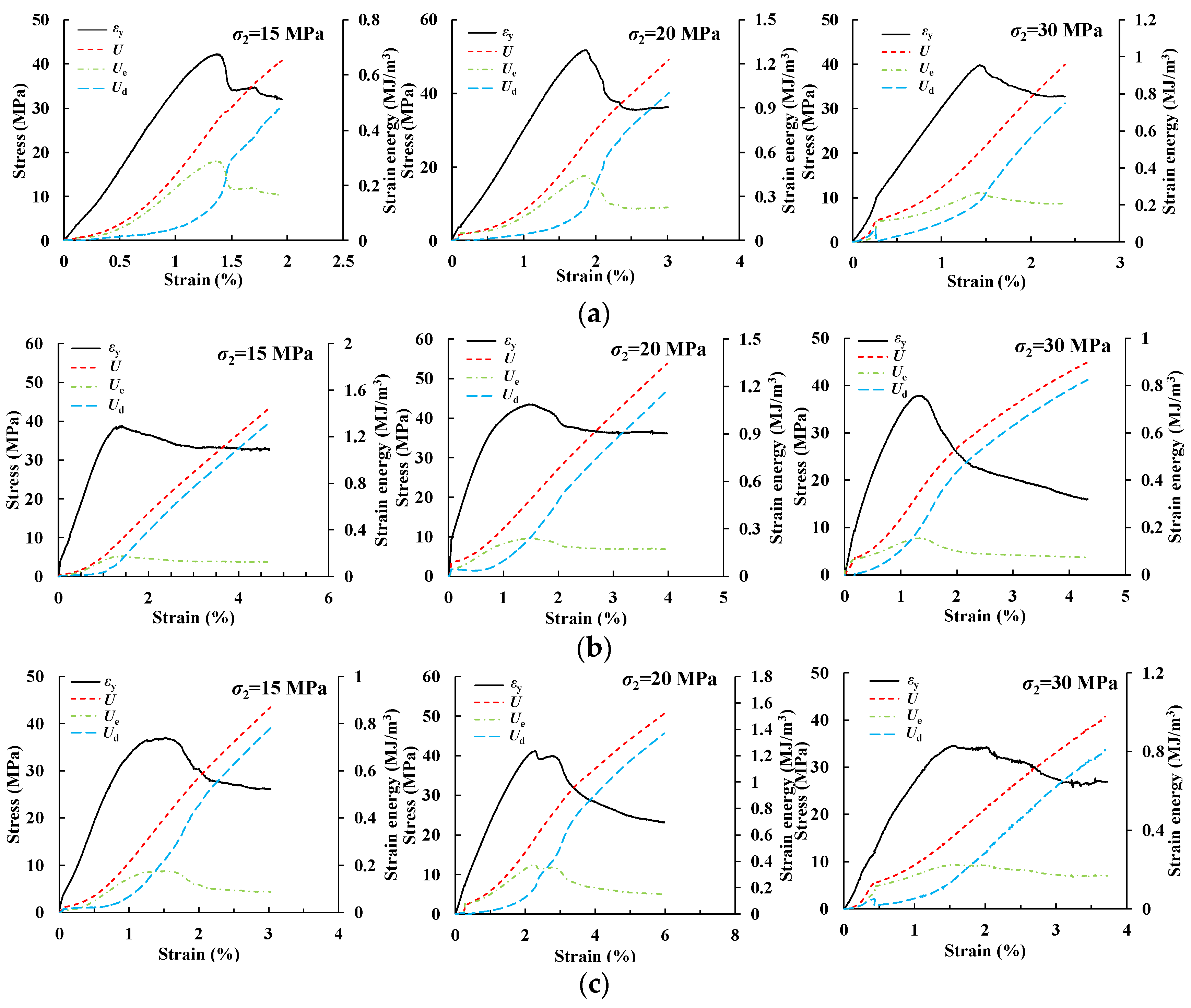

3.1. Energy Evolution Characteristics of Dry and Water-Saturated Coal under Different True Triaxial Stresses

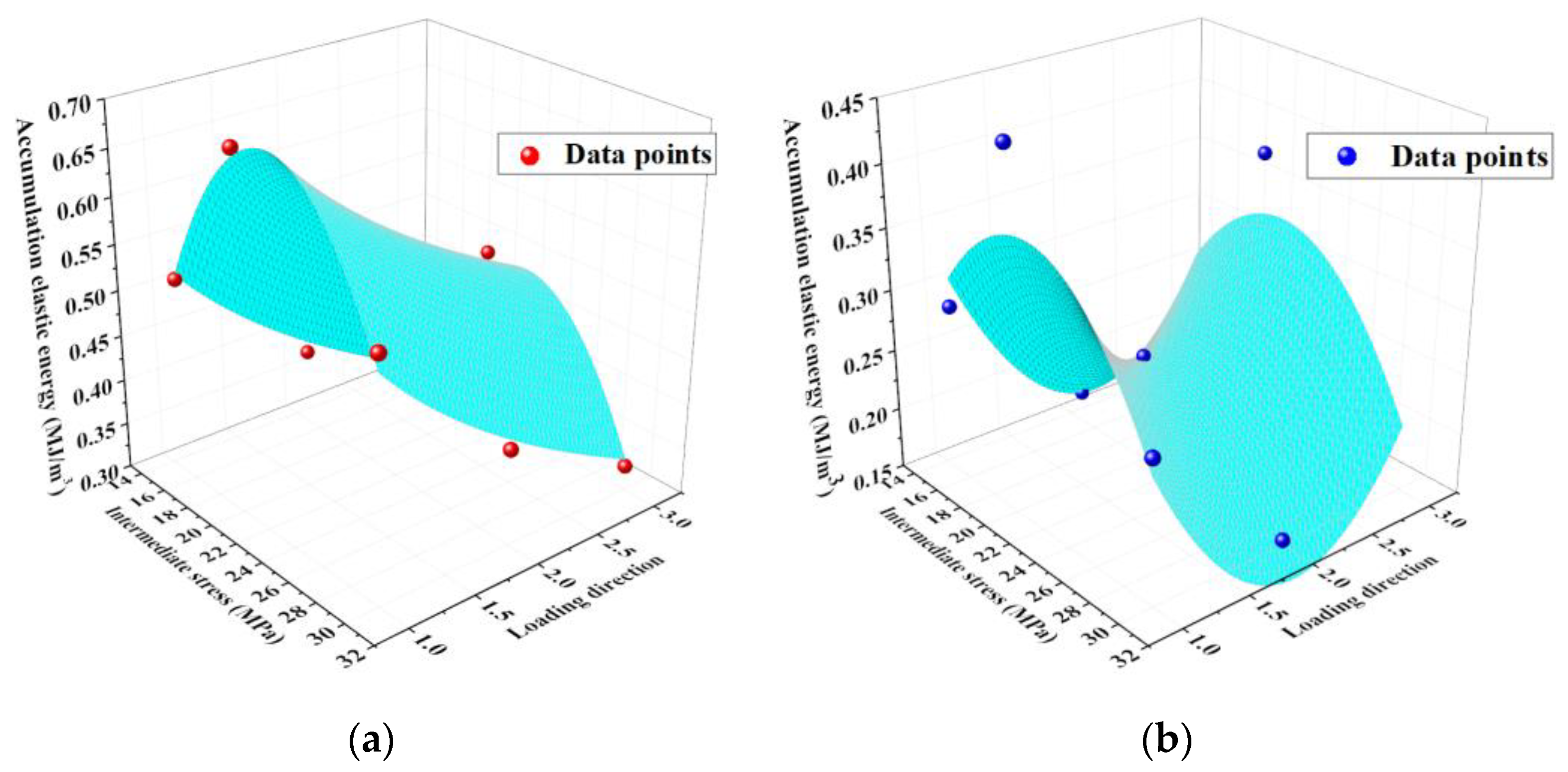

