A Comparative Study of the Effect of Moisture Susceptibility on Polyethylene Terephthalate–Modified Asphalt Mixes under Different Regulatory Procedures

Abstract

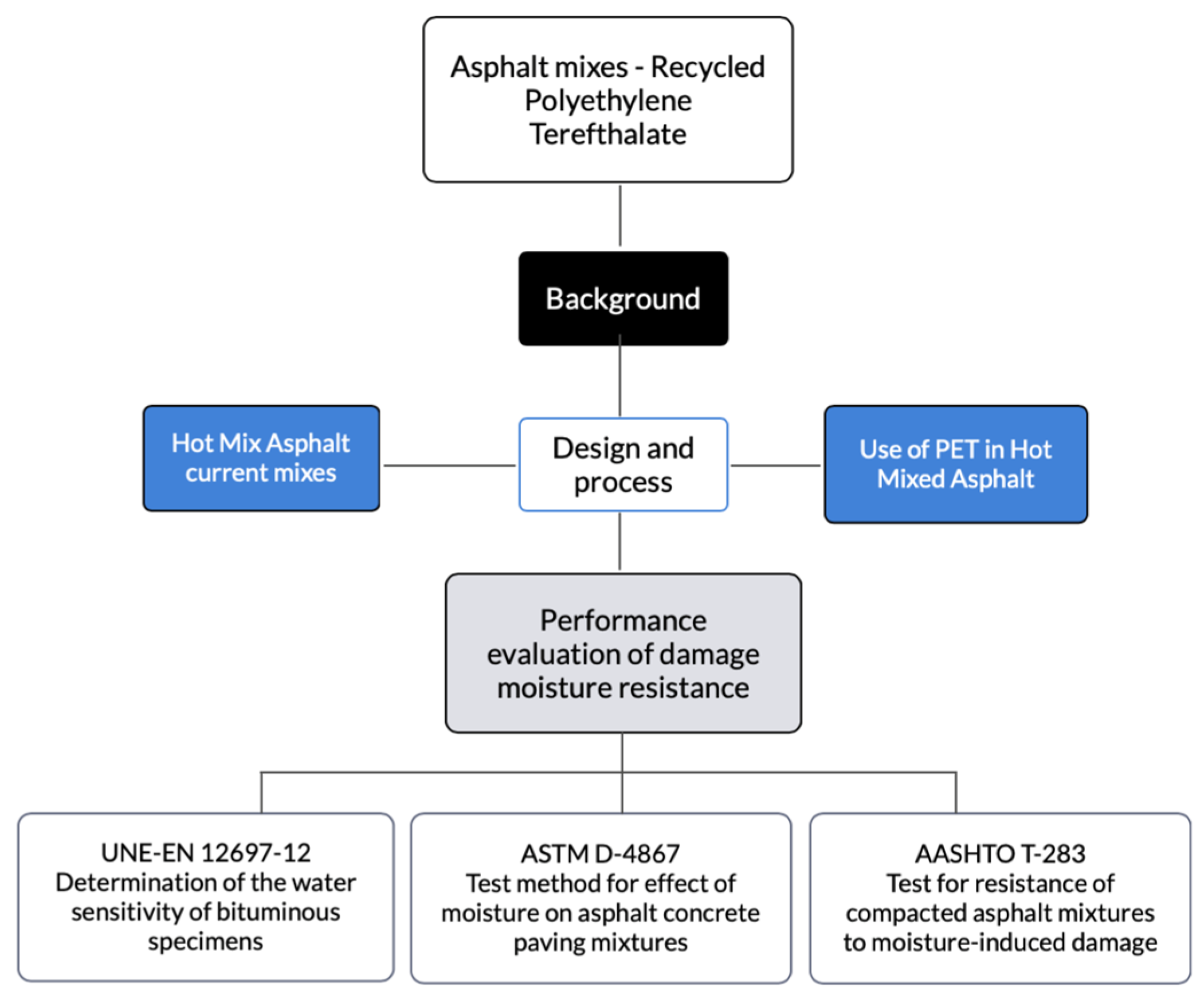

:1. Introduction

2. Materials and Methods

2.1. Aggregates

2.2. Bitumen

2.3. Polyethylene Terephthalate (PET)

2.4. Dosage, Production and Air Void Content

2.5. Indirect Tensile Strength on Moisture Damage

3. Laboratory Testing Results and Discussion

3.1. Optimal Bitumen Content

3.2. Volumetric Parameters of the Mixtures

3.3. Stability and Flow Marshall

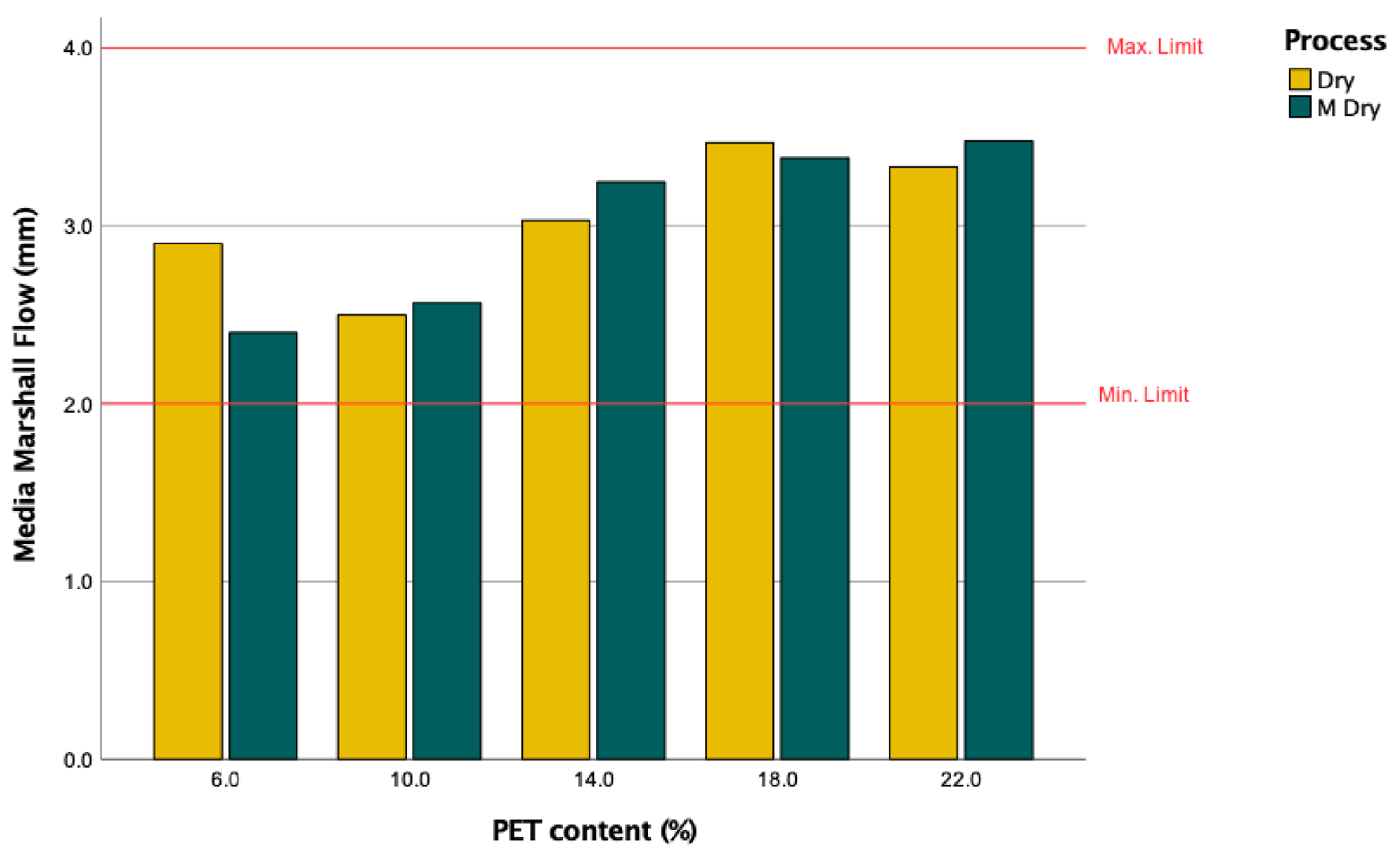

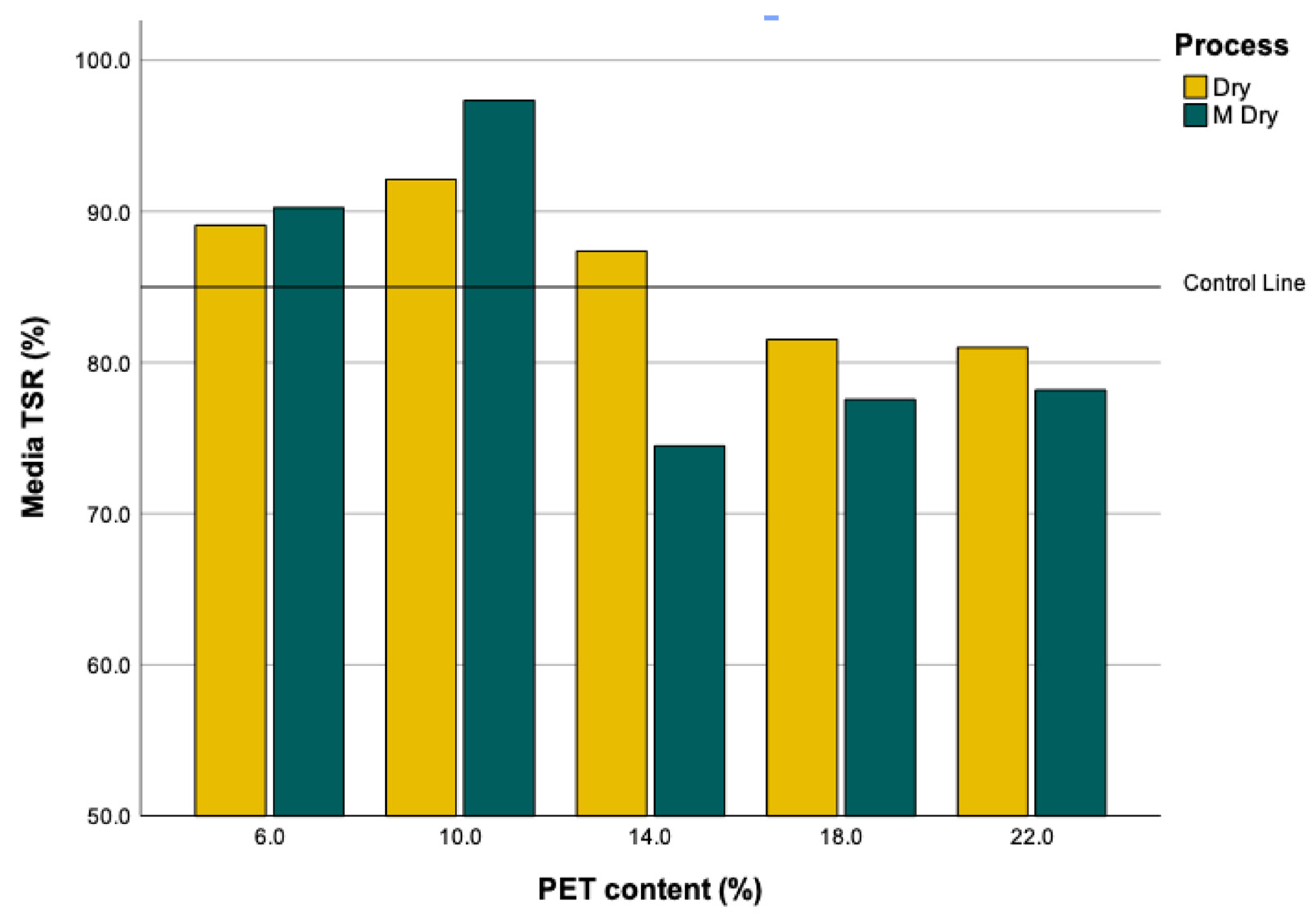

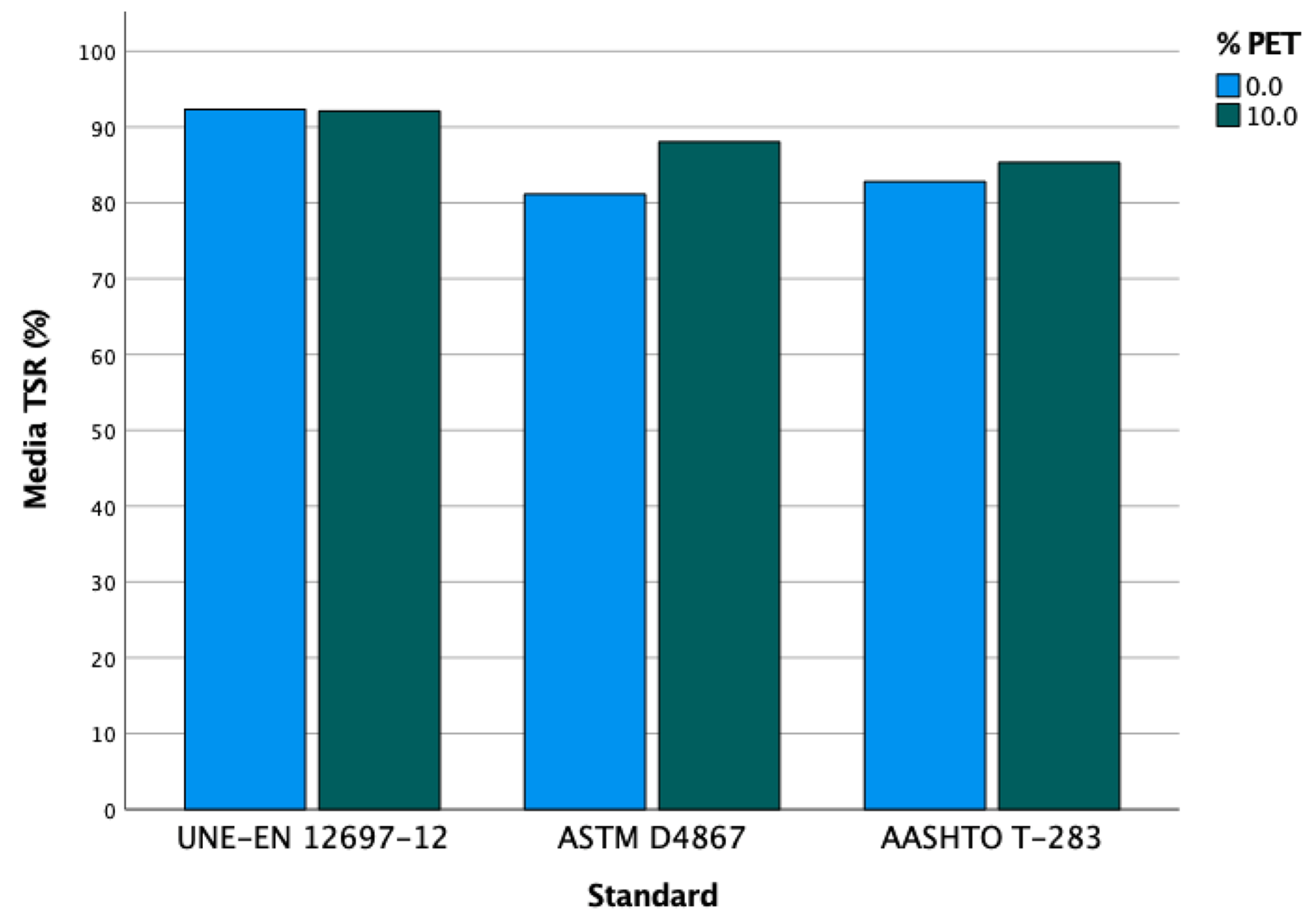

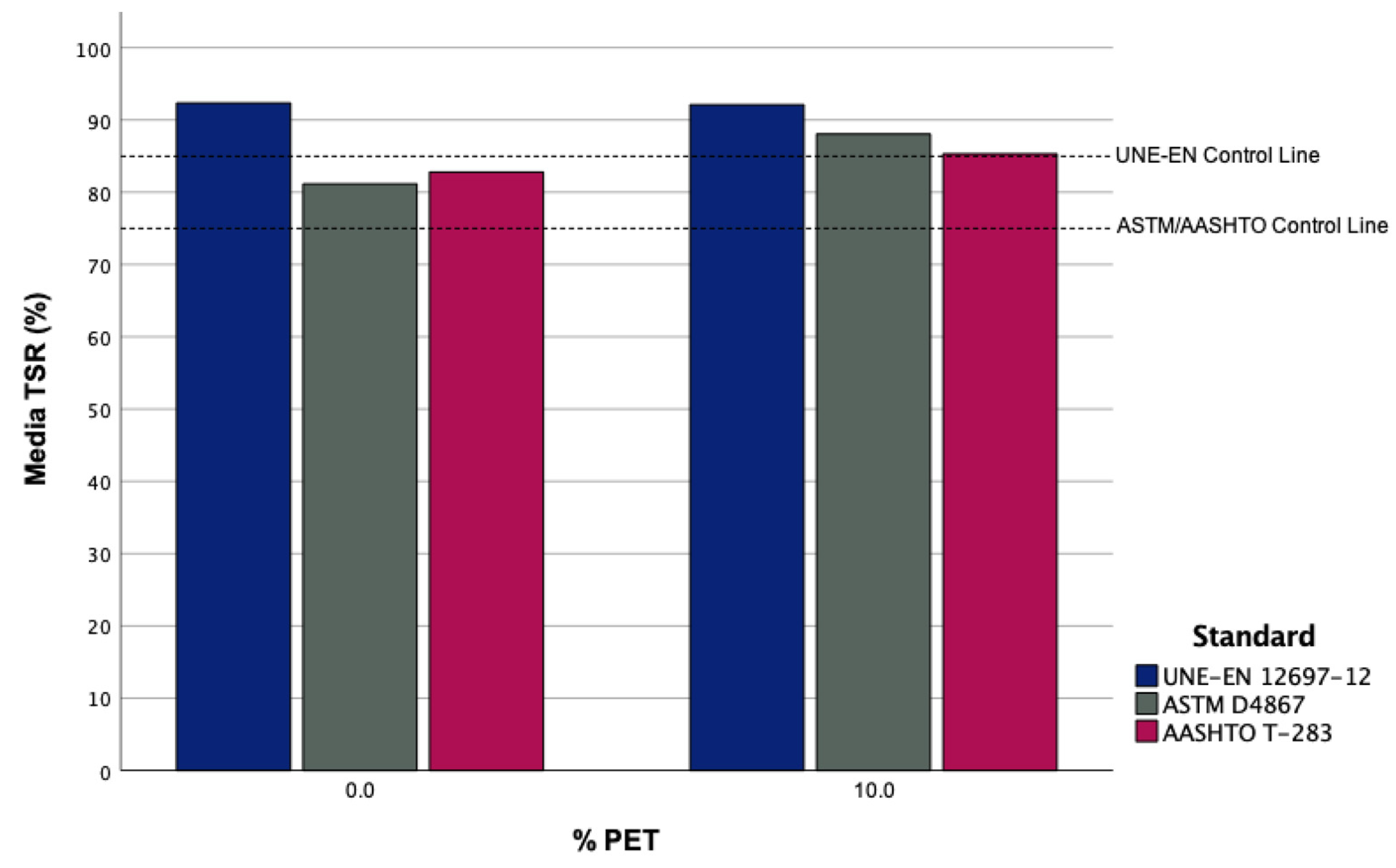

3.4. Moisture Susceptibility Test

3.5. American Standards (ASTM and AASHTO)

4. Conclusions

