4.1. Carbon Emissions Decomposition Analysis

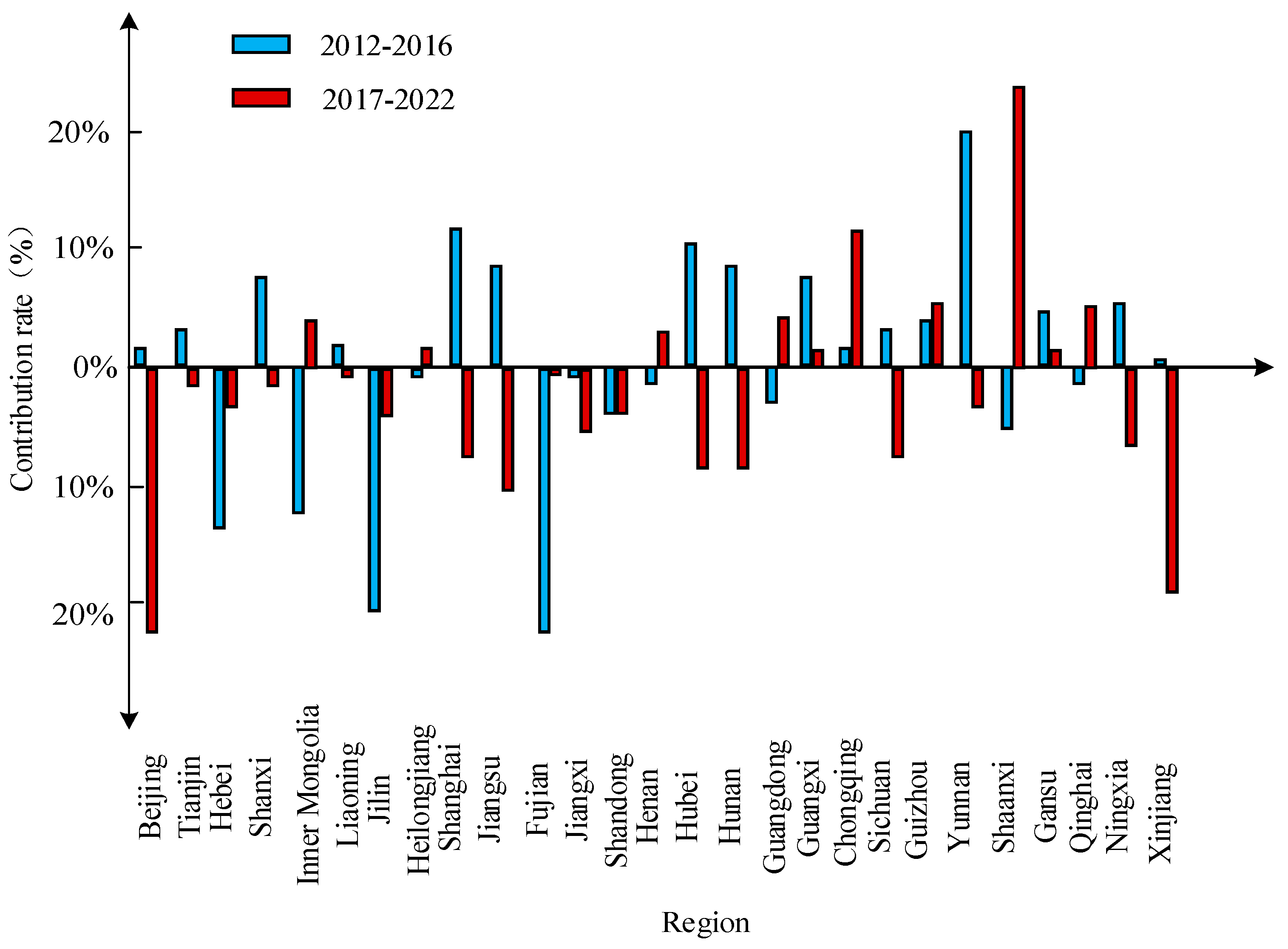

The study selected the period from 2012 to 2022 as the main data decomposition period, and the specific decomposition results for the period from 2012 to 2016 are shown in

Table 1.

