Valorization of Marble Waste Powder as a Replacement for Limestone in Clinker Production: Technical, Environmental and Economic Evaluation

Abstract

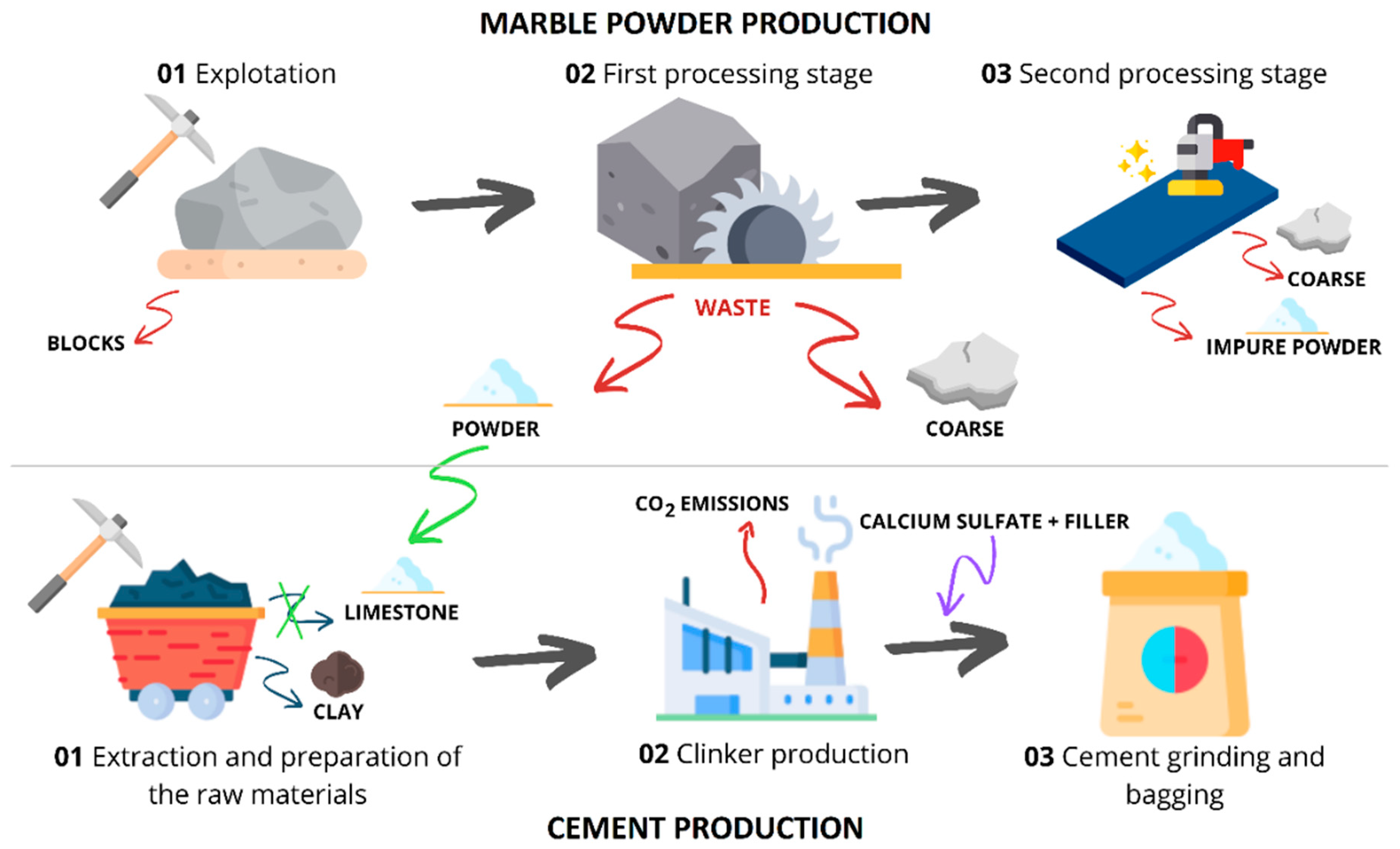

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Raw Materials’ Properties

- Skeletal Density

- Specific surface area

- Chemical composition (XRF)

- Mineralogical composition (XRD)

