Cyclic Fatigue Durability of Woven Geotextiles for Use in Sustainable Waste-Dewatering Systems

Abstract

:1. Introduction

1.1. Initial Concepts

1.2. Cyclic Fatigue in Waste Containment Systems

2. Materials and Methods

2.1. Tested Geotextile

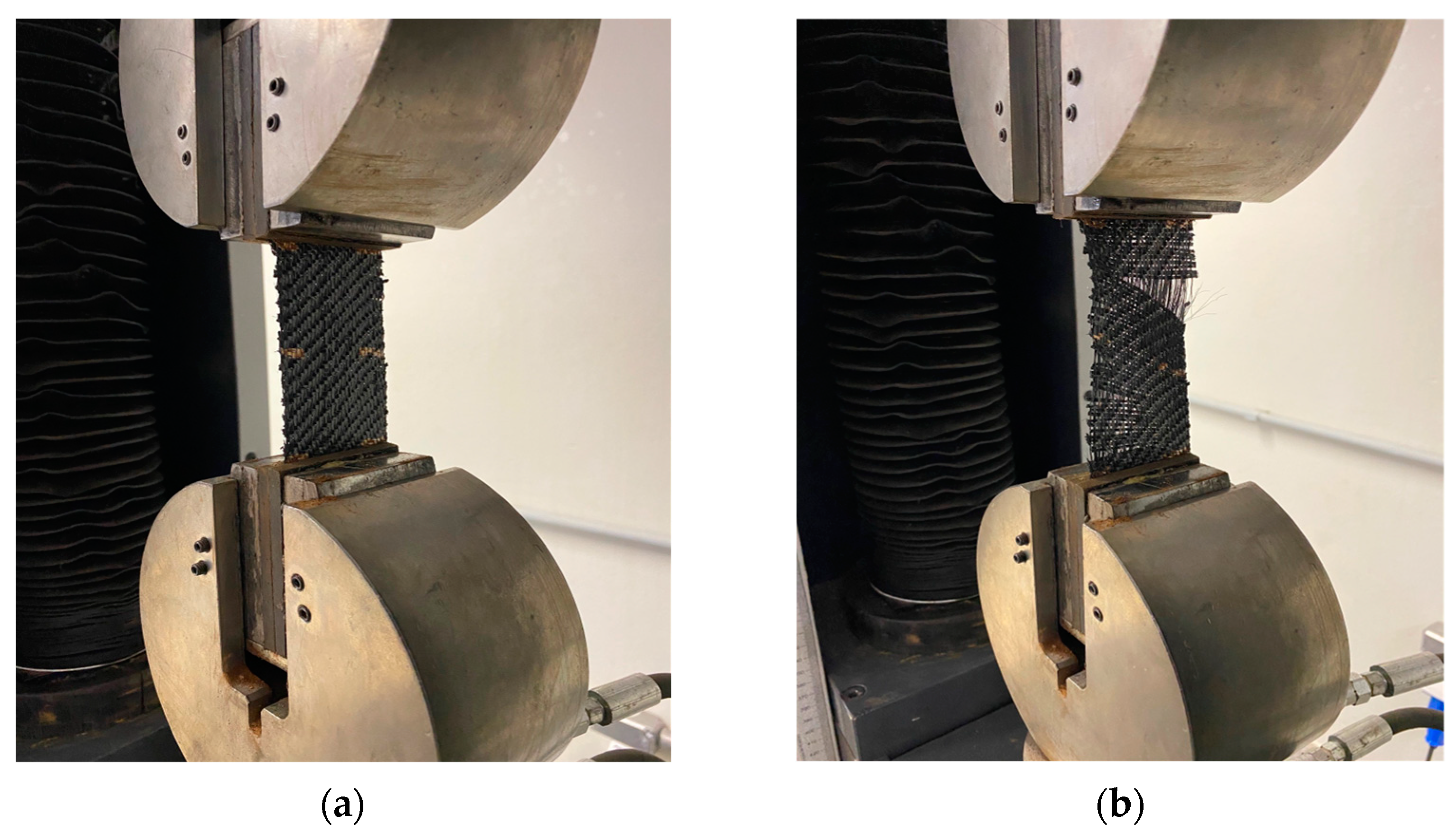

