Measuring and Indexing the Durability of Electrical and Electronic Equipment

Abstract

:1. Introduction and Motivation

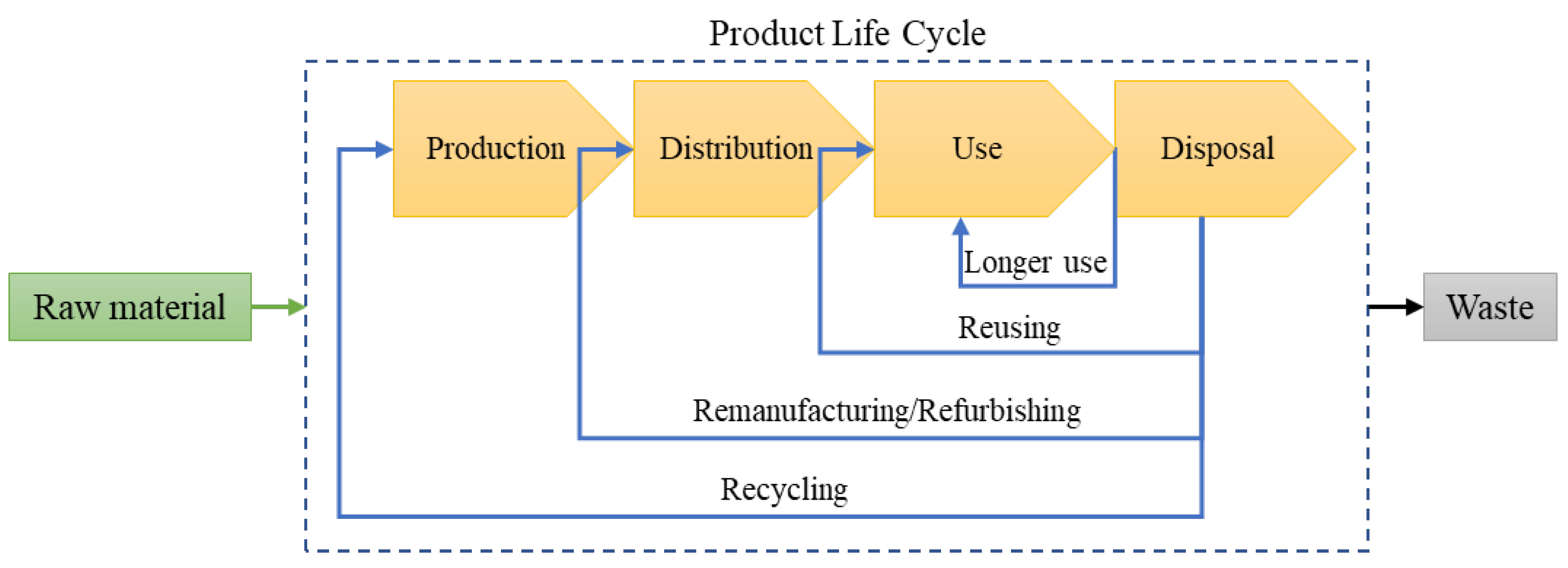

2. Circular Economy and Role of Product Durability

3. Product Durability Literature Review

3.1. Durability Definition

- In some of the definitions, durability is closely linked to product functionality. Therefore, when defining a product’s durability, defining its intended functionality is essential. This is particularly important for EEE products with multiple functionalities (e.g., smartphones can make phone calls, send text messages, and take photographs).

- In some of the technical definitions, the use conditions of a product have been included as a crucial factor for measuring durability. A product that is used in harsh environments or under heavy usage may experience more wear and lower durability than a product that is used in a less demanding setting.

- Maintenance and repair affect durability because they can prolong a product’s useful life and ensure that it continues to function at its intended quality and performance level.

| Reference | Provided Definition for Durability | Target Product in the Reference |

|---|---|---|

| Cooper [25] | Ability of a product to perform its required function over a lengthy period under normal conditions of use without excessive expenditure on maintenance or repair | - |

| EN 45552 [30] | Ability to function as required, under defined conditions of use, maintenance, and repair, until a limiting state is reached | energy-related products |

| MIL-STD-721C [29] | A measure of useful life (a special case of reliability) | - |

| ISO 11994 [31] | A feature of the product to retain the serviceability until a marginal condition is approached, with a predetermined system of maintenance and repair being used | cranes |

| ISO 14708-5 [32] | Ability of an item to perform a required function under given conditions of use and maintenance, until a limiting state is reached | active implantable medical devices |

| ISO 19867 [26] | Ability of a cookstove to continue to be operated for an extended period in a safe manner and with minimal loss in performance | cookstoves |

| ISO 11108 [33] | The ability to resist the effects of wear and tear when in use | archival papers |

| ISO 28842 [27] | Characteristic of a structure to resist gradual degradation of its serviceability in a given environment for the design service life | concrete bridges |