In

Table 1, the change value of carbon emissions shows a gradual upward trend. Under this trend, the contribution rate of energy intensity shows an upward trend, while the contribution rate of economic scale shows a downward trend. The specific decomposition results for the period from 2017 to 2022 are shown in

Table 2.

In

Table 2, it is observed that an increase in economic scale leads to higher emissions, while a decrease in economic scale results in reduced carbon emissions. Specifically, the expansion of the non-ferrous metal industry has a significant impact on emissions. The proportion of this impact on the economic scale is the highest among all the years analyzed. Notably, in 2018, the carbon emissions attributed to the economic scale experienced the most substantial change, reaching 66,087,600 tons. On average, from 2012 to 2022, CO

2 emissions caused by the economic scale accounted for 63% of the total changes.

Table 3 presents the results of provincial regional decomposition from 2012 to 2016.

According to the data in

Table 3, changes in the economic scale are the key factor leading emissions increasing in most provinces of the country, and this situation exists in all provinces. The decomposition results of provincial-level regions from 2017 to 2022 are shown in

Table 4.

Table 3 and

Table 4 provide insights into the impact of economic scale and energy structure changes on carbon dioxide (CO

2) emissions across different years. When considering economic scale, the expansion in Henan province had the most significant effect on CO

2 emissions. Specifically, the industry’s expansion contributed to 260,836 tons and 43.8477 million tons of emissions, accounting for 75% and 69% of the total emission changes, respectively. The analysis also reveals substantial differences in the influence of changes in energy structure on carbon dioxide emissions among various provinces. Enhancing energy intensity plays a crucial role in reducing emissions and is one of the factors with the most substantial negative impact on carbon dioxide emissions. Additionally, the reduction of the carbon dioxide emission coefficient is another critical factor contributing to the decrease in carbon dioxide emissions.

Figure 5 visually represents the contribution rates of changes in carbon dioxide emissions across different regions in the non-ferrous metal industry.

