Effect of Moisture Content on the Permanent Strain of Yellow River Alluvial Silt under Long-Term Cyclic Loading

Abstract

:1. Introduction

2. Experimental Methods

2.1. Test Material and Specimen Preparation

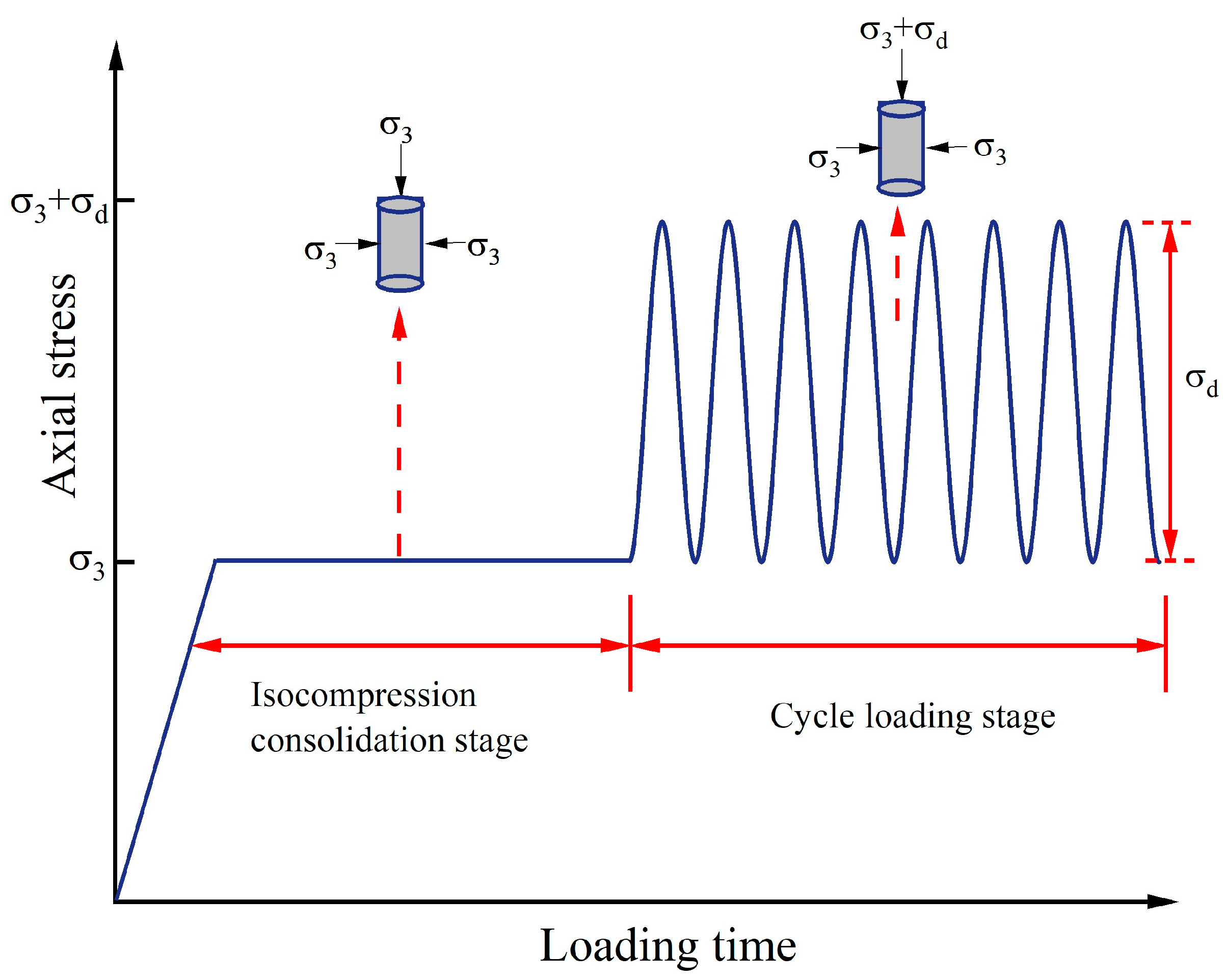

2.2. Test Procedure

3. Test Results and Discussion

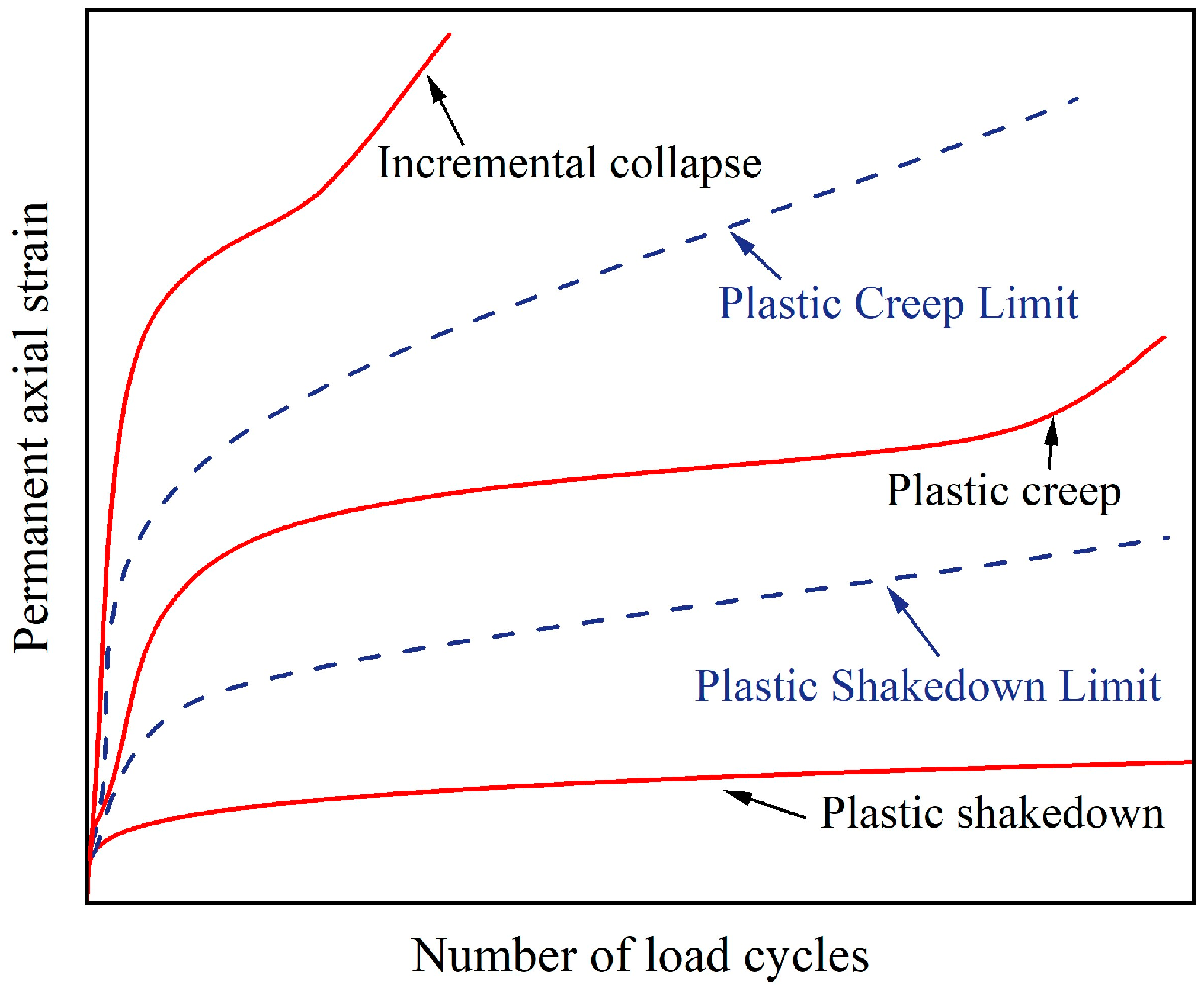

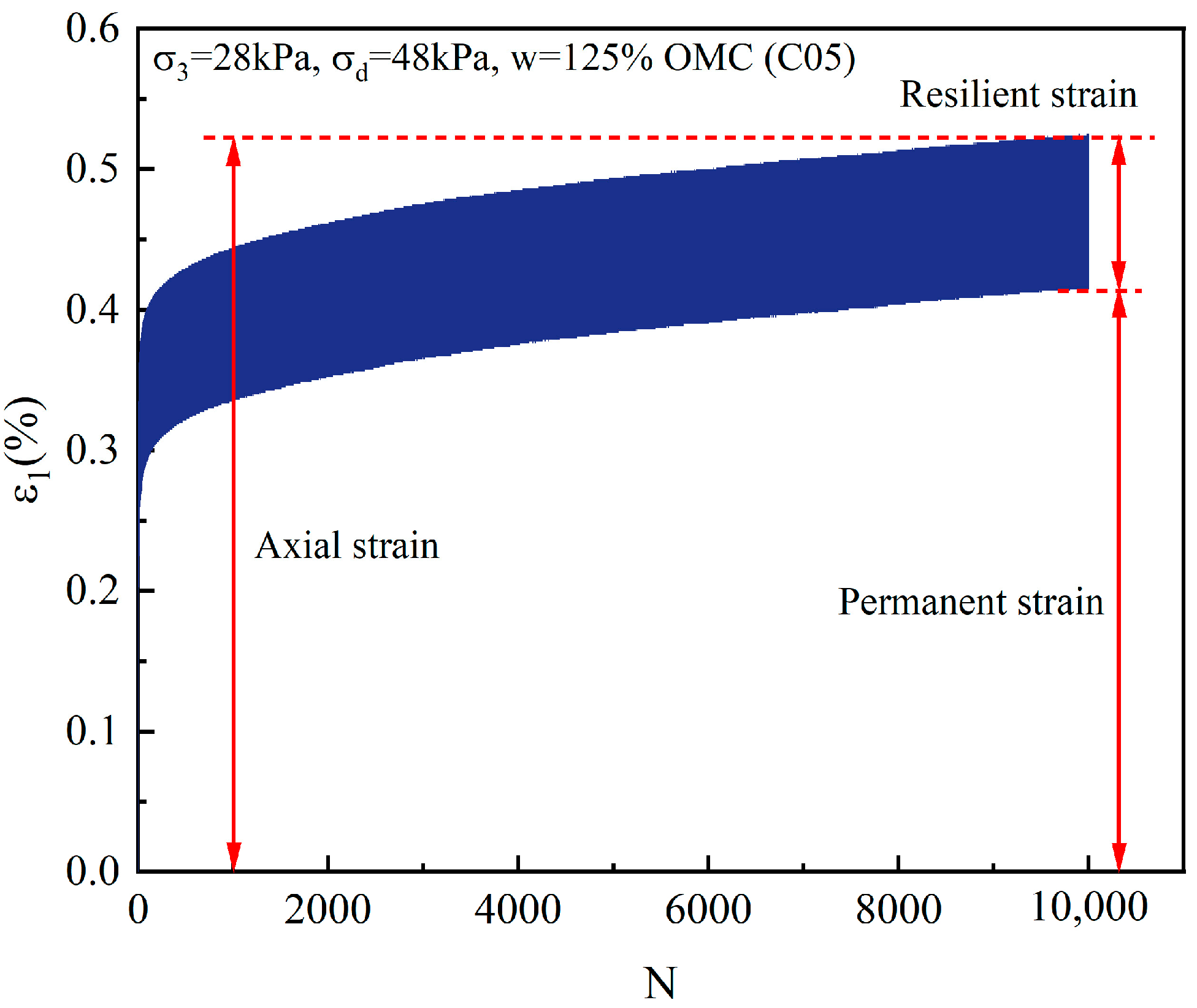

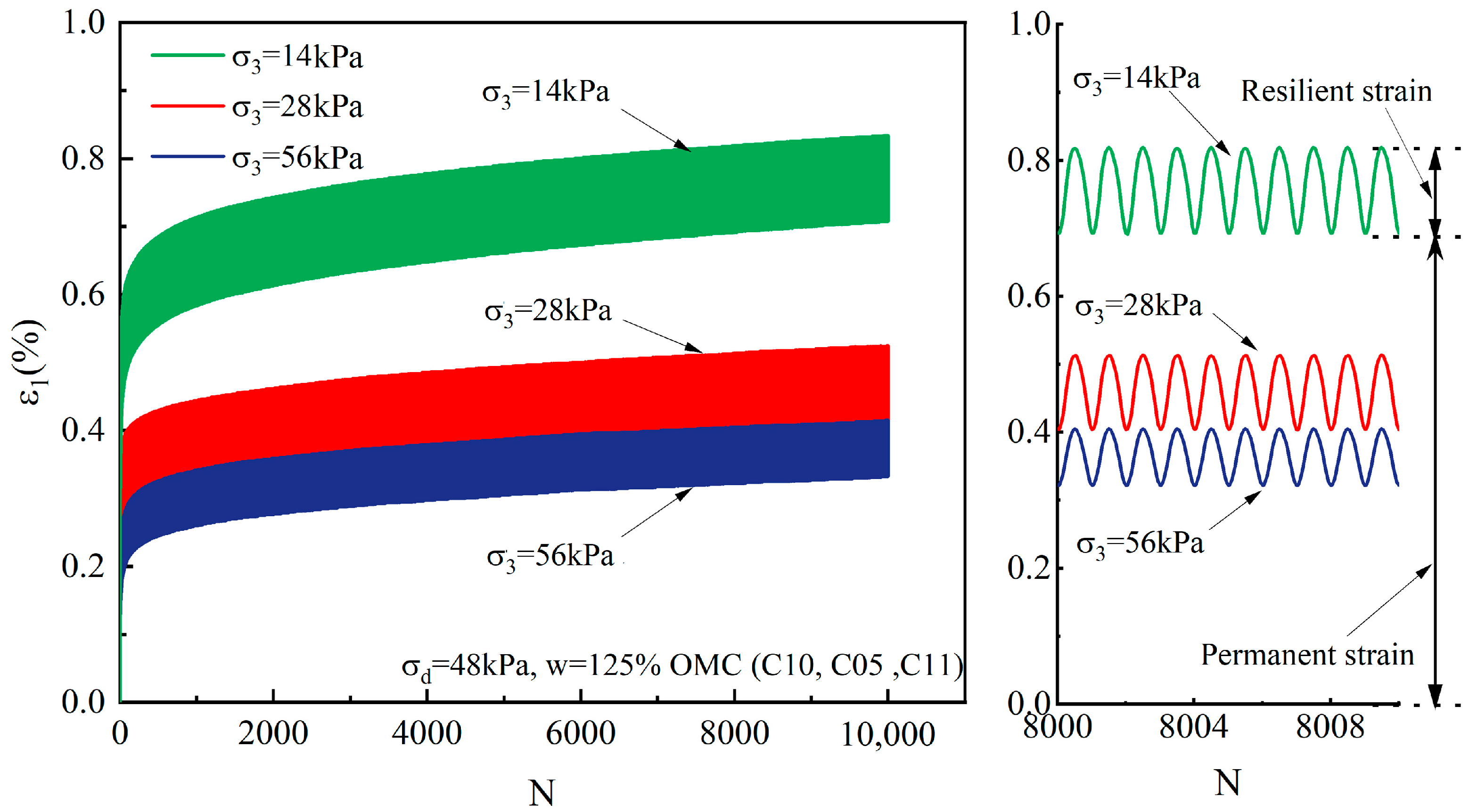