2.3. Clinker Dosage

- Clinker design with chemical modules

- Clinker design with Bogue equations

2.4. Clinker Production

2.5. Cement Paste Production

2.6. Compressive Strength of Cement Paste

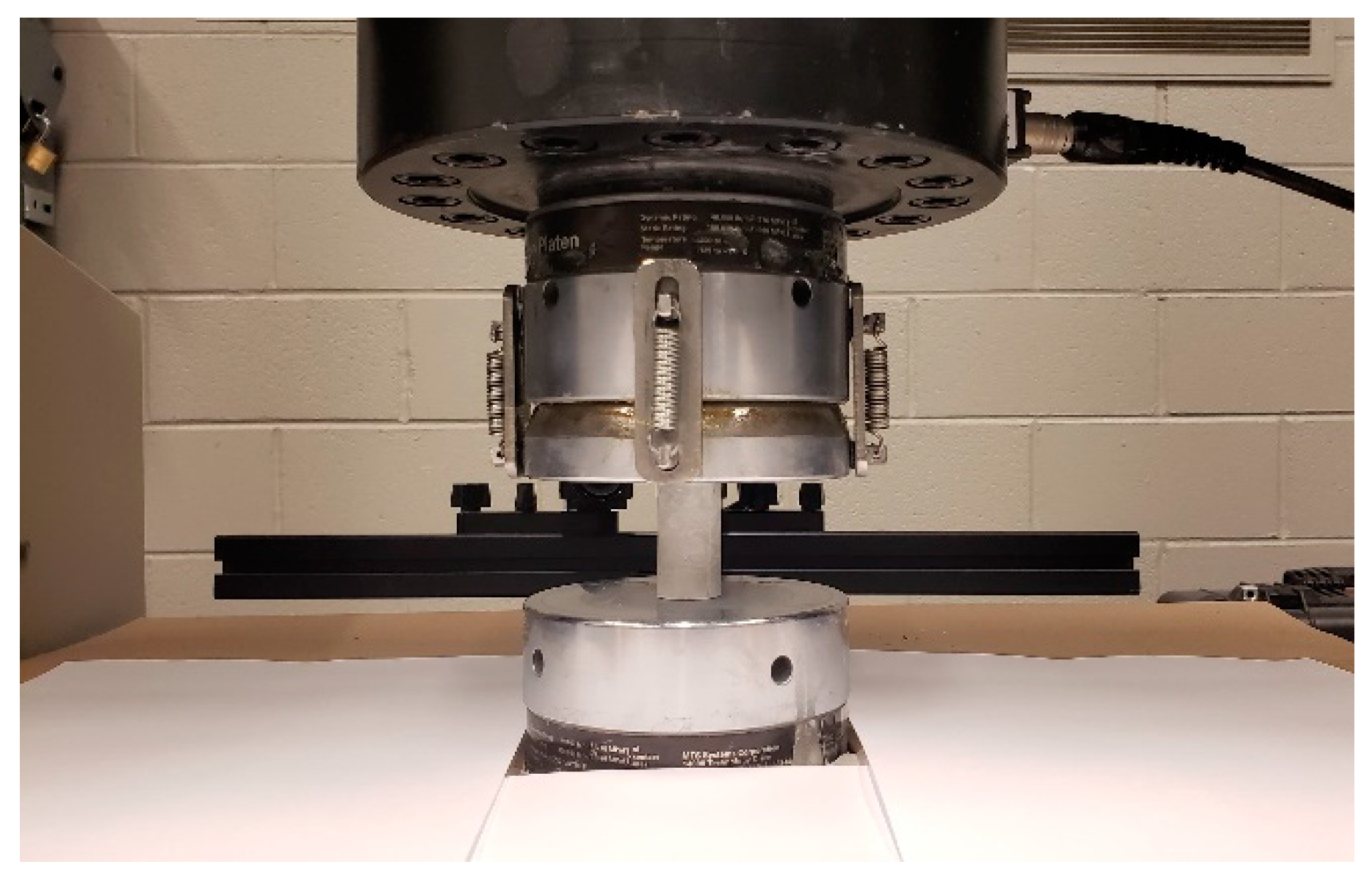

2.7. Life Cycle Assessment (LCA)

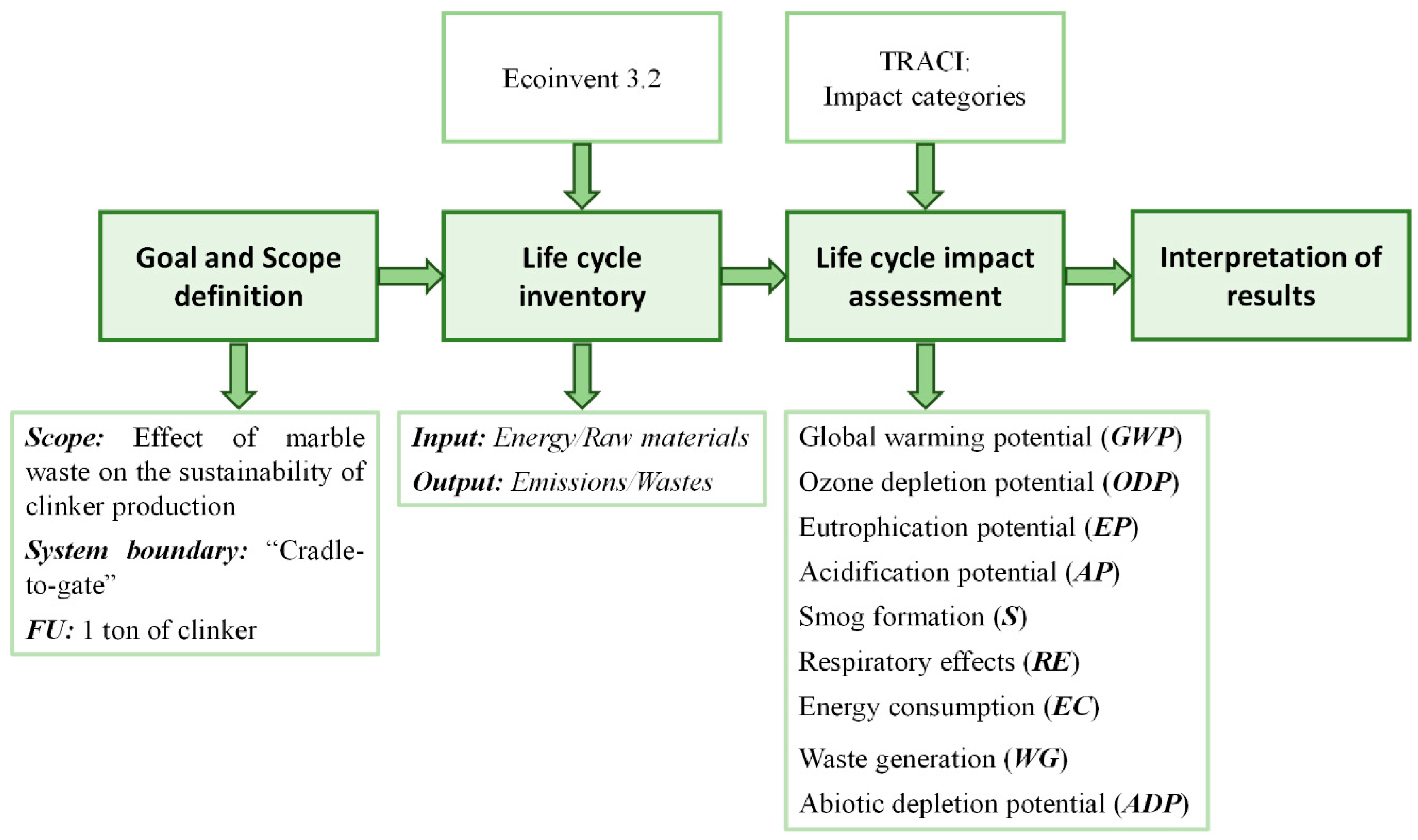

- Goal and scope definition

- Life cycle inventory (LCI)

- Life cycle impact assessment (LCIA)

