1. Introduction

Efficiently cooling the heat of electronic systems and uniformly distributing the heat is an important issue for thermal management. To enhance the heat transfer ability, many kinds of optimization methods have been applied to the design of heat sinks. Husain and Kim [

1] performed shape optimization of a microchannel heat sink, and obtained pareto-optimal solutions using a fast and elitist non-dominated sorting genetic algorithm (NSGA-II). Srisomporn and Bureerat [

2] demonstrated the use of the strength pareto evolutionary algorithm (SPEA), with and without the combination of RSM, for a multi-objective design of plate-fin heat sink geometry. The purpose of this study is to minimize the heat sink junction temperature and fan pumping power. Bureerat and Srisomporn [

3] used a multi-objective evolutionary algorithm (MOEA), namely population-based incremental learning (PBIL), to minimize the junction temperature and fan pumping power while meeting predefined constraints. Kanyakam and Bureerat [

4] obtained the optimal geometric parameters of the PFHS with proposals of the minimum junction temperature and fan power. Lampio and Karvinen [

5] used a multi-objective version of the particle swarm optimization (PSO) method to optimize the heat sink performance in forced and natural convection cases. For both cases, mass was minimized. The other criteria included maximizing the temperature for the forced convection case and heat sink outer volume for the natural convection case. Huang and Wang [

6] used global sensitivity analysis to analyze and optimize the cooling method. Pourfattah and Sabzpooshani [

7] combined the genetic algorithm (GA) and RSM to design the cooling system.