2.2. Cyclic Fatigue Tests

3. Results and Discussion

3.1. Statistical Analyses of Cyclic Fatigue Tests

3.1.1. Box Plot Analyses

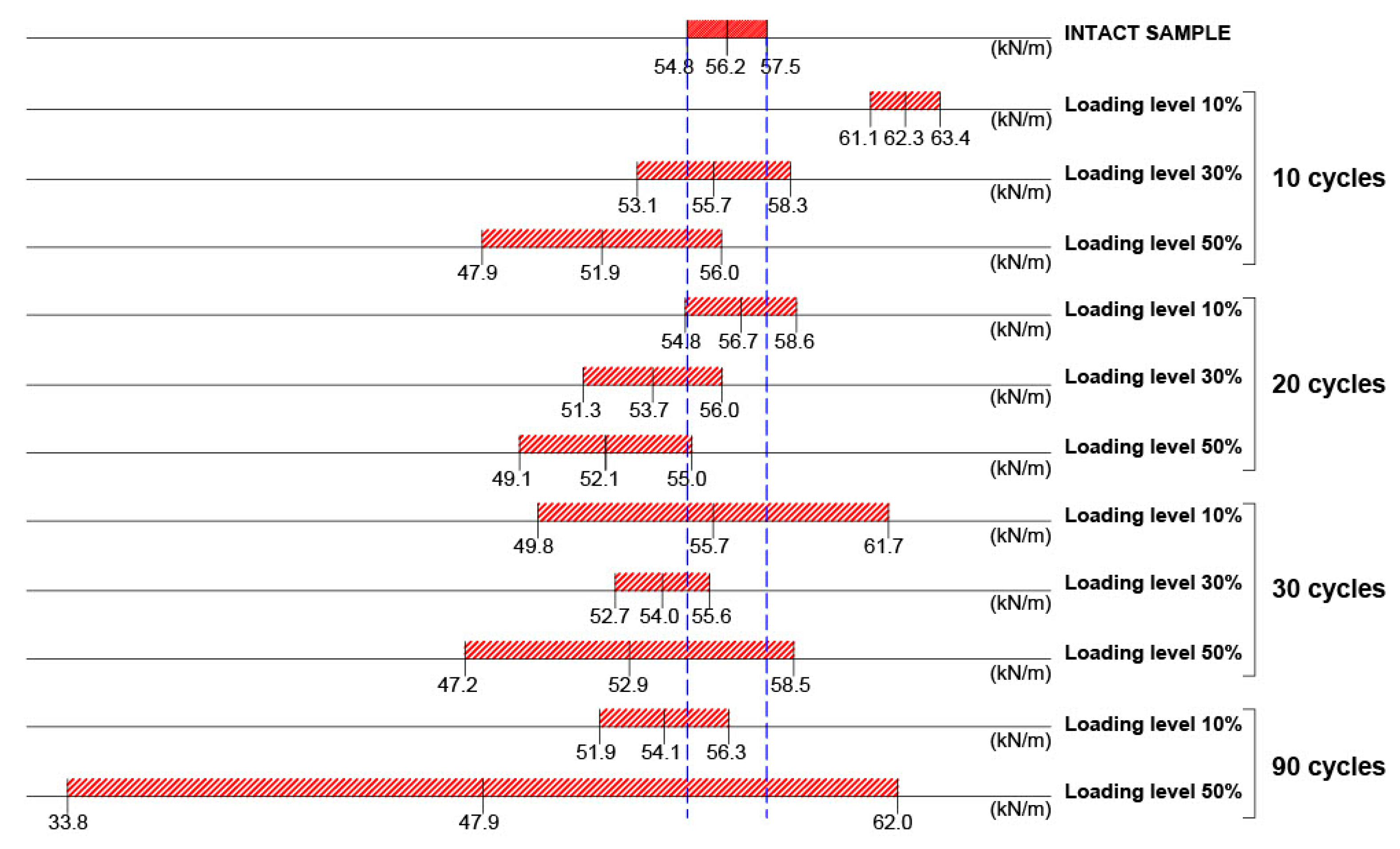

3.1.2. Confidence Interval Analyses

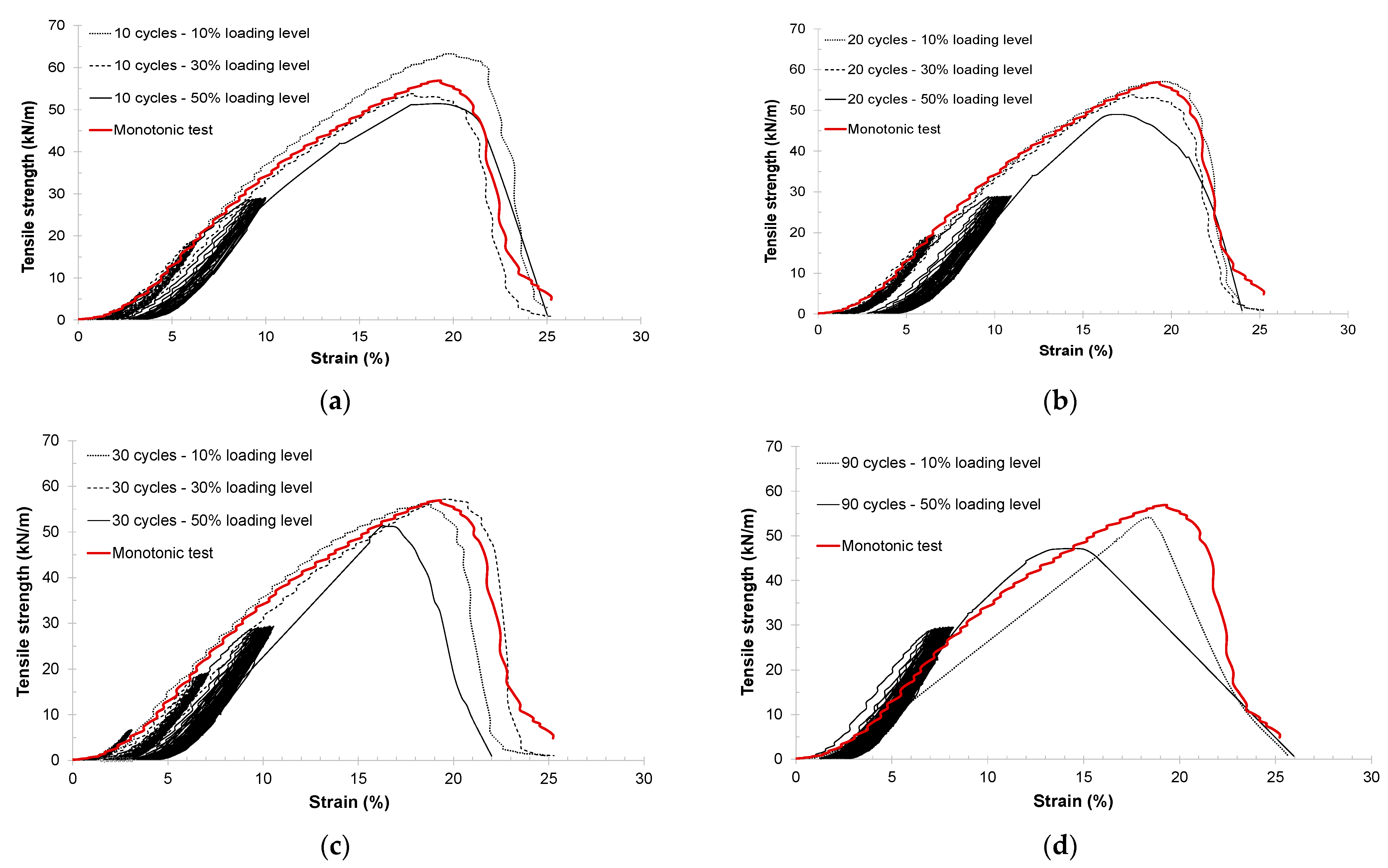

3.2. Tensile Strength in Monotonic and Cyclic Fatigue Tests

3.3. Hysteretic Stiffness under Cyclic Fatigue Tests

3.4. Mathematical Model for the Behavior of Woven Geotextile Using Cyclic Fatigue Tests

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| ρA | Mass per unit area (kg/m2) |