- Interpretation of results

3. Results and Discussion

3.1. Characterization of Raw Materials

3.2. Definition of Cement Raw Meals

3.3. Mineralogical Composition of Clinkers

3.4. Chemical and Physical Properties of Cement Pastes

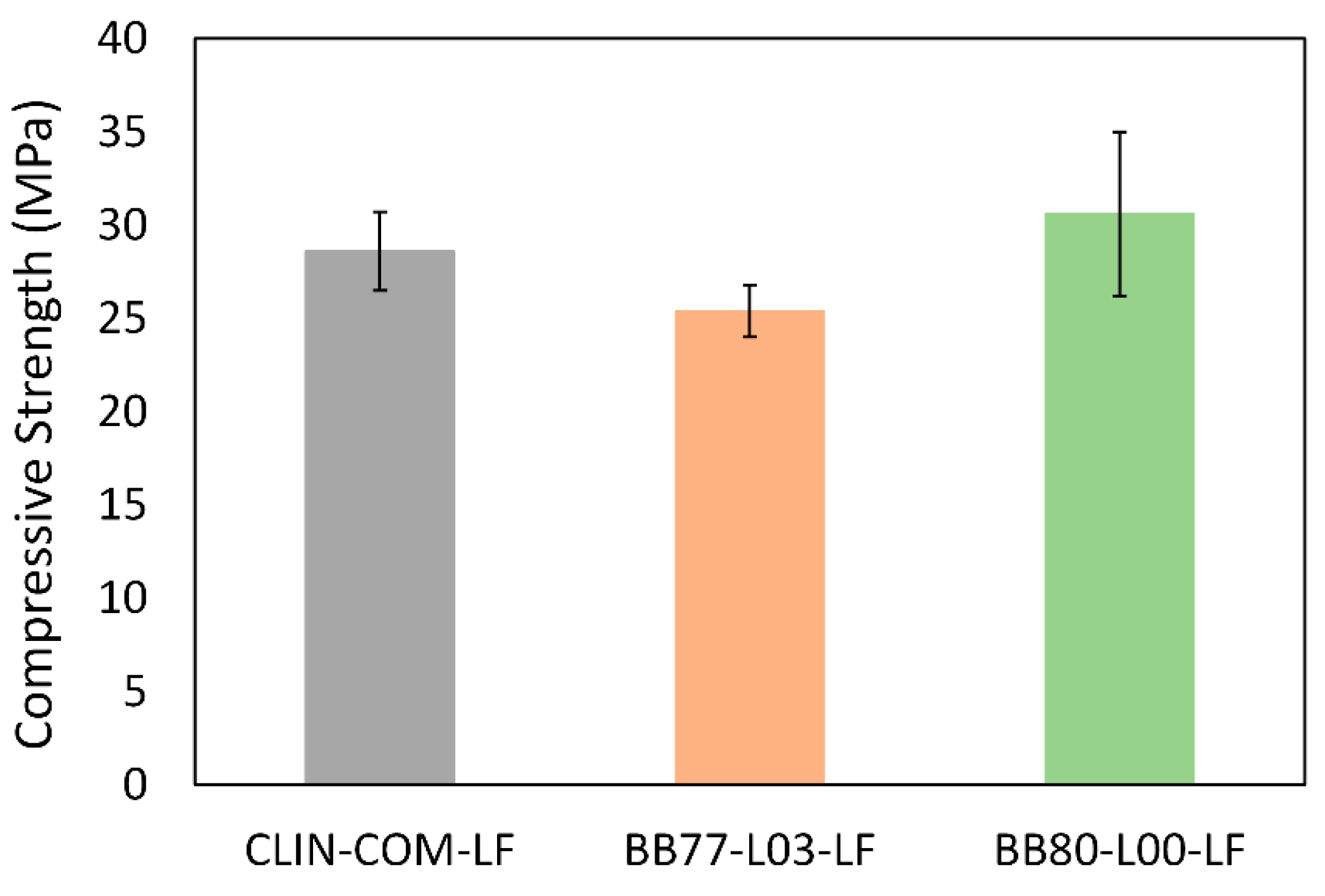

3.5. Compressive Strength of Cement Pastes

4. Environmental Assessment of Clinkers

5. Economic Viability

- PL: price, per ton, of the newly extracted limestone.