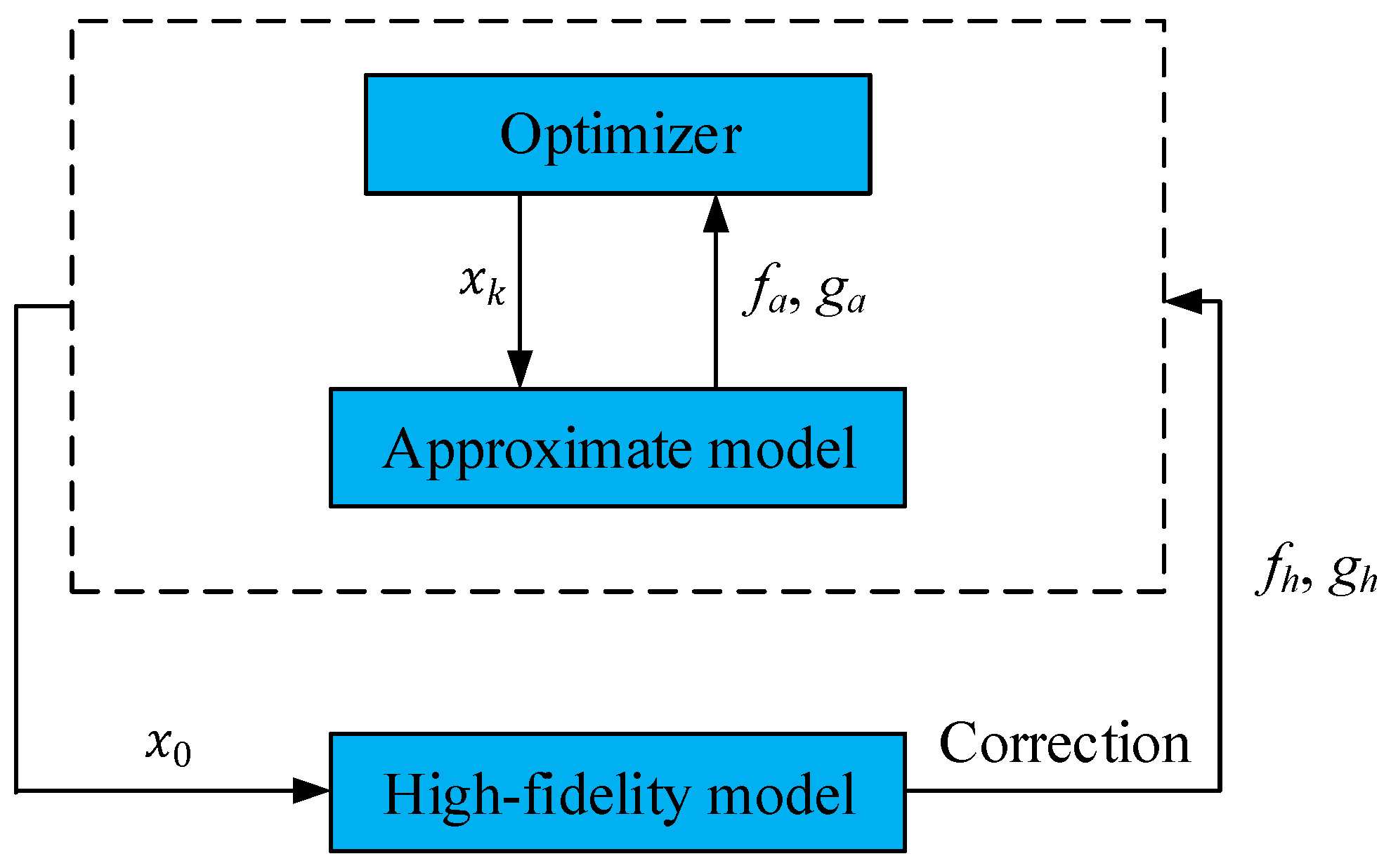

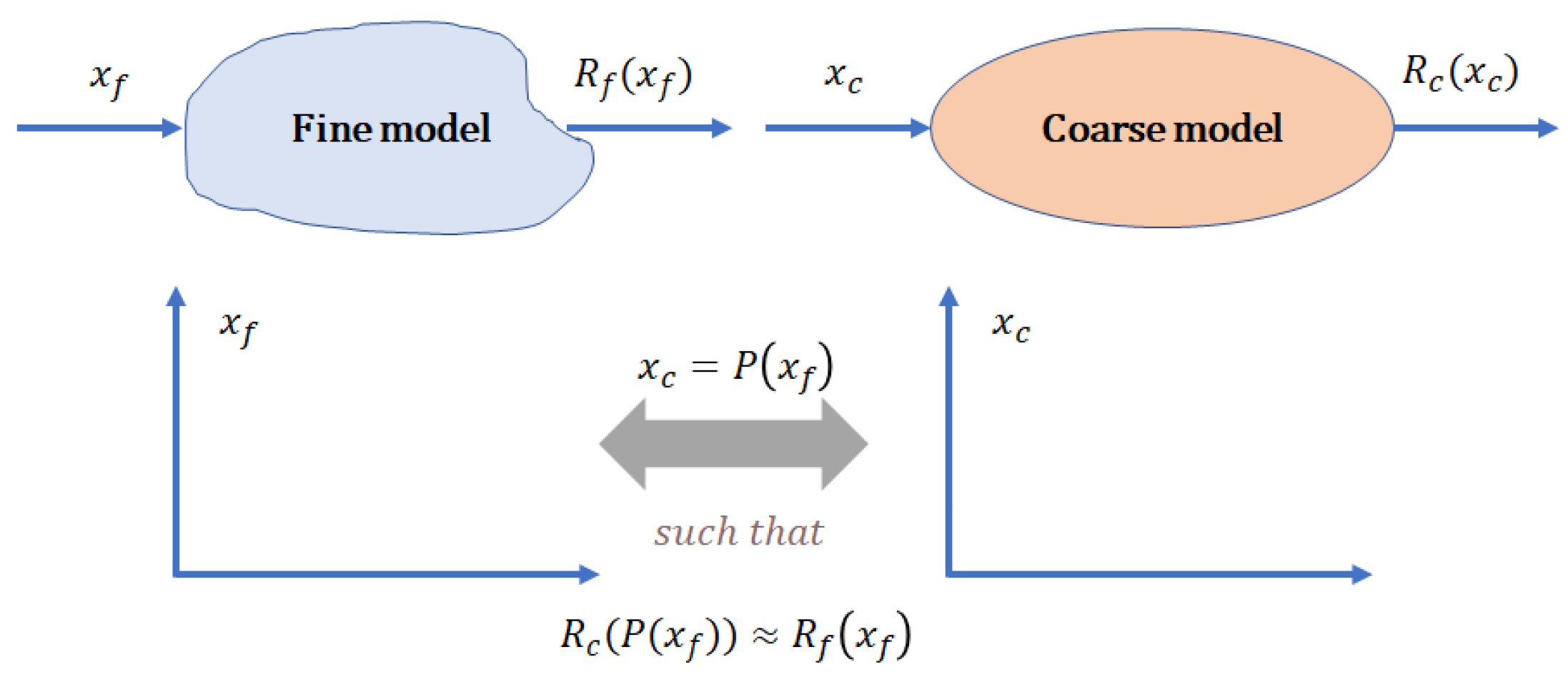

According to above mentioned applications, most cases can be optimized using evolutionary algorithms (EAs), such as GA (genetic algorithm), PSO, SPEA, and PBIL, because these methods can theoretically find the global optimal solution. However, these evolutionary algorithms usually require a large number of evaluations to converge. Obviously, if the heat sink design is optimized directly using evolutionary algorithms, especially for expensive evaluation problems, the computational cost is not feasible in practice. Thus, to improve the efficiency of optimization, VFMEM is suggested. Compared with related methods, both high- and low-fidelity models are constructed. The low-fidelity model is employed to roughly locate the global optimization region, thus the computational cost can be significantly reduced. In contrast, the high-fidelity model is introduced to exploit the global optimal region, enabling the accurate solution to be achieved. Compared with evolutionary algorithms, the suggested method can efficiently achieve global optimization.

In this study, the design of a heat sink with polygonal pin fins is a natural convection case with nine design variables. As a commonly used heat transfer enhancement device, the PFHS is widely used in the heat dissipation of electronic components. Different shapes of PFHSs affect the heat transfer performance of the heat sink. To date, numerous studies have been dedicated to the optimization of heat sinks with various fin geometries, such as rectangular, diamond, square, pentagonal, or cylindrical geometries. Ramphueiphad and Bureerat [

8] and Vanapalli and Brake [

9] studied six different pin fins with the same cross section. Matsumoto et al. [

10] experimentally and numerically studied five types of PFHS under natural convection and analyzed the influences of the size, height, and number of fins on the thermal performance. Zhao et al. [

11] numerically studied flow and heat transfer characteristics of micro square PFHS and obtained optimal geometric parameters. Although this problem has been widely investigated, few studies have used an optimization method for PFHS structural design. Therefore, the introduction of a multi-objective design for PFHS should further improve heat transfer performance.

The rest of paper is organized as follows.

Section 2 describes some basic concepts related VFO and EA.

Section 3 presents the details of the suggested method. Two cases are carried out to evaluate the performance of the suggested method in

Section 4. In

Section 5, a PFHS structural design is successfully solved by VFMEM. Finally, the conclusion is given.

3. Variable-Fidelity Multi-Objective Evolutionary Method (VFMEM)

VFMEM is based on the integration of VFO and MOPSO algorithms. In VFMEM, the LFM is for global searching and HFM is for local searching. As mentioned before, circulation distance elimination (CDE) and parameter transfer (PT) strategies are integrated so that VFMEM can use LFMs and HFMs according to the accuracy criterion. The CDE strategy is to uniformly select part of the optimal solutions from the LFM’s Pareto set in order to reduce the number of calculations of the HFM. The PT strategy is used to transfer the parameters of the selected optimal solutions of the LFM to the HFM so that the HFM can perform the local search more easily and accurately.

