Mapping the Reality of Hg-Free Artisanal Small-Scale Gold Mining

Abstract

:1. Introduction

1.1. Artisanal Mining in Chile

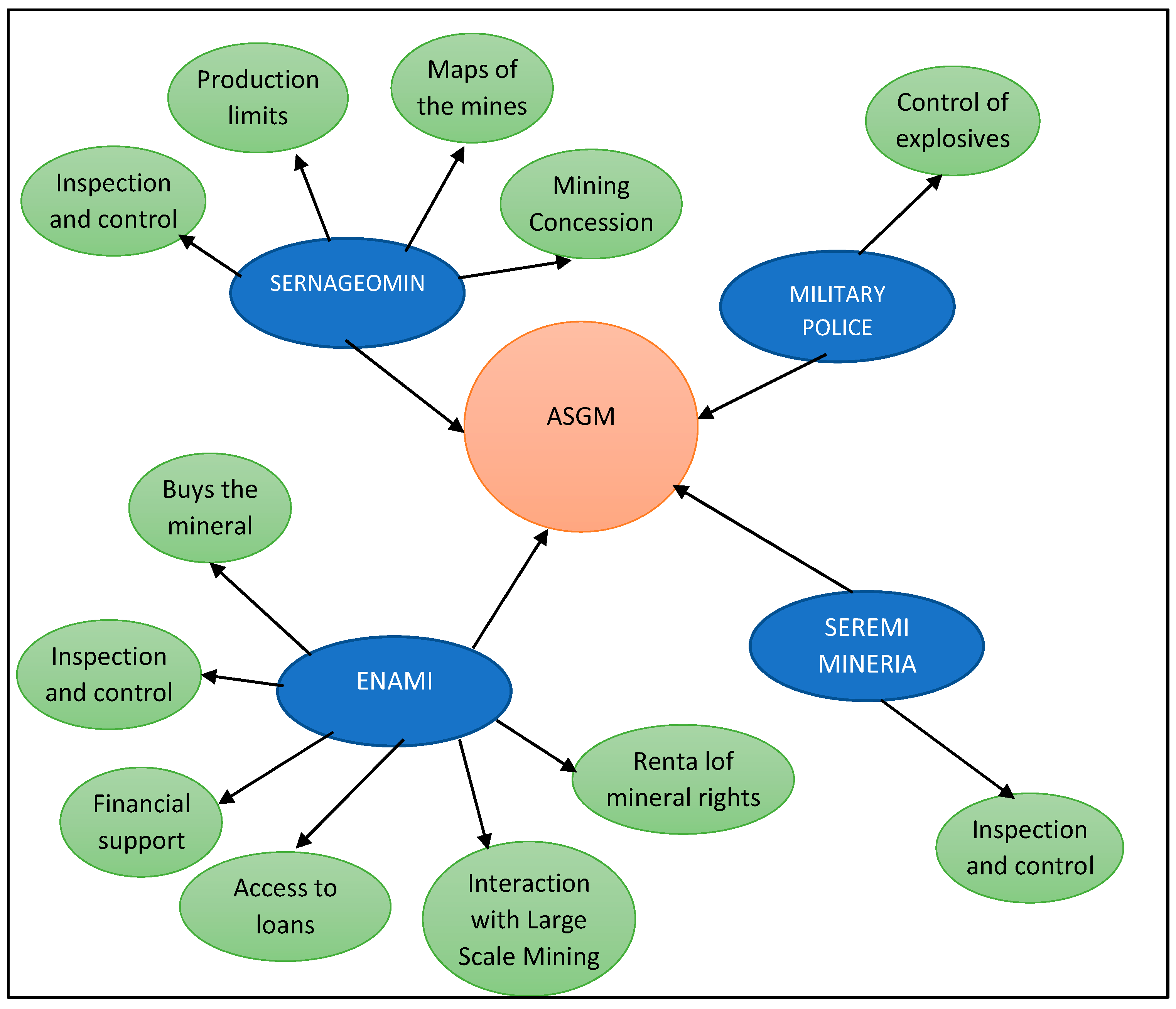

1.2. The Support of Public Agencies for Small-Scale Mining in Chile

ENAMI

- i.

- ENAMI buys the minerals from miners

- ii.

- Non-refundable financial support

- Development of the Competitive Capacities Program: The objective of the program is to incorporate and develop technical and business management capacities. The maximum amount is USD 2500 for individual projects and USD 20,000 for projects of associated miners. The nomination options are fostering innovation, technological transfer and training.

- Recognition of resources and/or reserves and mine planning: This involves financing exploratory drilling or reconnaissance tunnels for the preparation of a mining project. To apply for this financing mechanism, it is necessary to wait for a national competition managed by ENAMI.

- Technical assistance: This is specialized consultancy for the development of mining projects, including the study of the entire mineral production chain, from topographic surveys to the sale of ores.

- District Studies Program: This involves bidding for geological studies of areas predefined by ENAMI. The maximum annual amount is USD 150,000 per mining district. In this case, the benefit to small-scale miners is having access to maps to help postulate other development instruments.

- Production Support Program: This attends to the specific technical requirements of the miners, such as equipment repair, mining works or the purchase of materials. The maximum amount is USD 5000 per project.

- iii.

- Loans

- Support for safe production: This is a loan to adapt the mine closure plan, ground support, ventilation, emergency exits, and other works related to occupational hygiene and safety; payment for consultancy in management and risk prevention; quality; and the environment. The maximum amount is USD 30,000 per project. The payment period is 5 years, with a grace period of up to 1 year. The method of payment sales discounts at the rate of 1 USD/ton of mineral sold to ENAMI. There is no warranty, and the interest rate is fixed by ENAMI.

- Mine Reactivation Program: This is a program for putting an inactive mine back into production. The amount per project is USD 35,000. The return period is up to 2 years.

- Credits for the operation: This is a loan to stabilize cash flow and finance the purchase of minor equipment and other materials. The maximum amount is USD 50,000, with a payment term of up to one year and a grace period of three months. The interest rate is set semi-annually, and the commission is 2.5%.

- Credit for mine development: This is funding for open-pit or underground development to access the orebody. The maximum amount is USD 300,000, with a term of up to 5 years and a grace period of 1 year. The interest rate is set semi-annually. In this case, it is necessary to present real guarantees. The loan is released gradually as the progress of the project is monitored.

- Credit for investments: This is a loan for the purchase and renovation of equipment, innovations, the construction of access roads, environmental care and working capital, among other activities related to mining work. There is a term of up to 5 years with a grace period of 1 year. The interest rate is defined every six months and the commission is 2.5%. In this case, it is necessary to present real guarantees. The project will determine the value and the loan is released gradually as the progress of the project is monitored.