3.2. Durability Attributes

4. Proposed Framework

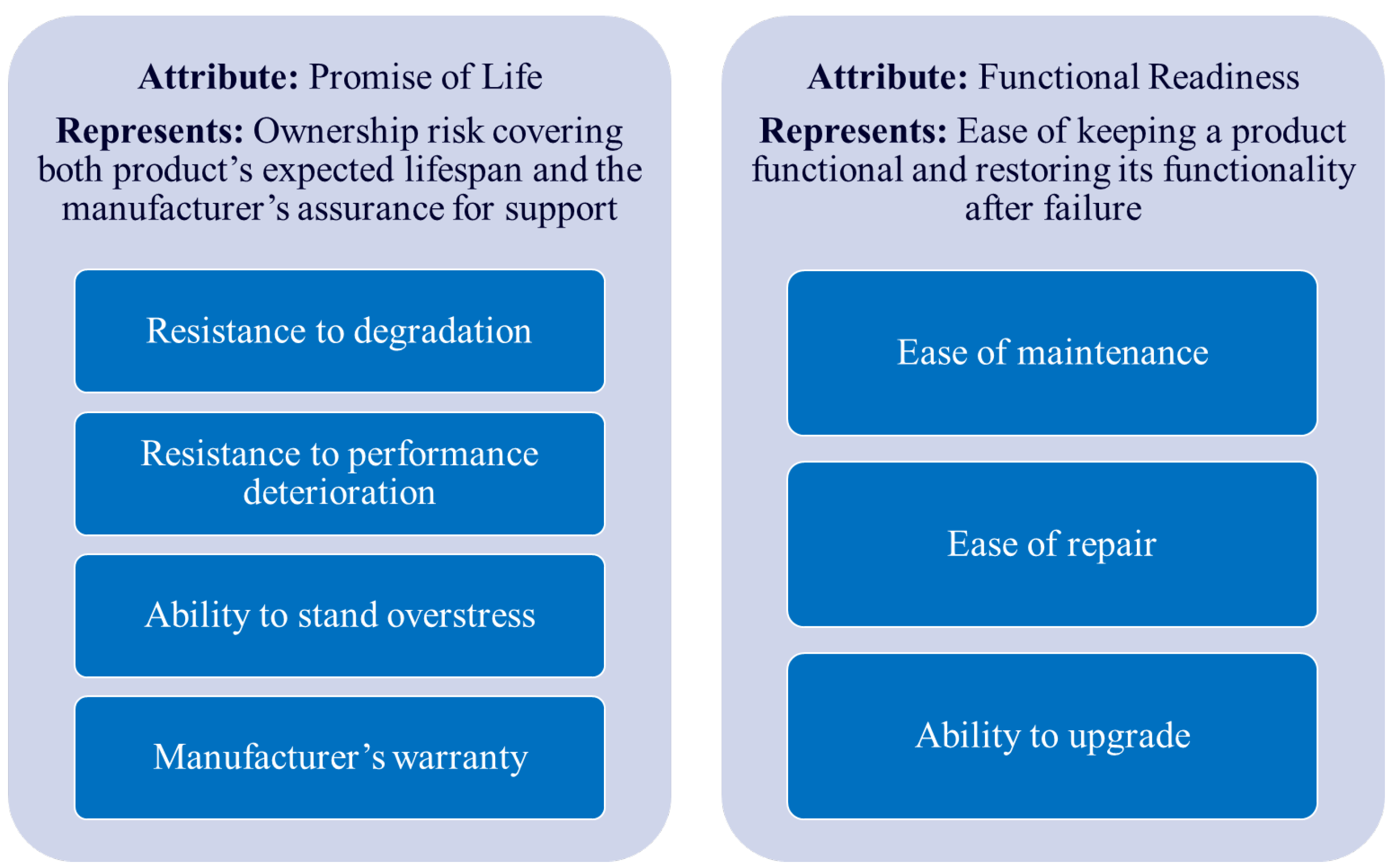

4.1. Defining Durability and its Key Attributes

4.2. Durability Index Framework

4.2.1. Promise of Life

Resistance to Degradation, Resistance to Performance Deterioration, and Ability to Stand Overstress: Relative Index

Resistance to Degradation, Resistance to Performance Deterioration, and Ability to Stand Overstress: Absolute Index

