Abstract

A large number of massive repair machines are urgently necessary for a post-disaster rescue. These machines also need to be operated by professionals, and the demands require the participation of different industries in the whole society since they cannot be met via the national emergency resource storage system. Therefore, the support of extensive emergency resources from different industries across the entire society is needed in the rescue process, that is, social emergency resource sharing. To achieve this sharing, an emergency resource scheduling model should have the ability to allocate resources from the whole society. However, traditional emergency scheduling models have not considered the suppliers’ willingness to take part in the scheduling activities and their abilities to supply the resources. To solve the above issues, this paper designs a scheduling model for social emergency resource sharing based on an emergency contribution index (SSERS). The emergency contribution index (ECI) can be used to find the enterprises that not only have the ability to provide efficient emergency resources on time but also have the willingness to participate in emergency rescue. The results show that our model effectively optimizes the basic models to some extent and achieves social emergency resource sharing.

1. Introduction

The existing emergency resource scheduling models (traditional models) can be mainly divided into two types, i.e., single-objective models and multi-objective models. The single-objective models mainly aim to minimize time [1,2,3,4], minimizing distance [5,6,7], maximizing satisfaction [8,9,10], etc. The multi-objective models combine the above objectives to find the best solution [11,12,13,14,15,16,17,18,19]. These models are mainly applicable to the suppliers of daily living materials, such as the national emergency resource reserve system, and they focus more on providing basic emergency materials, such as food and water, to disaster-affected areas in the shortest time and with the lowest costs, but they fail to consider the specific situations in terms of a dynamic and open environment. Large and specialized engineering equipment, such as the graders, road rollers, and pavers required for road repair construction, are not only expensive and require a great deal of storage space, but they also need to be operated by professionals to function, so they are not included in the national reserve system. In this case, the massive resources existing in various industries across the entire society need to be used in the post-disaster emergency process so as to effectively compensate for the lack of national emergency resource reserves, minimize disaster losses, and protect people’s lives and property.

In summary, due to the differences between the national reserve system and social emergency resource sharing, i.e., that the suppliers of the social emergency resource sharing come from different industries across the entire society, and their resource abilities and willingness to participate in emergency resource scheduling are quite different, scientific social emergency resource sharing requires emergency resource scheduling to be transformed from a static, closed national emergency resource system to an environment which adapts to a dynamic and open society.

However, in previous research [1,2,3,4,5], the researchers mainly focused on the constraints of the amount of emergency resources, the scheduling time, or the costs, and they did not take production ability and the willingness of the suppliers into account.

In the traditional model [1], each supplier is a national emergency resource reserve base, the types of emergency resources stored are basically the same, and only the distances from the disaster site are different for each. In this case, the only things that need to be considered during emergency resource scheduling are the time and cost of transportation. However, in social emergency resource sharing, things are quite different, and the abilities and willingness of the enterprises providing emergency resources will affect the efficiency of the scheduling. Currently, there are a large number of enterprises that can produce emergency resources from many industries in China, but their supply capacities are different. On the other hand, some enterprises may prioritize pursuing their own interests rather than the common goal of completing an emergency rescue. These differences will affect the efficiency of social emergency resource sharing, but as far as we know, no research has been published on the impacts of enterprises’ intrinsic factors (abilities and willingness to provide emergency resources) on social emergency resource sharing.

Briefly, there are two issues that must be addressed in the design of a new model. First, the participants have different abilities to provide emergency resources, and some may not be suitable for social emergency resource sharing. Second, it is difficult to coordinate and efficiently complete emergency resource-sharing operations because of the different interests and demands of the participants.

Therefore, in this paper, an emergency contribution index is introduced into the traditional emergency resource scheduling; it includes two components: emergency production capacity and enterprise willingness. The emergency production capacity of an enterprise is used to reflect its ability to supply various emergency resources, which is characterized by the enterprise’s capital information and business scope. The enterprise’s willingness can be divided into staff motivation and leadership enthusiasm. The staff motivation is used to reflect the commitment of the staff to the enterprise; the higher the staff motivation is, the greater the production capacity will be. Leadership enthusiasm is used to reflect the willingness of the leaders in an enterprise to participate in emergency resource-sharing activities. It is characterized by the ratio of the enterprise’s philanthropy expenditures in the previous year to the total expenditures of that year.

After considering the emergency resources needed and the spatial distance involved, the introduction of the emergency contribution index is helpful in choosing an enterprise that has both strong production capacity and a strong willingness to participate in social emergency resource-sharing activities from among a large number of emergency resource production enterprises, so as to optimize the traditional emergency resource scheduling program.

The innovations of this paper are listed below.

- (1)

- The “Emergency Production Capacity” was innovatively designed and used to quantitatively describe an enterprise’s ability to provide emergency resources; thus, it is helpful in choosing enterprises that can provide more suitable emergency resources.

- (2)

- More Powerful Participation WillingnessWe first designed the “Enterprise Willingness”, which can be used as a quantitative evaluation indicator to select enterprises with a strong willingness to participate in social emergency resource scheduling.

- (3)

- SSERS ModelIn this paper, we proposed the SSERS Model for the first time. On the basis of the traditional multi-objective emergency resource scheduling models that merely considered the requests of demand-side (scheduling time and costs, etc.), this model takes the supply side into account, i.e., the supply capabilities (emergency production capacity and staff motivation) of emergency resources and the willingness to participate in emergency resource scheduling (leadership enthusiasm). This innovation gives the model the ability to quantitatively describe the capacity and willingness for the first time; thus, the enterprises with stronger supply abilities and willingness to participate in the emergency resource scheduling can be chosen as suppliers of the emergency resources.

