Context Analysis for Transformative Change in the Ceramic Industry

Abstract

1. Introduction

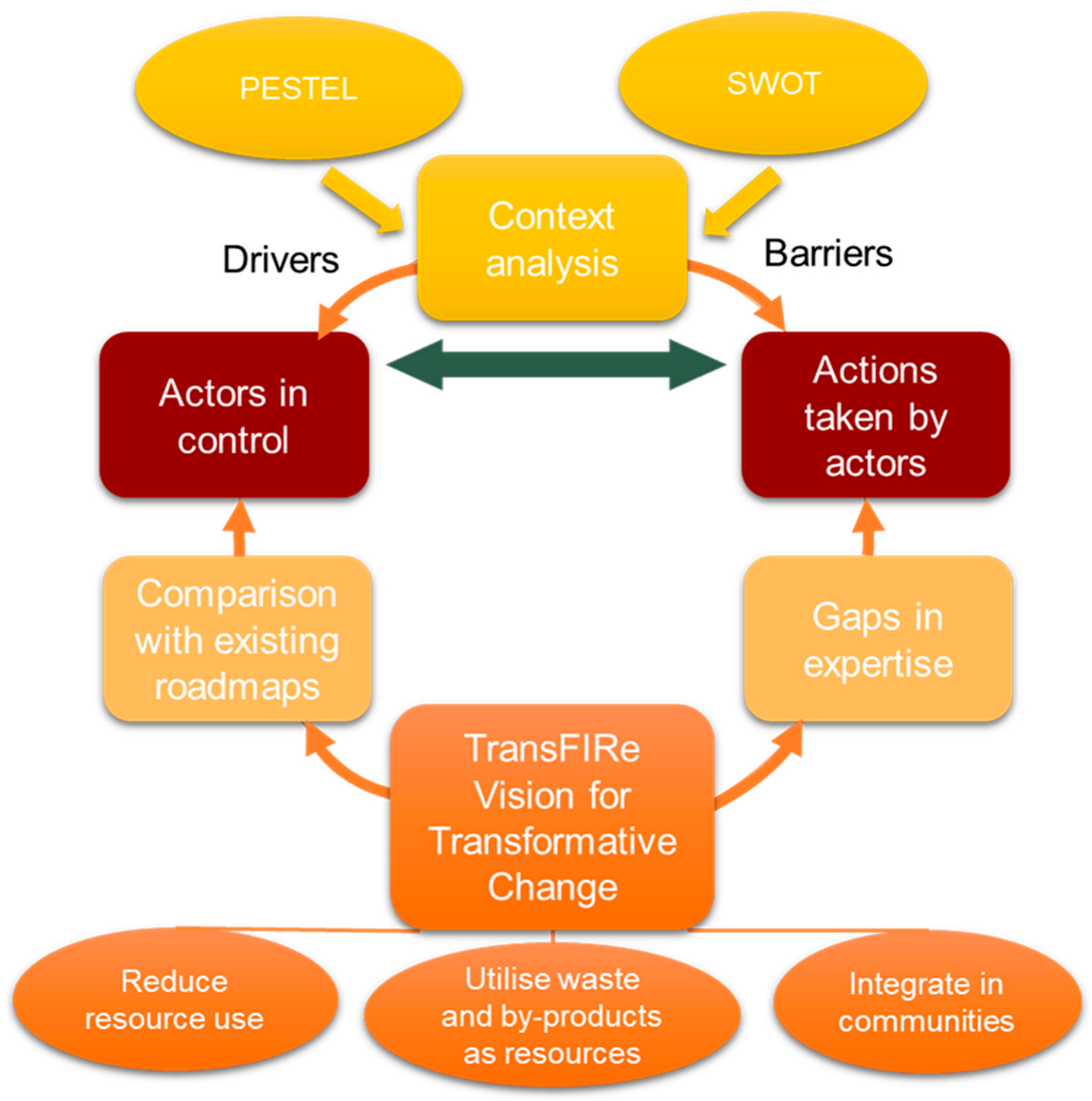

2. Materials and Methods

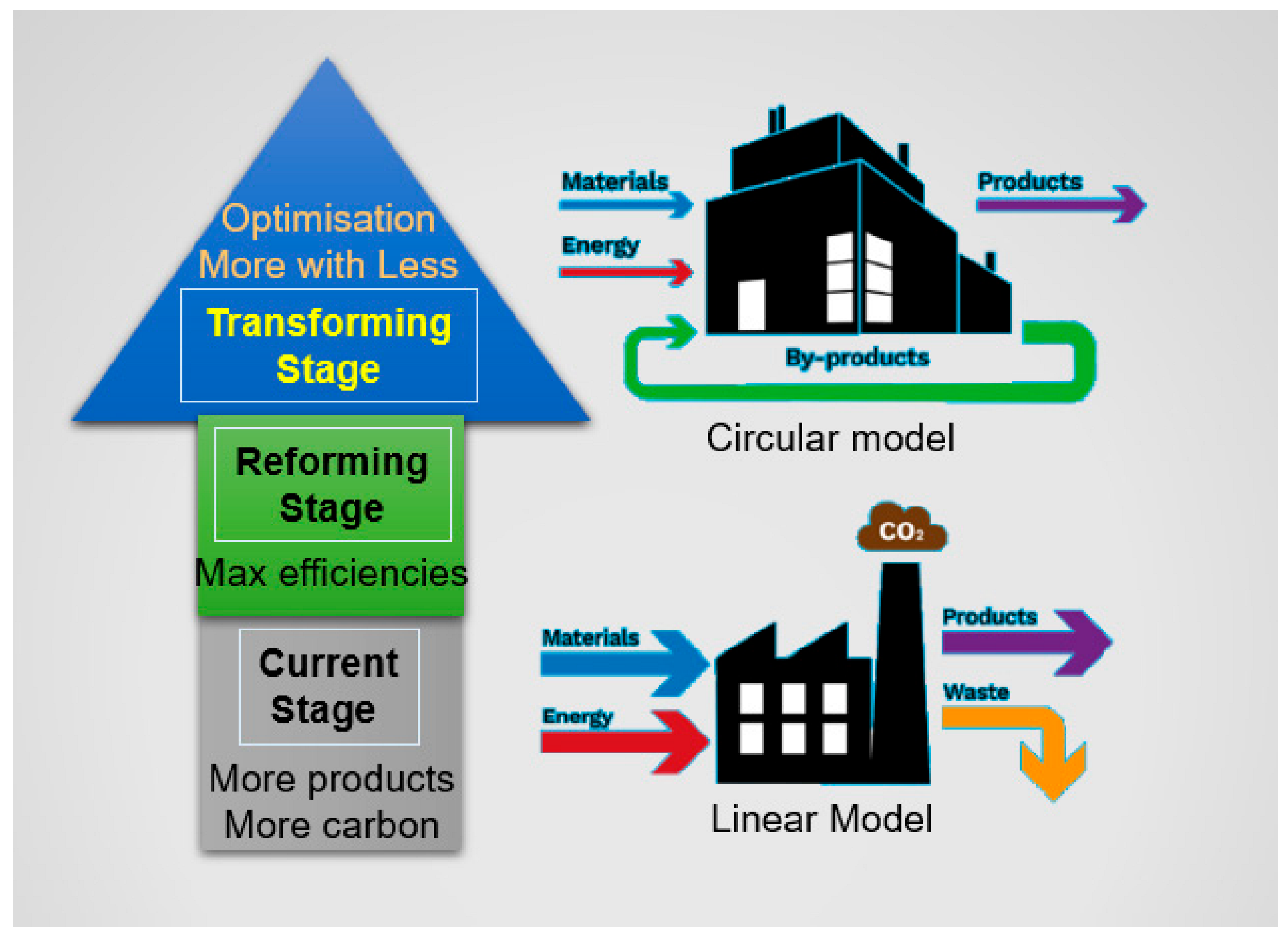

3. Results

3.1. Roadmaps and Visions

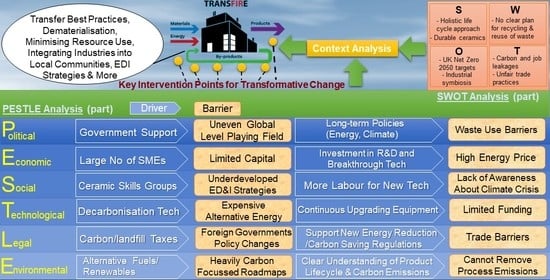

3.2. PESTLE Analysis

3.2.1. Political

3.2.2. Economic

3.2.3. Social

3.2.4. Technological

- On-site combined heat and power generation;

- Process optimisation;

- New kiln design including electrified models;

- Energy management;

- Raw materials formulation changes for more efficient firing energy;

- Clay/raw material preconditioning;

- Heat exchanger in kiln stack.