- The use of polyethylene terephthalate (PET) as an additive in asphalt mixtures causes a decrease in the mass-to-volume ratio (density) relative to the reference samples and an increase in the void ratio of the asphalt mixtures.

- The reference samples (0%) tested according to the UNE standard complied with the limits established for application in surface layers. However, adding 10% PET considerably improved their resistance, reaching 98% TSR. The samples made with 10%, 14%, 18%, and 22% PET did not meet the strength requirements established in the standard and were therefore discarded from further analysis.

- The samples tested according to ASTM D4867 showed higher moisture susceptibility indices for the reference mixtures (0%), behaving as unstable mixtures under the study conditions. However, with the addition of 10% PET, the mixtures’ stability increased, and their susceptibility to water decreased, obtaining results that were within the limits established by the standards.

- The samples tested according to the AASHTO T-283 standard showed a lower susceptibility to water than those following the previous standard. This is due to the ageing of the samples prior to compaction, where the aggregate achieves a better adhesion with the binder, which in turn improves the indirect tensile strength behaviour of the sample.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Brasileiro, L.; Moreno-Navarro, F.; Tauste-Martínez, R.; Matos, J.; Rubio-Gámez, M. Reclaimed Polymers as Asphalt Binder Modifiers for More Sustainable Roads: A Review. Sustainability 2019, 11, 646. [Google Scholar] [CrossRef]

- Ben Zair, M.M.; Jakarni, F.M.; Muniandy, R.; Hassim, S. A Brief Review: Application of Recycled Polyethylene Terephthalate in Asphalt Pavement Reinforcement. Sustainability 2021, 13, 1303. [Google Scholar] [CrossRef]

- Flores, R.F.; Montoliu, C.M.-P.; Bustamante, E.G. Life Cycle Engineering for Roads (LCE4ROADS), The New Sustainability Certification System for Roads from the LCE4ROADS FP7 Project. Transp. Res. Procedia 2016, 14, 896–905. [Google Scholar] [CrossRef]