- Emergency credit: This is a loan to solve unforeseen situations caused by natural catastrophes. There are limits of USD 25,000 if raw minerals are sold and USD 50,000 if mineral products are sold. There are terms of up to 1 year, with a grace period of 3 months. The interest rate is set semi-annually, and the commission is 2.5%.

- Supervising miners who have some type of promotion or active credit.

- Interaction with big-scale mining companies: the rental of areas belonging to large companies.

- Leasing properties: the lease of mining prospects from ENAMI to small-scale miners.

2. Materials and Methodology

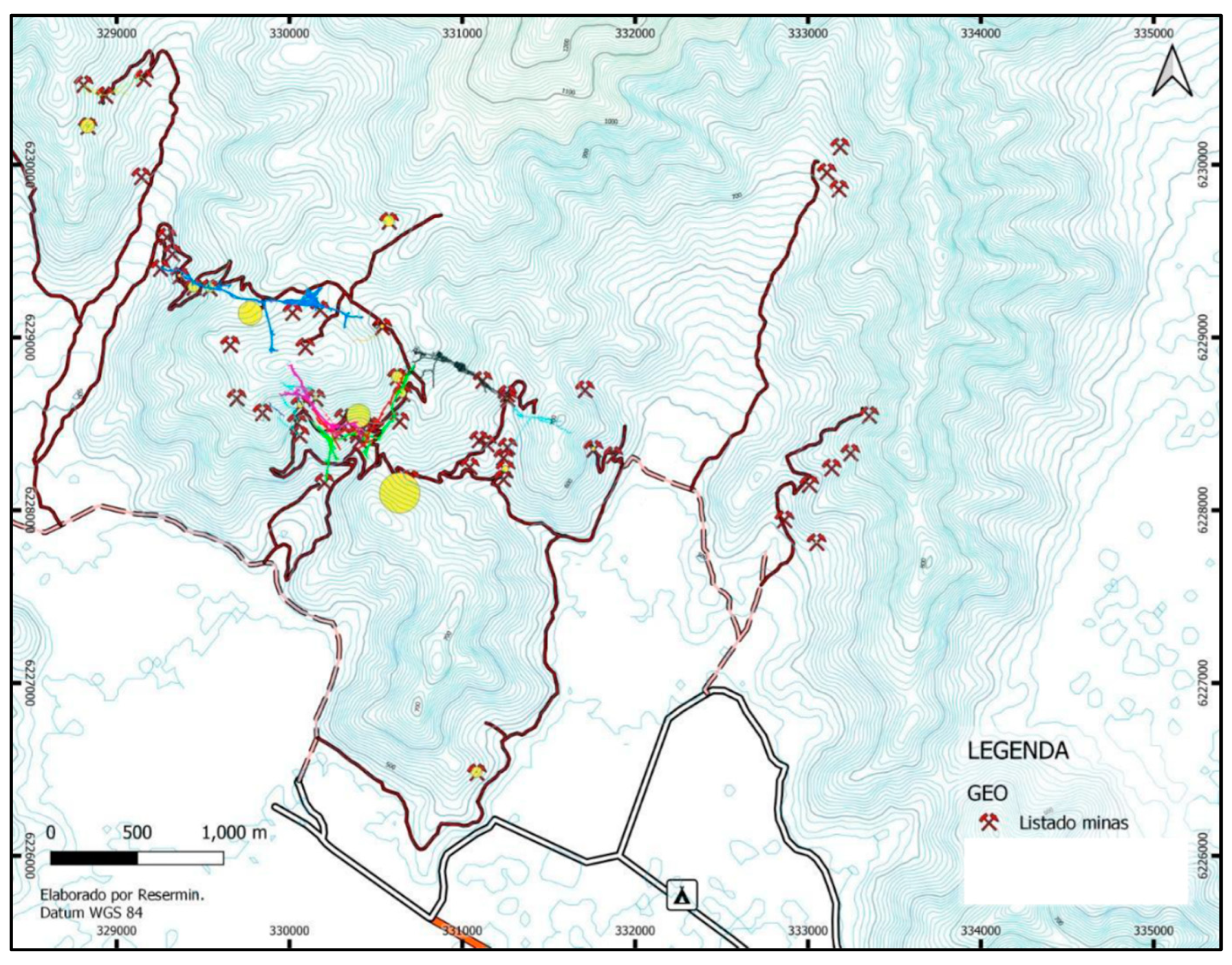

2.1. Study Population

2.2. Methodology

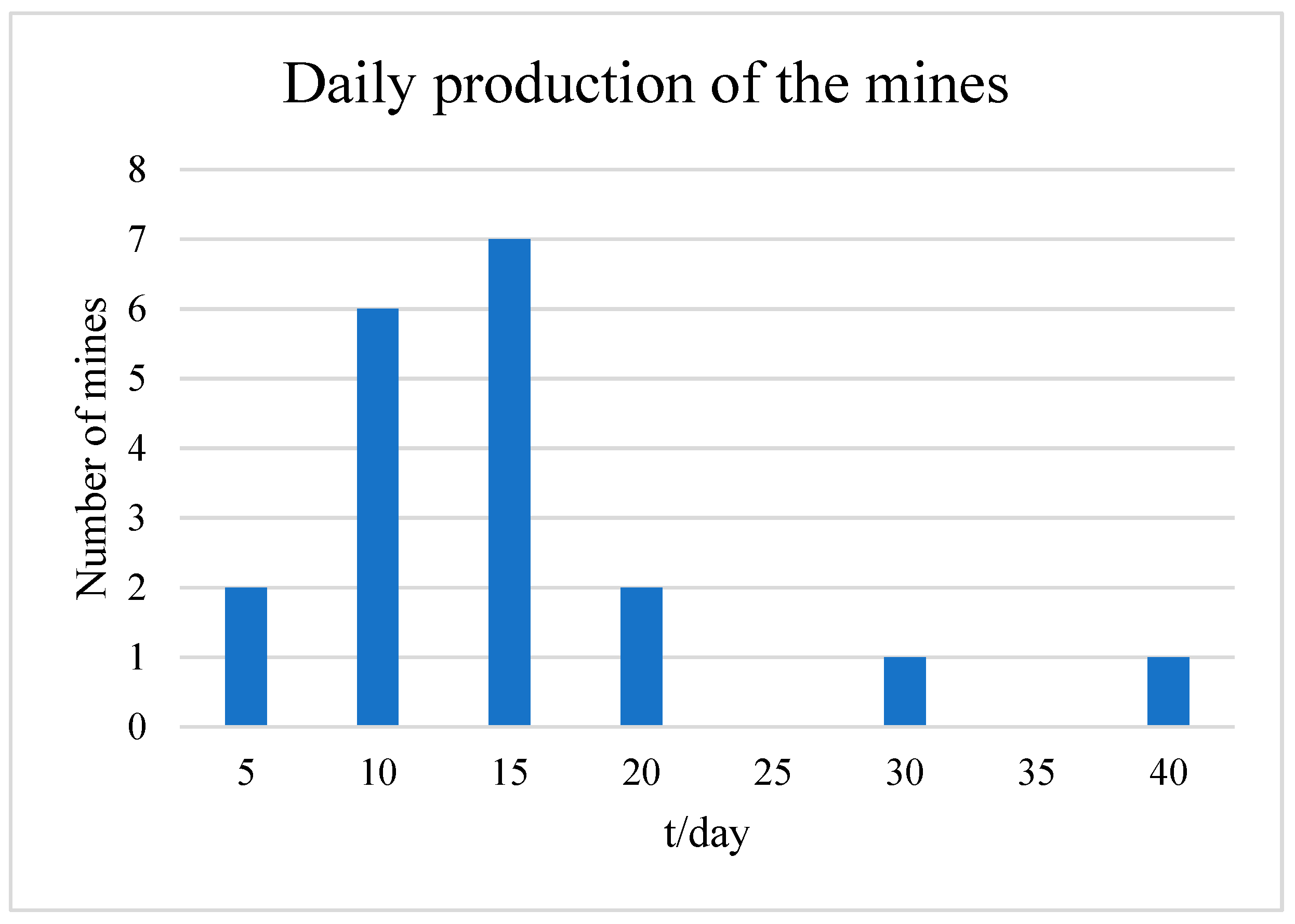

3. Results

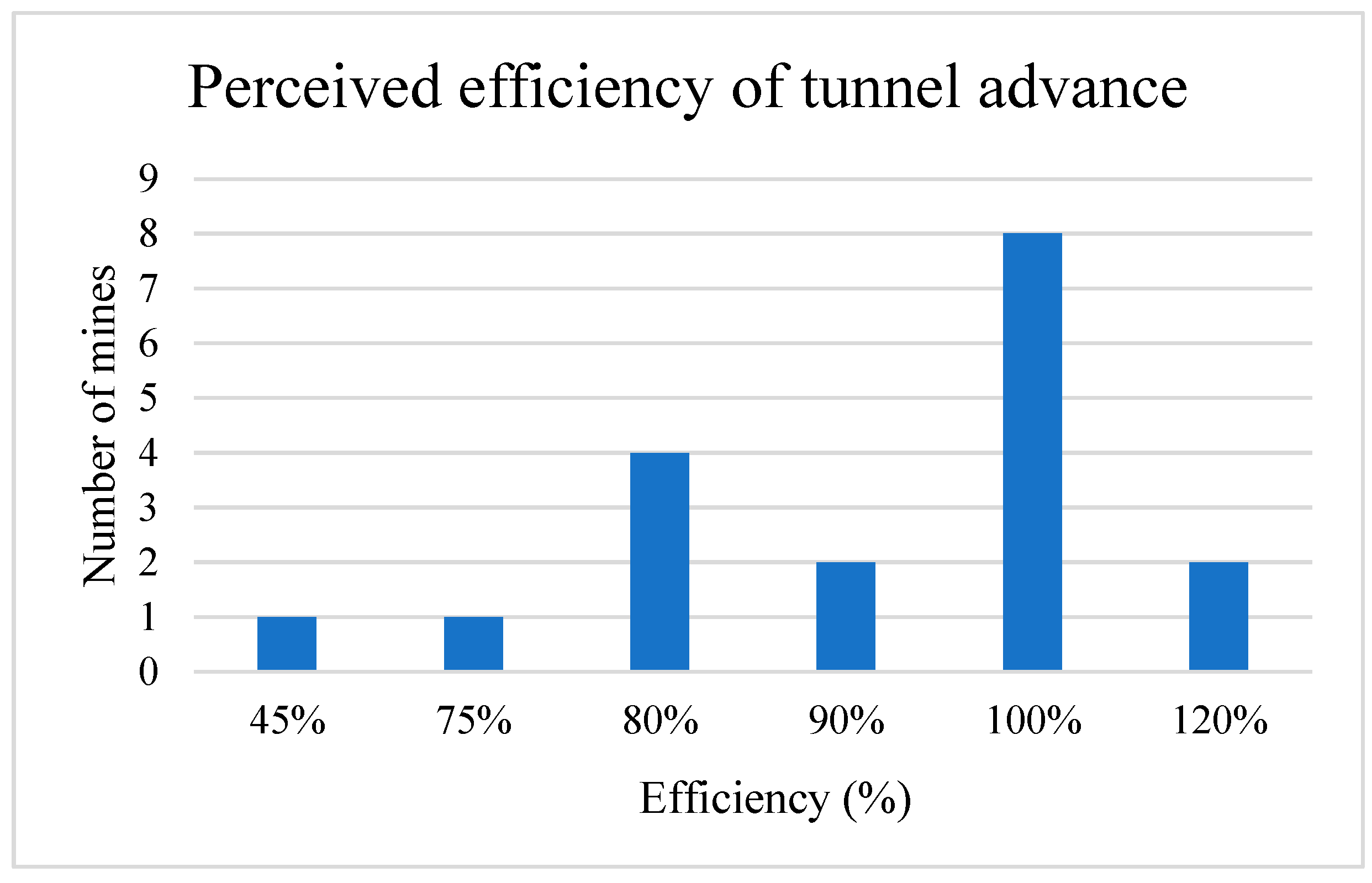

3.1. Drilling and Blasting

3.2. Loading and Hauling to the Mine Stockpile

3.3. Transport from the Mine Stockpile to the Plant

3.4. Workforce

3.5. Materials and Supplies

- The operation consumed around 200 L of water per day. The sources were local spring water, mine drainage water, water brought in from the city or water from a reservoir.

- Potable water for human consumption was about 20 L per operator per day.

- Diesel consumption varied between 250 and 3000 L per month. This wide range was due to the fact that some mines employed used equipment bought from large-scale mines.

- Oil consumption for equipment lubrication was not registered by the miners, as equipment maintenance was only carried out inconsistently.

- There was no electricity beamline. Two mines had solar-powered systems for their office and cafeteria.

