Enablers for Adopting Restriction of Hazardous Substances Directives by Electronic Manufacturing Service Providers

Abstract

:1. Introduction

2. Literature Review

2.1. EMS and Global Market

2.2. Green Manufacturing

2.3. RoHS

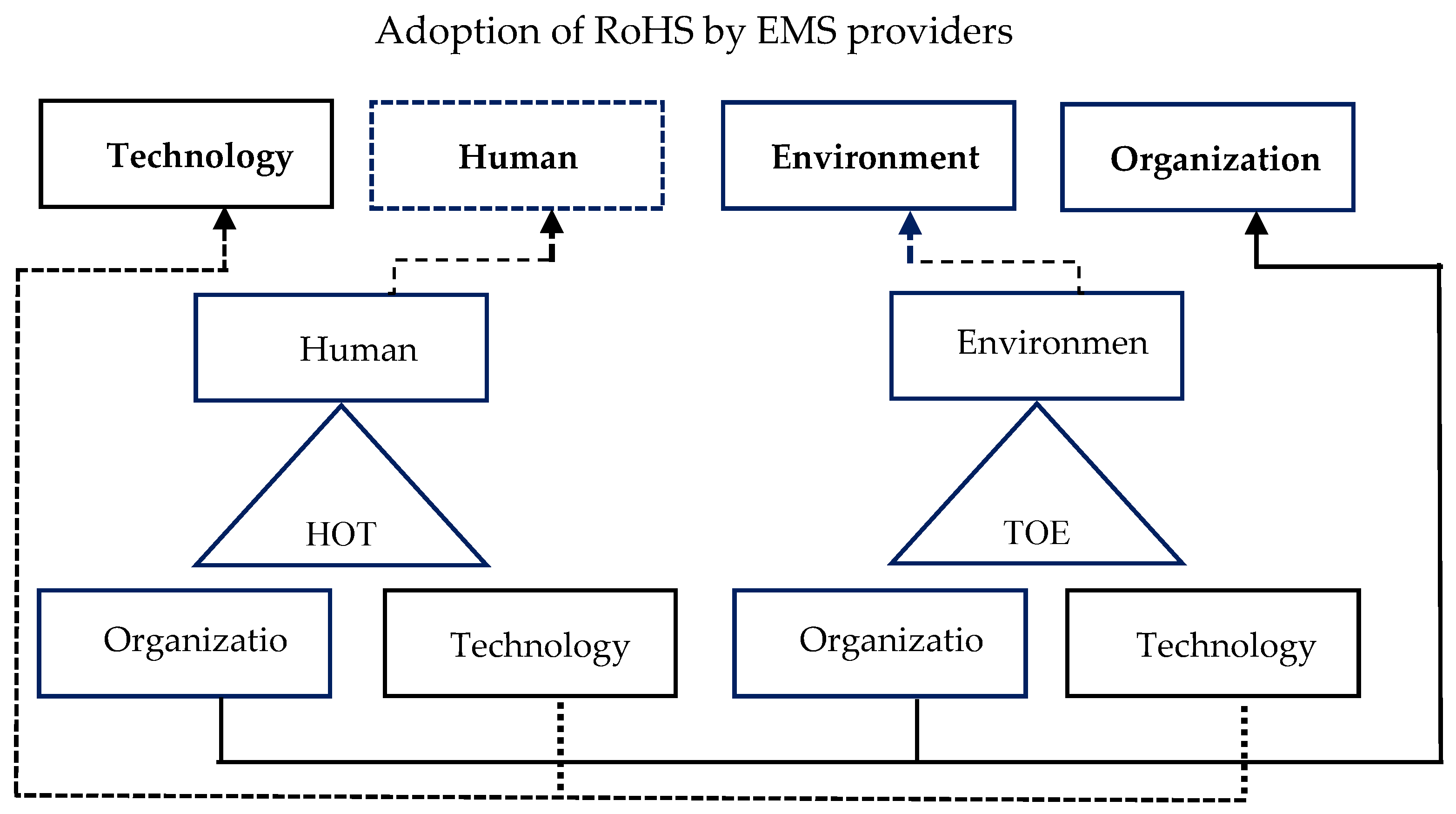

2.4. TOE Theory

2.5. HOT-Fit Theory

2.6. Integrated TOE-HOT Fit Framework

2.7. Research Gap

2.8. Research Hypotheses

2.8.1. Technological Dimension

Cost

Complexity

Compatibility

System Integration

2.8.2. Organizational Dimension

Relative Advantage

Adequate Resource

2.8.3. Environmental Dimension

Institutional Pressure

Perceived Industry Pressure

2.8.4. Human Dimension

Expert Resources

Verification Capability

Innovation

Moderation Effect

3. Research Method

3.1. Modified Delphi Method

3.2. PLS-SEM

3.3. Sample and Measures

3.4. Data Analysis

4. Results

4.1. Data Normality Analysis

4.2. Measurement Model

4.3. Structural Model

4.3.1. Collinearity

4.3.2. Coefficient of Determination (R2)

4.3.3. Predictive Relevance (Q2)

4.3.4. Effect Size (f2)

4.4. Hypothesis Testing Results

4.5. Common Method Variance Test

4.6. Discussion

4.6.1. Theoretical Implications

Most Related Aspects of RoHS Adoption by EMS Providers

Discussion of Non-Significant Hypotheses

- Perspective of H2 (CC→AORD)

- Perspective of H3 (CO→AORD)

- Perspective of H4 (SI→AORD)

4.6.2. Discussion of Significant Hypotheses Supported by the Empirical Study Results

- Perspective of H1 (CA→AORD)

- Perspective of H5 (RA→AORD)

- Perspective of H6 (AR→AORD)

- Perspective of H7 (INP→AORD)

- Perspective of H8 (PIP→AORD)

- Perspective of H9 (ER→AORD)

- Perspective of H10 (VA→AORD)

- Perspective of H11 (IN→AORD)

4.6.3. Practical Implications

Most Related Aspects of RoHS Adoption by EMS Providers

Non-Significant Hypotheses

Discussion of Significant Hypotheses Supported by the Empirical Study Results

- Perspective of H1 (CA→AORD)

- Perspective of H5 (RA→AORD)

- Perspective of H6 (AR→AORD)

- Perspective of H7 (INP→AORD)

- Perspective of H8 (PIP→AORD)

- Perspective of H9 (ER→AORD)

- Perspective of H10 (VA→AORD)

- Perspective of H11 (IN→AORD)

4.6.4. Moderating Effect Analysis of Gender and Age

| Variable | Male | Female | t-Value | p-Value | ||

|---|---|---|---|---|---|---|

| Mean | Std | Mean | Std | |||

| CA | 1.425 | 0.567 | 2.078 | 0.896 | 5.733 | 0.000 |

| CC | 2.001 | 0.250 | 3.073 | 1.171 | 13.955 | 0.000 |

| CO | 3.327 | 0.464 | 3.611 | 0.733 | 3.054 | 0.045 |

| SI | 3.371 | 0.292 | 3.592 | 0.652 | 3.479 | 0.076 |

| RA | 2.188 | 0.209 | 3.356 | 1.196 | 15.833 | 0.000 |

| AR | 4.163 | 0.231 | 3.807 | 0.787 | −6.022 | 0.019 |

| INP | 1.429 | 0.229 | 2.578 | 1.390 | 13.603 | 0.000 |

| PIP | 4.304 | 0.286 | 4.350 | 0.548 | 0.775 | 0.651 |

| ER | 1.803 | 0.294 | 2.625 | 1.140 | 10.183 | 0.000 |

| VA | 4.381 | 0.516 | 3.778 | 0.850 | −5.774 | 0.001 |

| IN | 3.760 | 0.501 | 3.587 | 0.643 | −1.774 | 0.077 |

| Variable | Under 30 | 30–40 | 40–50 | Over 50 | t-Value | p-Value | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mean | Std | Mean | Std | Mean | Std | Mean | Std | |||

| CA | 1.466 | 0.548 | 1.459 | 0.528 | 1.540 | 0.743 | 1.432 | 0.740 | 0.174 | 0.862 |

| CC | 2.124 | 0.621 | 2.000 | 0.234 | 2.208 | 0.711 | 2.111 | 0.444 | 1.406 | 0.161 |

| CO | 3.483 | 0.519 | 3.311 | 0.480 | 3.354 | 0.513 | 3.315 | 0.469 | −1.255 | 0.210 |

| SI | 3.418 | 0.376 | 3.369 | 0.291 | 3.397 | 0.375 | 3.403 | 0.371 | 0.106 | 0.915 |

| RA | 2.382 | 0.656 | 2.189 | 0.208 | 2.395 | 0.682 | 2.250 | 0.521 | 0.224 | 0.823 |

| AR | 4.193 | 0.339 | 4.138 | 0.234 | 4.060 | 0.467 | 4.200 | 0.209 | −0.634 | 0.527 |

| INP | 1.643 | 0.659 | 1.425 | 0.228 | 1.600 | 0.803 | 1.543 | 0.482 | 0.322 | 0.748 |

| PIP | 4.254 | 0.275 | 4.316 | 0.289 | 4.307 | 0.371 | 4.338 | 0.319 | 1.136 | 0.256 |

| ER | 2.017 | 0.652 | 1.781 | 0.284 | 1.928 | 0.607 | 1.875 | 0.442 | −0.248 | 0.804 |

| VA | 4.425 | 0.523 | 4.386 | 0.483 | 4.192 | 0.702 | 4.321 | 0.593 | −2.013 | 0.045 |

| IN | 3.828 | 0.520 | 3.733 | 0.495 | 3.701 | 0.552 | 3.782 | 0.504 | −0.579 | 0.563 |

4.6.5. Connection with the Three Pillars of Sustainability

4.6.6. Research Limitations and Future Research Possibilities

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| LVs | Items | Factor Loading | Cronbach’s α | ρA | CR | AVE | RDN |