The remainder of the paper is organized as follows: Section 2 presents a literature review of previous research on emergency resource scheduling. Section 3 describes the details of the SSERS Model. The experiments and analysis are illustrated in Section 4, and the conclusions are discussed in the final section.

2. Related Works

2.1. The Issues Exist in the Traditional Emergency Resource Scheduling Models

At this stage, some researchers have already studied the multi-object emergency resource dispatch and proposed different models, which can be divided into the following types.

2.1.1. Single Objective Emergency Resource Scheduling

When studying the scheduling plan of emergency resources, different researchers may have different goals. To improve the efficiency of rescue, some researchers chose minimum time as a goal. Hu et al. aimed for minimum time and put forward an emergency resource scheduling model of multi-vehicle types [1]. Yan et al. studied the emergency material scheduling for multi-rescue points under real-time conditions and then used an improved Genetic Algorithm (GA) to realize the dynamic path adjustment [2]. Lu et al. presented a rolling horizon based on real-time relief distribution of a disaster. [3]. Chai et al. defined the rescue route travel time as the sum of free flow travel time and queuing delay time then set the minimum travel time as a goal of the scheduling [4].

Apart from minimum time, other researchers prefer taking the shortest distance. Batmetan et al. calculated the shortest path to be selected by using a multi-objective optimization algorithm for cloud computing task scheduling based on an improved ant colony algorithm in the Lokon volcano [5]. Ferrer et al. built a compromise programming model for multi-criteria optimization in humanitarian last-mile distribution [6]. Vidal et al. established three emergency material scheduling (EMS) models with time windows, which were multi-cycle, multi-distribution center, and disaster point that can only be guaranteed by special vehicles [7].

Furthermore, other researchers took the satisfaction of the demand points in the scheduling as an objective. Das et al. constructed a warehouse location model with the goal of maximum satisfaction [8]. Chen et al. took the satisfaction of the whole disaster area as the objective of emergency resource scheduling and built a model for multi-commodity, multi-supply depots to maximize efficiency [9]. Wang et al. constructed a multi-level emergency material scheduling optimization model for marine disasters by using the cooperative scheduling method to maximize the reliability of material supply [10].

2.1.2. Multi-Objective Emergency Resource Scheduling

Ding et al. proposed an emergency supplies scheduling model based on multi-objectives, then designed the minimum time cost and the shortest route cost model. The results show that the two cost models can serve different scheduling needs and provide efficient scheduling for emergency supplies [11]. Wan et al. established a multi-objective, multi-constraint (EMS) model based on the above-mentioned principle. Subsequently, a hybrid ant colony optimization (HACO) was proposed to solve EMS. The experimental results show that HACO has better performance than other methods [12]. Chi et al. combined two rescue objectives, i.e., time and resource satisfaction, into a timeliness evaluation function, which provides new insight into the design of objective functions utilized in emergency resource scheduling [13]. Zhou et al. designed a multi-objective optimization model for multi-period dynamic emergency resource scheduling problems. The results show that the model can find a better candidate solution than traditional models [14]. Zhang et al. proposed a three-stage stochastic program model; its objectives were to minimize the time and costs of the scheduling and the number of unsatisfied demands [15]. Cui et al. came up with a post-disaster material transportation model to minimize the time and costs [16]. Wang et al. gave out a two-dimensional and multi-objective emergency resource scheduling model to achieve the shortest time and the lowest costs [17].

Behrooz et al. [18] formulated the Multi-Resource Scheduling and Routing Problem (MRSRP) for emergency relief and developed a solution framework. Results show that the six methods are valid when optimizing the existing solutions. Zhang et al. aimed to conduct a study on a novel dynamic multi-objective location-routing model with split delivery considering practical characteristics. A two-stage optimization model was proposed to address the model’s complexity [19]. Xu et al. proposed a plug-in-free three-dimensional spatial fusion scheme based on WebGL rendering technology and developed a visualization system for emergency rescue data fusion [20]. Li et al. developed an emergency resource dispatching model with random demands and optimized the expected total cost [21]. Wang et al. [22] presented a two-stage optimization model of emergency resource storage and scheduling. In the first stage of the model, the objective is to decrease the response time, while in the second stage, the objective turns to optimizing the resource scheduling satisfaction. Chen et al. proposed a co-scheduling model of emergency resources with the goals of minimizing time-consuming, cost, and shedding load [23].

Affected by COVID-19, Sun et al. proposed a multi-resource collaborative scheduling optimization model with the objectives of minimizing the makespan of Quay Crane and transportation energy consumption [24]. Ding et al. [25] put forward an emergency material scheduling model with multiple logistics supply points for multiple demand points. They achieved an optimization on this model by using a multi-objective algorithm based on a genetic algorithm.

The above-mentioned models improved the efficiency of the rescue to some extent. However, most of the above models use the national emergency material reserve base as the source; the materials they reserve are basically the same category, and the bases are only at different distances from the disaster point. As a result, these models only need to consider the time cost when completing the scheduling task. However, the social emergency resource-sharing process has the following differences:

- (1)

- The suppliers of social emergency resource sharing are from different industries; they have different abilities to provide the resources.