- TL: price, per ton, of transport of limestone.

- EMP: extra costs, per ton, due to the use of the residue.

- PMP: price, per ton, of marble powder waste.

- TMP: transport, per ton, of marble powder waste

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rehman, M.U.; Ahmad, M.; Rashid, K. Influence of fluxing oxides from waste on the production and physico-mechanical properties of fired clay brick: A review. J. Build. Eng. 2020, 27, 100965. [Google Scholar] [CrossRef]

- Amaral, L.F.; de Carvalho, J.P.R.G.; da Silva, B.M.; Delaqua, G.C.G.; Monteiro, S.N.; Vieira, C.M.F. Development of ceramic paver with ornamental rock waste. J. Mater. Res. Technol. 2019, 8, 599–608. [Google Scholar] [CrossRef]

- Marvila, M.T.; Alexandre, J.; Azevedo, A.R.G.; Zanelato, E.B.; Monteiro, S.N.; Xavier, G.C.; Goulart, M.; Mendes, B. Study of the incorporation of residue of ornamental rocks in ceramic tiles. Miner. Met. Mater. Ser. 2018, XIII, 677–682. [Google Scholar] [CrossRef]

- Saboya, F.; Xavier, G.; Alexandre, J. The use of the powder marble by-product to enhance the properties of brick ceramic. Constr. Build. Mater. 2007, 21, 1950–1960. [Google Scholar] [CrossRef]

- Raigón-Pichardo, M.; García-Ramos, G.; Sánchez-Soto, P. Characterization of a waste washing solid product of mining granitic tin-bearing sands and its application as ceramic raw material. Resour. Conserv. Recycl. 1996, 17, 109–124. [Google Scholar] [CrossRef]

- Prošek, Z.; Nežerka, V.; Tesárek, P. Enhancing cementitious pastes with waste marble sludge. Constr. Build. Mater. 2020, 255, 119372. [Google Scholar] [CrossRef]

- Danish, A.; Mosaberpanah, M.A.; Salim, M.U.; Fediuk, R.; Rashid, M.F.; Waqas, R.M. Reusing marble and granite dust as cement replacement in cementitious composites: A review on sustainability benefits and critical challenges. J. Build. Eng. 2021, 44, 102600. [Google Scholar] [CrossRef]

- Sato, V.Y.; Galina, A.P.L.; Teixeira, J.E.S.L. Contribution to the rheological study of cementitious pastes with addition of residues from the processing of ornamental rocks. Rev. IBRACON Estrut. Mater. 2018, 11, 1284–1307. [Google Scholar] [CrossRef]

- Ergün, A. Effects of the usage of diatomite and waste marble powder as partial replacement of cement on the mechanical properties of concrete. Constr. Build. Mater. 2011, 25, 806–812. [Google Scholar] [CrossRef]

- Barros, S.V.A.; Marciano, J.E.A.; Ferreira, H.C.; Menezes, R.R.; Neves, G.d.A. Addition of quartzite residues on mortars: Analysis of the alkali aggregate reaction and the mechanical behavior. Constr. Build. Mater. 2016, 118, 344–351. [Google Scholar] [CrossRef]

- Mármol, I.; Ballester, P.; Cerro, S.; Monrós, G.; Morales, J.; Sánchez, L. Use of granite sludge wastes for the production of coloured cement-based mortars. Cem. Concr. Compos. 2010, 32, 617–622. [Google Scholar] [CrossRef]

- Kabeer, K.S.A.; Vyas, A.K. Utilization of marble powder as fine aggregate in mortar mixes. Constr. Build. Mater. 2018, 165, 321–332. [Google Scholar] [CrossRef]

- Khyaliya, R.K.; Kabeer, K.S.A.; Vyas, A.K. Evaluation of strength and durability of lean mortar mixes containing marble waste. Constr. Build. Mater. 2017, 147, 598–607. [Google Scholar] [CrossRef]

- Shukla, A.; Gupta, N.; Gupta, A. Development of green concrete using waste marble dust. Mater. Today Proc. 2020, 26, 2590–2594. [Google Scholar] [CrossRef]

- Talah, A.; Kharchi, F.; Chaid, R. Influence of Marble Powder on High Performance Concrete Behavior. Procedia Eng. 2015, 114, 685–690. [Google Scholar] [CrossRef]

- Ural, N.; Karakurt, C.; Cömert, A.T. Influence of marble wastes on soil improvement and concrete production. J. Mater. Cycles Waste Manag. 2014, 16, 500–508. [Google Scholar] [CrossRef]

- Mashaly, A.O.; Shalaby, B.N.; Rashwan, M.A. Performance of mortar and concrete incorporating granite sludge as cement replacement. Constr. Build. Mater. 2018, 169, 800–818. [Google Scholar] [CrossRef]

- Vardhan, K.; Siddique, R.; Goyal, S. Strength, permeation and micro-structural characteristics of concrete incorporating waste marble. Constr. Build. Mater. 2019, 203, 45–55. [Google Scholar] [CrossRef]

- Vieira, L.B.; Ghirardi, G.C.; Viana, J.D.; Cardoso, L.D.S.P.; Dias, C.M.R. Technological Trends in the Use of Natural Marble Residue in the Cement Portland Production from Prospecting in Patent Documents. Rev. Gestão Inovação Tecnol. 2021, 11, 5671–5679. [Google Scholar] [CrossRef]

- Magalhães, A.C. Área de deposiçāo de estoque de remanescentes do Mármore Bege Bahia ADERBEGE. In VII Simpósio de Rochas Ornamentais do Nordeste; CETEM/MCTI: Rio De Janeiro, Brazil, 2009; pp. 1–8. Available online: https://mineralis.cetem.gov.br/handle/cetem/1471 (accessed on 11 April 2023).