Manufacturer’s Warranty

4.2.2. Functional Readiness

Ease of Repair

Ease of Maintenance

Ability to Upgrade

4.2.3. Combining Sub-Attributes and Attributes Indices

Single Durability Index

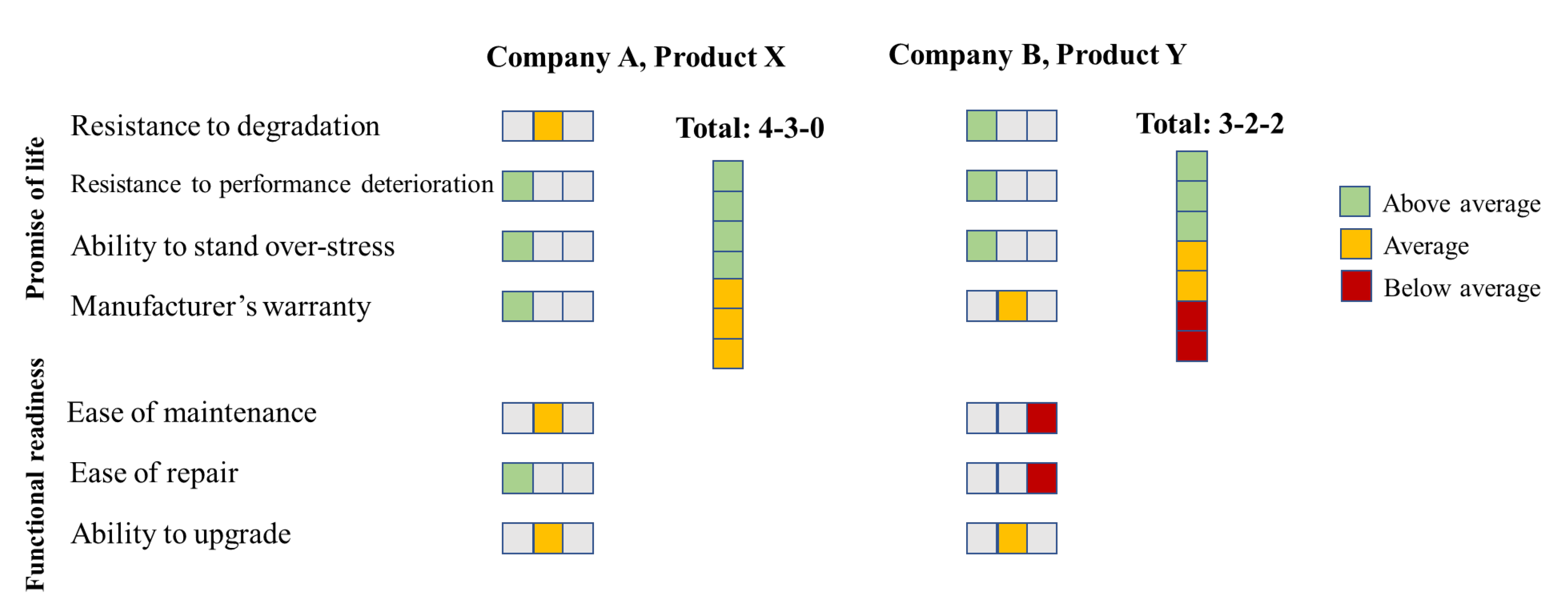

Multi-Measure Durability Index

4.3. Implementation of the Proposed Durability Index Framework

5. Smartphone Durability Indexing: An Application of the Proposed Framework

5.1. Promise of Life

5.1.1. Resistance to Degradation

5.1.2. Resistance to Performance Deterioration

5.1.3. Ability to Stand Over-Stress

5.1.4. Manufacturer’s Warranty

5.2. Functional Readiness

5.2.1. Ease of Repair

5.2.2. Ease of Maintenance

5.2.3. Ability to Upgrade

5.3. Combining Sub-Attributes and Attributes Indices

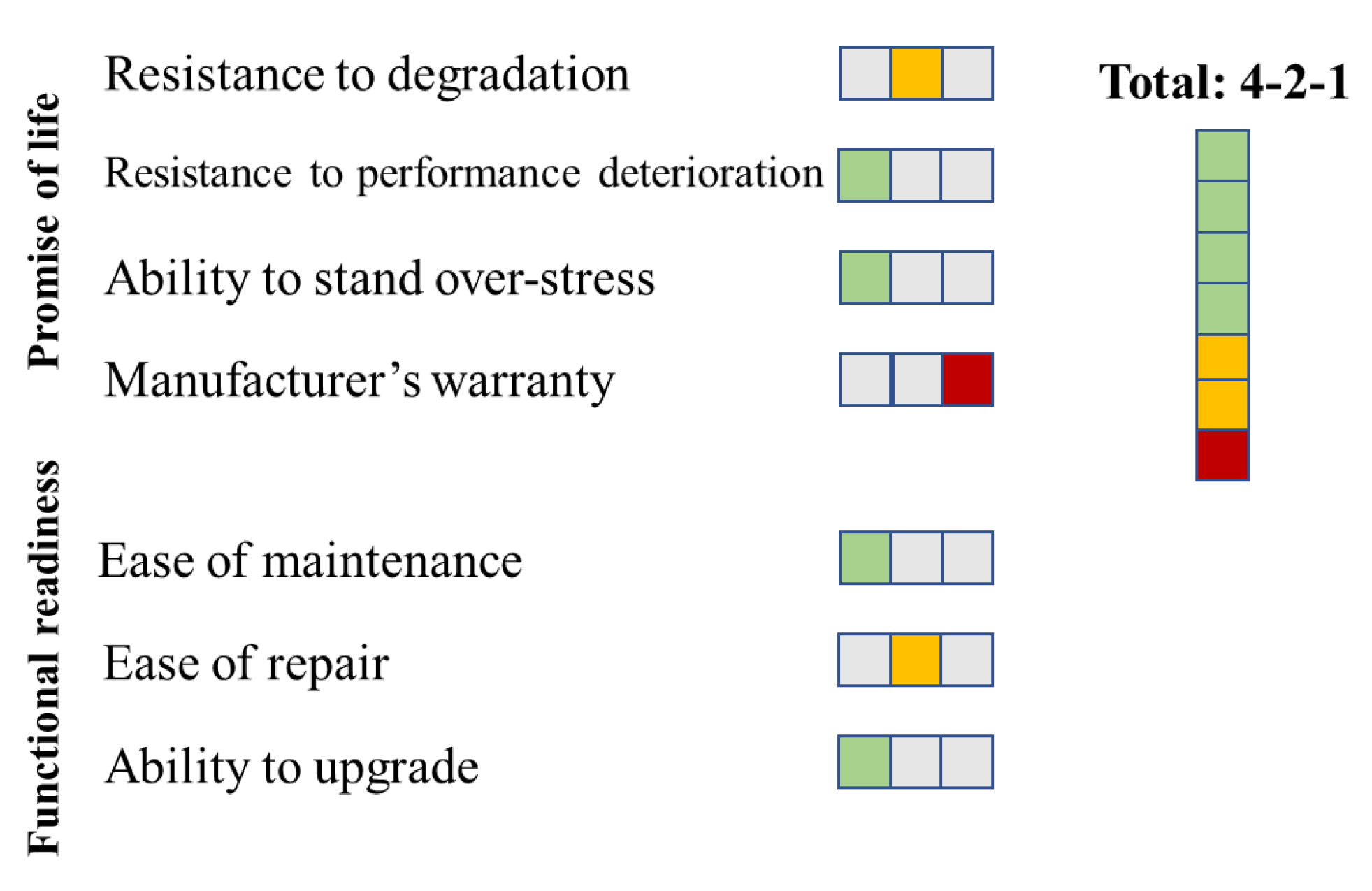

5.3.1. Single Durability Index

Promise of life = 0.36 × Resistance to degradation + 0.1 × Resistance to performance drop + 0.15 × Ability to stand overstress + 0.38 × Manufacturer’ s warranty

Functional readiness = 0.63 × Ease of repair + 0.19 × Ease of maintenance + 0.17 × Ability to upgrade

5.3.2. Multi-Measure Durability Index

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Forti, V.; Balde, C.P.; Kuehr, R.; Bel, G.; Monitor, T.G.E.-W. 2020: Quantities, Flows and the Circular Economy Potential; United Nations University (UNU)/United Nations Institute for Training and Research (UNITAR): Bonn, Germany; International Telecommunication Union (ITU): Geneva, Switzerland; International Solid Waste Association (ISWA): Rotterdam, The Netherlands, 2020. [Google Scholar]

- Möslinger, M.; Almásy, K.; Jamard, M.; De Maupeou, H. Towards an Effective Right to Repair for Electronics; Publications Office of the European Union: Luxembourg, 2022. [Google Scholar]

- Grant, K.; Goldizen, F.C.; Sly, P.D.; Brune, M.-N.; Neira, M.; Berg, M.V.D.; Norman, R.E. Health consequences of exposure to e-waste: A systematic review. Lancet Glob. Health 2013, 1, e350–e361. [Google Scholar] [CrossRef] [PubMed]