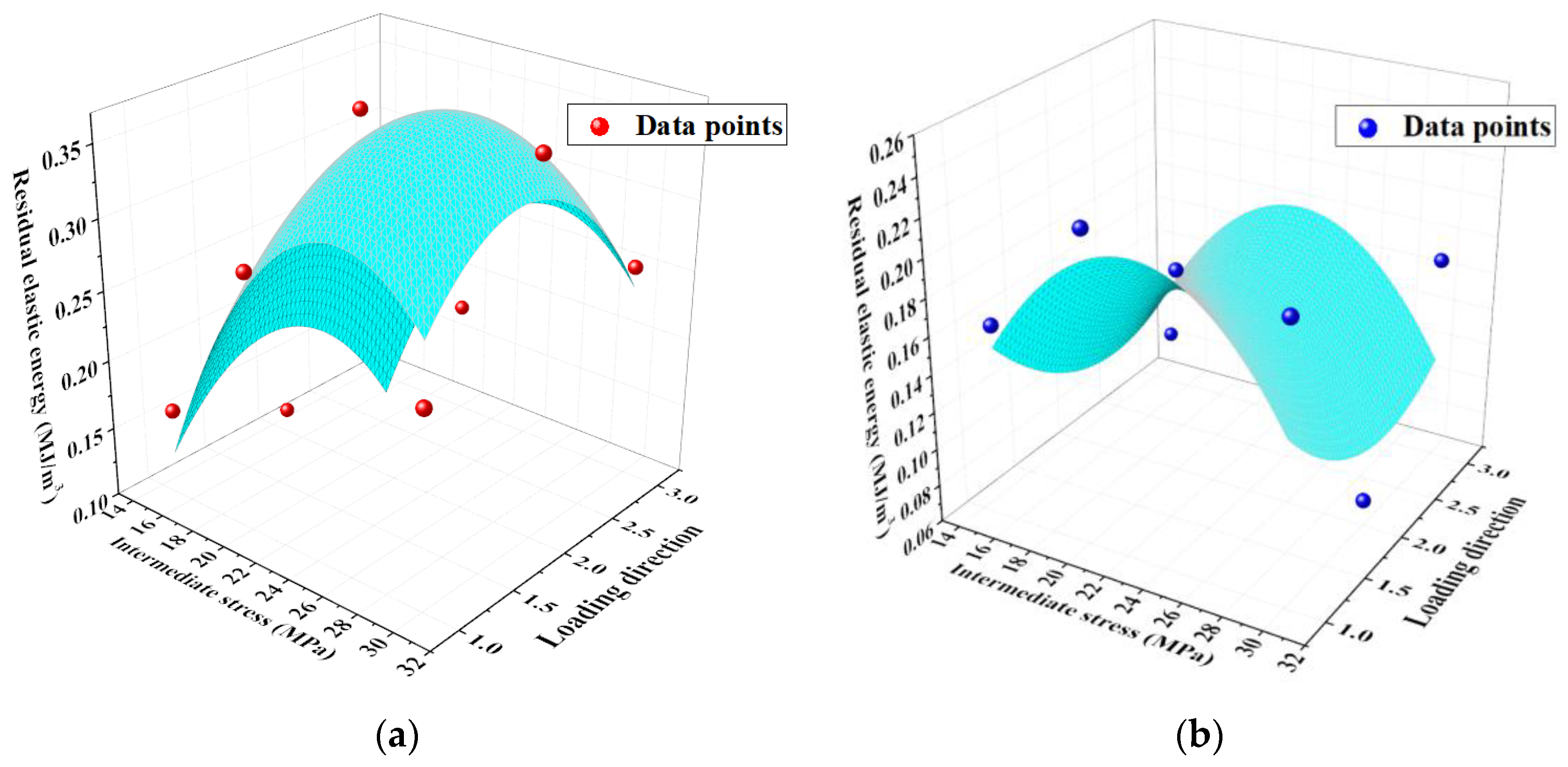

3.2. Accumulation and Residual Elastic Energy Analysis of Dry and Water-Saturated Coal under Different True Triaxial Stresses