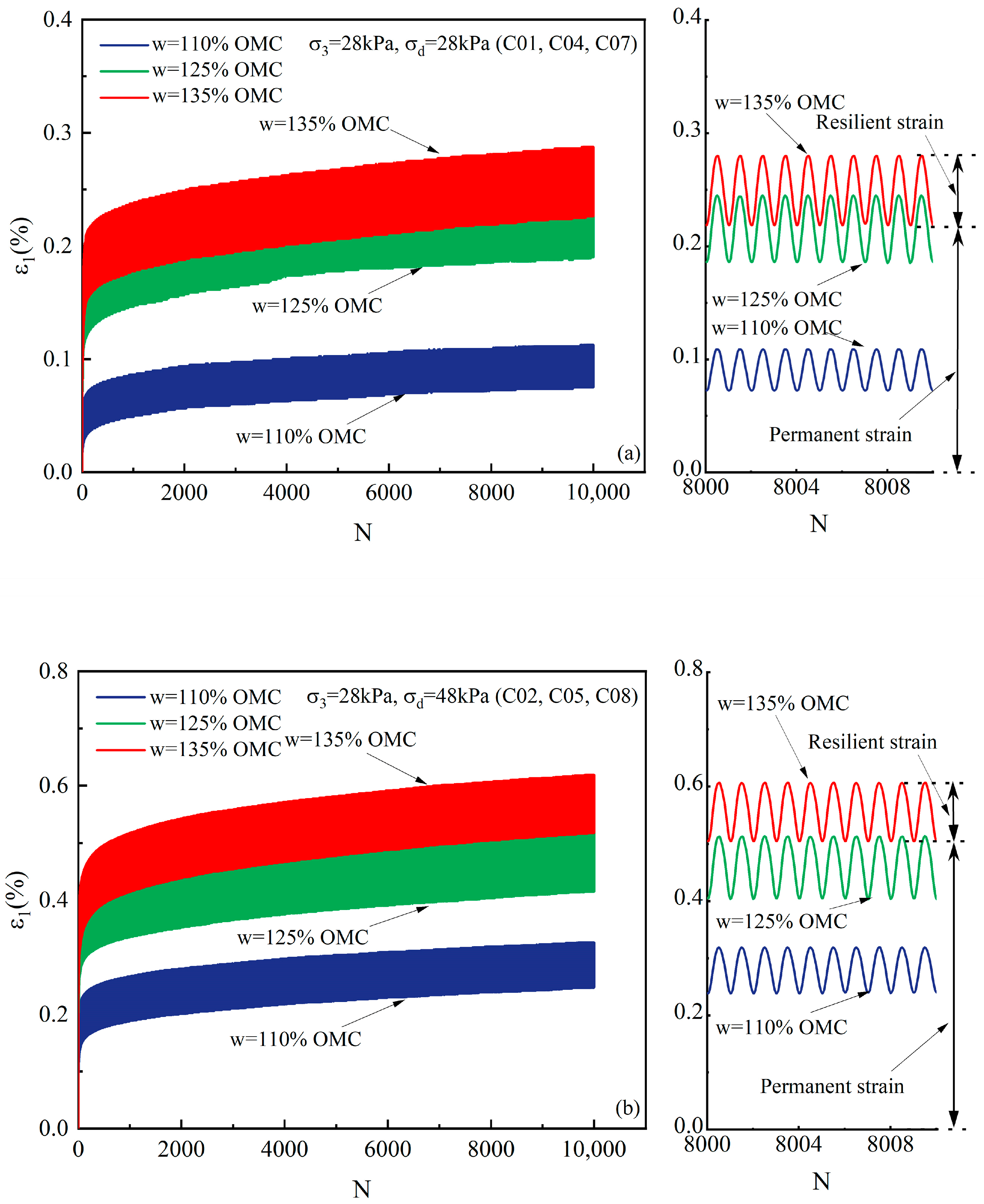

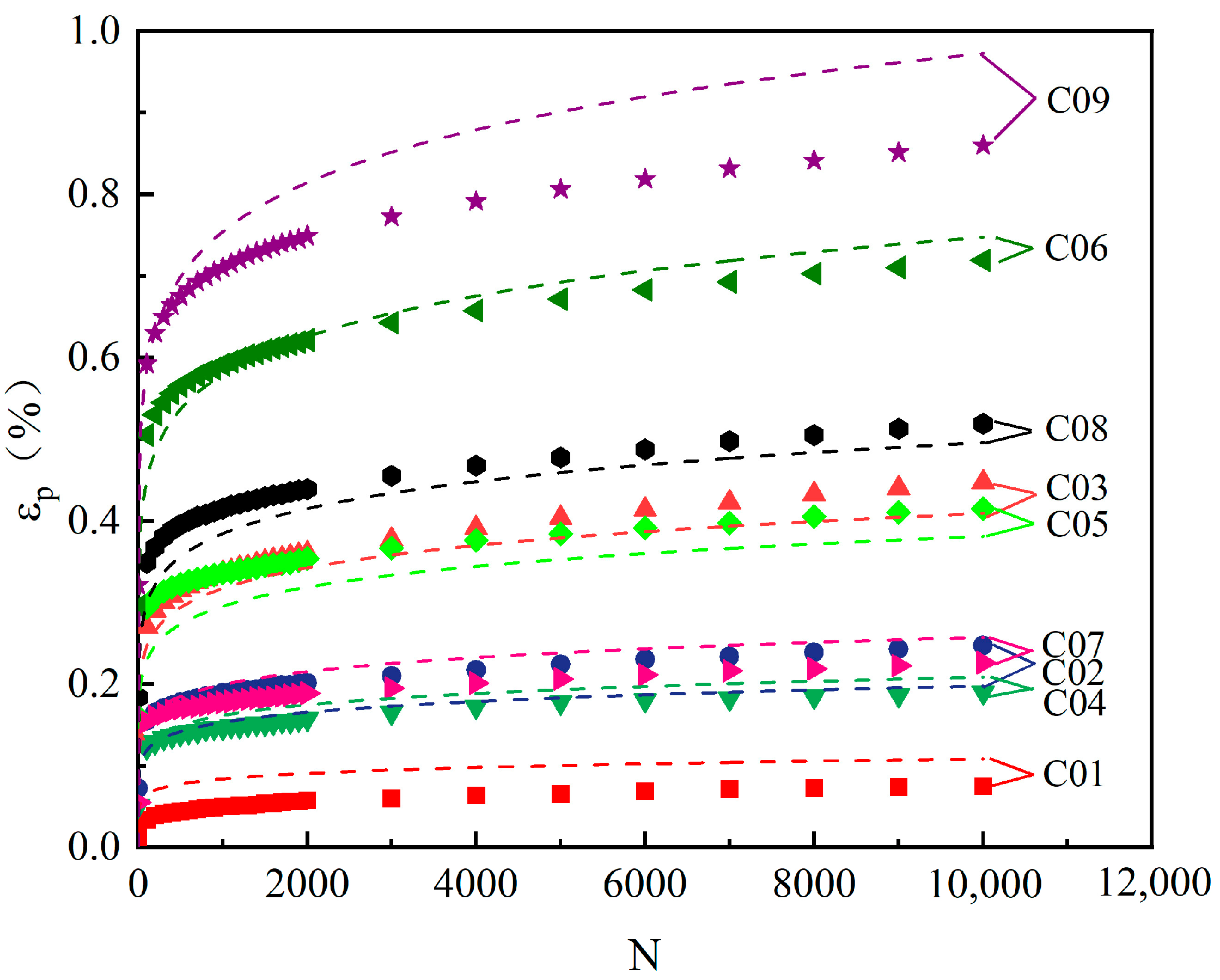

3.1. Typical Deformation Behavior of Silt under Long-Term Cyclic Loading

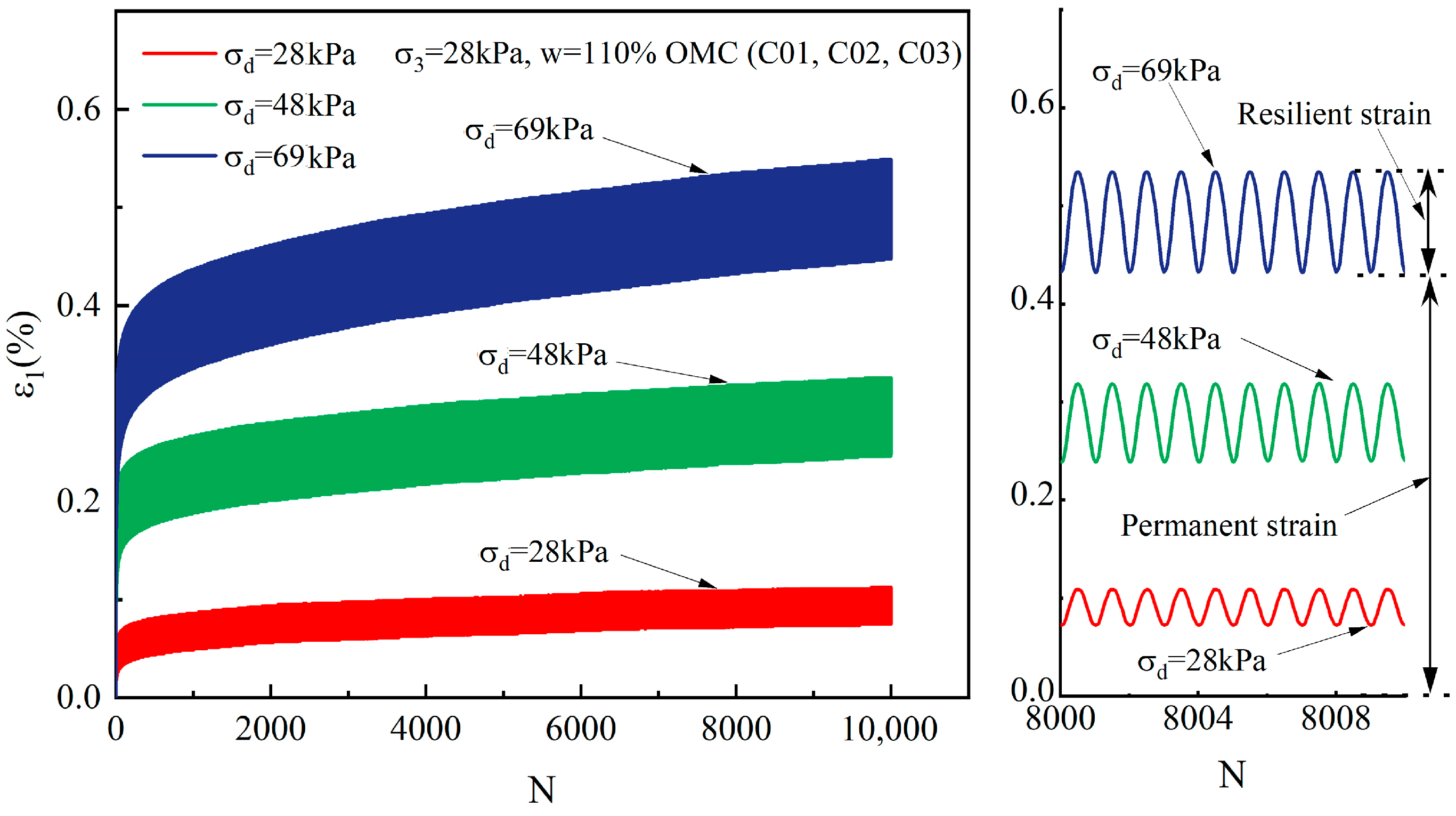

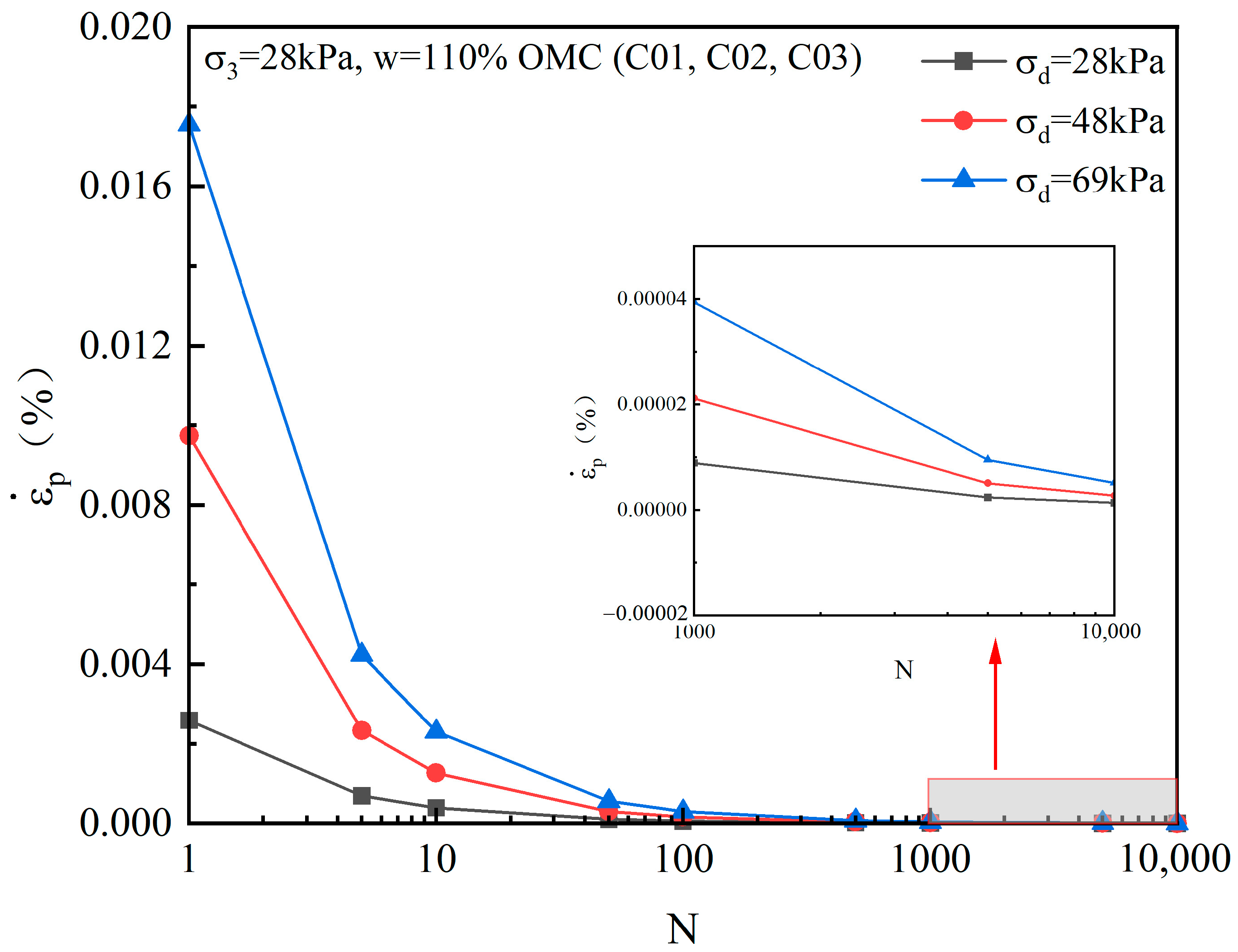