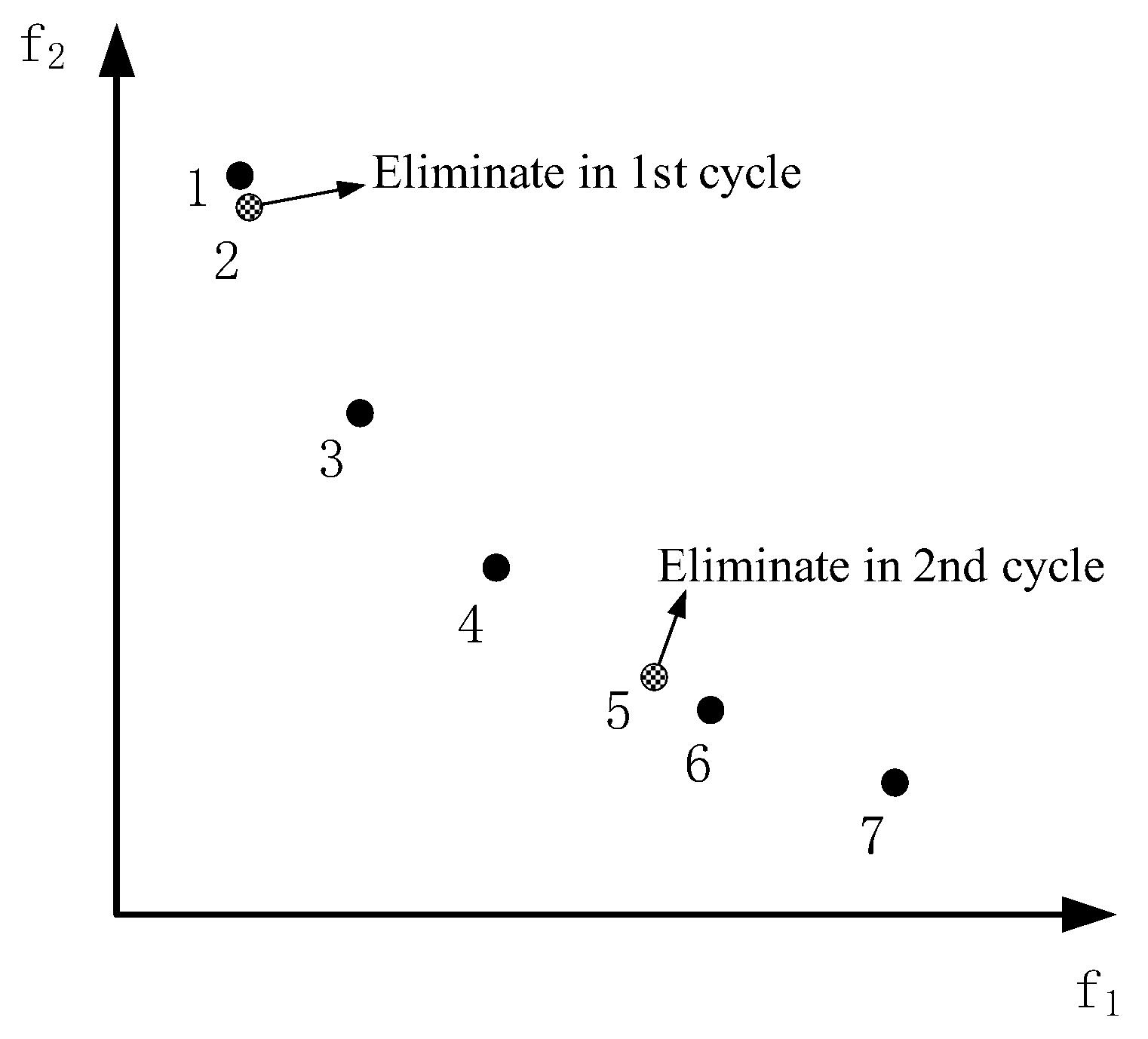

3.1. CDE

Usually, some particles of the Pareto frontier (PF) are locally concentrated after optimization of the LFM. If all of them are transferred by the PT, the amount of evaluation of the HFM will be greatly increased. Therefore, the CDE strategy is used to select part of the uniformly distributed particles. It is well known that the search direction of optimization is influenced by the accuracy of the physical model. If the LFM is too coarse, the direction of optimization may be wrong. Therefore, the two models are required to be similar. It is helpful for the HFM to obtain Pareto solutions with uniform distribution at the beginning by transferring the parameters of the uniformly distributed particles.

Before the selection of solutions from the LFM’s PF, the LFM’s objectives are all normalized to a range [0, 1]

where

is the function value of the

kth objective,

and

are respectively the minimum and maximum function values of the

kth objective, and

denotes the scaled

kth objective function values.

It is well known that the calculation of the Euclidean distance in design space between any two particles reflects their degrees of closeness.

Figure 4 shows the procedure of selecting PF. As shown in

Figure 4, the minimum Euclidean distance is between particles 1 and 2 of the obtained PF. First, the procedure should randomly eliminate one of the particles, and assume the removed particle is the second in the pair. Then, the Euclidean distance of any two particles in the rest should be calculated and sorted. In the rest of the particles, the minimum Euclidean distance is between particles 5 and 6. Similarly, one of the two particles should be randomly removed, and assume the removed particle is fifth one, and so on. The final particles are those that need to be preserved.

Figure 5 shows the pseudocode of the CDE. After completion of the CDE procedure, the information of the selected optimal solutions of LFM will be transferred to HFM through the PT strategy.