- (2)

- Unlike simple emergency material dispatch, social emergency resource sharing often involves professional services in related industries, which includes not only professional equipment but also the support of professional human resources.

- (3)

- The willingness of each enterprise to participate in the social emergency resource sharing is related to the form of the sharing (like paid or unpaid).

Therefore, the particularity of social emergency resource sharing must be incorporated into the model using quantitative indicators.

2.2. The Issues Exist in the Social Emergency Resource Sharing

In terms of the social emergency resource sharing, Zhang et al. established a tripartite evolutionary model of the government, enterprise, and society, explored the influencing factors of realizing government-enterprise cooperation, i.e., income variables, cost variables, initial willingness and stakeholder behaviors [26]. Meng presented an integrated social emergency resource monitoring system to optimize the collection and dispatch of emergency resources. A time-bound multi-layer recruitment network of emergency resources was modeled to maximize the amount of the collected resources and minimize the logistics costs [27]. Olanrewaju et al. proposed to integrate the decision-making of supplier selection into the preparedness stage in responding to disasters for the timely distribution of relief supplies [28]. Hu et al. presented a two-stage stochastic program model to produce plains, including facility location and inventory, supplier selection, and distribution of relief supplies [29].

The scheduling plan involved in the current research only considers the constraints of the quantity of the emergency materials while ignoring the supply capacity of the suppliers and their subjective willingness to participate in the social emergency resource sharing, which results in the lack of rationality of the emergency resource scheduling plan.

3. Methodology

In this chapter, we propose a scheduling model for social emergency resource sharing with multiple objectives. On the basis of the traditional model, the emergency production capacity and leadership enthusiasm of enterprises are taken into account so that we can choose enterprises with a strong ability to provide emergency resources and a strong willingness to participate in the sharing activities.

3.1. The Emergency Contribution Index of an Enterprise

To choose a better supplier from multiple candidate enterprises, the emergency contribution index (ECI) of an enterprise is defined, which includes two components: Emergency Production Capacity and Enterprise Willingness.

3.1.1. Enterprise Willingness

The Enterprise Willingness consists of two key parts: staff motivation and leadership enthusiasm. They are employed to quantitatively describe the willingness of an enterprise to participate in emergency resource sharing at the levels of employee and leader separately.

- (1)

- Staff Motivation

The staff motivation of an enterprise is an indicator used to evaluate the work motivation of the staff in the enterprise. It is affected by the ratio of the number of insured employees to the size of staff and the ratio of employees’ wages to the local average wage. The higher the number of insured employees in an enterprise, the more emphasis the enterprise attaches to employee benefits, thus the higher the enthusiasm of employees for work. The calculative formula is shown below:

where ω means the staff motivation of an enterprise, “i” means the insured persons, and “i0” means the total personnel of the enterprise. So, means the ratio of the number of insured persons to the size of personnel. “q” means the average salary of the staff in the enterprise, and “qa” means the local average salary. So, means the ratio of the average salary of the enterprise to the average salary of the city in which the enterprise is located. The “m” means the number of the parameters.

- (2)

- Leadership Enthusiasm

The leadership enthusiasm of an enterprise is an indicator used to evaluate the willingness of the leaders of an enterprise to participate in social emergency resource sharing. It is affected by the amount of charitable donations (including money and items) made by the enterprise in the previous year, the costs of human resources (such as labor cost for emergency resource transportation) in the previous year, and the output value of the previous year. The higher the proportion of an enterprise’s social donation in the previous year to its total output value in the previous year, the more emphasis the enterprise’s leaders attach to the corporation’s social responsibility. When natural disasters or social events occur, such leaders are often more willing to be active and get involved in the response. The calculative formula is shown below:

where θ means the leadership enthusiasm of an enterprise, “w” means the enterprise’s value of public donations in the previous year, “y” means the costs incurred by the enterprise in participating in emergency resource-sharing activities, and “v” means the total operating income in the previous year.

3.1.2. Emergency Production Capacity

The emergency production capacity can be used to evaluate the ability to provide emergency resources of an enterprise in the process of social emergency resource sharing. It is related to factors such as the enterprise’s operating status, unified social credit code, business scope change records, the ratio of the paid-in capital to the registered capital, and the ratio of the value of emergency resources produced by the enterprise to the total value of all products of the enterprise. These factors are divided into two types: control factors and contribution factors. The calculative formula of emergency production capacity is shown below.

where φ means the emergency production capacity of an enterprise, “b”, “s”, and “r” are the control factors of the emergency production capacity, which is the business status, business scope change records, and social credit code, respectively. The value of these factors is either 0 or 1, i.e., when an enterprise no longer exists or it changed the business scope before (which does not produce emergency resources anymore), these values of this enterprise will be 0; otherwise, they will be 1. The “” are contribution factors of the emergency production capacity, it means the ratio of the enterprise’s registered capital to paid-in capital and the “” means the ratio of the value of emergency supplies produced to the value of all products of an enterprise. These factors take values between 0 and 1. The “n” means the number of contribution factors; its value is 2 in this paper.

The purpose of introducing this indicator is to compare the enterprises’ operating conditions, social credit ratings, registered and paid-in capital, personnel scale, etc., and then to select enterprises with strong supply abilities for emergency resources from a large number of candidate enterprises as suppliers to participate in social emergency resource sharing.