| µ | Populational average (kN/m) |

| d | Thickness (m) |

| Tmax | Ultimate tensile strength (kN/m) |

| Ɛmax | Strain at ultimate tensile (%) |

| GTXw | Woven geotextile |

| Jh | Hysteretic stiffness |

| R2 | Coefficient of determination (dimensionless) |

| RFp | Partial reduction factor |

| CIs | Confidence Intervals |

| UN | United Nations |

| WCDE | World Commission on Environment and Development |

| WCSs | Waste Containment Systems |

| WTPs | Water Treatment Plants |

| WWTPs | Wastewater Treatment Plants |

References

- Biermann, F. The future of ‘environmental’ policy in the Anthropocene: Time for a paradigm shirf. Environ. Polit. 2021, 30, 61–80. [Google Scholar] [CrossRef]

- Dixon, N.; Fowmes, G.; Frost, M. Global challenges, geosynthetics solutions and counting carbon. Geosynth. Int. 2017, 24, 451–464. [Google Scholar] [CrossRef]

- Palmeira, E.M.; Araújo, G.L.S.; Santos, E.C.G. Sustainable solutions with geosynthetics and alternative construction materials—A review. Sustainability 2021, 13, 12756. [Google Scholar] [CrossRef]

- Rimoldi, P.; Shamrock, J.; Kawalec, J.; Touze, N. Sustainable use of geosynthetics in dykes. Sustainability 2021, 13, 4445. [Google Scholar] [CrossRef]

- Touze, N. Healing the world: A geosynthetics solution. Geosynth. Int. 2021, 28, 1–31. [Google Scholar] [CrossRef]

- Tseng, I.-F.; Hsu, C.-H.; Cheng, H.-C.; Chen, Y.-S. Application of geotextile tubes to coastal silt mitigation: A case study in Niaoyu Fishing Harbor. Sustainability 2023, 15, 32024. [Google Scholar] [CrossRef]

- Dabrowska, J.; Kiersnowska, A.; Zieba, Z.; Trach, Y. Sustainability of geosynthetics-based solutions. Environments 2023, 10, 64. [Google Scholar] [CrossRef]

- United Nations World Commission on Environment and Development. Report of the World Commission on Environment and Development: Our Common Future; Oxford University Press: Oxford, UK, 1987; 300p. [Google Scholar]

- Le, P.G.; Le, H.A.; Dinh, X.T.; Nguyen, K.L.P. Development of sustainability assessment criteria in selection of municipal solid waste treatment technology in developing countries: A case of Ho Chi Minh City, Vietnam. Sustainability 2023, 15, 7917. [Google Scholar] [CrossRef]

- Yee, T.W.; Lawson, C.R. Modelling the geotextile tube dewatering process. Geosynth. Int. 2012, 19, 339–353. [Google Scholar] [CrossRef]

- United Nations. Transforming Our World: The 2030 Agenda for Sustainable Development. Document A/RES/70/1; UN: New York, NY, USA, 2015. [Google Scholar]

- Baste, I.A.; Watson, R.T. Tackling the climate, biodiversity and pollution emergencies by making peace with nature 50 years after the Stockholm Conference. Glob. Environ. Chang. 2022, 73, 102466. [Google Scholar] [CrossRef]

- ISO 37120:2018; Sustainable Cities and Communities—Indicators for City Services and Quality of Life. International Organization for Standardization: Geneva, Switzerland, 2018.

- Fowler, J.; Duke, M.; Schmidt, M.L.; Crabtree, B.; Bagbby, R.M.; Etrainer, E. Dewatering sewage sludge and hazardous sludge with geotextile tubes. In Proceedings of the 7th International Conference on Geosynthetics, 7ICG, Nice, France, 22–27 September 2002. [Google Scholar]

- Lawson, C.R. Geotextile containment for hydraulic and environmental engineering. Geosynth. Int. 2008, 15, 384–427. [Google Scholar] [CrossRef]

- Perkins, S.W. Constitutive modeling of geosynthetics. Geotext. Geomembr. 2000, 18, 273–292. [Google Scholar] [CrossRef]