3.2. PT

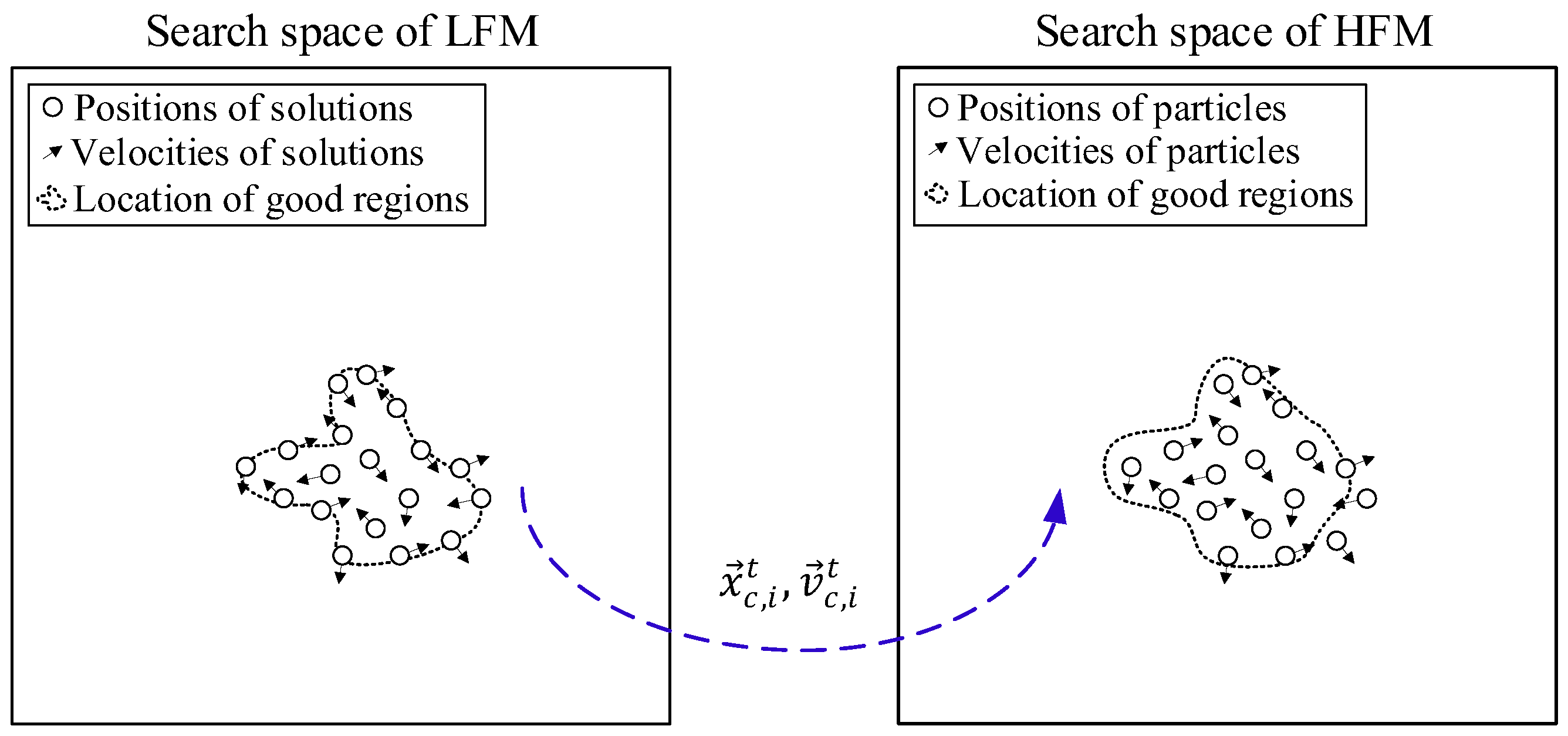

After optimization of the LFM, the particles usually search in the local regions. It is a critical issue to determine the searching direction. The search direction based on the HFM should guarantee the convergence of the entire optimization procedure. The parameters that need to be transferred are the velocities and positions of the LFM. As shown in

Figure 6, the velocities

and positions

of the LFM’s solutions selected by the CDE are used as the velocities

and positions

of the HFM’s initial population.

Considering that the two models are required to be similar, some of the particles might be transferred in the good regions when the transformation is complete. This might efficiently improve the convergence ratio. However, if the two models are widely different, it might lead to the wrong direction in the design space. Therefore, it is important to guarantee the accuracy of the LFM. Generally, the trend of the LFM should be in accordance. The criteria for this issue are presented in the following sections.

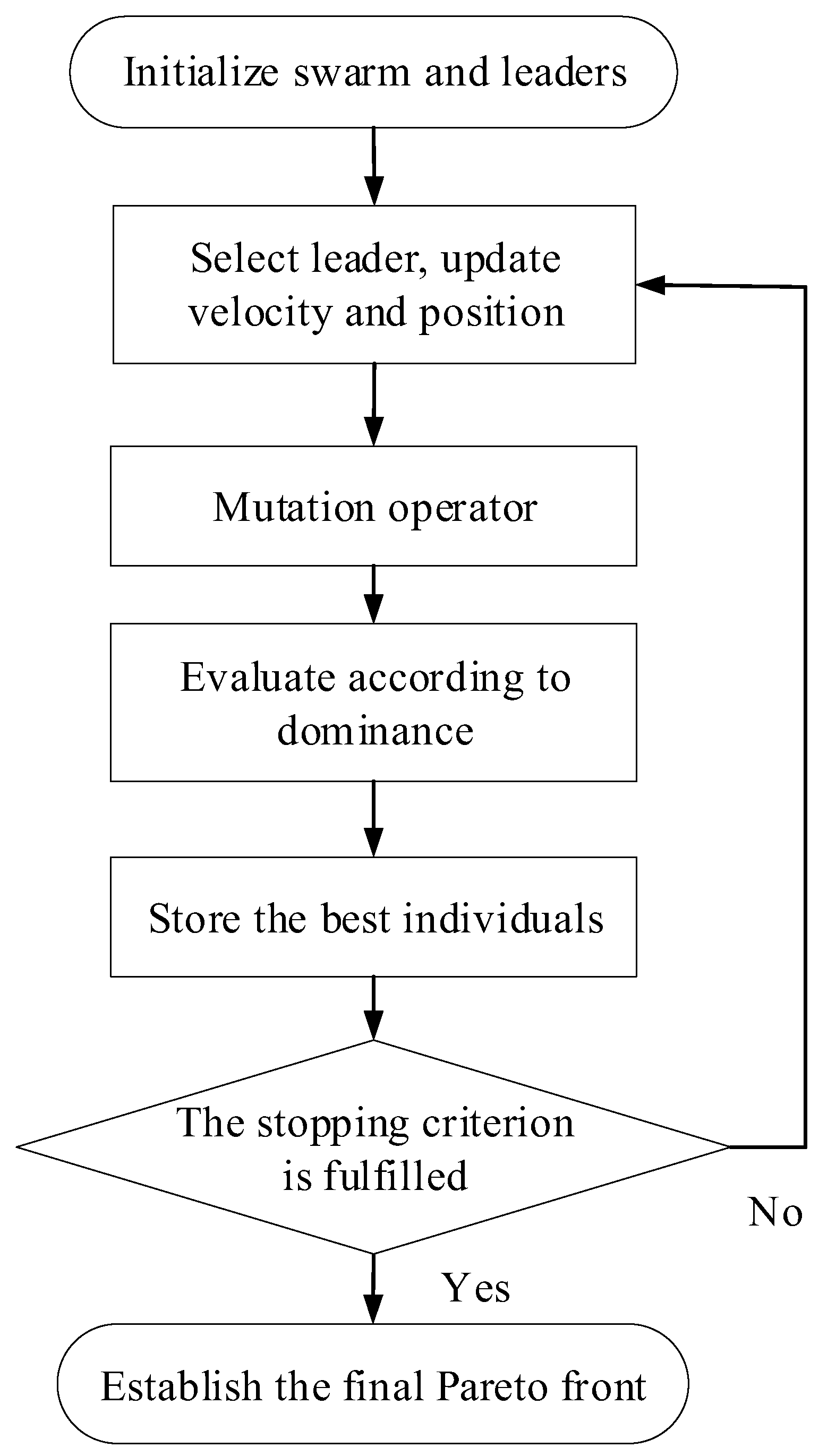

3.3. VFMEM

In this section, CDE and PT strategies are integrated in MOPSO. MOPSO is used to obtain the Pareto optimal solutions of the LFM and then the HFM. Theoretically, any multi-objective optimization can be used. MOPSO is engaged to reduce the control parameters. The CDE strategy is applied to uniformly select particles from the LFM’s Pareto-optimal set, and the PT strategy is used to transfer the parameters of the selected optimal particles of the LFM to the HFM.

The process of VFMEM is presented as follows:

Step 1 The Pareto-optimal set is obtained by MOPSO based on the LFM.