3.2.5. Legal

- Climate Change Levy (CCL);

- Climate change agreements (CCA);

- Energy Savings Opportunity Scheme (ESOS).

- Carbon Reduction Commitment Energy Efficiency Scheme (CRC);

- Mandatory greenhouse gas (GHG) reporting.

- Indirect EU ETS costs;

- Carbon price floor (CPF)/carbon price support (CPS);

- Levy Control Framework (LCF);

- Renewables Obligation (RO);

- Feed-in tariffs (FiTs);

- EMR (electricity market reform) FiTs with contracts for difference (CfD);

- EMR capacity market (CM).

3.2.6. Environmental

3.3. Drivers and Barriers

3.4. SWOT Analysis

4. Discussion and Next Steps

4.1. Dematerialisation

4.2. Reflecting upon TransFIRe’s Ambitions

4.3. Reflecting on the Broader Literature on Ceramic Industry Decarbonisation

4.4. Industry Reflections

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- UKRI—Transforming Foundation Industries Challenge. Available online: https://www.ukri.org/what-we-offer/our-main-funds/industrial-strategy-challenge-fund/clean-growth/transforming-foundation-industries-challenge/ (accessed on 2 September 2022).

- WSP|PARSONS BRINCKERHOFF. Industrial Decarbonisation & Energy Efficiency Roadmaps to 2050—Cross Sector Summary, 2015. Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/419912/Cross_Sector_Summary_Report.pdf (accessed on 11 June 2022).

- Met Office UK—Record High Temperatures Verified. Available online: https://www.metoffice.gov.uk/about-us/press-office/news/weather-and-climate/2022/record-high-temperatures-verified (accessed on 2 September 2022).

- GOV UK Guidance—Climate Change Explained. Available online: https://www.gov.uk/guidance/climate-change-explained (accessed on 2 September 2022).

- Masson-Delmotte, V.; Zhai, P.; Pirani, A.; Connors, S.L.; Péan, C.; Berger, S.; Caud, N.; Chen, Y.; Goldfarb, L.; Gomis, M.I. Climate Change 2021: The Physical Science Basis. In Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2021; Volume 2. [Google Scholar]

- Sayers, P.B.; Horritt, M.S.; Carr, S.; Kay, A.; Mauz, J.; Lamb, R.; Penning-Rowsell, E. Third UK Climate Change Risk Assessment (CCRA3): Future Flood Risk. Report Prepared for the Committee on Climate Change, UK, 2020. Available online: https://www.ukclimaterisk.org/wp-content/uploads/2020/07/Future-Flooding-Main-Report-Sayers-1.pdf (accessed on 3 June 2022).

- Huang, M.-T.; Zhai, P.-M. Achieving Paris Agreement Temperature Goals Requires Carbon Neutrality by Middle Century with Far-Reaching Transitions in the Whole Society. Adv. Clim. Change Res. 2021, 12, 281–286. [Google Scholar] [CrossRef]

- Caldeira-Pereira, N. Ceramics Industry. Available online: https://ukmfgreview.com/sectors/ceramics-industry/ (accessed on 2 September 2022).

- Lee, W.E.; Zhang, S.; Karakus, M. Refractories: Controlled Microstructure Composites for Extreme Environments. J. Mater. Sci. 2004, 39, 6675–6685. [Google Scholar]

- British Ceramic Confederation—Written Submission from British Ceramic Confederation (CVT0032). Available online: https://committees.parliament.uk/writtenevidence/2498/pdf/ (accessed on 11 June 2022).

- European Ceramic Industry Association—Ceramic Roadmap to 2050: Continuing Our Path towards Climate Neutrality. Available online: https://cerameunie.eu/media/ambd23os/ceramic-roadmap-to-2050.pdf (accessed on 10 April 2022).