- Maxwell, A.S.; Broughton, W.R.; Dean, G.; Sims, G.D. Review of Accelerated Ageing Methods and Lifetime Prediction Techniques for Polymeric Materials; NPL Report DEPC MPR 016; National Physical Laboratory: Teddington, UK, 2005; 84p. [Google Scholar]

- Allen, S.R. Geotextile durability. In Geotextiles: From Design to Applications; Koerner, R.M., Ed.; Woodhead Publishing: Cambridge, UK, 2016; pp. 177–215. [Google Scholar]

- Cardile, G.; Moraci, N.; Pisano, M. Tensile behaviour of an HDPE geogrid under cyclic loading: Experimental results and empirical modelling. Geosynth. Int. 2017, 24, 95–112. [Google Scholar] [CrossRef]

- Ardila, M.A.A.; Souza, S.T.; Silva, J.L.; Valentin, C.A.; Dantas, A.D.B. Geotextile tube dewatering performance assessment: An experimental study of sludge dewatering generated at a water treatment plant. Sustainability 2020, 12, 98129. [Google Scholar] [CrossRef]

- Guimarães, M.G.A.; Urashima, D.C.; Vidal, D.M. Dewatering of sludge from a water treatment plant in geotextile closed systems. Geosynth. Int. 2014, 21, 310–320. [Google Scholar] [CrossRef]

- Fowler, J.; Larkins, K.; Duke, M.L. Dredging Aerobic Digested Biosolids into Geotextile Tubes for Dewatering; New Orleans East Municipal Sewage Treatment Plant: New Orleans, LA, USA, 2005. [Google Scholar]

- Jiang, Y.; Liu, Z.; Cui, M.; Su, R.; Liu, Z.; Zhang, J.; Huang, R. Risk Assessment and treatment of the heavy metals contaminated sediments via stabilisation and dewatering in geotextile tubes. Chem. Eng. Trans. 2020, 81, 241–246. [Google Scholar] [CrossRef]

- Castro, N.P.B.; Melo, L.C.Q.C.; Escobar, L.G.B. Environmental integrated solution for septic tank sludge and landfill leachate using geotextile tubes dewatering technology. In Proceedings of the First Pan American Geosynthetics Conference & Exhibition, GeoAmericas 2008, Cancun, Mexico, 2–5 March 2008. [Google Scholar]

- Ruiz, N.R.; Rendón, M. Geotextile tubes in sludge confinement and dewatering applications at Eldorado International Airport. In Proceedings of the Second Pan American Geosynthetics Conference & Exhibition, GeoAmericas 2012, Lima, Peru, 6–9 May 2012. [Google Scholar]

- Guanaes, E.A.; Sampaio, D.V. Recent applications of geotextile tubes for sludge and slurry dewatering—Brazil. In Proceedings of the Second Pan American Geosynthetics Conference & Exhibition, GeoAmericas 2012, Lima, Peru, 6–9 May 2012. [Google Scholar]

- Yee, T.W.; Lawson, C.R.; Wang, Z.Y.; Ding, L.; Liu, Y. Geotextile tube dewatering of contaminated sediments, Tianjin Eco-City, China. Geotext. Geomembr. 2012, 31, 39–50. [Google Scholar] [CrossRef]

- Berg, G.V.D.; Oliveira, F.A.P. Adequacy of geotextile tube dewatering in three river remediation scenarios. WIT Trans. Ecol. Environ. 2019, 234, 155–165. [Google Scholar] [CrossRef]

- Yang, Y.; Wei, Z.; Cao, G.; Yang, Y.; Wang, H.; Zhuang, S. A case study on utilizing geotextile tubes for tailings dams construction in China. Geotext. Geomembr. 2019, 47, 187–192. [Google Scholar] [CrossRef]

- Kiffle, Z.B.; Bhatia, S.K.; Lebster, G.E. Dewatering of mine tailing slurries using geotextile tube: Case histories. Int. J. Geosynth. Ground Eng. 2023, 9, 10. [Google Scholar] [CrossRef]

- Wilke, M.; Breytenbach, M.; Reunanen, J.; Hilla, V.M. Efficient and environmentally sustainable tailings treatment and storage by geosynthetic dewatering tubes: Working principles and Talvivaara case study. In Proceedings of the Tailings and Mine Waste, Vancouver, BC, Canada, 26–28 October 2015. [Google Scholar]