- Vidal, F.; Azevedo, H.; Castro, N.F. Tecnologia de Rochas Ornamentais: Pesquisa, Lavra e Beneficiamento; CETEM/MCTI: Rio de Janeiro, Brazil, 2014; Volume 1.

- Alyamac, K.E.; Ghafari, E.; Ince, R. Development of eco-efficient self-compacting concrete with waste marble powder using the response surface method. J. Clean. Prod. 2017, 144, 192–202. [Google Scholar] [CrossRef]

- de Campos, A.R.; da CRibeiro, R.C.; Castro, N.F.; de Azevedo, H.C.A.; Cattabriga, L. Resíduos: Tratamentos e aplicações industriais. In Tecnologia de Rochas Ornamentais: Pesquisa, Lavra e Beneficiamento, 1st ed.; Vidal, F.W.H., Azevedo, H.C.A., Castro, N.F., Eds.; CETEM/MCTI: Rio de Janeiro, Brazil, 2013; Volume 1, pp. 433–492. [Google Scholar]

- Vasconcelos, C.S.A.; da Costa, J.M.; Ramos, M.A.F.; de Alima, L.R.P. Caracterizacão do rejeito fino gerado na serragem, do mármore bege-bahia. In Proceedings of the XXIII Encontro Nacional de Tratamento de Minérios e Metalurgia Extrativa, Porto Alegre, Brazil, 2009. pp. 707–712. Available online: https://www.researchgate.net/publication/330351350_CARACTERIZACAO_DO_REJEITO_FINO_GERADO_NA_SERRAGEM_DO_MARMORE_BEGE-BAHIA (accessed on 11 April 2023).

- Serviço Nacional de Aprendizagem Industrial. Memorial Descritivo do Projeto Conceitual—Otimização da Logística de Movimentação e Transporte dos Estoques Dremanescentes da Cadeira Produtiva do Mármore Bege Bahia; Serviço Nacional de Aprendizagem Industrial: Salvador, Brazil, 2019. [Google Scholar]

- André, A.; de Brito, J.; Rosa, A.; Pedro, D. Durability performance of concrete incorporating coarse aggregates from marble industry waste. J. Clean. Prod. 2014, 65, 389–396. [Google Scholar] [CrossRef]

- Hebhoub, H.; Aoun, H.; Belachia, M.; Houari, H.; Ghorbel, E. Use of waste marble aggregates in concrete. Constr. Build. Mater. 2011, 25, 1167–1171. [Google Scholar] [CrossRef]

- Prakash, B.; Saravanan, T.J.; Kabeer, K.S.A.; Bisht, K. Exploring the potential of waste marble powder as a sustainable substitute to cement in cement-based composites: A review. Constr. Build. Mater. 2023, 401, 132887. [Google Scholar] [CrossRef]

- Sutcu, M.; Alptekin, H.; Erdogmus, E.; Er, Y.; Gencel, O. Characteristics of fired clay bricks with waste marble powder addition as building materials. Constr. Build. Mater. 2015, 82, 1–8. [Google Scholar] [CrossRef]

- Buyuksagis, I.S.; Uygunoglu, T.; Tatar, E. Investigation on the usage of waste marble powder in cement-based adhesive mortar. Constr. Build. Mater. 2017, 154, 734–742. [Google Scholar] [CrossRef]

- Martínez-Martínez, S.; Pérez-Villarejo, L.; Eliche-Quesada, D.; Sánchez-Soto, P.J.; Christogerou, A.; Kanellopoulou, D.G.; Angelopoulos, G.N. New waste-based clinkers for the preparation of low-energy cements. A step forward toward circular economy. Int. J. Appl. Ceram. Technol. 2020, 17, 12–21. [Google Scholar] [CrossRef]

- Benjeddou, O.; Alyousef, R.; Mohammadhosseini, H.; Soussi, C.; Khadimallah, M.A.; Alabduljabbar, H.; Tahir, M.M. Utilisation of waste marble powder as low-cost cementing materials in the production of mortar. J. Build. Eng. 2020, 32, 101642. [Google Scholar] [CrossRef]

- Confederação Nacional da Indústria. Indústria Brasileira de Cimento: Base Para a Construção do Desenvolvimento; Confederação Nacional da Indústria: Brasília, Brazil, 2017; Available online: https://docplayer.com.br/7721124-Industria-de-cimento-base-para-a-construcao-encontro-da-industria-para-a-sustentabilidade.html (accessed on 11 April 2023).

- Kirgiz, M.S. Use of ultrafine marble and brick particles as raw materials in cement manufacturing. Mater. Struct. 2015, 48, 2929–2941. [Google Scholar] [CrossRef]

- El-Alfi, E.; Gado, R. Preparation of calcium sulfoaluminate-belite cement from marble sludge waste. Constr. Build. Mater. 2016, 113, 764–772. [Google Scholar] [CrossRef]

- ASTM C188; Standard Test Method for Density of Hydraulic Cement. American Society of Testing and Materials: West Conshohocken, PA, USA, 2017; Volume 4, p. 2.