Step 2n solutions are selected from by using the CDE;

Step 3 The velocities and positions of the chosen optimal particles, which are defined in Equations (6) and (7), are used as the velocities and positions of the HFM’s particle by the PT strategy. Since there should be some differences between two models, the value of weight should be initialized.

Step 4 Initialize the HFM, and the velocity and position of the

ith particle of HFM are updated as follows:

Step 5 Obtain the Pareto-optimal set of the HFM in the initialization and compare the responses of two models’ objectives. The similarity of the two models is verified by calculating their average relative error in the objectives

where

n is the number of solutions selected by the CDE,

k is the number of objectives,

and

are the objective values of the HFM and LFM, respectively. The smaller the

value, the more similar the two models. The value

indicates that the two models are the same. In this study, if

indicated a great difference between the two models. Then procedure reconstructs an LFM with higher accuracy and goes to

step 1 (If the LFM is a FE model with coarse grid, the accuracy of the LFM can be changed by using a finer grid. If it is a data fitting model such as the classical response surface model (RSM), spline, or kriging model, the accuracy can be changed by increasing the data of the HFM’s initialization). If not, the procedure goes to

step 6.

Step 6 The HFM is optimized using MOPSO. In the LFM-based optimization procedure, the value of the error between the two iterative steps named IE (iteration error) usually decreases gradually. The value of IE usually maintains a relatively stable value in the final optimization. Since the two models are similar, refer to the LFM. If the IE value of the HFM is smaller than the given value, the optimization is terminated and the HFM’s Pareto-optimal set is obtained.

The procedure of VFMEM is shown in

Figure 7. In the suggested procedure, if two models are similar, the particles of the HFM can easily to find the locations of good regions in the search space and obtain the Pareto optimal solutions.

5. Pin Fin Heat Sink Closed-Loop Optimization

The purpose of this work was to apply the suggested VFMEM to a polygonal pin fin heat sink optimization problem. The design of the pin fin heat sink was a natural convection case with nine design variables. The purpose of the design was to minimize the mass (), the base temperature (), and temperature difference () of the heat sink. Practically, an important issue is implementing an FE model in the closed-loop style optimization procedure. In this optimization, the heat sink is a parametric model and the mesh is automatically generated. The coarse grid was for the LFM and the fine grid was for the HFM. If the accuracy of the LFM did not meet the requirement, the accuracy could be improved by more grids.

(1) Optimization model

The objective function of the design is described as follows:

where

is design variable vector,

the base thickness,

fins height,

heat sink length,

heat sink width,

radius of the regular polygon circumscribed circle,

the initial phase angle of polygon,

the number of fins in longitudinal direction,

the number of fins in transverse direction, and

the number of regular polygon edges. As shown in the optimization results reported by Lampio and Karvinen [

5], an evolutionary algorithm such as PSO can usually deal with discrete variables, such as the number of fins and regular polygon edges.

(2) Parametric modeling

Figure 10 shows the in-line arrangement of a pin fin heat sink model [

35]. The distance between the centers of neighbor fins is

in the transverse direction, and the distance between the centers of neighbor fins is

in the longitudinal direction. The descriptions for design variables are listed in

Table 5.

(3) Physical model

Figure 11 shows a full three dimensional model of the computational domain. The heat sink was installed in the

rectangular duct.

,

, and

were 300, 100, and 50 mm, respectively. A constant input power of 8 W was applied to the heat source with the finite dimensions

. For all evaluations, the initial temperature of the whole system was set to

. The inlet flow was assigned a mean velocity (0.2 m/s) and temperature (25 °C).

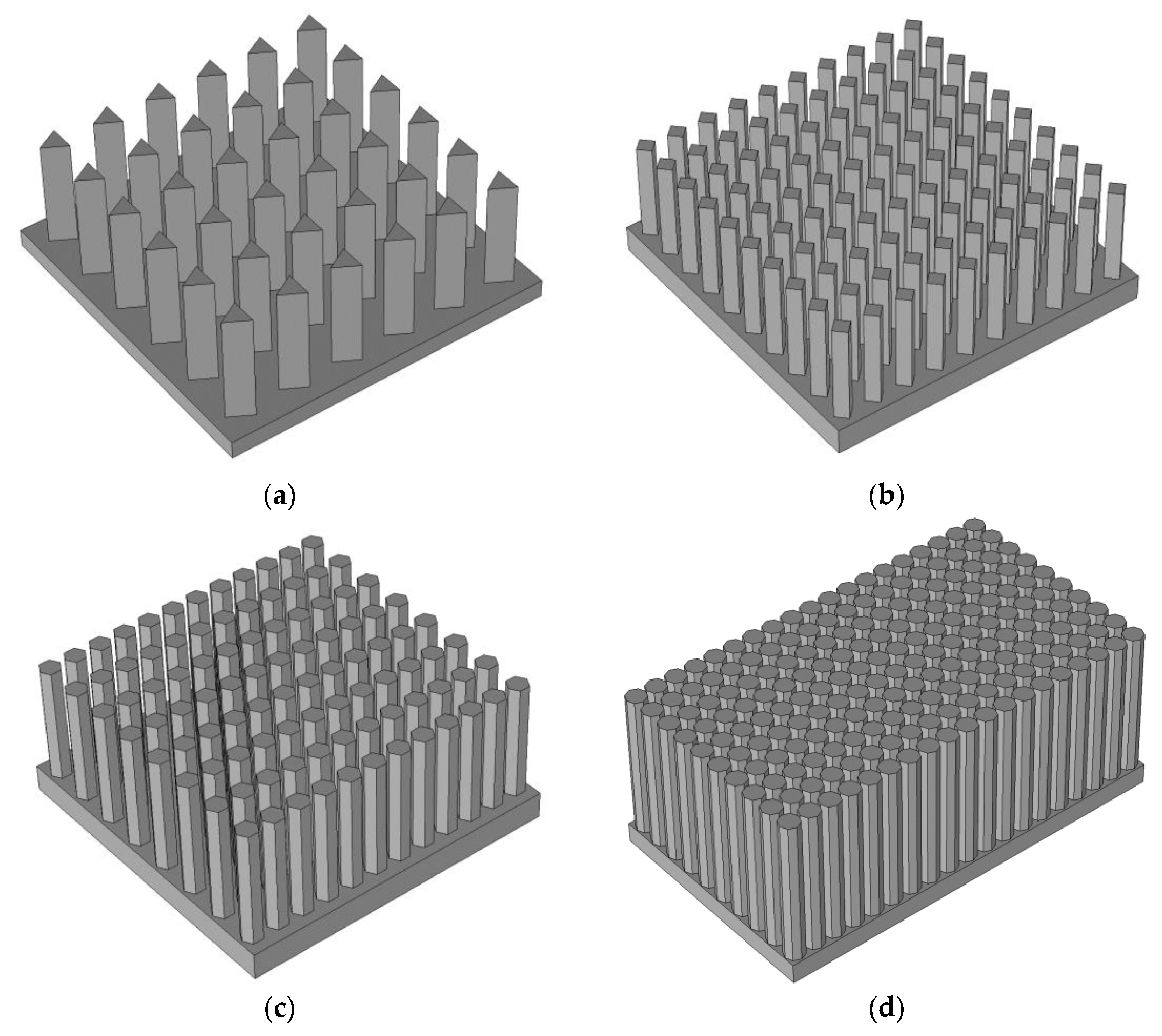

Four isometric views of physical model with different design variables of fins are shown in

Figure 12.