3.2. Effect of Cyclic Deviator Stress

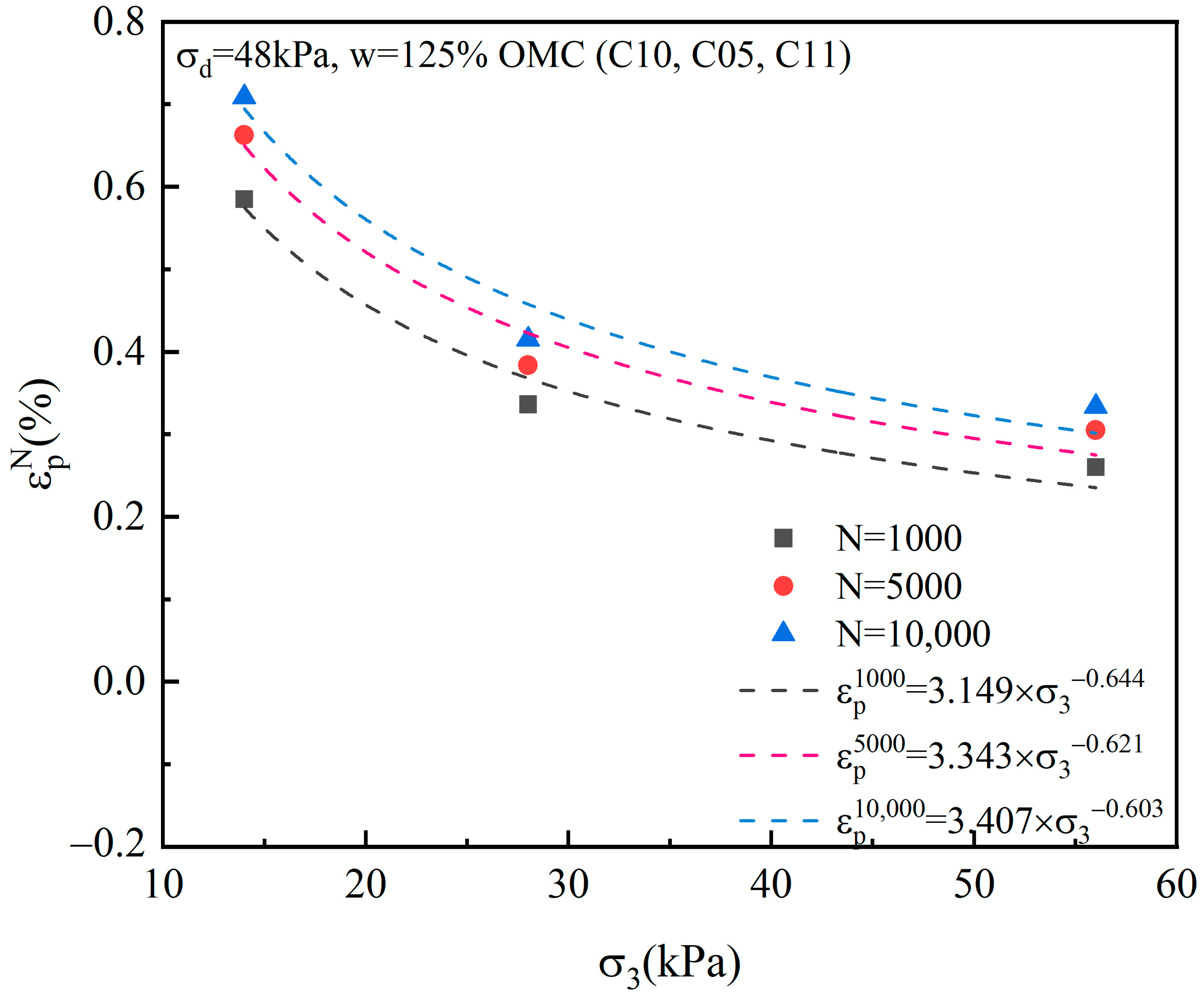

3.3. Effect of Confining Pressure

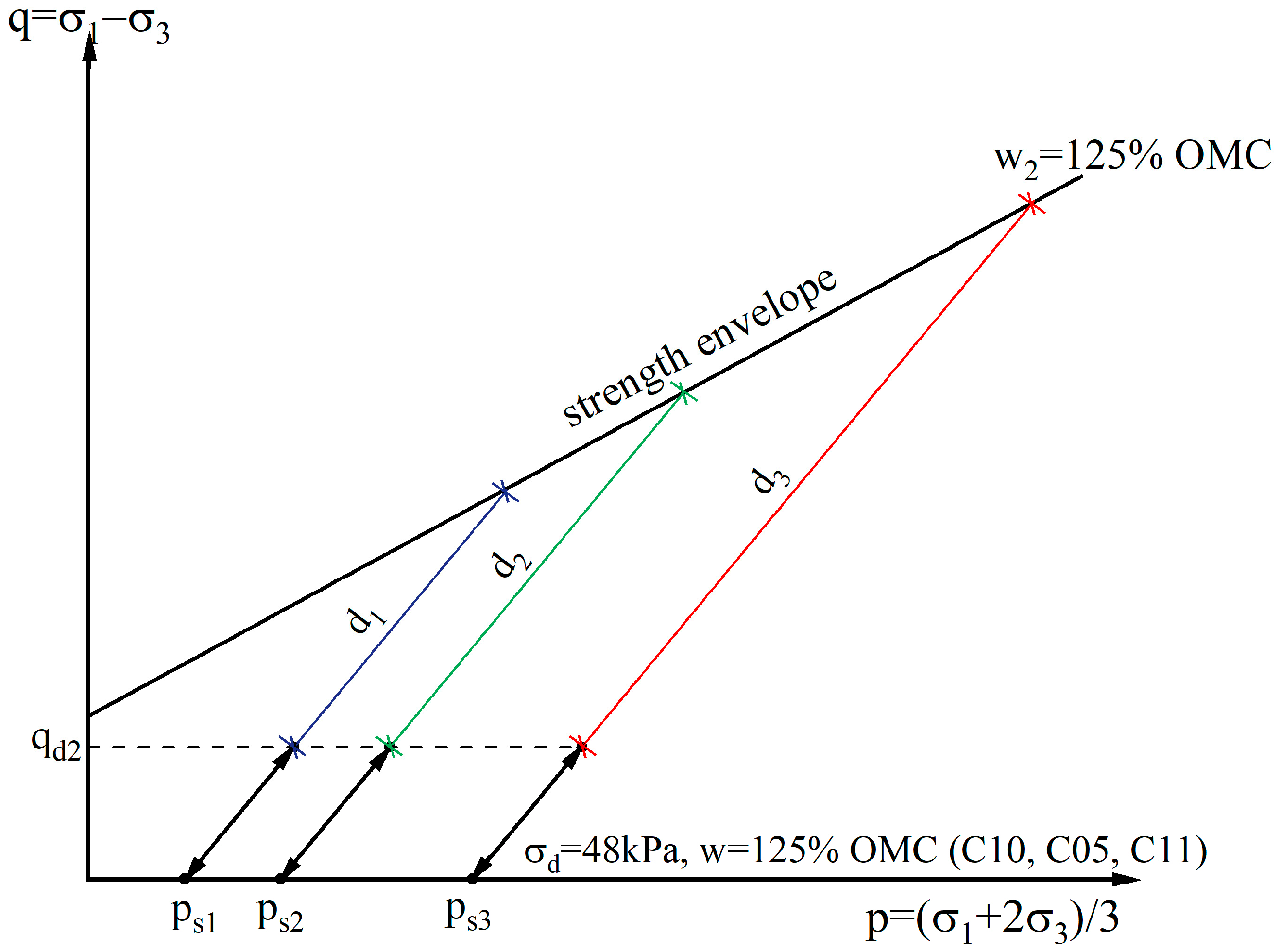

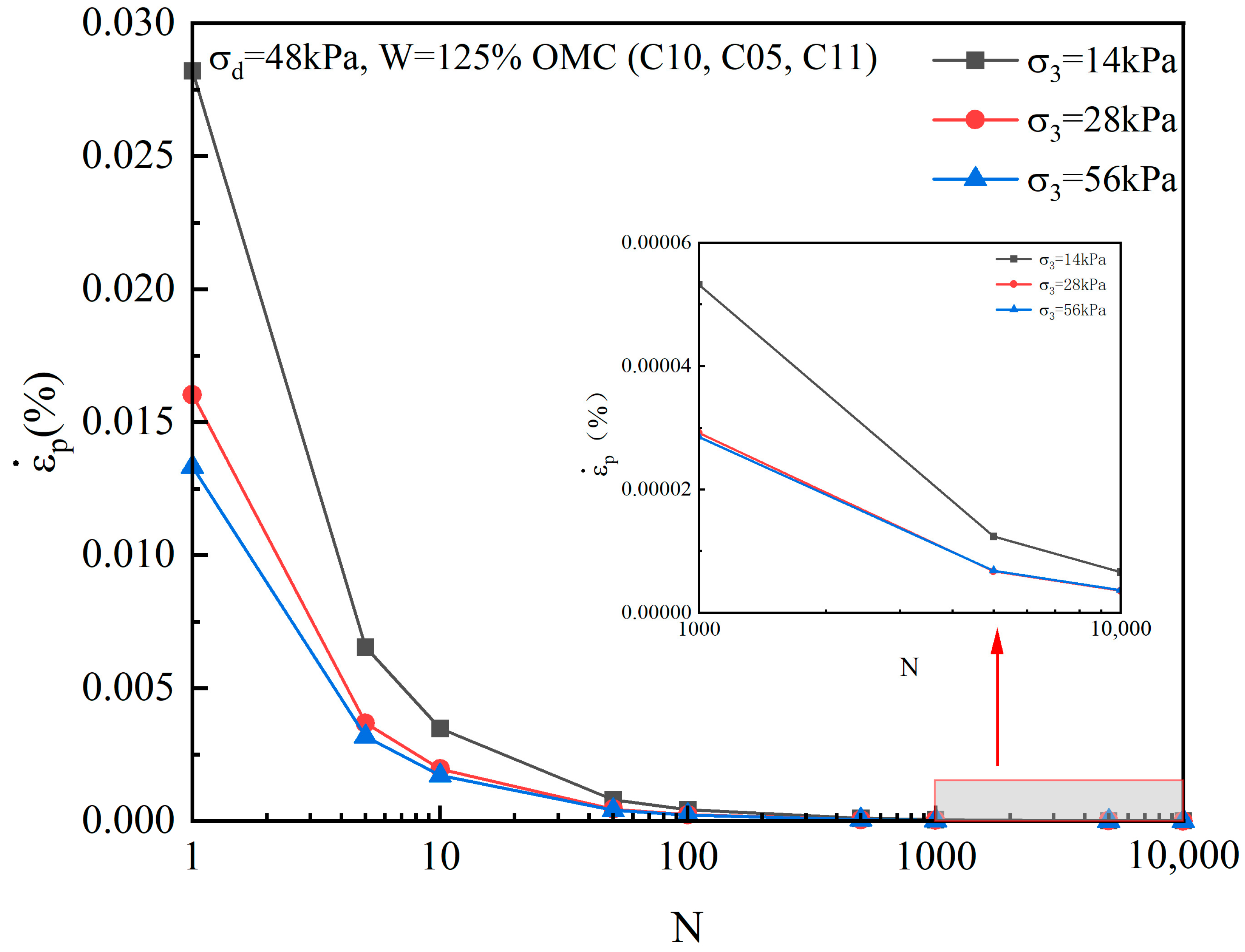