3.6. Geological Control and Mine Planning

3.7. Economic Analyses

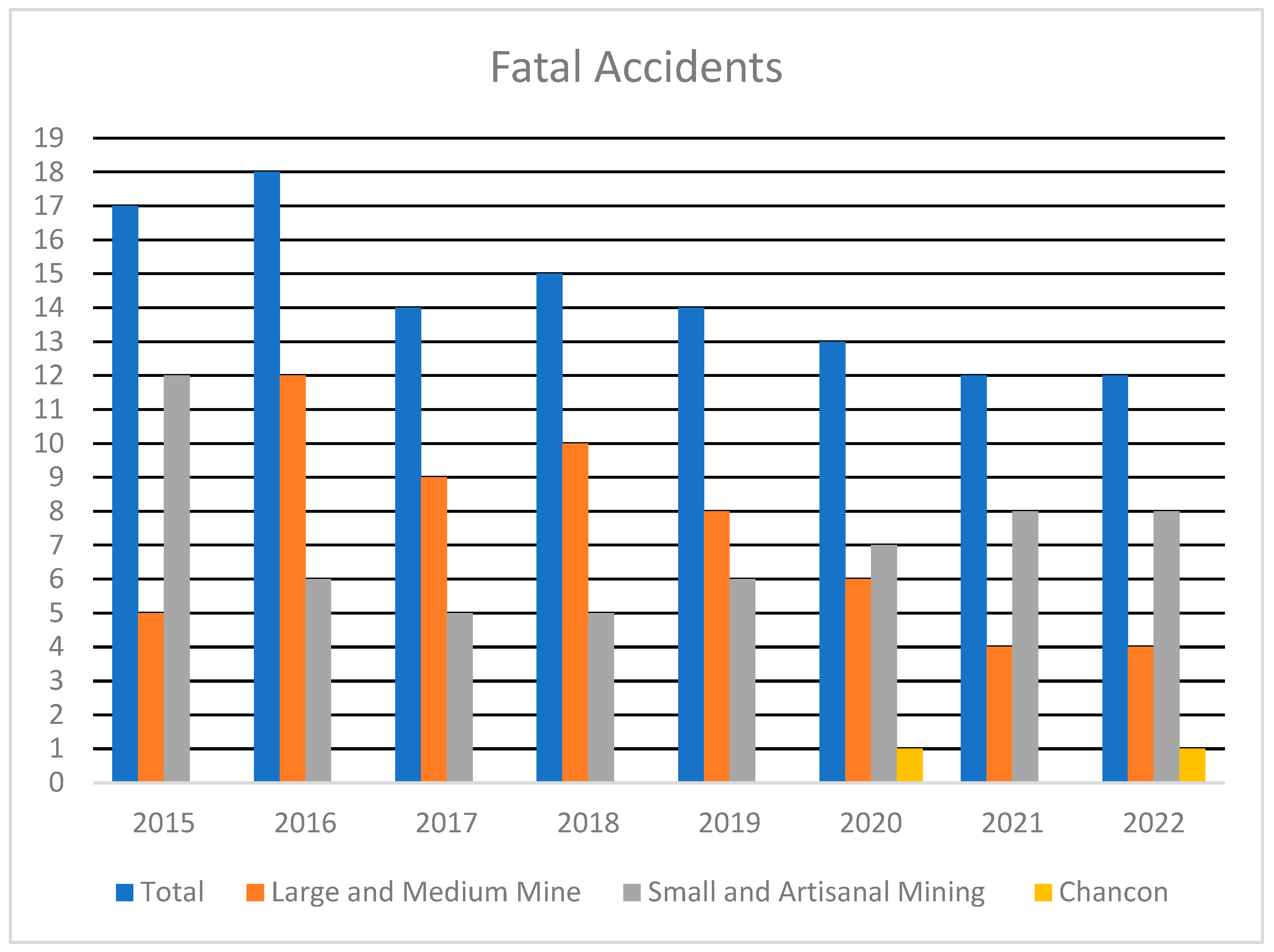

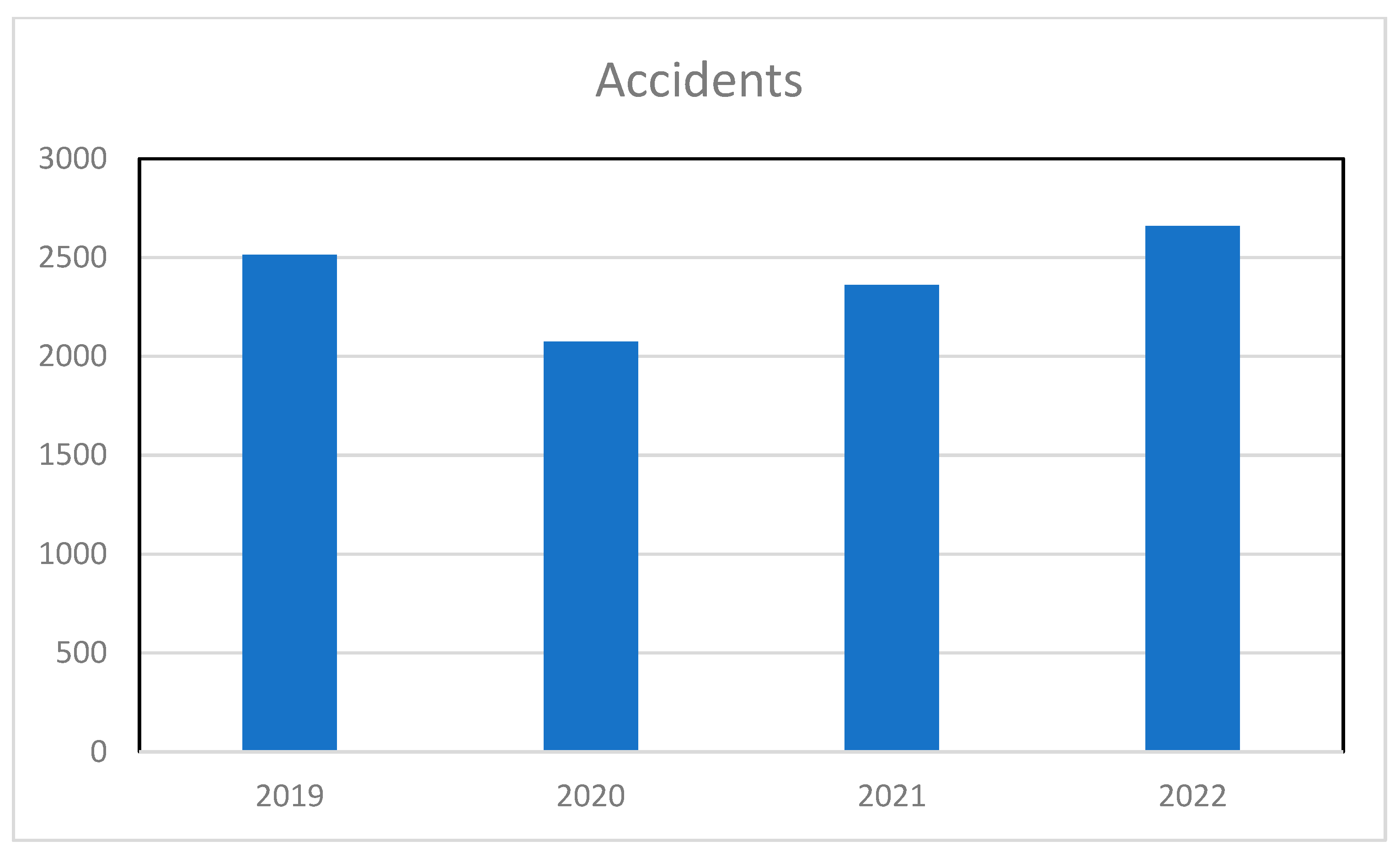

3.8. Accidents

3.9. Further Observations

- Of the mines, 60% had some type of funding from ENAMI. The range of funding was between CLP 5,000,000 and CLP 75,000,000.