- Centurione, S.L. A Mineralização do Clinquer Portland e Seus Benefícios Tecnológicos. Ph.D. Thesis, Universidade de São Paulo, São Paulo, Brazil, 1999. [Google Scholar] [CrossRef]

- Taylor, H.F.W. Cement Chemistry. 1997. Available online: https://www.icevirtuallibrary.com/doi/pdf/10.1680/cc.25929.fm (accessed on 11 April 2023).

- Santos, T.A.; Andrade Neto, J.d.S.; Ribeiro, D.V. Técnicas de caracterização de matrizes cimentícias. In Princípios da Ciência dos Materiais Cimentícios: Produção, Reações, Aplicações e Avanços Tecnológicos, 1st ed.; Ribeiro, D.V., Ed.; Appris: Curitiba, Brazil, 2021; pp. 185–268. [Google Scholar]

- Mariani, B.B. Produção de Clínquer Portland com Baixa Emissão de CO2 a Partir da Incorporação de Minério não Reagido (MNR) Advindo da Produção de TIO2. Master’s Thesis, Universidade Federal da Bahia (UFBA), Salvador, Brazil, 2018. Available online: https://repositorio.ufba.br/handle/ri/32946 (accessed on 11 April 2023).

- Santos, T.A.; Andrade Neto, J.d.S.; Ribeiro, D.V. Processo de produção e tipos de cimento. In Princípios da Ciência dos Materiais Cimentícios: Produção, Reações, Aplicações e Avanços Tecnológicos, 1st ed.; Ribeiro, D.V., Ed.; Appris: Curitiba, Brazil, 2021; Volume 1, pp. 29–66. [Google Scholar]

- Costa, F.N. Valorização do Resíduo de Construção Civil por Meio de Sua Incorporação ao Processo de Clinquerização; Universidade Federal da Bahia (UFBA): Salvador, Brazil, 2020. [Google Scholar]

- da Costa, E.B.; Nobre TR, S.; Guerreiro, A.Q.; Mancio, M.a.; Kirchheim, A.P. Clínquer Portland com reduzido impacto ambiental. Ambient. Construído 2013, 13, 75–86. [Google Scholar] [CrossRef]

- Vieira, C.F.F.; Soares, J.B.; Monteiro, S.N. Desenvolvimento de massas de revestimento cerâmico com argila caulinítica e nefelina sienito. Cerâmica 2008, 54, 184–192. [Google Scholar] [CrossRef]

- Associação Brasileira de Normas Técnicas. NBR 5739 Concrete—Compression Test of Cylindrical Specimens; Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2018; p. 9. [Google Scholar]

- Scrivener, K.L.; Snellings, R.; Lothenbach, B. A Practical Guide to Microstructural Analysis of Cementitious Materials; Taylor and Francis Ltd.: Abingdon, UK, 2016. [Google Scholar]

- Zhang, J.; Scherer, G.W. Comparison of methods for arresting hydration of cement. Cem. Concr. Res. 2011, 41, 1024–1036. [Google Scholar] [CrossRef]

- Briki, Y.; Zajac, M.; Ben Haha, M.; Scrivener, K. Impact of limestone fineness on cement hydration at early age. Cem. Concr. Res. 2021, 147, 106515. [Google Scholar] [CrossRef]

- Rodriguez, C.; Tobon, J.I. Influence of calcined clay/limestone, sulfate and clinker proportions on cement performance. Constr. Build. Mater. 2020, 251, 119050. [Google Scholar] [CrossRef]

- ISO 14044; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2006; p. 46.

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006; p. 20.

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Bare, J. TRACI 2.0: The tool for the reduction and assessment of chemical and other environmental impacts 2.0. Clean. Technol. Environ. Policy 2011, 13, 687–696. [Google Scholar] [CrossRef]

- Rodrigues, P.; Silvestre, J.D.; Flores-Colen, I.; Viegas, C.A.; De Brito, J.; Kurad, R.; Demertzi, M. Methodology for the Assessment of the Ecotoxicological Potential of Construction Materials. Materials 2017, 10, 649. [Google Scholar] [CrossRef]

- Kurda, R.; Silvestre, J.D.; de Brito, J. Life cycle assessment of concrete made with high volume of recycled concrete aggregates and fly ash. Resour. Conserv. Recycl. 2018, 139, 407–417. [Google Scholar] [CrossRef]

- Ryberg, M.; Vieira, M.D.M.; Zgola, M.; Bare, J.; Rosenbaum, R.K. Updated US and Canadian normalization factors for TRACI 2.1. Clean. Technol. Environ. Policy 2014, 16, 329–339. [Google Scholar] [CrossRef]

- Ghirardi, G.C. Avaliação das Propriedades da Argamassa Autoadensável com Incorporação de Resíduo de Serragem de Mármore Bege Bahia; Centro Universitário SENAI CIMATEC: Salvador, Brazil, 2020. [Google Scholar]

- Souza, A.J.; Pinheiro, B.C.A.; Holanda, J.N.F. Influência da incorporação de resíduo de rocha ornamental sobre as propriedades e microestrutura sinterizada de piso cerâmico. Matéria 2013, 18, 19–28. [Google Scholar] [CrossRef]