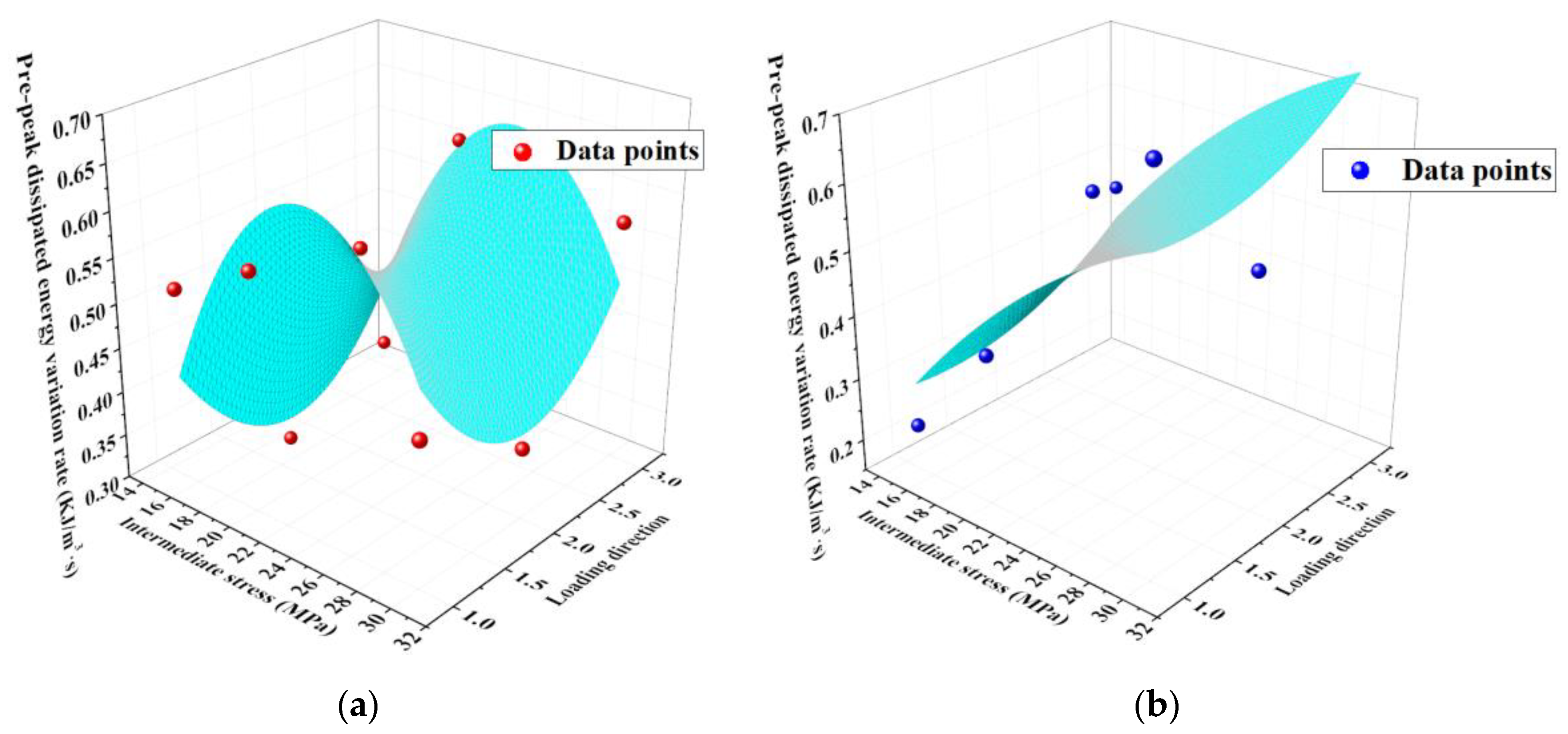

3.3. Dissipated Energy Variation Rate Analysis of Dry and Water-Saturated Coal under Different True Triaxial Stresses

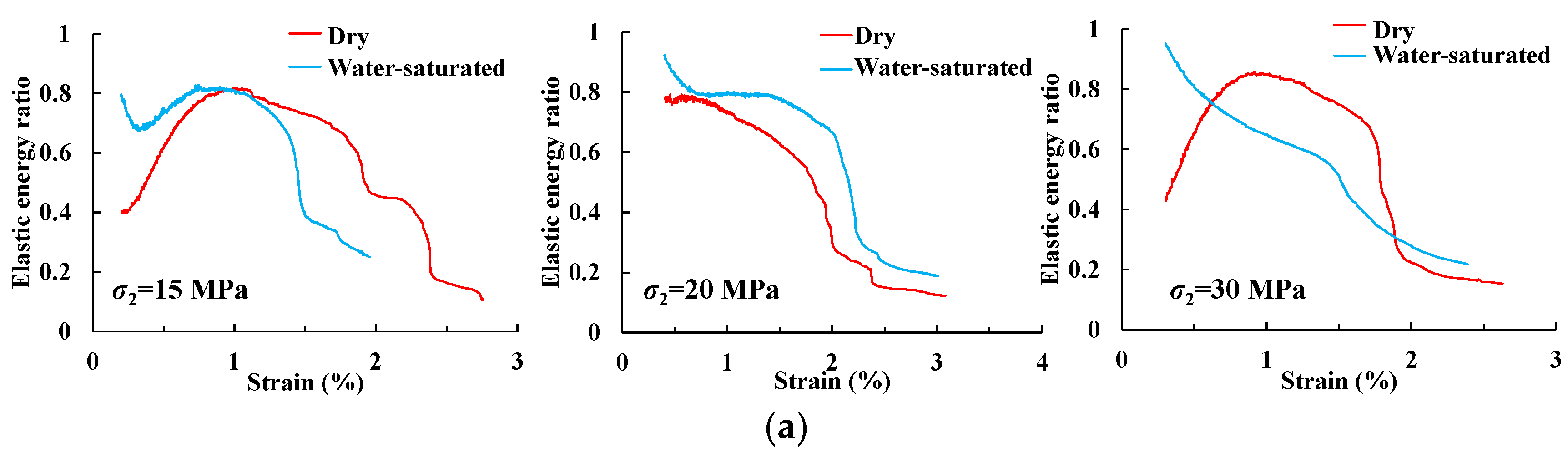