|---|---|---|---|---|---|---|---|

| AR | 0.942 | 0.943 | 0.955 | 0.811 | N.A | ||

| ar1 | 0.907 | ||||||

| ar2 | 0.940 | ||||||

| ar3 | 0.908 | ||||||

| ar4 | 0.927 | ||||||

| ar5 | 0.815 | ||||||

| CC | 0.957 | 0.945 | 0.967 | 0.854 | N.A | ||

| cc1 | 0.930 | ||||||

| cc2 | 0.979 | ||||||

| cc3 | 0.907 | ||||||

| cc4 | 0.875 | ||||||

| cc5 | 0.926 | ||||||

| CO | 0.957 | 0.946 | 0.967 | 0.853 | N.A | ||

| co1 | 0.932 | ||||||

| co2 | 0.941 | ||||||

| co3 | 0.948 | ||||||

| co4 | 0.905 | ||||||

| co5 | 0.890 | ||||||

| CA | 0.965 | 0.948 | 0.973 | 0.877 | N.A | ||

| ca1 | 0.950 | ||||||

| ca2 | 0.970 | ||||||

| ca3 | 0.928 | ||||||

| ca4 | 0.929 | ||||||

| ca5 | 0.904 | ||||||

| ER | 0.819 | 0.846 | 0.870 | 0.576 | N.A | ||

| er1 | 0.852 | ||||||

| er2 | 0.869 | ||||||

| er3 | 0.754 | ||||||

| er4 | 0.719 | ||||||

| er5 | 0.726 | ||||||

| IN | 0.829 | 0.869 | 0.876 | 0.568 | N.A | ||

| in1 | 0.748 | ||||||

| in2 | 0.828 | ||||||

| in3 | 0.753 | ||||||

| in4 | 0.761 | ||||||

| in5 | 0.733 | ||||||

| IP | 0.973 | 0.948 | 0.978 | 0.882 | N.A | ||

| ip1 | 0.938 | ||||||

| ip2 | 0.970 | ||||||

| ip3 | 0.927 | ||||||

| ip4 | 0.948 | ||||||

| ip5 | 0.929 | ||||||

| ip6 | 0.922 | ||||||

| PI | 0.968 | 0.947 | 0.975 | 0.886 | N.A | ||

| pi1 | 0.938 | ||||||

| pi2 | 0.915 | ||||||

| pi3 | 0.980 | ||||||

| pi4 | 0.898 | ||||||

| pi5 | 0.973 | ||||||

| RA | 0.907 | 0.914 | 0.937 | 0.754 | N.A | ||

| ra1 | 0.932 | ||||||

| ra2 | 0.956 | ||||||

| ra3 | 0.925 | ||||||

| ra4 | 0.933 | ||||||

| ra5 | 0.919 | ||||||

| SI | 0.916 | 0.934 | 0.937 | 0.750 | N.A | ||

| si1 | 0.872 | ||||||

| si2 | 0.892 | ||||||

| si3 | 0.956 | ||||||

| si4 | 0.779 | ||||||

| si5 | 0.822 | ||||||

| AORD | 0.842 | 0.845 | 0.888 | 0.615 | 0.316 | ||

| aord1 | 0.830 | 0.323 | |||||

| aord2 | 0.707 | 0.259 | |||||

| aord3 | 0.808 | 0.390 | |||||

| aord4 | 0.746 | 0.317 | |||||

| aord5 | 0.822 | 0.291 | |||||

| VA | 0.926 | 0.930 | 0.944 | 0.772 | N.A | ||

| va1 | 0.857 | ||||||

| va2 | 0.890 | ||||||

| va3 | 0.907 | ||||||

| va4 | 0.879 | ||||||

| va5 | 0.860 |

| LVs | AR | CO | CC | CA | ER | IN | IP | PIP | RA | SI | AORD | VA |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AR | 0.900 | |||||||||||

| CO | 0.466 | 0.924 | ||||||||||

| CC | 0.675 | 0.280 | 0.924 | |||||||||

| CA | 0.491 | 0.336 | 0.343 | 0.937 | ||||||||

| ER | 0.414 | 0.340 | 0.279 | 0.274 | 0.759 | |||||||

| IN | −0.040 | −0.150 | −0.032 | 0.053 | −0.317 | 0.765 | ||||||

| IP | 0.281 | 0.227 | 0.225 | 0.277 | 0.395 | −0.312 | 0.939 | |||||

| PI | 0.189 | 0.146 | 0.128 | 0.166 | 0.281 | −0.282 | 0.281 | 0.941 | ||||

| RA | 0.604 | 0.488 | 0.425 | 0.485 | 0.564 | −0.113 | 0.333 | 0.225 | 0.868 | |||

| SI | 0.509 | 0.375 | 0.336 | 0.425 | 0.447 | −0.117 | 0.358 | 0.306 | 0.451 | 0.866 | ||

| AORD | 0.439 | 0.344 | 0.300 | 0.267 | 0.483 | −0.538 | 0.410 | 0.366 | 0.328 | 0.336 | 0.784 | |

| VA | −0.160 | −0.168 | −0.087 | −0.049 | −0.231 | 0.404 | −0.175 | −0.138 | −0.187 | −0.210 | −0.344 | 0.879 |

| AR | CO | CC | CA | ER | IN | IP | PI | RA | SI | AORD | VA | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ar1 | 0.907 | 0.658 | 0.406 | 0.419 | 0.341 | −0.006 | 0.205 | 0.186 | 0.543 | 0.452 | 0.338 | −0.122 |

| ar2 | 0.940 | 0.594 | 0.449 | 0.485 | 0.405 | −0.070 | 0.311 | 0.174 | 0.590 | 0.478 | 0.477 | −0.187 |

| ar3 | 0.908 | 0.662 | 0.418 | 0.409 | 0.338 | 0.013 | 0.180 | 0.184 | 0.533 | 0.451 | 0.339 | −0.101 |

| ar4 | 0.927 | 0.630 | 0.444 | 0.505 | 0.422 | −0.049 | 0.326 | 0.156 | 0.584 | 0.480 | 0.462 | −0.173 |

| ar5 | 0.815 | 0.501 | 0.366 | 0.358 | 0.333 | −0.052 | 0.193 | 0.159 | 0.445 | 0.427 | 0.305 | −0.112 |

| co1 | 0.380 | 0.932 | 0.202 | 0.255 | 0.273 | −0.122 | 0.162 | 0.090 | 0.403 | 0.277 | 0.267 | −0.146 |

| co2 | 0.404 | 0.941 | 0.225 | 0.287 | 0.268 | −0.153 | 0.166 | 0.109 | 0.423 | 0.296 | 0.282 | −0.157 |

| co3 | 0.563 | 0.948 | 0.380 | 0.424 | 0.441 | −0.146 | 0.307 | 0.190 | 0.582 | 0.476 | 0.425 | −0.176 |

| co4 | 0.278 | 0.905 | 0.165 | 0.216 | 0.234 | −0.081 | 0.157 | 0.080 | 0.350 | 0.207 | 0.221 | −0.101 |

| co5 | 0.429 | 0.890 | 0.241 | 0.296 | 0.279 | −0.170 | 0.195 | 0.163 | 0.415 | 0.377 | 0.317 | −0.173 |

| cc1 | 0.651 | 0.261 | 0.930 | 0.323 | 0.277 | −0.046 | 0.222 | 0.154 | 0.401 | 0.383 | 0.291 | −0.085 |

| cc2 | 0.749 | 0.323 | 0.979 | 0.398 | 0.335 | −0.051 | 0.259 | 0.162 | 0.489 | 0.391 | 0.353 | −0.108 |

| cc3 | 0.579 | 0.202 | 0.907 | 0.273 | 0.192 | −0.011 | 0.181 | 0.078 | 0.358 | 0.194 | 0.236 | −0.092 |

| cc4 | 0.521 | 0.253 | 0.875 | 0.278 | 0.265 | 0.002 | 0.209 | 0.086 | 0.325 | 0.284 | 0.214 | −0.048 |

| cc5 | 0.564 | 0.233 | 0.926 | 0.280 | 0.190 | −0.024 | 0.150 | 0.084 | 0.352 | 0.256 | 0.256 | −0.058 |

| ca1 | 0.411 | 0.260 | 0.310 | 0.950 | 0.222 | 0.105 | 0.262 | 0.161 | 0.407 | 0.362 | 0.232 | −0.006 |

| ca2 | 0.582 | 0.388 | 0.410 | 0.970 | 0.362 | 0.033 | 0.325 | 0.183 | 0.559 | 0.477 | 0.343 | −0.072 |

| ca3 | 0.428 | 0.286 | 0.283 | 0.928 | 0.221 | 0.049 | 0.213 | 0.170 | 0.416 | 0.330 | 0.216 | −0.026 |

| ca4 | 0.438 | 0.304 | 0.287 | 0.929 | 0.202 | 0.011 | 0.218 | 0.123 | 0.441 | 0.380 | 0.226 | −0.081 |

| ca5 | 0.372 | 0.306 | 0.264 | 0.904 | 0.216 | 0.060 | 0.248 | 0.126 | 0.390 | 0.413 | 0.178 | −0.025 |

| er1 | 0.448 | 0.358 | 0.303 | 0.330 | 0.852 | −0.223 | 0.337 | 0.187 | 0.502 | 0.419 | 0.443 | −0.200 |

| er2 | 0.478 | 0.367 | 0.341 | 0.346 | 0.869 | −0.207 | 0.394 | 0.212 | 0.547 | 0.447 | 0.442 | −0.154 |

| er3 | 0.158 | 0.150 | 0.088 | 0.063 | 0.654 | −0.410 | 0.234 | 0.236 | 0.354 | 0.227 | 0.362 | −0.202 |

| er4 | 0.212 | 0.175 | 0.131 | 0.118 | 0.719 | −0.172 | 0.257 | 0.224 | 0.373 | 0.285 | 0.273 | −0.158 |

| er5 | 0.152 | 0.162 | 0.105 | 0.070 | 0.672 | −0.186 | 0.237 | 0.241 | 0.295 | 0.260 | 0.242 | −0.167 |

| in1 | 0.058 | −0.100 | 0.046 | 0.107 | −0.229 | 0.748 | −0.251 | −0.185 | −0.073 | −0.007 | −0.346 | 0.284 |

| in2 | −0.135 | −0.179 | −0.096 | 0.004 | −0.321 | 0.828 | −0.335 | −0.332 | −0.188 | −0.122 | −0.574 | 0.357 |

| in3 | 0.025 | −0.027 | 0.000 | 0.014 | −0.216 | 0.753 | −0.125 | −0.140 | −0.015 | −0.117 | −0.315 | 0.271 |

| in4 | −0.043 | −0.174 | −0.021 | 0.082 | −0.221 | 0.761 | −0.279 | −0.207 | −0.072 | −0.080 | −0.418 | 0.345 |

| in5 | 0.024 | −0.023 | 0.001 | 0.007 | −0.183 | 0.733 | −0.116 | −0.131 | −0.008 | −0.113 | −0.293 | 0.255 |

| ip1 | 0.291 | 0.199 | 0.232 | 0.247 | 0.363 | −0.268 | 0.938 | 0.273 | 0.344 | 0.355 | 0.381 | −0.145 |

| ip2 | 0.275 | 0.232 | 0.216 | 0.277 | 0.398 | −0.318 | 0.970 | 0.269 | 0.314 | 0.342 | 0.418 | −0.174 |

| ip3 | 0.300 | 0.199 | 0.221 | 0.256 | 0.358 | −0.265 | 0.927 | 0.271 | 0.341 | 0.350 | 0.379 | −0.148 |

| ip4 | 0.239 | 0.188 | 0.196 | 0.264 | 0.366 | −0.303 | 0.948 | 0.245 | 0.287 | 0.319 | 0.359 | −0.168 |

| ip5 | 0.238 | 0.244 | 0.215 | 0.252 | 0.377 | −0.320 | 0.929 | 0.275 | 0.309 | 0.327 | 0.398 | −0.183 |

| ip6 | 0.238 | 0.211 | 0.185 | 0.266 | 0.359 | −0.282 | 0.922 | 0.249 | 0.278 | 0.326 | 0.369 | −0.166 |