- Baltar, C.A.M.; Bastos, F.d.F.; da Luz, A.B. Gipsita. In Rochas e Minerais Industriais: Usos e Especificações; da Luz, A.B., Lins, F.A.F., Eds.; CETEM/MCT: Rio de Janeiro, Brazil, 2005; pp. 449–470. [Google Scholar]

- Sampaio, J.A.; de Almeida, S.L.M. Calcário e dolomito. In Rochas e Minerais Industriais no Brasil: Usos e Especificações, 2nd ed.; CETEM/MCTI: Rio de Janeiro, Brazil, 2008; pp. 363–387. [Google Scholar]

- Chotoli, F.F. Obtenção de Clínquer de Cimento a Partir da Escória de Aciaria a Oxigênio: Estudo em Escala Laboratorial; Instituto de Pesquisas Tecnológicas do Estado de São Paulo: São Paulo, Brazil, 2006. [Google Scholar]

- Centurione, S.L. Influência das Características das Matérias-Primas no Processo de Sinterização do Clínquer Portland; Universidade de São Paulo (USP): São Paulo, Brazil, 1993. [Google Scholar]

- NBR 16697; Cimento Portland—Requisitos. Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2018; p. 12.

- De Weerdt, K.; Ben Haha, M.; Le Saout, G.; Kjellsen, K.; Justnes, H.; Lothenbach, B. Hydration mechanisms of ternary Portland cements containing limestone powder and fly ash. Cem. Concr. Res. 2011, 41, 279–291. [Google Scholar] [CrossRef]

- Francioso, V.; Lopez-Arias, M.; Moro, C.; Jung, N.; Velay-Lizancos, M. Impact of Curing Temperature on the Life Cycle Assessment of Sugarcane Bagasse Ash as a Partial Replacement of Cement in Mortars. Sustainability 2023, 15, 142. [Google Scholar] [CrossRef]

- Benachio, G.L.F.; Freitas, M.D.C.D.; Tavares, S.F. Circular economy in the construction industry: A systematic literature review. J. Clean. Prod. 2020, 260, 121046. [Google Scholar] [CrossRef]

- Guerra, B.C.; Shahi, S.; Mollaei, A.; Skaf, N.; Weber, O.; Leite, F.; Haas, C. Circular economy applications in the construction industry: A global scan of trends and opportunities. J. Clean. Prod. 2021, 324, 129125. [Google Scholar] [CrossRef]

- Kalmykova, Y.; Sadagopan, M.; Rosado, L. Circular economy—From review of theories and practices to development of implementation tools. Resour. Conserv. Recycl. 2018, 135, 190–201. [Google Scholar] [CrossRef]

- Duran, X.; Lenihan, H.; O’regan, B. A model for assessing the economic viability of construction and demolition waste recycling—The case of Ireland. Resour. Conserv. Recycl. 2006, 46, 302–320. [Google Scholar] [CrossRef]

- Scannell, Y. The Regulation of Mining and Mining Waste in the European Union. Wash. Lee J. Energy Clim. Env’t. 2012, 3, 177. Available online: https://scholarlycommons.law.wlu.edu/jece/vol3/iss2/3 (accessed on 31 October 2022).

- Sáez, P.V.; Osmani, M. A diagnosis of construction and demolition waste generation and recovery practice in the European Union. J. Clean. Prod. 2019, 241, 118400. [Google Scholar] [CrossRef]

| Mineral Phases | Formula |

|---|---|

| C3S (Alite) | |

| C2S (Belite) | |

| C3A (Tricalcium aluminate) | |

| C4AF (Ferrite) |

| BB | Limestone | Clay | Copper Slag | Calcium Sulfate | |

|---|---|---|---|---|---|

| Chemical composition (%) | |||||

| CaO | 52.99 | 46.76 | 0.38 | 3.10 | 33.96 |

| SiO2 | 2.98 | 10.81 | 47.81 | 25.07 | 2.92 |

| Al2O3 | 0.4 | 3.29 | 33.57 | 6.55 | 1.03 |

| Fe2O3 | 0.17 | 1.22 | 2.32 | 55.58 | 0.58 |

| MgO | 2.02 | 2.02 | 1.16 | 1.23 | 0.00 |

| K2O | 0.08 | 0.99 | 3.83 | 0.65 | 0.21 |

| TiO2 | 0.0 | 0.17 | 0.2 | 0.00 | 0.00 |

| SO3 | 0.19 | 0.33 | 0.07 | 2.96 | 38.42 |

| Others | 0.02 | 0.0 | 0.2 | 4.76 | 1.91 |

| Loss of Ignition (LOI) | 44.14 | 34.11 | 10.46 | 0.1 | 20.98 |

| Physical properties | |||||

| Skeletal Density (g/cm3) | 2.69 | 2.71 | 2.73 | 4.00 | 2.45 |

| Specific surface area (BET) (m2/g) | 5.47 | 5.35 | 14.95 | 1.77 | 15.09 |

| Mineralogical composition (m%) | |||||

| Anhydrite (CaSO4) | 0.84 | ||||

| Bassanite (CaSO4.0.5H2O) | 4.04 | ||||

| Calcite (CACO3) | 91.02 | 85.88 | |||

| Kaolinite (Al2Si2O5(OH)4) | 73.67 | ||||

| Dolomite [CaMg(CO3)2] | 6.5 | 5.37 | |||

| Fayalite (Fe2SiO4) | 100 * | ||||

| Gypsum (CaSO4.H2O) | 93.70 | ||||

| Illite/Muscovite (K,H3O)(Al,Mg,Fe)2(Si,Al)4 O10[(OH)2,H2O)] (KAl2O10(OH,F)2) | 11.75 | ||||