The details of the design variables of

Figure 12 are shown in

Table 6. The heat sink was enhanced with the shown fins.

The heat sink was made of aluminum alloy material. The fluid was air in the optimization. The effects of gravity and radiative heat transfer were neglected. The flow was steady and three dimensional. The governing equations of continuity, momentum, and energy in laminar flow are shown in Equations (20)–(23), respectively.

The energy equation for the solid parts is given by:

where

is the velocity vector showing the flow field,

is the density of the fluid,

is the pressure gradient for convection,

ν is the kinematic viscosity,

is the thermal diffusivity, and

is the fluid temperature.

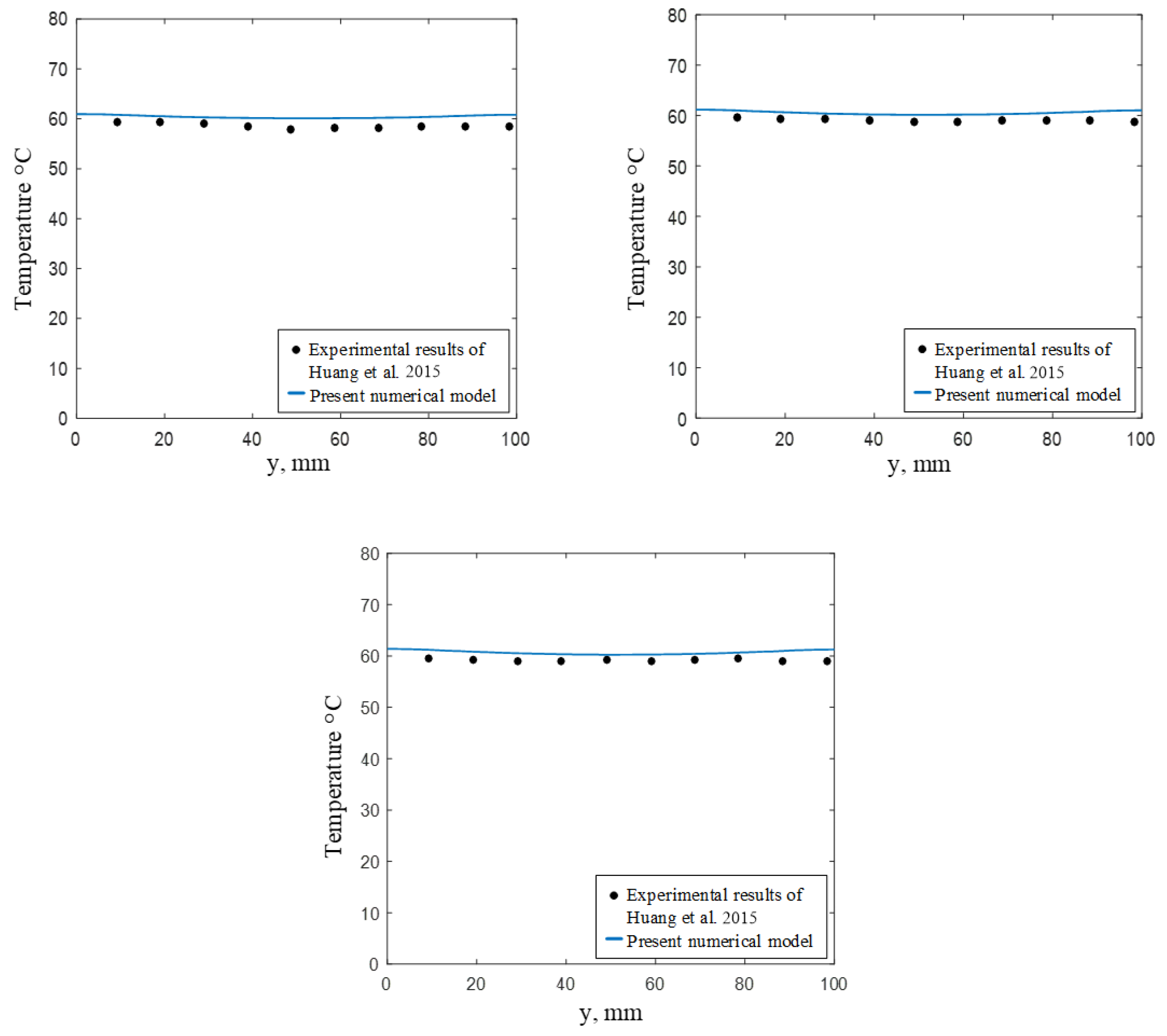

Figure 13a–c shows a comparison between the results of the present numerical model and the experimental data of Huang et al. [

36] for different temperature distributions. According to

Figure 13, the error between the simulation results of the present model and the experimental results of Huang et al. [

36] was acceptable since the average error was approximately 3%. Therefore, the present numerical model was reliable and could be used for the study.

(4) Optimization and results

Generally, the size of the grid affects the accuracy of the model. A fine grid has high accuracy but is computationally expensive, and a coarse grid is computationally cheaper but less accurate. The details of the initial heat sink during the simulation are listed in

Table 7.

For the initial heat sink FE model, the number of elements was 47,286 for the LFM and 544,521 for the HFM. The maximum number of iterations was set to 40 for optimization of the LFM. The suggested method used a population of 40 particles for the LFM, a mutation rate of 0.1, and a repository size of 200 for both t models. The number selected by the CDE was 40. Let

0.9,

1.0,

2.0.