- Rawlings, R.D.; Wu, J.P.; Boccaccini, A.R. Glass-Ceramics: Their Production from Wastes—A Review. J. Mater. Sci. 2006, 41, 733–761. [Google Scholar] [CrossRef]

- Furszyfer Del Rio, D.D.; Sovacool, B.K.; Foley, A.M.; Griffiths, S.; Bazilian, M.; Kim, J.; Rooney, D. Decarbonizing the Glass Industry: A Critical and Systematic Review of Developments, Sociotechnical Systems and Policy Options. Renew. Sustain. Energy Rev. 2022, 155, 111885. [Google Scholar]

- Eurostat—Resource Productivity Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Resource_productivity_statistics (accessed on 13 December 2022).

- Haigh, L.; de Wit, M.; von Daniels, C.; Colloricchio, A.; Hoogzaad, J.; Fraser, M.; Sutherland, A.B.; McClelland, J.; Morgenroth, N.; Heidtmann, A. The Circularity Gap Report 2021. Circ. Econ. 2021. Available online: https://www.circularity-gap.world/2021#downloads (accessed on 1 June 2022).

- Giampietro, M.; Funtowicz, S.O. From Elite Folk Science to the Policy Legend of the Circular Economy. Environ. Sci. Policy 2020, 109, 64–72. [Google Scholar] [CrossRef]

- Cullen, J.M. Circular Economy: Theoretical Benchmark or Perpetual Motion Machine? J. Ind. Ecol. 2017, 21, 483–486. [Google Scholar]

- Hernandez, A.G.; Cullen, J.M. Exergy: A Universal Metric for Measuring Resource Efficiency to Address Industrial Decarbonisation. Sustain. Prod. Consum. 2019, 20, 151–164. [Google Scholar] [CrossRef]

- Parrique, T.; Barth, J.; Briens, F.; Kerschner, C.; Kraus-Polk, A.; Kuokkanen, A.; Spangenberg, J.H. Decoupling Debunked: Evidence and Arguments against Green Growth as a Sole Strategy for Sustainability. Eur. Environ. Bur. 2019. Available online: https://eeb.org/wp-content/uploads/2019/07/Decoupling-Debunked.pdf (accessed on 3 June 2022).

- O’Neill, D.W.; Fanning, A.L.; Lamb, W.F.; Steinberger, J.K. A Good Life for All within Planetary Boundaries. Nat. Sustain. 2018, 1, 88–95. [Google Scholar] [CrossRef]

- Reike, D.; Vermeulen, W.J.V.; Witjes, S. The Circular Economy: New or Refurbished as CE 3.0?—Exploring Controversies in the Conceptualization of the Circular Economy through a Focus on History and Resource Value Retention Options. Resour. Conserv. Recycl. 2018, 135, 246–264. [Google Scholar] [CrossRef]

- Velenturf, A.P.M.; Purnell, P. Principles for a Sustainable Circular Economy. Sustain. Prod. Consum. 2021, 27, 1437–1457. [Google Scholar] [CrossRef]

- Velenturf, A.P.M.; Archer, S.A.; Gomes, H.I.; Christgen, B.; Lag-Brotons, A.J.; Purnell, P. Circular Economy and the Matter of Integrated Resources. Sci. Total Environ. 2019, 689, 963–969. [Google Scholar] [CrossRef] [PubMed]

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product Design and Business Model Strategies for a Circular Economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Jolly, M.; Velenturf, A.P.M.; Salonitis, K.; Paddea, S. The UK Transforming the Foundation Industries Research and Innovation Hub (TransFIRe). In REWAS 2022: Developing Tomorrow’s Technical Cycles (Volume I); Lazou, A., Daehn, K., Fleuriault, C., Gökelma, M., Olivetti, E., Meskers, C., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 341–353. [Google Scholar]

- European Ceramic Industry Association—Paving the Way to 2050, The Ceramic Industry Roadmap. 2012. Available online: https://www.ceramtec.com/files/cu_ceramic_industry_roadmap_en.pdf (accessed on 11 June 2022).