- Lopes, M.P.; Lopes, M.L. The Durability of Geosynthetics; FEUP Edições: Porto, Portugal, 2010; 294p. (In Portuguese) [Google Scholar]

- Greenwood, J.H.; Schroeder, H.F.; Voskamp, W. Durability of Geosynthetics; CUR Committee C 187-Building & Infrastructure: Gouda, The Netherlands, 2012; 295p. [Google Scholar]

- ASTM D 5819:2022; Standard Guide for Selectiong Test Methods for Experimental Evaluation of Geosynthetics Durability. American Society for Testing and Materials. ASTM International: West Conshohocken, PA, USA, 2022.

- ISO/TS 13434:2020; Geosynthetics: Guidelines for the Assessment of Durability. International Organization for Standardization: Geneva, Switzerland, 2020.

- Bezuijen, A.; Vastenburg, E.W. Design Rules and Applications; CRC Press: Deltares, MD, USA, 2013; 166p. [Google Scholar]

- Vieira, C.S.; Lopes, M.L. Effects of the loading rate and cyclic loading on the strength and deformation properties of a geosynthetics. Constr. Build. Mater. 2013, 49, 758–765. [Google Scholar] [CrossRef]

- Perkins, S.W.; Haselton, H.N. Resilient response of geosynthetics from cyclic and sustained in-air tensile loading. Geosynth. Int. 2019, 26, 428–435. [Google Scholar] [CrossRef]

- Grubb, D.G.; Diesing, W.E., III; Cheng, S.C.J.; Sabanas, R.M. Comparison of geotextile durability to outdoor exposure conditions in the Peruvian Andes and Southeastern USA. Geosynth. Int. 2000, 7, 23–45. [Google Scholar] [CrossRef]

- Grubb, D.G.; Diesing, W.E., III; Cheng, S.C.J.; Sabanas, R.M. Comparison of the durability of geotextiles in an alkaline mine tailings environment. Geosynth. Int. 2001, 8, 49–80. [Google Scholar] [CrossRef]

- Barrentes, M.A.V.; Ribeiro, L.F.M.; Palmeira, E.M. Influence of the filling process on the behaviour of geotextile tubes. Soils Rock. 2023, 46, e2023010522. [Google Scholar] [CrossRef]

- Leshchinsky, D.; Leshchinsky, O.; Ling, H.I.; Gilbert, P.A. Geosynthetic Tubes for Confining Pressurized Slurry: Some Design Aspects. J. Geotech. Geoenviron. 1996, 122, 682–690. [Google Scholar] [CrossRef]

- Assinder, P.J.; Breytenbach, M.; Wiemers, J.; Hortkorn, F. Utilizing geotextile tubes to extend the life of a Tailings Storage Facility. In Proceedings of the First South African Geotechnical Conference, Sun City, South Africa, 5–6 May 2016. [Google Scholar]

- Cooke, T.; Rebenfeld, L. Effect of Chemical composition and physical structure of geotextiles on their durability. Geotext. Geomembr. 1988, 7, 7–22. [Google Scholar] [CrossRef]

- Fourie, A.B.; Kuchena, S.M. The influence of tensile stresses on the filtration characteristics of geotextiles. Geosynth. Int. 1995, 2, 455–471. [Google Scholar] [CrossRef]

- Fourie, A.B.; Addis, P.C. Changes in filtration opening size of woven geotextiles subjected to tensile loads. Geotext. Geomembr. 1999, 17, 331–340. [Google Scholar] [CrossRef]

- Wu, C.S.; Hong, Y.S.; Wang, R.H. The influence of uniaxial tensile strain on the pore size and filtration characteristics of geotextiles. Geotext. Geomembr. 2008, 26, 250–262. [Google Scholar] [CrossRef]

- Palmeira, E.M.; Melo, D.L.A.; Moraes-Filho, I.P. Geotextile filtration opening size under tension and confinement. Geotext. Geomembr. 2019, 47, 566–576. [Google Scholar] [CrossRef]

- Bathurst, R.J.; Cai, Z. In-isolation cyclic load-extension behaviour of two geogrids. Geosynth. Int. 1994, 1, 1–19. [Google Scholar] [CrossRef]