- Noel-Brune, M.; Goldizen, F.C.; Neira, M.; Berg, M.V.D.; Lewis, N.; King, M.; Suk, W.A.; Carpenter, D.O.; Arnold, R.G.; Sly, P.D. Health effects of exposure to e-waste. Lancet Glob. Health 2013, 1, e70. [Google Scholar] [CrossRef] [PubMed]

- Robinson, B.H. E-waste: An assessment of global production and environmental impacts. Sci. Total. Environ. 2009, 408, 183–191. [Google Scholar] [CrossRef] [PubMed]

- Akram, R.; Fahad, S.; Hashmi, M.Z.; Wahid, A.; Adnan, M.; Mubeen, M.; Khan, N. Trends of electronic waste pollution and its impact on the global environment and ecosystem. Environ. Sci. Pollut. Res. 2019, 26, 16923–16938. [Google Scholar] [CrossRef] [PubMed]

- Kaya, M. Recovery of metals and nonmetals from electronic waste by physical and chemical recycling processes. Waste Manag. 2016, 57, 64–90. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Achal, V. Environmental and health impacts due to e-waste disposal in China–A review. Sci. Total. Environ. 2020, 737, 139745. [Google Scholar] [CrossRef] [PubMed]

- Cooper, T. Inadequate life? Evidence of consumer attitudes to product obsolescence. J. Consum. Policy 2004, 27, 421–449. [Google Scholar] [CrossRef]

- Mugge, R. Product design and consumer behaviour in a circular economy. Sustainability 2018, 10, 3704. [Google Scholar] [CrossRef]

- Shevchenko, T.; Saidani, M.; Ranjbari, M.; Kronenberg, J.; Danko, Y.; Laitala, K. Consumer behavior in the circular economy: Developing a product-centric framework. J. Clean. Prod. 2023, 384, 135568. [Google Scholar] [CrossRef]

- Ministry of Ecological Transition and Territorial Cohesion, Ministry of Energy Transition of France Repairability Index. 1 December 2022. Available online: https://www.ecologie.gouv.fr/indice-reparabilite#scroll-nav__5 (accessed on 14 April 2023).