- WSP|PARSONS BRINCKERHOFF. Industrial Decarbonisation and Energy Efficiency Roadmaps to 2050—Ceramic Sector, 2015. Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/416676/Ceramic_Report.pdf (accessed on 11 June 2022).

- WSP|PARSONS BRINCKERHOFF. Industrial Decarbonisation and Energy Efficiency Roadmaps to 2050 Action Plan—Ceramic Sector, 2015. Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/651229/ceramics-decarbonisation-action-plan.pdf (accessed on 11 June 2022).

- Oxford College of Marketing—What Is a PESTEL Analysis? Available online: https://blog.oxfordcollegeofmarketing.com/2016/06/30/pestel-analysis/ (accessed on 11 June 2022).

- Furszyfer Del Rio, D.D.; Sovacool, B.K.; Foley, A.M.; Griffiths, S.; Bazilian, M.; Kim, J.; Rooney, D. Decarbonizing the Ceramics Industry: A Systematic and Critical Review of Policy Options, Developments and Sociotechnical Systems. Renew. Sustain. Energy Rev. 2022, 157, 112081. [Google Scholar]

- Kenton, W. SWOT Analysis: How to with Table and Example. Available online: https://www.investopedia.com/terms/s/swot.asp (accessed on 12 September 2022).

- Wales Government—Iron and Steel Production by Year, Measure and Area. Available online: https://statswales.gov.wales/Catalogue/Business-Economy-and-Labour-Market/Economic-Indices/Indices-of-Production-and-Construction/ironandsteelproduction-by-year-measure-area. (accessed on 3 June 2022).

- WSP|PARSONS BRINCKERHOFF. Industrial Decarbonisation and Energy Efficiency Roadmaps to 2050—Iron and Steel, 2015. Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/416667/Iron_and_Steel_Report.pdf (accessed on 11 June 2022).

- British Plastics Federation—About the British Plastics Industry. Available online: https://www.bpf.co.uk/industry/default.aspx (accessed on 6 July 2022).

- WSP|PARSONS BRINCKERHOFF. Industrial Decarbonisation and Energy Efficiency Roadmaps to 2050—Oil Refining, 2015. Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/416671/Oil_Refining_Report.pdf (accessed on 11 June 2022).

- Hasnain, S.; Ingram, J.; Zurek, M. Mapping the UK Food System—A Report for the UKRI Transforming UK Food Systems Programme. 2020. Available online: https://www.foodsecurity.ac.uk/wp-content/uploads/2009/10/Mapping-the-UK-food-system-Exec-Summary.pdf (accessed on 6 June 2022).

- Statista; Tiseo, I. Paper Industry in the UK—Statistics & Facts. Available online: https://www.statista.com/topics/6371/paper-industry-uk/#dossierKeyfigures (accessed on 2 June 2022).

- WSP|PARSONS BRINCKERHOFF. Industrial Decarbonisation and Energy Efficiency Roadmaps to 2050—Pulp and Paper, 2015. Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/416672/Food_and_Drink_Report.pdf (accessed on 11 June 2022).

- Global Cement—Cement in the UK in 2012–2013. Available online: https://www.globalcement.com/magazine/articles/791-cement-in-the-uk-in-2012-2013 (accessed on 11 June 2022).

- WSP|PARSONS BRINCKERHOFF. Industrial Decarbonisation and Energy Efficiency Roadmaps to 2050—Glass, 2015. Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/416675/Glass_Report.pdf (accessed on 11 June 2022).

- Barrett, J.; Scott, K. Link between Climate Change Mitigation and Resource Efficiency: A UK Case Study. Glob. Environ. Change 2012, 22, 299–307. [Google Scholar] [CrossRef]

- Cerame-Unie the European Ceramic Industry Association—Cerame-Unie’s Views on Resource Efficiency & the Circular Economy Package. 2014. Available online: https://cerameunie.eu/media/1326/14-07-02-cu-paper-on-circular-economy_final-1.pdf (accessed on 11 June 2022).