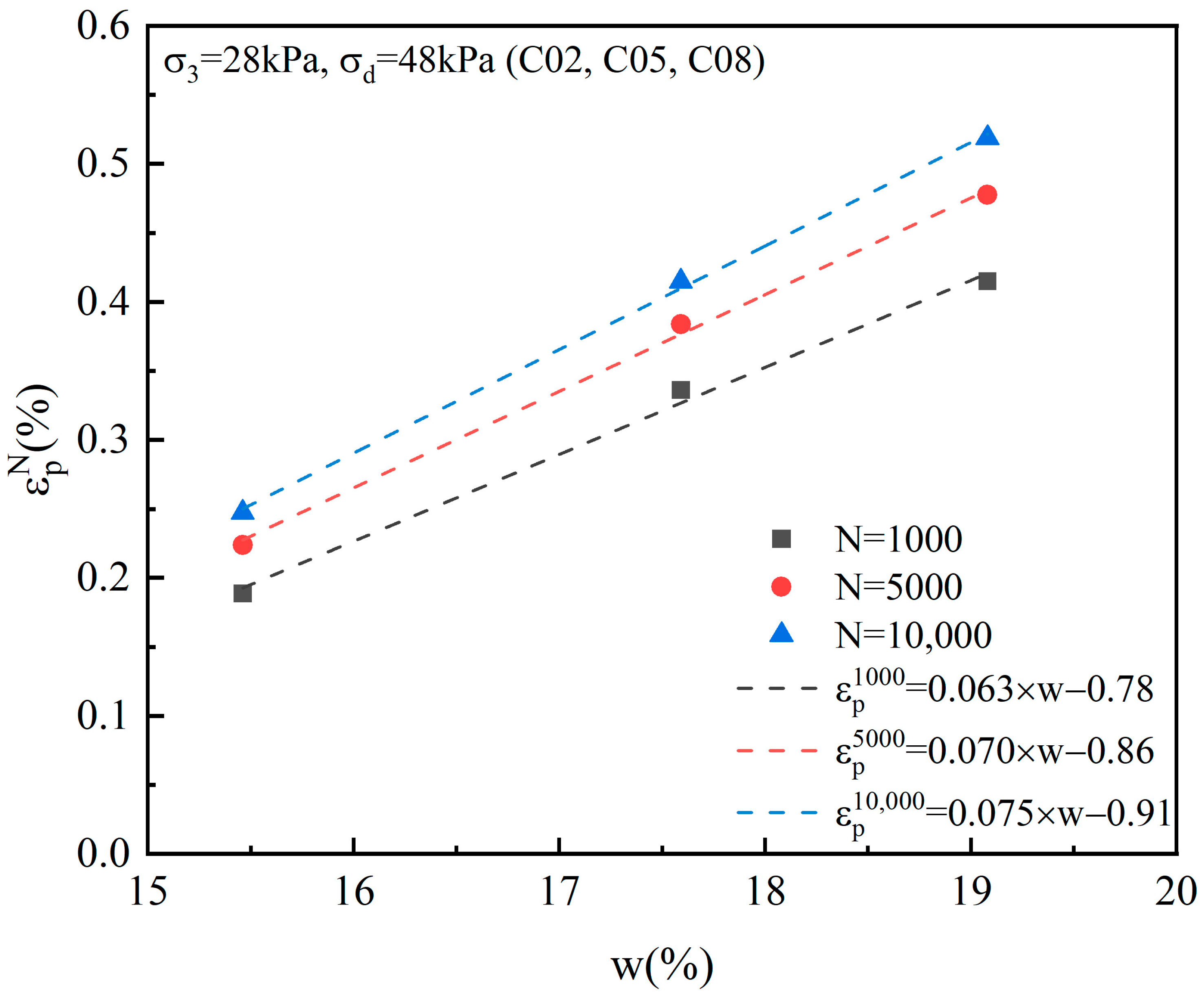

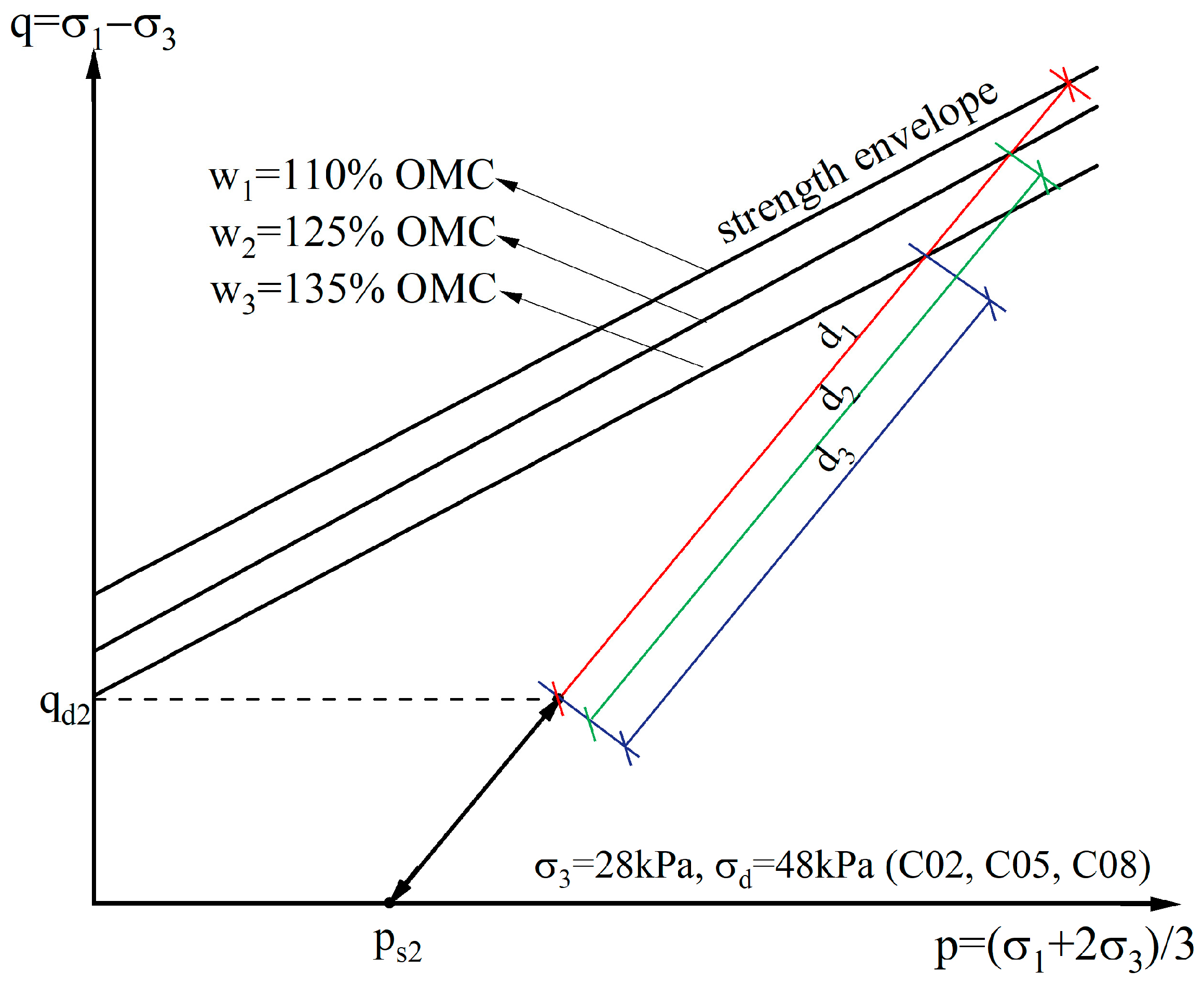

3.4. Effect of Moisture Content

4. An Empirical Model for Permanent Axial Strain Prediction

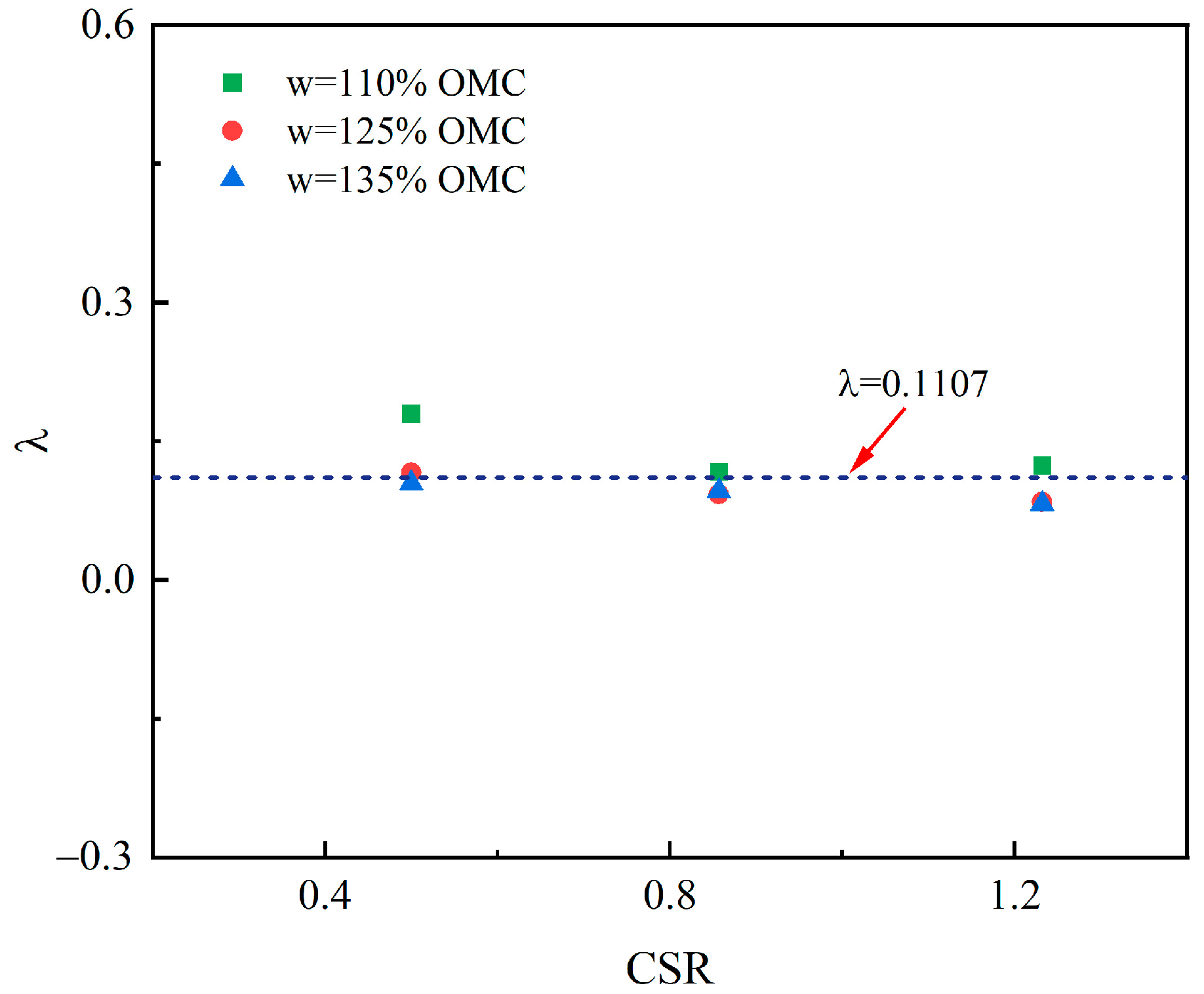