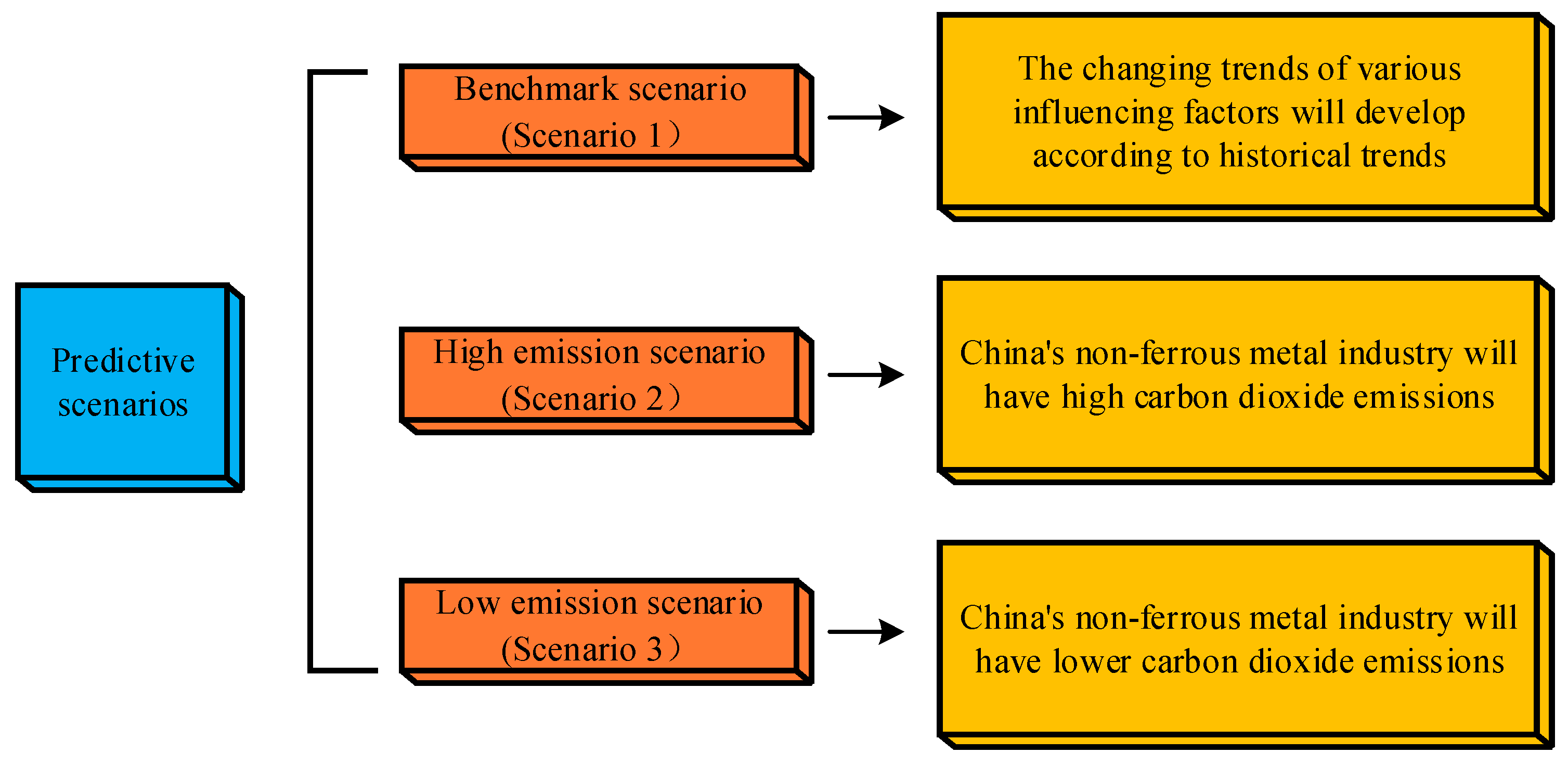

4.3. Carbon Emissions Prediction and Analysis in the Non-Ferrous Metal Industry

The carbon emission prediction analysis results under the first and second scenarios are shown in

Figure 6.

In the first scenario, based on the model’s prediction, carbon emissions are projected to increase by 1028.23 million tons by 2033 compared to the levels in 2022. This represents a significant growth rate of up to 245%. In the second scenario, assuming a two-percentage-point increase in the economic scale, energy intensity, power growth rate, and power emission coefficient of the non-ferrous metals industry compared to the original situation, the model calculates a considerable increase in carbon emissions. By 2033, carbon emissions are estimated to have risen by 1886.88 million tons compared to the growth observed in 2011, reflecting a growth rate of 449%. Conversely, if the economic scale, energy intensity, power growth rate, and power emission coefficient of the non-ferrous metals industry are two percentage points lower than the original situation, the model predicts a comparatively smaller increase in carbon emissions. By 2033, the carbon emissions are projected to rise by 502.08 million tons, or 119%, compared to the levels in 2022. A detailed comparison of the influence and variation values of each factor is provided in

Table 7.

Among the three scenarios, the expansion of the economic scale primarily drives the increase in carbon emissions. In Scenario 1, the contribution of the economic scale to the carbon emissions increase accounts for 75.28% of all factors. In Scenario 2 and Scenario 3, although the impact of the economic scale has increased and decreased, respectively, its contribution proportion among all factors remains significant at 87.46% and 65.21%, respectively. Both the energy structure and carbon emission coefficient have a modest, but positive, effect on reducing carbon dioxide emissions. However, their impact is relatively small. In all three scenarios, their contribution to total carbon emissions does not exceed 8%. To assess the feasibility of reducing carbon dioxide emissions in China’s non-ferrous metal industry, two scenarios have been formulated: a stable emission reduction scenario and a positive emission reduction scenario. The implementation of the stable emission reduction scenario would result in a shift from Scenario 2 to Scenario 1 in terms of carbon dioxide emissions in the non-ferrous metal industry. On the other hand, adopting the positive emission reduction scenario would lead to a shift from Scenario 2 to Scenario 3 in terms of emissions changes.

Table 8 presents the potential for emissions reduction in both scenarios.