- Sariatli, F. Linear economy versus circular economy: A comparative and analyzer study for optimization of economy for sustainability. Visegr. J. Bioecon. Sustain. Dev. 2017, 6, 31–34. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Pieroni, M.P.; Pigosso, D.C.; Soufani, K. Circular business models: A review. J. Clean. Prod. 2020, 277, 123741. [Google Scholar] [CrossRef]

- IEEE1680.1-2018; IEEE Standard for Environmental and Social Responsibility Assessment of Computers and Displays. IEEE: New York, NY, USA, 2018. Available online: https://ieeexplore.ieee.org/document/8320570 (accessed on 25 February 2023).

- Chen, Y. On the competition between two modes of product recovery: Remanufacturing and refurbishing. Prod. Oper. Manag. 2019, 28, 2983–3001. [Google Scholar] [CrossRef]

- Cui, J.; Roven, H.J.; Waste, E. Waste: A Handbook for Management; Academic Press: Cambridge, MA, USA, 2011; pp. 281–296. [Google Scholar]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.; Hultink, E.J. The Circular Economy–A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Vidal-Ayuso, F.; Akhmedova, A.; Jaca, C. The circular economy and consumer behaviour: Literature review and research directions. J. Clean. Prod. 2023, 418, 137824. [Google Scholar] [CrossRef]

- Islam, M.T.; Huda, N.; Baumber, A.; Shumon, R.; Zaman, A.; Ali, F.; Hossain, R.; Sahajwalla, V. A global review of consumer behavior towards e-waste and implications for the circular economy. J. Clean. Prod. 2021, 316, 128297. [Google Scholar] [CrossRef]

- Watson, D.; Gylling, A.C.; Tojo, N.; Throne-Holst, H.; Bauer, B.; Milios, L. Circular Business Models in the Mobile Phone Industry; Nordic Council of Ministers: Copenhagen, Denmark, 2017.

- Cooper, T. Slower consumption reflections on product life spans and the “throwaway society”. J. Ind. Ecol. 2005, 9, 51–67. [Google Scholar] [CrossRef]

- Merriam-Webster Online Dictionary; Durable. Available online: https://www.merriam-webster.com/dictionary/durability#h1 (accessed on 24 February 2023).

- Soukhanov, H. Websters II New Riverside University Dictionary; Houghton-Mifflin Company: Boston, MA, USA, 1984. [Google Scholar]

- Cooper, T. Beyond Recycling: The Longer Life Option; New Economics Foundation: London, UK, 1994. [Google Scholar]

- ISO 19867-1:2018; Clean Cookstoves and Clean Cooking Solutions—Harmonized Laboratory Test Protocols—Part 1: Standard Test Sequence for Emissions and Performance, Safety and Durability. ISO: Geneva, Switzerland, 2018. Available online: https://www.iso.org/standard/66519.html (accessed on 27 February 2023).

- ISO 28842:2013; Guidelines for Simplified Design of Reinforced Concrete Bridges. ISO: Geneva, Switzerland, 2013. Available online: https://www.iso.org/standard/56096.html (accessed on 27 February 2023).

- Department of Defense. MIL-HDBK-470A Designing and Developing Maintainable Products and Systems. 4 August 1997. Available online: https://www.acqnotes.com/Attachments/MIL-HDBK-470A.pdf (accessed on 27 February 2023).

- Department of Defense. MIL-STD-721C Definitions of Terms for Reliability and Maintainability. 1981. Available online: http://everyspec.com/MIL-STD/MIL-STD-0700-0799/MIL-STD-721C_1040/ (accessed on 27 February 2023).

- EN 45552:2020; General Method for the Assessment of the Durability of Energy-Related Products. European Committee for Standardization: Luxembourg, 2020. Available online: https://standards.iteh.ai/catalog/standards/cen/ed936aa8-4368-4a13-bae1-93ec80357a95/en-45552-2020 (accessed on 2 March 2023).

- ISO 11994:1997; Cranes—Availability—Vocabulary. ISO: Geneva, Switzerland, 1997. Available online: https://www.iso.org/standard/20622.html (accessed on 24 February 2023).

- ISO 14708-5:2020; Implants for Surgery—Active Implantable Medical Devices—Part 5: Circulatory Support Devices. ISO: Geneva, Switzerland, 2020. Available online: https://www.iso.org/standard/69898.html (accessed on 24 February 2023).

- ISO 11108:1996; Information and Documentation—Archival Paper—Requirements for Permanence and Durability. ISO: Geneva, Switzerland, 1996. Available online: https://www.iso.org/standard/1708.html (accessed on 27 February 2023).