- Europeia, C. EU Green Public Procurement Criteria for Road Design, Construction and Maintenance; European Commission: Brussels, Belgium, 2016.

- Moretti, L.; Mandrone, V.; D’Andrea, A.; Caro, S. Evaluation of the Environmental and Human Health Impact of Road Construction Activities. J. Clean. Prod. 2018, 172, 1004–1013. [Google Scholar] [CrossRef]

- Khaleel, O.R.; Al Gharbi, L.K.N.; Fayyadh, M.M. Enhancing Bitumen Properties through the Utilization of Waste Polyethylene Terephthalate and Tyre Rubber. Sustainability 2023, 15, 9298. [Google Scholar] [CrossRef]

- Delbeke, J.; Runge-Metzger, A.; Slingenberg, Y.; Werksman, J. (Eds.) Towards a Climate-Neutral Europe: Curving the trend; European Union: Maastricht, The Netherlands, 2019; p. 22. [Google Scholar]

- Eltwati, A.; Putra Jaya, R.; Mohamed, A.; Jusli, E.; Al-Saffar, Z.; Hainin, M.R.; Enieb, M. Effect of Warm Mix Asphalt (WMA) Antistripping Agent on Performance of Waste Engine Oil-Rejuvenated Asphalt Binders and Mixtures. Sustainability 2023, 15, 3807. [Google Scholar] [CrossRef]

- Bajracharya, R.M.; Manalo, A.C.; Karunasena, W.; Lau, K. An Overview of Mechanical Properties and Durability of Glass-Fibre Reinforced Recycled Mixed Plastic Waste Composites. Mater. Des. (1980–2015) 2014, 62, 98–112. [Google Scholar] [CrossRef]

- Ragaert, K.; Delva, L.; Van Geem, K. Mechanical and Chemical Recycling of Solid Plastic Waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, Use, and Fate of All Plastics Ever Made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef]

- Chidambarampadmavathy, K.; Karthikeyan, O.P.; Heimann, K. Sustainable Bio-Plastic Production through Landfill Methane Recycling. Renew. Sustain. Energy Rev. 2017, 71, 555–562. [Google Scholar] [CrossRef]