- Ashmawy, A.K.; Bourdeau, P.L. Response of a woven and a nonwoven geotextile to monotonic and cyclic simple tension. Geosynth. Int. 1996, 3, 496–515. [Google Scholar] [CrossRef]

- Kongkitkul, W.; Hirakawa, D.; Tatsuoka, F.; Uchimura, T. Viscous deformation of geosynthetic reinforcement under cyclic loading conditions and its model simulation. Geosynth. Int. 2004, 11, 73–99. [Google Scholar] [CrossRef]

- Moraci, N.; Cardile, G. Influence of cyclic tensile loading on pullout resistance of geogrids embedded in a compacted granular soil. Geotext. Geomembr. 2009, 27, 475–487. [Google Scholar] [CrossRef]

- Zanzinger, H.; Hangen, H.; Alexiew, D. Fatigue behaviour of a PET-Geogrid under cyclic loading. Geotext. Geomembr. 2010, 28, 251–261. [Google Scholar] [CrossRef]

- Leonardi, G.; Lo Bosco, D.; Palamara, R.; Suraci, F. Finite element analysis of geogrid-stabilized unpaved roads. Sustainability 2020, 12, 51929. [Google Scholar] [CrossRef]

- Leonardi, G.; Suraci, F. A 3D-FE model for the rutting prediction in geogrid reinforced flexible pavements. Sustainability 2022, 14, 63695. [Google Scholar] [CrossRef]

- Minster, J. Prediction of long-term geosynthetic strength using cumulative damage theory. Geotext. Geomembr. 1986, 3, 77–88. [Google Scholar] [CrossRef]

- Liu, H.; Ling, H.I. Modeling cyclic behavior of geosynthetics using mathematical functions: Masing rule and bounding surface plasticity. Geosynth. Int. 2006, 13, 234–245. [Google Scholar] [CrossRef]

- ASTM D 7556:2019; Standard Test Methods for Determing Small-Strain Tensile Properties of Geogrids and Geotextiles by In-Air Cyclic Tension Tests. American Society for Testing and Materials, ASTM International: West Conshohocken, PA, USA, 2019.

- Koerner, R.M. Designing with Geosynthetics, 6th ed.; Xlibris Corporation: Bloomington, IN, USA, 2012; Volume 1, 526p. [Google Scholar]

- ISO 9862:2005; Geosynthetics—Sampling and Preparation of Test Specimens. International Organization for Standardization: Geneva, Switzerland, 2005.

- ASTM D 5035:2019; Standard Test Method for Breaking Force and Elongation of Textile Fabrics (Strip Method). American Society for Testing and Materials, ASTM International: West Conshohocken, PA, USA, 2019.

- ISO 9864:2005; Geosynthetics—Test Method for the Determination of Mass per Unit Area of Geotextiles and Geotextile-Related Products. International Organization for Standardization: Geneva, Switzerland, 2005.

- ISO 9863-1:2016; Geosynthetics—Determination of Thickness at Specified Pressures—Part 1: Single Layers. International Organization for Standardization: Geneva, Switzerland, 2016.

- ISO 10319:2015; Geosynthetics: Wide-Width Tensile Test. International Organization for Standardization: Geneva, Switzerland, 2015.

- Dias Filho, J.L.E.; Maia, P.C.A.; Xavier, G.C. A short-term model for extrapolating unconfined creep deformation data for woven geotextiles. Geotext. Geomembr. 2019, 47, 792–797. [Google Scholar] [CrossRef]

- Guimarães, M.G.A.; Vidal, D.M.; Urashima, D.C.; Castro, C.A.C. Degradation of polypropylene woven geotextile: Tensile creep and weathering. Geosynth. Int. 2017, 24, 213–223. [Google Scholar] [CrossRef]

- Urashima, B.M.C. Methodology for Determining the Failure Probability during the Geosynthetics’ Projects Service Life. Master’s Thesis, Master in Geotechnics, Federal University of Ouro Preto (NUGEO/EM/UFOP), Ouro Preto, Brazil, 30 May 2022. (In Portuguese). [Google Scholar]