- French Agency for Environment and Energy Management (ADEME). Preparatory Study for the Introduction of a Durability Index. July 2021. Available online: https://librairie.ademe.fr/dechets-economie-circulaire/4853-preparatory-study-for-the-introduction-of-a-durability-index.html (accessed on 20 February 2023).

- Cordella, M.; Alfieri, F.; Clemm, C.; Berwald, A. Durability of smartphones: A technical analysis of reliability and repairability aspects. J. Clean. Prod. 2020, 286, 125388. [Google Scholar] [CrossRef] [PubMed]

- European Commission. Circular Economy: New Rules to Make Phones and Tablets More Durable, Energy Efficient and Easier to Repair, Enabling Sustainable Choices by Consumers. 16 June 2023. Available online: https://ec.europa.eu/commission/presscorner/detail/en/ip_23_3315 (accessed on 14 July 2023).

- Khan, M.A.; Mittal, S.; West, S.; Wuest, T. Review on upgradability-A product lifetime extension strategy in the context of product service systems. J. Clean. Prod. 2018, 204, 1154–1168. [Google Scholar] [CrossRef]

- Cordella, M.; Alfieri, F.; Sanfelix, J. Guidance for the Assessment of Material Efficiency: Application to Smartphones; Joint Research Center: Seville, Spain, 2020. [Google Scholar]

- Stamminger, R.; Tecchio, P.; Ardente, F.; Mathieux, F.; Niestrath, P. Towards a durability test for washing-machines. Resour. Conserv. Recycl. 2018, 131, 206–215. [Google Scholar] [CrossRef]

- Defense, D.O. MIL-HDBK-338A Electronic Reliability Design Handbook. 1988. Available online: https://www.navsea.navy.mil/Portals/103/Documents/NSWC_Crane/SD-18/Test%20Methods/MILHDBK338B.pdf (accessed on 27 February 2023).

- Defense, D.O. MIL-HDBK-217F Reliability Prediction of Electronic Equipment. 1990. Available online: http://everyspec.com/MIL-HDBK/MIL-HDBK-0200-0299/MIL-HDBK-217F_14591/ (accessed on 27 February 2023).

- 1413.1-1998; IEEE Standard for Reliability Qualification of Integrated Circuits. IEEE: New York, NY, USA, 1998.

- IEC 60068; Environmental Testing. International Electrotechnical Commission: Geneva, Switzerland, 2017.

- JESD22-B102E; Accelerated Stress Testing, Bias Life Test, and Burn-In of Integrated Circuits. Joint Electron Device Engineering Council: Arlington County, VA, USA, 2018.

- Davila-Frias, A.; Yadav, O.P.; Marinov, V. A review of methods for the reliability testing of flexible hybrid electronics. IEEE Trans. Compon. Packag. Manuf. Technol. 2020, 10, 1902–1912. [Google Scholar] [CrossRef]

- Song, Y.; Wang, B. Survey on reliability of power electronic systems. IEEE Trans. Power Electron. 2012, 28, 591–604. [Google Scholar] [CrossRef]

- Richter, J.L.; Svensson-Hoglund, S.; Dalhammar, C.; Russell, J.D.; Thidell, Å. Taking stock for repair and refurbishing: A review of harvesting of spare parts from electrical and electronic products. J. Ind. Ecol. 2023, 27, 868–881. [Google Scholar] [CrossRef]

- Fazio, F.D.; Bakker, C.; Flipsen, B.; Balkenende, R. The Disassembly Map: A new method to enhance design for product repairability. J. Clean. Prod. 2021, 320, 128552. [Google Scholar] [CrossRef]

- EN 45554:2020; General Methods for the Assessment of the Ability to Repair, Reuse and Upgrade Energy-Related Products. European Committee for Standardization: Luxembourg, 2020. Available online: https://standards.iteh.ai/catalog/standards/clc/ed9b48c0-a4a9-421a-a14f-4ff341199918/en-45554-2020 (accessed on 5 March 2023).

- Cordella, M.; Alfieri, F.; Sanfelix, J. Analysis and Development of a Scoring System for Repair and Upgrade of Products; Joint Research Center: Seville, Spain, 2019. [Google Scholar]

- Bracquené, E.; Brusselaers, J.; Dams, Y.; Peeters, J.; Schepper, K.D.; Duflou, J.; Dewulf, W. Repairability Criteria for Energy Related; BeNeLux: Brussels, Belgium, 2018. [Google Scholar]

- ONR 192102:2006; Durability Mark for Electric and Electronic Appliances Designed for Easy Repair (White and Brown Goods) (Austrian Standard). Austrian Standardization Institute: Vienna, Austria, 2006. Available online: https://webstore.ansi.org/standards/on/onr1921022006 (accessed on 5 March 2023).