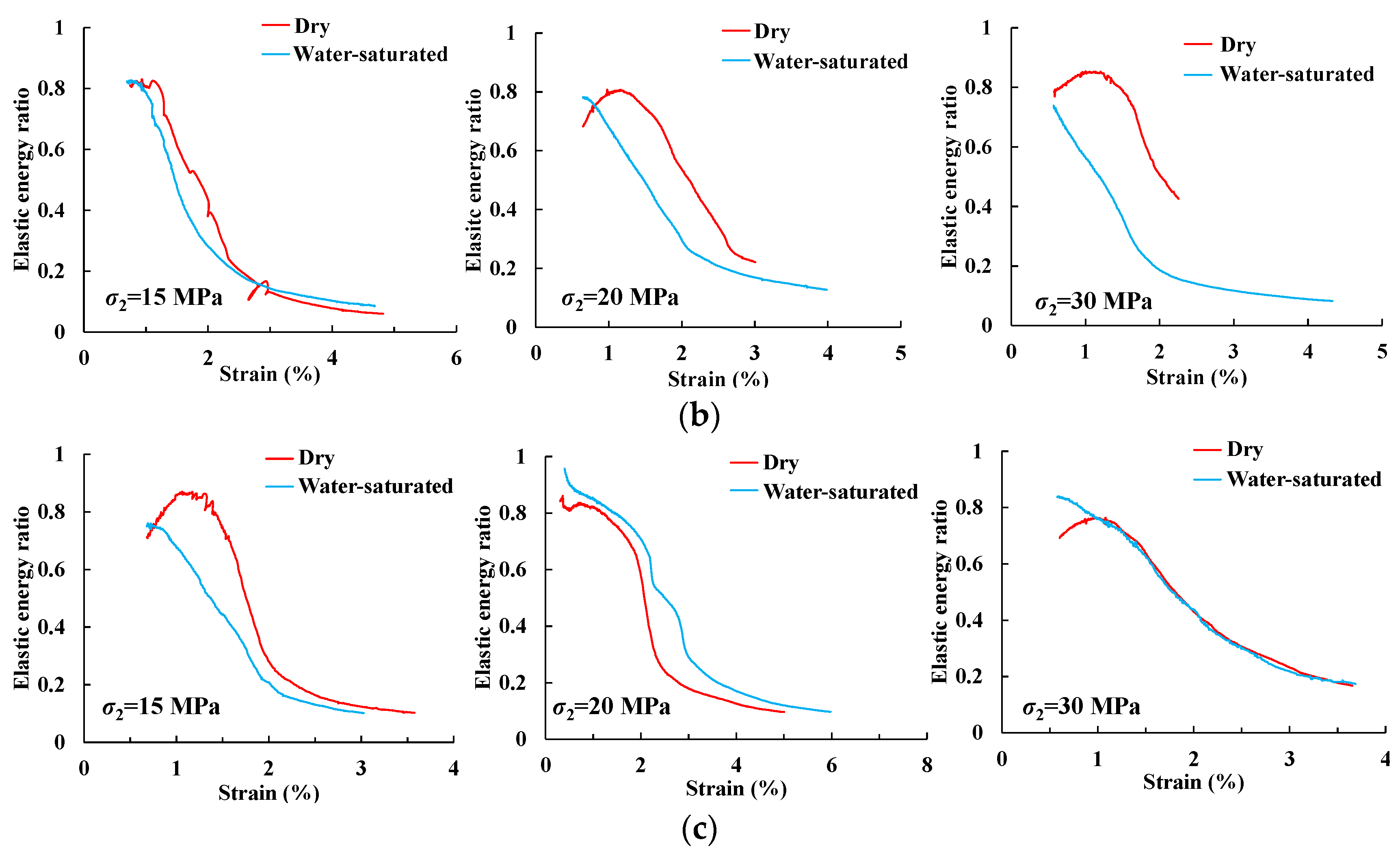

3.4. Ratio of Elastic Energy to Total Energy Variation Analysis of Dry and Water-Saturated Coal under Different True Triaxial Stresses