As the carbon dioxide emission factor increases, the predicted carbon dioxide emissions by the model will also increase accordingly; this indicates that the model has a certain sensitivity to changes in carbon dioxide emission factors. As the energy intensity factor increases, the carbon dioxide emissions predicted by the model will also increase accordingly; this indicates that the model also has a certain sensitivity to changes in energy intensity factors. As the energy structure factor increases, the carbon dioxide emissions predicted by the model will decrease; this indicates that the model has a certain sensitivity to changes in energy structure factors. As the economic scale factor increases, the carbon dioxide emissions predicted by the model will increase; this indicates that the model has a certain sensitivity to changes in economic scale factors.

In

Table 9, the potential to reduce CO

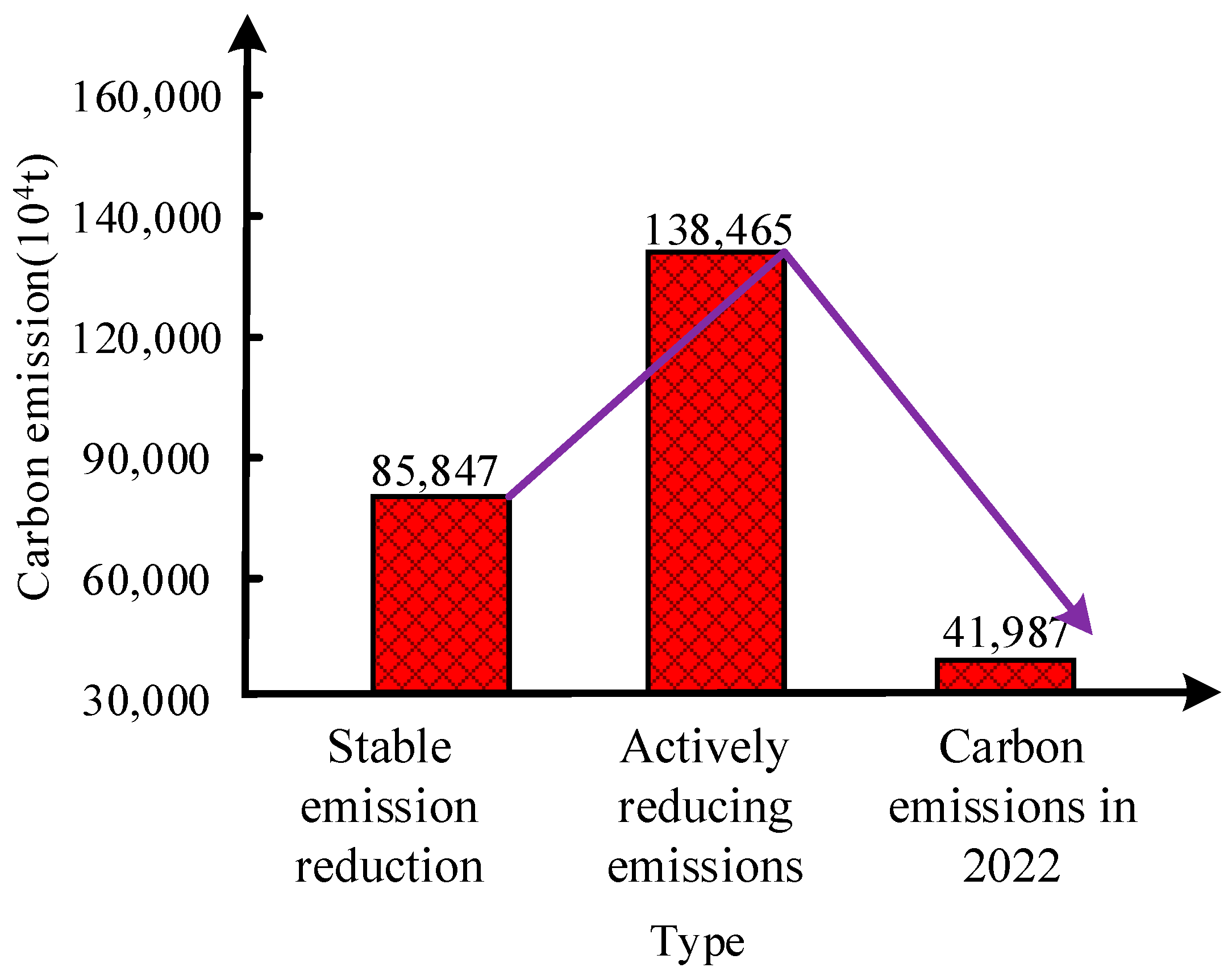

2 emissions in the future is very great. In the scenario of stable emission reduction, the industry’s emission reduction potential by 2033 is 858.47 million tons of standard coal, accounting for 59.29% of the total emissions that year. In the active emission reduction scenario, its potential will reach 1384.65 million tons of standard coal by 2033, which is 150.19% of the total emissions that year. The comparison between carbon emissions and predicted results in 2022 is shown in

Figure 7.