- The government is present in the region: at least every six months, an agency visits each mine. In the case of mines with active financing, visits from the funding agency may take place on a monthly basis.

- In general, miners had only one work front available, which did not allow for operational flexibility and generated periods of pure cost, extracting only waste rock.

- The time taken to analyze the samples of the material sent to ENAMI. The miners used these results as a control tool to know what mineral grade was present in the ore they extracted. Therefore, they would know if they were excavating in the right direction or not. The average time to obtain the grade was 30 days; therefore, when the result arrived, the area had already been mined.

- There is a systematic positive difference between the grade of the sample collected by the miners and sent for analysis and the grade of the lot sent to the processing plant and estimated by ENAMI. This is because the miners sampled the vein and, as mentioned, did not contemplate the concept of excavation dilution due to the size of the tunnel.

- The monthly production limit established by SERNAGEOMIN “strangled” cashflow, which was already compromised by all the other reductions documented above.

3.10. Issues with the Processing Plant

4. Discussion

- Economic point of view: The miners did not have a constant income; they had only one producing front and advances in the hope of finding ores. The system was to work as much as possible on the mineral with all the equipment and people available and, when operating in waste rock, work gradually, according to how much was possible to invest. Generally, the earnings from ore extraction were spent or saved and not used as working capital to invest in waste rock extraction. There was no planning for managing the sterile–mineral ratio (stripping ratio). If it were not for the support of ENAMI, many miners would not be able to sustain their operating costs.

- Social point of view: Even though the operation produced a small economy and socially impacted miners’ families and the surroundings (e.g., maintaining the presence of a school), this impact was not constant. There was no real development in the region, as there was no increase in or development of new schools, good medical care, clean water, sanitation, etc. This was due to the precarious income described above.

- Environmental point of view: As stated, Hg was not used in the area. Nevertheless, Hg is not the only environmental externality of a mining operation. Waste rock was simply deposited on the slopes of surrounding hills, creating a geotechnical hazard in the form of slope instability (also considering Chilean seismicity) and the potential for acid drainage. The mines were not closed, but simply abandoned, leaving a panorama of empty holes on hillsides, with many dangers associated with abandoned tunnels. There was no concern for material and equipment management. Machinery which did not work was set aside to rust or be used as a source of scrap materials. Used tires, diesel and motor oil were thrown away (one of the authors of this study needed some used tires for another project and found four at the side of the first bend of the road).

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cano, Á.; Kunz, N.C. Large-scale and small-scale mining in Peru: Exploring the interface. Resour. Policy 2022, 76, 102530. [Google Scholar] [CrossRef]

- CASM. Map of Artisanal and Small-Scale Miners around the World, Communities and Small-Scale Mining (CASM). 2012. Available online: http://www.artisanalmining.org/casm/minersmap (accessed on 20 August 2019).

- Cossa, H.; Scheidegger, R.; Leuenberger, A.; Ammann, P.; Munguambe, K.; Utzinger, J.; Macete, E.; Winkler, M.S. Health studies in the context of artisanal and small-scale mining: A scoping review. Int. J. Environ. Res. Public Health 2021, 18, 1555. [Google Scholar]

- Estrela, A.M.; Hilson, M.H. Cooperatives as a Centre Piece for Formalizing Small-Scale Mining in Sub-Saharan Africa: Rationale, Benefits and Limitations. In Routledge Handbook of the Extractive Industries and Sustainable Development; Routledge: London, UK, 2022. [Google Scholar]

- Hilson, G. ‘Formalization bubbles’: A blueprint for sustainable artisanal and small-scale mining (ASM) in sub-Saharan Africa. Extr. Ind. Soc. 2020, 7, 1624–1638. [Google Scholar] [CrossRef]

- Hinton, J.J.; Veiga, M.M.; Veiga, A.T.C. Clean artisanal gold mining: A utopian approach? J. Clean. Prod. 2003, 11, 99–115. [Google Scholar]

- McDaniels, J.; Chouinard, R.; Veiga, M.M. Appraising the Global Mercury Project: An adaptive management approach to combating mercury pollution in small-scale gold mining. Int. J. Environ. Pollut. 2010, 41, 242. [Google Scholar] [CrossRef]

- MMSD. Artisanal and Small-Scale Mining. In Final Report on Mining, Minerals and Sustainable Development; International Institute for Environment and Development and World Business Council for Sustainable Development: London, UK, 2002; Chapter 13. [Google Scholar]

- Purnomo, M.; Utomo, M.R.; Pertiwi, V.A.; Laili, F.; Pariasa, I.I.; Riyanto, S.; Andriatmoko, N.D.; Handono, S.Y. Resistance to mining and adaptation of Indonesia farmer’s household to economic vulnerability of small scale sand mining activities. Local Environ. 2021, 26, 1498–1511. [Google Scholar]

- Sousa, R.N.; Veiga, M.M.; Meech, J.; Jokinen, J.; Sousa, A.J. A simplified matrix of environmental impacts to support an intervention program in a small-scale mining site. J. Clean. Prod. 2011, 19, 580–587. [Google Scholar] [CrossRef]

- Urkidi, L. A local environmental movement against gold mining: Pascua–Lama in Chile. Ecol. Econ. 2010, 70, 219–227. [Google Scholar]

- Veiga, M.M.; Angeloci-Santos, G.; Meech, J.A. Review of barriers to reduce mercury use in artisanal gold mining. Extr. Ind. Soc. 2014, 1, 351–361. [Google Scholar] [CrossRef]

- Velásquez, J.R.; Schwartz, M.; Phipps, L.M.; Restrepo-Baena, O.J.; Lucena, J.; Smits, K.M. A review of the environmental and health implications of recycling mine tailings for construction purposes in artisanal and small-scale mining communities. Extr. Ind. Soc. 2022, 9, 101019. [Google Scholar] [CrossRef]

- Marin, T.; Seccatore, J.; De Tomi, G.; Veiga, M. Economic feasibility of responsible small-scale gold mining. J. Clean. Prod. 2016, 129, 531–536. [Google Scholar] [CrossRef]