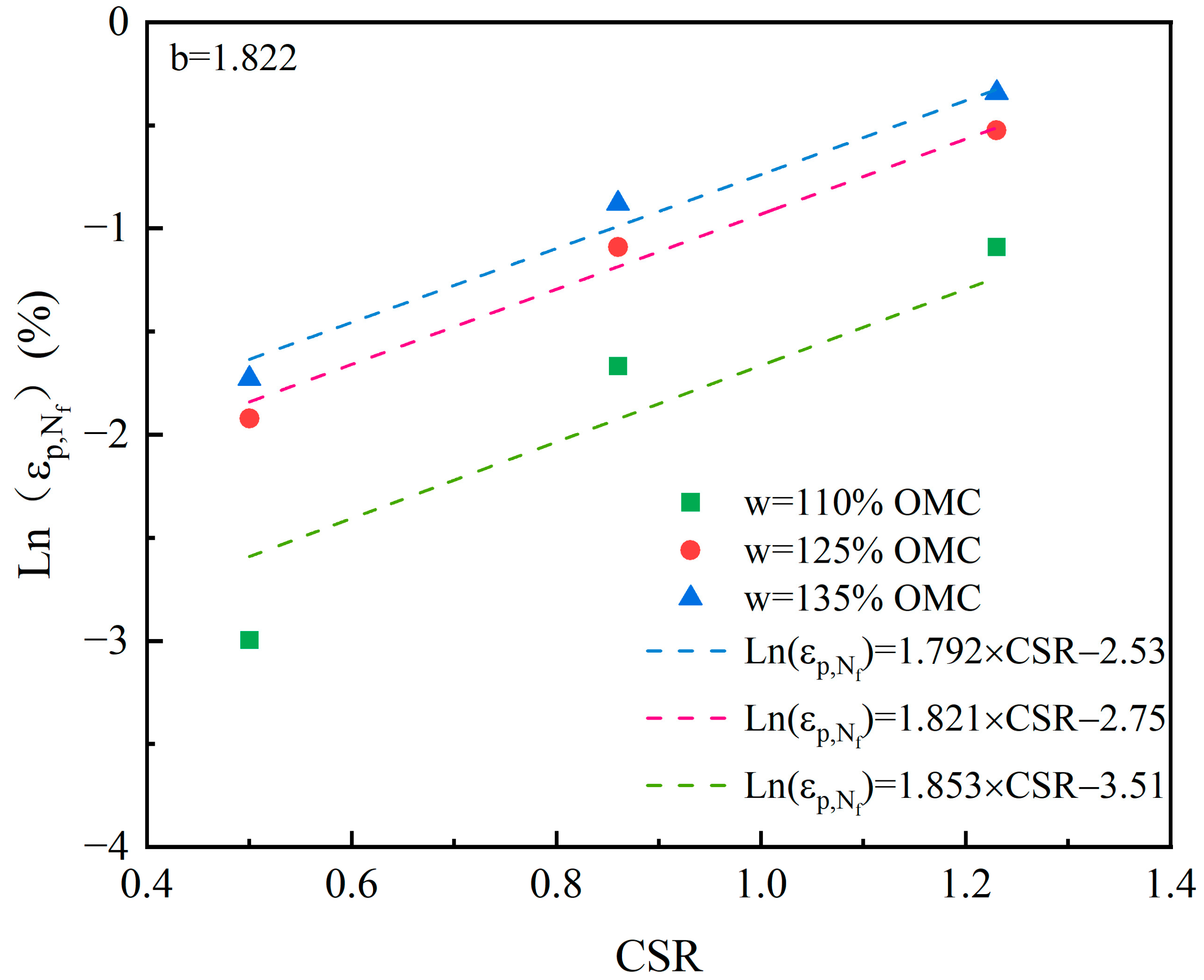

4.1. Empirical Model

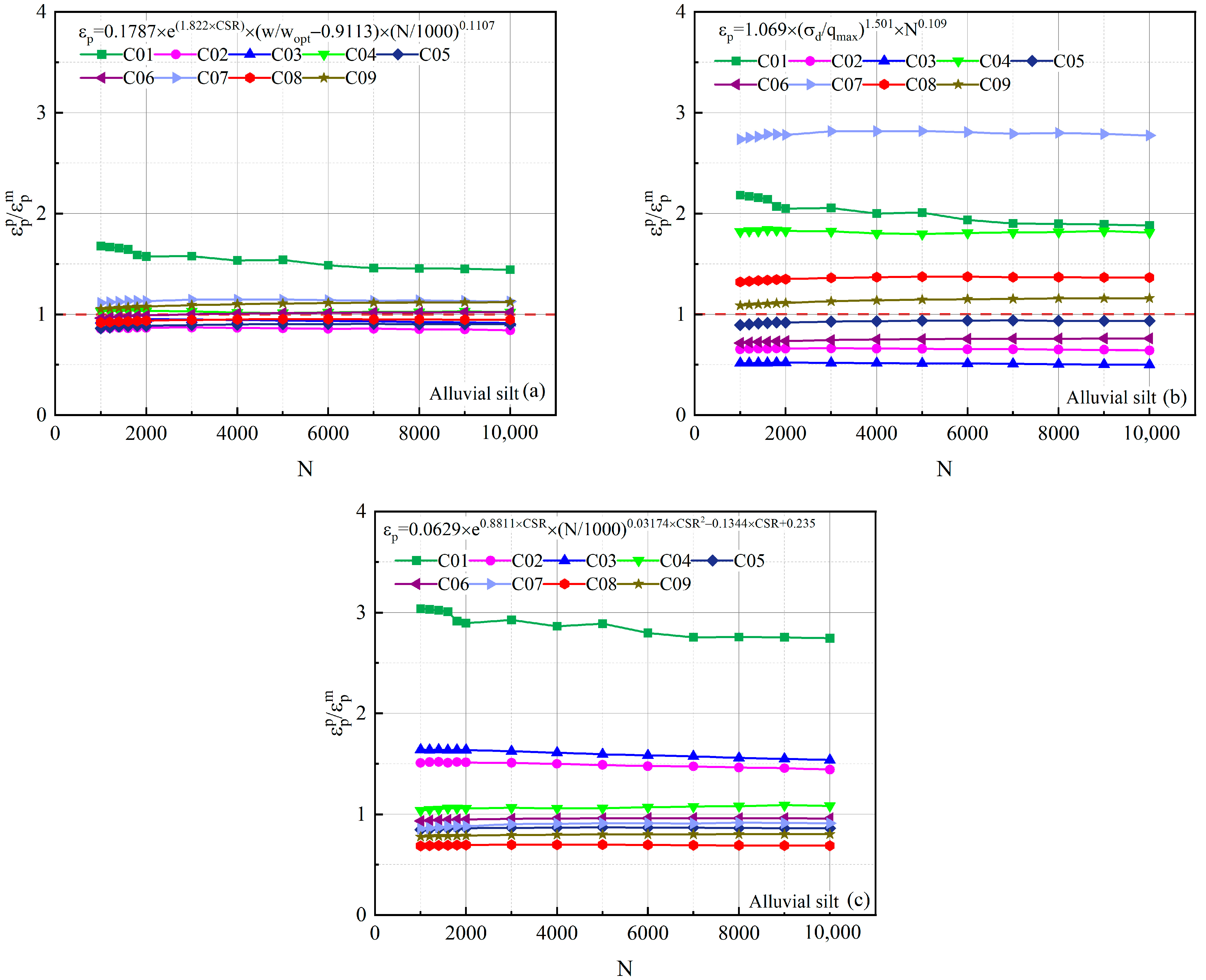

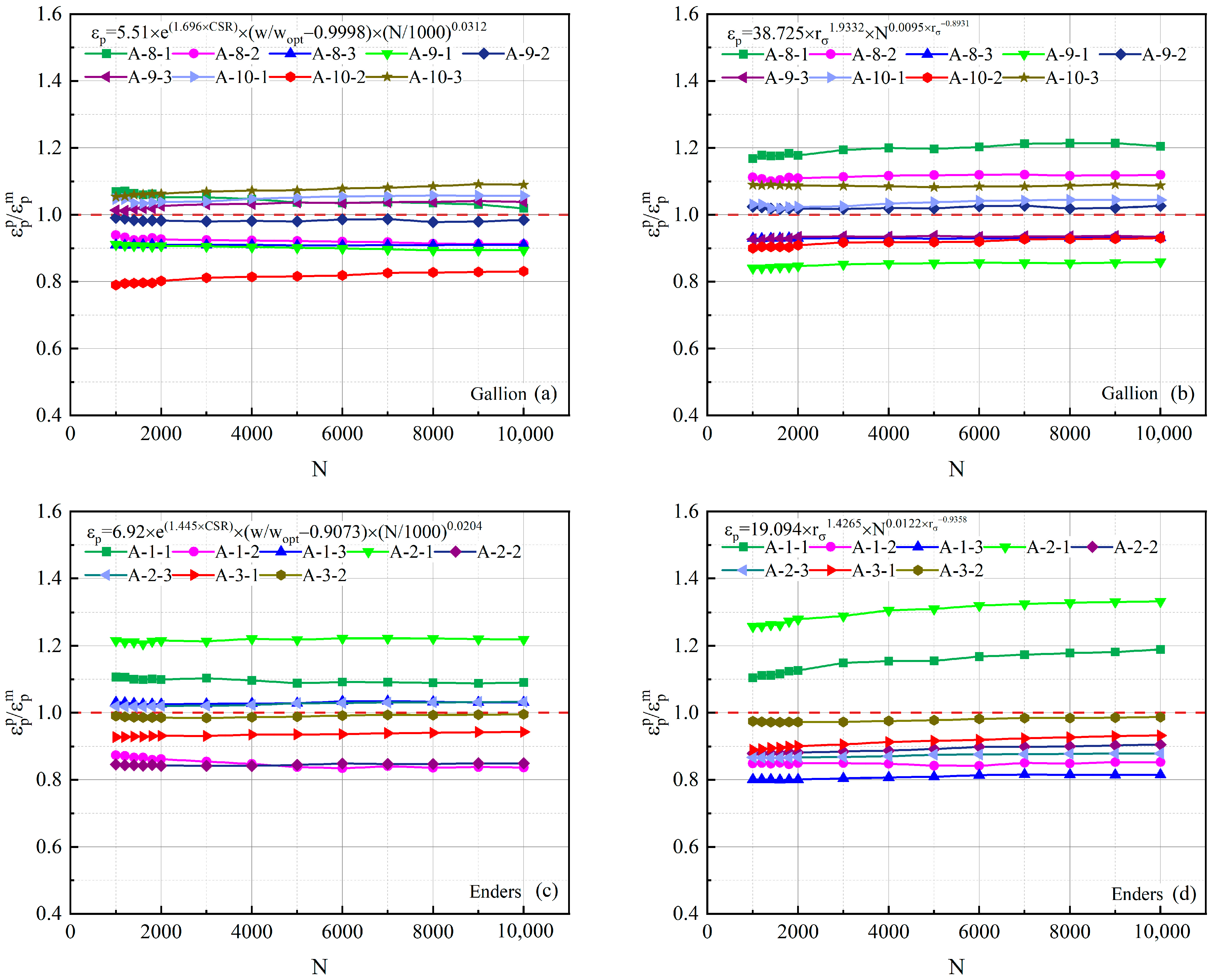

4.2. Verification of the Empirical Model

5. Summary and Conclusions

- (1)