- Padhan, R.K.; Gupta, A.A.; Badoni, R.P.; Bhatnagar, A.K. Poly(Ethylene Terephthalate) Waste Derived Chemicals as an Antistripping Additive for Bitumen—An Environment Friendly Approach for Disposal of Environmentally Hazardous Material. Polym. Degrad. Stab. 2013, 98, 2592–2601. [Google Scholar] [CrossRef]

- Shukla, S.R.; Harad, A.M. Aminolysis of Polyethylene Terephthalate Waste. Polym. Degrad. Stab. 2006, 91, 1850–1854. [Google Scholar] [CrossRef]

- Marques, D.V.; Barcelos, R.L.; Parma, G.O.C.; Girotto, E.; Júnior, A.C.; Pereira, N.C.; Magnago, R.F. Recycled Polyethylene Terephthalate and Aluminum Anodizing Sludge-Based Boards with Flame Resistance. Waste Manag. 2019, 92, 1–14. [Google Scholar] [CrossRef] [PubMed]

- García-Travé, G.; Tauste, R.; Sol-Sánchez, M.; Moreno-Navarro, F.; Rubio-Gámez, M.C. Mechanical Performance of SMA Mixtures Manufactured with Reclaimed Geomembrane–Modified Binders. J. Mater. Civ. Eng. 2018, 30, 04017284. [Google Scholar] [CrossRef]

- Osorto, M.R.R.; Casagrande, M.D.T. Environmental Impact Comparison Analysis between a Traditional Hot Mixed Asphalt (HMA) and with the Addition of Recycled Post-Consumer Polyethylene Terephthalate (RPET) through the Life Cycle Assessment (LCA) Methodology. Sustainability 2023, 15, 1102. [Google Scholar] [CrossRef]

- Tauste-Martínez, R.; Moreno-Navarro, F.; Sol-Sánchez, M.; Rubio-Gámez, M.C. Multiscale Evaluation of the Effect of Recycled Polymers on the Long-Term Performance of Bituminous Materials. Road. Mater. Pavement Des. 2021, 22, S99–S116. [Google Scholar] [CrossRef]

- Agha, N.; Hussain, A.; Ali, A.S.; Qiu, Y. Performance Evaluation of Hot Mix Asphalt (HMA) Containing Polyethylene Terephthalate (PET) Using Wet and Dry Mixing Techniques. Polymers 2023, 15, 1211. [Google Scholar] [CrossRef]

- Wang, W.; Wang, L.; Xiong, H.; Luo, R. A Review and Perspective for Research on Moisture Damage in Asphalt Pavement Induced by Dynamic Pore Water Pressure. Constr. Build. Mater. 2019, 204, 631–642. [Google Scholar] [CrossRef]

- Hamzah, M.O.; Kakar, M.R.; Quadri, S.A.; Valentin, J. Quantification of Moisture Sensitivity of Warm Mix Asphalt Using Image Analysis Technique. J. Clean. Prod. 2014, 68, 200–208. [Google Scholar] [CrossRef]

- Khorshidi, M.; Goli, A.; Orešković, M.; Khayambashi, K.; Ameri, M. Performance Evaluation of Asphalt Mixtures Containing Different Proportions of Alternative Materials. Sustainability 2023, 15, 13314. [Google Scholar] [CrossRef]

- Sapkota, K.; Yaghoubi, E.; Wasantha, P.L.P.; Van Staden, R.; Fragomeni, S. Mechanical Characteristics and Durability of HMA Made of Recycled Aggregates. Sustainability 2023, 15, 5594. [Google Scholar] [CrossRef]

- Lei, B.; Xiong, Q.; Tang, Z.; Yao, Z.; Jiang, J. Effect of Recycled Aggregate Modification on the Properties of Permeable Asphalt Concrete. Sustainability 2022, 14, 10495. [Google Scholar] [CrossRef]

- Li, R.; Leng, Z.; Yang, J.; Lu, G.; Huang, M.; Lan, J.; Zhang, H.; Bai, Y.; Dong, Z. Innovative Application of Waste Polyethylene Terephthalate (PET) Derived Additive as an Antistripping Agent for Asphalt Mixture: Experimental Investigation and Molecular Dynamics Simulation. Fuel 2021, 300, 121015. [Google Scholar] [CrossRef]

- Oldham, D.; Mallick, R.; Fini, E.H. Reducing Susceptibility to Moisture Damage in Asphalt Pavements Using Polyethylene Terephthalate and Sodium Montmorillonite Clay. Constr. Build. Mater. 2021, 269, 121302. [Google Scholar] [CrossRef]