| pi1 | 0.167 | 0.099 | 0.096 | 0.145 | 0.262 | −0.275 | 0.238 | 0.938 | 0.187 | 0.258 | 0.342 | −0.118 |

| pi2 | 0.178 | 0.137 | 0.130 | 0.153 | 0.241 | −0.245 | 0.251 | 0.915 | 0.195 | 0.280 | 0.326 | −0.142 |

| pi3 | 0.186 | 0.155 | 0.113 | 0.148 | 0.276 | −0.282 | 0.263 | 0.980 | 0.219 | 0.291 | 0.366 | −0.138 |

| pi4 | 0.190 | 0.155 | 0.128 | 0.184 | 0.282 | −0.251 | 0.291 | 0.898 | 0.264 | 0.338 | 0.325 | −0.119 |

| pi5 | 0.170 | 0.143 | 0.135 | 0.155 | 0.263 | −0.272 | 0.280 | 0.973 | 0.201 | 0.277 | 0.363 | −0.134 |

| ra1 | 0.489 | 0.819 | 0.346 | 0.373 | 0.316 | 0.020 | 0.243 | 0.100 | 0.532 | 0.391 | 0.256 | −0.109 |

| ra2 | 0.568 | 0.360 | 0.382 | 0.439 | 0.556 | −0.119 | 0.289 | 0.222 | 0.956 | 0.405 | 0.292 | −0.194 |

| ra3 | 0.498 | 0.318 | 0.379 | 0.420 | 0.524 | −0.149 | 0.320 | 0.203 | 0.925 | 0.376 | 0.278 | −0.170 |

| ra4 | 0.508 | 0.329 | 0.378 | 0.446 | 0.487 | −0.112 | 0.304 | 0.230 | 0.933 | 0.387 | 0.305 | −0.172 |

| ra5 | 0.533 | 0.317 | 0.342 | 0.399 | 0.526 | −0.116 | 0.270 | 0.204 | 0.919 | 0.380 | 0.276 | −0.152 |

| si1 | 0.468 | 0.324 | 0.283 | 0.378 | 0.358 | −0.140 | 0.307 | 0.255 | 0.379 | 0.872 | 0.306 | −0.234 |

| si2 | 0.379 | 0.321 | 0.263 | 0.317 | 0.381 | −0.082 | 0.290 | 0.261 | 0.367 | 0.892 | 0.255 | −0.139 |

| si3 | 0.543 | 0.403 | 0.377 | 0.464 | 0.504 | −0.129 | 0.399 | 0.310 | 0.514 | 0.956 | 0.386 | −0.218 |

| si4 | 0.452 | 0.310 | 0.300 | 0.324 | 0.363 | −0.026 | 0.277 | 0.206 | 0.388 | 0.779 | 0.232 | −0.156 |

| si5 | 0.321 | 0.235 | 0.199 | 0.321 | 0.286 | −0.106 | 0.243 | 0.283 | 0.253 | 0.822 | 0.233 | −0.137 |

| aord1 | 0.421 | 0.320 | 0.270 | 0.322 | 0.350 | −0.373 | 0.294 | 0.305 | 0.312 | 0.299 | 0.830 | −0.237 |

| aord2 | 0.247 | 0.186 | 0.210 | 0.029 | 0.312 | −0.435 | 0.322 | 0.254 | 0.088 | 0.163 | 0.707 | −0.248 |

| aord3 | 0.335 | 0.281 | 0.229 | 0.184 | 0.443 | −0.494 | 0.318 | 0.316 | 0.246 | 0.296 | 0.808 | −0.339 |

| aord4 | 0.293 | 0.237 | 0.188 | 0.180 | 0.439 | −0.451 | 0.394 | 0.273 | 0.317 | 0.249 | 0.746 | −0.297 |

| aord5 | 0.419 | 0.318 | 0.279 | 0.324 | 0.337 | −0.346 | 0.278 | 0.282 | 0.311 | 0.299 | 0.822 | −0.217 |

| va1 | −0.162 | −0.151 | −0.069 | −0.096 | −0.151 | 0.382 | −0.167 | −0.104 | −0.157 | −0.188 | −0.344 | 0.857 |

| va2 | −0.153 | −0.158 | −0.078 | −0.030 | −0.211 | 0.374 | −0.135 | −0.162 | −0.208 | −0.218 | −0.301 | 0.890 |

| va3 | −0.145 | −0.152 | −0.103 | −0.030 | −0.217 | 0.328 | −0.118 | −0.140 | −0.158 | −0.177 | −0.295 | 0.907 |

| va4 | −0.133 | −0.165 | −0.063 | −0.071 | −0.237 | 0.335 | −0.170 | −0.112 | −0.203 | −0.200 | −0.266 | 0.879 |

| va5 | −0.106 | −0.111 | −0.071 | 0.020 | −0.208 | 0.346 | −0.177 | −0.088 | −0.098 | −0.138 | −0.292 | 0.860 |

| LVs | AR | CO | CC | CA | ER | IN | IP | PIP | RA | SI | AORD | VA |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AR | ||||||||||||

| CO | 0.465 | |||||||||||

| CC | 0.700 | 0.270 | ||||||||||

| CA | 0.491 | 0.326 | 0.338 | |||||||||

| ER | 0.426 | 0.341 | 0.280 | 0.260 | ||||||||

| IN | 0.087 | 0.147 | 0.059 | 0.077 | 0.365 | |||||||

| IP | 0.281 | 0.221 | 0.229 | 0.279 | 0.429 | 0.319 | ||||||

| PI | 0.200 | 0.142 | 0.127 | 0.169 | 0.325 | 0.288 | 0.290 | |||||

| RA | 0.651 | 0.520 | 0.450 | 0.507 | 0.632 | 0.123 | 0.356 | 0.241 | ||||

| SI | 0.538 | 0.371 | 0.341 | 0.437 | 0.487 | 0.140 | 0.371 | 0.324 | 0.486 | |||

| AORD | 0.478 | 0.363 | 0.326 | 0.293 | 0.554 | 0.602 | 0.452 | 0.404 | 0.375 | 0.369 | ||

| VA | 0.164 | 0.173 | 0.090 | 0.061 | 0.269 | 0.446 | 0.184 | 0.146 | 0.205 | 0.222 | 0.384 |

References

- Mihai, F.-C.; Gnoni, M.-G.; Meidiana, C.; Ezeah, C.; Elia, V. Waste electrical and electronic equipment (WEEE): Flows, quantities, and management—A global scenario. In Electronic Waste Management and Treatment Technology; Prasad, M.N.V., Vithanage, M., Eds.; Butterworth-Heinemann: Oxford, UK, 2019; pp. 1–34. [Google Scholar]

- Peet, R.; Robbins, P.; Watts, M. Global Political Ecology; Routledge: Oxfordshire, UK, 2010. [Google Scholar]

- Tortorella, G.L.; Fettermann, D.; Fogliatto, F.S.; Kumar, M.; Jurburg, D. Analysing the influence of organisational culture and leadership styles on the implementation of lean manufacturing. Prod. Plan. Control. 2021, 32, 1282–1294. [Google Scholar] [CrossRef]

- Rehman Khan, S.A.; Yu, Z. Assessing the eco-environmental performance: An PLS-SEM approach with practice-based view. Int. J. Logist. Res. 2021, 24, 303–321. [Google Scholar] [CrossRef]

- Li, G.; Li, L.; Choi, T.M.; Sethi, S.P. Green supply chain management in Chinese firms: Innovative measures and the moderating role of quick response technology. J. Oper. Manag. 2020, 66, 958–988. [Google Scholar] [CrossRef]

- Hwang, B.N.; Huang, C.Y.; Wu, C.H. A TOE approach to establish a green supply chain adoption decision model in the semiconductor industry. Sustainability 2016, 8, 168. [Google Scholar] [CrossRef] [Green Version]

- Yadegaridehkordi, E.; Nilashi, M.; Nasir, M.H.N.B.M.; Ibrahim, O. Predicting determinants of hotel success and development using Structural Equation Modelling (SEM)-ANFIS method. Tour. Manag. 2018, 66, 364–386. [Google Scholar] [CrossRef]

- Chien, M.-K.; Shih, L.-H. Relationship between management practice and organisation performance under European Union directives such as RoHS: A case-study of the electrical and electronic industry in Taiwan. Afr. J. Environ. Sci. 2007, 1, 37–48. [Google Scholar]

- Clemons, E.K. Information systems for sustainable competitive advantage. Inf. Manag. Decis. 1986, 11, 131–136. [Google Scholar] [CrossRef]

- Van Liemt, G. Subcontracting in Electronics: From Contract Manufacturers to Providers of Electronic Manufacturing Services (EMS); International Labour Office: Geneva, Switzerland, 2007. [Google Scholar]

- Barnes, E.; Dai, J.; Deng, S.; Down, D.; Goh, M.; Lau, H.C.; Sharafali, M. Electronics Manufacturing Service Industry; Georgia Institute of Technology: Atlanta, GA, USA, 2000. [Google Scholar]

- Gencer, C.; Gürpinar, D. Analytic network process in supplier selection: A case study in an electronic firm. Appl. Math. Model. 2007, 31, 2475–2486. [Google Scholar] [CrossRef]

- Randall, S. The Worldwide Electronics Manufacturing Services Market; New Venture Research Corp.: Nevada City, CA, USA, 2022; Volume 2023. [Google Scholar]

- Ecer, F. Multi-criteria decision making for green supplier selection using interval type-2 fuzzy AHP: A case study of a home appliance manufacturer. Oper. Res. 2022, 22, 199–233. [Google Scholar]

- Rajput, S.P.; Datta, S. Sustainable and green manufacturing–A narrative literature review. Mater. Today 2020, 26, 2515–2520. [Google Scholar] [CrossRef]

- Rehman, M.A.; Shrivastava, R. Green manufacturing (GM): Past, present and future (a state of art review). World Rev. Sci. Technol. Sustain. Dev. 2013, 10, 17–55. [Google Scholar] [CrossRef]

- Dornfeld, D.A. Green Manufacturing: Fundamentals and Applications; Springer Science & Business Media: New York, NY, USA, 2012. [Google Scholar]

- Deif, A.M. A system model for green manufacturing. J. Clean. Prod. 2011, 19, 1553–1559. [Google Scholar] [CrossRef] [Green Version]

- Stark, J. Product Lifecycle Management (PLM); Springer: New York, NY, USA, 2020; pp. 1–33. [Google Scholar]

- ElMaraghy, W.; ElMaraghy, H.; Tomiyama, T.; Monostori, L. Complexity in engineering design and manufacturing. CIRP Ann 2012, 61, 793–814. [Google Scholar] [CrossRef]

- Fromme, H.; Körner, W.; Shahin, N.; Wanner, A.; Albrecht, M.; Boehmer, S.; Parlar, H.; Mayer, R.; Liebl, B.; Bolte, G. Human exposure to polybrominated diphenyl ethers (PBDE), as evidenced by data from a duplicate diet study, indoor air, house dust, and biomonitoring in Germany. Environ. Int. 2009, 35, 1125–1135. [Google Scholar] [CrossRef] [PubMed]