4. Discussion

5. Conclusions

- (1)

- For water-saturated coal samples, the overall energy is weakened due to the water adsorption, as indicated by the lower values in the total, elastic, and dissipated energy evolution curves than dry coal samples. In addition, all the values of pre-peak and post-peak dissipated energy variations rates of water-saturated coal samples under different intermediate stresses and loading directions are lower than the dry coal samples. The elastic energy ratio evolution of dry coal samples mainly behaves as an increasing-then-decreasing trend. In contrast, the elastic energy ratio evolution shows a decreasing trend for most water-saturated coal samples.

- (2)

- The water-weakening effect on the overall energy of water-saturated coal is more pronounced when perpendicular to the bedding plane direction than in the other two cleat directions. At the same intermediate stresses, the elastic and total energy of dry and water-saturated coal samples were higher in pre-peak stages when tested perpendicular to the bedding planes. Moreover, at the same intermediate stress, the dry and water-saturated coal samples have higher values for accumulation and residual elastic energy when tested perpendicular to the bedding plane than parallel to the face cleat plane and butt cleat plane.

- (3)

- Both accumulation and residual elastic energy of dry and water-saturated coal samples show an increasing-then-decreasing trend with intermediate stress increase. In addition, both pre-peak dissipated energy variation rates of dry coal samples show an increasing-then-decreasing trend with intermediate stress increase.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zou, Q.; Liu, H.; Zhang, Y.; Li, Q.; Fu, J.; Hu, Q. Rationality evaluation of production deployment of outburst-prone coal mines: A case study of nantong coal mine in Chongqing, China. Saf. Sci. 2020, 122, 104515. [Google Scholar] [CrossRef]

- Dai, S.; Finkelman, R.B. Coal geology in China: An overview. Int. Geol. Rev. 2018, 60, 531–534. [Google Scholar] [CrossRef]

- Ranjith, P.G.; Zhao, J.; Ju, M.; De Silva, R.V.S.; Rathnaweera, T.D.; Bandara, A.K.M.S. Opportunities and challenges in deep mining: A brief review. Engineering 2017, 3, 546–551. [Google Scholar] [CrossRef]

- Du, J.; Chen, J.; Pu, Y.; Jiang, D.; Chen, L.; Zhang, Y. Risk assessment of dynamic disasters in deep coal mines based on multi-source, multi-parameter indexes, and engineering application. Process. Saf. Environ. Prot. 2021, 155, 575–586. [Google Scholar] [CrossRef]

- Wang, W.; Wang, H.; Zhang, B.; Wang, S.; Xing, W. Coal and gas outburst prediction model based on extension theory and its application. Process. Saf. Environ. 2021, 154, 329–337. [Google Scholar] [CrossRef]

- Liu, P.; Fan, J.; Jiang, D.; Li, J. Evaluation of underground coal gas drainage performance: Mine site measurements and parametric sensitivity analysis. Process. Saf. Environ. 2021, 148, 711–723. [Google Scholar] [CrossRef]

- Lu, J.; Jiang, C.; Jin, Z.; Wang, W.; Zhuang, W.; Yu, H. Three-dimensional physical model experiment of mining-induced deformation and failure characteristics of roof and floor in deep underground coal seams. Process. Saf. Environ. 2021, 150, 400–415. [Google Scholar] [CrossRef]

- Chen, D.; Li, N.; Sun, W. Rupture properties and safety assessment of raw coal specimen rupture process under true triaxial hydraulic fracturing based on the source parameters and magnitude. Process. Saf. Environ. 2022, 158, 661–673. [Google Scholar] [CrossRef]

- Zhang, Y.; Lebedev, M.; Al-Yaseri, A.; Yu, H.; Xu, X.; Sarmadivaleh, M.; Barifcani, A.; Iglauer, S. Nanoscale rock mechanical property changes in heterogeneous coal after water adsorption. Fuel 2018, 218, 23–32. [Google Scholar] [CrossRef]

- Liu, T.; Lin, B.; Fu, X.; Zhao, Y.; Gao, Y.; Yang, W. Modeling coupled gas flow and geomechanics process in stimulated coal seam by hydraulic flushing. Int. J. Rock Mech. Min. Sci. 2021, 142, 104769. [Google Scholar] [CrossRef]

- Liu, Y.; Yin, G.; Zhang, D.; Li, M.; Deng, B.; Liu, C.; Zhao, H.; Yin, S. Directional permeability evolution in intact and fractured coal subjected to true-triaxial stresses under dry and water-saturated conditions. Int. J. Rock Mech. Min. Sci. 2019, 119, 22–34. [Google Scholar] [CrossRef]

- Li, N.; Fang, L.; Sun, W.; Zhang, X.; Chen, D. Evaluation of borehole hydraulic fracturing in coal seam using the microseismic monitoring method. Rock Mech. Rock Eng. 2021, 54, 607–625. [Google Scholar] [CrossRef]