- Flipsen, B.; Huisken, M.; Opsomer, T.; Depypere, M. Smartphone reparability scoring: Assessing the self-repair potential of mobile ICT devices. In PLATE.; European Union: Brussels, Belgium, 2019. [Google Scholar]

- Dangal, S.; Faludi, J.; Balkenende, R. Design Aspects in Repairability Scoring Systems: Comparing Their Objectivity and Completeness. Sustainability 2022, 14, 8634. [Google Scholar] [CrossRef]

- Bracquene, E.; Peeters, J.; Alfieri, F.; Sanfelix, J.; Duflou, J.; Dewulf, W.; Cordella, M. Analysis of evaluation systems for product repairability: A case study for washing machines. J. Clean. Prod. 2021, 281, 125122. [Google Scholar] [CrossRef]

- Modarres, M.; Kaminskiy, M.P.; Krivtsov, V. Reliability Engineering and Risk Analysis: A Practical Guide; CRC Press: Boca Raton, FL, USA, 2009. [Google Scholar]

- Wei, Z.; Hamilton, J.; Ling, J.; Pan, J. Reliability Analysis Based on Stress–Strength Interference Model. Wiley Encyclopedia of Electrical and Electronics Engineering; Wiley: Hoboken, NJ, USA, 1999; pp. 1–4. [Google Scholar]

- Crowder, M.J.; Kimber, A.C. Statistical modeling of reliability using the incomplete beta distribution. Technometrics 1999, 41, 147–157. [Google Scholar]

- Harmer, L.; Cooper, T.; Fisher, T.; Salvia, G.; Barr, C. Design, Dirt and Disposal: Influences on the maintenance of vacuum cleaners. J. Clean. Prod. 2019, 228, 1176–1186. [Google Scholar] [CrossRef]

- Ishizaka, A.; Labib, A. Review of the main developments in the analytic hierarchy process. Expert Syst. Appl. 2011, 38, 14336–14345. [Google Scholar]

- Parnell, G.S.; Trainor, T.E. Using the swing weight matrix to weight multiple objectives. INCOSE Int. Symp. 2009, 19, 283–298. [Google Scholar] [CrossRef]

- Németh, B.; Molnár, A.; Bozóki, S.; Wijaya, K.; Inotai, A.; Campbell, J.D.; Kaló, Z. Comparison of weighting methods used in multicriteria decision analysis frameworks in healthcare with focus on low-and middle-income countries. J. Comp. Eff. Res. 2019, 8, 195–204. [Google Scholar] [CrossRef]

- Steer-Stephenson, C. Mobile Phones and the Building e-Waste Mountain. 3 August 2022. Available online: https://mobile-magazine.com/articles/mobile-phones-and-the-rising-e-waste-mountain (accessed on 25 September 2023).

- Halte à l’Obsolescence Programmée. The French Repairability Index: A First Assessment—One Year after Its Implementation. 2022. Available online: https://www.halteobsolescence.org/wp-content/uploads/2022/02/Rapport-indice-de-reparabilite.pdf (accessed on 10 March 2023).

- Garbett, S.L. 11 Cleaning Tricks to Make Your Phone Look Like New. 2 May 2022. Available online: https://www.makeuseof.com/cleaning-tricks-to-make-your-phone-look-like-new/ (accessed on 9 September 2023).

- Haslam, K. How Long Does Apple Support iPhones? Macworld, 14 June 2023. Available online: https://www.macworld.com/article/675021/how-long-does-apple-support-iphones.html#:~:text=Apple%20will%20support%20iPhones%20(and,it%20sold%20that%20particular%20model (accessed on 8 September 2023).

| Criteria | Sub-Criteria | Score of Sub-Criteria | Weight of Sub-Criteria | Score of Criteria | Total Score |

|---|---|---|---|---|---|

| Documentation |

| /10 | 2 | /20 | /100 |

| Disassembling, access, tools, fasteners |

| /10 | 1 | /20 | |

| /10 | 0.5 | ||||

| /10 | 0.5 | ||||

| Availability of spare parts |

| /10 | 1 | /20 | |

| /10 | 0.5 | ||||

| /10 | 0.3 | ||||

| /10 | 0.2 | ||||

| Price of spare parts |

| /10 | 2 | /20 | |

| Specific criterion | - | /10 | 2 | /20 | |

| Index | /10 |

| Criteria | Sub-Criteria | Score of Sub-Criteria | Weight of Sub-Criteria | Score of Criteria | Total Score |

|---|---|---|---|---|---|

| Documentation |

| /10 | x | /25 | /100 |

| /10 | x | ||||

| Parts availability |

| /10 | x | /25 | |

| /10 | x | ||||

| Complexity |

| /10 | x | /25 | |

| /10 | x | ||||

| /10 | x | ||||

| Cost |

| /10 | x | /25 | |

| Index | /1 |

| Criteria | Sub-Criteria | Score of Sub-Criteria | Weight of Sub-Criteria | Score of Criteria | Total Score |

|---|---|---|---|---|---|

| Software upgradability | Security | /25 | 1 | /50 | /100 |

| Applications | /25 | 1 | |||

| Hardware upgradability | - | /50 | 1 | /50 | |

| Index | /1 |

| Sub-Attribute | Data Needed for Relative Indexing | How to Collect Data | Considered Data for the Example |