- Montgomery, D.C. Design and Analysis of Experiments, 7th ed.; John Wiley & Sons Inc.: New York, NY, USA, 2008; 680p. [Google Scholar]

| Parameters | Standards | Value 3 |

|---|---|---|

| Mass per unit area (ρA) | ISO 9864 [62] | 271.8 g/m2 (3.2%) |

| Thickness (d) | ISO 9863-1 [63] | 0.97 mm (5.9%) |

| Ultimate tensile strength (Tmax) 1 | ASTM D 5035 [61] | 56.2 kN/m (3.6%) |

| Strain at ultimate tensile (Ɛmax) 1 | ASTM D 5035 [61] | 19.2% (4.0%) |

| Ultimate tensile strength (Tmax) 2 | ASTM D 5035 [61] | 60.6 kN/m (4.9%) |

| Strain at ultimate tensile (Ɛmax) 2 | ASTM D 5035 [61] | 16.9% (4.1%) |

| Cyclic Tensile Loading Levels (Setpoint) 1 | Number of Cycles | Maximum Load Applied (kN) |

|---|---|---|

| 10% | 10, 20, 30 and 90 | 0.281 |

| 30% 2 | 10, 20 and 30 | 0.843 |

| 50% | 10, 20, 30 and 90 | 1.405 |

| Number of Cycles | Cyclic Tensile Loading Levels (Setpoint) | Parameters 1 | Tensile Strength Loss (%) | Partial Reduction Factor (RFp) 2 | |

|---|---|---|---|---|---|

| Tmax (kN/m) | Ɛmax (%) | ||||

| 10 cycles | 10% | 62.3 (1.5%) | 20.0 (2.0%) | NA | 1.0 |

| 30% | 55.7 (3.8%) | 19.6 (5.3%) | 0.9 | 1.0 | |

| 50% | 51.9 (6.3%) | 18.8 (6.9%) | 7.7 | 1.1 | |

| 20 cycles | 10% | 56.7 (2.7%) | 19.9 (2.9%) | 0 | 1.0 |

| 30% | 53.7 (3.5%) | 18.6 (5.8%) | 4.4 | 1.0 | |

| 50% | 52.1 (4.6%) | 19.3 (10.0%) | 7.3 | 1.1 | |

| 30 cycles | 10% | 55.7 (8.6%) | 18.8 (8.8%) | 0.9 | 1.0 |

| 30% | 54.0 (2.4%) | 19.2 (3.6%) | 3.9 | 1.0 | |

| 50% | 52.9 (8.6%) | 17.4 (4.9%) | 5.9 | 1.1 | |

| 90 cycles | 10% | 54.1 (3.3%) | 18.7 (4.8%) | 3.7 | 1.0 |

| 30% | N/A | N/A | N/A | N/A | |

| 50% | 47.9 (23.8%) | 15.7 (25.1%) | 14.8 | 1.2 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guimarães, M.G.A.; Oliveira, P.V.G.d.; Urashima, D.d.C.; Pereira, E.L.; Urashima, B.M.C. Cyclic Fatigue Durability of Woven Geotextiles for Use in Sustainable Waste-Dewatering Systems. Sustainability 2023, 15, 13807. https://doi.org/10.3390/su151813807

Guimarães MGA, Oliveira PVGd, Urashima DdC, Pereira EL, Urashima BMC. Cyclic Fatigue Durability of Woven Geotextiles for Use in Sustainable Waste-Dewatering Systems. Sustainability. 2023; 15(18):13807. https://doi.org/10.3390/su151813807

Chicago/Turabian StyleGuimarães, Mag Geisielly Alves, Pedro Victor Garcia de Oliveira, Denise de Carvalho Urashima, Eleonardo Lucas Pereira, and Beatriz Mydori Carvalho Urashima. 2023. "Cyclic Fatigue Durability of Woven Geotextiles for Use in Sustainable Waste-Dewatering Systems" Sustainability 15, no. 18: 13807. https://doi.org/10.3390/su151813807

APA StyleGuimarães, M. G. A., Oliveira, P. V. G. d., Urashima, D. d. C., Pereira, E. L., & Urashima, B. M. C. (2023). Cyclic Fatigue Durability of Woven Geotextiles for Use in Sustainable Waste-Dewatering Systems. Sustainability, 15(18), 13807. https://doi.org/10.3390/su151813807