- Li, N.; Sun, W.; Huang, B.; Chen, D.; Zhang, S.; Yan, M. Acoustic emission source location monitoring of laboratory-scale hydraulic fracturing of coal under true triaxial stress. Nat. Res. Res. 2021, 30, 2297–2315. [Google Scholar] [CrossRef]

- Ai, T.; Wu, S.; Zhang, R.; Gao, M.; Zhou, J.; Xie, J.; Ren, L.; Zhang, Z. Changes in the structure and mechanical properties of a typical coal induced by water immersion. Int. J. Rock Mech. Min. Sci. 2021, 138, 104597. [Google Scholar] [CrossRef]

- Zhang, J. Investigations of water inrushes from aquifers under coal seams. Int. J. Rock Mech. Min. Sci. 2005, 42, 350–360. [Google Scholar] [CrossRef]

- Ma, L.; Liu, C.; Bi, Y.; Peng, S.; Jiang, K.; Zhang, H.; Luo, Q.; Xue, F.; Xu, T.; Li, T.; et al. Experimental study on impermeability law of aquiclude reconstructed by mudstone of external dump in arid zone. Adv. Civ. Eng. 2021, 2021, 5561794. [Google Scholar] [CrossRef]

- Ma, L.; Zhang, J.; Xu, C.; Lai, X.; Luo, Q.; Liu, C.; Li, K. Comprehensive evaluation of blast casting results based on unascertained measurement and intuitionistic fuzzy set. Shock Vib. 2021, 2021, 8864618. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, Z.; Ge, Z.; Zhong, C.; Liu, L. Brittleness evaluation of saturated coal based on energy method from stress–strain curves of uniaxial compression. Rock Mech. Rock Eng. 2021, 54, 3193–3207. [Google Scholar] [CrossRef]

- Qin, L.; Ma, C.; Li, S.; Lin, H.; Ding, Y.; Liu, P.; Wang, P.; Gao, Z. Liquid nitrogen’s effect on the mechanical properties of dried and water-saturated frozen coal. Energ. Fuel 2022, 36, 1894–1903. [Google Scholar] [CrossRef]

- Tang, C.; Yao, Q.; Xu, Q.; Shan, C.; Xu, J.; Han, H.; Guo, H. Mechanical failure modes and fractal characteristics of coal samples under repeated drying–saturation conditions. Nat. Resour. Res. 2021, 30, 4439–4456. [Google Scholar] [CrossRef]

- Yao, Q.; Chen, T.; Tang, C.; Sedighi, M.; Wang, S.; Huang, Q. Influence of moisture on crack propagation in coal and its failure modes. Eng. Geol. 2019, 258, 105156. [Google Scholar] [CrossRef]

- Ali, M.; Wang, E.; Li, Z.; Jia, H.; Li, D.; Jiskani, I.M.; Ullah, B. Study on acoustic emission characteristics and mechanical behavior of water-saturated coal. Geofluids 2021, 2021, 20215247988. [Google Scholar] [CrossRef]

- Zhang, X.; Ranjith, P.G.; Lu, Y.; Ranathunga, A.S. Experimental investigation of the influence of CO2 and water adsorption on mechanics of coal under confining pressure. Int. J. Coal Geol. 2019, 209, 117–129. [Google Scholar] [CrossRef]

- Zhang, M.; Nie, R. Experimental investigation on the influence of water content on the mechanical properties of coal under conventional triaxial compression. Shock Vib. 2020, 2020, 8872438. [Google Scholar] [CrossRef]

- Hu, Q.; Zhang, Y.; Li, Q.; Cao, J.; Song, M.; Hu, L.; Liu, J.; Deng, Y.; Shi, J.; Zheng, X. Experimental research on progressive failure characteristics of water-immersed coal: Implications for hydraulic fracturing. Eng. Geol. 2022, 308, 106809. [Google Scholar] [CrossRef]

- Wang, W.; Yao, Q.; Tang, C.; Li, X.; Chong, Z. Study of the mechanical properties and fracture evolution of sandstone with different moisture contents under true triaxial stress. Arab. J. Sci. Eng. 2021, 46, 11497–11518. [Google Scholar] [CrossRef]

- Minaeian, V.; Dewhurst, D.N.; Rasouli, V. Deformational behaviour of a clay-rich shale with variable water saturation under true triaxial stress conditions. Geomech. Energy Environ. 2017, 11, 1–13. [Google Scholar] [CrossRef]

- Liu, Y.; Yin, G.; Li, M.; Zhang, D.; Huang, G.; Liu, P.; Liu, C.; Zhao, H.; Yu, B. Mechanical properties and failure behavior of dry and water-saturated anisotropic coal under true-triaxial loading conditions. Rock Mech. Rock Eng. 2020, 53, 4799–4818. [Google Scholar] [CrossRef]

- Alexeev, A.D.; Revva, V.N.; Alyshev, N.A.; Zhitlyonok, D.M. True triaxial loading apparatus and its application to coal outburst prediction. Int. J. Coal Geol. 2004, 58, 245–250. [Google Scholar] [CrossRef]

- Liu, Y.; Lebedev, M.; Zhang, Y.; Wang, E.; Li, W.; Liang, J.; Feng, R.; Ma, R. Micro-cleat and permeability evolution of anisotropic coal during directional CO2 flooding: An in situ micro-CT study. Nat. Resour Res. 2022, 31, 2805–2818. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, E.; Jiang, C.; Zhang, D.; Li, M.; Yu, B.; Zhao, D. True triaxial experimental study of anisotropic mechanical behavior and permeability evolution of initially fractured coal. Nat. Resour. Res. 2023, 1–19. [Google Scholar] [CrossRef]

- International Standard ISO 11760; Classification of Coals. International Organization for Standardization: Geneva, Switzerland, 2018.