| Microcline (K(AlSi3O8)) | 7.04 | ||||

| Quartz (SiO2) | 2.48 | 8.75 | 7.55 | 1.42 | |

| BB49-L35 | BB77-L03 | BB80-L00 | |

|---|---|---|---|

| Cement raw meal composition (%) | |||

| BB | 49.20 | 77.00 | 80.30 |

| Limestone | 35.60 | 03.50 | 00.00 |

| Clay | 10.70 | 13.50 | 14.50 |

| Slag | 4.40 | 6.00 | 5.20 |

| Values for LSF, SM, and AM | |||

| Lime Saturation Factor (LSF) | 98.00 | 98.00 | 98.00 |

| Silica Modulos (SM) | 1.35 | 1.13 | 1.16 |

| Alumina Modulus (AM) | 1.63 | 1.40 | 1.63 |

| Potential mineralogical composition (Bogue) (m%) | |||

| Alite (C3S) | 54.57 | 57.11 | 51.02 |

| Belite (C2S) | 10.09 | 10.21 | 11.41 |

| Tricalcium aluminate (C3A) | 13.50 | 12.90 | 15.01 |

| Ferrite (C4AF) | 15.63 | 19.44 | 17.38 |

| CLIN-COM | BB49-L35 | BB77-L03 | BB80-L00 | |

|---|---|---|---|---|

| Alite (C3S) | 69.14 | 44.10 | 63.92 | 64.34 |

| Belite (C2S) | 10.83 | 31.70 | 12.45 | 11.46 |

| Tricalcium aluminate (C3A) | 1.41 | 4.69 | 3.42 | 3.78 |

| Ferrite (C4AF) | 13.78 | 14.46 | 18.07 | 17.67 |

| Lime (CaO) | 0.67 | 0.11 | 0.11 | 0.26 |

| Periclase (MgO) | 4.17 | 4.96 | 2.05 | 2.52 |

| Notation | Type of Clinker |

|---|---|

| CLIN-COM-LF | Commercial clinker |

| BB77-L03-LF | Produced with limestone (3.5%), BB (77%), clay, and copper slag |

| BB80-L00-LF | Produced with BB (80%), clay, and copper slag |

| LF = Limestone Filler |

| CLIN-COM-LF | BB77-L03-LF | BB80-L00-LF | |||

|---|---|---|---|---|---|

| Chemical composition (%) | Obtained | Expected | Obtained | Expected | |

| CaO | 56.35 | 54.87 | 57.42 | 56.69 | 57.34 |

| SiO2 | 18.04 | 18.22 | 15.18 | 18.46 | 15.17 |

| Al2O3 | 3.84 | 8.50 | 2.83 | 6.63 | 2.82 |

| Fe2O3 | 2.62 | 5.40 | 6.90 | 4.69 | 6.90 |

| MgO | 3.17 | 2.75 | 0.86 | 2.86 | 0.86 |

| K2O | 1.25 | 0.73 | 4.29 | 0.75 | 4.29 |

| TiO2 | 0.19 | 0.18 | 0.81 | 0.17 | 0.81 |

| SO3 | 3.31 | 2.45 | 1.92 | 2.46 | 1.83 |

| Others | 0.59 | 0.62 | 0.09 | 0.49 | 0.09 |

| Loss on Ignition (LOI) | 11.26 | 9.14 | 9.71 | 10.34 | 9.89 |

| Physical property | |||||

| Skeletal Density (g/cm3) | 2.58 | 2.67 | - | 2.63 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Batalha Vieira, L.; Francioso, V.; Bueno Mariani, B.; Moro, C.; Dantas Viana Barbosa, J.; da Silva Paes Cardoso, L.; Ribeiro Dias, C.M.; Velay-Lizancos, M. Valorization of Marble Waste Powder as a Replacement for Limestone in Clinker Production: Technical, Environmental and Economic Evaluation. Sustainability 2023, 15, 13902. https://doi.org/10.3390/su151813902

Batalha Vieira L, Francioso V, Bueno Mariani B, Moro C, Dantas Viana Barbosa J, da Silva Paes Cardoso L, Ribeiro Dias CM, Velay-Lizancos M. Valorization of Marble Waste Powder as a Replacement for Limestone in Clinker Production: Technical, Environmental and Economic Evaluation. Sustainability. 2023; 15(18):13902. https://doi.org/10.3390/su151813902

Chicago/Turabian StyleBatalha Vieira, Luara, Vito Francioso, Bruna Bueno Mariani, Carlos Moro, Josiane Dantas Viana Barbosa, Larissa da Silva Paes Cardoso, Cleber Marcos Ribeiro Dias, and Mirian Velay-Lizancos. 2023. "Valorization of Marble Waste Powder as a Replacement for Limestone in Clinker Production: Technical, Environmental and Economic Evaluation" Sustainability 15, no. 18: 13902. https://doi.org/10.3390/su151813902

APA StyleBatalha Vieira, L., Francioso, V., Bueno Mariani, B., Moro, C., Dantas Viana Barbosa, J., da Silva Paes Cardoso, L., Ribeiro Dias, C. M., & Velay-Lizancos, M. (2023). Valorization of Marble Waste Powder as a Replacement for Limestone in Clinker Production: Technical, Environmental and Economic Evaluation. Sustainability, 15(18), 13902. https://doi.org/10.3390/su151813902