- Iacovidou, E.; Millward-Hopkins, J.; Busch, J.; Purnell, P.; Velis, C.A.; Hahladakis, J.N.; Zwirner, O.; Brown, A. A Pathway to Circular Economy: Developing a Conceptual Framework for Complex Value Assessment of Resources Recovered from Waste. J. Clean. Prod. 2017, 168, 1279–1288. [Google Scholar] [CrossRef]

- Purnell, P.; Velenturf, A.P.M.; Marshall, R. Chapter 16: New Governance for Circular Economy: Policy, Regulation and Market Contexts for Resource Recovery from Waste. In Resource Recovery from Wastes; RSC Green Chemistry; Royal Society of Chemistry: London, UK, 2020. [Google Scholar]

- Velenturf, A.P.M.; Jopson, J.S. Making the Business Case for Resource Recovery. Sci. Total Environ. 2019, 648, 1031–1041. [Google Scholar] [CrossRef]

- Newswire, P.R. Ceramic Tiles Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2017–2022. REPORT-CeramicTiles. 2017. Available online: https://www.prnewswire.com/news-releases/ceramic-tiles-market-global-industry-trends-share-size-growth-opportunity-and-forecast-2017-2022-300417388.html (accessed on 15 June 2022).

- Office for National Statistics—Coronavirus and the Impact on Output in the UK Economy: January 2021. Available online: https://www.ons.gov.uk/economy/grossdomesticproductgdp/articles/coronavirusandtheimpactonoutputintheukeconomy/january2021. (accessed on 11 May 2022).

- British Ceramics Confederation Careers—Join the Ceramic Industry. Available online: https://www.ceramfed.co.uk/careers/ (accessed on 11 June 2022).

- Lundgren-Kownacki, K.; Kjellberg, S.M.; Gooch, P.; Dabaieh, M.; Anandh, L.; Venugopal, V. Climate Change-Induced Heat Risks for Migrant Populations Working at Brick Kilns in India: A Transdisciplinary Approach. Int. J. Biometeorol. 2018, 62, 347–358. [Google Scholar] [CrossRef]

- Inbaraj, L.; Haebar, O.; Saj, F.; Dawson, S.; Paul, P.; Prabhakar, A.K.; Mohan, V.; Alex, R. Prevalence of Musculoskeletal Disorders among Brick Kiln Workers in Rural Southern India. Indian J. Occup. Environ. Med. 2013, 17, 71–75. [Google Scholar] [CrossRef]

- Guttikunda, S.K.; Khaliquzzaman, M. Health Benefits of Adapting Cleaner Brick Manufacturing Technologies in Dhaka, Bangladesh. Air Qual. Atmos. Health 2014, 7, 103–112. [Google Scholar] [CrossRef]

- Monfort, E.; Mezquita, A.; Granel, R.; Vaquer, E.; Escrig, A.; Miralles, A.; Zaera, V. Analysis of Energy Consumption and Carbon Dioxide Emissions in Ceramic Tile Manufacture. Bol. Soc. Esp. Ceram. Vidr. 2010, 49, 303–310. [Google Scholar]

- Smith, A. Clay Bricks and Clay Blocks: A Resource Efficiency Action Plan. Green Constr. Board Brick Dev. Assoc. 2013. Available online: https://www.wrap.org.uk/sites/files/wrap/CBCB%20REAP%20October%202013.pdf (accessed on 12 June 2022).

- Muñoz Velasco, P.; Morales Ortíz, M.P.; Mendívil Giró, M.A.; Muñoz Velasco, L. Fired Clay Bricks Manufactured by Adding Wastes as Sustainable Construction Material—A Review. Constr. Build. Mater. 2014, 63, 97–107. [Google Scholar]

- Venkatarama Reddy, B.V.; Jagadish, K.S. Embodied Energy of Common and Alternative Building Materials and Technologies. Energy Build. 2003, 35, 129–137. [Google Scholar] [CrossRef]

- Yüksek, İ.; Öztaş, S.K.; Tahtalı, G. The Evaluation of Fired Clay Brick Production in Terms of Energy Efficiency: A Case Study in Turkey. Energy Effic. 2020, 13, 1473–1483. [Google Scholar] [CrossRef]

- Maithel, S.; Lalchandani, D.; Malhotra, G.; Bhanware, P.; Uma, R.; Ragavan, S.; Athalye, V.; Bindiya, K.R.; Reddy, S.; Bond, T.; et al. A Roadmap for Cleaner Brick Production in India. Analysis 2012. Available online: https://www.gkspl.in/wp-content/uploads/2018/10/REBM1a.pdf (accessed on 20 June 2022).