- Rahimi, A.; Shirazi, S.Y.B.; Naderi, K.; Nazari, H.; Nejad, F.M. Reducing Production Temperature of Asphalt Rubber Mixtures Using Recycled Polyethylene Wax and Their Performance against Rutting. Adv. Civ. Eng. Mater. 2020, 9, 117–127. [Google Scholar]

- Taherkhani, H.; Arshadi, M.R. Investigating the Mechanical Properties of Asphalt Concrete Containing Waste Polyethylene Terephthalate. Road. Mater. Pavement Des. 2019, 20, 381–398. [Google Scholar] [CrossRef]

- Lugeiyamu, L.; Kunlin, M.; Mensahn, E.S.K.; Faraz, A. Utilization of Waste Polyethylene Terephthalate (PET) as Partial Replacement of Bitumen in Stone Mastic Asphalt. Constr. Build. Mater. 2021, 309, 125176. [Google Scholar] [CrossRef]

- Monticelli, R.; Roberto, A.; Romeo, E.; Tebaldi, G. Mixed Design Optimization of Polymer-Modified Asphalt Mixtures (PMAs) Containing Carton Plastic Packaging Wastes. Sustainability 2023, 15, 10574. [Google Scholar] [CrossRef]

- Kalantar, Z.N.; Karim, M.R.; Mahrez, A. A Review of Using Waste and Virgin Polymer in Pavement. Constr. Build. Mater. 2012, 33, 55–62. [Google Scholar] [CrossRef]

- Lo Presti, D. Recycled Tyre Rubber Modified Bitumens for Road Asphalt Mixtures: A Literature Review. Const. Build. Mater. 2013, 49, 861–863. [Google Scholar] [CrossRef]

- Elnaml, I.; Liu, J.; Mohammad, L.N.; Wasiuddin, N.; Cooper, S.B.; Cooper, S.B. Developing Sustainable Asphalt Mixtures Using High-Density Polyethylene Plastic Waste Material. Sustainability 2023, 15, 9897. [Google Scholar] [CrossRef]

- Fakhri, M.; Arzjani, D.; Ayar, P.; Mottaghi, M.; Arzjani, N. Performance Evaluation of WMA Containing Re-Refined Acidic Sludge and Amorphous Poly Alpha Olefin (APAO). Sustainability 2021, 13, 3315. [Google Scholar] [CrossRef]

- Mashaan, N.; Chegenizadeh, A.; Nikraz, H. Performance of PET and Nano-Silica Modified Stone Mastic Asphalt Mixtures. Case Stud. Constr. Mater. 2022, 16, e01044. [Google Scholar] [CrossRef]

| Aggregate | Test | Value | Limits |

|---|---|---|---|

| Coarse | Specific weight (g/cm3) | 2.796 | - |

| Slab index (%) | <1% | ≤20% | |

| Los Angeles abrasion (%) | 13 | ≤15% | |

| Water absorption (%) | 0.60 | <1% | |

| Fine | Specific weight (g/cm3) | 2.726 | - |

| Sand equivalent | 77 | >55 |

| Properties | Value | Limits |

|---|---|---|

| Penetration at 25 °C (0.1 mm) | 54 | 50–70 |

| Softening point (°C) | 50 | 46–54 |

| Frass breaking point (°C) | −13 | ≤−8 |

| Specific weight (g/cm3) | 1.033 | - |

| Asphalt Mixture | % PET | Nº Samples | Normative |

|---|---|---|---|

| M1 | 0 (ref.) | 16 | European Standard |

| M2 | 6 | 16 | |

| M3 | 10 | 16 | |

| M4 | 14 | 16 | |

| M5 | 18 | 16 | |

| M6 | 22 | 16 | |

| M7 | 0 (ref.) | 12 | ASTM Standard |

| M8 | 10 | 12 | |

| M9 | 0 (ref.) | 12 | AASHTO Standard |

| M10 | 10 | 12 |

| Author/Year | Main Findings |

|---|---|

| Rui, L., et al. (2022) [25] | “Innovative application of waste polyethylene terephthalate (PET) derived additive as an antistripping agent for asphalt mixture: Experimental investigation and molecular dynamics simulation”. The results of experimental tests and simulations show that the PET-derived additive significantly improves the loosening resistance in asphalt mixtures. The additive helps reduce water adhesion to aggregates and improves the bonding capacity between aggregates and the asphalt. This leads to a higher mixture stability and increased resistance to loosening. |

| Oldham, D., et al. (2021) [26] | “Reducing susceptibility to moisture damage in asphalt pavements using polyethylene terephthalate and sodium montmorillonite”. The results show that adding PET and sodium montmorillonite clay improves the moisture damage resistance of asphalt pavements. These additives help to reduce water absorption by the binder and improve the cohesion and strength of the mixture. In addition, an improvement in the tensile strength and wear resistance of the modified pavements is observed. |