Therefore, emergency production capacity is an indicator that can effectively exclude some small and weak enterprises that are limited by their own conditions and cannot efficiently complete the process of post-disaster rescue.

3.1.3. Emergency Contribution Index

The ECI is an indicator that can comprehensively describe the ability to provide emergency resources and the willingness to participate in emergency resource sharing of an enterprise. The calculative formula is shown below:

where θ means the leadership enthusiasm of an enterprise, ω means the staff motivation of an enterprise, and φ means the emergency production capacity of an enterprise. The three parameters commonly form the ECI. The higher the value of these parameters, the higher the value of ECI, indicating that the enterprise is more capable of providing emergency resources and simultaneously has a stronger willingness to participate in social emergency resource sharing.

3.2. Social Emergency Resource Sharing Scheduling Model Based on ECI

In this section, the ECI is combined into the traditional emergency resource scheduling model, giving it the ability to quantify the production capacities and willingness of the enterprises, thus compensating for the weakness of the traditional model that it only focuses on the demand side.

3.2.1. The SSERS Model

In this section, we will establish a function for analysis with the goal of minimizing total delay time and total cost and then improve it on the basis of the previous studies. The improved scheduling model is shown below.

The constraints of the model are shown below:

In the above equations, the 1 − ECIa is a selection factor; the higher the ECI, the lower the value of the select factor, and the more suitable it is to participate in social emergency resource sharing. The (tab − tb) is the total delay time in transporting emergency resources from the supply point (a) to the demand point (b), xab is the number of emergency resources that have been transported from the supply point (a) to the demand point (b). cab is the cost of transporting a unit of emergency resource from the supply point (a) to the demand point (b).

Among the above equations, Equations (5) and (6) are objective functions, which indicate that the total delay time and total economic cost in the emergency resource transportation process are the lowest. Equations (7)–(10) are the restrictions, where Equation (7) means that the total supply of emergency resources should be equal to the total demand. Equation (8) indicates that the total amount of emergency resources shipped from each supply point to the transfer station near the disaster area should be equal to the total demand for the transfer station. Equation (9) means that the emergency resource supply of each supply point cannot exceed the maximum amount it can provide. Equation (10) means that the number of emergency resources transferred from the supply points to the demand point is a non-negative number.

3.2.2. Model Analysis

Compared with the traditional model, a selection factor, 1 − ECI, is added to our model, as shown in Equations (5) and (6). Enterprises with higher ECI have greater production capacity and willingness, and accordingly, their values of 1 − ECI are lower, and thus, the total delay time and total costs will be lower. Therefore, such enterprises are more likely to be selected to participate in social emergency-sharing activities so that the defect of the traditional model of treating all emergency resource suppliers indiscriminately can be solved.

The improved model has the following advantages:

- (1)

- This model can select the enterprises that best provide the emergency resources required by the disaster area in sufficient quantity in the shortest time based on the Emergency Production Capacities.The factors of registered and paid-in capital, size of personnel, and the nature of the enterprises in the emergency production capacity are able to identify larger state-owned enterprises. In addition, the factors of industry and business scope enable the scheduling program to filter equipment wholesale and retail enterprises. The model prefers enterprises that can provide equipment and technical staff at the same time. For example, in the process of road rescue, the model can choose road engineering service enterprises (with professional engineers) instead of enterprises that solely sell machines.

- (2)

- When comprehensively considering emergency production capacity and leadership enthusiasm, the model is able to select enterprises that can not only provide appropriate emergency resources but also have a strong willingness to participate in emergency resource sharing.While analyzing the supply capacity of various supply enterprises using their emergency production capacities, their leadership enthusiasms can be analyzed by calculating the percentage of their charitable donations in the total output in the previous year. This indicator is able to select enterprises with a higher willingness to participate in social emergency resource sharing.

4. Experiments

In 2008, a massive 8.0 magnitude earthquake occurred in Wenchuan County, Sichuan Province in China; the direct economic loss caused by the earthquake was about 845.14 billion RMB, of which the value of damaged roads was about 185 billion RMB [30,31]. In this section, the calculation process and results of the SSERS Model will be shown.

4.1. Introduction of the Experimental Area

This study involves an area in Wenchuan, Sichuan Province. The remote sensing image was taken on 1 July 2008 by Worldview-1 satellite; its spatial resolution is 0.5 m. The latitude and longitude ranges are 31°25′48″ N to 31°31′23″ N and 103°31′34″ E to 103°38′13″ E, respectively. These ranges cover an area of 149.36 square kilometers. The entire research area is shown in Figure 1.

Figure 1.

The research area of this study (Wenchuan).

4.2. The Process of the Experiments

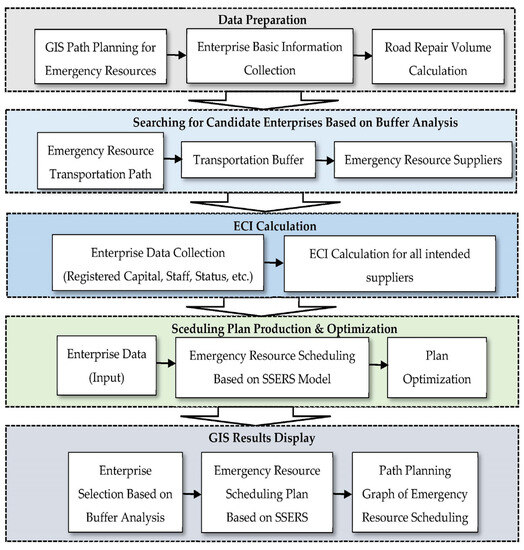

In this study, the experiments can be divided into five stages. Figure 2 shows the details of these stages.