|---|---|---|---|

| Resistance to degradation | Target product life distribution and reference life distribution considering degradation | After defining the failure based on degradation intensity (e.g., the specific crack size on casing), failure-terminated drop tests should be performed on a set of target smartphones and a sufficient sample of available smartphones on the market to collect cycles to failure. |

|

| Resistance to performance deterioration | Target product life distribution and reference life distribution considering performance deterioration | Same as collecting data for degradation, with the difference that failure should be defined based on performance (e.g., a specific amount of noise in the smartphone’s output voice). |

|

| Ability to stand over-stress | Target product life distribution and reference life distribution considering robustness (probability of failure versus height rather than time) | Same as collecting data for degradation, with the difference that instead of collecting cycles to failures, drop heights of failures should be collected to obtain the probability of failure versus height. |

|

| Manufacturer’s warranty |

| Warranty periods for a sufficient sample of smartphones from different manufacturers should be collected. |

|

| Sub-Attribute | Data Needed for Absolute Indexing | How to Collect Data | Considered Data for the Example |

|---|---|---|---|

| Resistance to degradation | Results of pass-or-fail tests considering degradation of the target product | After defining the failure based on degradation intensity (e.g., the specific crack size casing), cycle-terminated drop tests should be performed on a set of smartphones to collect the number of failed samples. | Assumed 2 failures out of 50 smartphones |

| Resistance to performance deterioration | Results of pass-or-fail tests considering performance of the target product | Same as collecting data for degradation, with the difference that failure should be defined based on performance (e.g., a specific amount of noise in smartphone output voice). | Assumed 3 failures out of 50 smartphones |

| Ability to stand over-stress | Results of pass-or-fail tests considering robustness of the target product | After determining the destruct limit of the smartphone, over-stress drop tests should be performed to collect the number of failed samples. | Assumed 1 failure out of 100 smartphones |

| Manufacturer’s warranty | Reference table for mapping warranty period to an index | Experts’ opinions and customer expectations can be collected through surveys to prepare a reference table. | Assumed 12-month warranty for the target product and also a reference table for conversion to an index |

| Warranty Period | Absolute Index |

|---|---|

| 36 | 1 |

| 30 | 0.8 |

| 24 | 0.6 |

| 18 | 0.4 |

| 12 | 0.2 |

| <12 | 0 |

| Sub-Attribute | Data Needed for Indexing | How to Collect Data | Considered Data for the Example |

|---|---|---|---|

| Ease of repair |

|

| Different devices were previously indexed with more details by investigators to validate the provided scores by the manufacturers [64]. |

| Ease of maintenance |

| Like repairability, the only way to acquire the necessary information for indexing maintainability is by obtaining it from the manufacturers. | Cleaning and drying are the only maintenance activities for smartphones. |

| Ability to upgrade |

|

|

|

| Commitment Period (Year) | Absolute Index |

|---|---|

| 1 | |

| 0.8 | |

| 0.6 | |

| 0.4 | |

| 0.2 | |

| 0 |

| Criteria | Sub-Criteria | Score of Sub-Criteria | Weight of Sub-Criteria | Score of Criteria | Total Score |

|---|---|---|---|---|---|

| Software upgradability | Security | 25/25 | 1 | 35/50 | 85/100 |

| Applications | 10/25 | 1 | |||

| Hardware upgradability | Increasing memory capacity | 25/25 | 1 | 50/50 | |

| Second SIM | 25/25 | 1 | |||

| Index | 0.85/1 |

| Attribute | Sub-Attribute | Index |

|---|---|---|

| Promise of life | Resistance to degradation | 0.34 |

| Resistance to performance deterioration | 0.63 | |

| Ability to stand over-stress | 0.67 | |

| Manufacturer’s warranty | 0.22 | |

| Functional readiness | Ease of repair | 0.58 |

| Ease of maintenance | 1 | |

| Ability to upgrade | 0.85 |

| Index Range | Ordinal Scale Value |

|---|---|

| Above average | |

| Average | |

| Below average |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Habibollahi Najaf Abadi, H.; Herrmann, J.W.; Modarres, M. Measuring and Indexing the Durability of Electrical and Electronic Equipment. Sustainability 2023, 15, 14386. https://doi.org/10.3390/su151914386

Habibollahi Najaf Abadi H, Herrmann JW, Modarres M. Measuring and Indexing the Durability of Electrical and Electronic Equipment. Sustainability. 2023; 15(19):14386. https://doi.org/10.3390/su151914386

Chicago/Turabian StyleHabibollahi Najaf Abadi, Hamidreza, Jeffrey W. Herrmann, and Mohammad Modarres. 2023. "Measuring and Indexing the Durability of Electrical and Electronic Equipment" Sustainability 15, no. 19: 14386. https://doi.org/10.3390/su151914386

APA StyleHabibollahi Najaf Abadi, H., Herrmann, J. W., & Modarres, M. (2023). Measuring and Indexing the Durability of Electrical and Electronic Equipment. Sustainability, 15(19), 14386. https://doi.org/10.3390/su151914386