| Yengejeh, A., et al. (2020) [27] | “Reducing production temperature of asphalt rubber mixtures using recycled polyethylene wax and their performance against rutting”. The results obtained indicate that the use of recycled polyethylene waxes allows a reduction in the production temperature of asphalt rubber mixtures. Furthermore, it can be observed that mixtures modified with these waxes show a better performance against rutting compared to mixtures without additives or with conventional additives. |

| Taherkhani, H., et al. (2019) [28] | “Investigating the mechanical properties of asphalt concrete containing waste polyethylene terephthalate”. The results show that adding recycled PET to asphalt concrete improves some of its mechanical properties. An increase in tensile strength and higher fatigue strength were observed in the samples containing PET. This indicates that recycled PET can improve an asphalt pavement’s durability and service life. In addition, the effect of recycled PET particle size on the mechanical properties of asphalt is highlighted, with smaller PET particles having a more significant impact on durability. |

| Lugeiyamu, L., et al. (2021) [29] | “Utilization of waste polyethylene terephthalate (PET) as partial replacement for bitumen in stone mastic asphalt”. The results show that the addition of PET waste to stone mastic asphalt (SMA) as a partial replacement for bitumen positively affected the mechanical and performance properties of the mixture. An improvement in tensile strength, wear resistance and resistance to permanent deformation was observed in mixtures containing recycled PET. In addition, the effect of temperature on the properties of SMA with PET was analysed. It was found that the PET blends showed better performance at higher temperatures, indicating higher resistance to softening and deformation under hot climatic conditions. |

| Test Parameters | UNE-EN 12697-12 | ASTM D4867 | AASHTO T-283 |

|---|---|---|---|

| Pre-ageing | Not required | Not required | Resting for 2 h at 25 °C. Later, in the oven for 16 h. |

| % Air voids | No limit (just use 50 blows per side of the sample) | 6–8 | 6.5–7.5 |

| Saturation | Do not expand sample by more than 2% of its initial volume. | 55–80% 5 min at 525 mm Hg | 70–80% for 5–10 min between 254–600 mm Hg |

| Ice and thaw cycle | Not required | Optional | −18 °C for 16 h. |

| Temperature and conditioning time | 20 ± 5 °C for 16–24 h | 60 °C for 24 h | 60 °C for 24 ± 1 h |

| Test temperature ITS | 15 ± 5 °C at 51 mm/min | 25 ± 1 °C at 51 mm/min | 25 ± 1 °C at 51 mm/min |

| TSR (%) | 85 | 75 | 80 |

| Visual analysis | Not required | Not required | Only requires doing so |

| Parameter | Requirement | Result |

|---|---|---|

| Marshall stability at 60 °C, kN | Min. 9 | 14 |

| Marshall flow, mm | 2–4 | 3.3 |

| Marshall quotient, kN/mm | 2–5 | 3.9 |

| Air voids, % | 4–6 | 5.1 |

| Voids in mineral aggregates, % | Min. 13 | 16.0 |

| Voids filled with bitumen, % | 65–75 | 74.5 |

| Bulk density, g/cm3 | - | 2.390 |

| Factor | Process Type p-Value, S/NS | PET Content p-Value, S/NS |

|---|---|---|

| Bulk density (g/cm3) | 0.168, NS | <0.001, S |

| Marshall stability (kN) | <0.001, S | <0.001, S |

| Marshall flow (mm) | 0.840, NS | <0.001, S |

| TSR (%) | 0.325, NS | <0.001, S |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Movilla-Quesada, D.; Raposeiras, A.C.; Guíñez, E.; Frechilla-Alonso, A. A Comparative Study of the Effect of Moisture Susceptibility on Polyethylene Terephthalate–Modified Asphalt Mixes under Different Regulatory Procedures. Sustainability 2023, 15, 14519. https://doi.org/10.3390/su151914519

Movilla-Quesada D, Raposeiras AC, Guíñez E, Frechilla-Alonso A. A Comparative Study of the Effect of Moisture Susceptibility on Polyethylene Terephthalate–Modified Asphalt Mixes under Different Regulatory Procedures. Sustainability. 2023; 15(19):14519. https://doi.org/10.3390/su151914519

Chicago/Turabian StyleMovilla-Quesada, Diana, Aitor C. Raposeiras, Edgardo Guíñez, and Almudena Frechilla-Alonso. 2023. "A Comparative Study of the Effect of Moisture Susceptibility on Polyethylene Terephthalate–Modified Asphalt Mixes under Different Regulatory Procedures" Sustainability 15, no. 19: 14519. https://doi.org/10.3390/su151914519

APA StyleMovilla-Quesada, D., Raposeiras, A. C., Guíñez, E., & Frechilla-Alonso, A. (2023). A Comparative Study of the Effect of Moisture Susceptibility on Polyethylene Terephthalate–Modified Asphalt Mixes under Different Regulatory Procedures. Sustainability, 15(19), 14519. https://doi.org/10.3390/su151914519