- Massaro, L.; de Theije, M. Understanding small-scale gold mining practices: An anthropological study on technological innovation in the Vale do Rio Peixoto (Mato Grosso, Brazil). J. Clean. Prod. 2018, 204, 618–635. [Google Scholar]

- Teschner, B.; Smith, N.M.; Borrillo-Hutter, T.; John, Z.Q.; Wong, T.E. How efficient are they really? A simple testing method of small-scale gold miners’ gravity separation systems. Miner. Eng. 2017, 105, 44–51. [Google Scholar] [CrossRef]

- Calvimontes, J.; Massaro, L.; Araujo, C.; Moraes, R.; Mello, J.; Ferreira, L.; de Theije, M. Small-scale gold mining and the COVID-19 pandemic: Conflict and cooperation in the Brazilian Amazon. Extr. Ind. Soc. 2020, 7, 1347–1350. [Google Scholar] [CrossRef]

- Hilson, G.; Van Bockstael, S.; Sauerwein, T.; Hilson, A.; McQuilken, J. Artisanal and small-scale mining, and COVID-19 in sub-Saharan Africa: A preliminary analysis. World Dev. 2021, 139, 105315. [Google Scholar] [CrossRef]

- Perks, R.; Schneck, N. COVID-19 in artisanal and small-scale mining communities: Preliminary results from a global rapid data collection exercise. Environ. Sci. Policy 2021, 121, 37–41. [Google Scholar] [CrossRef]

- Pijpers, R.J.; Luning, S. We have so many challenges: Small-scale mining, COVID-19 and constant interruptions in West Africa. Anthropol. Today 2021, 37, 10–14. [Google Scholar]

- Springer, S.K.; Peregovich, B.G.; Schmidt, M. Capability of social life cycle assessment for analyzing the artisanal small-scale gold mining sector—Case study in the Amazonian rainforest in Brazil. Int. J. Life Cycle Assess. 2020, 25, 2274–2289. [Google Scholar] [CrossRef]

- Ulmer, G. The Earth Is Hungry: Amerindian Worlds and the Perils of Gold Mining in the Peruvian Amazon. J. Lat. Am. Caribb. Anthropol. 2020, 25, 324–339. [Google Scholar] [CrossRef]

- Siqueira-Gay, J.; Sánchez, L.E. The outbreak of illegal gold mining in the Brazilian Amazon boosts deforestation. Reg. Environ. Chang. 2021, 21, 28. [Google Scholar] [CrossRef]

- Kaufmann, C.; Côte, M. Frames of extractivism: Small-scale goldmining formalization and state violence in Colombia. Political Geogr. 2021, 91, 102496. [Google Scholar] [CrossRef]

- IIMP—El Instituto de Ingenieros de Minas del Perú. Colombia y Peru Buscan Centralizar Compra de Oro Para Combatir Crime e Informalidad. 2021. Available online: https://iimp.org.pe/raiz/colombia-y-peru-buscan-centralizar-compra-de-oro-para-combatir-crimen-e-informalidad (accessed on 17 January 2022). (In Spanish).

- DW; El Oro De Los Latinoamericanos: ¿Qué Tanto Se Conserva En Los Bancos Centrales? 2022. Available online: https://www.dw.com/es/el-oro-de-los-latinoamericanos-qu%C3%A9-tanto-se-conserva-en-los-bancos-centrales/a-56776949 (accessed on 15 July 2022). (In Spanish).

- MCH. Invertirán $792 Millones Para Modernizar Plantas de Procesamiento de Oro Libre de Mercurio en Atacama. 2021. Available online: https://www.mch.cl/2021/02/15/invertiran-792-millones-para-modernizar-plantas-de-procesamiento-de-oro-libre-de-mercurio-en-atacama/# (accessed on 10 May 2022). (In Spanish).

- Faúndez, P.I.; Marquardt, C.; Jara, J.J.; Guzmán, J.I. Valuation and Prioritization of Early-Stage Exploration Projects: A Case Study of Cu–Ag and Au-Mineralized Systems in the Tiltil Mining District, Chile. Nat. Resour. Res. 2020, 29, 2989–3014. [Google Scholar] [CrossRef]

- Poveda-Bautista, R.; Gonzalez-Urango, H.; Ramírez-Olivares, E.; Diego-Mas, J.-A. Engaging Stakeholders in Extraction Problems of the Chilean Mining Industry through a Combined Social Network Analysis-Analytic Network Process Approach. Complexity 2022, 2022, 9096744. [Google Scholar] [CrossRef]

- Seccatore, J.; Gonzalez, P.; Herrera, M. Peculiarities of drilling and blasting in underground small-scale mines. REM-Int. Eng. J. 2020, 73, 387–394. [Google Scholar] [CrossRef]

- Tripodi, E.E.M.; Rueda, J.A.G.; Céspedes, C.A.; Vega, J.D.; Gómez, C.C. Characterization and geostatistical modelling of contaminants and added value metals from an abandoned Cu–Au tailing dam in Taltal (Chile). J. South Am. Earth Sci. 2019, 93, 183–202. [Google Scholar] [CrossRef]

- Reinoso, F.; Rodrigo, P. Formulación de Instrumentos de Fomento a la Innovación em Pequeña Minería. Tesis Para Optar al Grado de Magíster em Gestión Políticas Públicas. Ph.D. Thesis, Universidade de Chile, Facultad de Ciencias Físicas y Matemáticas, Departamento de Ingeniería Industrial, Santiago, Chile, 2013. (In Spanish). [Google Scholar]

- BBCL—BioBio Chile. 2022. Available online: https://www.biobiochile.cl/noticias/nacional/region-de-ohiggins/2022/03/24/rescatan-a-minero-que-quedo-atrapado-tras-derrumbe-en-el-maiten-de-chacon-de-rancagua.shtml (accessed on 7 October 2022). (In Spanish).

- MIREME. Ministério dos Recursos Minerais e Energia, Republica de Mocambique. 2022. Available online: https://www.mireme.gov.mz/index.php?option=com_content&view=article&id=2:ministra-dos-recursos-minerais-inteira-se-do-acidente-na-mina-de-ouro-em-nampula&catid=9:comunicados&Itemid=101 (accessed on 10 May 2022). (In Portuguese)

- NYTIMES. Mining Disasters. 2022. Available online: https://www.nytimes.com/topic/subject/mining-disasters (accessed on 2 May 2022).

- Veiga, M.M.; Fadina, O. A review of the failed attempts to curb mercury use at artisanal gold mines and a proposed solution. Extr. Ind. Soc. 2020, 7, 1135–1146. [Google Scholar] [CrossRef]

- ENAMI—Empresa Nacional de Mineria. 2023. Available online: www.enami.cl (accessed on 8 February 2023). (In Spanish).