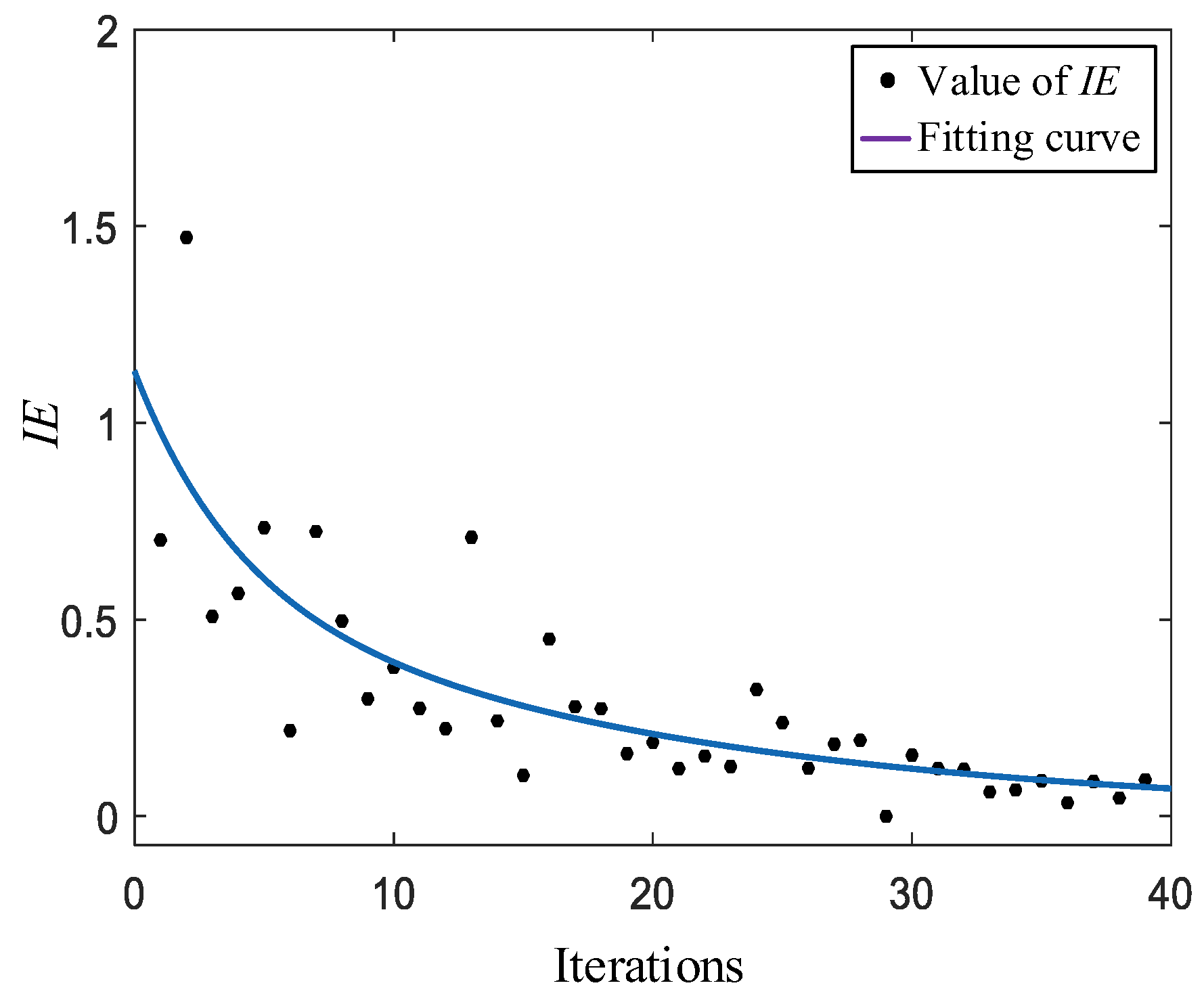

Figure 14 shows the change in

IE with the number of iterations in the optimization of the LFM. According to

Figure 14, the given stopping criterion was set to

= 0.2.

As shown in

Figure 14, in the initial search stage of the algorithm, the value of

IE changed considerably, meaning the particles were searching in the global region. With an increasing number of iterations, the procedure entered the local search stage, and the value

IE became small and did not change much.

At the beginning of the optimization, compared with the HFM, the relative error

of the LHF was 13.58%, suggesting that the two models could be used for optimization.