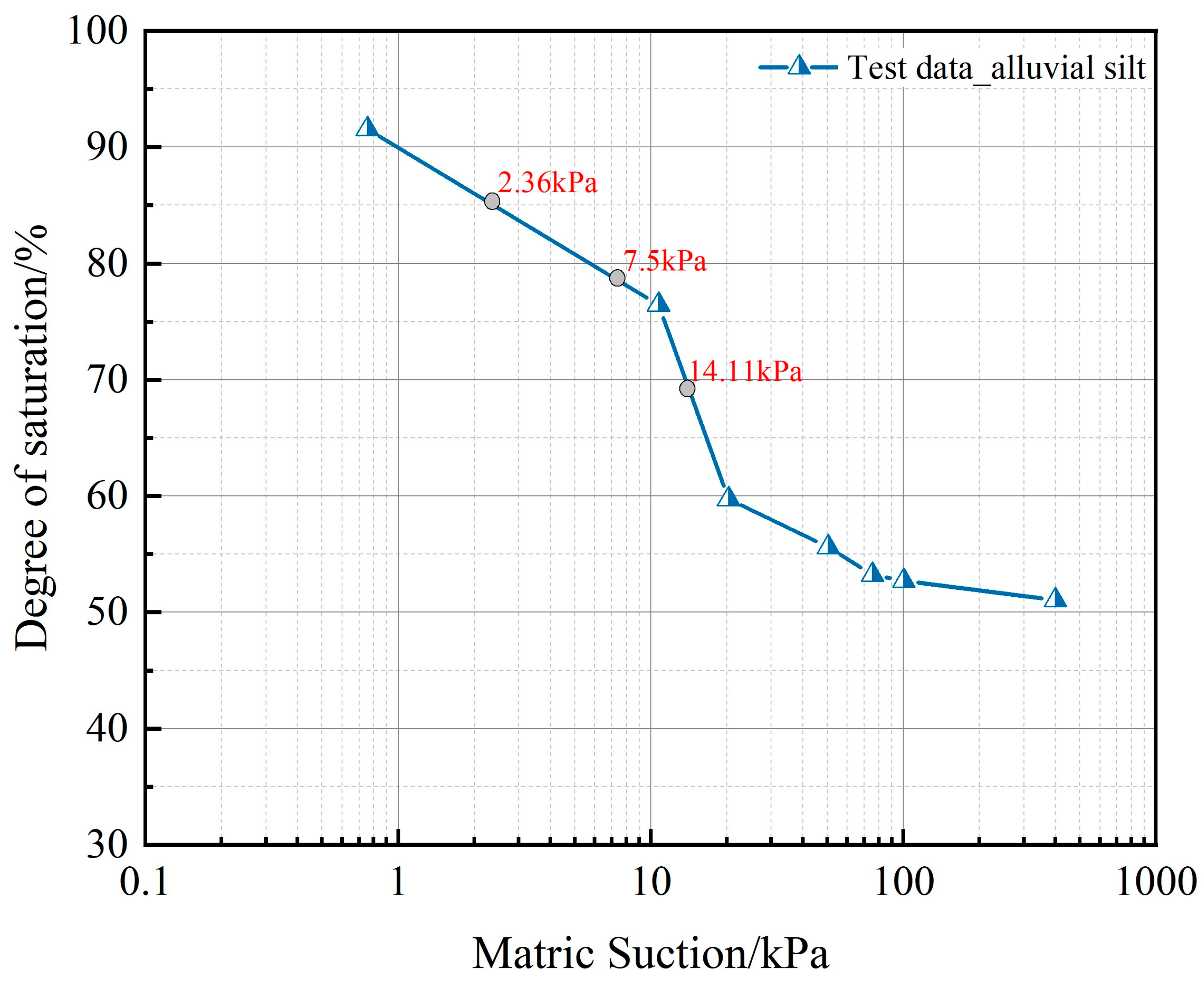

- When the moisture content is greater than the optimal moisture content, the static strength of silt decreases with the increase in moisture content, and the internal friction angle does not change with the change in moisture content. The decrease in static strength is mainly caused by the decrease in cohesion. The matric suction of alluvial silt in the Yellow River is more sensitive to the change in moisture content. When the moisture content increases from 110% OMC to 135% OMC, the matric suction decreases by 83.3%, which is the main reason for the decrease in cohesion.

- (2)

- Under the condition of the plastic shakedown state, the axial permanent strain of silt accumulates rapidly during the first 1000 cycles of cyclic loading, and the permanent strain accounts for more than 75% of the total permanent strain of the total number of cycles. The effect of the early stage of loading on the total permanent strain is significant. As the cyclic loading progresses, the area of the hysteresis curve gradually decreases and the tilt angle increases, indicating that the permanent strain accumulation rate gradually slows down.

- (3)

- With the increase in moisture content and cyclic deviator stress, and the decrease in confining pressure, the axial permanent strain and the accumulating rate of permanent strain of the silt increases. The increase in permanent strain has a linear relationship with the increase in moisture content and cyclic deviator stress, and a power relationship with the decrease in confining pressure. The influence of cyclic deviator stress on permanent deformation is the most significant, and the influence of confining pressure is the smallest. The permanent strain of silt under different influencing factors increases with the decrease in the distance between the peak point of the cyclic stress path and the strength envelope.

- (4)

- A prediction model with a wide applicability to predicting the permanent strain of the silt under cyclic loading with different moisture contents was established by introducing the reference number of cycles. The comparison with the existing prediction models and the prediction for the experimental data in previous literature demonstrated the advantages of the proposed model, including easy acquisition of the model parameters, a simple calculation method and high prediction accuracy. This model can provide useful references for the engineering design and construction of silt subgrades. In the future, the hollow cylinder torsional shear test can be carried out to study the engineering properties of silt under the heart-shaped stress path and predict the permanent deformation of silt subgrade caused by traffic load.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, J.; Xiao, J. Experimental study on the stability of railroad silt subgrade with increasing train speed. J. Geotech. Geoenviron. Eng. 2010, 136, 833–841. [Google Scholar] [CrossRef]

- Li, M.; Li, Y.; Islam, M.R. Effects of water content and interface roughness on the shear strength of silt–cement mortar interface. Soils Found. 2021, 61, 1615–1629. [Google Scholar] [CrossRef]

- Wang, Y.; Cao, T.; Shao, J.; Song, Y.; Wan, Y. Experimental study on static characteristics of the Yellow River silt under (triaxial) consolidated undrained conditions. Mar. Georesour. Geotechnol. 2023, 41, 285–294. [Google Scholar] [CrossRef]

- Drumm, E.C.; Reeves, J.S.; Madgett, M.R.; Trolinger, W.D. Subgrade resilient modulus correction for saturation effects. J. Geotech. Geoenviron. Eng. 1997, 123, 663–670. [Google Scholar] [CrossRef]

- Guan, Y.; Drumm, E.C.; Jackson, N.M. Weighting factor for seasonal subgrade resilient modulus. Transp. Res. Rec. 1998, 1619, 94–101. [Google Scholar] [CrossRef]

- Yang, L.; Shao, S.; Wang, F.; Wang, L. Experimental Study on the Axial Deformation Characteristics of Compacted Lanzhou Loess under Traffic Loads. Sustainability 2023, 15, 10939. [Google Scholar] [CrossRef]

- Marr, W.A., Jr.; Chrisitian, J.T. Permanent displacements due to cyclic wave loading. J. Geotech. Eng. Div. 1981, 107, 1129–1149. [Google Scholar] [CrossRef]

- Wichtmann, T.; Niemunis, A.; Triantafyllidis, T. Strain accumulation in sand due to cyclic loading: Drained triaxial tests. Soil Dyn. Earthq. Eng. 2005, 25, 967–979. [Google Scholar] [CrossRef]

- Wichtmann, T.; Niemunis, A.; Triantafyllidis, T. Validation and calibration of a high-cycle accumulation model based on cyclic triaxial tests on eight sands. Soils Found. 2009, 49, 711–728. [Google Scholar] [CrossRef]

- Saeidaskari, J.; Alibolandi, M.; Azizkandi, A.S. Undrained monotonic and cyclic behavior of Qeshm calcareous sand. Mar. Georesour. Geotechnol. 2021, 39, 798–811. [Google Scholar] [CrossRef]

- Li, M.; Dai, M.; Yao, S.; Gao, S.; Yuan, G. Effects of frequencies on the cyclic behavior of marine soft clay under different consolidated stress paths. Mar. Georesour. Geotechnol. 2023, 41, 436–445. [Google Scholar] [CrossRef]

- Ramos, A.; Correia, A.G.; Indraratna, B.; Ngo, T.; Calçada, R.; Costa, P.A. Mechanistic-empirical permanent deformation models: Laboratory testing, modelling and ranking. Transp. Geotech. 2020, 23, 100326. [Google Scholar] [CrossRef]

- Prévost, J.H. Mathematical modelling of monotonic and cyclic undrained clay behaviour. Int. J. Numer. Anal. Methods Geomech. 1977, 1, 195–216. [Google Scholar] [CrossRef]

- Manzari, M.T.; Dafalias, Y.F. A critical state two-surface plasticity model for sands. Géotechnique 1997, 47, 255–272. [Google Scholar] [CrossRef]

- Chen, C.; Xu, G.; Zhou, Z.; Kong, L.; Zhang, X.; Yin, S. Undrained dynamic behaviour of peaty organic soil under long-term cyclic loading, Part II: Constitutive model and simulation. Soil Dyn. Earthq. Eng. 2020, 129. [Google Scholar] [CrossRef]

- Li, S.L.; He, S.Y.; Wang, X.T.; Chen, S.W.; Guo, X.Y. Prediction of Soft Ground Settlement by BP Neural Network. Appl. Mech. Mater. 2014, 608, 825–828. [Google Scholar] [CrossRef]

- Monismith, C.L.; Ogawa, N.; Freeme, C.R. Permanent deformation characteristics of subgrade soils due to repeated loading. Transp. Res. Rec. 1975, 1–17. [Google Scholar]

- Li, D.; Selig, E.T. Cumulative plastic deformation for fine-grained subgrade soils. J. Geotech. Eng. 1996, 122, 1006–1013. [Google Scholar] [CrossRef]

- Chai, J.C.; Miura, N. Traffic-load-induced permanent deformation of road on soft subsoil. J. Geotech. Geoenviron. Eng. 2002, 128, 907–916. [Google Scholar] [CrossRef]

- Guo, L.; Wang, J.; Cai, Y.; Liu, H.; Gao, Y.; Sun, H. Undrained deformation behavior of saturated soft clay under long-term cyclic loading. Soil Dyn. Earthq. Eng. 2013, 50, 28–37. [Google Scholar] [CrossRef]

- Jamali, H.; Tolooiyan, A.; Dehghani, M.; Asakereh, A.; Kalantari, B. Long-term dynamic behaviour of Coode Island Silt (CIS) containing different sand content. Appl. Ocean Res. 2018, 73, 59–69. [Google Scholar] [CrossRef]

- Qian, J.; Li, S.; Gu, X.; Zhang, J. A unified model for estimating the permanent deformation of sand under a large number of cyclic loads. Ocean Eng. 2019, 181, 293–302. [Google Scholar] [CrossRef]

- Wu, H.N.; Shen, S.L.; Chai, J.C.; Zhang, D.M.; Xu, Y.S. Evaluation of train-load-induced settlement in metro tunnels. Proc. Inst. Civ. Eng.-Geotech. Eng. 2015, 168, 396–406. [Google Scholar] [CrossRef]

- Qian, J.; Li, S.; Zhang, J.; Jiang, J.; Wang, Q. Effects of OCR on monotonic and cyclic behavior of reconstituted Shanghai silty clay. Soil Dyn. Earthq. Eng. 2019, 118, 111–119. [Google Scholar] [CrossRef]

- Chik, Z.; Aljanabi, Q.A.; Kasa, A.; Taha, M.R. Tenfold cross validation artificial neural network modeling of the settlement behavior of a stone column under a highway embankment. Arab. J. Geosci. 2014, 7, 4877–4887. [Google Scholar] [CrossRef]

- Ren, X.W.; Tang, Y.Q.; Li, J.; Yang, Q. A prediction method using grey model for cumulative plastic deformation under cyclic loads. Nat. Hazards 2012, 64, 441–457. [Google Scholar] [CrossRef]

- Xu, G.; Wang, Y.; Liu, S.; Wang, S. Tensioning-phase box girder deformation prediction model based on ant colony algorithm and residual correction. Math. Probl. Eng. 2018, 2018, 1872578. [Google Scholar] [CrossRef]

- Werkmeister, S.; Dawson, A.R.; Wellner, F. Permanent deformation behavior of granular materials and the shakedown concept. Transp. Res. Rec. 2001, 1757, 75–81. [Google Scholar] [CrossRef]

- Cerni, G.; Cardone, F.; Virgili, A.; Camilli, S. Characterisation of permanent deformation behaviour of unbound granular materials under repeated triaxial loading. Constr. Build. Mater. 2012, 28, 79–87. [Google Scholar] [CrossRef]

- Salour, F.; Erlingsson, S. Permanent deformation characteristics of silty sand subgrades from multistage RLT tests. Int. J. Pavement Eng. 2017, 18, 236–246. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, Y.; Liu, X.; Liu, J.; Liu, J. Shakedown behavior of yellow river alluvial silt stabilized with lignin–lime combined additive. J. Mater. Civ. Eng. 2020, 32, 04019318. [Google Scholar] [CrossRef]

- Li, Y.; Nie, R.; Yue, Z.; Leng, W.; Guo, Y. Dynamic behaviors of fine-grained subgrade soil under single-stage and multi-stage intermittent cyclic loading: Permanent deformation and its prediction model. Soil Dyn. Earthq. Eng. 2021, 142, 106548. [Google Scholar] [CrossRef]

- Elliott, R.P.; Dennis, N.D.; Qiu, Y. Permanent Deformation of Subgrade Soils; Fayetteville, Mack-Blackwell Transportation Center Publ.: Fayetteville, AR, USA, 1998. [Google Scholar]

- Puppala, A.J.; Saride, S.; Chomtid, S. Experimental and modeling studies of permanent strains of subgrade soils. J. Geotech. Geoenviron. Eng. 2009, 135, 1379–1389. [Google Scholar] [CrossRef]

- Xiao, J.; Juang, C.H.; Xu, C.; Li, X.; Wang, L. Strength and deformation characteristics of compacted silt from the lower reaches of the Yellow River of China under monotonic and repeated loading. Eng. Geol. 2014, 178, 49–57. [Google Scholar] [CrossRef]

- ASTM D854-14; Standard Test Methods for Specific Gravity of Soil Solids by Water Pycnometer. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM D4318-10; Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM International: West Conshohocken, PA, USA, 2010.