- Espinoza, C.; Seccatore, J.; Herrera, M. Chilean artisanal mining: A gambling scenario. REM-Int. Eng. J. 2020, 73, 241–246. [Google Scholar] [CrossRef]

- Seccatore, J.; Magny, L.; De Tomi, G. Technical and operational aspects of tunnel rounds in artisanal underground mining. REM Rev. Esc. Minas 2014, 67, 303–310. [Google Scholar] [CrossRef]

- SERNAGEOMIN. Atlas de Faenas Mineras, Regiones de Valparaíso, del Libertador General Bernardo O´Higgins y Metropolitana de Santiago (Versión Actualizada); Servicio Nacional de Geología y Minería, Mapas y Estadísticas de Faenas Mineras de Chile: Santiago, Chile, 2012; No 9; 177p. (In Spanish) [Google Scholar]

- ENAMI. Estudio Geológico Distrital Enami Chancon; Propriedade ENAMI: Santiago, Chile, 2014; 112p. (In Spanish) [Google Scholar]

- El Rancaguino. Fallece Trabajador en Mina don Hector Ubicada en Chancon. 2022. Available online: https://www.elrancaguino.cl/2022/10/28/fallece-trabajador-en-mina-don-hector-ubicada-en-chancon/ (accessed on 11 July 2023). (In Spanish).

- Portal Minero. Tras Estar Atrapado Por Mas de Seis Horas Fue Rescatado Minero En Chancon. 2022. Available online: https://www.portalminero.com/wp/tras-estar-atrapado-por-mas-de-seis-horas-fue-rescatado-minero-en-chancon/ (accessed on 11 July 2023). (In Spanish).

- El Tipografo. Trabajador Minero Fallece en Chan-Con. 2020. Available online: https://eltipografo.cl/2020/05/trabajador-minero-fallece-en-chancon (accessed on 11 July 2023). (In Spanish).

- Revista Tecnicos Mineros. Trabajadores Resultan Lesionados en Faenas Mineras de Chan-Con. 2016. Available online: https://www.revistatecnicosmineros.com/2016/12/trabajadores-resultan-lesionados-en-faenas-mineras-de-chancon/ (accessed on 11 July 2023). (In Spanish).

- Sernageomin. Estadísticas de Accidentabilidad. Industria Extractiva Minera. Servicio Nacional de Geología y Minería. 2023. Available online: https://www.sernageomin.cl/accidentabilidad-minera/ (accessed on 11 July 2023). (In Spanish).

- Castro, S.H.; Sánchez, M. Environmental viewpoint on small-scale copper, gold and silver mining in Chile. J. Clean. Prod. 2003, 11, 207–213. [Google Scholar] [CrossRef]

- Ghorbani, Y.; Kuan, S.H. A review of sustainable development in the Chilean mining sector: Past, present and future. Int. J. Min. Reclam. Environ. 2017, 31, 137–165. [Google Scholar] [CrossRef]

- Higueras, P.; Oyarzun, R.; Oyarzún, J.; Maturana, H.; Lillo, J.; Morata, D. Environmental assessment of copper–gold–mercury mining in the Andacollo and Punitaqui districts, northern Chile. Appl. Geochem. 2004, 19, 1855–1864. [Google Scholar] [CrossRef]

- Higueras, P.; Oyarzun, R.; Lillo, J.; Oyarzún, J.; Maturana, H. Atmospheric mercury data for the Coquimbo region, Chile: Influence of mineral deposits and metal recovery practices. Atmos. Environ. 2005, 39, 7587–7596. [Google Scholar] [CrossRef]

- Higueras, P.; Oyarzun, R.; Kotnik, J.; Esbrí, J.M.; Martínez-Coronado, A.; Horvat, M.; López-Berdonces, M.A.; Llanos, W.; Vaselli, O.; Nisi, B.; et al. A compilation of field surveys on gaseous elemental mercury (GEM) from contrasting environmental settings in Europe, South America, South Africa and China: Separating fads from facts. Environ. Geochem. Health 2014, 36, 713–734. [Google Scholar] [CrossRef] [PubMed]

- Oyarzún, J.; Castillo, D.; Maturana, H.; Kretschmer, N.; Soto, G.; Amezaga, J.M.; Rötting, T.S.; Younger, P.L.; Oyarzún, R. Abandoned tailings deposits, acid drainage and alluvial sediments geochemistry, in the arid Elqui River Basin, North-Central Chile. J. Geochem. Explor. 2012, 115, 47–58. [Google Scholar] [CrossRef]

- Rector, J.L. The History of Chile, 2nd ed.; Greenwood: Santa Barbara, CA, USA, 2019; ISBN 9781440863738. [Google Scholar]

- Veiga, M.M.; Nunes, D.; Klein, B.; Shandro, J.A.; Velasquez, P.C.; Sousa, R.N. Mill leaching: A viable substitute for mercury amalgamation in the artisanal gold mining sector? J. Clean. Prod. 2009, 17, 1373–1381. [Google Scholar] [CrossRef]

- Veiga, M.M. Introducing New Technologies for Abatement of Global Mercury Pollution in Latin America; CETEM/CNPq: Rio de Janeiro, Brazil, 1997; p. 94. [Google Scholar]

- Drace, K.; Kiefer, A.M.; Veiga, M.M.; Williams, M.K.; Ascari, B.; Knapper, K.A.; Logan, K.M.; Breslin, V.M.; Skidmore, A.; Bolt, D.A.; et al. Mercury-free, small-scale artisanal gold mining in Mozambique: Utilization of magnets to isolate gold at clean tech mine. J. Clean. Prod. 2012, 32, 88–95. [Google Scholar] [CrossRef]

- García, O.; Veiga, M.M.; Cordy, P.; Suescún, O.E.; Molina, J.M.; Roeser, M. Artisanal gold mining in Antioquia, Colombia: A successful case of mercury reduction. J. Clean. Prod. 2015, 90, 244–252. [Google Scholar] [CrossRef]

- Veiga, M.M.; Angeloci, G.; Ñiquen, W.; Seccatore, J. Reducing mercury pollution by training Peruvian artisanal gold miners. J. Clean. Prod. 2015, 94, 268–277. [Google Scholar] [CrossRef]

- Zolnikov, T.R.; Ortiz, D.R. A systematic review on the management and treatment of mercury in artisanal gold mining. Sci. Total Environ. 2018, 633, 816–824. [Google Scholar] [CrossRef]

- Purvis, B.; Mao, Y.; Robinson, D. Three pillars of sustainability: In search of conceptual origins. Sustain. Sci. 2019, 14, 681–695. [Google Scholar] [CrossRef]