- George, E.; Pecht, M. RoHS compliance in safety and reliability critical electronics. J. Mater. Sci. Mater. Electron. 2016, 65, 1–7. [Google Scholar] [CrossRef]

- Danso, A.; Adomako, S.; Amankwah-Amoah, J.; Owusu-Agyei, S.; Konadu, R. Environmental sustainability orientation, competitive strategy and financial performance. Bus. Strategy Environ. 2019, 28, 885–895. [Google Scholar] [CrossRef]

- Ghazilla, R.A.R.; Sakundarini, N.; Abdul-Rashid, S.H.; Ayub, N.S.; Olugu, E.U.; Musa, S.N. Drivers and barriers analysis for green manufacturing practices in Malaysian SMEs: A preliminary findings. Procedia CIRP 2015, 26, 658–663. [Google Scholar] [CrossRef] [Green Version]

- Althaf, S.; Babbitt, C.W.; Chen, R. The evolution of consumer electronic waste in the United States. J. Ind. Ecol. 2021, 25, 693–706. [Google Scholar] [CrossRef]

- Tornatzky, L.G.; Fleischer, M.; Chakrabarti, A.K. Processes of Technological Innovation; Lexington Books: Lanham, MD, USA, 1990. [Google Scholar]

- Malik, S.; Chadhar, M.; Vatanasakdakul, S.; Chetty, M. Factors affecting the organizational adoption of blockchain technology: Extending the technology–organization–environment (TOE) framework in the Australian context. Sustainability 2021, 13, 9404. [Google Scholar] [CrossRef]

- Baker, J. The technology–organization–environment framework. In Information Systems Theory; Dwivedi, Y., Wade, M., Schneberger, S., Eds.; Springer: New York, NY, USA, 2012; pp. 231–245. [Google Scholar]

- Yusof, M.M.; Kuljis, J.; Papazafeiropoulou, A.; Stergioulas, L.K. An evaluation framework for Health Information Systems: Human, organization and technology-fit factors (HOT-fit). Int. J. Med. Inform. 2008, 77, 386–398. [Google Scholar] [CrossRef]

- Hapsari, W.P.; Labib, U.A.; Haryanto, H.; Safitri, D.W. A Literature Review of Human, Organization, Technology (HOT)–Fit Evaluation Model. In 6th International Seminar on Science Education (ISSE 2020); Atlantis Press: Amsterdam, The Netherlands, 2021; pp. 876–883. [Google Scholar]

- Feng, B.; Hu, X.; Orji, I.J. Multi-tier supply chain sustainability in the pulp and paper industry: A framework and evaluation methodology. Int. J. Prod. Res. 2023, 61, 4657–4683. [Google Scholar] [CrossRef]

- Bsharat, M.; Ibrahim, O. Quality of service acceptance in cloud service utilization: An empirical study in Palestinian higher education institutions. Educ. Inf. Technol. 2020, 25, 863–888. [Google Scholar] [CrossRef]

- Lindermann, C.; Jahnke, U.; Moi, M.; Koch, R. Analyzing product lifecycle costs for a better understanding of cost drivers in additive manufacturing. In 2012 International Solid Freeform Fabrication Symposium; University of Texas at Austin: Austin, TX, USA, 2012. [Google Scholar]

- Sharif, A.M.; Irani, Z. Applying a fuzzy-morphological approach to complexity within management decision making. Manag. Decis. 2006, 44, 930–961. [Google Scholar] [CrossRef]

- Grady, J.O. System Integration; CRC Press: Boca Raton, FL, USA, 1994. [Google Scholar]

- Henningsson, S.; Yetton, P.W.; Wynne, P.J. A review of information system integration in mergers and acquisitions. J. Inf. Technol. 2018, 33, 255–303. [Google Scholar] [CrossRef] [Green Version]

- Gong, D.-C.; Hsiao, W.-C.; Ho, P.-S. Information integration architecture of risk management for RoHS. In Proceedings of the 2008 International Conference on Computer Science and Software Engineering, Wuhan, China, 12–14 December 2008; pp. 512–515. [Google Scholar]

- Rogers, E.M. Diffusion of Innovations, 3rd ed.; Simon and Schuster: New York, NY, USA, 1983. [Google Scholar]

- Cooper, R.G.; Kleinschmidt, E.J. Benchmarking the firm’s critical success factors in new product development. J. Prod. Innov. Manag. Int. Publ. Prod. Dev. Manag. Assoc. 1995, 12, 374–391. [Google Scholar] [CrossRef]

- Pattanayak, D.; Koilakuntla, M.; Punyatoya, P. Investigating the Influence of TQM, Service Quality and Market Orientation on Customer Satisfaction and Loyalty in the Indian Banking Sector. Int. J. Qual. Reliab. Manag. 2017, 34, 362–377. [Google Scholar] [CrossRef]

- Wang, S.; Li, J.; Zhao, D. Institutional pressures and environmental management practices: The moderating effects of environmental commitment and resource availability. Bus. Strategy Environ. 2018, 27, 52–69. [Google Scholar] [CrossRef]

- Torres-Coronas, T. Social E-Enterprise: Value Creation through ICT: Value Creation through ICT; Information Science Reference: Hershey, PA, USA, 2012. [Google Scholar]

- Griffith, E.E.; Hammersley, J.S.; Kadous, K. Audits of complex estimates as verification of management numbers: How institutional pressures shape practice. Contemp. Account. Res. 2015, 32, 833–863. [Google Scholar] [CrossRef]

- Laursen, K.; Foss, N.J. New human resource management practices, complementarities and the impact on innovation performance. Camb. J. Econ. 2003, 27, 243–263. [Google Scholar] [CrossRef]

- Li, X.; Wang, B.; Peng, T.; Xu, X. Greentelligence: Smart manufacturing for a greener future. Chin. J. Mech. 2021, 34, 116. [Google Scholar] [CrossRef]

- Wu, C.-C. A Derivation of Key Success Factors for Influencing the Adoption of RoHS Process Materials by Mobile Phone Manufacturers. Master’s Thesis, National Taiwan Normal University, Taipei, Taiwan, 2018. [Google Scholar]

- Grinstein, A.; Goldman, A. Characterizing the technology firm: An exploratory study. Res. Policy. 2006, 35, 121–143. [Google Scholar] [CrossRef]

- Stacey, R.D. Complexity and Creativity in Organizations; Berrett-Koehler Publishers: San Francisco, CA, USA, 1996; 312p. [Google Scholar]

- Rounaghi, M.M.; Jarrar, H.; Dana, L.-P. Implementation of strategic cost management in manufacturing companies: Overcoming costs stickiness and increasing corporate sustainability. Future Bus. J. 2021, 7, 31. [Google Scholar] [CrossRef]

- Cooper, R. Supply Chain Development for the Lean Enterprise: Interorganizational Cost Management; Routledge: Oxfordshire, UK, 2017. [Google Scholar]

- Huang, C.-M.; Raj, A.; Osterman, M.; Pecht, M. Assembly options and challenges for electronic products with lead-free exemption. IEEE Access 2020, 8, 134194–134208. [Google Scholar] [CrossRef]

- Hobday, M. Product complexity, innovation and industrial organisation. Res. Policy. 1998, 26, 689–710. [Google Scholar] [CrossRef]

- Amini, M.; Javid, N.J. A Multi-Perspective Framework Established on Diffusion of Innovation (DOI) Theory and Technology, Organization and Environment (TOE) Framework Toward Supply Chain Management System Based on Cloud Computing Technology for Small and Medium Enterprises. Int. J. Inf. Technol. Innov. Adop. 2023, 11, 1217–1234. [Google Scholar]

- Cenci, M.P.; Scarazzato, T.; Munchen, D.D.; Dartora, P.C.; Veit, H.M.; Bernardes, A.M.; Dias, P.R. Eco-friendly electronics—A comprehensive review. Adv. Mater. Technol. 2022, 7, 2001263. [Google Scholar] [CrossRef]

- Paez, O.; Dewees, J.; Genaidy, A.; Tuncel, S.; Karwowski, W.; Zurada, J. The lean manufacturing enterprise: An emerging sociotechnological system integration. Hum. Factors Ergon. Manuf. 2004, 14, 285–306. [Google Scholar] [CrossRef]

- Pellinen, J.; Teittinen, H.; Järvenpää, M. Performance measurement system in the situation of simultaneous vertical and horizontal integration. Int. J. Oper. Prod. Manag. 2016, 36, 1182–1200. [Google Scholar] [CrossRef]

- Rajaguru, R.; Matanda, M.J. Effects of inter-organizational compatibility on supply chain capabilities: Exploring the mediating role of inter-organizational information systems (IOIS) integration. Ind. Mark. Manag. 2013, 42, 620–632. [Google Scholar]

- Wang, C.-H. How organizational green culture influences green performance and competitive advantage: The mediating role of green innovation. J. Manuf. Technol. Manag. 2019, 30, 666–683. [Google Scholar] [CrossRef]

- Gold, S.; Seuring, S.; Beske, P. Sustainable supply chain management and inter-organizational resources: A literature review. Corp. Soc. Responsib. Environ. 2010, 17, 230–245. [Google Scholar]

- Fishbein, M.; Ajzen, I. Belief, Attitude, Intention, and Behavior: An Introduction to Theory and Research; Addison-Wesley: Reading, MA, USA, 1975. [Google Scholar]

- Davis, F.D. Perceived usefulness, perceived ease of use, and user acceptance of information technology. MIS Q. 1989, 13, 319–340. [Google Scholar] [CrossRef] [Green Version]

- Jain, S.; Singhal, S.; Jain, N.K.; Bhaskar, K. Construction and demolition waste recycling: Investigating the role of theory of planned behavior, institutional pressures and environmental consciousness. J. Clean. Prod. 2020, 263, 121405. [Google Scholar]

- Baah, C.; Opoku-Agyeman, D.; Acquah, I.S.K.; Agyabeng-Mensah, Y.; Afum, E.; Faibil, D.; Abdoulaye, F.A.M. Examining the correlations between stakeholder pressures, green production practices, firm reputation, environmental and financial performance: Evidence from manufacturing SMEs. Sustain. Prod. Consum. 2021, 27, 100–114. [Google Scholar]

- Liu, H.; Ke, W.; Wei, K.K.; Gu, J.; Chen, H. The role of institutional pressures and organizational culture in the firm’s intention to adopt internet-enabled supply chain management systems. J. Oper. Manag. 2010, 28, 372–384. [Google Scholar] [CrossRef]

- Yong, J.Y.; Yusliza, M.Y.; Ramayah, T.; Seles, B.M.R.P. Testing the stakeholder pressure, relative advantage, top management commitment and green human resource management linkage. Corp. Soc. Responsib. Environ. 2022, 29, 1283–1299. [Google Scholar] [CrossRef]

- Betts, T.K.; Wiengarten, F.; Tadisina, S.K. Exploring the impact of stakeholder pressure on environmental management strategies at the plant level: What does industry have to do with it? J. Clean. Prod. 2015, 92, 282–294. [Google Scholar]