- BEIS. Prices of Fuels Purchased by Manufacturing Industry in Great Britain (Original Units) (QEP 3.1.1 to 3.1.4). 2022. Available online: https://www.gov.uk/government/statistical-data-sets/prices-of-fuels-purchased-by-manufacturing-industry (accessed on 30 June 2022).

- Norman, J.; Barrett, J.; Betts-Davies, S.; Carr-Whitworth, R.; Garvey, A.; Giesekam, J.; James, K.; Styles, R.; Scott, K. Resource Efficiency Scenarios for the UK: A Technical Report. 2021. Available online: https://www.creds.ac.uk/wp-content/uploads/CREDS-Resource-efficiency-scenarios-UK-technical-report.pdf (accessed on 15 June 2022).

- Mazzucato, M. The Inclusive Entrepreneurial State: Collective Wealth Creation and Distribution; Institute for Fiscal Studies: London, UK, 2022; Volume 1. [Google Scholar]

- Raworth, K. Doughnut Economics: Seven Ways to Think Like a 21st-Century Economist—Kate Raworth; Chelsea Green Publishing: Chelsea, VT, USA, 2016; Volume 38. [Google Scholar]

- Quinteiro, P.; Araújo, A.; Oliveira, B.; Dias, A.C.; Arroja, L. The Carbon Footprint and Energy Consumption of a Commercially Produced Earthenware Ceramic Piece. J. Eur. Ceram. Soc. 2012, 32, 2087–2094. [Google Scholar] [CrossRef]

- Jouhara, H.; Bertrand, D.; Axcell, B.; Montorsi, L.; Venturelli, M.; Almahmoud, S.; Milani, M.; Ahmad, L.; Chauhan, A. Investigation on a Full-Scale Heat Pipe Heat Exchanger in the Ceramics Industry for Waste Heat Recovery. Energy 2021, 223, 120037. [Google Scholar] [CrossRef]

- Delpech, B.; Axcell, B.; Jouhara, H. Experimental Investigation of a Radiative Heat Pipe for Waste Heat Recovery in a Ceramics Kiln. Energy 2019, 170, 636–651. [Google Scholar] [CrossRef]

- Peng, J.; Zhao, Y.; Jiao, L.; Zheng, W.; Zeng, L. CO2 Emission Calculation and Reduction Options in Ceramic Tile Manufacture-The Foshan Case. Energy Procedia 2012, 16, 467–476. [Google Scholar] [CrossRef]

- González, I.; Galán, E.; Miras, A.; Vázquez, M.A. CO2 Emissions Derived from Raw Materials Used in Brick Factories. Applications to Andalusia (Southern Spain). Appl. Clay. Sci. 2011, 52, 193–198. [Google Scholar] [CrossRef]

- Akinshipe, O.; Kornelius, G. Quantification of Atmospheric Emissions and Energy Metrics from Simulated Clamp Kiln Technology in the Clay Brick Industry. Environ. Pollut. 2018, 236, 580–590. [Google Scholar] [CrossRef] [PubMed]

- Solgi, E.; Moattar Husseini, S.M.; Ahmadi, A.; Gitinavard, H. A Hybrid Hierarchical Soft Computing Approach for the Technology Selection Problem in Brick Industry Considering Environmental Competencies: A Case Study. J. Environ. Manag. 2019, 248, 109219. [Google Scholar] [CrossRef]

- Higazy, M.; Essa, K.S.M.; Mubarak, F.; El-Sayed, E.S.M.; Sallam, A.M.; Talaat, M.S. Analytical Study of Fuel Switching from Heavy Fuel Oil to Natural Gas in Clay Brick Factories at Arab Abu Saed, Greater Cairo. Sci. Rep. 2019, 9, 10081. [Google Scholar] [CrossRef]

- Joshi, S.K.; Dudani, I. Environmental Health Effects of Brick Kilns in Kathmandu Valley. Kathmandu Univ. Med. J. 2008, 6, 3–11. [Google Scholar]