In the scenario of stable emission reduction, its future potential reaches 858.47 million tons, nearly twice the carbon dioxide emissions of 419.87 million tons in 2011. Under the active emission reduction scenario, its potential will reach 1384.65 million tons, nearly three times the emissions in 2011.

Based on the above research results, the following policy recommendations are proposed:

Optimize industrial structure. Encourage the upgrading of high-energy-consuming non-metallic industries and develop low-carbon, green, and circular economy industries. Through policy guidance, promote enterprises to transform and upgrade towards high-end, intelligent, and green directions; increase industrial added value; and reduce energy consumption and emission intensity.

Strengthen regional coordinated development. Based on the resource endowment, industrial foundation, and development potential of each region, formulate differentiated industrial policies to guide the concentration of funds, technology, and talent in advantageous regions. At the same time, strengthen cross-regional cooperation, achieve complementary advantages and share resources, and improve overall industrial competitiveness.

Improve energy efficiency. Promote advanced energy-saving technologies and equipment to reduce enterprise energy consumption. Implement an energy management system, strengthen energy supervision and assessment of enterprises, and ensure that they meet national and industry energy consumption standards. In addition, encourage enterprises to replace traditional energy with clean energy to reduce carbon emissions.

Establish a carbon emission trading market. By establishing a carbon emission trading market, companies are incentivized to reduce carbon emissions. The government can limit and manage emissions, and trade the remaining emission rights in the market. This can not only regulate the carbon emission behavior of enterprises, but also provide effective carbon reduction mechanisms for the market.

Strengthen the enforcement of environmental regulations. Strengthen environmental supervision of high-energy-consuming non-metallic industries and strictly implement environmental protection regulations. For enterprises that violate environmental regulations, their legal responsibilities should be pursued in accordance with the law, forming an effective deterrent effect. At the same time, encourage enterprises to take proactive environmental protection measures to reduce pollution emissions.

In summary, in order to achieve the sustainable development goal of China’s high-energy-consuming non-metallic industry, we need to start from optimizing industrial structure, strengthening regional coordinated development, improving energy utilization efficiency, establishing a carbon emission trading market, strengthening the enforcement of environmental regulations, etc., to formulate practical and feasible policies and measures to achieve emission reduction goals and promote the healthy development of the industry.

The Jiang T team pointed out that climate change will bring more uncertainty and risks to China’s agriculture. Therefore, a series of measures need to be taken to address climate change, including optimizing planting structures and developing adaptive crop varieties. This study focuses more on developing targeted emission reduction policies in the high-energy-consuming industry [

28]. The Yang C team studied the impact of urbanization on the environment in China and proposed a sustainable urbanization model, pointing out the need to establish a sustainable urbanization model, including promoting low-carbon city construction, strengthening garbage classification and treatment, and improving energy utilization efficiency. This study focuses on the specific development of industries in the process of urbanization, focusing on high-energy-consuming industries, and conducting targeted analysis [

29]. Hart S L proposed strategies to promote balanced development of international trade, pointing out the need to adopt a series of strategies, including strengthening intellectual property protection, promoting the construction of free trade zones, and strengthening regional economic cooperation [

30]. This study mainly focuses on the direction of industrial development, with a greater emphasis on formulating targeted emission reduction policies in high-energy-consuming industries. In summary, the advantages of this study compared to the above three literature studies are as follows: firstly, in-depth research was conducted on the special situation of the high-energy-consumption industry; secondly, the Logarithmic Mean Divisia Index model was used for empirical analysis, providing more accurate data support; finally, suggestions were put forward to formulate different emission reduction goals and policies for different situations, which have strong practicality and operability.