- Liang, H.; Saraf, N.; Hu, Q.; Xue, Y. Assimilation of enterprise systems: The effect of institutional pressures and the mediating role of top management. MIS Q. 2007, 31, 59–87. [Google Scholar] [CrossRef]

- Cahyono, D.; Suryani, E. The Suitability Evaluation of Procurement Information Systems to the Needs of Users and Management Using Human, Organization, Technology-Fit (HOT-Fit) Framework. IPTEK J. Technol. Sci. 2020, 31, 101–110. [Google Scholar] [CrossRef]

- Xu, J.; Lu, W. Developing a human-organization-technology fit model for information technology adoption in organizations. Technol. Soc. 2022, 70, 102010. [Google Scholar] [CrossRef]

- Akman, I.; Mishra, A. Green information technology practices among IT professionals: Theory of planned behavior perspective. Probl. Ekorozwoju 2014, 9, 47–54. [Google Scholar]

- Riess, A.; Lepmets, M.; McKechnie, S.; Walker, A. Verification of the effectiveness of risk management in the medical device industry. In European Conference on Software Process Improvement; Springer: Berlin/Heidelberg, Germany, 2018; pp. 380–386. [Google Scholar]

- Esmaeilian, B.; Sarkis, J.; Lewis, K.; Behdad, S. Blockchain for the future of sustainable supply chain management in Industry 4.0. Resour. Conserv. Recycl. 2020, 163, 105064. [Google Scholar] [CrossRef]

- Gupta, H.; Barua, M.K. Evaluation of manufacturing organizations ability to overcome internal barriers to green innovations. In Strategic Decision Making for Sustainable Management of Industrial Networks; Rezaei, J., Ed.; Springer: Cham, Switzerland, 2021; pp. 139–160. [Google Scholar]

- Ullah, S.; Ahmad, N.; Khan, F.U.; Badulescu, A.; Badulescu, D. Mapping interactions among green innovations barriers in manufacturing industry using hybrid methodology: Insights from a developing country. Int. J. Environ. Res. Public Health 2021, 18, 7885. [Google Scholar] [PubMed]

- Kanapathy, K.; Yee, G.W.; Zailani, S.; Aghapour, A.H. An intra-regional comparison on RoHS practices for green purchasing management among electrical and electronics SMEs in Southeast Asia. Int. J. Procure. Manag. 2016, 9, 249–271. [Google Scholar] [CrossRef]

- Pumpinyo, S.; Nitivattananon, V. Investigation of barriers and factors affecting the reverse logistics of waste management practice: A case study in Thailand. Sustainability 2014, 6, 7048–7062. [Google Scholar]

- Byrnes, J.P.; Miller, D.C.; Schafer, W.D. Gender differences in risk taking: A meta-analysis. Psychol. Bull. 1999, 125, 367. [Google Scholar] [CrossRef]

- Tripathi, S. Moderating effects of age and experience on the factors influencing the actual usage of cloud computing. J. Int. Technol. Inf. Manage 2018, 27, 121–158. [Google Scholar]

- Zhu, J.; Zhu, C.; Lu, D.; Wang, G.G.; Zheng, X.; Cao, J.; Zhang, J. Regeneration and succession: A 50-year gap dynamic in temperate secondary forests, Northeast China. For. Ecol. Manage 2021, 484, 118943. [Google Scholar]

- Tsai, J.-F.; Wu, S.-C.; Pham, T.K.L.; Lin, M.-H. Analysis of key factors for green supplier selection: A case study of the electronics industry in Vietnam. Sustainability 2023, 15, 7885. [Google Scholar] [CrossRef]

- Hasson, F.; Keeney, S.; McKenna, H. Research guidelines for the Delphi survey technique. J. Adv. Nurs. 2000, 32, 1008–1015. [Google Scholar]

- Wold, H. Path models with latent variables: The NIPALS approach. In Quantitative Sociology; Blalock, H.M., Ed.; Elsevier: Amsterdam, The Netherlands, 1975; pp. 307–357. [Google Scholar]

- Hair, J.; Hollingsworth, C.L.; Randolph, A.B.; Chong, A.Y.L. An updated and expanded assessment of PLS-SEM in information systems research. Ind. Manage. Data Syst. 2017, 117, 442–458. [Google Scholar] [CrossRef]

- Hair, J.F., Jr.; Hult, G.T.M.; Ringle, C.M.; Sarstedt, M.; Danks, N.P.; Ray, S. Partial Least Squares Structural Equation Modeling (PLS-SEM) Using R: A Workbook; Springer Nature: London, UK, 2021. [Google Scholar]

- Ali, F.; Rasoolimanesh, S.M.; Sarstedt, M.; Ringle, C.M.; Ryu, K. An assessment of the use of partial least squares structural equation modeling (PLS-SEM) in hospitality research. Int. J. Contemp. Hosp. Manage 2018, 30, 514–538. [Google Scholar] [CrossRef] [Green Version]

- Hair, J.F., Jr.; Hult, G.T.M.; Ringle, C.M.; Sarstedt, M. A Primer on Partial Least Squares Structural Equation Modeling (PLS-SEM), 3rd ed.; Sage Publications: Thousand Oaks, CA, USA, 2021; ISBN 9781544396422. [Google Scholar]

- Wold, H. Soft modelling: The basic design and some extensions. In Systems under Indirect Observation, Part II; North-Holland: Amsterdam, The Netherlands, 1982; pp. 36–37. [Google Scholar]

- Lohmöller, J.-B. Predictive vs. Structural Modeling: PLS vs. ML. In Latent Variable Path Modeling with Partial Least Squares; Physica: Heidelberg, Germany, 1989; pp. 199–226. [Google Scholar]

- Sarstedt, M.; Ringle, C.M.; Hair, J.F. Partial least squares structural equation modeling. In Handbook of Market Research; Homburg, C., Klarmann, M., Vomberg, A., Eds.; Springer: Cham, Switzerland, 2021; pp. 587–632. [Google Scholar]

- Chin, W.W. The partial least squares approach to structural equation modeling. In Modern Methods for Business Research; Marcoulides, G.A., Ed.; Lawrence Erlbaurn Associates, Inc.: Mahwah, NJ, USA, 1998; pp. 295–336. [Google Scholar]

- Tenenhaus, M.; Vinzi, V.E.; Chatelin, Y.-M.; Lauro, C. PLS path modeling. Comput. Stat. Data Anal. 2005, 48, 159–205. [Google Scholar] [CrossRef]

- Noonan, R.; Wold, H. PLS path modeling with indirectly observed variables: A comparison of alternative estimates for the latent variable. In Systems under Indirect Observations: Part II; Jöreskog, K.G., Wold, H.O.A., Eds.; North-Holland: Amsterdam, The Netherlands, 1982; pp. 75–94. [Google Scholar]

- Becker, J.-M.; Rai, A.; Rigdon, E. Predictive validity and formative measurement in structural equation modeling: Embracing practical relevance. In Proceedings of the International Conference on Information Systems, Milano, Italy, 15–18 December 2013. [Google Scholar]

- Henseler, J. On the convergence of the partial least squares path modeling algorithm. Comput. Stat. 2010, 25, 107–120. [Google Scholar] [CrossRef] [Green Version]

- Russo, D.; Stol, K.-J. PLS-SEM for software engineering research: An introduction and survey. ACM Comput. Surv. 2021, 54, 78. [Google Scholar]

- Uraon, R.S.; Gupta, M. Do HRD practices affect perceived market performance through operational performance? Evidence from software industry. Int. J. Prod. Perform. Manag. 2020, 69, 85–108. [Google Scholar] [CrossRef]

- Hair, J.F., Jr.; Matthews, L.M.; Matthews, R.L.; Marko, S. PLS-SEM or CB-SEM: Updated guidelines on which method to use. Int. J. Multivar. Data Anal. 2017, 1, 107–123. [Google Scholar] [CrossRef]

- Dash, G.; Paul, J. CB-SEM vs PLS-SEM methods for research in social sciences and technology forecasting. Technol. Forecast. Soc. Change 2021, 173, 121092. [Google Scholar] [CrossRef]

- Hair, J.F., Jr.; Hult, G.T.M.; Ringle, C.; Sarstedt, M. A Primer on Partial Least Squares Structural Equation Modeling (PLS-SEM), 2nd ed.; Sage Publications: Thousand Oaks, CA, USA, 2016; ISBN 9781483377452. [Google Scholar]

- Chen, X.; Yu, H.; Yu, F. What is the optimal number of response alternatives for rating scales? From an information processing perspective. J. Mark. Anal. 2015, 3, 69–78. [Google Scholar] [CrossRef]

- Weijters, B.; Cabooter, E.; Schillewaert, N. The effect of rating scale format on response styles: The number of response categories and response category labels. Int. J. Res. Mark. 2010, 27, 236–247. [Google Scholar]

- George, B.; Harris, A.; Mitchell, A. Cost-effectiveness analysis and the consistency of decision making. Pharmacoeconomics 2001, 19, 1103–1109. [Google Scholar] [CrossRef] [PubMed]

- Martens, B.; Teuteberg, F. Decision-making in cloud computing environments: A cost and risk based approach. Inf. Syst. Front. 2012, 14, 871–893. [Google Scholar] [CrossRef]

- Stacey, R.D. Strategic Management and Organisational Dynamics: The Challenge of Complexity to Ways of Thinking about Organisations, 6th ed.; Pearson Education: London, UK, 2011. [Google Scholar]

- Teisman, G.R. Complexity and management of improvement programmes: An evolutionary approach. Public Manag. Rev. 2008, 10, 341–359. [Google Scholar] [CrossRef]

- Giachetti, R.E. A decision support system for material and manufacturing process selection. J. Intell. Manuf. 1998, 9, 265–276. [Google Scholar] [CrossRef]

- Lee, J.-C.; Shiue, Y.-C.; Chen, C.-Y. Examining the impacts of organizational culture and top management support of knowledge sharing on the success of software process improvement. Comput. Hum. Behav. 2016, 54, 462–474. [Google Scholar] [CrossRef]

- Bon, A.T.; Zaid, A.A.; Jaaron, A. Green human resource management, Green supply chain management practices and Sustainable performance. In Proceedings of the 8th International Conference on Industrial Engineering and Operations Management (IEOM), Bandung, Indonesia, 6–8 March 2018; pp. 6–8. [Google Scholar]

- Boxall, P.; Purcell, J. Strategy and Human Resource Management; Macmillan International Higher Education: New York, NY, USA, 2011. [Google Scholar]

- Thong, J.Y.; Yap, C.-S.; Raman, K. Top management support, external expertise and information systems implementation in small businesses. Inf. Syst. Res. 1996, 7, 248–267. [Google Scholar] [CrossRef]

- Lado, A.A.; Zhang, M.J. Expert systems, knowledge development and utilization, and sustained competitive advantage: A resource-based model. J. Inf. Syst. 1998, 24, 489–509. [Google Scholar]

- Takala, J.; Bhufhai, A.; Phusavat, K. Proposed verification method for the content suitability of the customer satisfaction survey. Ind. Manag. Data Syst. 2006, 106, 841–854. [Google Scholar] [CrossRef]