Figure 2.

The process of our experiment.

Step 1: Data Preparation. First, a path for emergency resource transportation between the supply points to the disaster-affected area will be planned. Then, the data for road repair volume calculation will be collected, which includes the level of the roads, the construction standards of the roads, the essential materials for road repair, etc. Finally, the total volume for road repair and the number of road repair machinery required to complete the repair project within the specified time will be calculated.

Step 2: Enterprise Initial Selection Based on Buffer Analysis. The beginning city of resource transportation will be determined based on the time and the transportation costs. Then, the enterprises can be initially selected based on the buffer analysis.

Step 3: ECI Calculation. First, the basic information of all the enterprises that passed the initial selection will be collected, which includes operation status, registered capital, number of staff, etc. Then, for the ith supplier (Si), calculate its ECIi by using Formula (4).

Step 4: Scheduling Plan Production and Optimization. For every supplier (Si), we bring its ECIi into the Formulas (5) and (6), then the emergency resource scheduling plan with Si can come out.

Step 5: GIS Results Display. Combining the initial enterprise screening based on buffer analysis and the emergency resource scheduling plan based on the SSERS Model, a path planing graph of emergency resource transportation based on GIS will be displayed.

4.3. Emergency Resource Scheduling Based on the SSERS Model

In this section, the 24-h post-disaster road repair is selected as an example; then the SSERS Model will be used to design the road repair equipment scheduling scheme.

- (1)

- Data Preparation—the Demands of the Volume of Road Reparation

The demands of road repair equipment are related to the volume of the repair, so the working efficiency of every set of equipment should be determined first, then the total volume of road repair should come out. Based on these parameters, the number of sets of equipment required to complete road repair within the specified time can be derived.

The equipment used to repair such pavement and its efficiency are shown below. The equipment is generally provided in sets. Table 1 shows a set of equipment.

Table 1.

Equipment used in road repairment (1 set) Reprinted/adapted with permission from [32].

In this section, the number of sets of road repair equipment needs to be determined, so we designed the following formula.

where n means the number of sets of equipment required in the road repairment (sets). The “D”, which equals to Atlρ, means the total mass of construction materials required in the course of road repairs (t), it is used to indicate the total project of the road repairs. ps means the product ratio of each set of equipment (t/h), its value is 1400, and T means the total time required in the repairment (h).

The average density of cement and soil is 2.5 t/m3. As a result, the total mass of materials required in road repair (D) should be:

D = At × l × ρ = 198,000 m2 × 0.5 m × 2.5 t/m3 = 247,500 t

In order to complete the road repairs as soon as possible, we design that the repairs need to be finished within 24 h after the earthquake. If the equipment is transported from Chengdu City, the distance between Chengdu and Wenchuan is 128 km, based on the speed of 80 km/h. The transport time should be 1.6 h, so the repair time should be 22.4 h.

In summary, the sets of equipment required in the process of road repairs should be:

The above result means that the road repairs need to be finished within 24 h, and the 8 sets of equipment should work simultaneously. That includes 8 of each of the three types of mixing machines, 16 cement booth machines, a number of sand and soil booth machines, and asphalt booth machines is 8, respectively. Further, 64 loaders and 8 graders are also required.

- (2)

- Enterprise Initial Selection Based on Buffer Analysis

The equipment is set to be dispatched from Chengdu; considering the actual situation, the target time is designed to be 2 h, which means the loaders should be transported to Wenchuan within 2 h. Using an average speed of 80 km/h, it takes 1.8 h to reach Wenchuan from Chengdu. The total delay time from Chengdu to Wenchuan is calculated below:

T = tab − tb = 1.85 − 2 = −0.15

So, the radius of the buffer will be:

R = 80 km/h × 0.15 = 12 km

Based on this calculation and the buffer analysis, there are six enterprises that can meet the needs, which are recorded as No. 1–No. 6. The number of loaders shipped from Chengdu to Wenchuan is x1–x6. The details of these enterprises are shown below.

The above table shows the basic information of the six enterprises, including the registered and paid-in capitals, numbers of the total and insured staff, the profits of produced emergency resources, the profits of all products of every enterprise, the donations and labor expenses, and their industries.

- (3)

- ECI Calculation

The emergency production capacity and leadership enthusiasm of the above enterprises can be calculated based on Equations (1)–(3); the data used in the calculation comes from Table 2. The results are shown in the Table 3. We assume that all the enterprises have no business scope change records, so their values are 1.

Table 2.

Details of the six enterprises in Chengdu in 2021.

Table 3.

The Values of the Components of ECI of the 6 Enterprises.

- (4)

- Scheduling Plan Production and Optimization (Emergency Resource Scheduling Based on SSERS)

This model adds emergency production capacity and emergency willingness of the enterprises simultaneously on the basis of the traditional model, which can make the scheduling plan more reasonable. The related indicators of the above-mentioned six enterprises are shown below.