- Feng, X.; Haimson, B.; Li, X.; Chang, C.; Ma, X.; Zhang, X.; Ingraham, M.; Suzuki, K. ISRM suggested method: Determining deformation and failure characteristics of rocks subjected to true triaxial compression. Rock Mech. Rock Eng. 2019, 52, 2011–2020. [Google Scholar] [CrossRef]

- Liu, Y.; Li, M.; Yin, G.; Zhang, D.; Deng, B. Permeability evolution of anthracite coal considering true triaxial stress conditions and structural anisotropy. J. Nat. Gas. Sci. Eng. 2018, 2, 492–506. [Google Scholar] [CrossRef]

- Yin, S.; Song, D.; He, X.; Lou, Q.; Qiu, L.; Li, Z.; Chen, P.; Li, J.; Liu, Y. Structural health monitoring of building rock based on stress drop and acoustic-electric energy release. Struct. Control Health 2022, 29, e2875. [Google Scholar] [CrossRef]

- Xie, H.; Li, L.; Peng, R.; Ju, Y. Energy analysis and criteria for structural failure of rocks. J. Rock Mech. Geotech. Eng. 2009, 1, 11–20. [Google Scholar] [CrossRef]

- Hao, X.; Du, W.; Jiang, Y.; Tannant, D.; Zhao, Y.; Guo, Y. Influence of bedding and cleats on the mechanical properties of a hard coal. Arab. J. Geosci. 2018, 11, 200. [Google Scholar] [CrossRef]

- Gao, F.; Stead, D.; Kang, H. Numerical investigation of the scale effect and anisotropy in the strength and deformability of coal. Int. J. Coal Geol. 2014, 136, 25–37. [Google Scholar] [CrossRef]

- Okubo, S.; Fukui, K.; Qingxin, Q. Uniaxial compression and tension tests of anthracite and loading rate dependence of peak strength. Int. J. Coal Geol. 2006, 68, 196–204. [Google Scholar] [CrossRef]

- Erguler, Z.A.; Ulusay, R. Water-induced variations in mechanical properties of clay-bearing rocks. Int. J. Rock Mech. Min. Sci. 2009, 46, 355–370. [Google Scholar] [CrossRef]

- Poulsen, B.A.; Shen, B.; Williams, D.J.; Huddlestone-Holmes, C.; Erarslan, N.; Qin, J. Strength reduction on saturation of coal and coal measures rocks with implications for coal pillar strength. Int. J. Rock Mech. Min. Sci. 2014, 71, 41–52. [Google Scholar] [CrossRef]

- Zhang, Z.; Gao, F. Experimental investigation on the energy evolution of dry and water-saturated red sandstones. Int. J. Min. Sci. Technol. 2015, 25, 383–388. [Google Scholar] [CrossRef]

- Liu, W.; Yang, K.; Zhang, S.; Zhang, Z.; Xu, R. Energy evolution and water immersion-induced weakening in sandstone roof of coal mines. Int. J. Coal Sci. Technol. 2022, 9, 53. [Google Scholar] [CrossRef]

- Khan, N.M.; Ma, L.; Cao, K.; Hussain, S.; Liu, W.; Xu, Y.; Yuan, Q.; Gu, J. Prediction of an early failure point using infrared radiation characteristics and energy evolution for sandstone with different water contents. B Eng. Geol. Environ. 2021, 80, 6913–6936. [Google Scholar] [CrossRef]

- Benson, P.M.; Meredith, P.G.; Platzman, E.S. Relating pore fabric geometry to acoustic and permeability anisotropy in Crab Orchard Sandstone: A laboratory study using magnetic ferrofluid. Geophys. Res. Lett. 2003, 2003, 30. [Google Scholar] [CrossRef]

- Hu, J.; Gao, C.; Xie, H.; Wang, J.; Li, M.; Li, C. Anisotropic characteristics of the energy index during the shale failure process under triaxial compression. J. Nat. Gas. Sci. Eng. 2021, 95, 104219. [Google Scholar] [CrossRef]

- Song, Z.; Zhang, J.; Wang, S.; Dong, X.; Zhang, Y. Energy evolution characteristics and weak structure-“energy flow” impact damaged mechanism of deep-bedded sandstone. Rock Mech. Rock Eng. 2022, 1–31. [Google Scholar] [CrossRef]

- Zhang, Q.; Fan, X.; Chen, P.; Ma, T.; Zeng, F. Geomechanical behaviors of shale after water absorption considering the combined effect of anisotropy and hydration. Eng. Geol. 2020, 269, 105547. [Google Scholar] [CrossRef]

- Zhang, Z.; Xie, H.; Zhang, R.; Zhang, Z.; Gao, M.; Jia, Z.; Xie, J. Deformation damage and energy evolution characteristics of coal at different depths. Rock Mech. Rock Eng. 2019, 52, 1491–1503. [Google Scholar] [CrossRef]