- Gupta, A.K.; Tesluk, P.E.; Taylor, M.S. Innovation at and across multiple levels of analysis. Organ. Sci. 2007, 18, 885–897. [Google Scholar] [CrossRef]

- Goodland, R. The concept of environmental sustainability. Annu. Rev. Ecol. Evol. Syst. 1995, 26, 1–24. [Google Scholar] [CrossRef]

- Armstrong, J.S.; Overton, T.S. Estimating nonresponse bias in mail surveys. J. Mark. Res. 1977, 14, 396–402. [Google Scholar] [CrossRef] [Green Version]

- Ringle, C.M.; Wende, S.; Becker, J.-M. SmartPLS 3. Boenningstedt; SmartPLS GmbH: Hamburg, Germany, 2015. [Google Scholar]

- Wagner, W.E., III. Using IBM® SPSS® Statistics for Research Methods And Social Science Statistics; Sage Publications: Los Angeles, CA, USA, 2019. [Google Scholar]

- Wijaya, T.T.; Jiang, P.; Mailizar, M.; Habibi, A. Predicting Factors Influencing Preservice Teachers’ Behavior Intention in the Implementation of STEM Education Using Partial Least Squares Approach. Sustainability 2022, 14, 9925. [Google Scholar] [CrossRef]

- McKinney, V.; Yoon, K.; Zahedi, F.M. The measurement of web-customer satisfaction: An expectation and disconfirmation approach. Inf. Syst. Res. 2002, 13, 296–315. [Google Scholar] [CrossRef]

- Hair, J.F.; Sarstedt, M.; Ringle, C.M.; Mena, J.A. An assessment of the use of partial least squares structural equation modeling in marketing research. J. Acad. Mark. Sci. 2012, 40, 414–433. [Google Scholar] [CrossRef]

- Huang, C.-Y.; Wang, H.-Y.; Yang, C.-L.; Shiau, S.J. A derivation of factors influencing the diffusion and adoption of an open source learning platform. Sustainability 2020, 12, 7532. [Google Scholar] [CrossRef]

- Smirnov, N.V. On the estimation of the discrepancy between empirical curves of distribution for two independent samples. Bull. Math. Univ. 1939, 2, 3–14. [Google Scholar]

- Kim, H.-Y. Statistical notes for clinical researchers: Assessing normal distribution (2) using skewness and kurtosis. Restor. Dent. Endod. 2013, 38, 52–54. [Google Scholar] [CrossRef]

- Bagozzi, R.P.; Yi, Y. On the evaluation of structural equation models. J. Acad. Mark. Sci. 1988, 16, 74–94. [Google Scholar] [CrossRef]

- Jöreskog, K.G. Structural analysis of covariance and correlation matrices. Psychometrika 1978, 43, 443–477. [Google Scholar] [CrossRef]

- Fornell, C.; Larcker, D.F. Structural Equation Models with Unobservable Variables and Measurement Error: Algebra and Statistics; Sage Publications: Los Angeles, CA, USA, 1981. [Google Scholar]

- Ali, Z.; Sun, H.; Ali, M. The impact of managerial and adaptive capabilities to stimulate organizational innovation in SMEs: A complementary PLS–SEM approach. Sustainability 2017, 9, 2157. [Google Scholar] [CrossRef] [Green Version]

- Henseler, J.; Ringle, C.M.; Sarstedt, M. A new criterion for assessing discriminant validity in variance-based structural equation modeling. J. Acad. Mark. Sci. 2015, 43, 115–135. [Google Scholar] [CrossRef] [Green Version]

- Becker, J.-M.; Ringle, C.M.; Sarstedt, M.; Völckner, F. How collinearity affects mixture regression results. Mark. Lett. 2015, 26, 643–659. [Google Scholar] [CrossRef]

- Kock, N. Common method bias in PLS-SEM: A full collinearity assessment approach. Int. J. e-Collab. 2015, 11, 1–10. [Google Scholar]

- Johnson, D.H. The insignificance of statistical significance testing. J. Wildl. Manag. 1999, 63, 763–772. [Google Scholar] [CrossRef] [Green Version]

- Browen, M.; Cudeck, R. Alternative ways of assessing model fit. In Testing Structural Equation Models; Bollen, K.A., Long, J.S., Eds.; Sage: Thousand Oaks, CA, USA, 1993. [Google Scholar]

- Hu, L.t.; Bentler, P.M. Cutoff criteria for fit indexes in covariance structure analysis: Conventional criteria versus new alternatives. Struct. Equ. Model. 1999, 6, 1–55. [Google Scholar] [CrossRef]

- Podsakoff, P.M.; MacKenzie, S.B.; Moorman, R.H.; Fetter, R. Transformational leader behaviors and their effects on followers’ trust in leader, satisfaction, and organizational citizenship behaviors. Leadersh Q 1990, 1, 107–142. [Google Scholar] [CrossRef]

- Chang, S.-J.; Van Witteloostuijn, A.; Eden, L. Common Method Variance in International Business Research; Springer: New York, NY, USA, 2020; pp. 385–398. [Google Scholar]

- Stacey, R.D.; Griffin, D.; Shaw, P. Complexity and Management: Fad or Radical Challenge to Systems Thinking? Roudedge: New York, NY, USA, 2000. [Google Scholar]

- Yu, J.; Welford, R.; Hills, P. Industry responses to EU WEEE and ROHS Directives: Perspectives from China. Corp. Soc. Responsib. Environ. 2006, 13, 286–299. [Google Scholar] [CrossRef]

- Lau, J.H. Reliability of RoHS-compliant 2D and 3D IC Interconnects; McGraw-Hill Education: New York, NY, USA, 2011. [Google Scholar]

- Veleva, V.; Sethi, S. The electronics industry in a new regulatory climate: Protecting the environment and shareholder value. Corp. Environ. Strategy 2004, 11, 207–224. [Google Scholar]

- Zhou, C.H.; Shi, H.; Wang, X.N. Study on RoHS data integration system based on Optical Character Recognition. Appl. Mech. Mater. 2012, 220, 2083–2086. [Google Scholar] [CrossRef]

- Bernardo, M.; Casadesus, M.; Karapetrovic, S.; Heras, I. Do integration difficulties influence management system integration levels? J. Clean. Prod. 2012, 21, 23–33. [Google Scholar] [CrossRef]

- Koh, S.C.; Gunasekaran, A.; Tseng, C. Cross-tier ripple and indirect effects of directives WEEE and RoHS on greening a supply chain. Int. J. Prod. Econ. 2012, 140, 305–317. [Google Scholar] [CrossRef]

- Hu, A.H.; Hsu, C.W. Critical factors for implementing green supply chain management practice: An empirical study of electrical and electronics industries in Taiwan. Manag. Res. Rev. 2010, 33, 586–608. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, Q.; Zhang, S.; Zhao, X. Effects of customer and cost drivers on green supply chain management practices and environmental performance. J. Clean. Prod. 2018, 189, 673–682. [Google Scholar] [CrossRef]

- Harrington, S.J.; Ruppel, C.P. Telecommuting: A test of trust, competing values, and relative advantage. IEEE Trans. Commun. 1999, 42, 223–239. [Google Scholar] [CrossRef]

- Premkumar, G.; Ramamurthy, K.; Nilakanta, S. Implementation of electronic data interchange: An innovation diffusion perspective. J. Inf. Syst. 1994, 11, 157–186. [Google Scholar] [CrossRef]

- Johansson, G.; Winroth, M. Introducing environmental concern in manufacturing strategies. Manag. Res. Rev. 2010, 33, 877–899. [Google Scholar] [CrossRef]

- Zhu, K.; Kraemer, K.; Xu, S. Electronic business adoption by European firms: A cross-country assessment of the facilitators and inhibitors. Eur. J. Inf. Syst. 2003, 12, 251–268. [Google Scholar] [CrossRef] [Green Version]

- Butler, T. Compliance with institutional imperatives on environmental sustainability: Building theory on the role of Green IS. J. Strateg. Inf. Syst. 2011, 20, 6–26. [Google Scholar] [CrossRef]

- Leonidou, L.C.; Christodoulides, P.; Kyrgidou, L.P.; Palihawadana, D. Internal drivers and performance consequences of small firm green business strategy: The moderating role of external forces. J. Bus. Ethics. 2017, 140, 585–606. [Google Scholar] [CrossRef] [Green Version]

- Karahanna, E.; Straub, D.W.; Chervany, N.L. Information technology adoption across time: A cross-sectional comparison of pre-adoption and post-adoption beliefs. MIS Q. 1999, 23, 183–213. [Google Scholar] [CrossRef]

- Plouffe, C.R.; Hulland, J.S.; Vandenbosch, M. Richness versus Parsimony in Modeling Technology Adoption Decisions—Understanding Merchant Adoption of a Smart Card-Based Payment System. Inf. Syst. Res. 2001, 12, 208–222. [Google Scholar] [CrossRef]

- Bohlouli, M.; Mittas, N.; Kakarontzas, G.; Theodosiou, T.; Angelis, L.; Fathi, M. Competence assessment as an expert system for human resource management: A mathematical approach. Expert Syst. Appl. 2017, 70, 83–102. [Google Scholar] [CrossRef] [Green Version]

- Bae, S.; Seol, I. An exploratory empirical investigation of environmental audit programs in S&P 500 companies. Manag. Res. News 2006, 29, 573–579. [Google Scholar]

- Laura-Diana, R. The impact of auditing on green information and communication technologies. Financ. Audit. 2016, 14, 217. [Google Scholar]

- Puttlitz, K.J.; Galyon, G.T. Impact of the ROHS directive on high-performance electronic systems. In Lead-Free Electronic Solders; Springer: Berlin/Heidelberg, Germany, 2006; pp. 347–365. [Google Scholar]

- Song, W.; Yu, H.; Xu, H. Effects of green human resource management and managerial environmental concern on green innovation. Eur. J. Innov. 2020, 24, 951–967. [Google Scholar] [CrossRef]

- Grant, D.; Yeo, B. A global perspective on tech investment, financing, and ICT on manufacturing and service industry performance. Int. J. Inf. Manag. 2018, 43, 130–145. [Google Scholar] [CrossRef]

- Lin, Y.-H.; Lee, P.-C.; Chang, T.-P. Practical expert diagnosis model based on the grey relational analysis technique. Expert Syst. Appl. 2009, 36, 1523–1528. [Google Scholar] [CrossRef]

- Mesa, J.; Maury, H.; Arrieta, R.; Corredor, L.; Bris, J. A novel approach to include sustainability concepts in classical DFMA methodology for sheet metal enclosure devices. Res. Eng. Des. 2018, 29, 227–244. [Google Scholar] [CrossRef]

- Menon, S.; George, E.; Osterman, M.; Pecht, M. High lead solder (over 85%) solder in the electronics industry: RoHS exemptions and alternatives. J. Mater. Sci. Mater. Electron. 2015, 26, 4021–4030. [Google Scholar] [CrossRef]