- ASTM D422-63; Standard Test Method for Particle-Size Analysis of Soils. ASTM International: West Conshohocken, PA, USA, 2007.

- ASTM D698-12; Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D2487-17; Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). ASTM International: West Conshohocken, PA, USA, 2017.

- Chen, D.; Tang, J.; Yang, X. Effects of Drying–Wetting Cycle and Fines Content on Hysteresis and Dynamic Properties of Granite Residual Soil under Cyclic Loading. Appl. Sci. 2023, 13, 6660. [Google Scholar] [CrossRef]

- Lackenby, J.; Indraratna, B.; McDowell, G.; Christie, D. Effect of confining pressure on ballast degradation and deformation under cyclic triaxial loading. Géotechnique 2007, 57, 527–536. [Google Scholar] [CrossRef]

- Rahman, M.S.; Erlingsson, S. Predicting permanent deformation behaviour of unbound granular materials. Int. J. Pavement Eng. 2015, 16, 587–601. [Google Scholar] [CrossRef]

- ASTM D5311-11; Standard Test Method for Load Controlled Cyclic Triaxial Strength of Soil. ASTM International: West Conshohocken, PA, USA, 2011.

- Uzan, J. Characterization of clayey subgrade materials for mechanistic design of flexible pavements. Transp. Res. Rec. 1998, 1629, 189–196. [Google Scholar] [CrossRef]

- Ren, H.; Liu, X.; Xuan, M.; Ye, X.; Li, Q.; Zhang, S. Study of cumulative plastic deformation of compacted silt under cyclic loading. Rock Soil Mech. 2021, 42, 1045–1055. [Google Scholar]

- Chen, R.; Chen, J.; Zhao, X.; Bian, X.; Chen, Y. Cumulative settlement of track subgrade in high-speed railway under varying water levels. Int. J. Rail Transp. 2014, 2, 205–220. [Google Scholar] [CrossRef]

- Wu, T.; Jin, H.; Guo, L.; Sun, H.; Tong, J.; Jiang, Y.; Wei, P. Predicting method on settlement of soft subgrade soil caused by traffic loading involving principal stress rotation and loading frequency. Soil Dyn. Earthq. Eng. 2022, 152, 107023. [Google Scholar] [CrossRef]

| Specific Gravity | Plastic Limit (%) | Liquid Limit (%) | Plasticity Index (%) | Percent of Particle Size (%) | Optimal Moisture Content (%) | Maximum Dry Density (g/cm3) | ||

|---|---|---|---|---|---|---|---|---|

| 0.075–0.25 mm | 0.005–0.075 mm | <0.005 mm | ||||||

| 2.68 | 14.40 | 24.00 | 9.60 | 26.73 | 61.21 | 3.79 | 14.00 | 1.86 |

| No. | w (%) | (kPa) | (kPa) | (%) |

|---|---|---|---|---|

| C01 | 110% OMC | 28 | 28 | 0.0750 |

| C02 | 110% OMC | 28 | 48 | 0.2475 |

| C03 | 110% OMC | 28 | 69 | 0.4475 |

| C04 | 125% OMC | 28 | 28 | 0.1900 |

| C05 | 125% OMC | 28 | 48 | 0.4150 |

| C06 | 125% OMC | 28 | 69 | 0.7188 |

| C07 | 135% OMC | 28 | 28 | 0.2262 |

| C08 | 135% OMC | 28 | 48 | 0.5188 |

| C09 | 135% OMC | 28 | 69 | 0.8600 |

| C10 | 125% OMC | 14 | 48 | 0.7088 |

| C11 | 125% OMC | 56 | 48 | 0.3337 |

| Test Moisture Content w (%) | Cohesive Force C (kPa) | Friction Angle φ (°) | Test Degree of Saturation S (%) | Corresponding Matric Suction (kPa) |

|---|---|---|---|---|

| 110% OMC | 35.4 | 32.4 | 69.05 | 14.11 |

| 125% OMC | 29.1 | 33.4 | 78.57 | 7.52 |

| 135% OMC | 23.9 | 32.6 | 85.22 | 2.36 |

| Test Number | w (%) | (kPa) | (kPa) | (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Measured | Xiao’s Model | H. Jamali’s Model | This Study | |||||||

| Estimated | Error (%) | Estimated | Error (%) | Estimated | Error (%) | |||||

| C01 | 110% OMC | 28 | 28 | 0.0750 | 0.1592 | 112.3 | 0.2058 | 174.4 | 0.1082 | 44.3 |

| C02 | 110% OMC | 28 | 48 | 0.2475 | 0.1776 | −28.2 | 0.3568 | 44.2 | 0.2085 | −15.8 |

| C03 | 110% OMC | 28 | 69 | 0.4475 | 0.2424 | −45.8 | 0.6887 | 53.9 | 0.4091 | −8.6 |

| C04 | 125% OMC | 28 | 28 | 0.1900 | 0.3574 | 88.1 | 0.2058 | 8.3 | 0.1942 | 2.2 |

| C05 | 125% OMC | 28 | 48 | 0.4150 | 0.3989 | −3.9 | 0.3568 | −14.2 | 0.3742 | −9.8 |

| C06 | 125% OMC | 28 | 69 | 0.7188 | 0.5443 | −24.3 | 0.6887 | −4.2 | 0.7344 | 2.2 |

| C07 | 135% OMC | 28 | 28 | 0.2262 | 0.6163 | 172.5 | 0.2058 | −9.0 | 0.2550 | 12.7 |

| C08 | 135% OMC | 28 | 48 | 0.5188 | 0.6877 | 32.6 | 0.3568 | −31.2 | 0.4914 | −5.3 |

| C09 | 135% OMC | 28 | 69 | 0.8600 | 0.9384 | 9.1 | 0.6887 | −19.9 | 0.9642 | 12.1 |

| Test Number | w (%) | (kPa) | (kPa) | |||||

|---|---|---|---|---|---|---|---|---|

| Measured | Elliott et al. | This Study | ||||||

| Estimated | Error (%) | Estimated | Error (%) | |||||

| A-8-1 | 105% OMC | 21 | 28 | 0.9083 | 1.0944 | 20.5 | 0.9259 | 1.9 |

| A-8-2 | 105% OMC | 21 | 41 | 1.7165 | 1.9214 | 11.9 | 1.5663 | −8.8 |

| A-8-3 | 105% OMC | 21 | 62 | 4.0169 | 3.7431 | −6.8 | 3.6574 | −8.9 |

| A-9-1 | 110% OMC | 21 | 28 | 2.0662 | 1.7749 | −14.1 | 1.8481 | −10.6 |

| A-9-2 | 110% OMC | 21 | 41 | 3.1746 | 3.2582 | 2.6 | 3.1265 | −1.5 |

| A-9-3 | 110% OMC | 21 | 62 | 7.0259 | 6.5662 | −6.5 | 7.3002 | 3.9 |

| A-10-1 | 120% OMC | 21 | 28 | 3.4937 | 3.6475 | 4.4 | 3.6924 | 5.7 |

| A-10-2 | 120% OMC | 21 | 41 | 7.5169 | 6.9900 | −7.0 | 6.2467 | −16.9 |

| A-10-3 | 120% OMC | 21 | 62 | 13.3863 | 14.5554 | 8.7 | 14.5858 | 9.0 |

| A-1-1 | 105% OMC | 21 | 28 | 2.5000 | 2.9727 | 18.9 | 2.7259 | 9.0 |

| A-1-2 | 105% OMC | 21 | 41 | 5.1000 | 4.3503 | −14.7 | 4.2664 | −16.3 |

| A-1-3 | 105% OMC | 21 | 62 | 8.5200 | 6.9452 | −18.5 | 8.7869 | 3.1 |

| A-2-1 | 110% OMC | 21 | 28 | 3.0200 | 4.0244 | 33.3 | 3.6811 | 21.9 |

| A-2-2 | 110% OMC | 21 | 41 | 6.7800 | 6.1350 | −9.5 | 5.7613 | −15.0 |

| A-2-3 | 110% OMC | 21 | 62 | 11.4900 | 10.0984 | −12.1 | 11.8658 | 3.3 |

| A-3-1 | 120% OMC | 21 | 28 | 5.9300 | 5.5286 | −6.8 | 5.5913 | −5.7 |

| A-3-2 | 120% OMC | 21 | 41 | 8.7900 | 8.6773 | −1.3 | 8.7510 | −0.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, Z.; Zhang, Z.; Wang, L.; Zhang, J.; Li, Y. Effect of Moisture Content on the Permanent Strain of Yellow River Alluvial Silt under Long-Term Cyclic Loading. Sustainability 2023, 15, 13155. https://doi.org/10.3390/su151713155

Du Z, Zhang Z, Wang L, Zhang J, Li Y. Effect of Moisture Content on the Permanent Strain of Yellow River Alluvial Silt under Long-Term Cyclic Loading. Sustainability. 2023; 15(17):13155. https://doi.org/10.3390/su151713155

Chicago/Turabian StyleDu, Zibo, Zheng Zhang, Lei Wang, Jingwei Zhang, and Yonghui Li. 2023. "Effect of Moisture Content on the Permanent Strain of Yellow River Alluvial Silt under Long-Term Cyclic Loading" Sustainability 15, no. 17: 13155. https://doi.org/10.3390/su151713155

APA StyleDu, Z., Zhang, Z., Wang, L., Zhang, J., & Li, Y. (2023). Effect of Moisture Content on the Permanent Strain of Yellow River Alluvial Silt under Long-Term Cyclic Loading. Sustainability, 15(17), 13155. https://doi.org/10.3390/su151713155