- Du, X.; Xue, J.; Shi, Y.; Cao, C.; Shu, C.; Li, K.; Ma, Q.; Zhan, K.; Chen, Z.; Wang, S. Triaxial mechanical behaviour and energy conversion characteristics of deep coal bodies under confining pressure. Energy 2022, 266, 126443. [Google Scholar] [CrossRef]

- Feng, X.; Ding, Z.; Ju, Y.; Zhang, Q.; Ali, M. “Double peak” of dynamic strengths and acoustic emission responses of coal masses under dynamic loading. Nat. Resour. Res. 2022, 31, 1705–1720. [Google Scholar] [CrossRef]

- Feng, X.; Ding, Z.; Hu, Q.; Zhao, X.; Ali, M.; Banquando, J. Orthogonal numerical analysis of deformation and failure characteristics of deep roadway in coal mines: A case study. Minerals 2022, 12, 185. [Google Scholar] [CrossRef]

- Zhang, Q.; Fan, X.; Liang, Y.; Li, M.; Li, G.; Ma, T.; Nie, W. Mechanical behavior and permeability evolution of reconstituted coal samples under various unloading confining pressures-implications for wellbore stability analysis. Energies 2017, 10, 292. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, X.; Wei, Y.; Ali, M. Experimental study of electric potential response characteristics of different lithological samples subject to uniaxial loading. Rock Mech. Rock Eng. 2021, 54, 397–408. [Google Scholar] [CrossRef]

- Jiang, C.; Yang, Y.; Wei, W.; Duan, M.; Yu, T. A new stress-damage-flow coupling model and the damage characterization of raw coal under loading and unloading conditions. Int. J. Rock Mech. Min. Sci. 2021, 138, 104601. [Google Scholar] [CrossRef]

| Sample ID | Accumulation Elastic Energy (MJ/m3) | Residual Elastic Energy (MJ/m3) | Sample ID | Accumulation Elastic Energy (MJ/m3) | Residual Elastic Energy (MJ/m3) |

|---|---|---|---|---|---|

| Coal-15-1D | 0.516 | 0.162 | Coal-15-1W | 0.289 | 0.163 |

| Coal-20-1D | 0.685 | 0.284 | Coal-20-1W | 0.442 | 0.224 |

| Coal-30-1D | 0.561 | 0.241 | Coal-30-1W | 0.268 | 0.207 |

| Coal-15-2D | 0.383 | 0.117 | Coal-15-2W | 0.175 | 0.122 |

| Coal-20-2D | 0.518 | 0.359 | Coal-20-2W | 0.240 | 0.172 |

| Coal-30-2D | 0.406 | 0.365 | Coal-30-2W | 0.154 | 0.074 |

| Coal-15-3D | 0.334 | 0.120 | Coal-15-3W | 0.178 | 0.089 |

| Coal-20-3D | 0.490 | 0.180 | Coal-20-3W | 0.375 | 0.149 |

| Coal-30-3D | 0.327 | 0.254 | Coal-30-3W | 0.226 | 0.170 |

| Sample ID | Pre-Peak Dissipated Energy Variation Rate (KJ/m3·s) | Post-Peak Dissipated Energy Variation Rate (KJ/m3·s) | Sample ID | Pre-Peak Dissipated Energy Variation Rate (KJ/m3·s) | Post-Peak Dissipated Energy Variation Rate (KJ/m3·s) |

|---|---|---|---|---|---|

| Coal-15-1D | 0.515 | 3.377 | Coal-15-1W | 0.222 | 1.173 |

| Coal-20-1D | 0.567 | 4.622 | Coal-20-1W | 0.386 | 3.329 |

| Coal-30-1D | 0.463 | 5.777 | Coal-30-1W | 0.746 | 4.779 |

| Coal-15-2D | 0.273 | 2.505 | Coal-15-2W | 0.324 | 1.670 |

| Coal-20-2D | 0.536 | 4.118 | Coal-20-2W | 0.557 | 1.741 |

| Coal-30-2D | 0.381 | 2.727 | Coal-30-2W | 0.523 | 1.520 |

| Coal-15-3D | 0.330 | 2.237 | Coal-15-3W | 0.456 | 1.733 |

| Coal-20-3D | 0.606 | 3.148 | Coal-20-3W | 0.500 | 2.289 |

| Coal-30-3D | 0.571 | 2.357 | Coal-30-3W | 0.433 | 1.860 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Wang, E.; Zhao, D.; Zhang, L. Energy Evolution Characteristics of Water-Saturated and Dry Anisotropic Coal under True Triaxial Stresses. Sustainability 2023, 15, 1431. https://doi.org/10.3390/su15021431

Liu Y, Wang E, Zhao D, Zhang L. Energy Evolution Characteristics of Water-Saturated and Dry Anisotropic Coal under True Triaxial Stresses. Sustainability. 2023; 15(2):1431. https://doi.org/10.3390/su15021431

Chicago/Turabian StyleLiu, Yubing, Enyuan Wang, Dong Zhao, and Li Zhang. 2023. "Energy Evolution Characteristics of Water-Saturated and Dry Anisotropic Coal under True Triaxial Stresses" Sustainability 15, no. 2: 1431. https://doi.org/10.3390/su15021431

APA StyleLiu, Y., Wang, E., Zhao, D., & Zhang, L. (2023). Energy Evolution Characteristics of Water-Saturated and Dry Anisotropic Coal under True Triaxial Stresses. Sustainability, 15(2), 1431. https://doi.org/10.3390/su15021431