When calculating the data, we will first use the traditional model to analyze the scheduling and analyze the irrationality of only considering the restriction of the amount of emergency resources. On the basis of this analysis, the emergency production capacity and leadership enthusiasm of every enterprise will be considered. We will use the same restrictions to compare different scheduling plans, and then the best plan can be developed.

In this example, there is only one demand point for emergency resources (Wenchuan), so the value of “b” is 1. Thus, Equations (3)–(5) will be changed into:

To make the results more realistic, the restrictions of this model are shown below. x1 < 100, x2 < 100, x3 < 100, x4 < 200, x5 < 200, x6 < 200,

The calculative result is: x1 = 4, x2 = 0, x3 = 60, x4 = x5 = x6 = 0.

When considering emergency production capacity and leadership enthusiasm simultaneously, the scheduling plan is shown in Table 4.

Table 4.

The scheduling plan of loaders is based on the SSERS Model.

- (5)

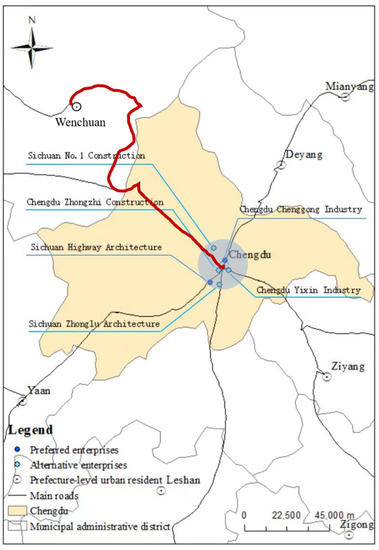

- GIS Result Display

Figure 3 shows the spatial distribution of the six selected enterprises, of which Chengdu Chenggong Industry and Sichuan Highway Industry (shown as blue points) are the two preferred enterprises to participate in the social emergency resource scheduling. The red line in the figure is the transportation path of the emergency resource from the preferred enterprises to Wenchuan based on the SSERS Model.

Figure 3.

The spatial distribution of the six selected enterprises.

5. Discussion

In this section, the traditional model will be used to design an emergency resource scheduling plan first; then, it will be compared with the plan based on the SSERS Model to testify to the effects of our model.

5.1. Emergency Resource Scheduling Based on the Traditional Model

This model only considers the restrictions of the number of resources and does not take the emergency production capacity and enterprise willingness of the enterprises into account. In the extreme emergency period, the total demand on loaders was 64; the model and its restrictions are shown below.

The constraints of the model are shown below:

In the above equations, (tab − tb) is the total delay time in transporting emergency resources from the supply point (a) to demand point (b), xab is the number of emergency resources that have been transported from the supply point (a) to demand point (b). cab is the cost of transporting a unit of emergency resource from the supply point (a) to the demand point (b).

Among the above equations, (17) and (18) are objective functions, which indicate that the total delay time and total economic cost in the emergency resource transportation process are the lowest. Equations (19)–(22) are the restrictions, where Equation (19) means that the total supply of emergency resources should be equal to the total demand. Equation (20) indicates that the total amount of emergency resources shipped from each supply point to the transfer station near the disaster area should be equal to the total demand for the transfer station. Equation (21) means that the emergency resource supply of each supply point cannot exceed the maximum amount it can provide. Equation (22) means that the number of emergency resources transferred from the supply points to the demand point is a non-negative number.

In this example, there is only one demand point (Wenchuan), so the “b” in Equation (17) equals 1. The Equation used here is:

The constraints of the model are shown below:

x1 < 100, x2 < 100, x3 < 100, x4 < 200, x5 < 200, x6 < 200,

The calculative result is: x1 = x2 = x3 = x4 = x5 = 0 and x6 = 64.

When only considering the restriction of the amount, the scheduling plan is shown in Table 5.

Table 5.

The scheduling plan of loaders is based on the traditional model.

The ECI values of the six enterprises are calculated according to the formula (4), and the data used in the calculation comes from Table 3.

The above result shows that when only considering the restrictions of amount, all 64 loaders would be provided only by Chengdu Blue Eagle Beverage Co., Ltd. (Chengdu, China). However, its ECI value is 0.03, which ranked 6th among the six enterprises.

5.2. A Comparison of the Traditional Model and the SSERS Model

The results of the two models are integrated in Table 6.

Table 6.

The results of the two models.

The above results show that when considering the emergency contribution index, 64 of the loaders can be provided by Chengdu Chenggong Co., Ltd. and Sichuan Highway Architecture Co., Ltd.

Sichuan Highway Architecture and Chengdu Chenggong Industry ranked among the top two out of the six enterprises in terms of the ECI (0.26 and 0.23, respectively). These enterprises have the following advantages:

- (1)

- They have a stronger willingness to participate in social emergency resource sharing.

The leadership enthusiasm of the two enterprises is 0.53 and 0.43, respectively, which are ranked in the top two among the six enterprises. This means the enterprises are keen on leadership enthusiasm and have a strong sense of social responsibility. Further, the staff motivation of these enterprises is 0.54 and 0.89, respectively, positioning them at the top among these enterprises, so they have a high value on the enterprise willingness. It means that in these two enterprises, both the leaders and the employees are passionate about social charity work; they are willing to contribute to relief efforts when disasters happen.

- (2)

- They have stronger abilities to provide emergency resources.