- Latif, B.; Mahmood, Z.; Tze San, O.; Mohd Said, R.; Bakhsh, A. Coercive, normative and mimetic pressures as drivers of environmental management accounting adoption. Sustainability 2020, 12, 4506. [Google Scholar] [CrossRef]

- Wing-Hung Lo, C.; Fryxell, G.E.; Tang, S.-Y. Stakeholder pressures from perceived environmental impacts and the effect on corporate environmental management programmes in China. Environ. Politics 2010, 19, 888–909. [Google Scholar] [CrossRef]

- Song, M.; Wang, S.; Zhang, H. Could environmental regulation and R&D tax incentives affect green product innovation? J. Clean. Prod. 2020, 258, 120849. [Google Scholar]

- Business & Legal Reports, Inc. Global Environmental Challenge for U.S. Business: Are you Ready? Business & Legal Reports, Inc.: Old Saybrook, CT, USA, 2009. [Google Scholar]

- Goodship, V.; Stevels, A.; Huisman, J. Waste Electrical and Electronic Equipment (WEEE) Handbook; Elsevier Science: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Pecht, M.; Fukuda, Y.; Rajagopal, S. The impact of lead-free legislation exemptions on the electronics industry. IEEE Trans. Compon. Packag. Manuf. Technol. 2004, 27, 221–232. [Google Scholar] [CrossRef]

- Carver, R. The case against statistical significance testing. Harv. Educ. Rev. 1978, 48, 378–399. [Google Scholar] [CrossRef]

- Allen, C.; Mehler, D.M. Open science challenges, benefits and tips in early career and beyond. PLoS Biol. 2019, 17, e3000246. [Google Scholar]

- Van Ark, B.; O’Mahoney, M.; Timmer, M.P. The Productivity Gap between Europe and the United States: Trends and Causes. J. Econ. Perspect. 2008, 22, 25–44. [Google Scholar] [CrossRef] [Green Version]

- Mante-Meijer, E.; Haddon, L.; Concejero, P.; Klamer, L.; Heres, J.; Ling, R.; Thomas, F.; Smoreda, Z.; Vrieling, I. Checking It Out with the People–ICT Markets and Users in Europe; EURESCOM: Heidelberg, Germany, 2001. [Google Scholar]

- Koruza, J.; Bell, A.J.; Frömling, T.; Webber, K.G.; Wang, K.; Rödel, J. Requirements for the transfer of lead-free piezoceramics into application. J. Mater. 2018, 4, 13–26. [Google Scholar] [CrossRef]

| Aspect | Variable | Abbreviation | Explanations |

|---|---|---|---|

| Technology | Cost | CA | Cost (CA) refers to an EMS provider’s operation cost for RoHS compliance [33]. |

| Complexity | CO | Complexity (CO) refers to the difficulties faced in implementing the RoHS practice [34]. | |

| Compatibility | CC | Compatibility (CC) is the degree of compliance of an EMS provider’s operations with RoHS [34]. | |

| System integration | SI | System integration (SI) offers a systems-based approach to resolving complex issues and serves as a robust foundation for integrating both products and processes [35,36]. As all components of the entire green supply chain may be accountable for any noncompliance with RoHS regulations, the integration of ISs up to a certain level assumes a critical role [37]. | |

| Organization | Relative advantage | RA | As per Rogers [38], relative advantage (RA) denotes the perceived superiority of an innovation compared to a current concept or method; the higher the perceived relative benefit of an innovation, the faster its adoption rate within an organization [33]. |

| Adequate resource | AR | Adequate resources (ARs) have a direct effect on a firm’s decisions about innovation, investment, and business strategies [39]. | |

| Environment | Institutional pressure | INP | Institutional pressure (INP) refers to the influence stemming from the institutional environment, including governmental and non-governmental entities, which can impact a company’s managerial choices and practices [40,41]. |

| Perceived industry pressure | PIP | Perceived industry pressure (PIP) alludes to the environmental influence originating from supply chains, competitors, and clients that could potentially sway a company’s decision-making process [41]. | |

| Human | Expert resource | ER | Expert resource (ER) means individuals who are capable of helping with a particular task [42]. |

| Verification | VA | Verification is a process to measure the firm’s policies and procedures to a degree based on the customer’s requirements and/or standards [43]. | |

| Innovation | IN | Innovation (IN) refers to the practical realization of ideas that lead to the creation of new products or services, or the enhancement of existing ones [44]. |

| Latent Variable | Item Code | Descriptions | Source |

|---|---|---|---|

| Costs | ca1 | The adoption of RoHS improved manufacturing efficiency | Revised from George, Harris, and Mitchell [102], Martens and Teuteberg [103] |

| ca2 | The adoption of RoHS increased profits | ||

| ca3 | RoHS can increase financial performance | ||

| ca4 | Returning costs has been reduced since the firm adopted the RoHS | ||

| ca5 | Marketing, customer-related service time, and costs have been reduced after the firm adopted the RoHS | ||

| Complexity | cc1 | Employees’ learning about new RoHS regulations is not complicated | Revised from Stacey [104], Teisman [105] |

| cc2 | Upgrading existing systems to comply with new RoHS regulations is easy and not difficult | ||

| cc3 | Maintaining RoHS systems is not complicated | ||

| cc4 | In the development of a new product, compliance with RoHS regulations was deemed simple to handle | ||

| cc5 | Introducing RoHS regulations into the supply chain is not complicated | ||

| Compatibility | co1 | The supply chain system is compatible with RoHS | Revised from Giachetti [106], Stacey [104] |

| co2 | The current facilities of the software system can be phased into the RoHS requirement | ||

| co3 | The current quality management system is compatible with the RoHS standard | ||

| co4 | The conversion process, including establishing a design and tracking system, is followed with RoHS requirements | ||

| co5 | Our employees are familiar with RoHS regulations | ||

| System Integration | si1 | Supply chain systems can be adapted to the new RoHS regulations | Revised from Paez et al. [55], Stacey [104], Teisman [105] |

| si2 | The current firm’s operating systems (e.g., PLM, ERP, and shop flow) can be adapted to meet RoHS requirements | ||

| si3 | The current quality management system (e.g., ISO, Eco-Management and Audit Scheme (EMAS)) is adapted to the new RoHS directive | ||

| si4 | The ERP system contains our database for tracking RoHS requirements | ||

| si5 | Our employees are familiar with the firm’s system, which is frequently updated with the latest RoHS regulations, and know how to comply with them | ||

| Relative Advantage | ra1 | The adoption of RoHS will substantially increase the business opportunities of our firm | Revised from Giachetti [106], Stacey [104], Lee, Shiue, and Chen [107] |

| ra2 | After the firm adopted RoHS, our firm’s relationship with the customer improved | ||

| ra3 | After the firm adopted RoHS, our firm’s customer service quality improved | ||

| ra4 | The core competitiveness of the firm was increased after it adopted RoHS | ||

| ra5 | The management capability of the supply chain was improved after the firm adopted RoHS | ||

| ra6 | The firm’s image was enhanced after adopting the RoHS | ||

| Adequate Resource | ar1 | In order to promote the RoHS program, management pays adequate attention to dealing with supply chain management | Revised from Bon et al. [108], Boxall and Purcell [109] |

| ar2 | In order to promote the RoHS program, management gave an adequate implementation time frame to deal with supply chain management | ||

| ar3 | In order to promote the RoHS program, management allocated an adequate budget to deal with supply chain management | ||

| ar4 | In order to promote the RoHS program, management dispatched an adequate team to assist with supply chain management | ||

| ar5 | To promote the RoHS program, management provided an adequate encouraged and reward for excellent supply chain management | ||

| Institutional Pressure | ip1 | The government asked us for RoHS compliance | Revised from Thong et al. [110], Lee et al. [107] |

| ip2 | The government requested us to provide the RoHS tracking records | ||

| ip3 | The government asked us to follow the most updated RoHS standard | ||

| ip4 | The government informed us that we have to assist with the supply chain to follow RoHS | ||

| ip5 | Our firm and supply chain have been audited by government experts | ||

| Ip6 | In the event that the RoHS certification is not obtained, the government will take enforcement actions | ||

| Perceived Industry Pressure | pi1 | Our major customers believe that our operation should comply with the RoHS directive | Revised from Thong et al. [110], Lee et al. [107] |

| pi2 | Our customers treat us as the most competitive firm in the industry since we took a lead in RoHS adoption | ||

| pi3 | Our major suppliers believe that they should comply with the RoHS directive | ||

| pi4 | Our suppliers of key components comply with the RoHS directive | ||

| pi5 | Our major competitors have benefited after they adopted the RoHS | ||

| Expert Resource | er1 | To recruit and select RoHS experts, we formulate proactive recruiting and operating procedures (e.g., system engineering, IT) | Revised from Bon et al. [108], Boxall and Purcell [109], Lado et al. [111] |

| er2 | We conduct regular RoHS-related training for all employees | ||

| er3 | Our suppliers formulated a proactive human resource plan for recruiting and selecting RoHS experts (e.g., system engineering, IT) | ||

| er4 | Our major competitors formulated a proactive human resource plan for recruiting and selecting RoHS experts (e.g., system engineering, IT) | ||

| er5 | Our customers formulated a proactive human resource plan for recruiting and selecting RoHS experts (e.g., system engineering, IT) | ||

| Verification Ability | va1 | Internal inspections of RoHS-related work will be conducted irregularly | Revised from Takala, Bhufhai, and Phusavat [112] |

| va2 | We provide regular reports on the management of various indicators of RoHS implementation | ||

| va3 | Our company has formed an audit team to examine the RoHS process | ||

| va4 | In the company, we use the sampling inspection of raw materials to make sure our products comply with RoHS regulations | ||

| va5 | Our company or organization sends personnel to important raw material suppliers to conduct RoHS inspections | ||

| Innovation | in1 | Companies or organizations regularly review and improve the RoHS system and reward innovation | Revised from Deif [18], Gupta, Tesluk, and Taylor [113] and Goodland [114] |

| in2 | As part of our commitment to RoHS, we send workers to participate in organizations relevant to the issue and transfer effective solutions from other factories | ||

| in3 | I think universities, the government, and the industry should set up a group to brainstorm RoHS-related policy innovations | ||

| in4 | RoHS experts from an outside organization are often invited to analyze and improve our company’s system | ||

| in5 | Our company provides an incentive program to the supply chain for the innovation of RoHS |