- Seccatore, J.; Marin, T.; De Tomi, G.; Veiga, M. A practical approach for the management of resources and reserves in Small-Scale Mining. J. Clean. Prod. 2014, 84, 803–808. [Google Scholar] [CrossRef]

| Mineral Grade | Discount |

|---|---|

| 0.00–5.00 g/t | 22% |

| 5.01–6.00 g/t | 27% |

| 6.01–7.00 g/t | 33% |

| >7.01 g/t | 38% |

| Scenario 1—Net Cash Provided by Operating Activities for: 200 t/Month (CLP/Month) | |||||||

|---|---|---|---|---|---|---|---|

| Grade (g/t) | INCOME (CLP) | Cost CLP/t | |||||

| 10,000 | 15,000 | 20,000 | 25,000 | 30,000 | 35,000 | ||

| 2 | 18,664 | 1,732,712 | 732,712 | (267,288) | (1,267,288) | (2,267,288) | (3,267,288) |

| 3 | 42,248 | 6,449,602 | 5,449,602 | 4,449,602 | 3,449,602 | 2,449,602 | 1,449,602 |

| 4 | 65,832 | 11,166,492 | 10,166,492 | 9,166,492 | 8,166,492 | 7,166,492 | 6,166,492 |

| 5 | 89,417 | 15,883,383 | 14,883,383 | 13,883,383 | 12,883,383 | 11,883,383 | 10,883,383 |

| Scenario 2—Net Cash Provided by Operating Activities: 300 t/Month (CLP/Month) | |||||||

|---|---|---|---|---|---|---|---|

| Grade (g/t) | INCOME (CLP) | Cost/t | |||||

| 10,000 | 15,000 | 20,000 | 25,000 | 30,000 | 35,000 | ||

| 2 | 18,664 | 2,599,068 | 1,099,068 | (400,932) | (1,900,932) | (3,400,932) | (4,900,932) |

| 3 | 42,248 | 9,674,404 | 8,174,404 | 6,674,404 | 5,174,404 | 3,674,404 | 2,174,404 |

| 4 | 65,832 | 16,749,739 | 15,249,739 | 13,749,739 | 12,249,739 | 10,749,739 | 9,249,739 |

| 5 | 89,417 | 23,825,074 | 22,325,074 | 20,825,074 | 19,325,074 | 17,825,074 | 16,325,074 |

| Year | Type of Accident | Number of Miners Involved | Fatal | Source |

|---|---|---|---|---|

| 2022 | Fall from height | 1 | Yes | 2022 [42] |

| 2022 | Rockfall | 1 | No | 2022 [43] |

| 2020 | Rockfall | 1 | Yes | 2020 [44] |

| 2016 | Premature detonation of explosives | 3 | No | 2016 [45] |

| Month | Type of Accident | Mine Type | Number of Miners Involved | Number of Deaths |

|---|---|---|---|---|

| January | Getting crushed | Large | 1 | 1 |

| February | Fall from height | Small-Scale | 1 | 1 |

| February | Rockfall | Artisanal | 2 | 1 |

| March | Vehicle out of control | Exploration | 1 | 1 |

| April | Fall from height | Medium | 3 | 1 |

| Source | Place | Solution Proposed | Type of Solution |

|---|---|---|---|

| [55] | Latin America | Gravity concentration Flotation Electro-leaching Cyanidation NaCl electrolytic process Retort for Hg recovery Law enforcement Technical assistance Training artisanal miners | Technological Policy Strategic |

| [6] | Transversal | Construction of a training center for miners | Policy |

| [55] | Indonesia, Ecuador, Colombia | Mill leaching | Technological |

| [56] | Mozambique | Adopt clean technologies that obey the criteria of being economically beneficial, simple and expedient | Technological |

| [12] | Transversal | Mercury removal technology, miner education on mercury hazards, economic gains and policy | Policy |

| [57] | Colombia | Capacity building, education and the presence of trainers prior to introducing a new approach | Strategic |

| [58] | Ecuador–Peru | Gold isolation via centrifugal and magnetic removal of gangue materials | Strategic |

| [59] | Transversal | Incentivize gravity concentration | Technological–Policy |

| Issue Encountered | Solution Proposed | Type of Solution |

|---|---|---|

| High discount rates paid to Company C (the company that owned 80% of the concessions). The discounts are determined according to a rigid table with pre-fixed ranges of values of mineral grades (0.1 g/t above the limit value of the range, and the discount rate rises to the upper range). | Negotiate new rates with the company. Negotiate a continuous discount curve based on the grade and not a discrete set of values. | Economic Note: The government could help in the negotiation. |

| Waste rock: currently, it is dumped with no criterion or control on the slopes of hills. | Adopt a circular economy concept to give economical value to waste rock, e.g., for road pavement or construction material. Transform an environmental passive externality into an economic asset. Within the concept of the zero-waste operation. | Technological Market Note: The government could create projects for material use and valorization, together with entities such as universities. |

| Drilling and blasting. The drilling mesh, selection of the number of holes and their distribution is aleatorial. Hole ignition is still made by a safety fuse. | Create rules for a blasting plan (drill plan, charge per hole, initiation sequence) for each type of rock, and train miners in its implementation and realization. Adopt modern techniques (such as shock-tube initiation and employ delays). These solutions were discussed by Seccatore et al. [30,39] | Technological Training |

| Lack of geological control and mine planning. | Carry out studies for small-scale geological characterization (with auditable samples). Create auditable geological models. Implement a mine planning cycle for small-scale mining (thoroughly discussed in [14,61]). | Technology Transfer Economic Policies Note: Central and local governments and local agencies play a central role in helping public or private financing of these initiatives |

| Issues with the ENAMI processing plant: its technological efficiency and real recovery rate. | Public investment for upgrading the ENAMI plant. Promotion of investment to build competitive private plants with state-of-the-art technology and higher recovery. Build gravimetric concentration plants close to the mines to transport concentrate only. | Policy Technological Economic |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marin, T.; Seccatore, J.; Cheng, Y. Mapping the Reality of Hg-Free Artisanal Small-Scale Gold Mining. Sustainability 2023, 15, 13207. https://doi.org/10.3390/su151713207

Marin T, Seccatore J, Cheng Y. Mapping the Reality of Hg-Free Artisanal Small-Scale Gold Mining. Sustainability. 2023; 15(17):13207. https://doi.org/10.3390/su151713207

Chicago/Turabian StyleMarin, Tatiane, Jacopo Seccatore, and Yingchao Cheng. 2023. "Mapping the Reality of Hg-Free Artisanal Small-Scale Gold Mining" Sustainability 15, no. 17: 13207. https://doi.org/10.3390/su151713207

APA StyleMarin, T., Seccatore, J., & Cheng, Y. (2023). Mapping the Reality of Hg-Free Artisanal Small-Scale Gold Mining. Sustainability, 15(17), 13207. https://doi.org/10.3390/su151713207