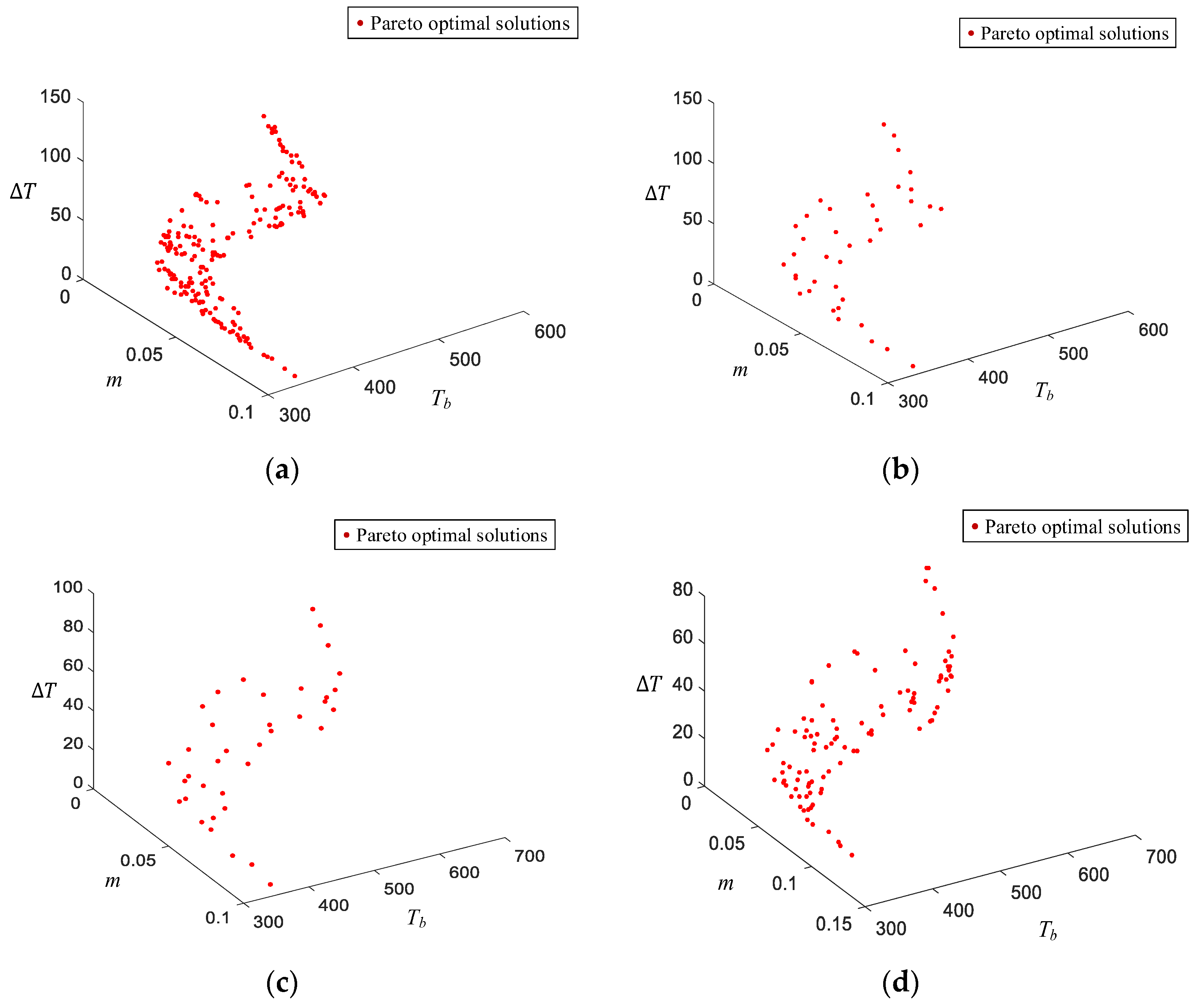

Figure 15 shows the optimization results. In this procedure, the total computational time of the LFM was approximately 40.5 h. A total of 200 Pareto solutions were obtained, as shown in

Figure 15a.

Figure 15b shows the solutions selected by the CDE.

Figure 15c shows the distribution of the Pareto-optimal set of the initial HFM. Comparing

Figure 15b,c, it can be seen that the two models were similar. The total computational time of the HFM was approximately 62 h. A total of 102 Pareto solutions were obtained, as shown in

Figure 15c. As shown in

Table 8, the HFM easily converged after 3 iterations using VFMEM. The updated speed of the Pareto solutions was much faster than that of the LFM during optimization, and the value of

IE was relatively small. This means that the optimization might have entered into the local region. Compared with direct optimization, the computational time could theoretically be reduced by 70–80% using the suggested method.

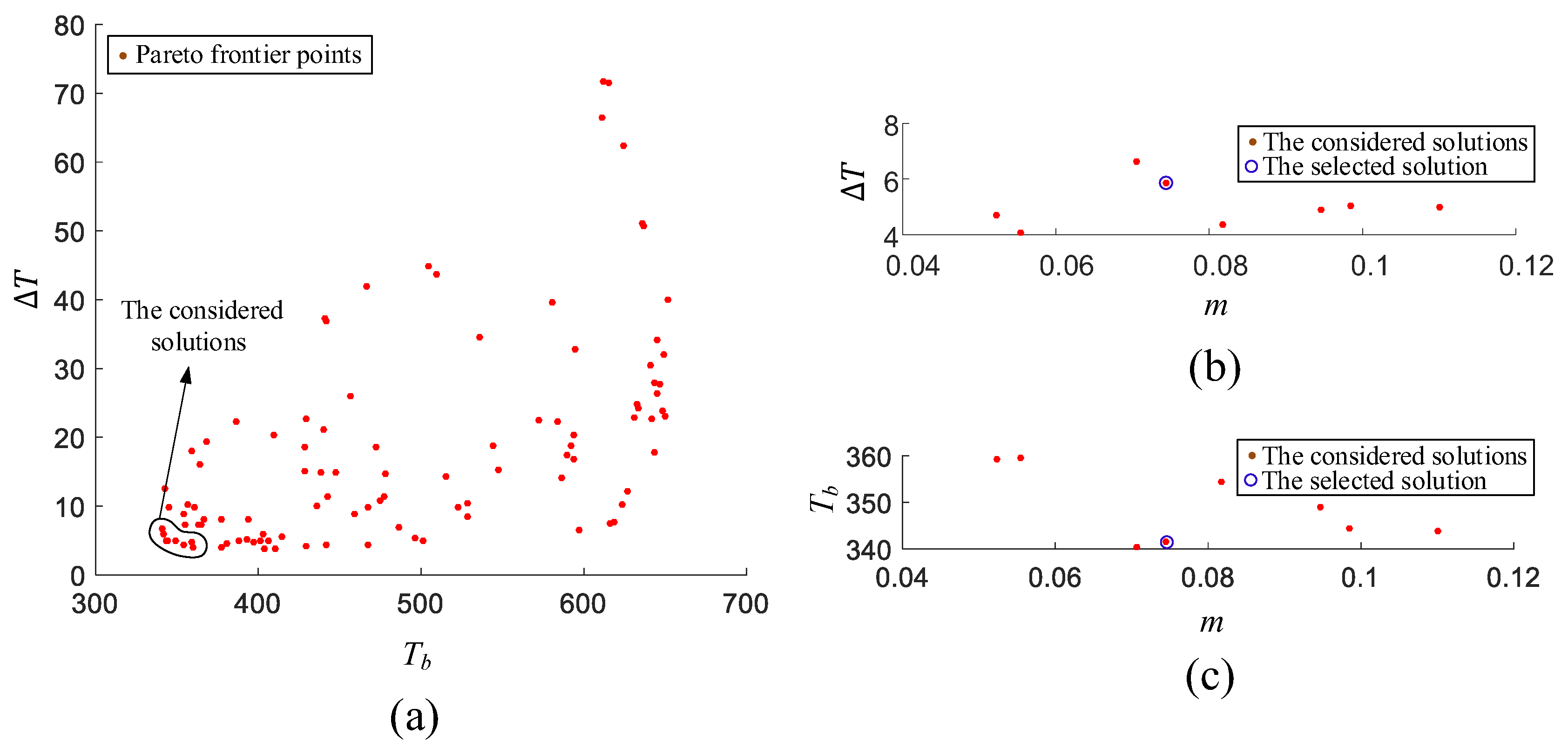

In this optimization, the base temperature and temperature difference were considered more than the mass. There were 102 solutions that could be selected. At first, we considered solutions in which the base temperature and temperature difference were both small. Then, we selected the final design according to the distribution of the considered solutions in the axis of the mass. The solution we selected is shown in

Figure 16, and the corresponding design variables are listed in

Table 9. The temperature distribution of the simulation of the initial and final heat sinks is shown in

Figure 17.

The mass of the initial heat sink was 74.7 g and that of the final heat sink was 70.6 g. After optimization, the mass , base temperature () and temperature difference () of the designed optimum heat sink decreased , , and , respectively, compared to the initial design.