The Emergency Production Capacity of the two enterprises is 0.69 and 0.8, respectively, which rank third and first among the six enterprises, which shows that both of them have a relatively strong ability to provide emergency resources. The Sichuan Highway Architecture has the largest number of personnel among the six enterprises, and its registered capital ranks highly, so its emergency production capacity reaches the highest level of 0.8. Further, both enterprises have strong economic strength (registered and paid-in capitals) in the six enterprises, which can strongly guarantee the production of emergency resources.

From the above analysis, it can be seen that both the emergency production capacity and the enterprise willingness of the two enterprises chosen using the SSERS Model are relatively high, which means that they have a strong ability and willingness to provide emergency resources. Regarding the enterprise chosen using the traditional model, the values of the three indicators, emergency production capacity, staff motivation, and leadership enthusiasm, for the enterprise are 0.65, 0.57, and 0.19, respectively. Among the six candidates, they rank 5th, 3rd, and 5th, respectively, which indicates that the emergency production capacity of the Chengdu Yixin Industry is not very strong; it may not be able to meet the resource demands during the post-disaster emergency rescue operation. On the other hand, the leaders and the staff in this enterprise are not enthusiastic about participating in emergency resource sharing. As a result, its ECI value is only 0.03, which is the lowest of the six candidates. Therefore, compared with the Chengdu Yixin industry, Sichuan Highway Architecture and Chengdu Chonggong Industry are fit for emergency resource sharing.

6. Conclusions

To quantify the supply ability and willingness to participate in social emergency resource sharing, this paper defines the emergency contribution index (ECI) of an enterprise, which includes emergency production capacity and enterprise willingness. Then, we proposed a multi-objective social emergency resource scheduling model based on the emergency contribution index (SSERS). It incorporates the ECI of an enterprise for the first time, addressing the limitations of traditional models that overlook supply-side conditions. As a result, the SSERS realizes the optimization of the social emergency resource scheduling and sharing scheme.

However, the model proposed in this paper still has some limitations: the calculation of Leadership enthusiasm only takes the enterprises’ information in the previous year into consideration, and it is disturbed using incomplete information.

Therefore, in the future, it will be necessary to use Big Data for trend analysis to more accurately describe the supply capabilities of emergency resources and the willingness to participate in social emergency resource sharing.

Author Contributions

Data curation, M.M.; Formal analysis, W.C. (Wenqi Cui) and Q.H.; Investigation, B.L.; Methodology, W.C. (Wenqi Cui) and W.C. (Wei Cui); Resources, X.C.; Validation, W.C. (Wei Cui); Writing—original draft, W.C. (Wenqi Cui); Writing—review and editing, X.X., Z.F. and J.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Hu, F.; Tian, C.; Zhao, M.; Han, X. Research on hierarchical linkage scheduling emergency supplies based on genetic algorithm. Appl. Res. Comput. 2017, 33, 439–443. [Google Scholar]

- Yan, J.; Guo, Y. Unconventional Emergency Aid Delivery Path Optimization Research. J. Catastr. 2017, 31, 193–200. [Google Scholar]

- Lu, C.C.; Ying, K.C.; Chen, H.J. Real-Time Relief Distribution in the Aftermath of a Disaster—A Rolling Horizon Approach. Transp. Res. E-Log. 2019, 93, 1–20. [Google Scholar] [CrossRef]

- Chai, G.; Cao, J.; Huang, W.; Guo, J.O. ptimized Travel Emergency Resource Schuding Using Time Vary Rescue Route Travel Time. Neurocompting 2018, 275, 1567–1575. [Google Scholar] [CrossRef]

- Batmetan, J.; Santoso, A.; Pranowo, A. Multiple-Objective Ant Colony Algorithm for Optimization Disaster Relief Logistics. Adv. Sci. Lett. 2017, 23, 2344–2347. [Google Scholar] [CrossRef]

- Ferrer, J.M.; Martín-Campo, F.J.; Ortuño, M.T.; Pedraza-Martínez, A.J.; Tirado, G.; Vitoriano, B. Multi-Criteria Optimization for Last Mile Distribution of Disaster Relief Aid. Eur. J Oper. Res. 2018, 269, 201–215. [Google Scholar] [CrossRef]

- Vidal, T.; Crainic, T.G.; Gendreau, M.; Prins, C. A Hybrid Genetic Algorithm with Adaptive Diversity Management for a Large Class of Vehicle Routing Problems with Two-Windows. Comput. Oper. Res. 2015, 40, 475–489. [Google Scholar]

- Das, R. Disaster Preparedness for Better Response: Logistics Perspectives. Int. J. Disast. Risk Reduct. 2018, 31, 153–159. [Google Scholar] [CrossRef]

- Chen, L.; Wang, H. Optimal Scheduling Model for Emergency Logistics based on Satisfaction under Lagrge-Scale Emergencies. China Saf. Sci. J. 2020, 20, 46. [Google Scholar]

- Wang, J.; Wang, M. Study on Optimizing of Emergency Resource Scheduling for Maritime Perils. China Saf. Sci. J. 2020, 23, 166–170. [Google Scholar]

- Ding, Z.; Zhao, Z.; Liu, D.; Cao, Y. Multi-Objective Scheduling of Relief Logistics Based on Swarm Intelligence Algorithms and Spatio-Temporal Traffic Flow. J. Safe Sci. Resil. 2021, 2, 222–229. [Google Scholar] [CrossRef]