- Madhusudanan, S.; Nallusamy, S. Analysis and Comparison of Thermal Conductance and Indoor Air Temperature on Industrial Slag with Conventional Bricks. Int. J. Ambient. Energy 2021, 43, 4555–4568. [Google Scholar] [CrossRef]

- Dixit, M.K.; Fernández-Solís, J.L.; Lavy, S.; Culp, C.H. Identification of Parameters for Embodied Energy Measurement: A Literature Review. Energy Build. 2010, 42, 1238–1247. [Google Scholar] [CrossRef]

- Pampuch, R.; Pampuch, R. A Brief History of Ceramic Innovation. In An Introduction to Ceramics; Springer: Berlin/Heidelberg, Germany, 2014; pp. 1–17. [Google Scholar]

- UN Climate Change Conference UK 2021—What Did the UK Presidency Aim to Achieve at COP26? Available online: https://ukcop26.org/cop26-goals/ (accessed on 5 January 2023).

- UNFCCC—COP27 Reaches Breakthrough Agreement on New “Loss and Damage” Fund for Vulnerable Countries. Available online: https://unfccc.int/news/cop27-reaches-breakthrough-agreement-on-new-loss-and-damage-fund-for-vulnerable-countries (accessed on 5 January 2023).

- Zhongming, Z.; Linong, L.; Xiaona, Y.; Wangqiang, Z.; Wei, L. AR6 Synthesis Report: Climate Change 2022; The Intergovernmental Panel on Climate Change (IPCC): Geneva, Switzerland, 2022. Available online: https://www.ipcc.ch/report/sixth-assessment-report-cycle/ (accessed on 23 July 2022).

- Krawchenko, T.A.; Gordon, M. How Do We Manage a Just Transition? A Comparative Review of National and Regional Just Transition Initiatives. Sustainability 2021, 13, 6070. [Google Scholar] [CrossRef]

- Wesseling, J.H.; Lechtenböhmer, S.; Åhman, M.; Nilsson, L.J.; Worrell, E.; Coenen, L. The Transition of Energy Intensive Processing Industries towards Deep Decarbonization: Characteristics and Implications for Future Research. Renew. Sustain. Energy Rev. 2017, 79, 1303–1313. [Google Scholar]

- García-Muiña, F.E.; Medina-Salgado, M.S.; Ferrari, A.M.; Cucchi, M. Sustainability Transition in Industry 4.0 and Smart Manufacturing with the Triple-Layered Business Model Canvas. Sustainability 2020, 12, 2364. [Google Scholar] [CrossRef]

- Velenturf, A.; Marshall, R.; Suarez-Suarez, A.; Christensen, H.; Yu, E.; Falagan, C.; Sapsford, D.; Gomes, H.; Mayes, W. Participatory Situational Analysis: How Can Policy and Regulation Support Resource Recovery? Synthesis Workshop Report. 2018. Available online: https://eprints.whiterose.ac.uk/163448/ (accessed on 23 July 2022).

| PESTLE | Driver | Barrier |

|---|---|---|

| Political/Legal |

|

|

| Economic |

|

|

| Social |

|

|

| Technological |

|

|

| Environmental |

|

|

| Strengths | Opportunities |

|

|

| Weaknesses | Threats |

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khalil, A.M.E.; Velenturf, A.P.M.; Ahmadinia, M.; Zhang, S. Context Analysis for Transformative Change in the Ceramic Industry. Sustainability 2023, 15, 12230. https://doi.org/10.3390/su151612230

Khalil AME, Velenturf APM, Ahmadinia M, Zhang S. Context Analysis for Transformative Change in the Ceramic Industry. Sustainability. 2023; 15(16):12230. https://doi.org/10.3390/su151612230

Chicago/Turabian StyleKhalil, Ahmed M. E., Anne P. M. Velenturf, Masoud Ahmadinia, and Shaowei Zhang. 2023. "Context Analysis for Transformative Change in the Ceramic Industry" Sustainability 15, no. 16: 12230. https://doi.org/10.3390/su151612230

APA StyleKhalil, A. M. E., Velenturf, A. P. M., Ahmadinia, M., & Zhang, S. (2023). Context Analysis for Transformative Change in the Ceramic Industry. Sustainability, 15(16), 12230. https://doi.org/10.3390/su151612230