| Type of Firm/Department | Title | Experience (Year) |

|---|---|---|

| 1. EMS/Procurement | Manager | 19 |

| 2. Semiconductor/Sales | Director | 23 |

| 3. EMS/Quality Assurance | Director | 20 |

| 4. EMS/Production | Senior Vice President | 27 |

| 5. University/Industrial Management | Professor | 18 |

| 6. EMS/Logistic | Manager | 15 |

| 7. EMS/IT | Manager | 17 |

| 8. EMS/Project Management | Associate Vice President | 21 |

| 9. EMS/Sales | Vice President | 24 |

| Profile Category | Frequency | Percentage (%) |

|---|---|---|

| Gender | ||

| Female | 30 | 7.915% |

| Male | 349 | 92.085% |

| Age (years) | ||

| <30 | 58 | 15.303% |

| 30–40 | 170 | 44.855% |

| 40–50 | 97 | 25.594% |

| >50 | 54 | 14.248% |

| Education | ||

| Bachelor | 202 | 52.299% |

| Master | 173 | 46.646% |

| Ph.D. | 4 | 1.055% |

| Experience | ||

| 5 years or less | 92 | 24.275% |

| 10 years or less | 234 | 61.742% |

| 15 years or less | 44 | 11.609% |

| 20 years or less | 5 | 1.319% |

| Over 20 years | 4 | 1.055% |

| Department | ||

| Procurement | 40 | 10.554% |

| Purchasing | 33 | 8.707% |

| Quality Assurance | 34 | 8.971% |

| Engineering | 91 | 24.011% |

| Production | 53 | 13.984% |

| Logistics (In/Outbound) | 33 | 8.707% |

| Finance and Sales | 22 | 5.805% |

| IT | 39 | 10.290% |

| Management | 34 | 8.971% |

| Variable | Mean | Mdn | Min | Max | SD | Excess Kurtosis | Skewness | Variable | Mean | Mdn | Min | Max | SD | Excess Kurtosis | Skewness |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ar1 | 2.201 | 2 | 1 | 5 | 0.631 | 0.531 | 0.184 | ip1 | 2.087 | 2 | 1 | 5 | 0.806 | 0.822 | 0.569 |

| ar2 | 2.137 | 2 | 1 | 5 | 0.516 | 0.155 | 0.039 | ip2 | 2.087 | 2 | 1 | 5 | 0.841 | 0.339 | 0.475 |

| ar3 | 2.206 | 2 | 1 | 5 | 0.633 | 0.513 | 0.18 | ip3 | 2.087 | 2 | 1 | 5 | 0.819 | 0.633 | 0.532 |

| ar4 | 2.124 | 2 | 1 | 5 | 0.506 | 0.172 | 0.041 | ip4 | 2.071 | 2 | 1 | 5 | 0.879 | −0.059 | 0.422 |

| ar5 | 2.164 | 2 | 1 | 5 | 0.59 | 0.77 | 0.227 | ip5 | 2.09 | 2 | 1 | 5 | 0.842 | 0.317 | 0.467 |

| ca1 | 2.245 | 2 | 1 | 5 | 0.554 | 0.345 | 0.134 | ip6 | 2.077 | 2 | 1 | 5 | 0.906 | −0.243 | 0.405 |

| ca2 | 2.288 | 2 | 1 | 5 | 0.649 | 0.568 | 0.202 | pi1 | 2.269 | 2 | 1 | 5 | 0.8 | −0.359 | −0.027 |

| ca3 | 2.269 | 2 | 1 | 5 | 0.587 | 0.293 | 0.135 | pi2 | 2.224 | 2 | 1 | 4 | 0.697 | −0.321 | 0.039 |

| ca4 | 2.293 | 2 | 1 | 5 | 0.596 | 0.326 | 0.145 | pi3 | 2.288 | 2 | 1 | 5 | 0.747 | 0.15 | 0.161 |

| ca5 | 2.256 | 2 | 1 | 5 | 0.586 | 0.434 | 0.146 | pi4 | 2.274 | 2 | 1 | 5 | 0.7 | 0.723 | 0.398 |

| cc1 | 2.272 | 2 | 1 | 5 | 0.619 | 0.246 | 0.122 | pi5 | 2.272 | 2 | 1 | 4 | 0.714 | −0.502 | −0.102 |

| cc2 | 2.293 | 2 | 1 | 5 | 0.622 | 0.435 | 0.182 | ra1 | 2.074 | 2 | 1 | 5 | 0.741 | 0.28 | 0.113 |

| cc3 | 2.285 | 2 | 1 | 5 | 0.597 | 0.414 | 0.166 | ra2 | 1.913 | 2 | 1 | 5 | 0.86 | 0.225 | 0.119 |

| cc4 | 2.251 | 2 | 1 | 5 | 0.615 | 0.233 | 0.102 | ra3 | 1.918 | 2 | 1 | 5 | 0.908 | 0.133 | 0.103 |

| cc5 | 2.272 | 2 | 1 | 5 | 0.57 | 0.234 | 0.131 | ra4 | 1.902 | 2 | 1 | 5 | 0.874 | 0.202 | 0.117 |

| co1 | 2.198 | 2 | 1 | 4 | 0.519 | 0.271 | 0.135 | ra5 | 1.908 | 2 | 1 | 5 | 0.921 | 0.116 | 0.102 |

| co2 | 2.201 | 2 | 1 | 4 | 0.526 | 0.301 | 0.149 | si1 | 2.098 | 2 | 1 | 5 | 0.354 | 0.194 | 0.039 |

| co3 | 2.219 | 2 | 1 | 5 | 0.601 | 0.641 | 0.221 | si2 | 2.074 | 2 | 1 | 5 | 0.411 | 0.196 | 0.035 |

| co4 | 2.172 | 2 | 1 | 4 | 0.498 | 0.278 | 0.122 | si3 | 2.084 | 2 | 2 | 5 | 0.382 | 0.28 | 0.051 |

| co5 | 2.243 | 2 | 1 | 5 | 0.603 | 0.357 | 0.165 | si4 | 2.047 | 2 | 1 | 5 | 0.485 | 0.104 | 0.019 |

| er1 | 2.222 | 2 | 1 | 5 | 0.725 | 0.222 | 0.084 | si5 | 2.058 | 2 | 1 | 4 | 0.336 | 0.187 | 0.035 |

| er2 | 2.198 | 2 | 1 | 5 | 0.662 | 0.416 | 0.135 | aord1 | 2.467 | 2 | 1 | 5 | 0.887 | 0.169 | 0.464 |

| er3 | 2.116 | 2 | 1 | 5 | 0.826 | 0.416 | 0.513 | aord2 | 2.443 | 2 | 1 | 5 | 0.649 | 1.051 | 0.532 |

| er4 | 2.172 | 2 | 1 | 5 | 0.681 | 0.219 | 0.088 | aord3 | 2.412 | 3 | 1 | 5 | 1.037 | −0.737 | 0.024 |

| er5 | 2.187 | 2 | 1 | 5 | 0.74 | 0.982 | 0.547 | aord4 | 2.454 | 2 | 1 | 5 | 0.969 | −0.318 | 0.419 |

| in1 | 2.148 | 2 | 1 | 5 | 1.386 | −0.12 | 1.066 | aprd5 | 2.446 | 2 | 1 | 5 | 0.901 | 0.111 | 0.456 |

| in2 | 2.092 | 2 | 1 | 5 | 1.009 | 0.506 | 0.82 | va1 | 2.765 | 3 | 1 | 5 | 0.755 | 0.264 | 0.678 |

| in3 | 2.011 | 2 | 1 | 5 | 1.237 | 0.203 | 1.005 | va2 | 2.768 | 3 | 2 | 5 | 0.761 | 0.089 | 0.743 |

| in4 | 2.148 | 2 | 1 | 5 | 1.111 | 0.261 | 0.888 | va3 | 2.734 | 3 | 1 | 5 | 0.822 | −0.182 | 0.758 |

| in5 | 1.971 | 2 | 1 | 5 | 1.231 | 0.406 | 1.096 | va4 | 2.763 | 3 | 1 | 5 | 0.79 | −0.131 | 0.707 |

| va5 | 2.657 | 2 | 1 | 5 | 0.824 | 0.032 | 0.966 |

| Hypothesis | Sample Mean (M) | Std. Dev. (STDEV) | Path Coeff. (β) | t Statistics | p Values | VIF | Total Effects | |

|---|---|---|---|---|---|---|---|---|

| H1 (CA→AORD) | 0.095 | 0.044 | 0.096 | 2.196 | 0.028 | 0.035 | 1.543 | 0.096 |

| H2 (CC→AORD) | 0.010 | 0.048 | 0.008 | 0.175 | 0.861 | 0.021 | 1.853 | 0.008 |

| H3 (CO→AORD) | 0.083 | 0.044 | 0.083 | 1.868 | 0.062 | 0.031 | 1.452 | 0.083 |

| H4 (SI→AORD) | −0.041 | 0.045 | −0.047 | 1.043 | 0.297 | 0.023 | 1.682 | −0.047 |

| H5 (RA→AORD) | −0.157 | 0.055 | −0.155 | 2.831 | 0.005 | 0.044 | 2.201 | −0.155 |

| H6 (AR→AORD) | 0.297 | 0.074 | 0.304 | 4.119 | 0.000 | 0.092 | 2.781 | 0.304 |

| H7 (INP→AORD) | 0.097 | 0.043 | 0.100 | 2.324 | 0.020 | 0.036 | 1.372 | 0.100 |

| H8 (PIP→AORD) | 0.129 | 0.040 | 0.128 | 3.164 | 0.002 | 0.049 | 1.215 | 0.128 |

| H9 (ER→AORD) | 0.195 | 0.045 | 0.195 | 4.368 | 0.000 | 0.066 | 1.781 | 0.195 |

| H10 (VA→AORD) | −0.081 | 0.041 | −0.081 | 1.995 | 0.046 | 0.031 | 1.252 | −0.081 |

| H11 (IN→AORD) | −0.380 | 0.045 | −0.379 | 8.347 | 0.000 | 0.230 | 1.473 | −0.379 |

| Hypotheses | Results |

|---|---|

| H1 (CA→AORD) | Supported |

| H2 (CC→AORD) | Not Supported |

| H3 (CO→AORD) | Not Supported |

| H4 (SI→AORD) | Not Supported |

| H5 (RA→AORD) | Supported |

| H6 (AR→AORD) | Supported |

| H7 (INP→AORD) | Supported |

| H8 (PIP→AORD) | Supported |

| H9 (ER→AORD) | Supported |

| H10 (VA→AORD) | Supported |

| H11 (IN→AORD) | Supported |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, J.-C.; Li, J.-F.; Huang, C.-Y. Enablers for Adopting Restriction of Hazardous Substances Directives by Electronic Manufacturing Service Providers. Sustainability 2023, 15, 12341. https://doi.org/10.3390/su151612341

Cheng J-C, Li J-F, Huang C-Y. Enablers for Adopting Restriction of Hazardous Substances Directives by Electronic Manufacturing Service Providers. Sustainability. 2023; 15(16):12341. https://doi.org/10.3390/su151612341

Chicago/Turabian StyleCheng, Jeng-Chieh, Jeen-Fong Li, and Chi-Yo Huang. 2023. "Enablers for Adopting Restriction of Hazardous Substances Directives by Electronic Manufacturing Service Providers" Sustainability 15, no. 16: 12341. https://doi.org/10.3390/su151612341

APA StyleCheng, J.-C., Li, J.-F., & Huang, C.-Y. (2023). Enablers for Adopting Restriction of Hazardous Substances Directives by Electronic Manufacturing Service Providers. Sustainability, 15(16), 12341. https://doi.org/10.3390/su151612341