- Wan, F.; Guo, H.; Li, J.; Gu, M.; Pan, W.; Ying, Y. A Scheduling and Planning Method for Geological Disasters. Appl. Soft Comput. 2021, 111, 107712. [Google Scholar] [CrossRef]

- Chi, H.; Li, J.; Shao, X. Timeliness Evaluation of Emergency Resource Scheduling. Eur. J. Oper. Res. 2017, 258, 1022–1032. [Google Scholar] [CrossRef]

- Zhou, Y.; Liu, J.; Zhang, Y.; Gan, X. A Multi-Objective Evolutionary Algorithm for Multi-Period Dynamic Emergency Resource Sheduling Problems. Transp. Res. E-Log. 2017, 99, 77–95. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, H.; Yu, G.; Ruan, J.; Chan, F.T. A Three-Stage and Multi-Objective Stochastic Programme Model to Improve the Sustainable Rescue Ability by Considering Secondary Disasters in Emergency Logistics. Comput. Ind. Eng. 2019, 135, 1145–1154. [Google Scholar] [CrossRef]

- Cui, S.; Liu, S.; Tang, X.; Zhu, T. Emergency Material Allocation Problem Considering Post-Disaster Impact. In Proceedings of the 8th International Conference on Industrial Technology and Management (ICITM), Cambridge, UK, 2–4 March 2019. [Google Scholar]

- Wang, H.; Xu, R. Research on the Optimized Dispatch and Transportation Scheme for Emergency Logistics. Procedia Comput. Sci. 2018, 129, 208–214. [Google Scholar] [CrossRef]

- Bodaghi, B.; Shahparvari, S.; Fadaki, M.; Lau, K.H.; Ekambaram, P.; Chhetri, P. Multi-Resource Scheduling and Routing for Emergency Recovery Operations. Int. J. Disast. Risk Reduct. 2020, 50, 101780. [Google Scholar] [CrossRef]

- Zhang, L.; Lu, J.; Yang, Z. Dynamic Optimization of Emergency Resource Scheduling in a Large-Scale Maritime Oil Spill Accident. Comput. Ind. Eng. 2021, 152, 107028. [Google Scholar] [CrossRef]

- Xu, C.; Song, Y.; Yu, Z.; Zhuang, Z. Multi-Source Detecting Data Fusion Technology for Emergency Rescue. Comput. Syst. Appl. 2019, 101, 104201. [Google Scholar]

- Li, X.; Li, Y. A Model on Emergency Resource Dispatch under Random Demand and Unreliable Transportation. Syst. Eng. Procedia 2012, 5, 248–253. [Google Scholar] [CrossRef][Green Version]

- Wang, Y.; Fan, J.; Wu, S. Research on the Scheduling Scheme of Resource Storage Locations in Deep-Sea Oil and Gas Exploitation. J. Petrol. Sci. Eng. 2023, 220, 111214. [Google Scholar] [CrossRef]

- Chen, L.; Li, Y.; Chen, Y.; Liu, N.; Li, C.; Zhang, H. Emergency Resource Schduling in Distribution System: From Cyber-Physical-Social System Perspective. Electr. Pow. Syst. Res. 2022, 210, 108114. [Google Scholar] [CrossRef]

- Sun, B.; Zhai, G.; Li, S.; Pei, B. Multi-Resource Collaborative Scheduling Problem of Automated Terminal Considering the AGV Charging Effect under COVID-19. Ocean Coast. Manag. 2023, 232, 106422. [Google Scholar] [CrossRef]

- Ding, Z.; Xu, X.; Jiang, S.; Yan, J.; Han, Y. Emergency Logistics Scheduling with Multiple Supply-Demand Points based on Gery Interval. J. Safe Sci. Rel. 2022, 3, 179–188. [Google Scholar]

- Zhang, M.; Kong, Z. A Tripartite Evolutionary Game Model of Emergency Supplies Joint Reserve among the Government, Enterprise and Society. Comput. Ind. Eng. 2022, 169, 108132. [Google Scholar] [CrossRef]

- Meng, Y. The Optimization and Coordination of Multi-Layer Recruitment Network for Social Emergency Resources. Comput. Ind. Eng. 2019, 130, 50–61. [Google Scholar] [CrossRef]

- Olanrewaju, O.; Dong, Z.; Hu, S. Supplier Selection Decision-Making in Disaster Response. Comput. Ind. Eng. 2020, 143, 106412. [Google Scholar] [CrossRef]

- Hu, S.; Dong, Z. Suppliers Selection and Pre-Positioning Strategy in Humanitarian Relief. Omega 2019, 83, 287–298. [Google Scholar] [CrossRef]

- Chinese National People’s Congress Website. The Direct Economic Loss of Wenchuan Earthquake. Available online: http://www.npc.gov.cn/zgrdw/npc/zt/2008-09/05/content_1448390.htm (accessed on 20 November 2022).

- Cui, W.; He, X.; Yao, M.; Wang, Z.; Li, J.; Hao, Y.; Wu, W.; Zhao, H.; Chen, X.; Cui, W. Landslide Image Captioning Method Based on Semantic Gate and Bi-Temporal LSTM. ISPRS Int. J. Geo.-Inf. 2020, 9, 194. [Google Scholar] [CrossRef]

- Wang, J. Rational Configuration and Methods of Highway Construction Mechanization. Value Eng. 2017, 36, 3. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).